Foam glass prepared from waste high-aluminum alkali-free boron-free glass fiber and manufacturing method thereof

A glass fiber and foam glass technology, which is applied in the field of foam glass and its manufacture, can solve the problems of incomplete foaming of foam glass, inability to provide oxygen, and high material density, and achieve low production cost, thin bubble wall, and high quality. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

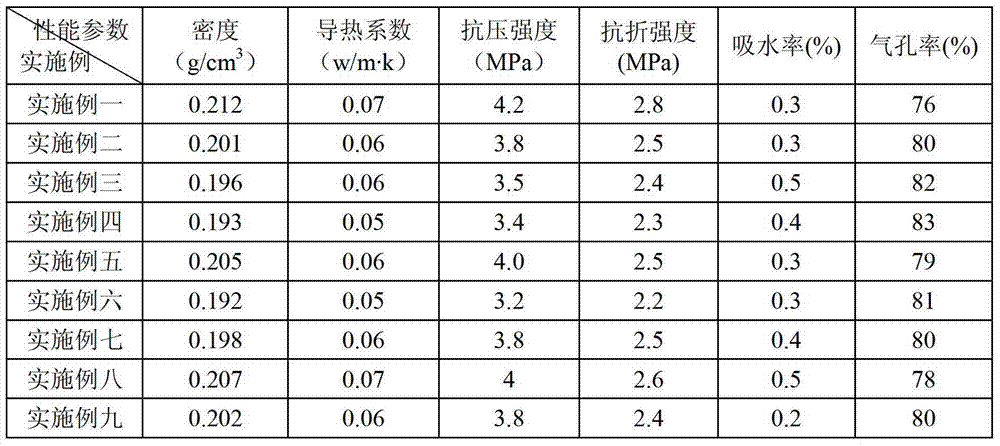

Examples

Embodiment Construction

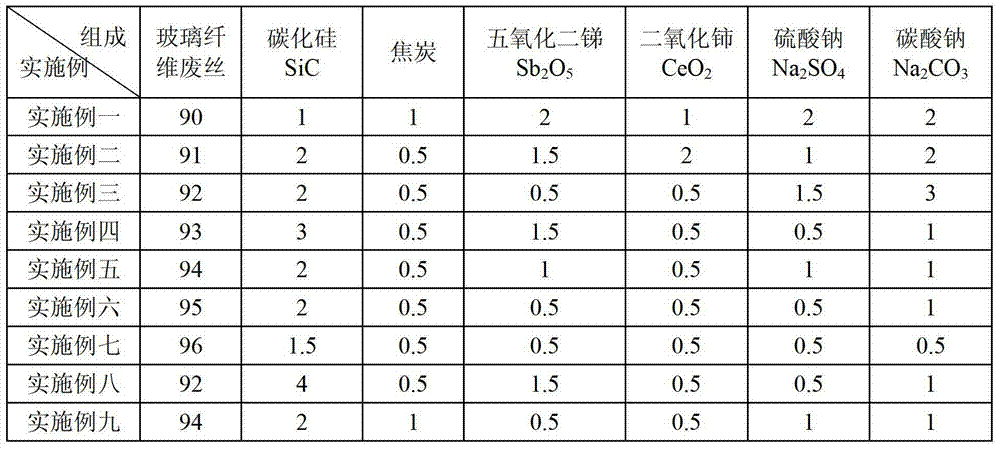

[0026] The embodiment of the present invention adopts alkali-free, boron-free and high-aluminum (containing Al 2 O 3 16wt%) Glass fiber waste is the main raw material. The raw material composition of foam glass in each example is shown in Table 1.

[0027] Table 1 The raw material composition (wt%) of foam glass in each embodiment of the present invention

[0028]

[0029] The steps of the method for manufacturing foam glass in the embodiment of the present invention are as follows:

[0030] a. After cleaning, drying, ball milling, and passing through a 250-mesh sieve of glass fiber waste silk, glass powder is obtained;

[0031] b. Add the glass powder and its components to the ball mill for 2 hours to form a foam glass batch;

[0032] c. Add the foam glass batch material to the heat-resistant steel mold, and put it into the foaming furnace for the following foaming process:

[0033] In the preheating stage, the temperature is increased from room temperature to 300-500°C at a rate of 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com