Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

A technology of hemihydrate gypsum and dihydrate gypsum, which is applied in the field of preparation of α hemihydrate gypsum, which can solve the problems of unstrict control of dihydrate-semihydrate crystallization conditions, unreasonable distribution of aspect ratio of α hemihydrate gypsum, and α hemihydrate gypsum. Low gypsum strength and other problems, to achieve the effect of appropriate aspect ratio distribution range, good environmental and economic benefits, and concentrated aspect ratio distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

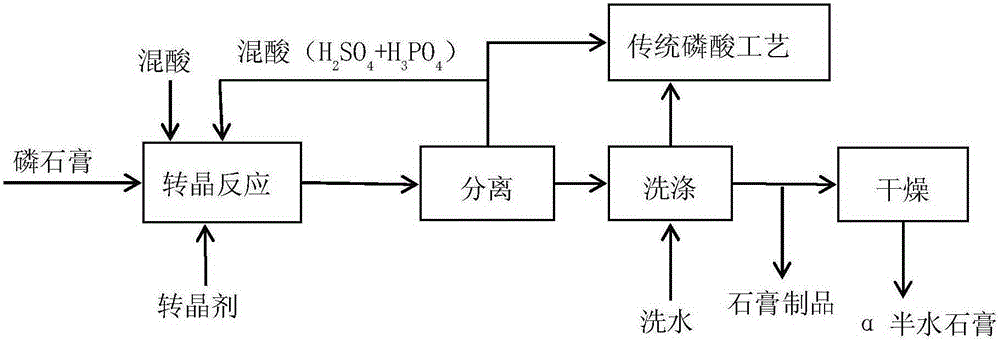

Method used

Image

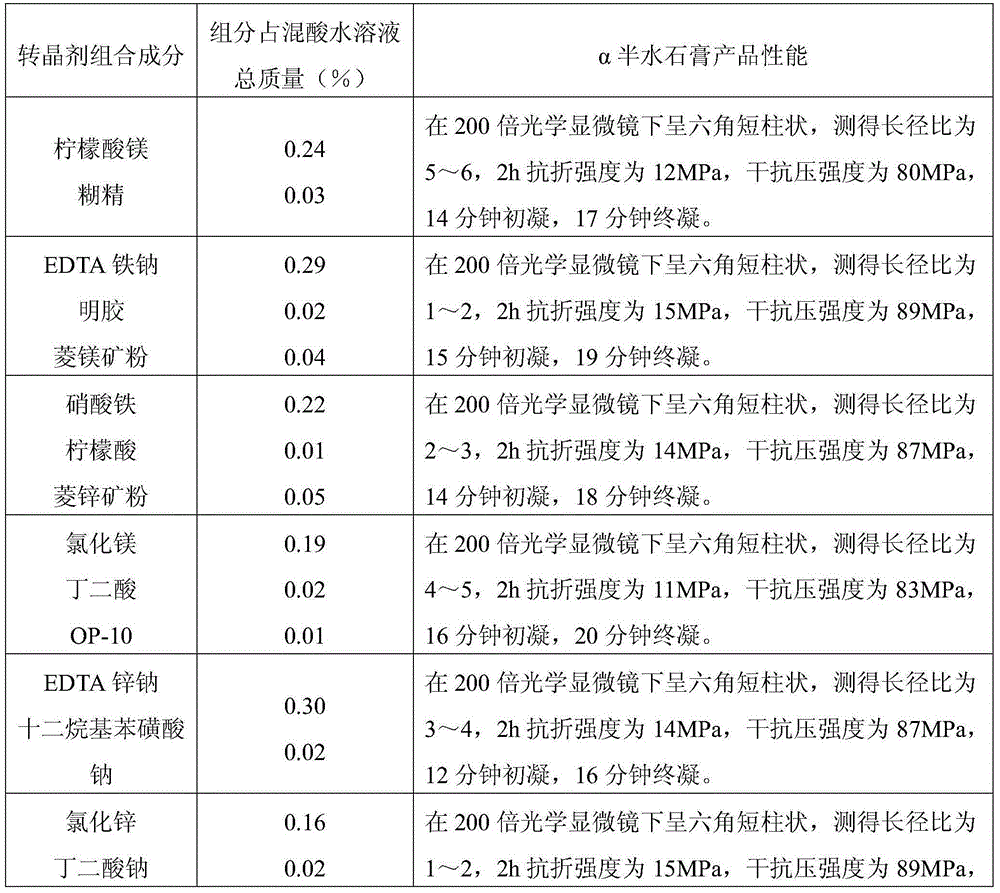

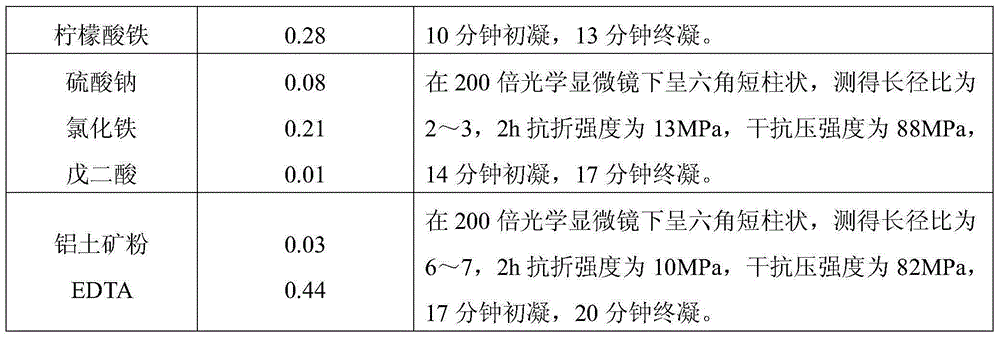

Examples

Embodiment 1

[0045] Raw material 1: Phosphogypsum, collection location: Kingenta Ecological Engineering Group Co., Ltd.

[0046] Raw material 2: Phosphoric acid, 60%, commercially available

[0047] Raw material 3: sulfuric acid, 97%, commercially available

[0048] Raw material 4: sodium citrate, commercially available

[0049] Raw material 5: EDTA, commercially available

[0050] Raw material 6: iron sulfate, commercially available

[0051] Preparation:

[0052] (1) Add dihydrate gypsum into the strong acid aqueous solution containing sulfuric acid and phosphoric acid mixed acid according to the solid-to-liquid ratio of 1:2.5, and mix evenly to obtain mixed slurry A, wherein the mass of sulfuric acid is expressed as H 2 SO 4 The mass fraction of mixed acid is 9.00%, and the mass of phosphoric acid is represented by P 2 o 5 The mass fraction of the mixed acid is 20.00%, and the mass fraction of the added water is 34.79% of the mixed acid aqueous solution.

[0053] (2) Add a crysta...

Embodiment 2

[0061] Raw material 1: desulfurized gypsum, collection location: Linyi Power Plant

[0062] Raw material 2: Phosphoric acid, 60%, commercially available

[0063] Raw material 3: sulfuric acid, 97%, commercially available

[0064] Raw material 4: sodium dodecylbenzenesulfonate, commercially available

[0065] Raw material 5: EDTA, commercially available

[0066] Raw material 6: aluminum sulfate, commercially available

[0067] Preparation:

[0068] (1) Add dihydrate gypsum into the strong acidic aqueous solution containing sulfuric acid and phosphoric acid mixed acid according to the ratio of solid-to-liquid ratio of 1:3, and mix evenly to prepare mixed slurry A, wherein the mass of sulfuric acid is expressed as H 2 SO 4 The mass fraction of mixed acid is 10%, and the mass of phosphoric acid is expressed as P 2 o 5 The mass fraction of the mixed acid is 22%, and the mass fraction of the water is 31.27% of the mixed acid aqueous solution.

[0069] (2) Add a crystal-trans...

Embodiment 3

[0077] Raw material 1: Phosphogypsum, collection location: Kingenta Ecological Engineering Group Co., Ltd.

[0078] Raw material 2: Phosphoric acid, 60%, commercially available

[0079] Raw material 3: sulfuric acid, 97%, commercially available

[0080] Raw material 4: sodium glutarate, commercially available

[0081] Raw material 5: EDTA, commercially available

[0082] Raw material 6: aluminum sulfate, commercially available

[0083] Preparation:

[0084] (1) Add dihydrate gypsum into the strong acidic aqueous solution containing sulfuric acid and phosphoric acid mixed acid according to the ratio of solid to liquid ratio of 1:4, and mix evenly to prepare mixed slurry A, wherein the mass of sulfuric acid is expressed as H 2 SO 4 The mass fraction of mixed acid is 14%, and the mass of phosphoric acid is represented by P 2 o 5 The mass fraction of the mixed acid is 25%, and the mass fraction of the water is 20.99% of the mixed acid aqueous solution.

[0085] (2) Add a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com