Replaceable sleeve

a technology of sleeves and sleeves, applied in the field of replacement sleeves, can solve the problems of inconvenient and expensive, sleeves are typically expensive, and cannot be replaced, and achieve the effect of convenient fabrication and convenient mounting on the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

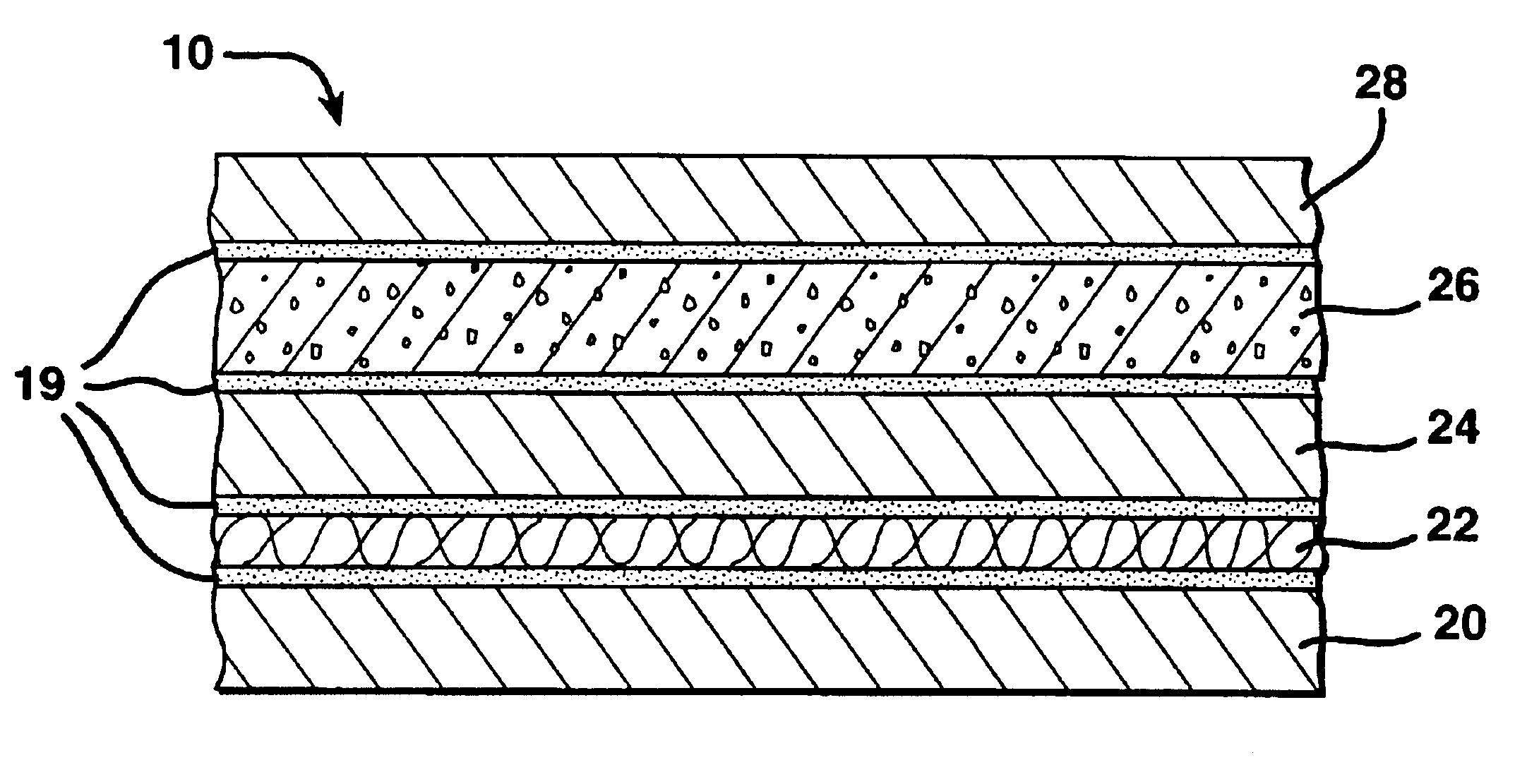

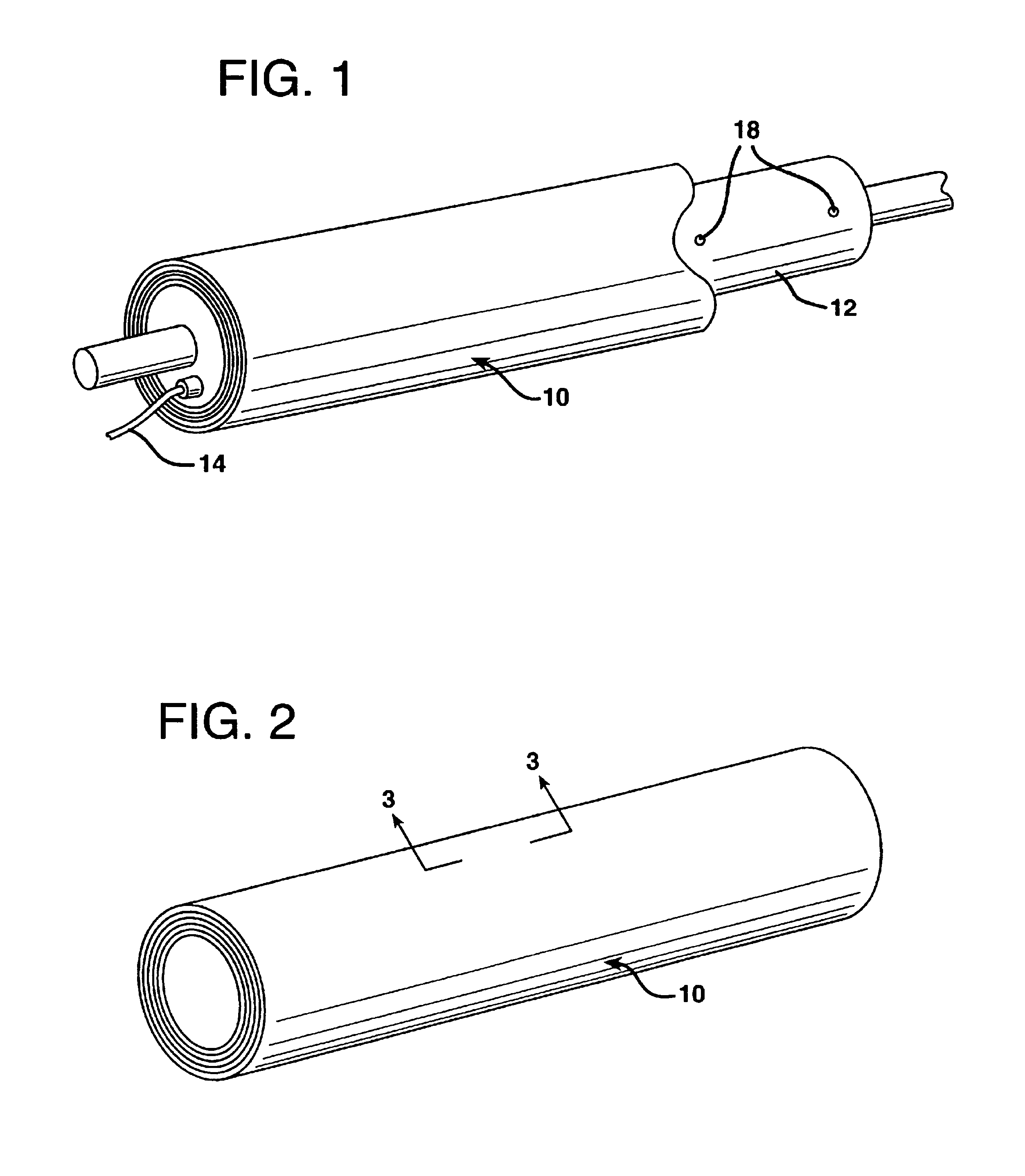

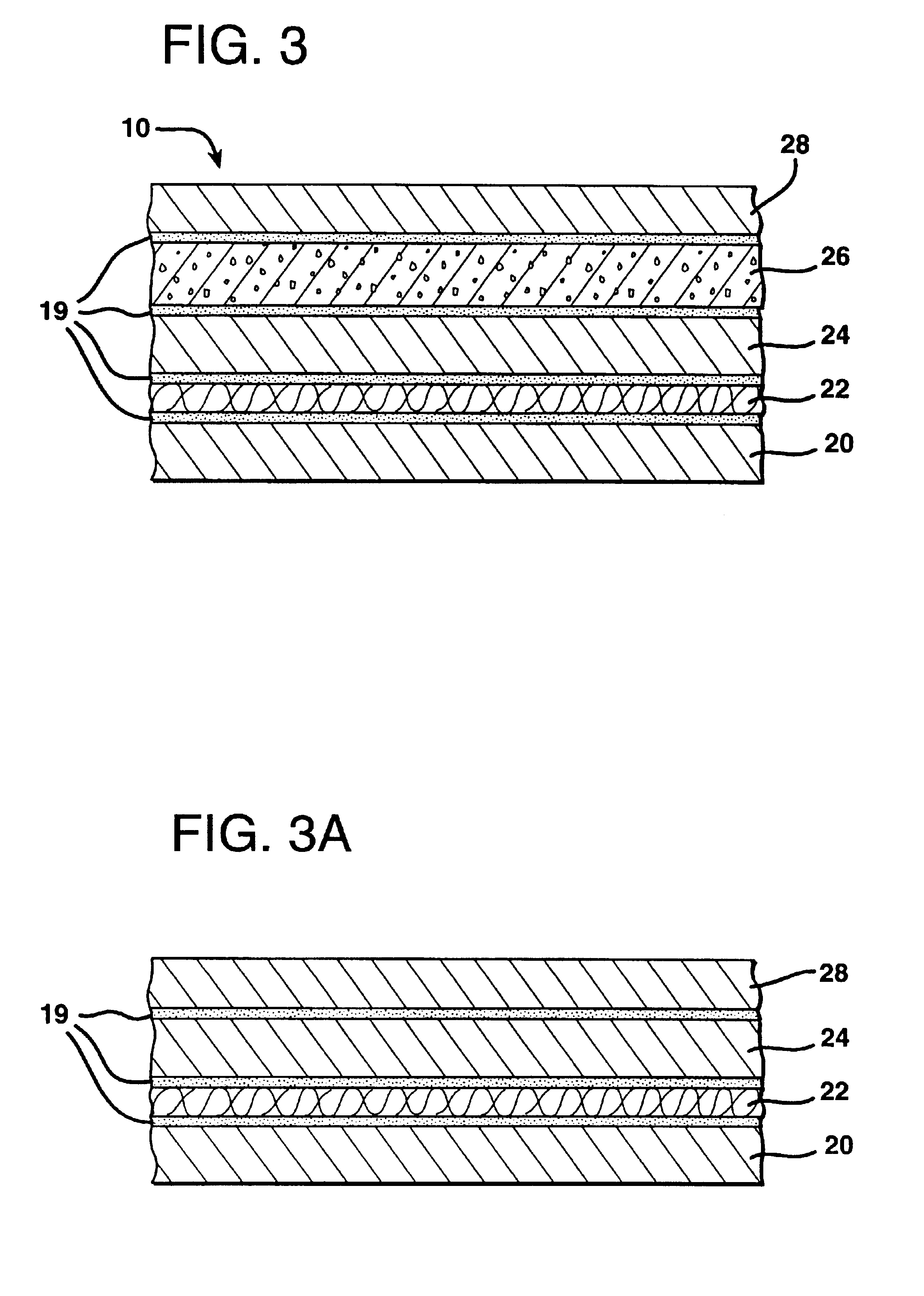

The replaceable sleeve of the present invention provides several advantages over other prior sleeves that are covered with rubber or polymer in that all of the layers comprising the sleeve are seamless and may be cured in a single step, which allows the sleeve to be produced more efficiently. And, because the layers comprising the sleeve are not limited to the use of specific polymers or curing methods, the properties of the sleeve may be tailored as desired for specific applications. For example, where the sleeve is used in printing operations, the outer layer of the sleeve may be finished so that it can be used as the printing surface, thus eliminating the requirement for the attachment of separate printing plates. The sleeve of the present invention also offers the advantage that it may be easily replaced on-site without having to shut down processing equipment for extended periods of time. That is, when the sleeve surface becomes worn or otherwise needs replacement, the sleeve m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com