Method for preparing carbon microsphere by utilizing waste cotton fibre

A technology of waste cotton and carbon microspheres, which is applied in the preparation/purification of carbon and the removal of solid waste, etc., and can solve the problem of single structure and composition of carbon microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

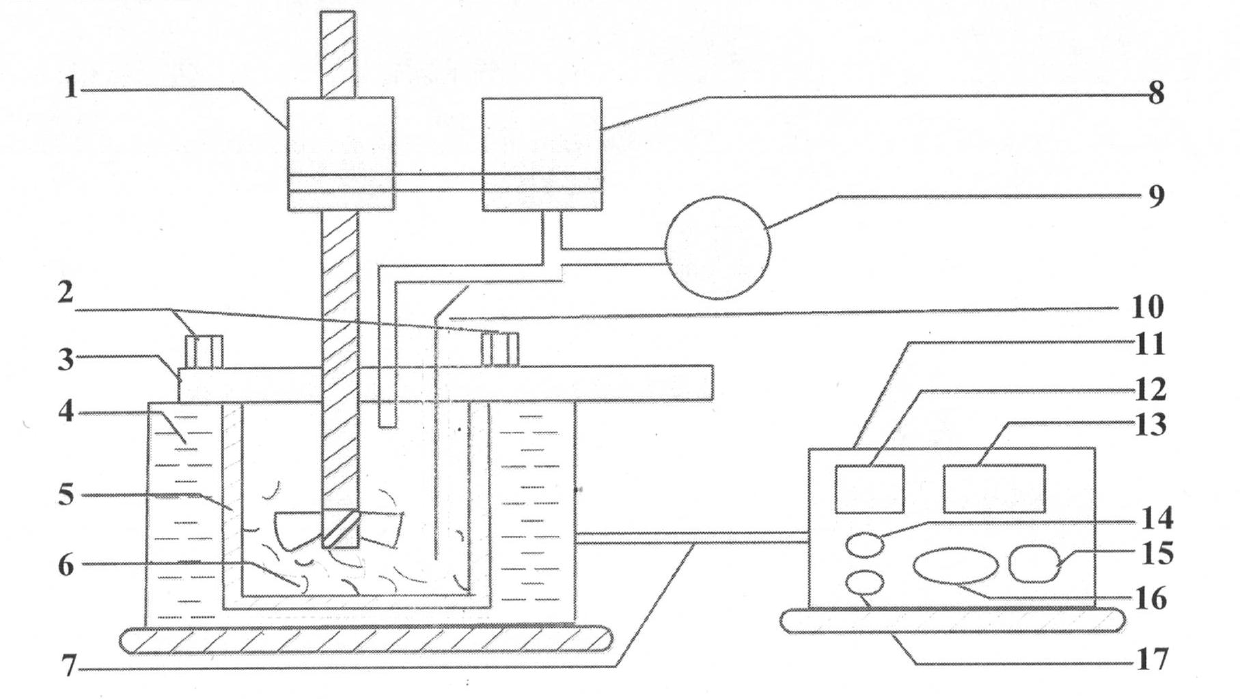

[0111] The present invention will be further described below in conjunction with accompanying drawing:

[0112] figure 1 As shown, the state diagram of cotton fiber carbon microspheres prepared for the reactor, the position of each part, the connection relationship must be correct, according to the proportion of the amount, and operate in sequence.

[0113] Quantities of the chemical substances used in the preparation are determined according to a preset range, with grams and milliliters as measurement units.

[0114] The preparation of carbon microspheres from waste cotton fibers is carried out in a reactor; it is completed under the conditions of high temperature, high pressure and stirring; the reactor 5 is cylindrical, and the outside of the reactor 5 is an insulating heating layer 4, and the inside of the reactor 5 is placed Waste cotton fiber + deionized water dispersion 6, on the upper part of the reaction kettle 5 is a kettle cover 3 fixed and sealed by bolts 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com