Jacket for impression cylinder or transport cylinder of printing press

A technology of embossing rollers and conveying rollers, which is applied to printing machine roller jackets, general parts of printing machinery, printing machines, etc., and can solve problems such as restrictions on washing silicone resin, decreased productivity, and heavy burdens on operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

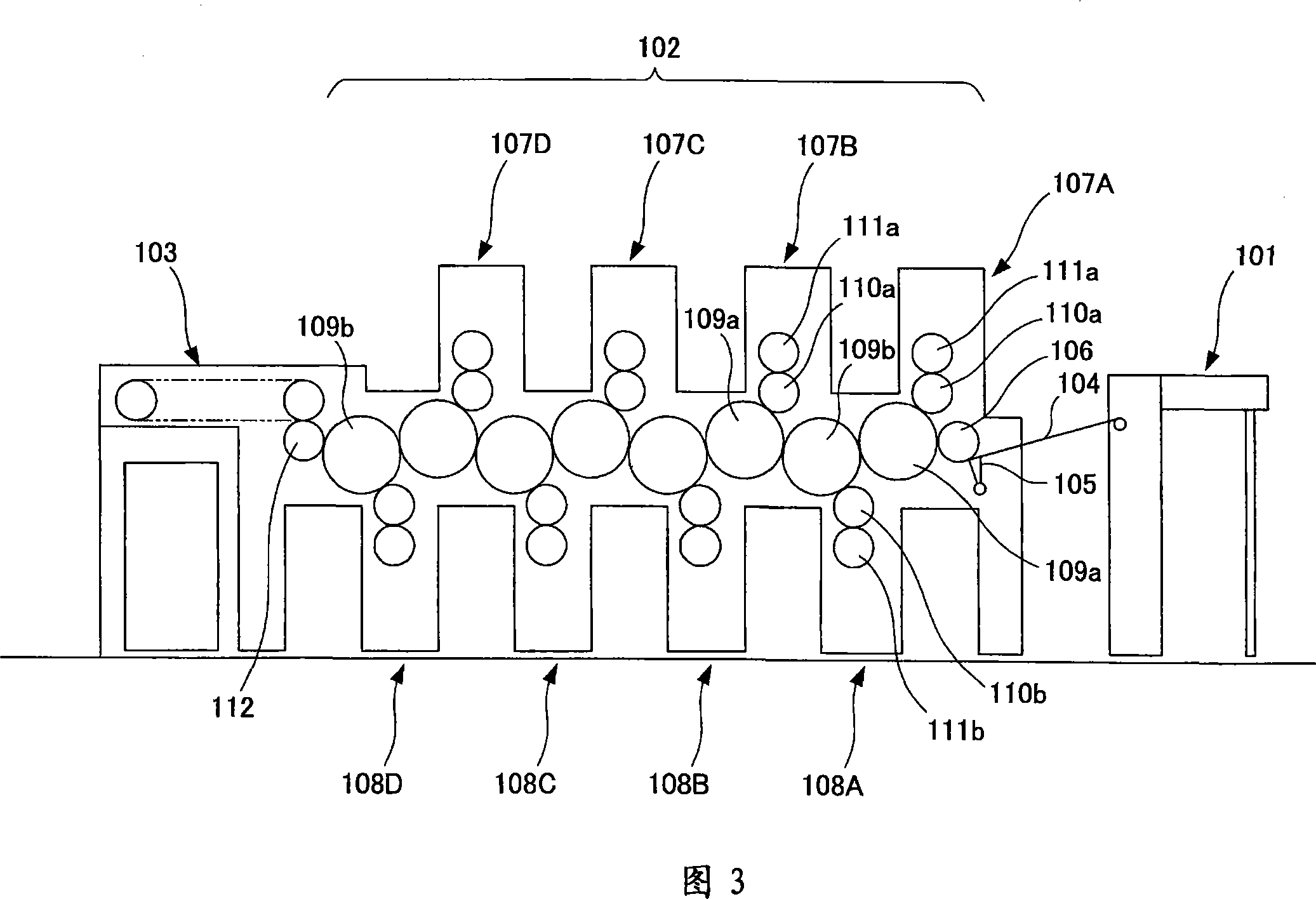

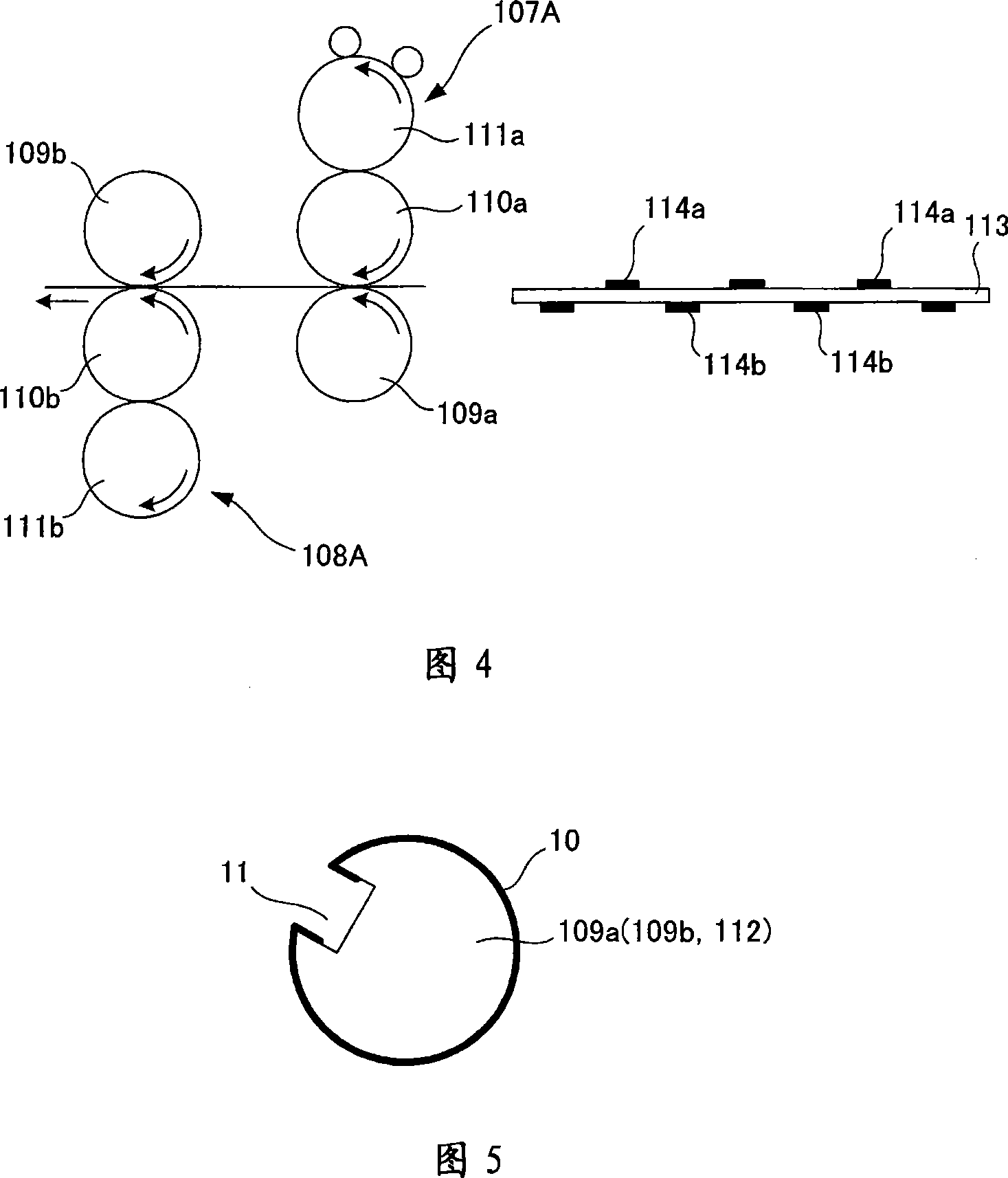

[0018] First, FIG. 3 shows an example of a printing machine equipped with an impression cylinder and a delivery cylinder, in which the covering of the present invention is used. The press is a sheet-fed rotary press for printing on both sides of the paper. The printing machine includes a paper feeder 101 , a printing unit 102 and a paper discharge unit 103 . Sheets stacked in the sheet feeder 101 are taken out there one by one. Then, the sheet thus taken out is fed to the printing unit 102 via the registration plate 104 , the swing gripper 105 , and the transfer roller 106 .

[0019] The printing unit 102 includes four front printing units 107A, 107B, 107C and 107D, and four rear printing units 108A, 108B, 108C and 108D. The front printing units 107A-107D provide first to fourth colors respectively. Each of the front printing units 107A-107D is composed of an impression cylinder 109a, a blanket cylinder (rubber cylinder) 110a, a plate cylinder 111a and an inking device (not...

Embodiment 2

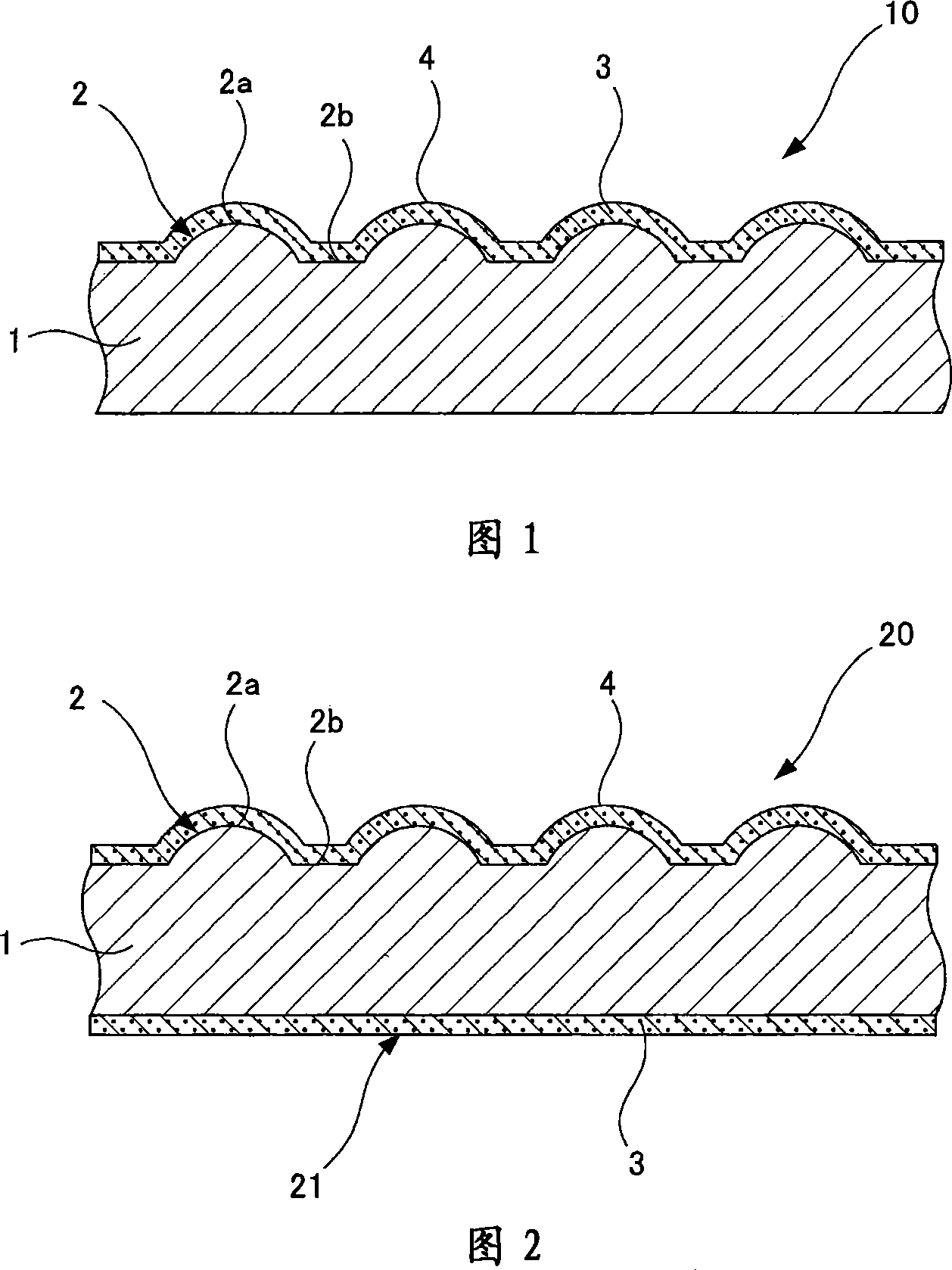

[0041] 2 is a partial sectional view of a cover for an impression cylinder or a transfer cylinder according to another embodiment of the present invention.

[0042] In the covering body 20 of this embodiment, the electroless nickel plating layer 21 having ink repellency is also coated on the back surface of the base material 1 . Forming the layer of the nickel plating layer 21 on the back surface improves the sliding properties of the covering body 20 to the surface of an impression cylinder or the like on which the covering body 20 is mounted. Therefore, when the covering body 20 is stretched to be mounted on a drum, tension can be smoothly applied. As a result, the covering 20 is uniformly bonded to the drum. Since the ink-repelling particles 3, such as modified fluorine-containing resin particles, are dispersed in the plating layer 21, the self-lubricating properties of the particles 3 improve sliding properties. Therefore, by forming the same nickel plating layer on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com