pH responding type polyoxazoline-nano silver layer by layer self-assembly multilayer film and preparation method thereof

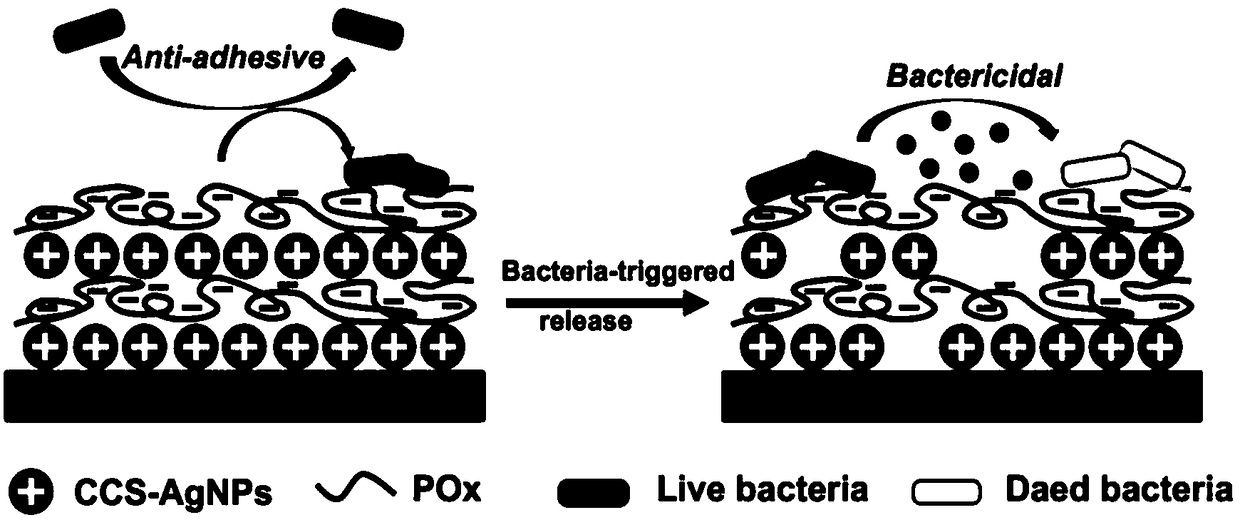

A layer-by-layer self-assembly and polyoxazoline technology, applied in coatings, pharmaceutical formulations, medical science, etc., can solve the problem of difficult removal of bacterial biofilms, achieve broad-spectrum high-efficiency antibacterial properties, easy end groups, and cytotoxicity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

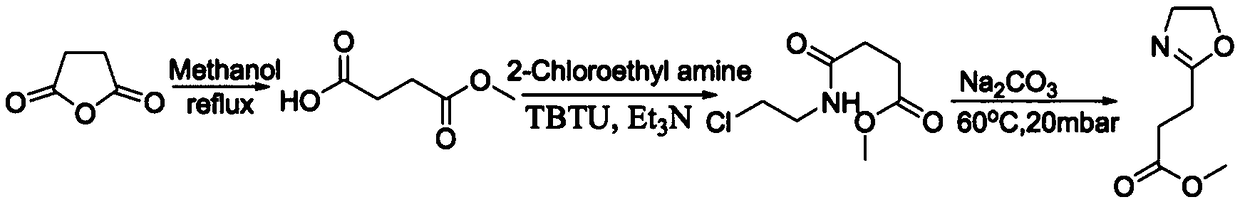

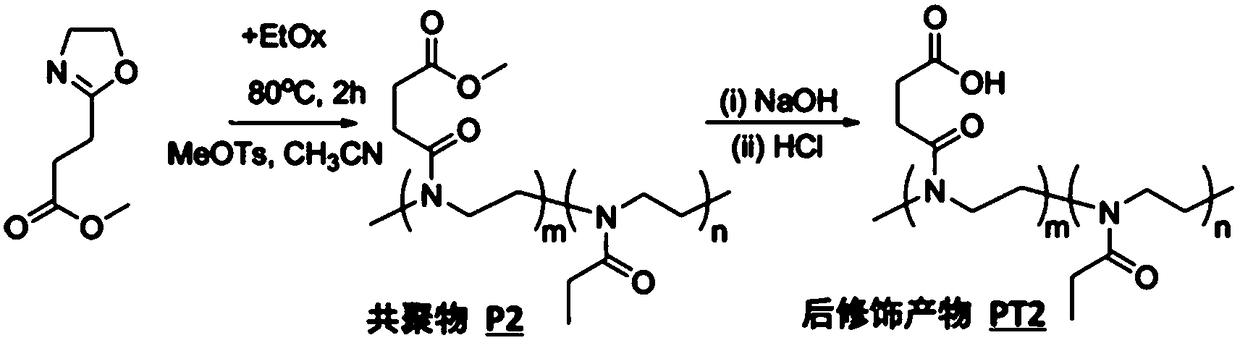

Method used

Image

Examples

Embodiment 1

[0037] 1) Prepare the following solutions for use: PBS 0.01M, BPEI 3mg / mL, CSS-AgNPs 1mg / mL, POx 1mg / mL.

[0038] 2) Soak the slides in BPEI solution for pre-assembly, take them out after 30 min, wash them with PBS buffer and dry them three times.

[0039] 3) Soak the slides in the CSS-AgNPs solution, take them out after 30 min, rinse them with PBS buffer and dry them three times.

[0040] 4) Soak the slides in the POx solution, take them out after 30 min, wash them repeatedly with PBS buffer solution and dry them three times.

[0041] 5) Repeat alternate soaking and assembly until the required number of assembly layers is reached.

Embodiment 2

[0043] 1) Prepare the following solutions for use: PBS 0.01M, BPEI 2mg / mL, CSS-AgNPs 2mg / mL, POx 2mg / mL.

[0044] 2) Soak the slides in BPEI solution for pre-assembly, take them out after 30 min, wash them with PBS buffer and dry them three times.

[0045] 3) Soak the slides in the CSS-AgNPs solution, take them out after 30 min, rinse them with PBS buffer and dry them three times.

[0046] 4) Soak the slides in the POx solution, take them out after 30 min, wash them repeatedly with PBS buffer solution and dry them three times.

[0047]5) Repeat alternate soaking and assembly until the required number of assembly layers is reached.

Embodiment 3

[0049] 1) Prepare the following solutions for use: PBS 0.01M, BPEI 2mg / mL, CSS-AgNPs 1mg / mL, POx 1mg / mL.

[0050] 2) Soak the slides in BPEI solution for pre-assembly, take them out after 30 min, wash them with PBS buffer and dry them three times.

[0051] 3) Soak the slides in the CSS-AgNPs solution, take them out after 30 min, rinse them with PBS buffer and dry them three times.

[0052] 4) Soak the slides in the POx solution, take them out after 30 min, wash them repeatedly with PBS buffer solution and dry them three times.

[0053] 5) Repeat alternate soaking and assembly until the required number of assembly layers is reached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com