Positive image thermal-sensitive UV-resistant printing ink CTP material

A positive image, plate technology, applied in the direction of heat-sensitive coatings, printing plates, printing processes, etc., can solve the problems of poor alcohol resistance of the photosensitive layer, insufficient printing resistance, and the coating film is easily scratched, so as to achieve the printing resistance. Strong, improve print durability, improve solvent resistance and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The preparation method of copolymer 1 for lower layer resin layer:

[0090] Add 250g of isopropanol, 150g of deionized water, 30g of N,N-dimethylformamide, 10g of amyl acrylate, and 5g of dioctylsuccinic acid into a 1000ml three-necked flask equipped with a stirrer, a reflux tube, and a dropping funnel. Sodium, 1.2g AIBN (azobisisobutyronitrile), stir evenly, and use hot water bath to heat to 80 ° C, dropwise add 26g N-(4-acetoxyphenyl) maleimide, 27g acrylonitrile , 7g of acrylic acid, 0.8g of AIBN (azobisisobutyronitrile) was dissolved in a mixed solution of 250g of isopropanol, and the addition was completed dropwise in 1.5 hours. The reaction was completed after 8 hours at a constant temperature.

[0091] The solid content is 17.1%, the weight average molecular weight is 28000, and the number average molecular weight is 2100.

[0092] The preparation method of copolymer 2 for the lower resin layer:

[0093] Add 250g of isopropanol, 150g of deionized water, 23g of...

Embodiment 1

[0100] The preparation of lower layer resin layer coating liquid L1, prepares the bottom layer coating liquid of positive heat-sensitive lithographic printing plate precursor according to following formula:

[0101] Prepare the resin layer L1 of the positive thermosensitive lithographic printing plate according to the following formula:

[0102] Prepare the resin layer L1 of the positive thermosensitive lithographic printing plate according to the following formula:

[0103]

[0104] Prepare the heat-sensitive layer coating liquid A of positive heat-sensitive lithographic printing plates according to the following formula:

[0105]

[0106]

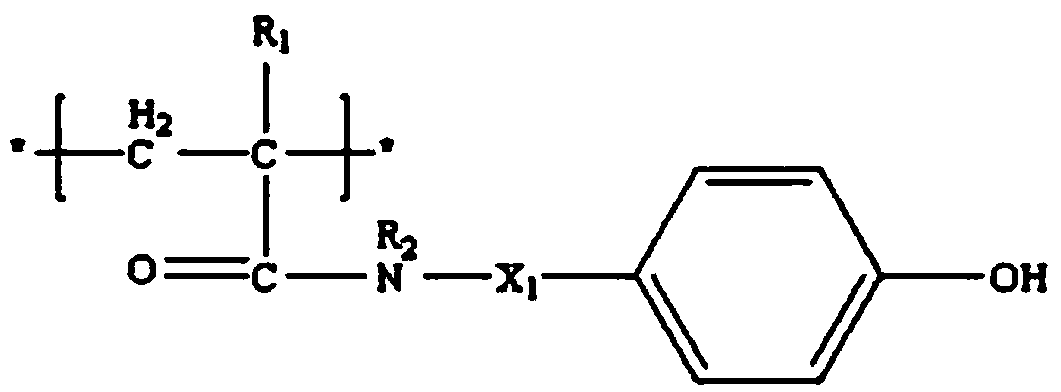

[0107] The monomers used to synthesize the copolymer-01 for the upper layer are: styrene, methacrylic acid and p-sulfonamide benzyl methacrylamide.

[0108] The monomers used to synthesize the copolymer-02 for the upper layer are: polyvinyl alcohol, 4-hydroxybenzaldehyde and p-toluenesulfonic acid.

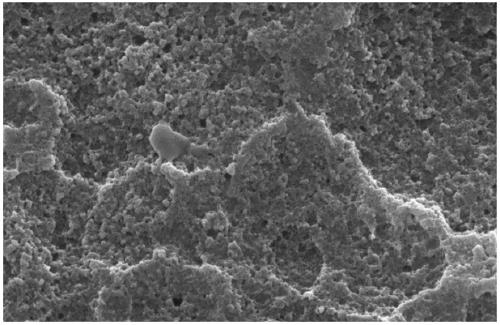

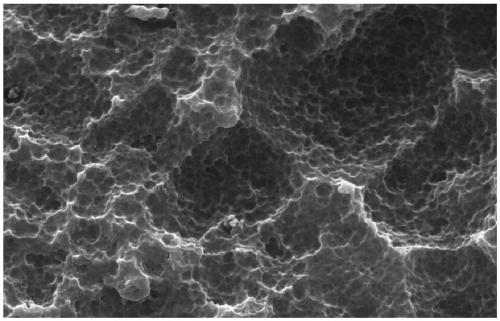

[0109] Example 1 Coating so...

Embodiment 2

[0117] The preparation of lower layer resin layer coating liquid L2, prepares the bottom layer coating liquid of positive heat-sensitive lithographic printing plate precursor according to following formula:

[0118] Prepare the resin layer L2 of the positive thermosensitive lithographic printing plate according to the following formula:

[0119]

[0120]

[0121] Prepare the heat-sensitive layer coating liquid A of positive heat-sensitive lithographic printing plates according to the following formula:

[0122]

[0123] The monomers used to synthesize the copolymer-01 for the upper layer are: styrene, methacrylic acid and p-sulfonamide benzyl methacrylamide.

[0124] The monomers used to synthesize the copolymer-02 for the upper layer are: polyvinyl alcohol, 4-hydroxybenzaldehyde and p-toluenesulfonic acid.

[0125] Example 2 Coating solution L2 is used for the lower layer, and coating solution A for the heat-sensitive layer is used for the upper layer. Plate base i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com