Patents

Literature

74results about How to "Good luminous effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

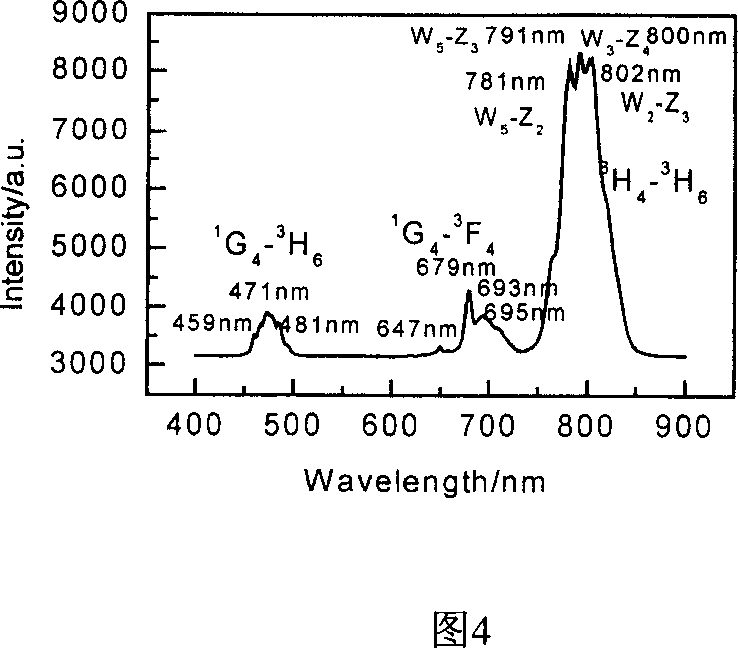

Rare earth ion doped YAG micro crystalline glass and its preparation method

The present invention discloses a rare earth ion doped YAG nucleated glass and its preparation method. Its composition contains: (by mol%) CaO 17-44, Y2O3 0.1-13, Al2O3 16-32, SiO2 26-46, RE2O3 0.1-9, TiO2 0-15, in which RE2O3 is at least one kind of Yb2O3, Er2O3 and Tm2O3. Its preparation method includes the following steps: firstly, adopting melting process to prepare CaO-Y2O3-Al2O3-SiO2-RE2O3-TiO2 system glass, making heat treatment to obtain nano-grade nucleated glass. Said nucleated glass is transparent, and has no devitrification, and its physical and chemical properties are good.

Owner:NINGBO UNIV

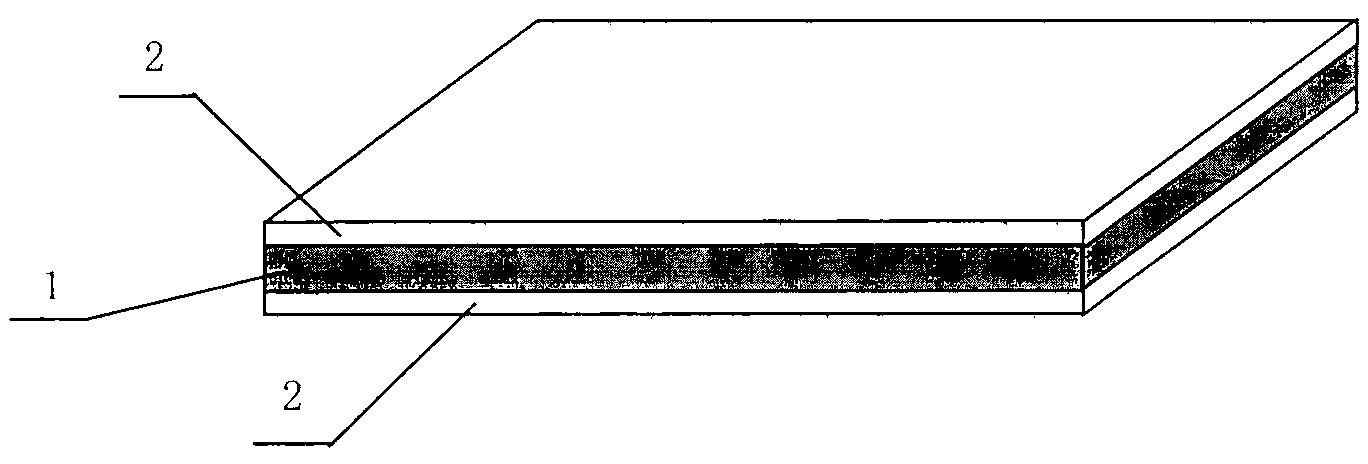

Luminous glass film

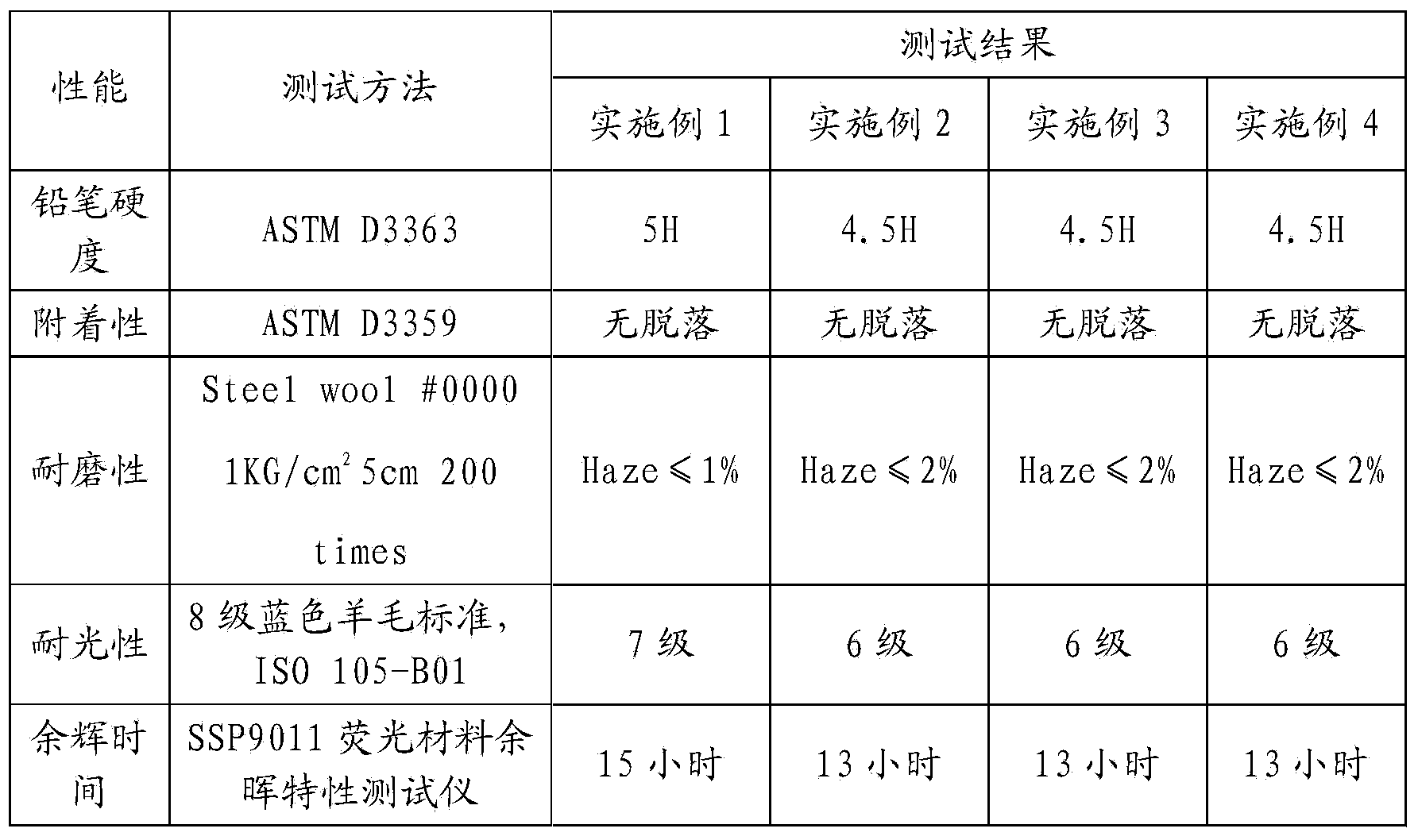

InactiveCN102618180AImprove luminous brightnessGood luminous effectNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer resinPolyresin

The invention belongs to the technical field of interlayers in interlayer glass, and particularly relates to a luminous glass film. The layer structure of the luminous glass film comprises a luminous layer, wherein the luminous layer comprises the following components in parts by weight: 100 parts of polymer resin, 5-50 parts of light-storing long-afterglow lightening paint, 0-10 parts by weight of a dispersing agent and 0-5 parts by weight of a coupling agent. The glass film has high luminous performance, the interlayer glass manufactured by using the glass film can be applied to decoration, safety indication, display function and the like, and has the safety of interlayer glass.

Owner:TIANJIN SUNRAY PLASTIC PROD

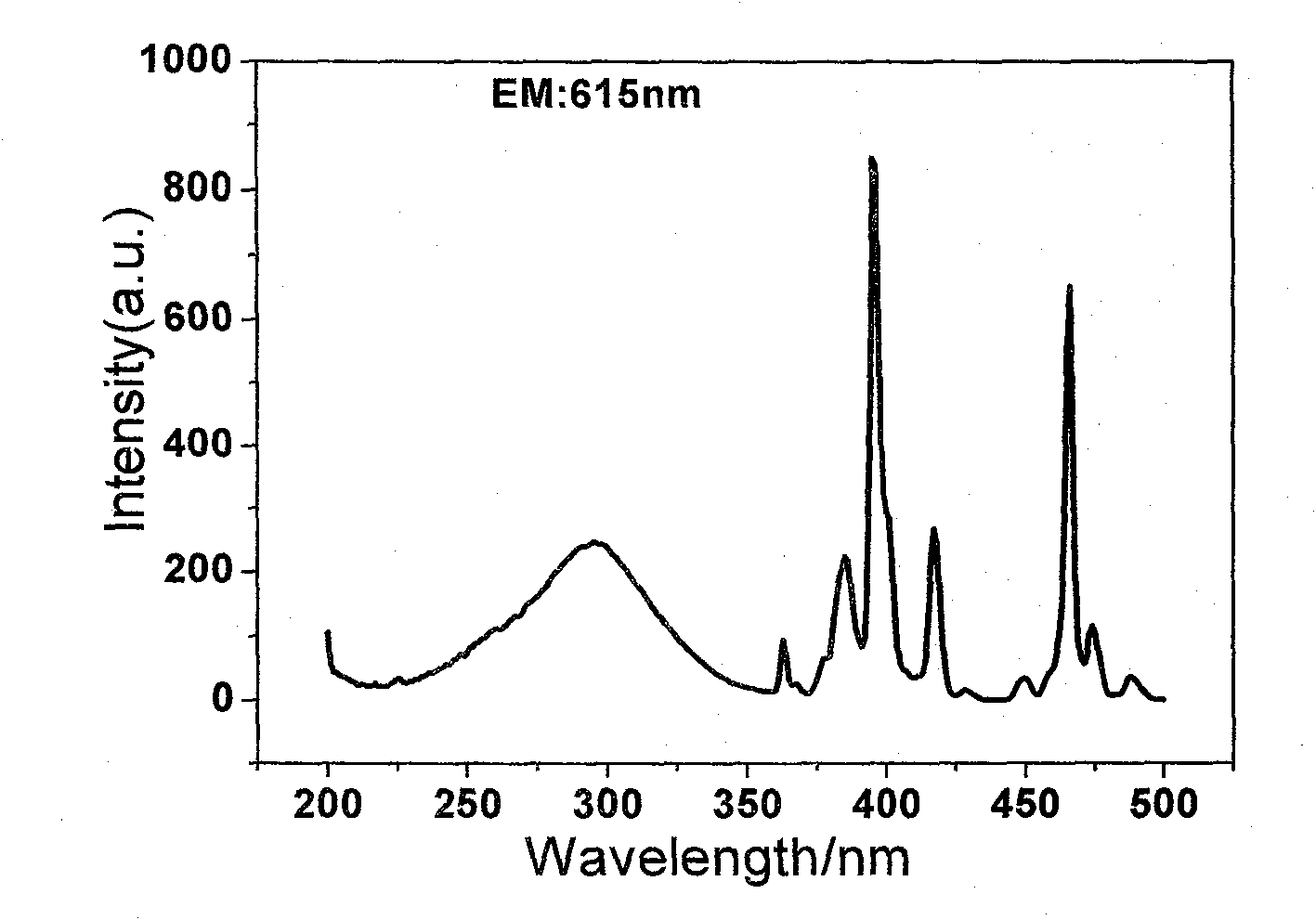

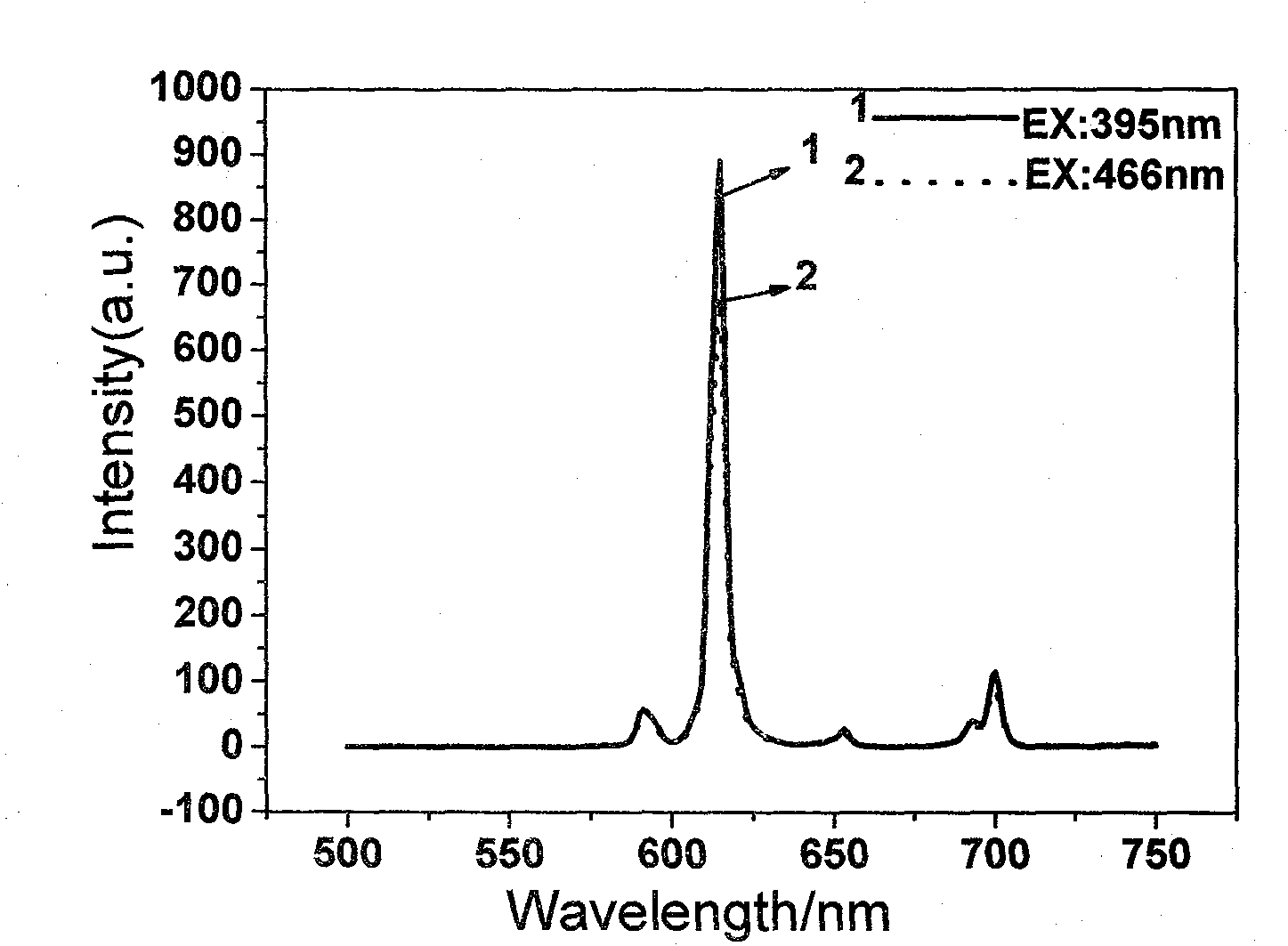

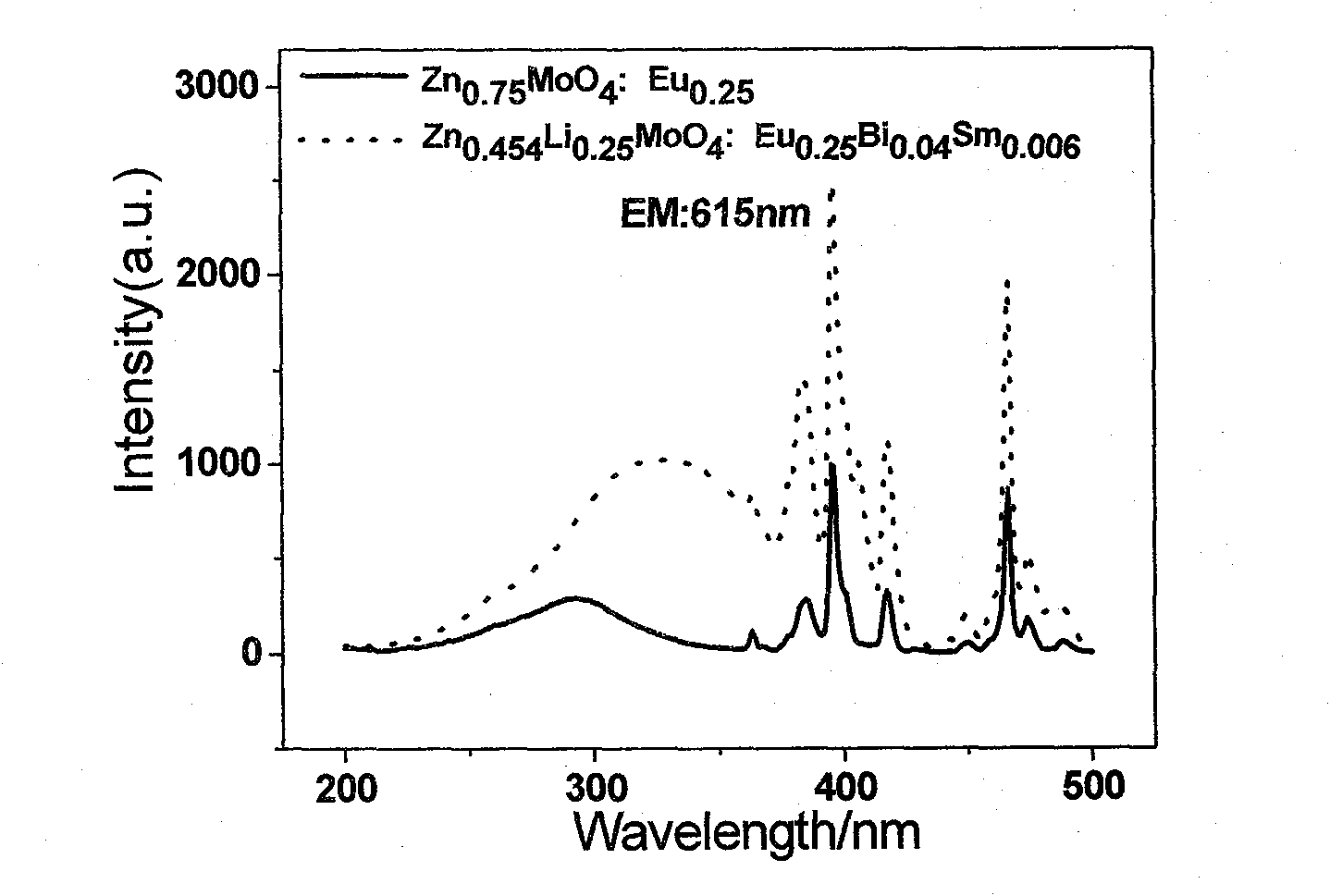

Red fluorescent powder capable of being simultaneously effectively excited by near ultraviolet and blue LED light

InactiveCN101928562AWide range of excitation wavelengthsGood luminous effectLuminescent compositionsChemical compositionPhotochemistry

The invention discloses red fluorescent powder capable of being simultaneously effectively excited by near ultraviolet and blue LED light. In the red fluorescent powder, ZnMoO4 is taken as a substrate, Eu3+ is taken as an activation center, and one or more of Li+, Na+, K+, Rb+ and Ag+ are taken as charge compensators, and one or more of Bi3+, Sm3+, Gd3+, Sc3+, Y3+, La3+, Gd3+ and Yb3+ with proper concentration are introduced to partially replace Zn so as to improve the absorption of the Eu3+ under the excitation at 395 nm and 466nm. The chemical composition general formula of the red fluorescent powder is Zn1-2x-y-zAxByMoO4:EuxBizSmw, wherein A is one or more of Li, Na, K, Rb and Ag; B is one or more of Sc, Y, La, Gd and Yb; and x is more than or equal to 0.05 and less than or equal to 0.4, y is more than or equal to 0 and less than or equal to 0.1, z is more than or equal to 0 and less than or equal to 0.1, and w is more than or equal to 0 and less than or equal to 0.05. The invention is applied to the preparation of the red fluorescent powder capable of being simultaneously effectively excited by the near ultraviolet and blue LED light.

Owner:NANCHANG UNIV

Night-gloss glass printing ink, preparation method and printing method on glass product

ActiveCN101974264AGood luminous effectMaintain luminous performanceInksOther printing apparatusPrinting inkDefoaming Agents

The invention discloses night-gloss glass printing ink, a preparation method and a printing method on a glass product. The night-gloss glass printing ink is prepared from long afterglow fluorescent powder, light-transmitting glass pigment, a suspensoid agent, a solid dispersion agent and a defoaming agent. The night-gloss glass printing ink is prepared by uniformly mixing the long afterglow fluorescent powder with the light-transmitting glass pigment, adding the mixture in the fused supensoid agent, solid dispersion agent and defoaming agent, and stirring and cooling. The printing method is realized by the following steps of: silk printing night-gloss patterns on the glass product with the night-gloss ink; raising the temperature of the glass product to 520-650DEG C; and maintaining the temperature for 20-30 minutes and then cooling to obtain the finished product. The night-gloss glass printing ink is roasted silk printing ink for resisting the high temperature of 520-650DEG C and being applied to the glass product and is ink which can be quickly cured and has remarkable night-gloss effect, strong adhesive force and friction resistance; and the preparation method has simple process, and is convenient to operate and suitable for industrial production.

Owner:SHENZHEN HUAXI BIO TECH LTD

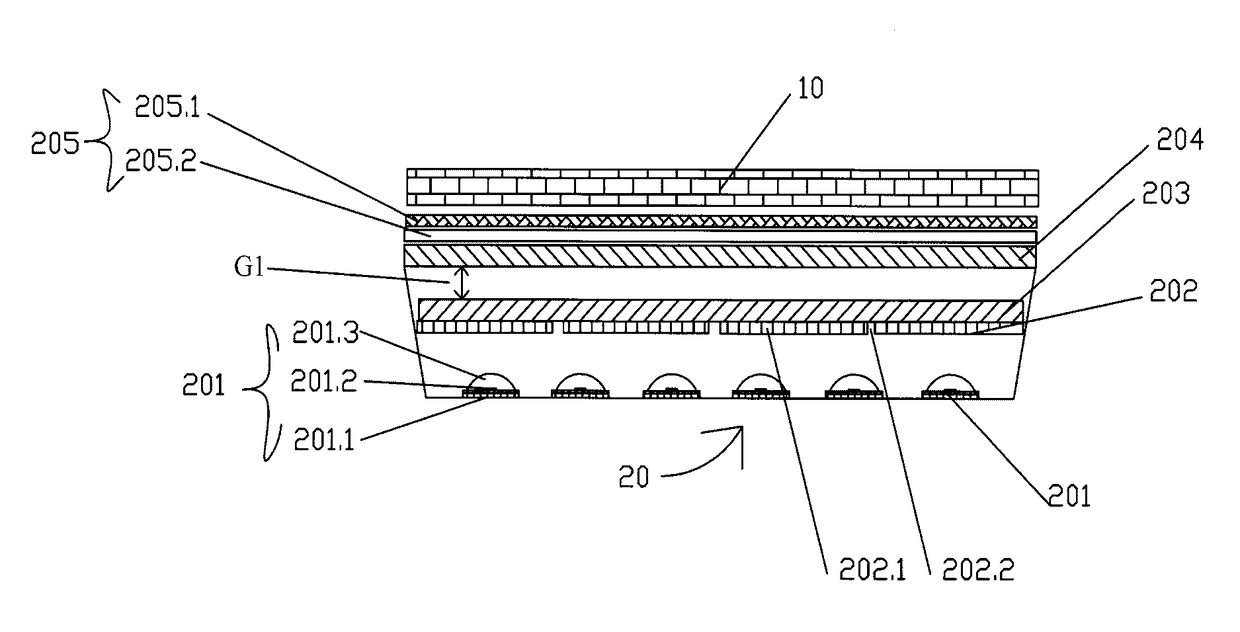

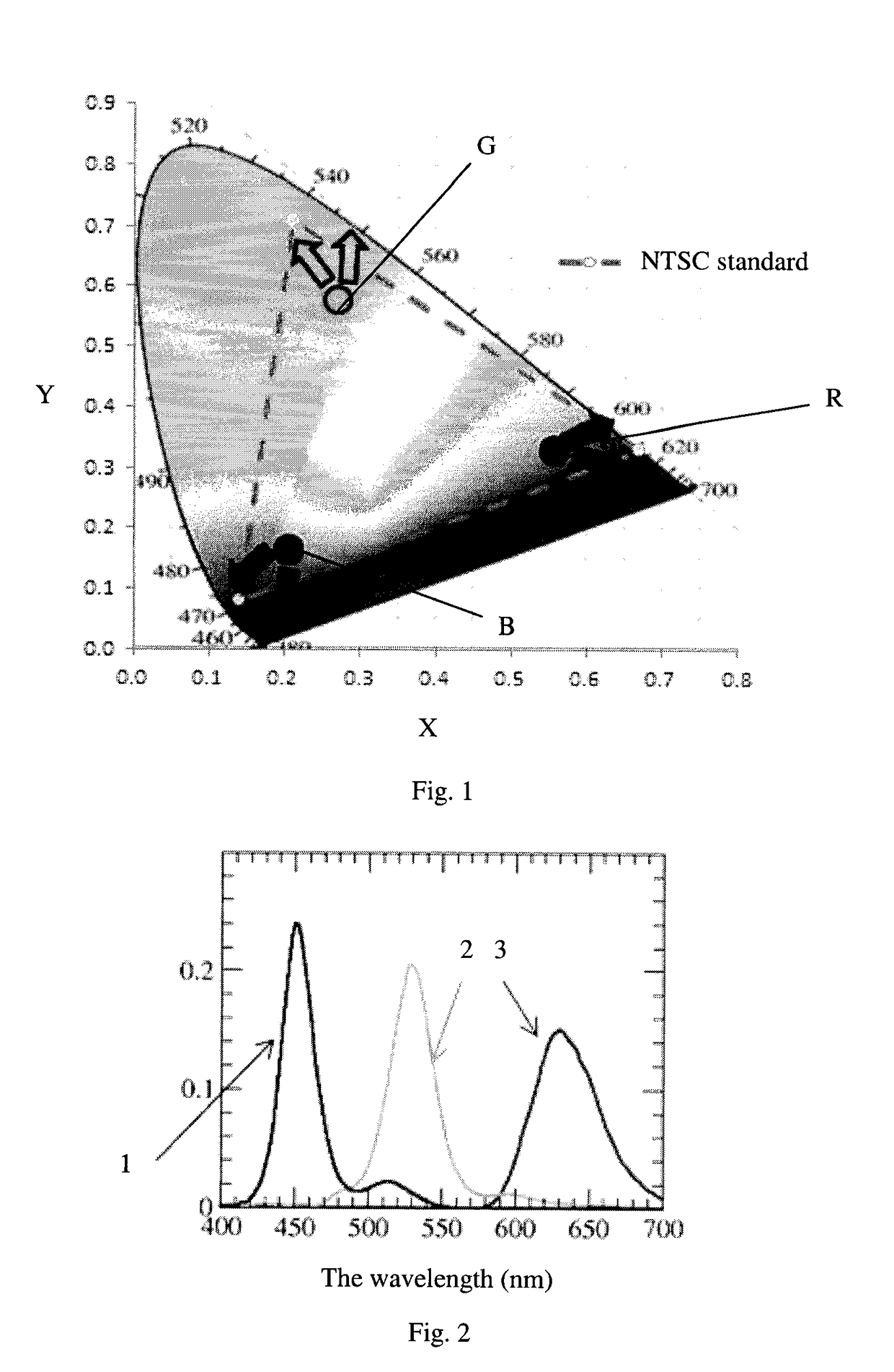

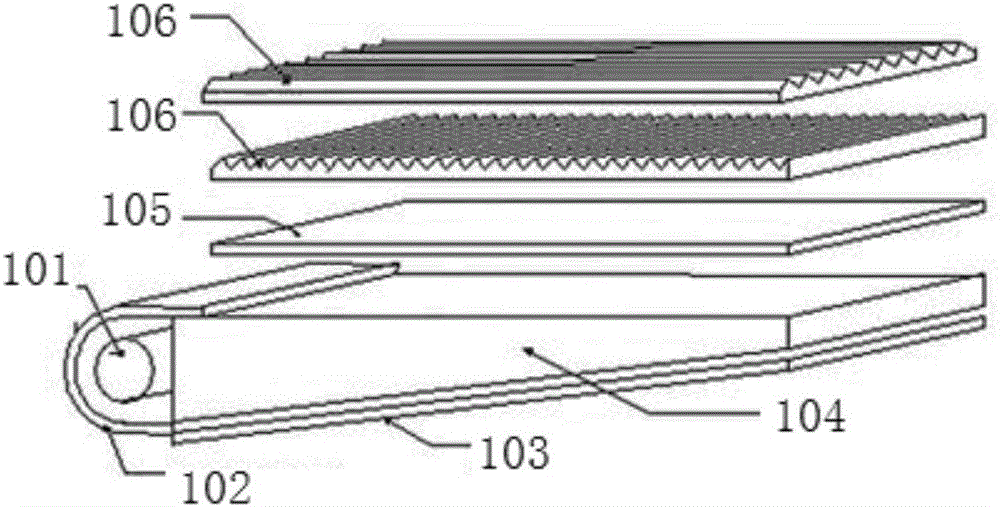

Backlight module

ActiveUS20170168351A1High light-emitting efficiencyLow qualified rateMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayQuantum dot

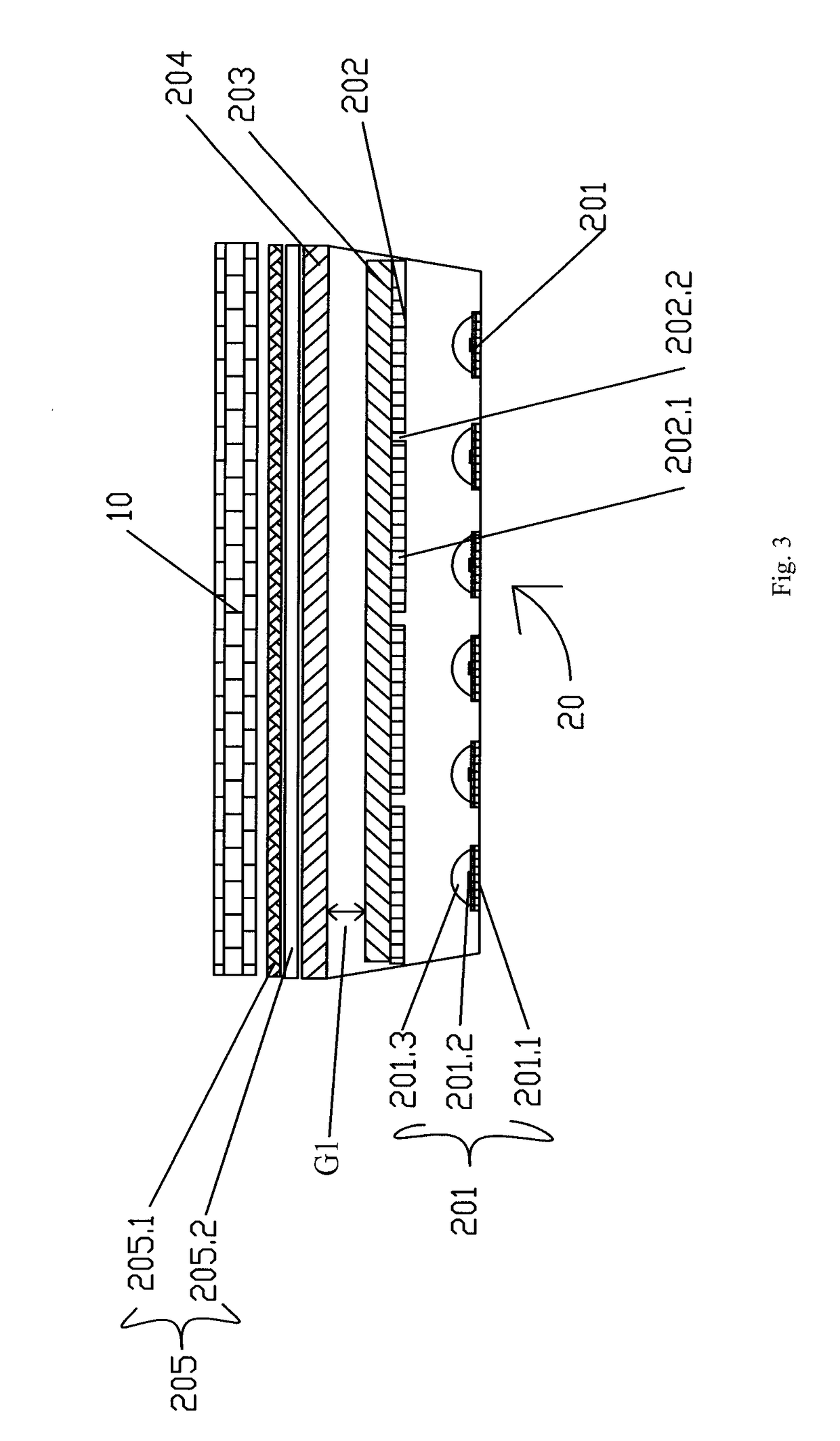

The present disclosure relates to LCD manufacturing field, and particularly relates to a backlight module. A backlight module is disclosed, said backlight module comprising a light-emitting element, which can emit a first light with a wavelength in a first wavelength range, a quantum dot diaphragm, which is formed by combining a plurality of sub-diaphragms each with a small area together and can emit a second light with a wavelength in a second wavelength range and a third light with a wavelength in a third wavelength range, and a diffusing plate used for light homogenization. The defects of low qualified rate of quantum dot diaphragm with large area manufactured currently and a poor homogeneity thereof can be avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

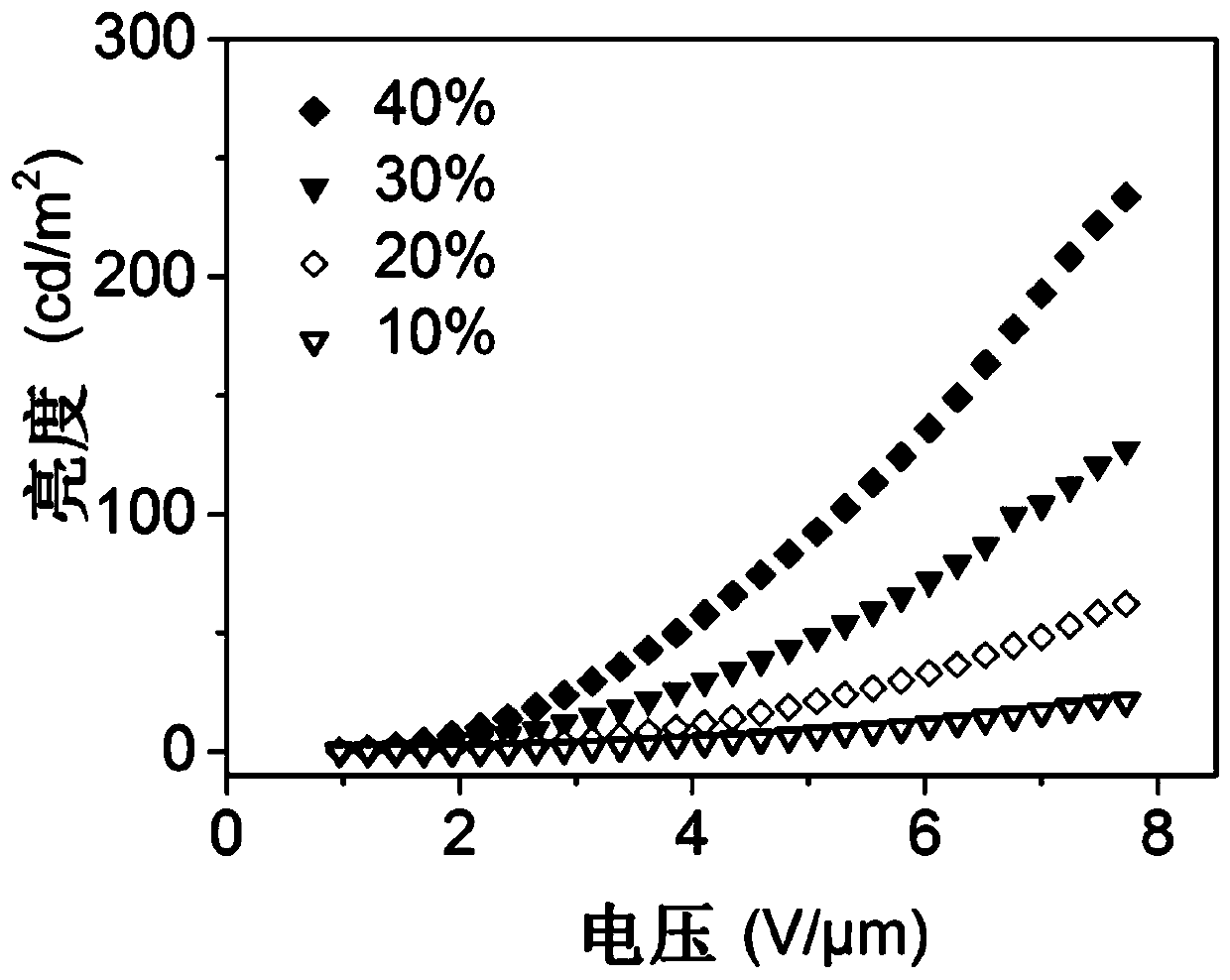

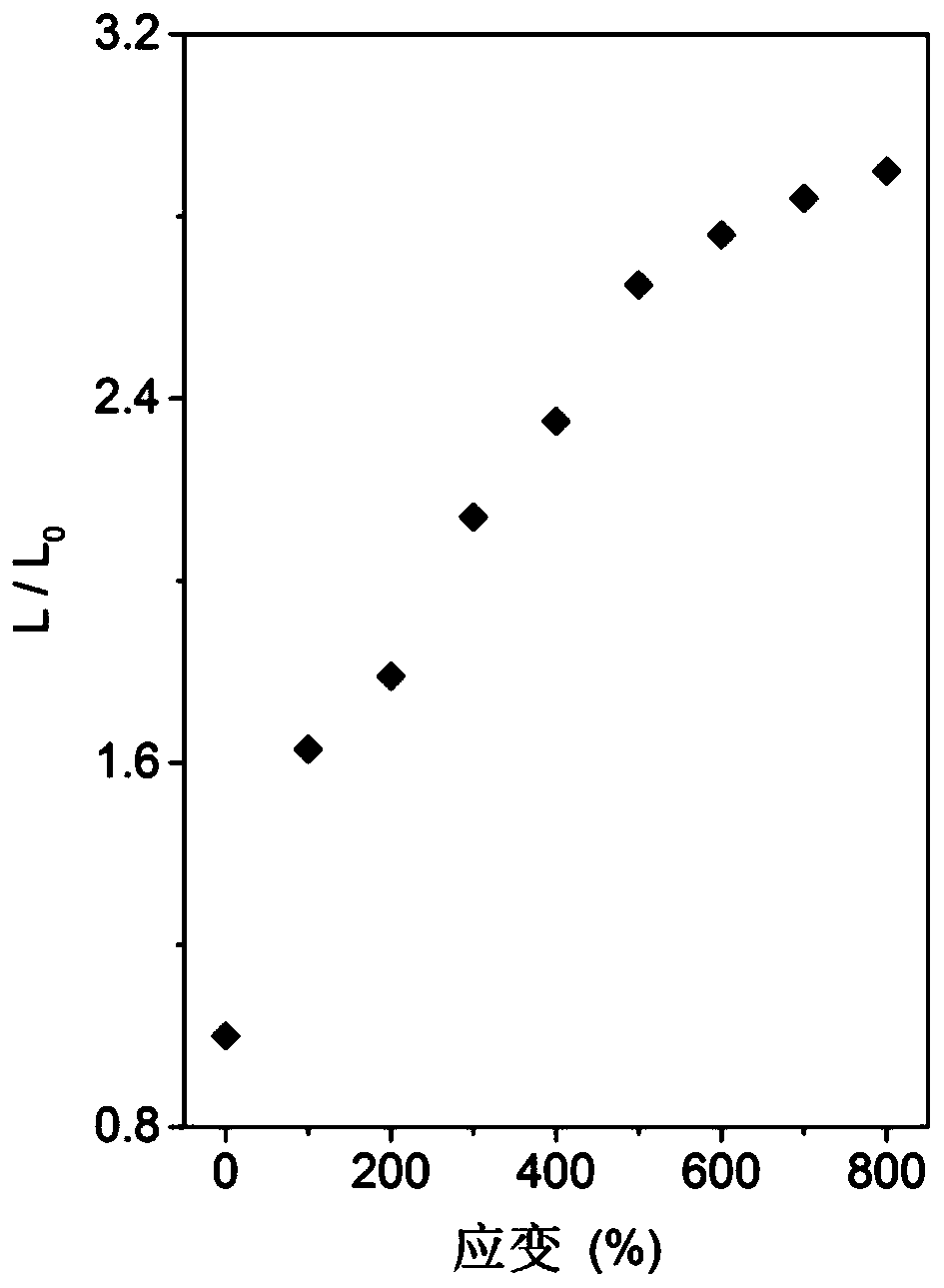

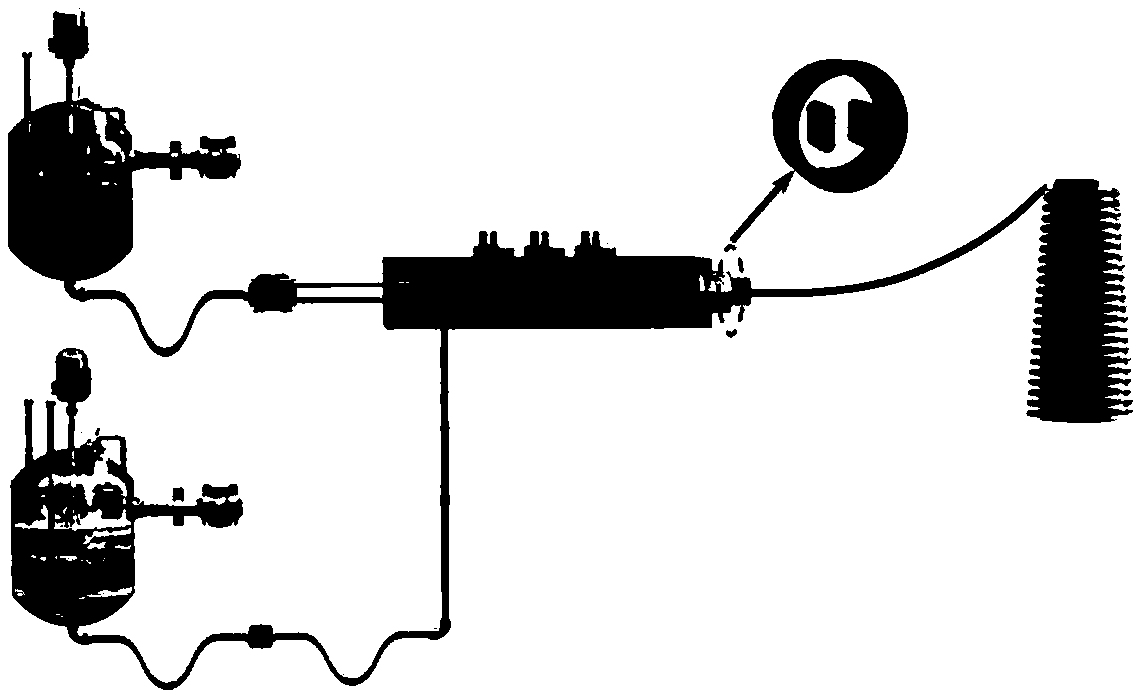

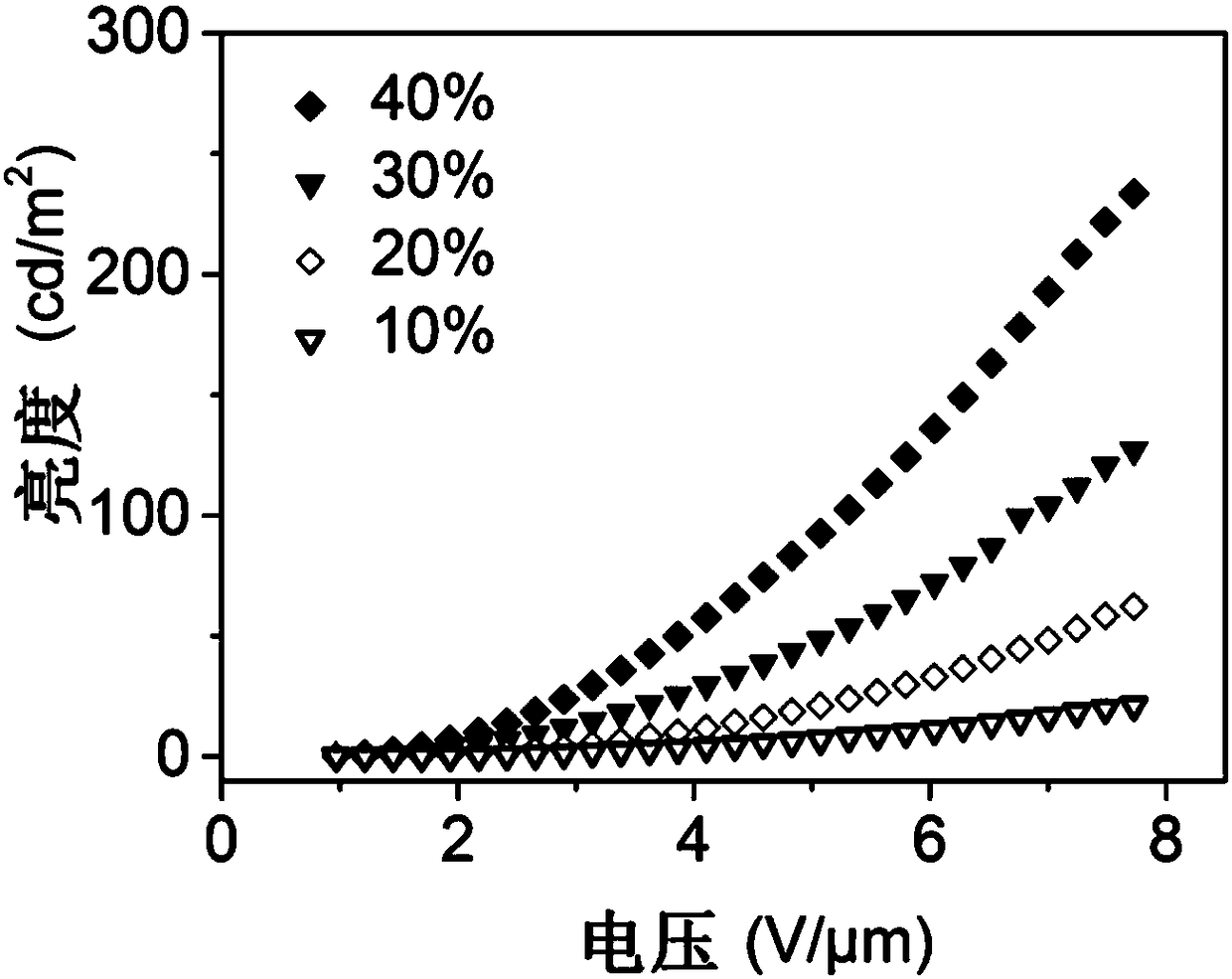

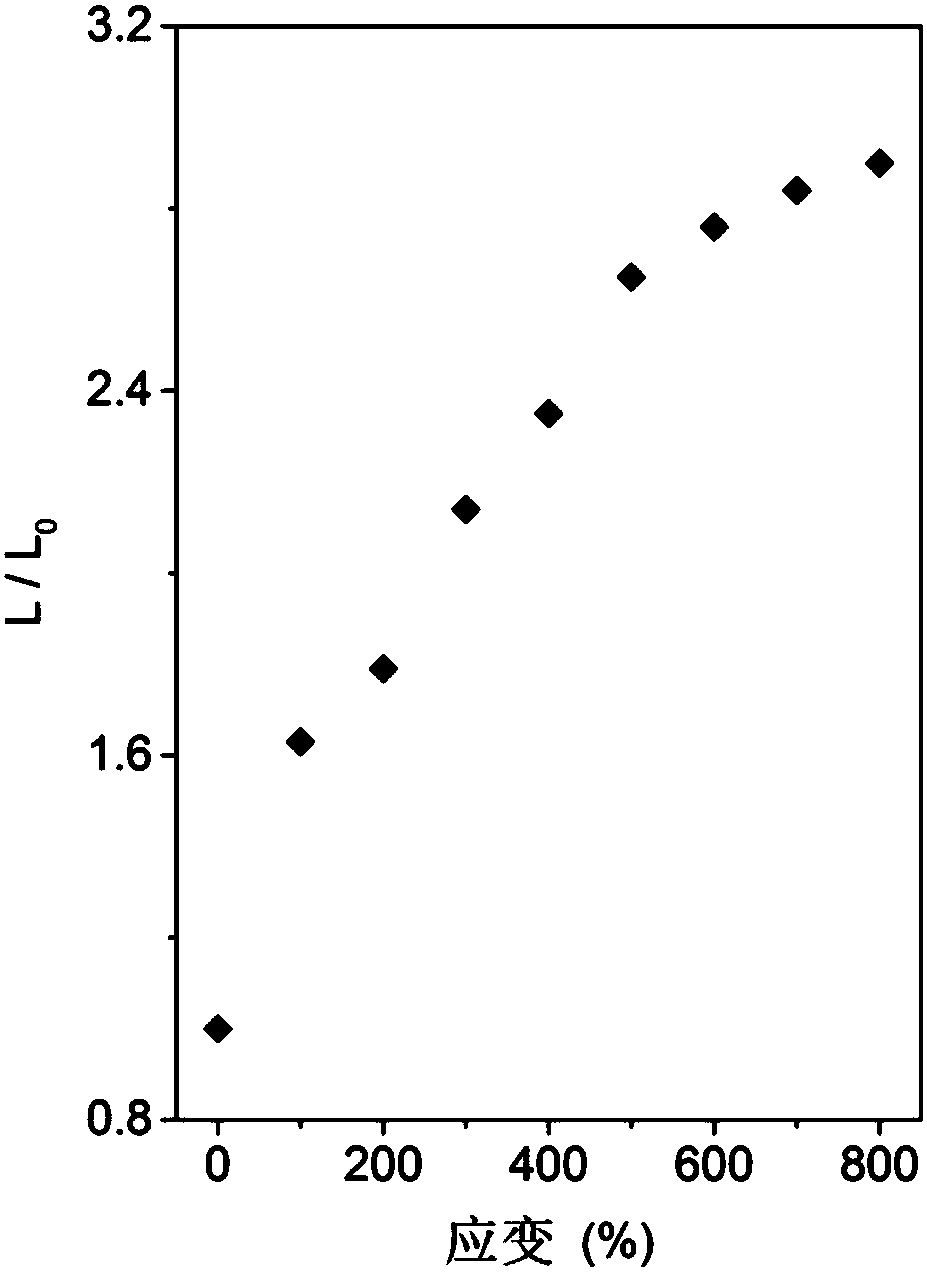

High-elasticity electroluminescent fiber and preparation method thereof

ActiveCN108093535AImprove wearing comfortGood luminous effectElectrical apparatusElectroluminescent light sourcesElectrical conductorGel electrode

The invention belongs to the technical field of intelligent electronic devices, and particularly relates to a high-elasticity electroluminescent fiber and a preparation method thereof. The method comprises preparing a frozen cross-linked hydrogel ion conductor as a transparent and high-elasticity electrode; and preparing a polydimethylsiloxane oligomer-electroluminescent powder mixed light-emitting active material with extrusion formability to be further cured and formed after extrusion. The multi-channel parallel extrusion needle head is designed, so that the light-emitting active layer is wrapped with two gel electrodes which are arranged in parallel, and the viscosity of the mixed light-emitting active material can ensure that the extruded fiber structure does not deform after the viscosity of the mixed light-emitting active material is controlled. The polydimethylsiloxane and the conductive gel have high elasticity, and the final luminescent fiber can still keep normal work when the tensile strength reaches up to 800%, the stable circulating tensile quantity can reach 300%, the cycling stability is more than 100 times, and the highest luminous brightness reaches 242. 6cd / m2. The light-emitting fibers can be further woven into clothes, and have very high wearing comfort and attractive light-emitting effects.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Preparation method of luminous decorative plate

The invention discloses a preparation method of a luminous decorative plate. The preparation method comprises the following steps: 1) preparing material: water-based luminous ink is prepared by the following raw materials in percentage by weight: a material A composed of 5-20% of water-based acrylic resin, 8-20% of luminous powder, 0.5-2% of a dispersant, 0.2-0.5% of a defoaming agent and 15-20% of tap water, a material B composed of 10-20% of a casein solution, 0.3-0.5% of a defoaming agent, 0.5-2% of an anti-settling agent, 5-10% of ethanol, 2-5% of propylene glycol, 20-40% of tap water and 1-2% of a leveling wetting agent and a material C composed of 0.5-2% of a thickening agent and 0.5-1% of a pH value regulator; 2) printing; 3) dipping; 4) pressing, so as to obtain the luminous decorative plate. The luminous decorative plate prepared through the method provided by the invention has the effect of environmental protection and a long-term luminous function, and further has the characteristics of light fastness, scratch resistance, wear resistance, and natural and vivid texture.

Owner:CHANGZHOU WEIXING DECORATIVE MATERIALS

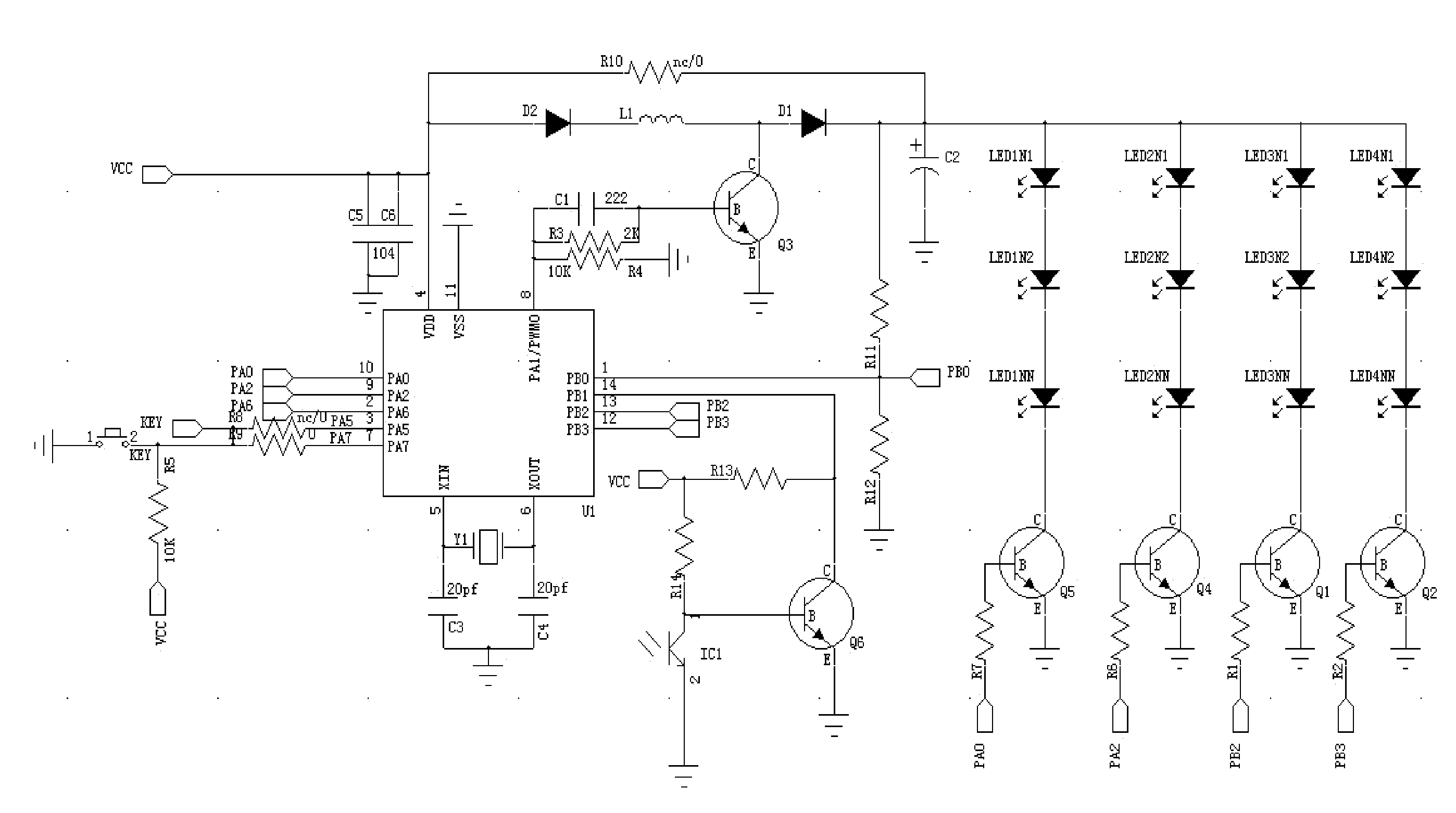

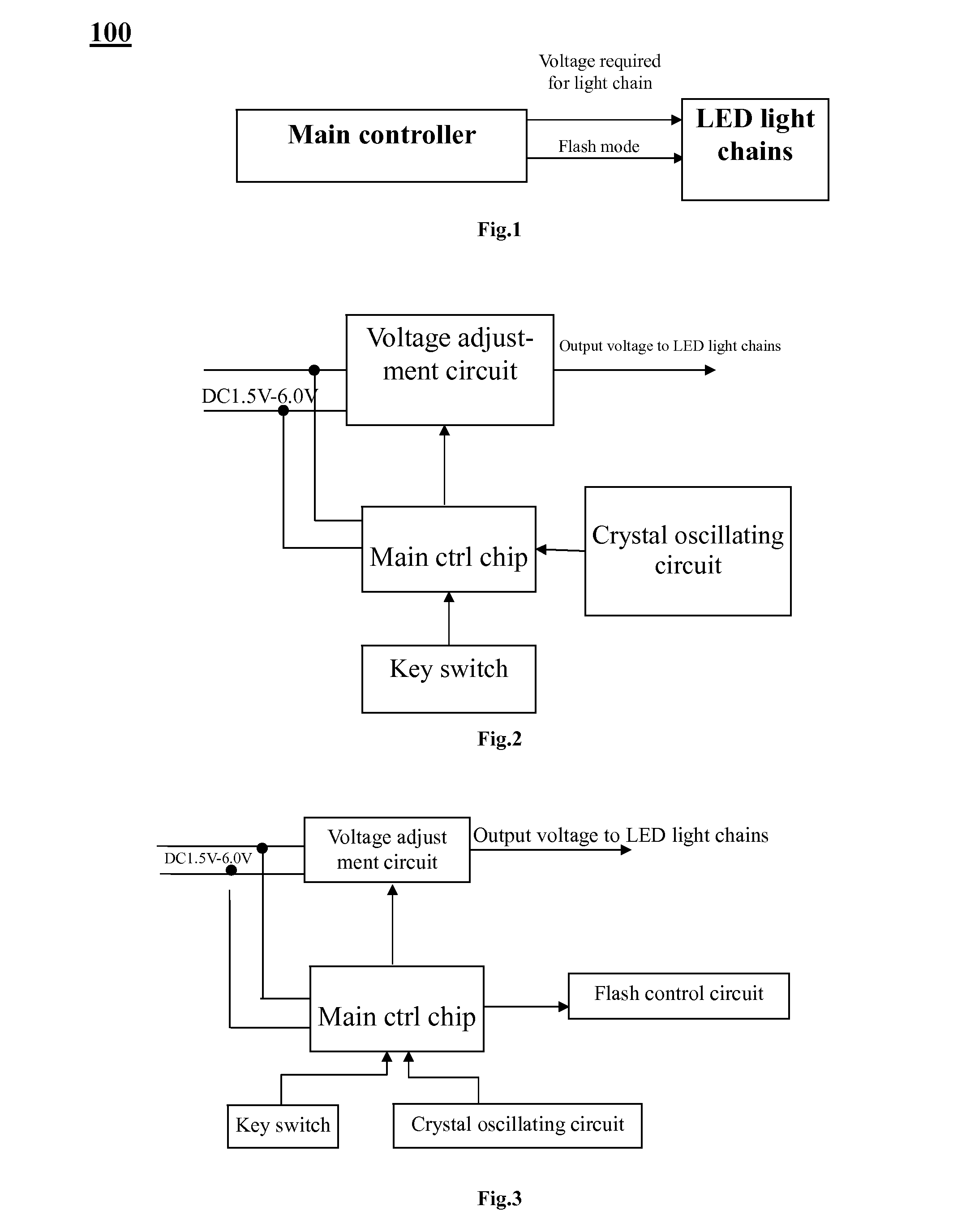

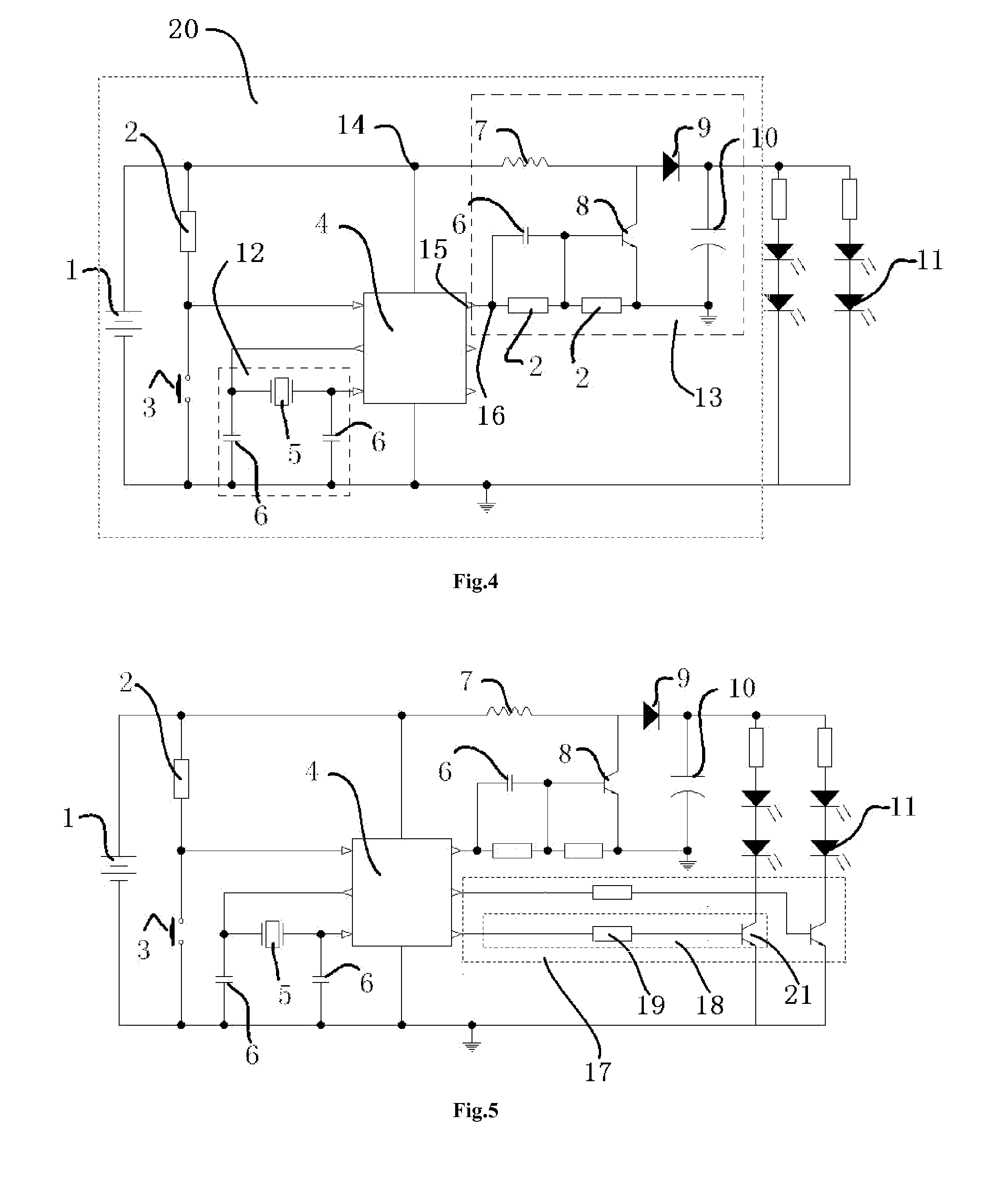

LED decorative light

InactiveUS20120299488A1Good luminous effectElectrical apparatusElectroluminescent light sourcesInstruction cycleVoltage regulation

LED decorative light comprising DC power supply, main controller, and LED light chains; said main controller consists of key switch, crystal oscillating access circuit, and main control chip, with said key switch and crystal oscillating access circuit connected to said main control chip respectively; said main control chip pulse width modulation end outputs variable duty ratio PWM; said crystal oscillating circuit is used to provide instruction cycle required for main control chip; and said key switch is used to control operating state of main control chip; wherein said main controller also includes a voltage adjustment circuit, used to adjust DC power supply voltage to the value required for LED light chains, with input end of this circuit connected to said DC power supply, its control end connected to pulse width modulation end of said main control chip, and its output end connected to LED light chain input end.

Owner:ZHANG XIUHONG +1

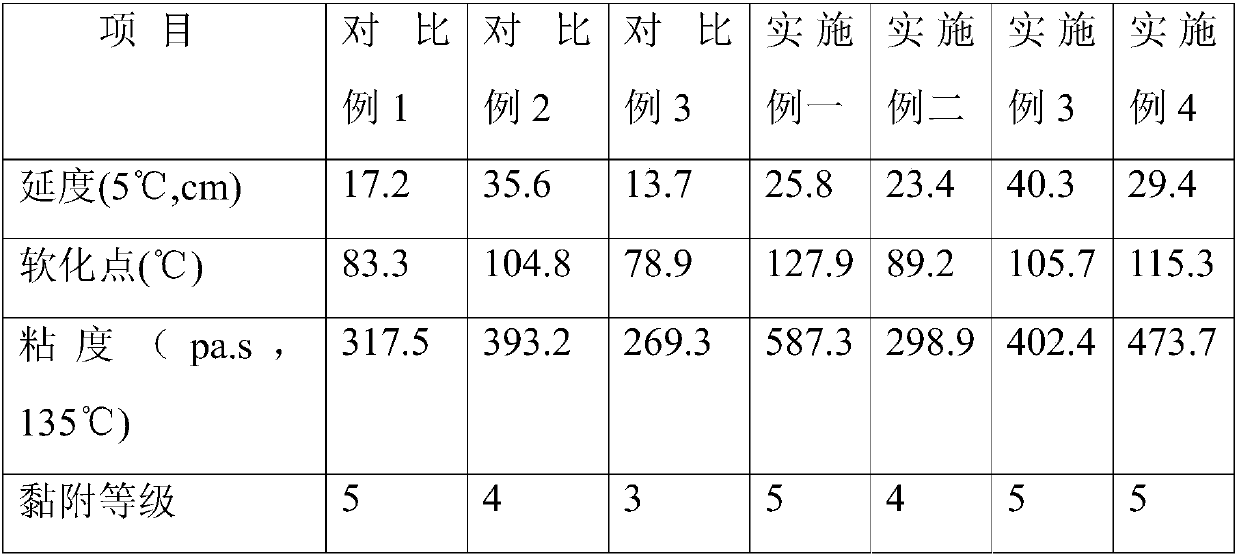

Modified luminous colored asphalt for dry method and preparation method of modified luminous colored asphalt

The invention discloses modified luminous colored asphalt for a dry method and a preparation method of the modified luminous colored asphalt. The modified luminous colored asphalt is prepared from components in parts by weight as follows: 31.5-81 parts of base asphalt, 4-15 parts of a modifier, 2.5-6.5 parts of an anti-stripping agent, 2-15 parts of a luminescent material, 0.2-1.0 part of an antioxidant, 0.3-1.0 part of a weather resistant agent and 10-30 parts of color pigment. The modified luminous colored asphalt can be applied to the dry method, is convenient to construct, higher in viscosity and good in luminous effect, high-temperature performance, water damage resistance and low-temperature resistance of an asphalt pavement are improved, and the asphalt has good using effect in actual application.

Owner:GUANGZHOU HONGJIN SYNTHETIC MATERIAL CO LTD

High-performance light-storing noctilucent master batch for polyolefin plastic and preparation method thereof

The invention relates to a high-performance light-storing noctilucent master batch for polyolefin plastic and a preparation method thereof. The high-performance noctilucent master batch for polyolefin plastic comprises: 10-15.5% of LLDPE (the melt flow rate is 15-25g / 10min, and the particle size is 30-60 meshes), 27.5-5% of LDPE (the melt flow rate is 5-10g / 10min, an the particle size is 50-100 meshes), 60-75% of one (or multiple) noctilucent pigment, 2.0-3.0% of polyethylene wax (the molecular weight is 3000-4000) and 0.5-1.5% of ethylene bis stearamide. The preparation method comprises the following steps: putting 60% of the noctilucent pigment and the other components into a mixer, uniformly mixing, and performing melt blending through a double screw extruder, wherein the temperature is controlled at 140-180 DEG C; meanwhile, feeding the residual 40% of the noctilucent pigment into a machine barrel of the extruder through lateral charging in a uniform metering manner, and mixing and extruding together with the main materials; then granulating and molding in a brace water-cooling cutting and drawing manner or a mold surface air-cooling cutting and drawing manner; and finally, drying to obtain the master batch provided by the invention. The master batch can be used for coloring of plastic products in plastic processing industry.

Owner:CHANGZHOU HONGMEI PLASTIC MASTERBATCH

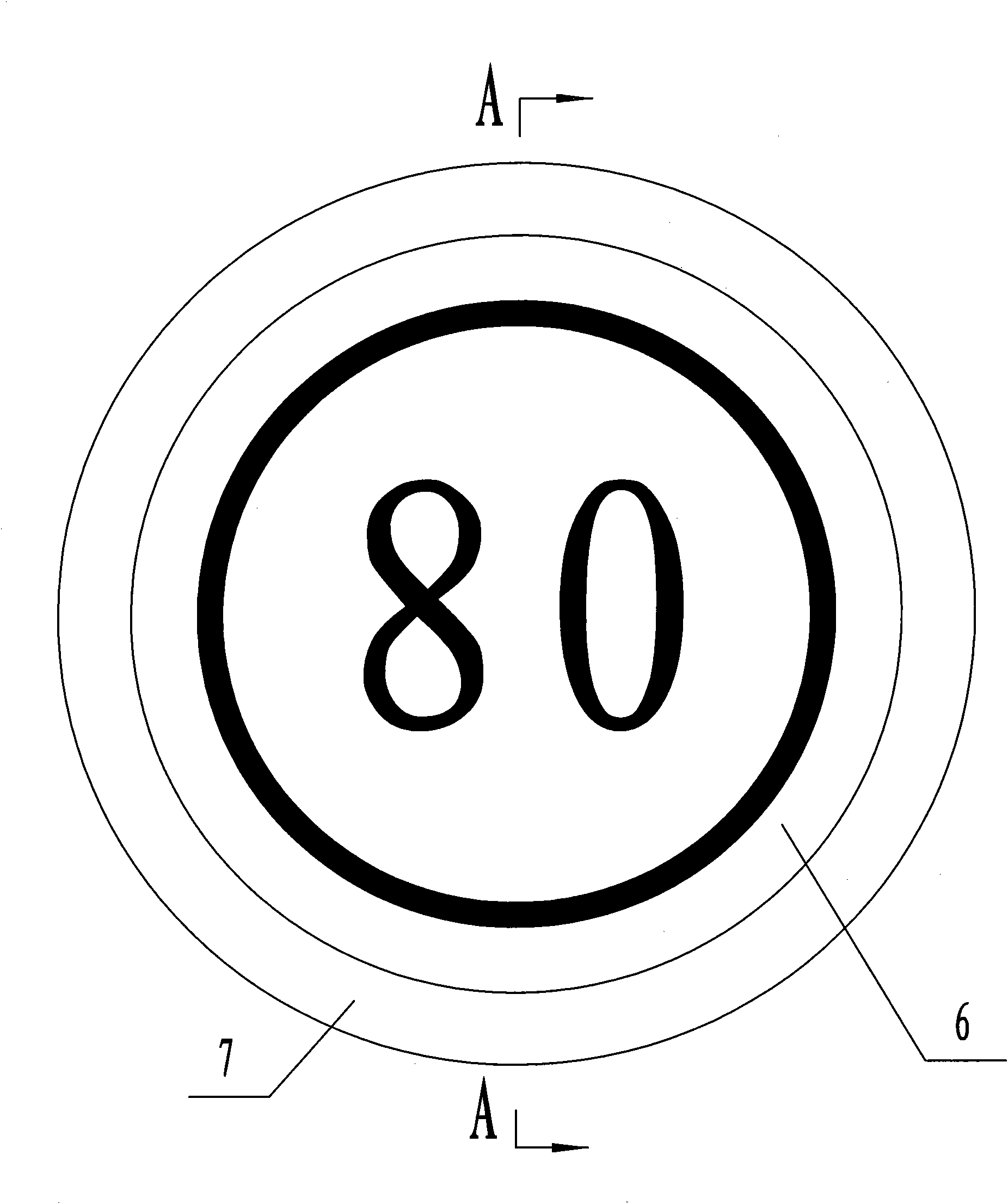

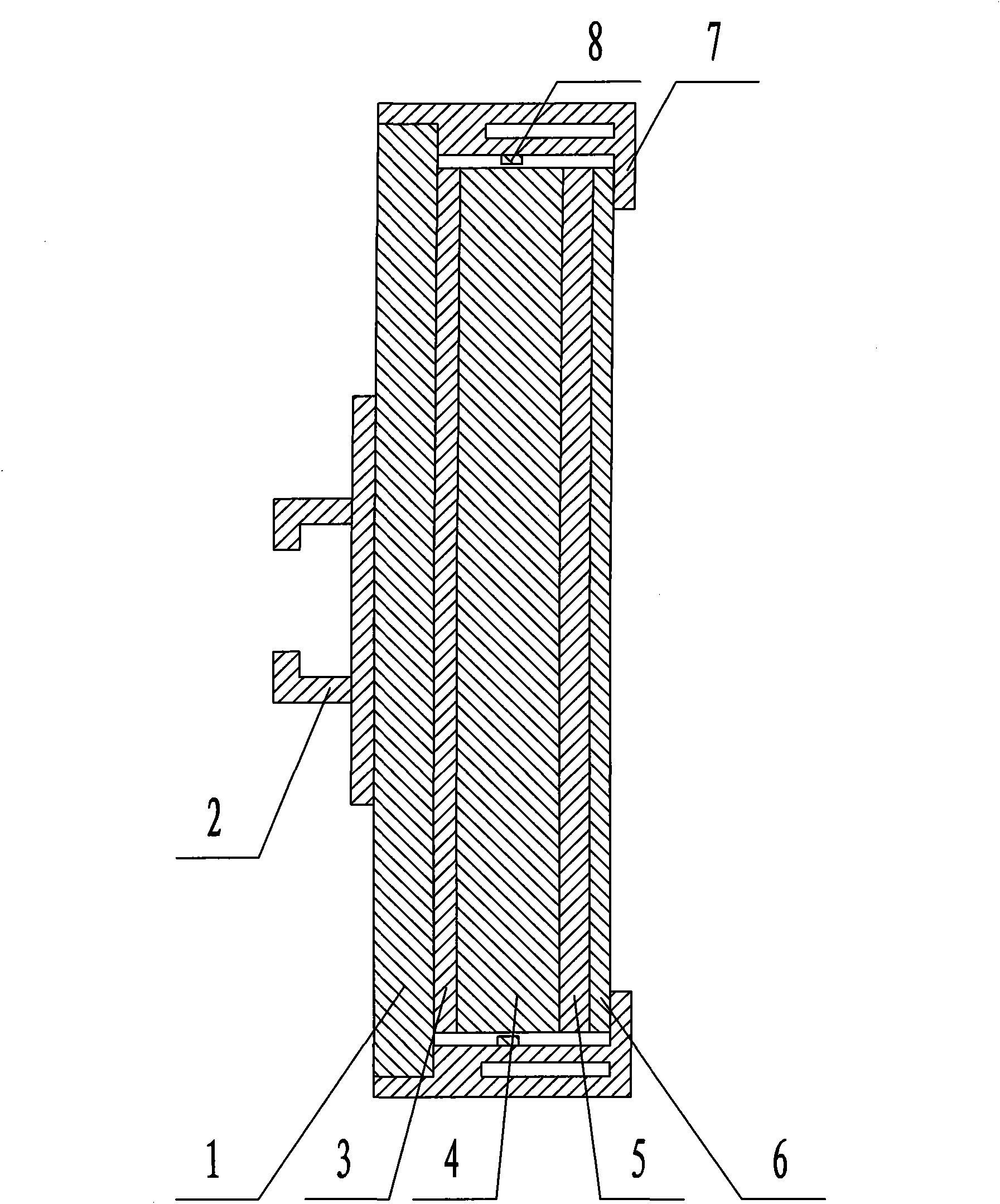

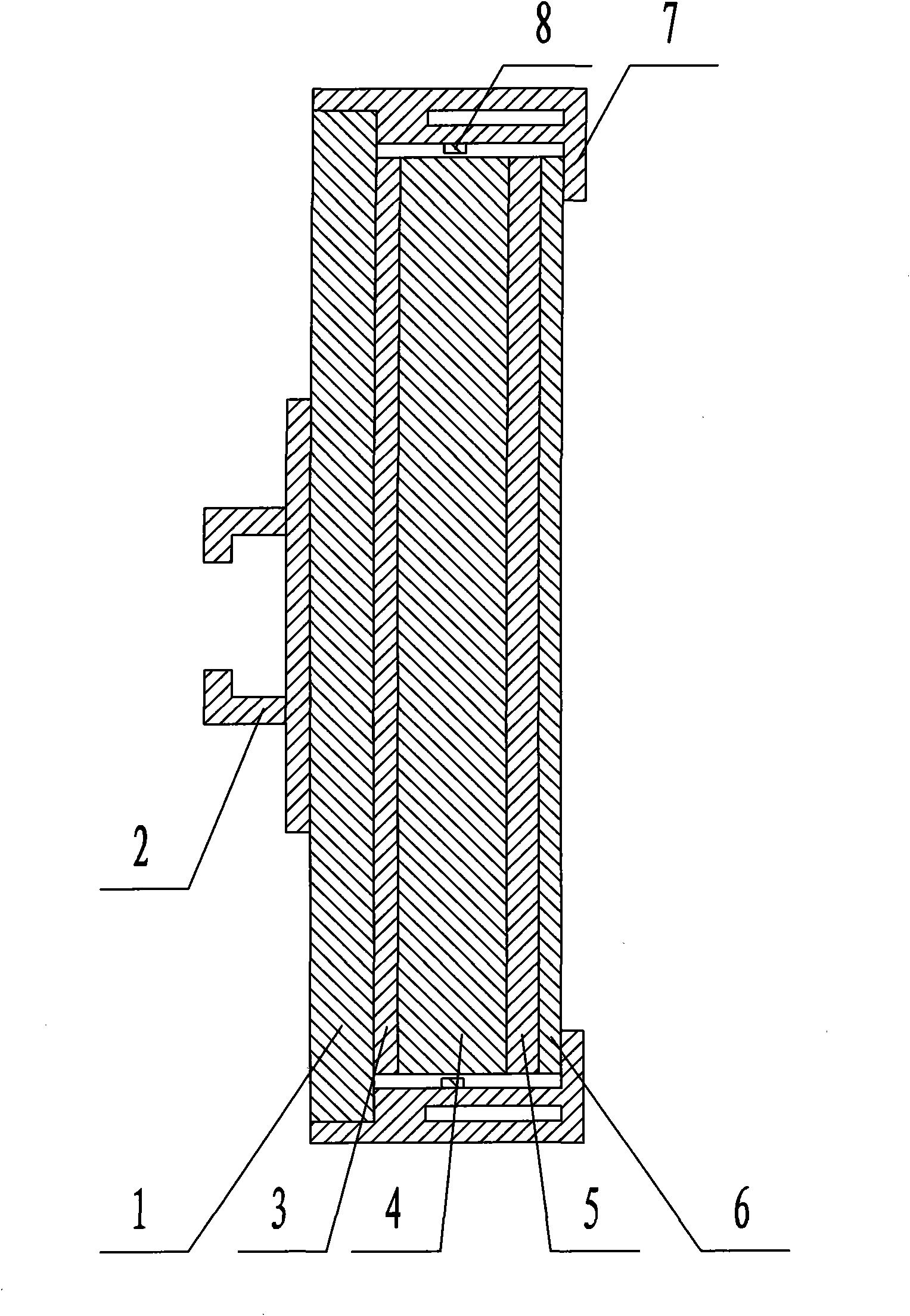

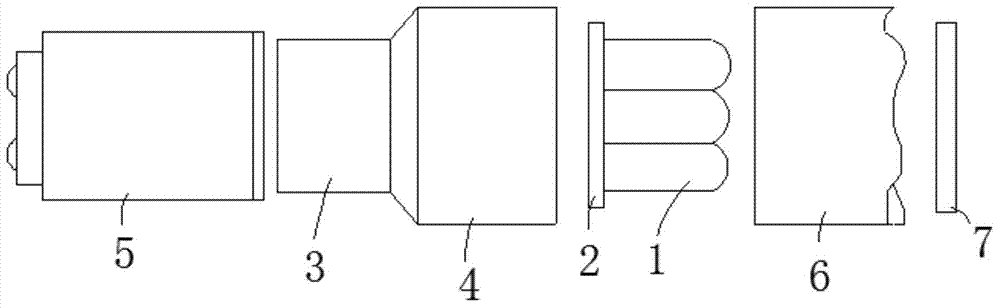

Luminous road traffic sign board with LED panel

The invention discloses a luminous road traffic sign board with an LED panel, comprising a bottom plate. The luminous road traffic sign board with the LED panel is characterized in that an organic light guide plate is arranged at the front end of the bottom plate; a panel is arranged at the front end of the organic light guide plate; a road traffic sign indication film is arranged on the panel; the bottom plate, the organic light guide plate, the panel and the periphery of the road traffic sign indication film are provided with a peripheral protection layer; and a plurality of LED light sources are arranged on the inner wall of the peripheral protection layer facing to the organic light guide plate. The invention has the advantages of obvious luminous effect, lower manufacture cost, low energy consumption and no dazzling phenomenon under a condition of poor external light ray, and the road traffic sign board can realize the function of indicating the road traffic and carry out luminescence indication by using the LED when the LED light sources are switched off.

Owner:包士祥

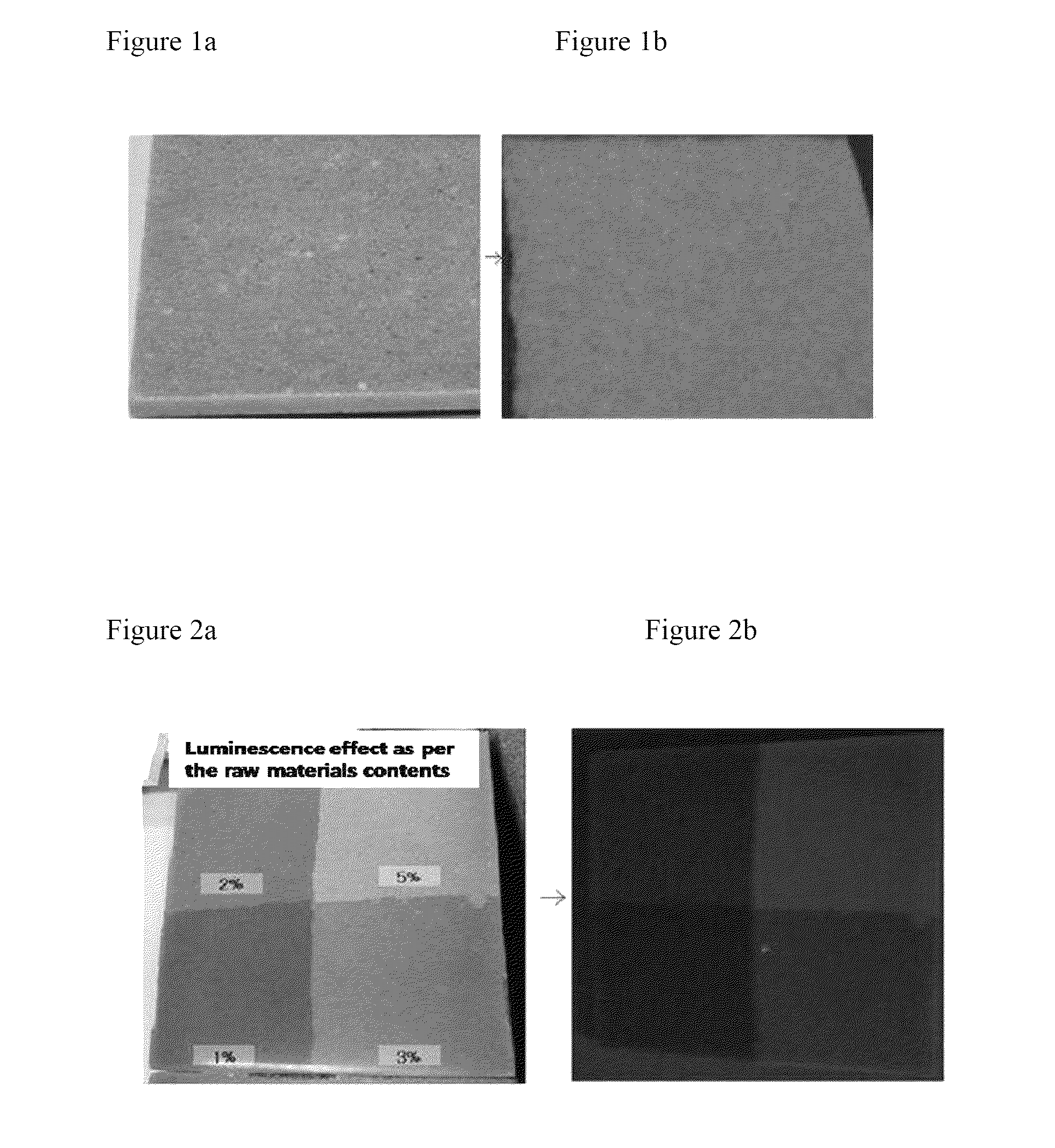

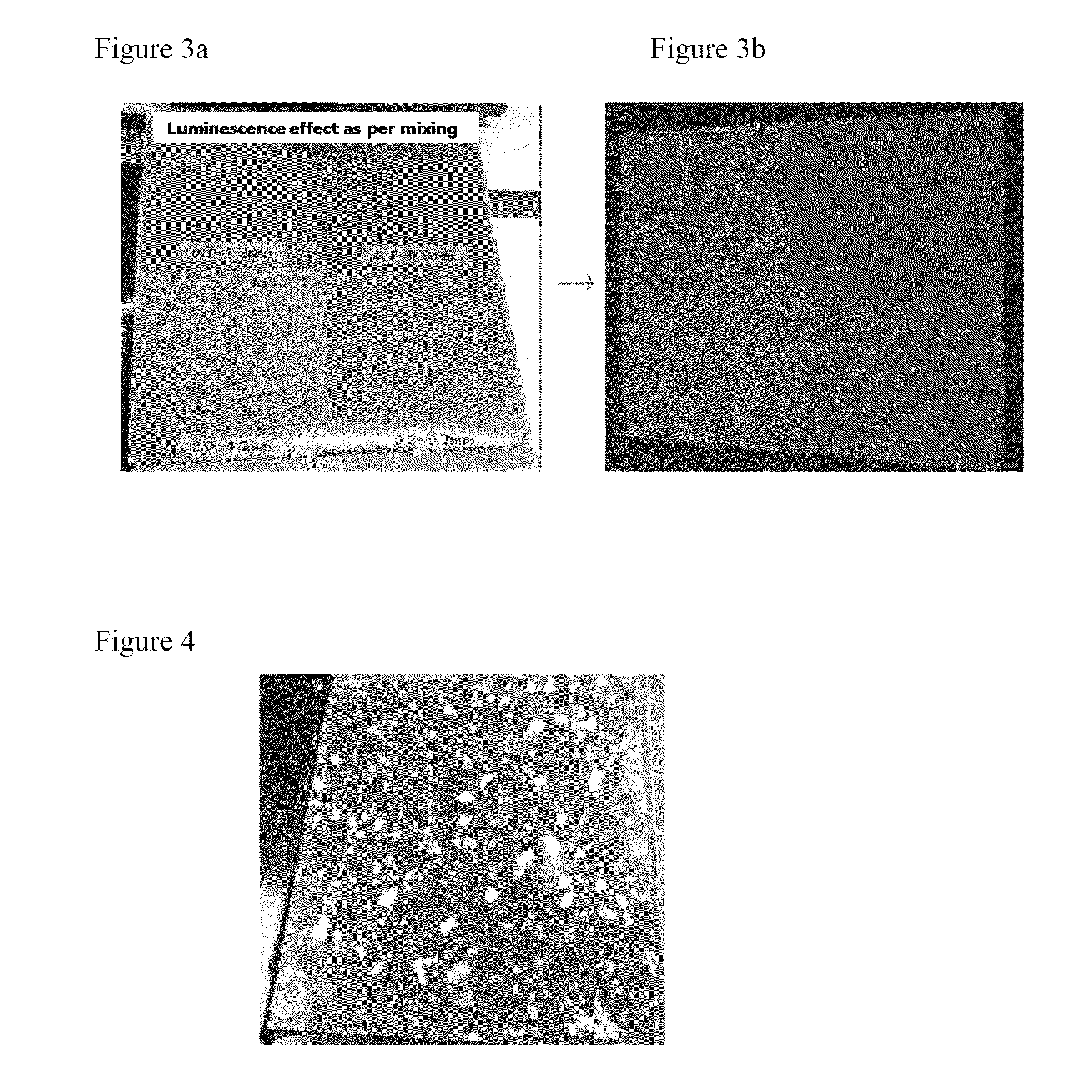

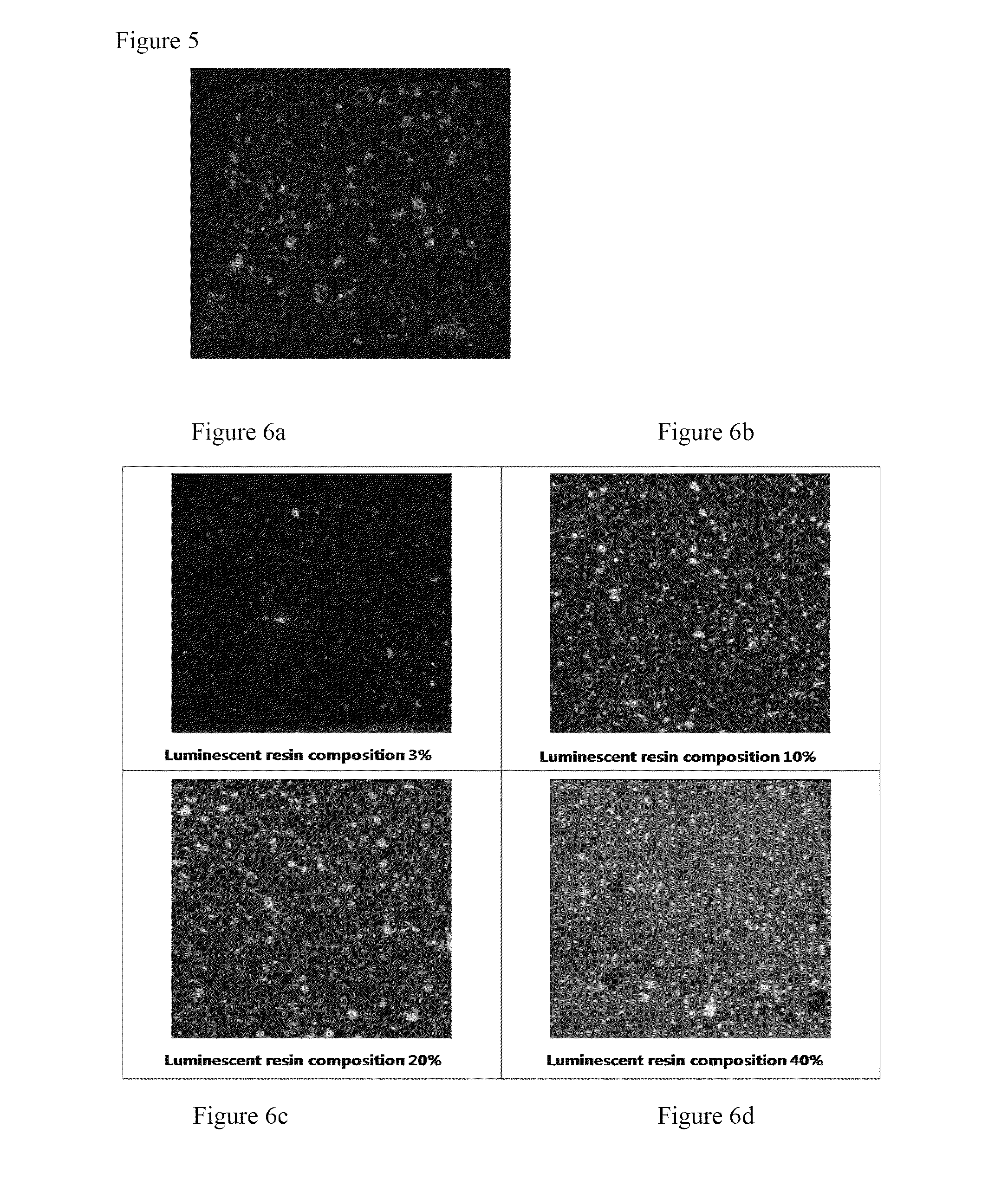

Artificial marble having natural textures and luminescent patterns and method of preparing the same

ActiveUS8999199B2Bright enoughNatural textureNatural patternsSpecial tyresPolymer sciencePolyester resin

An artificial marble includes unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (C). An artificial marble according to a second embodiment includes about 70 to about 95% by weight of a non-luminescent base material (I) comprising unsaturated polyester resin (A), compound including silica (B), and organic / inorganic pigment (C) and about 5 to about 30% by weight of a luminescent amorphous pattern part (II) comprising unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (D). An artificial marble according to a third embodiment includes unsaturated polyester resin (A), compound including silica (B), and amorphous luminescent chip (C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Preparation method of rare-earth fluorescent microspheres

InactiveCN105085776AGood shape structureGood luminous effectLuminescent compositionsMethyl methacrylatePre treatment

The invention relates to a preparation method of rare-earth fluorescent microspheres, belonging to the technical field of fluorescent substance preparation. The method comprises the following steps: carrying out pretreatment to obtain a monomer refined methyl methacrylate and an initiator refined azodiisobutyronitrile, preparing a rare-earth high-luminescent-intensity three-element coordination compound with polymerization activity by a coprecipitation process, copolymerizing the three-element coordination compound with methyl methacrylate to obtain a high-molecular-weight high-polymer rare-earth metal copolymer solid material which is the rare-earth fluorescent microspheres. The example proves that the rare-earth fluorescent microspheres can be used in the aspects of biological detection, fluorescent markers, special-type inks, medical immune detection and cell markers, can not injure the human body, and has stable and efficient luminous emissivity and longer fluorescent lifetime (by 30% or above).

Owner:JIANGSU ZHENYU ENVIRONMENTAL PROTECTION TECH

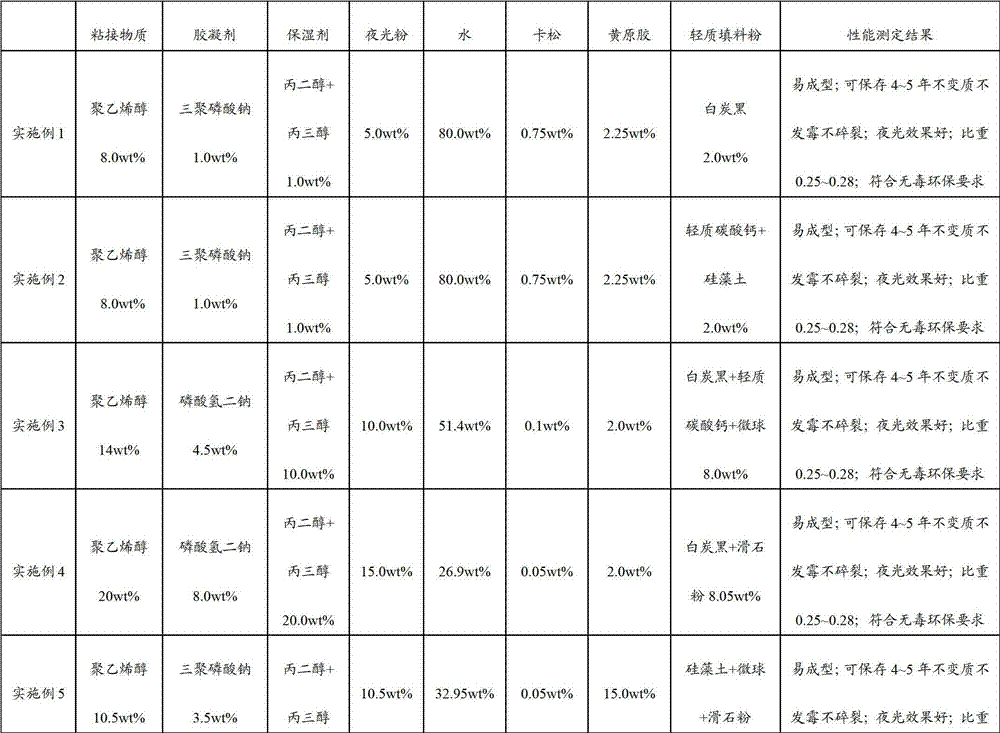

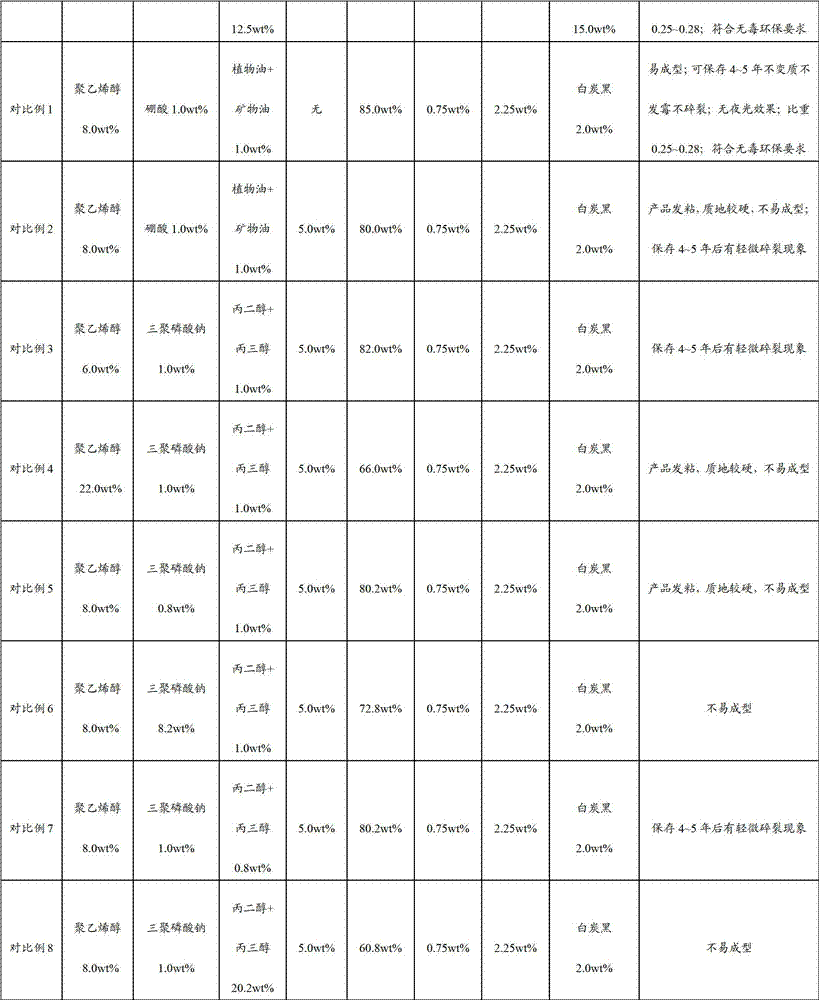

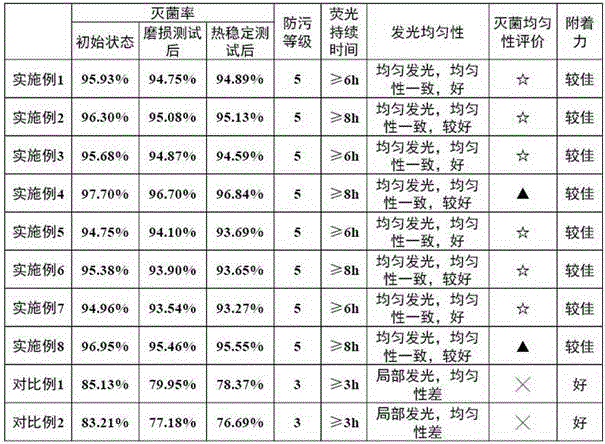

Noctilucent clay

The invention discloses a noctilucent clay, comprising by weight: 8.0-20.0% of polyvinyl alcohol, 26.9-80.0% of water, 0.05-0.1% of kathon, 1.0-20.0% of propylene glycol and glycerin, 2.0-15.0% of xanthan gum, 2.0-15.0% of lightweight filler powder, 1.0-8.0% of phosphate, and 5.0-15.0% of noctilucent powder. The noctilucent clay provided by the present invention is easy to mold, non-toxic, lightweight, long-lasting and good in noctilucent effect, is good to make up the market gap of the noctilucent clays, helps to open up the development space for clay, and has a very broad market prospect.

Owner:河源市云彩实业有限公司

Automobile lamp

InactiveCN104501057ALuminous intensityGood luminous effectPoint-like light sourceLighting heating/cooling arrangementsLamp shellEngineering

The invention relates to an automobile lamp which comprises an LED light-emitting component, a circuit board, a lamp shell, a cooling ring, a lamp holder, a reflecting cover and a front lens. The LED light-emitting component is fixedly installed at the front end of the circuit board, the lamp holder is fixedly installed at the rear end of the circuit board, the cooling ring is arranged on the outer periphery of the circuit board, the rear end of the cooling ring is fixedly connected with the lamp holder, the front end of the cooling ring is detachably connected with the reflecting cover which is located on the outer periphery of the LED light-emitting component, the lamp holder is detachably installed at the rear end of the lamp holder, and the front lens is fixedly installed at the front end of the reflecting cover. Compared with the prior art, the automobile lamp is good in lighting effect, high in light intensity, good in cooling and long in service life.

Owner:龙桂山

Noctilucent antibacterial lead and cadmium-free low-temperature frit and preparing method thereof

The invention discloses an noctilucent antibacterial lead and cadmium-free low-temperature frit and a preparing method thereof. The method comprises the steps of: A mixing: mixing and grinding evenly 10-18% of quartz, 5-12% of feldspar, 15-25% of borax, 3 -12% of carbonate, 20 - 35% of boric acid, 3- 8% of spodumene, 1 - 4% of fluorinated salt and 0 - 5% of kaolin, adding 0.1-5% of antibacterial composite and 1 to 5% of noctilucent powder composite, grinding evenly to prepare a mixture; b melting, and c cooling for molding. Compared with the conventional low-temperature frit, the low-temperature frit prepared by the method has the advantages of scientific ingredients, reasonable preparation, stable performance and no toxic substances, such as lead and cadmium, meanwhile, the frit has the persistent antibaterical property of spectra, the antifouling self-cleaning function and the noctilucent function, does not have agglomeration and is high in uniformity and stability of luminance and antibacterial stability, which further broads the application range of the low-temperature frit. The frit can be used as raw materials to manufacture rich building materials,such as noctilucent antibacterial mosaic, noctilucent antibacterial microcrystalline ceramic composite panels and noctilucent antibacterial low-temperature ceramic ink.

Owner:佛山市高明区诚睿基科技有限公司

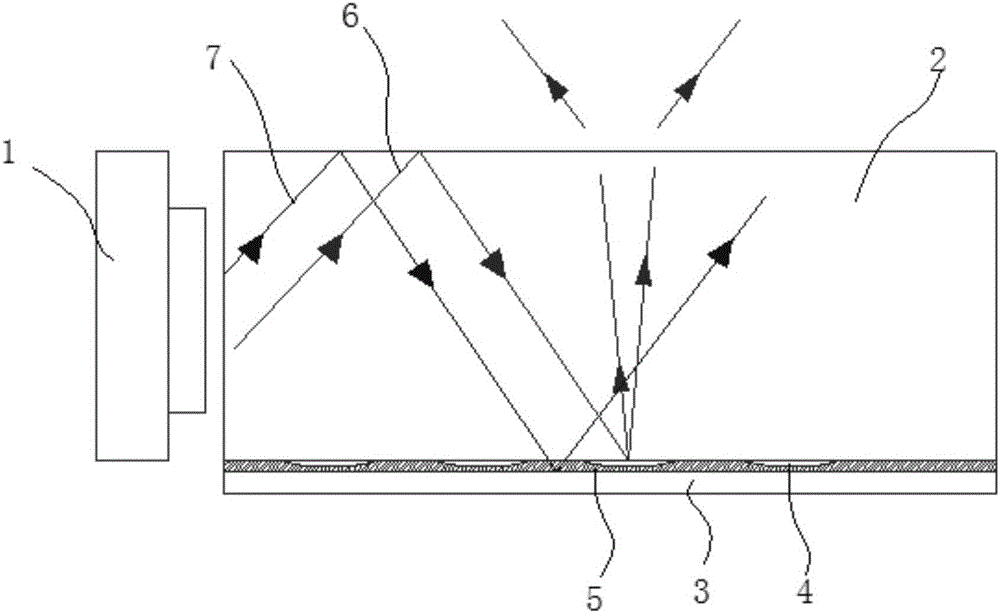

Backlight module

InactiveCN105698047AGood luminous effectReduce module thicknessMechanical apparatusLight guides detailsMirror reflectionOptoelectronics

The invention provides a backlight module which comprises a light source, a light guide plate and a reflector plate. The light source is located on the side face of the light guide plate. The bottom face of the light guide plate is provided with a plurality of lattice points arranged at intervals. The reflector plate is attached to the bottom face of the light guide plate and covers the multiple lattice points. The reflector plate is a mirror reflector plate with a mirror reflection function. The backlight module is good in light emitting effect, the thickness of the module can be reduced, and ultrathin complete machine design can be achieved.

Owner:吴冬梅

Noctilucent fabric and noctilucent clothes and red scarf made from same

InactiveCN103057195AEasy to joinAddress limitationsSynthetic resin layered productsScarvesFiberTransmittance

The invention relates to a noctilucent fabric which comprises a fabric base body and a membrane layer with light transmittance of lower than 80 percent, wherein the membrane layer contains a noctilucent material, the fabric base body comprises fibers and setting dye or pigment, the membrane layer is adhered on the surface of at least one side of the fabric base body, and the noctilucent material in the membrane layer is covered on an outer layer of the setting dye or pigment on the fabric base body. The invention also relates to noctilucent clothing and a scarf which are made of the noctilucent fabric. According to the invention, the problem that the color with the noctilucent function on the fabric is only restricted to the light and bright colors is solved, the fabric with a deep and thick color can obtain a better noctilucent effect, therefore, noctilucent elements can be conveniently added to the clothing and the scarf with the deep and thick color and further the functions of safety and warning are achieved.

Owner:李佳翰

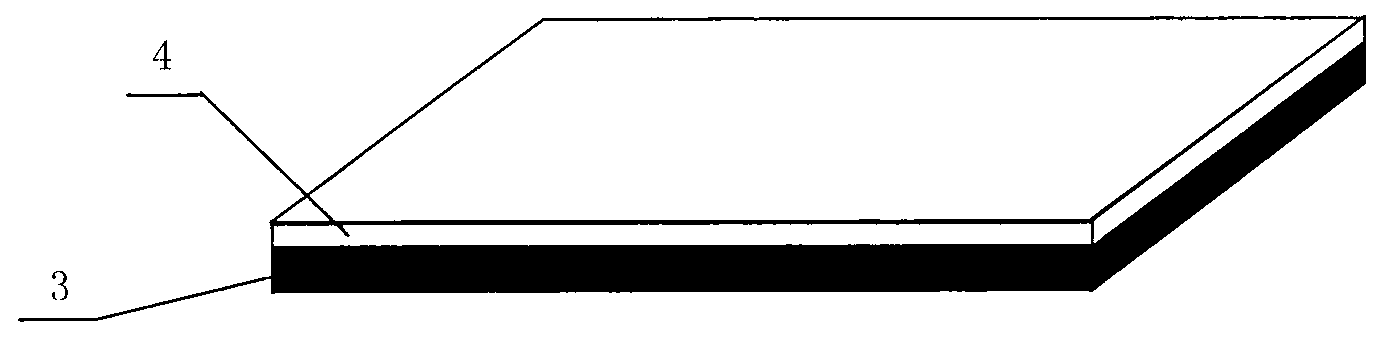

Auto-luminescent metal roller coating plate and process for preparing the same

InactiveCN1733468AChemically stableNo radioactivityMetal layered productsLuminous paintAlkaline earth metal

The self-luminescence metal roller coating plate is prepared by that rolling costing luminous paint on metal plate surface; wherein, the method comprises following steps: mixing evenly the baking-varnish resin and alkali earth metal luminous paint at normal temperature, rolling coating the said paint on metal plate; baking at 100~350Deg for 30~120s; finally, taking surface treatment and obtaining the product. This invention has wide application and no harm to human or environment, absorbs solar energy to cycle use, and belongs to green environmental friend product.

Owner:张德铭

Anion bionic quartz stone and preparing method thereof

InactiveCN106348652AImprove fire performanceAvoid it happening againAluminium hydroxideWork in process

The invention discloses an anion bionic quartz stone and preparing method thereof comprising the steps of A, preparing modified resin; B, evenly mixing, by weight, 80-90% of quartz, 8-12% of modified resin, 0.01-1% of curing agent, 0.01-1% of coupling agent, 1-3% of noctilucence compound, 1-3% of aluminium hydroxide powder, and 0.1-2% of pigment to get a mixture; C, spraying the mixture on the formwork for the first time, molding by vibration, demolding, cutting and making arrangement by preset pattern to semi-finished product; spraying for the second time, molding by vibration, drying and molding, and processing to finished product. Compared with the prior bionic quartz stone, the bionic quartz stone prepared by the anion bionic quartz stone and preparing method thereof is scientifically burdened and reasonably prepared with steady property and high mechanical strength, which is not inclined to deform or age; and the anion compound, noctilucence compound and antibacterial powder in reasonable combination enable the bionic quartz stone to have good properties of bacteria resistance, air purification and noctilucence, further expanding range of application of the bionic quartz stone.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

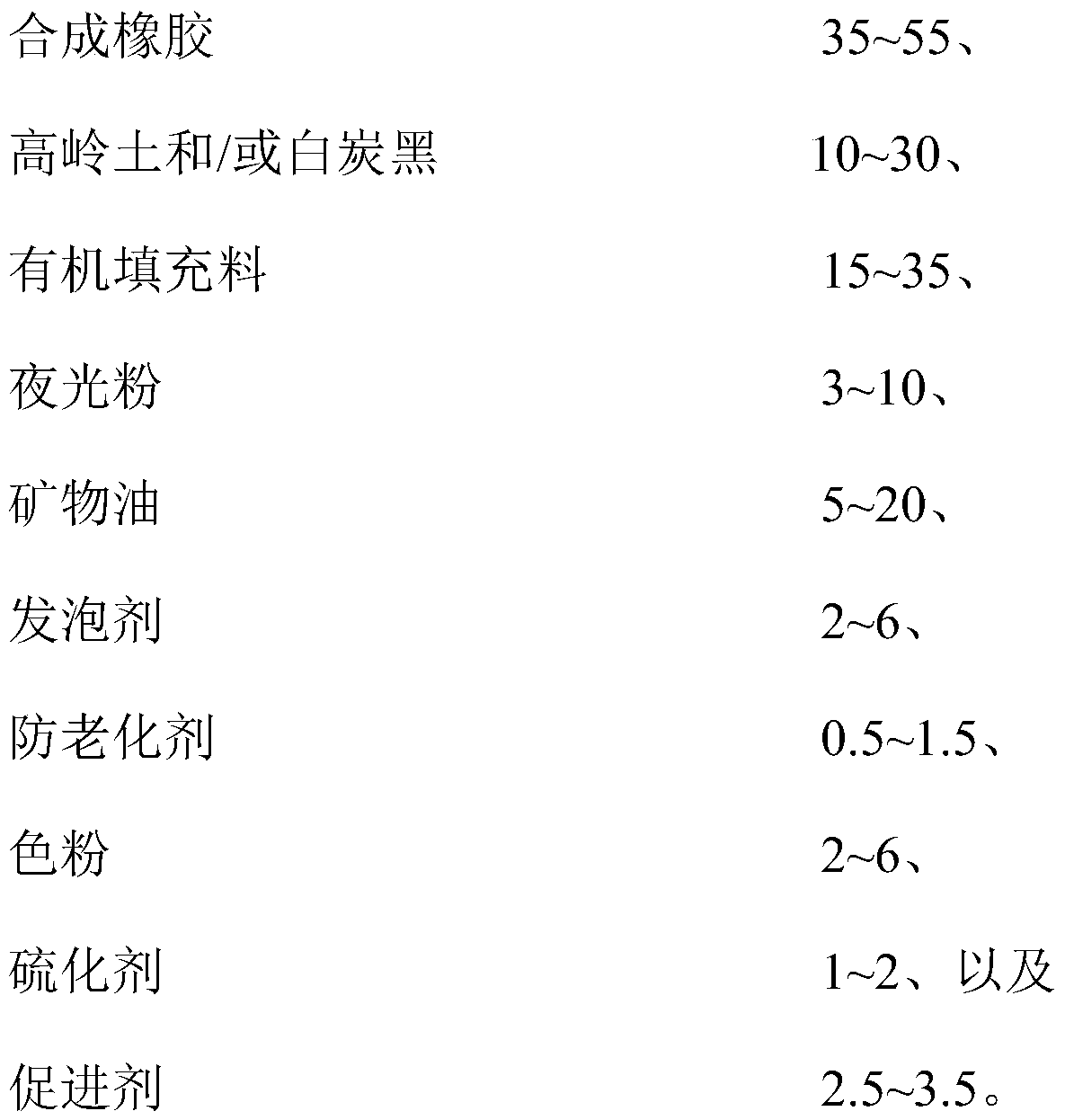

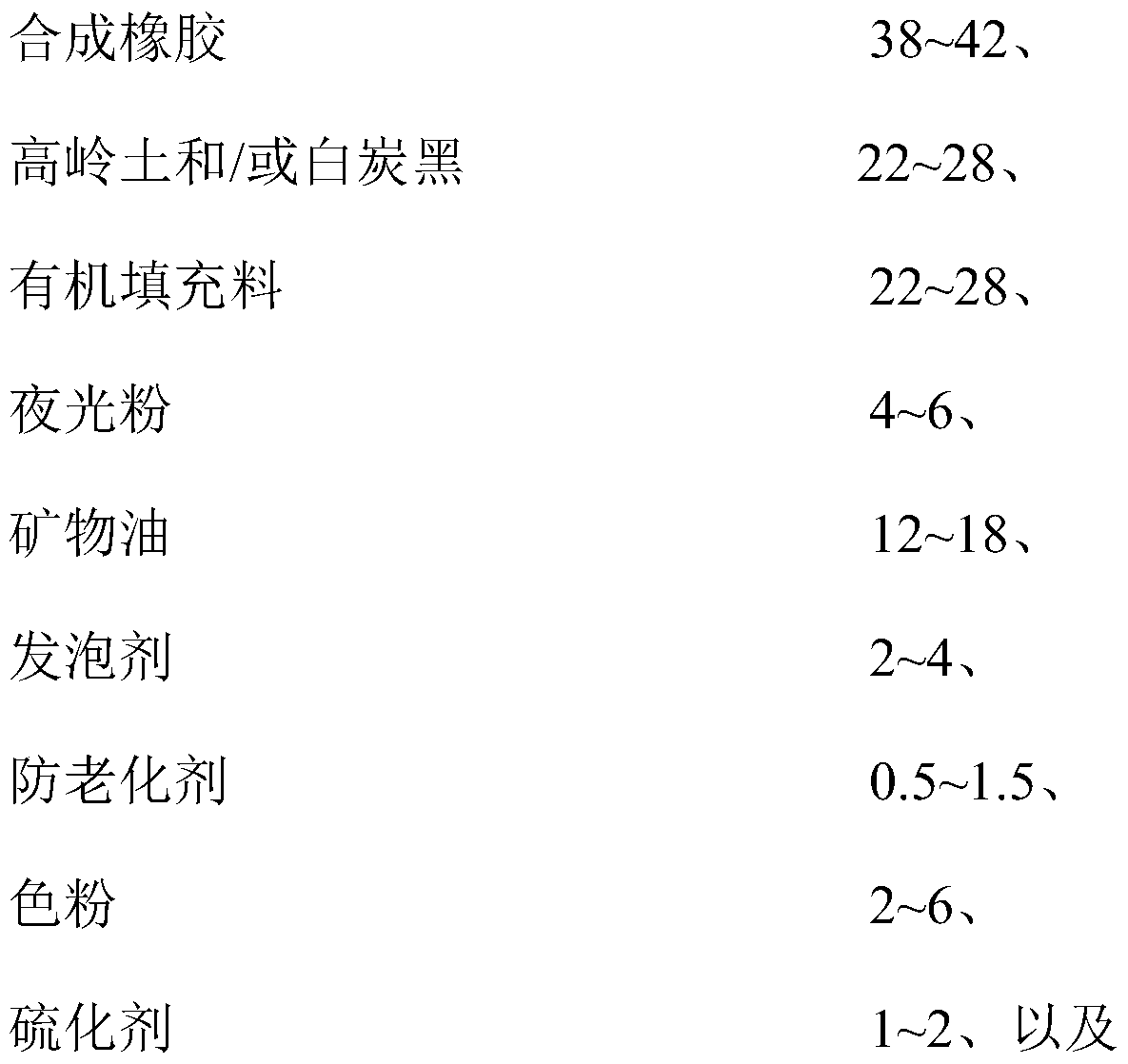

Luminous prefabricated sports surface layer, luminous prefabricated sports paving material, and preparation method of paving material

ActiveCN110467763AGood light storage during the dayGuaranteed physical and chemical propertiesGround pavingsTraffic signalsFoaming agentLight energy

The invention relates to a luminous prefabricated sports surface layer, a luminous prefabricated sports paving material, and a preparation method of the paving material. The luminous prefabricated sports surface layer is prepared from, by weight, 35-55 parts of synthetic rubber, 10-30 parts of kaolin and / or white carbon black, 15-35 parts of an organic filler, 3-10 parts of luminous powder, 5-20 parts of mineral oil, 2-6 parts of a foaming agent, 0.5-1.5 parts of an anti-aging agent, 2-6 parts of a toner, 1-2 parts of a vulcanizing agent and 2.5-3.5 parts of an accelerator. The prefabricated sports surface layer meets the requirements of relevant national standards for the physical and chemical properties of prefabricated sports paving materials, has the functions of absorbing and reserving light energy during the day and emitting light at night, and is convenient for sports people to perform night sports.

Owner:广州同欣体育股份有限公司

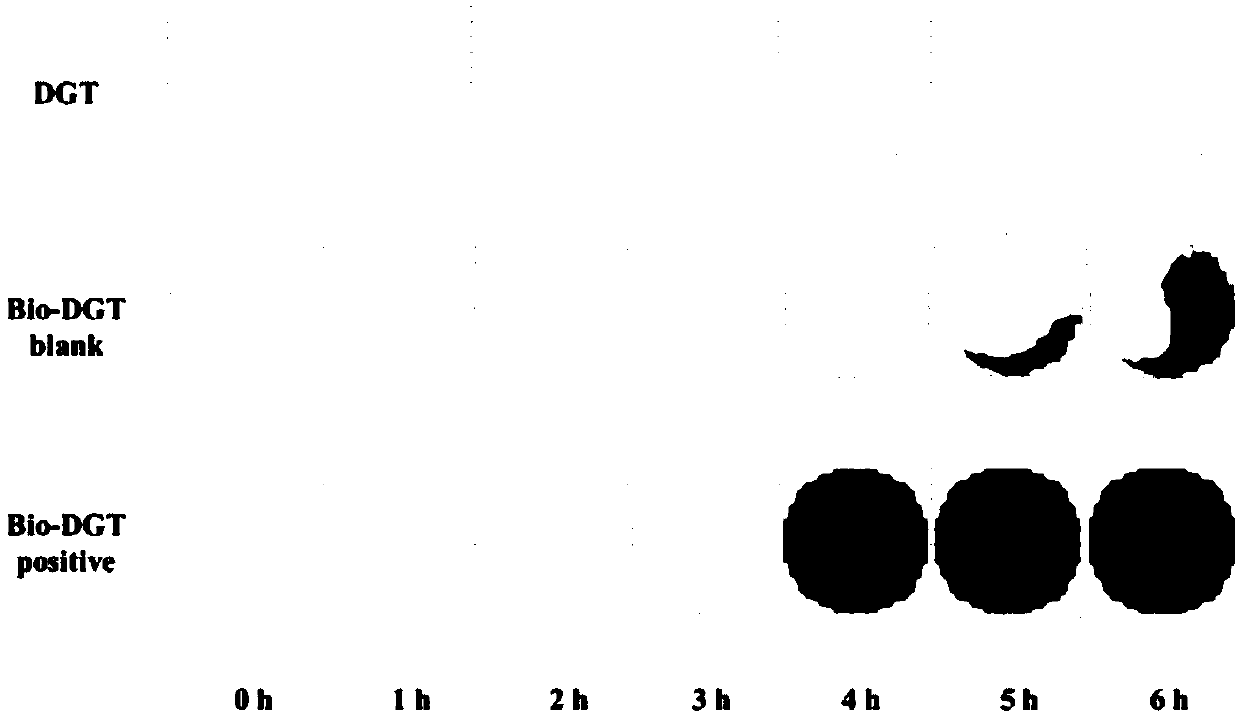

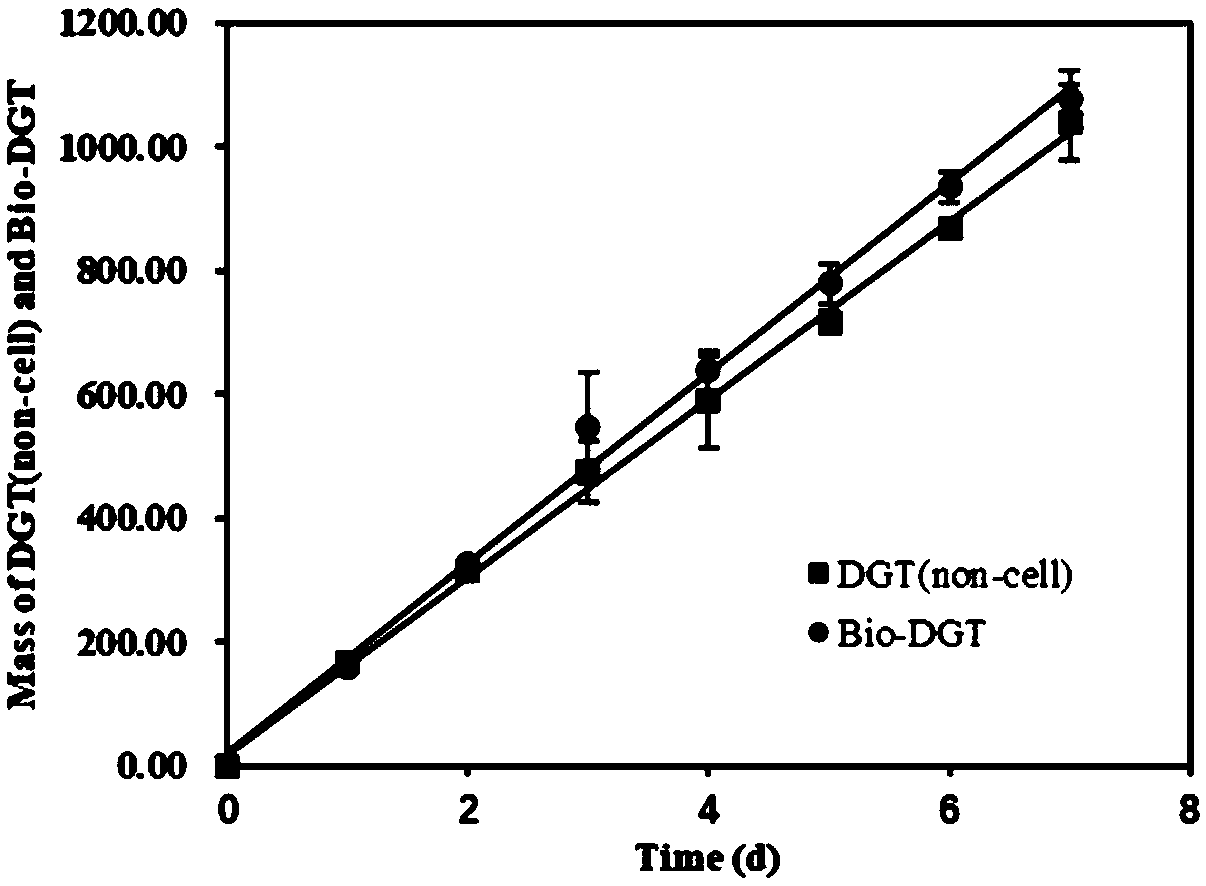

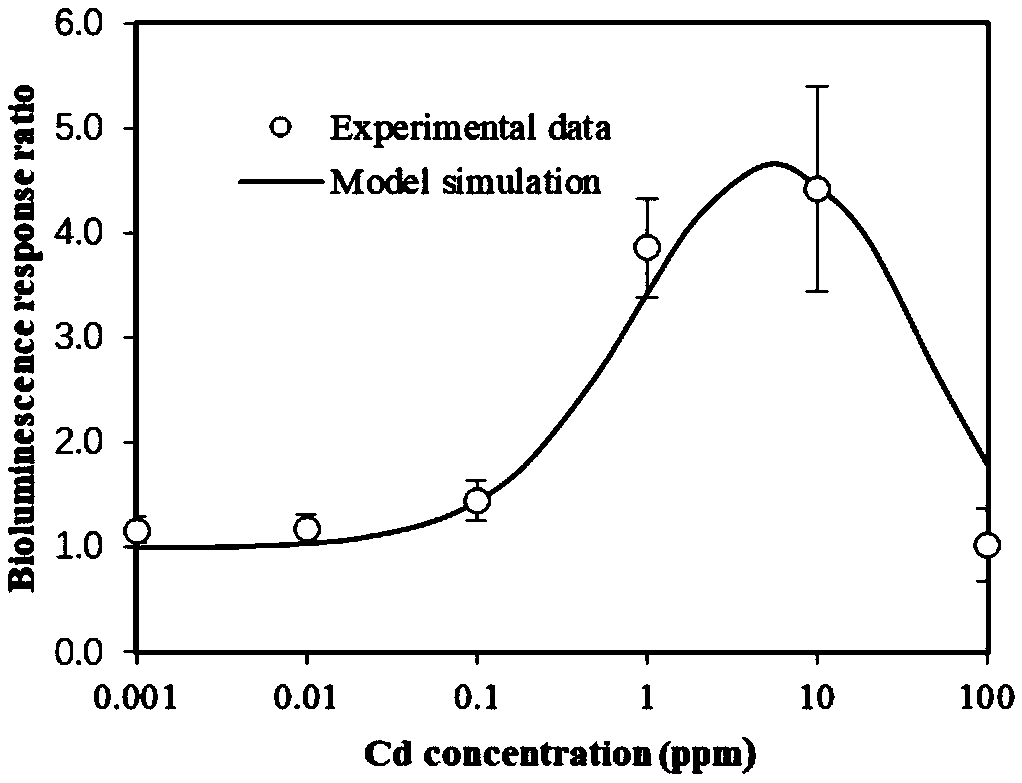

Biological membrane DGT device and method for simultaneously and quantitatively monitoring effective state content and cell genetic toxicity of target

InactiveCN109580762AMeet the survival conditionsMeet the needs of toxicity testingMaterial analysis by electric/magnetic meansColor/spectral properties measurementsBiological membraneBiosensor

The invention discloses a biological membrane DGT device and a method for simultaneously and quantitatively monitoring the effective state content and the cell genetic toxicity of a target, and belongs to the field of environment science. A diffusion membrane in the biological membrane DGT device is an agarose hydrogel tablet in which a biosensor is attached. The biological membrane DGT device isadopted for carrying out target collection; the effective state content and the cell genetics / genetic toxicity of the target are determined after pretreatment; the cell genetic toxicity is determinedby determining a fluorescence response value of the target in the diffusion membrane; and the cell genetic toxicity is analyzed by using a FLUOstar Omega microplate reader, so that the operation is simple and convenient, and the consumed time is short. The combination of the biosensor and a DGT technology is realized for the first time, so that the effective state content and the cell genetic toxicity of the target can be simultaneously and quantitatively monitored.

Owner:南京维申环保科技有限公司

Noctilucent aerosol paint and preparation method thereof

InactiveCN114686030AHigh absorption and emission efficiencyGood luminous effectLuminescent paintsReflecting/signal paintsAcrylic resinAerosol Mist

The noctilucent aerosol paint is prepared from the following components in parts by weight: 28 to 40 parts of mixed modified acrylic resin, 10 to 15 parts of silicone acrylic resin, 10 to 20 parts of environment-friendly solvent, 4.5 to 10 parts of bentonite, 12 to 24 parts of noctilucent powder, 1.5 to 4 parts of nano graphite powder, 0.5 to 2.5 parts of silane coupling agent, 0.2 to 1 part of flatting agent, 0.3 to 1 part of defoaming agent, 2 to 4 parts of total reflection glass beads of 150 to 500 meshes and 15 to 27 parts of environment-friendly propellant. The noctilucent powder adopting the technical scheme has the advantages that the noctilucent powder is high in light absorbing and releasing efficiency and good in noctilucent performance; the formula is optimized, the solid content is high, and the hardness and the adhesive force performance are excellent; aerial fog packaging and storage stability are achieved, use is safe and convenient, and construction efficiency is high; and the paint is environment-friendly and low in VOC. The invention also discloses a preparation method of the noctilucent aerosol paint.

Owner:GUANGDONG SANVO CHEM IND TECH

Environment-friendly high-efficiency waterborne coating for noctilucent markings and preparation method thereof

InactiveCN106085142AHigh strengthIncreased durabilityLuminescent paintsEpoxy resin coatingsGreen environmentEmulsion

The invention specifically relates to an environment-friendly high-efficiency waterborne coating for noctilucent markings, which belongs to the technical field of road paving materials. The coating comprises the following raw materials by weight: 61 to 67% of epoxy acrylic acid emulsion, 32 to 38% of high-light noctilucent sand and 0.5 to 1.5% of color paste. According to the invention, the produced coating is a green environment-friendly product which is prepared through stirring by a high-speed dispenser and has good strength, weatherability and usage performance. The invention also discloses a preparation method for the environment-friendly high-efficiency waterborne coating used for noctilucent markings.

Owner:HANZHOU LANNAS ROAD ENG TECH CO LTD

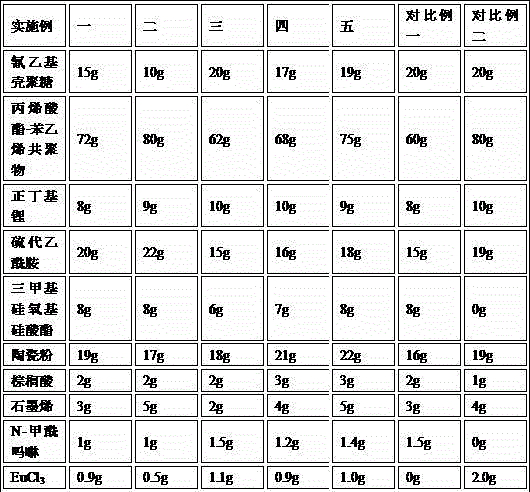

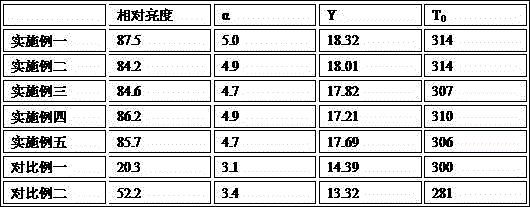

Novel luminescent composite material

InactiveCN104962021AReasonable compositionImprove mechanical propertiesLuminescent compositionsMeth-Morpholine

The invention relates to a novel luminescent composite material. EuCl3 and trimethylsilanolate silicate ester are mixed for 2 hours to obtain a mixture; thioacetamide and ceramic powder are sequentially added into the mixture; the materials are stirred for 4 hours; then, palmitic acid and n-butyllithium are added; the materials are stirred for 2 hours at 80 DEG C; next, cyanoethyl chitosan and grapheme are added, and are stirred for 1 hour at 120 DEG C; finally, acrylic ester- styrol copolymers and N-formyl morpholine are added; the materials are stirred for 4 hours at 130 DEG C to obtain luminescent compounds; then, the luminescent components are added into a mold and is subjected to molding pressing to obtain the novel luminescent composite material. A preparing method disclosed by the invention has the advantages that the raw material resources are wide, the preparing process is simple and controllable, only conventional operation is needed, and the industrialization is easily realized.

Owner:SUZHOU KEMIAO NEW MATERIAL

Night-gloss glass printing ink, preparation method and printing method on glass product

A luminous glass printing ink is made of long persistence phosphor powder, transparent glass pigment, suspending agent, solid dispersing agent, and defoaming agent. The method for preparing the ink comprises: mixing the long persistence phosphor powder with the transparent glass pigment uniformly; adding to the molten mixture of suspending agent, solid dispersing agent, and defoaming agent; and then cooling while stirring. The printing method comprises screen-printing the ink on glassware to produce the luminous patterns; then increasing the temperature of the glass product to 520-650°C and holding the temperature for 20-30 min; and then cooling. The ink can withstand the temperature as high as 520-650°C and be used for screen-printing on glassware.

Owner:SHENZHEN HUAXI BIO TECH LTD

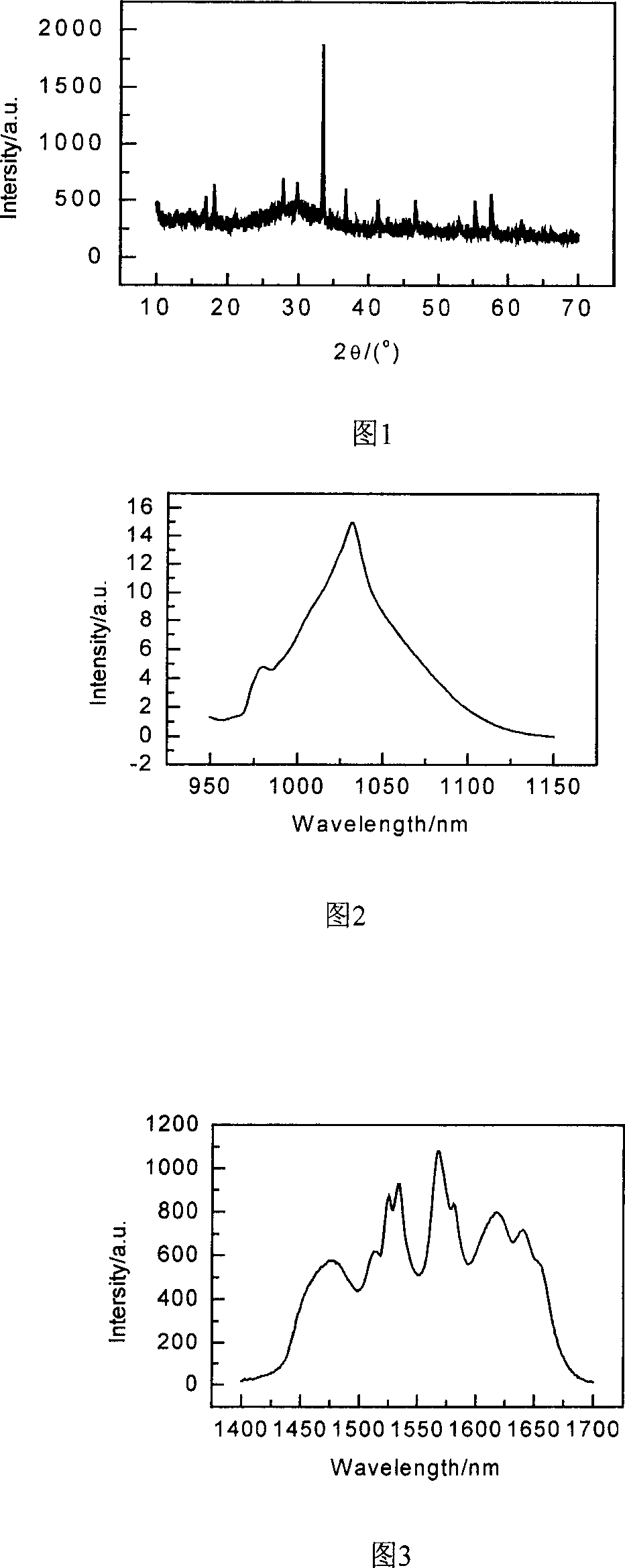

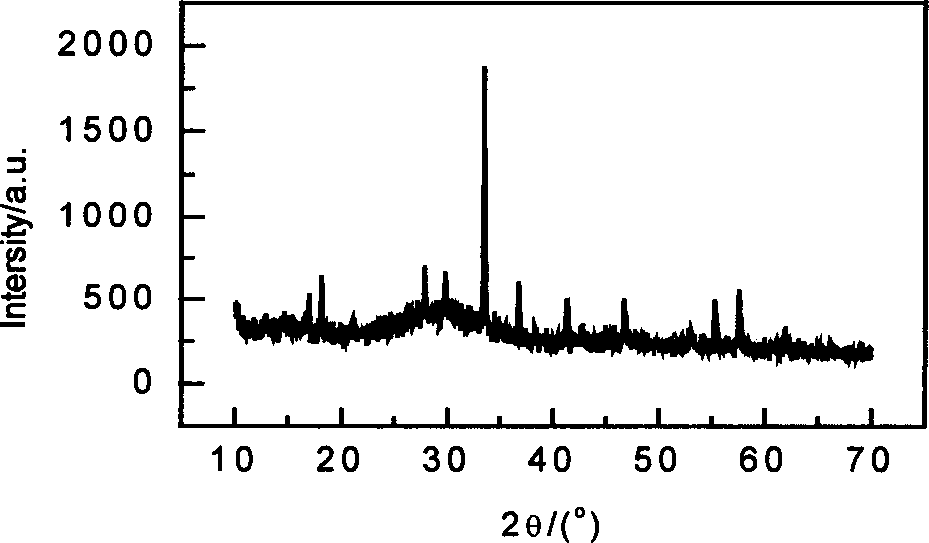

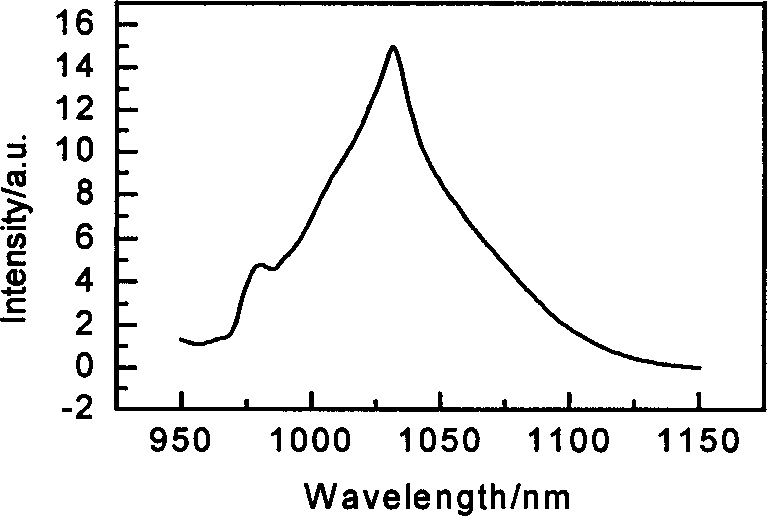

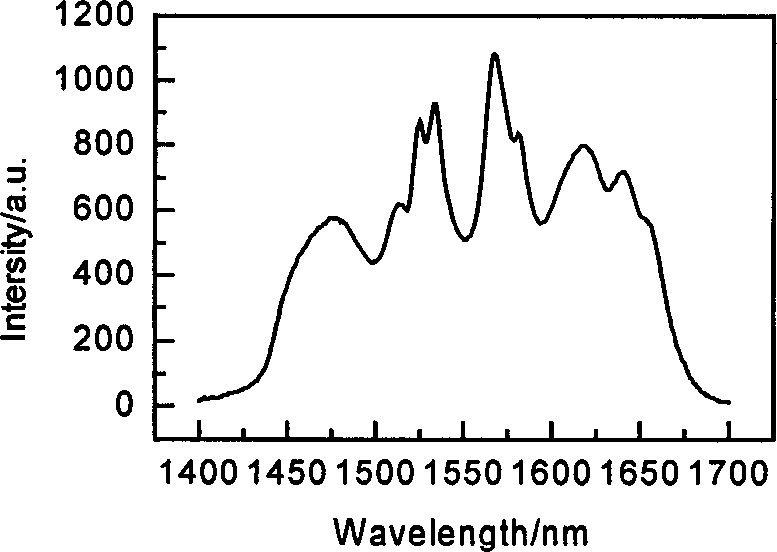

Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer

InactiveCN105778061ALower LUMO levelBroad absorption spectrumOrganic chemistrySulfoneOrganic semiconductor

The invention belongs to the field of synthesis of organic compounds, relates to a novel polymer applied to the field of organic semiconductor materials, and in particular relates to a benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer and a copolymer of the benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer. The benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer is a highly-symmetrical heteroatom-containing compound; sulfone is a strong electron withdrawing group and has very good planeness, so that the monomer can be used as a very good small-molecular acceptor material and can be applied to organic solar cells; the monomer has a very good luminous effect, so that the monomer can also be applied to light-emitting diodes.

Owner:WUHAN UNIV OF TECH

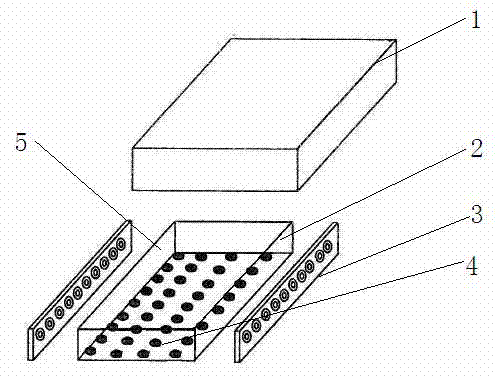

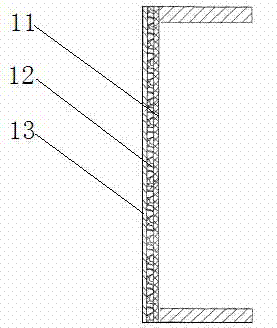

Ultra-thin LED indicator lamp saving energy

InactiveCN103883945AGood luminous effectIncrease display brightnessLighting applicationsMechanical apparatusEngineeringLight guide

The invention relates to an indication sign, in particular to an ultra-thin LED indicator lamp saving energy. The ultra-thin LED indicator lamp saving the energy comprises a lampshade provided with indication patterns in an engraving mode, and LED lamp bars. A light guide board is arranged in the lampshade. The two sides of the light guide board are provided with the LED lamp bars respectively. The light-emitting faces of the LED lamp bars directly face the side face of the light guide board. The bottom face of the light guide board is provided with a light reflection net point. The lampshade is of a three-layer structure formed by overlapping a transparent base layer, a self-luminous material coating and an indication pattern layer, wherein the transparent base layer, the self-luminous material coating and the indication pattern layer are sequentially arranged from inside to outside. According to the ultra-thin LED indicator lamp, as the light guide board is arranged, the light-emitting effect is good, the display brightness of the indicator lamp is improved, the light-emitting brightness of an LED light source is high, and the energy consumption is low; the self-luminous material coating is arranged on the lampshade, even if power is off or the LED lamp is damaged, the indication patterns on the indicator lamp can be displayed for a period of time, and therefore the risk of failure of the indicator lamp under the emergent circumstance can be reduced.

Owner:CHENGDU KAIYU ELECTRICAL APPLIANCE

Rare earth ion doped YAG micro crystalline glass and its preparation method

The present invention discloses a rare earth ion doped YAG nucleated glass and its preparation method. Its composition contains: (by mol%) CaO 17-44, Y2O3 0.1-13, Al2O3 16-32, SiO2 26-46, RE2O3 0.1-9, TiO2 0-15, in which RE2O3 is at least one kind of Yb2O3, Er2O3 and Tm2O3. Its preparation method includes the following steps: firstly, adopting melting process to prepare CaO-Y2O3-Al2O3-SiO2-RE2O3-TiO2 system glass, making heat treatment to obtain nano-grade nucleated glass. Said nucleated glass is transparent, and has no devitrification, and its physical and chemical properties are good.

Owner:NINGBO UNIV

A kind of high elasticity electroluminescent fiber and its preparation method

ActiveCN108093535BImprove wearing comfortGood luminous effectElectrical apparatusElectroluminescent light sourcesElectrical conductorGel electrode

The invention belongs to the technical field of intelligent electronic devices, and particularly relates to a high-elasticity electroluminescent fiber and a preparation method thereof. The method comprises preparing a frozen cross-linked hydrogel ion conductor as a transparent and high-elasticity electrode; and preparing a polydimethylsiloxane oligomer-electroluminescent powder mixed light-emitting active material with extrusion formability to be further cured and formed after extrusion. The multi-channel parallel extrusion needle head is designed, so that the light-emitting active layer is wrapped with two gel electrodes which are arranged in parallel, and the viscosity of the mixed light-emitting active material can ensure that the extruded fiber structure does not deform after the viscosity of the mixed light-emitting active material is controlled. The polydimethylsiloxane and the conductive gel have high elasticity, and the final luminescent fiber can still keep normal work when the tensile strength reaches up to 800%, the stable circulating tensile quantity can reach 300%, the cycling stability is more than 100 times, and the highest luminous brightness reaches 242. 6cd / m2. The light-emitting fibers can be further woven into clothes, and have very high wearing comfort and attractive light-emitting effects.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer](https://images-eureka.patsnap.com/patent_img/d8f99cb2-48c4-4712-a4c6-20ab6bb4a5b1/HDA0000952000180000011.PNG)

![Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer](https://images-eureka.patsnap.com/patent_img/d8f99cb2-48c4-4712-a4c6-20ab6bb4a5b1/HDA0000952000180000012.PNG)

![Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer Novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer as well as copolymer and application of novel benzo[b]thieno[3,2-b]benzo[b]thiophene disulfone monomer](https://images-eureka.patsnap.com/patent_img/d8f99cb2-48c4-4712-a4c6-20ab6bb4a5b1/BDA0000952000170000021.PNG)