Storage battery electrode plate curing chamber with automatic temperature control

A technology of plate curing and curing chamber, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of poor plate performance consistency, increased labor intensity and time for product transfer, large temperature difference between upper and lower, and achieve convenient production and battery products. The effect of superior quality performance and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

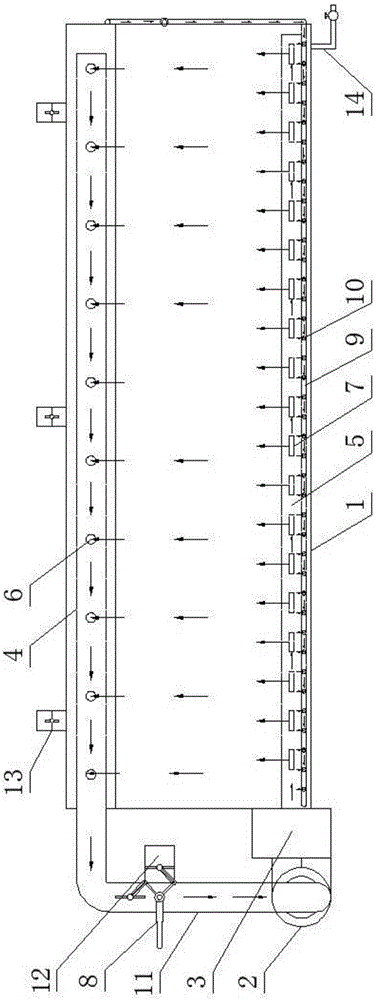

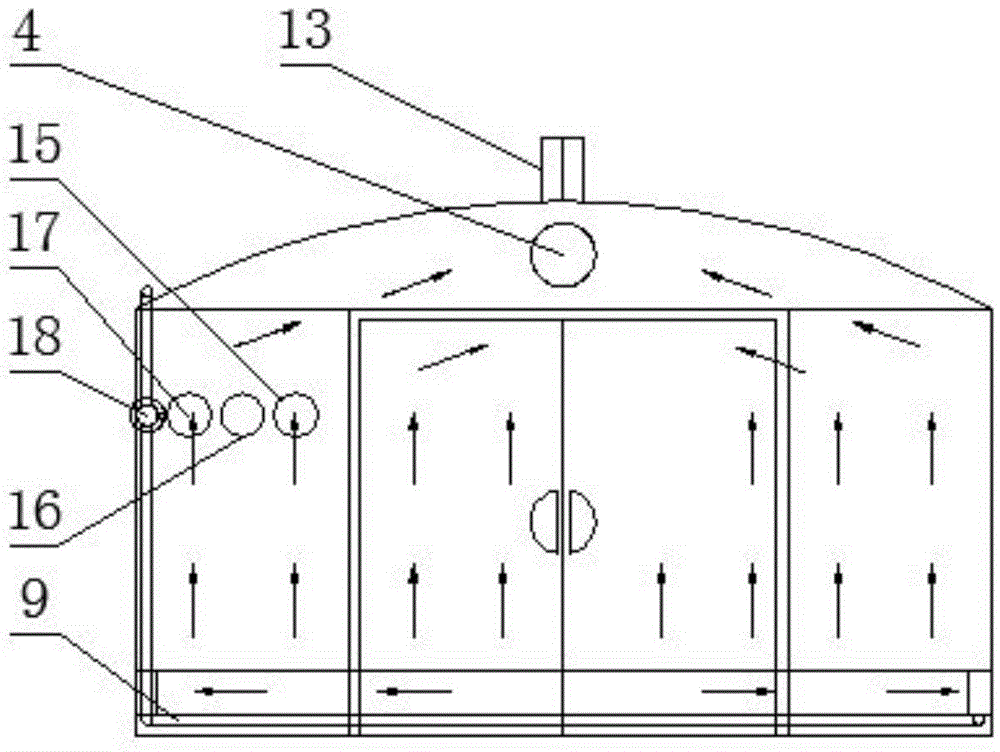

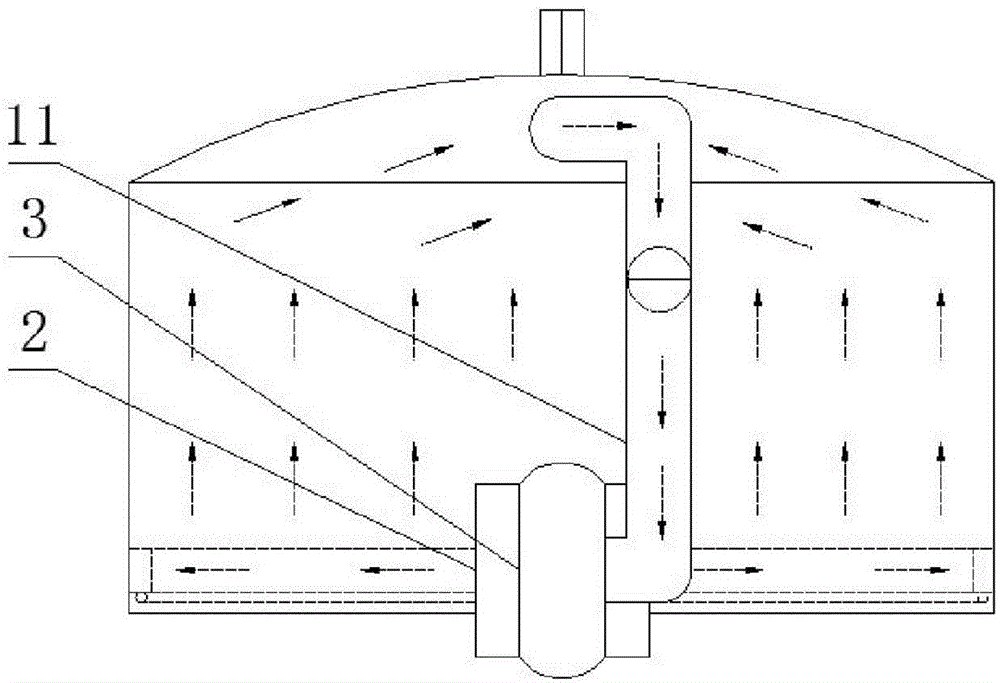

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like Figure 1-Figure 4 As shown, the present invention discloses a battery plate curing chamber with automatic temperature control, comprising a curing chamber body 1, a circulation fan 2 and a steam heating box 3, the air outlet of the circulation fan 2 is connected to the steam heating box 3 and It is arranged on one side of the curing room body 1, and the other side of the curing room body 1 is also provided with a humidity controller 15, a circulating fan frequency conversion device 16 and a circulating air temperature setting device 17, and the circulating fan frequency conversion device 16 and The circulation fan is connected in 3 phases;

[0024] On the top of the curing chamber body 1, several drying vents 13 are evenly arranged horizontally, at the bottom of the curing chamber body 1, a drainage pipe 14 is arranged, and at the central part of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com