Anion bionic quartz stone and preparing method thereof

A negative ion and quartz stone technology, applied in the field of quartz stone, can solve problems such as single, not having multiple functions, and limited application range, so as to achieve the effects of preventing smoke, safe use, and good flame retardant and fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

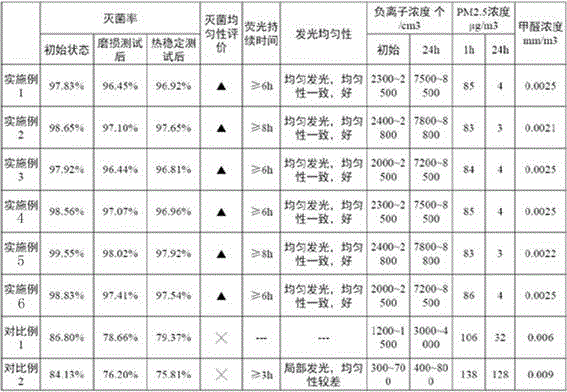

Examples

Embodiment 1

[0033] A negative ion bionic quartz stone and a preparation method thereof, the preparation method comprising the following steps:

[0034] Step A, preparation of modified resin: by weight percentage, mix 89% resin, 6% antibacterial powder and 5% dispersant with a high-speed mixer, heat and melt, and use a twin-screw extruder with a length-to-diameter ratio of 1:40 Extrusion granulation, its melt mixing dispersion extrusion temperature is: 100 ° C ~ 280 ° C; the resin is epoxy resin, phenolic resin, acrylic resin, polyurethane resin mixed in a weight ratio of 3:2:2:1;

[0035] Step B, by weight percentage, weigh 82% quartz (quartz sand and quartz powder are mixed at 3:1), 13% modified resin, 0.5% methyl ethyl ketone peroxide, 0.5% vinyltriethoxysilane, 1% Luminous compound, 2% aluminum hydroxide powder and 1% colorant; put quartz sand, aluminum hydroxide powder, and luminous compound in the first mixer and stir evenly to obtain a premix. The stirring speed is 1000r / min, and th...

Embodiment 2

[0053] A negative ion bionic quartz stone and a preparation method thereof, the preparation method comprising the following steps:

[0054] Step A, preparation of modified resin: by weight percentage, mix 90% resin, 4% antibacterial powder and 6% dispersant with a high-speed mixer, heat and melt, and use a twin-screw extruder with a length-to-diameter ratio of 1:40 Extrusion granulation, its melt mixing dispersion extrusion temperature is: 100 ° C ~ 280 ° C; the resin is epoxy resin, phenolic resin, acrylic resin, polyurethane resin mixed in a weight ratio of 3:2:2:1;

[0055] Step B, by weight percentage, weigh 80% quartz (quartz sand and quartz powder are mixed at 3:1), 13% modified resin, 0.5% methyl ethyl ketone peroxide, 0.5% vinyltriethoxysilane, 2% Luminous compound, 3% aluminum hydroxide powder and 1% colorant; put quartz sand, aluminum hydroxide powder, and luminous compound in the first mixer and stir evenly to obtain a premix. The stirring speed is 1000r / min, and th...

Embodiment 3

[0073] A negative ion bionic quartz stone and a preparation method thereof, the preparation method comprising the following steps:

[0074] Step A, preparation of modified resin: by weight percentage, mix 92% resin, 2% antibacterial powder and 6% dispersant with a high-speed mixer, heat and melt, and use a twin-screw extruder with a length-to-diameter ratio of 1:40 Extrusion granulation, its melt mixing dispersion extrusion temperature is: 100 ° C ~ 280 ° C; the resin is epoxy resin, phenolic resin, acrylic resin, polyurethane resin mixed in a weight ratio of 3:2:2:1;

[0075] Step B, by weight percentage, weigh 82% quartz (quartz sand and quartz powder are mixed at 3:1), 12% modified resin, 0.5% methyl ethyl ketone peroxide, 0.5% vinyltriethoxysilane, 3% Luminous compound, 1% aluminum hydroxide powder and 1% colorant; put quartz sand, aluminum hydroxide powder, and luminous compound in the first mixer and stir evenly to obtain a premix. The stirring speed is 1000r / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com