Patents

Literature

84results about How to "Good shape structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

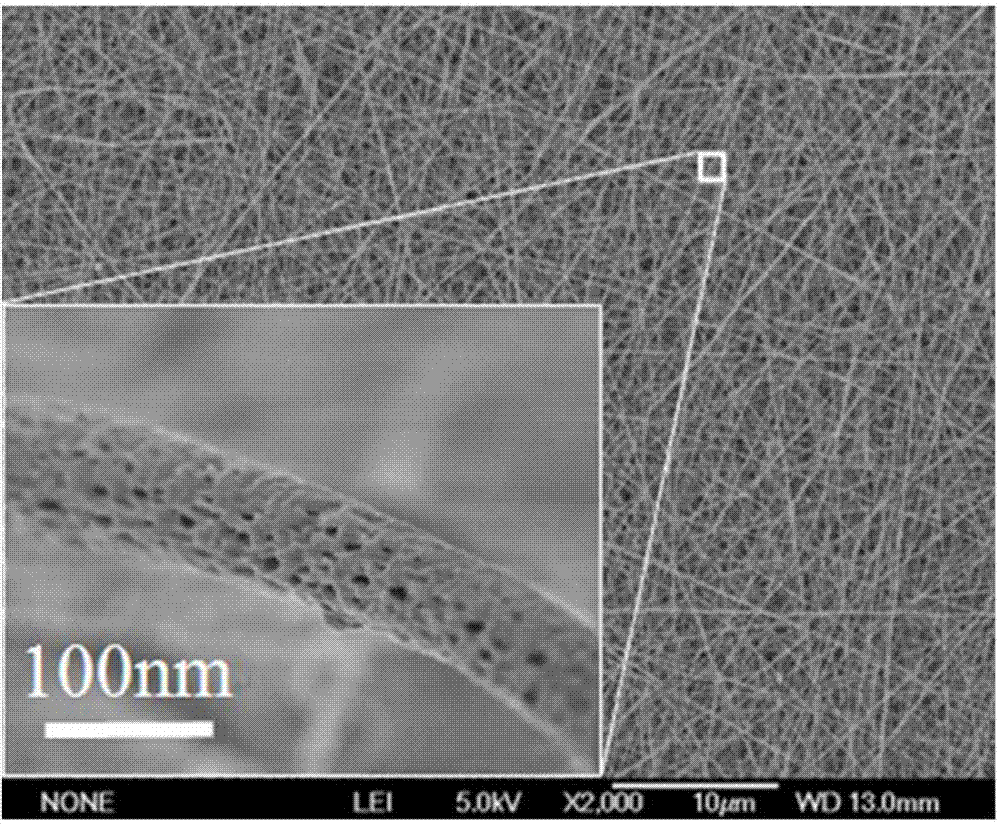

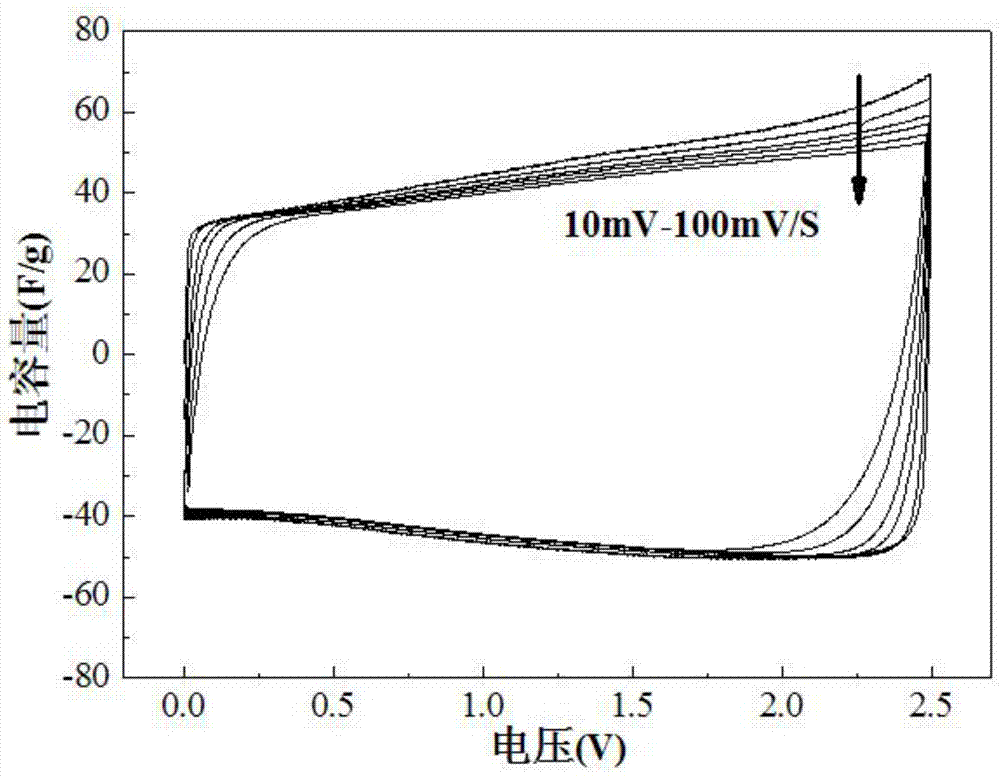

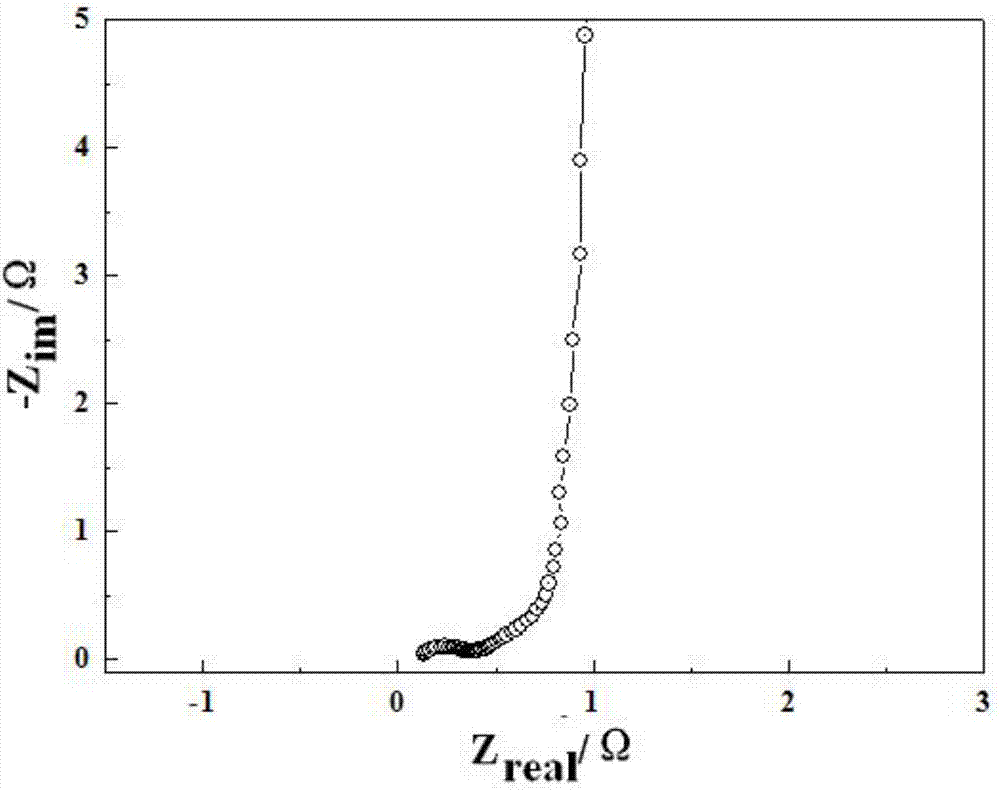

Method for preparing polyimide porous nanofiber electrode diaphragm

ActiveCN104752665AImprove stabilityHigh mechanical strengthHybrid capacitor separatorsCell component detailsMetal oxide nanoparticlesAcid anhydride formation

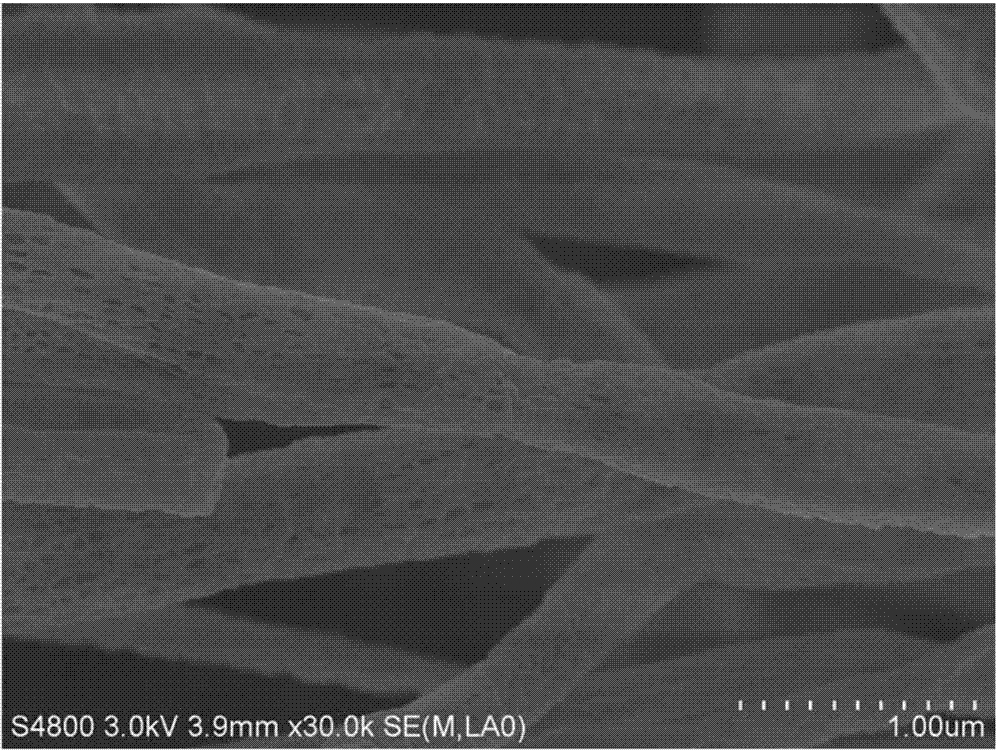

The invention discloses a method for preparing a polyimide porous nanofiber electrode diaphragm. The method comprises the following steps: carrying out condensation reaction by adopting binary organic amine and binary organic acid anhydride in an organic solvent, thereby obtaining a polyamide acid solution; adding a soluble metal salt to prepare a spinning precursor, preparing a polyamide acid-metal salt electrostatic spinning fiber diaphragm by virtue of high-voltage electrostatic spinning, and performing thermal imidization treatment, thereby obtaining a polyimide-metallic oxide fiber composite diaphragm; and dissolving the composite diaphragm in an inorganic acid aqueous solution for performing acid treatment, so that metallic oxide nanoparticles are converted into soluble metal salts so as to be dissolved in the inorganic acid aqueous solution so as to obtain the polyimide nano / micron porous fiber diaphragm. The method has the advantages that according to the polyimide nano / micron porous fiber diaphragm, the mechanical strength, thermal stability, liquid holdup, permeability, wettability and migration rate of conductive ions of the diaphragm can be effectively improved, and the liquid junction resistance of the diaphragm and electrolyte and the contact resistance of the diaphragm and the electrode can be reduced, so that the electrochemical performance of a supercapacitor is improved.

Owner:锦州凯美能源有限公司

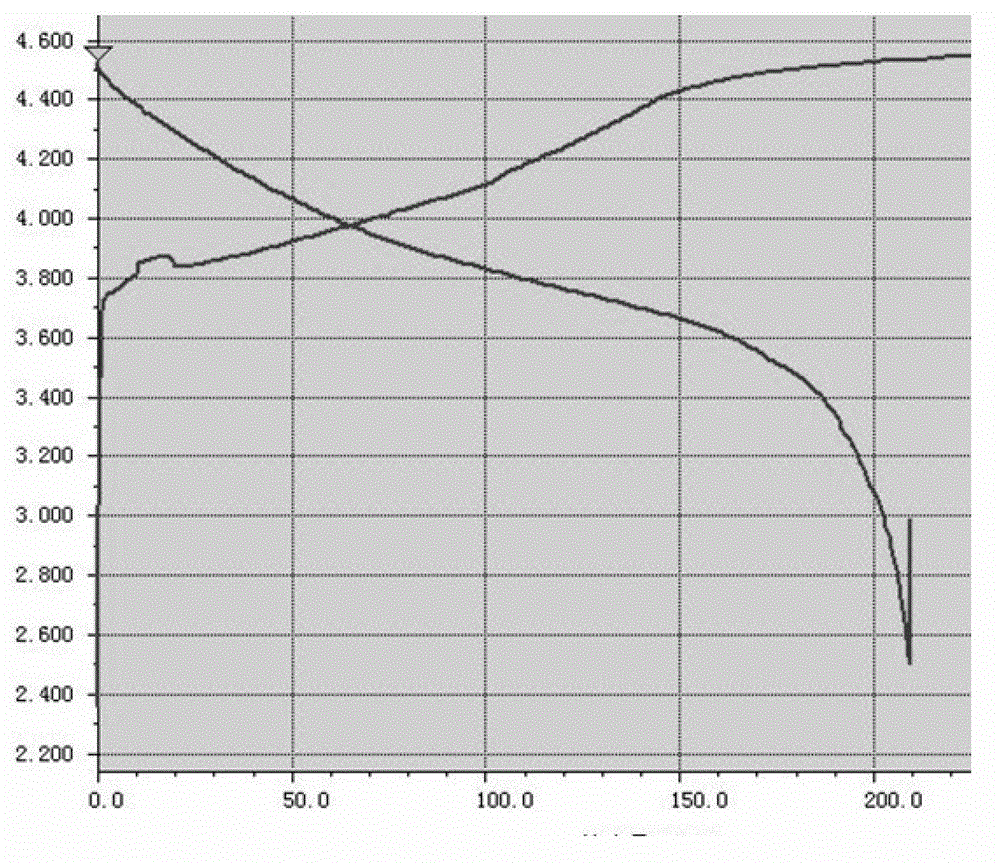

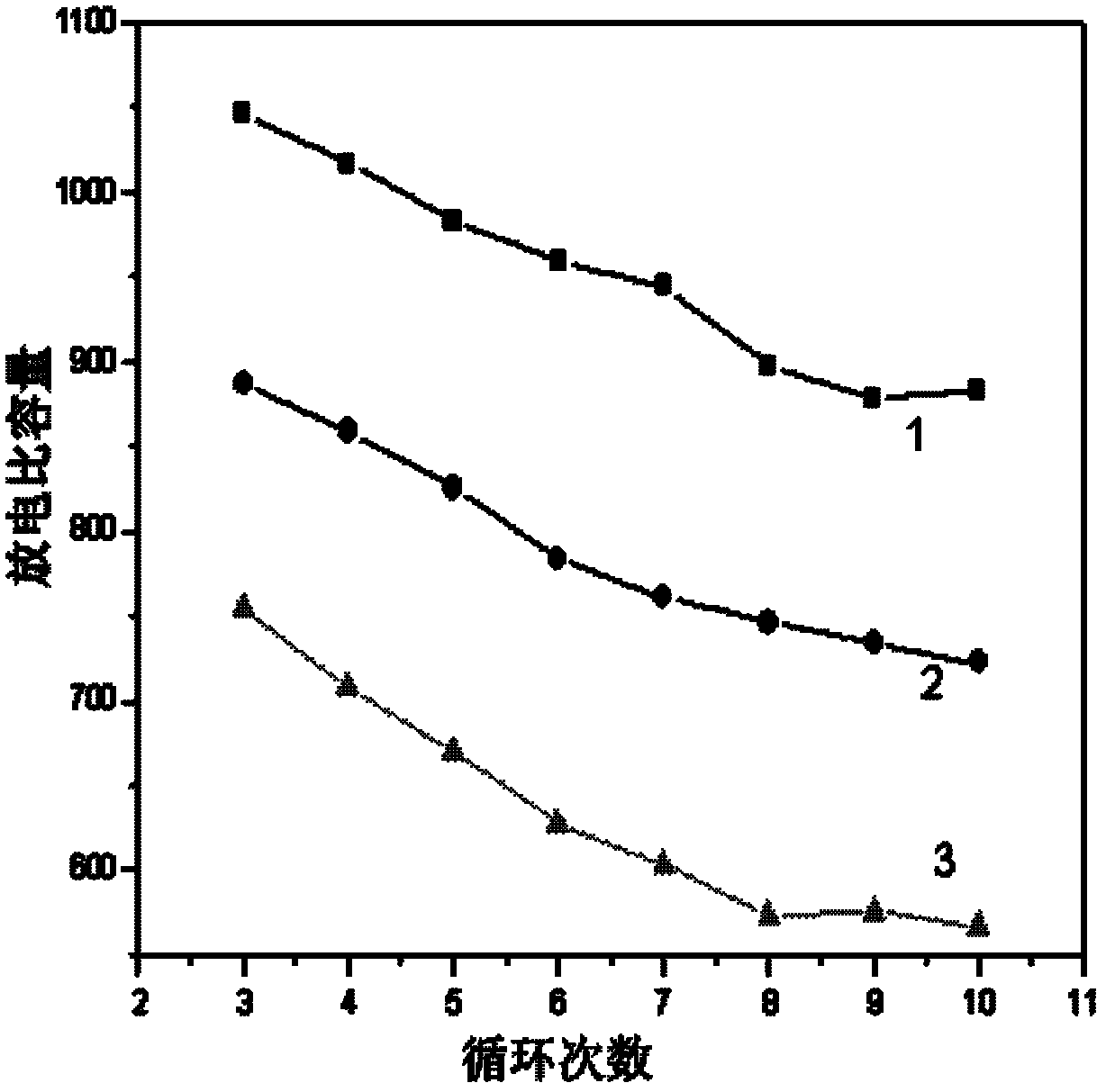

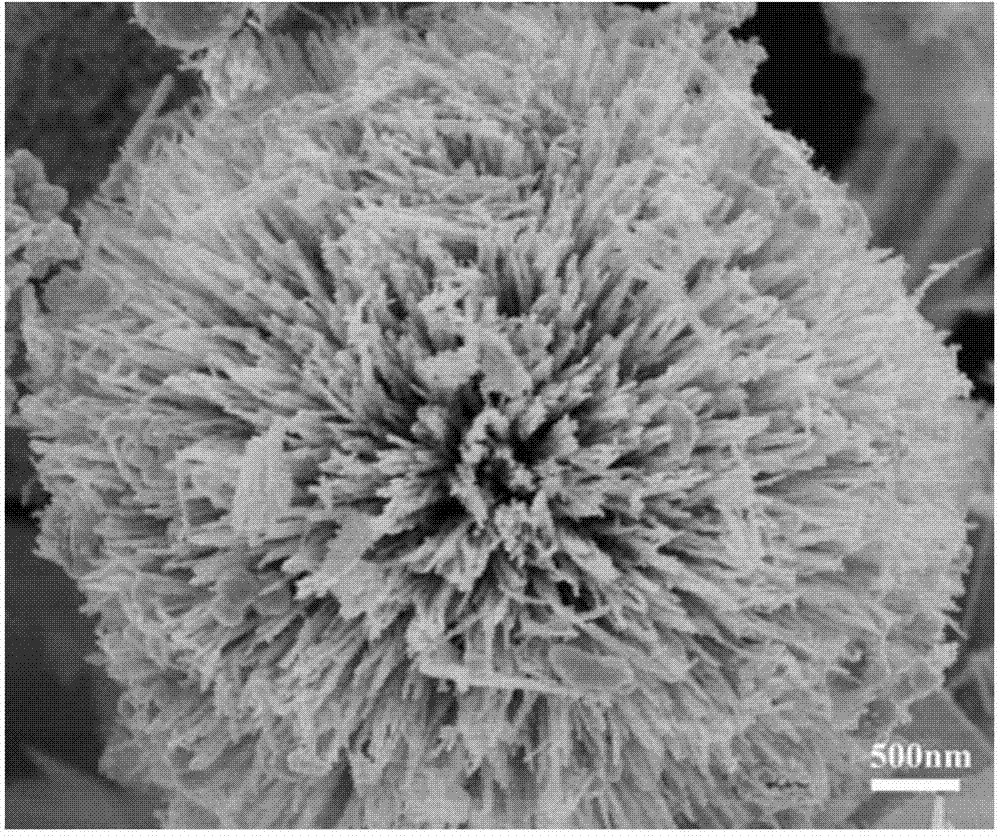

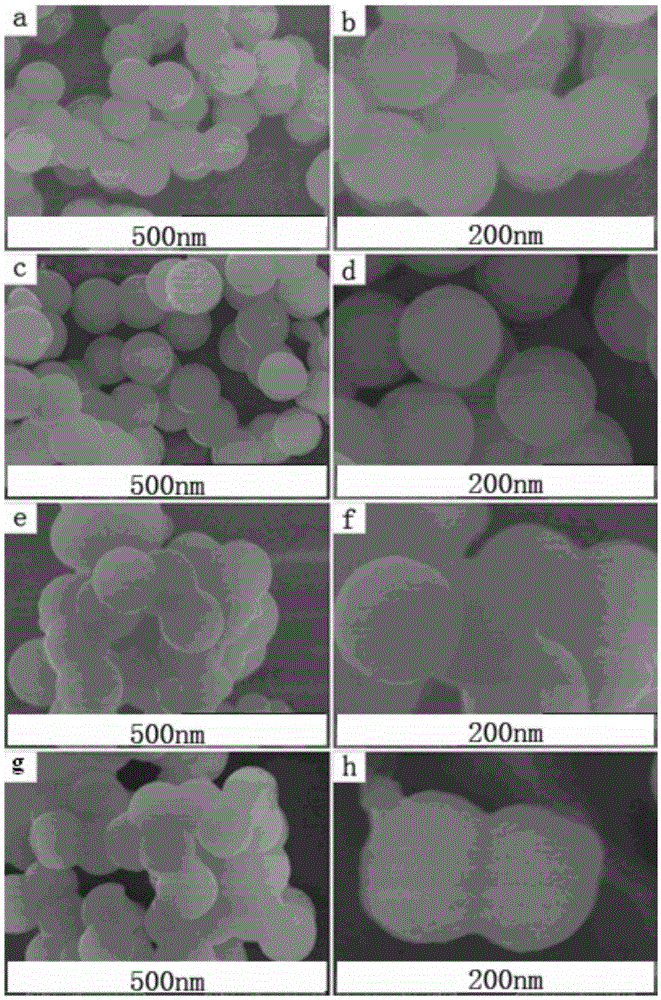

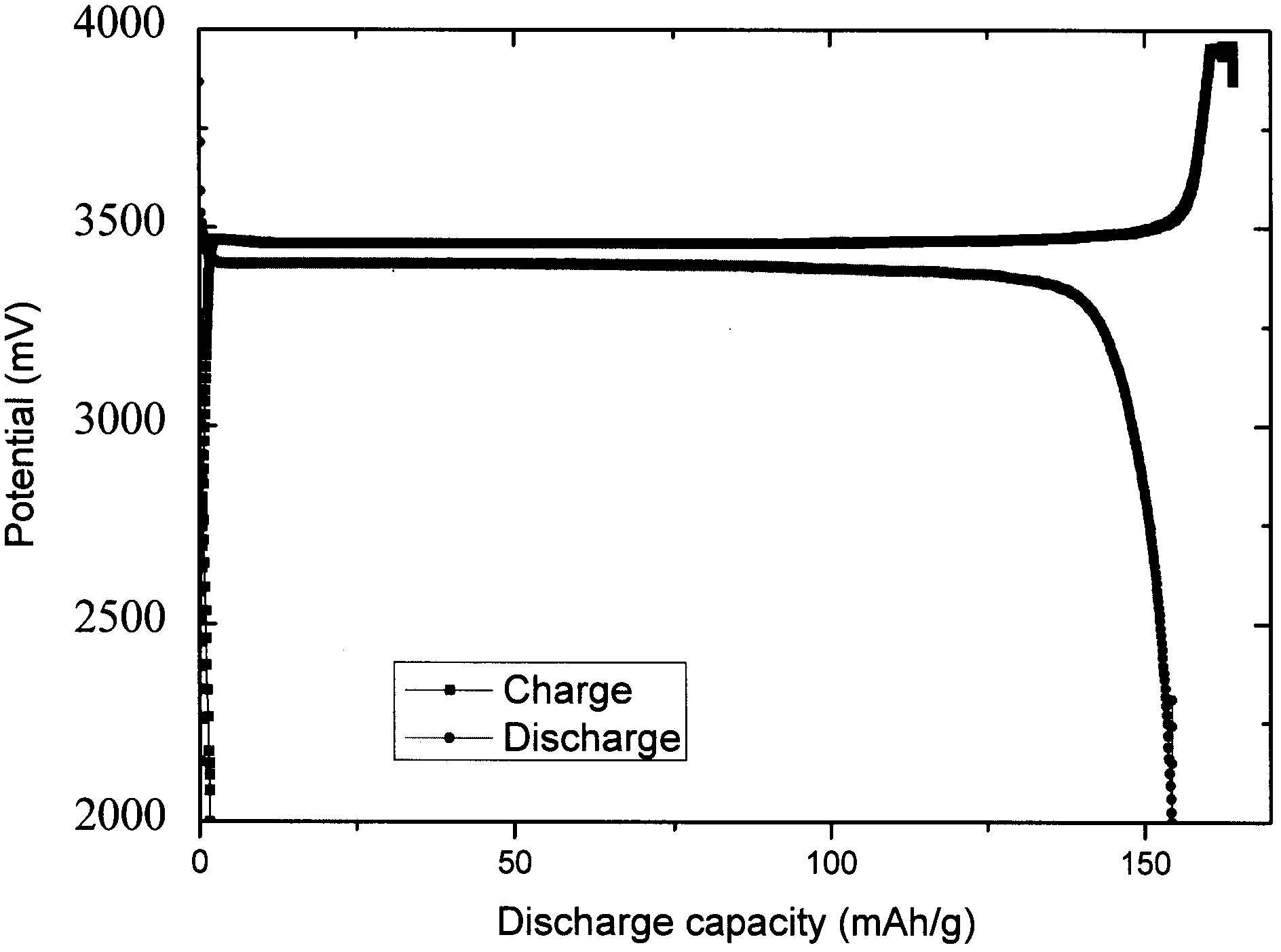

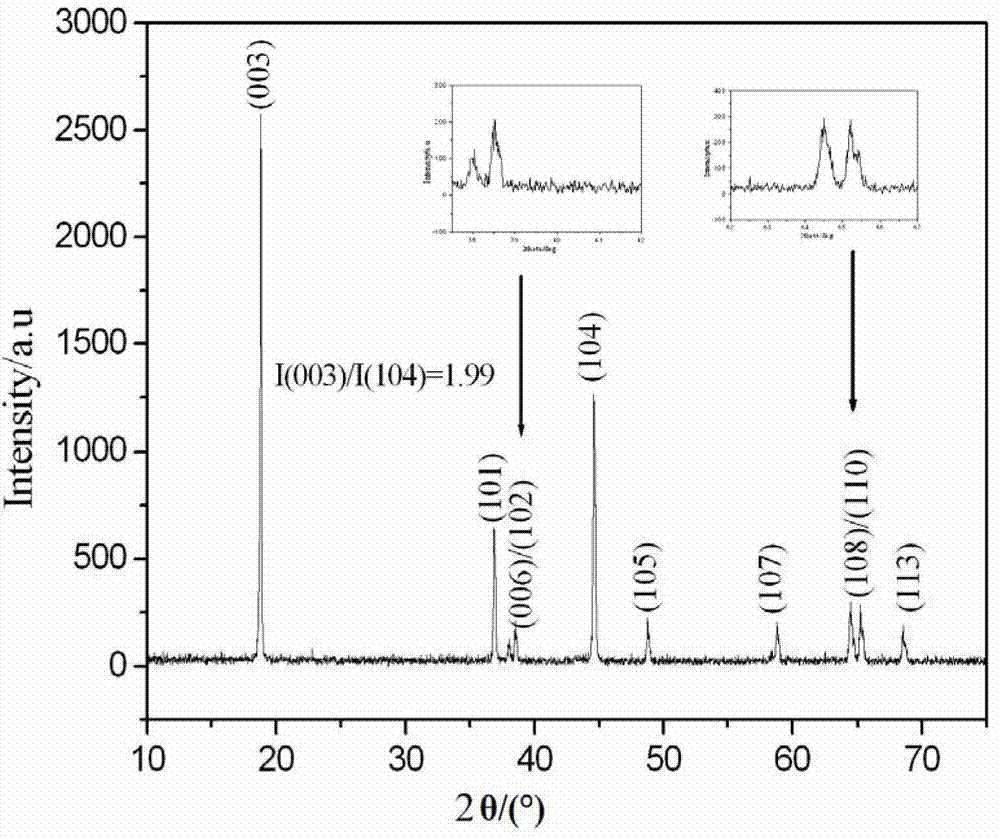

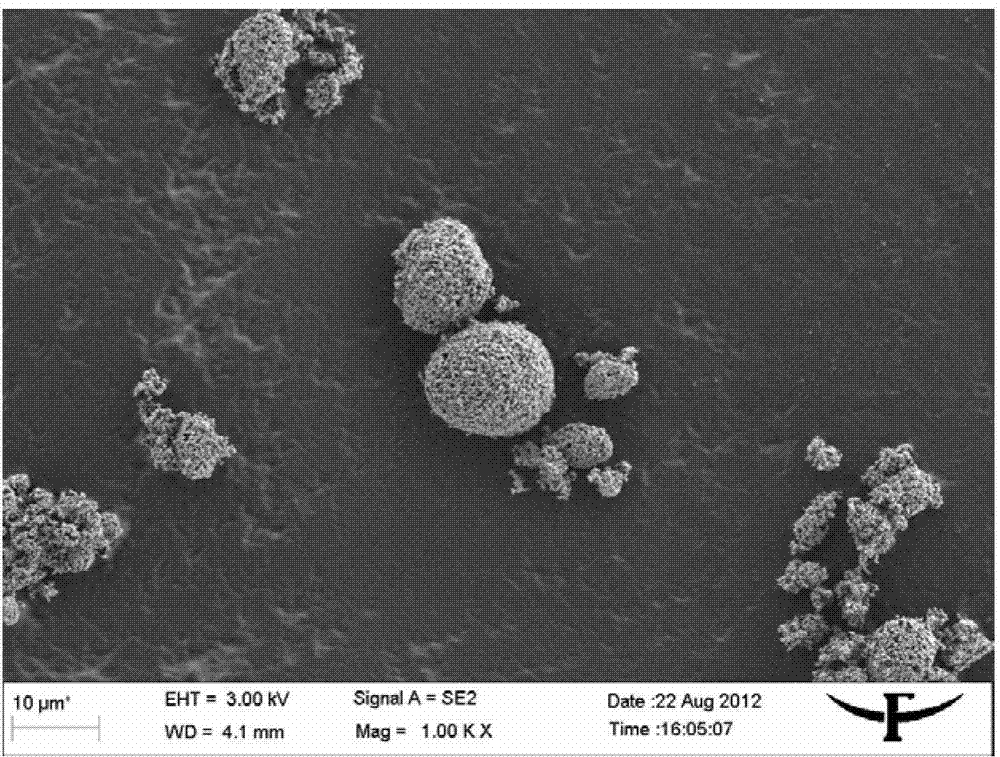

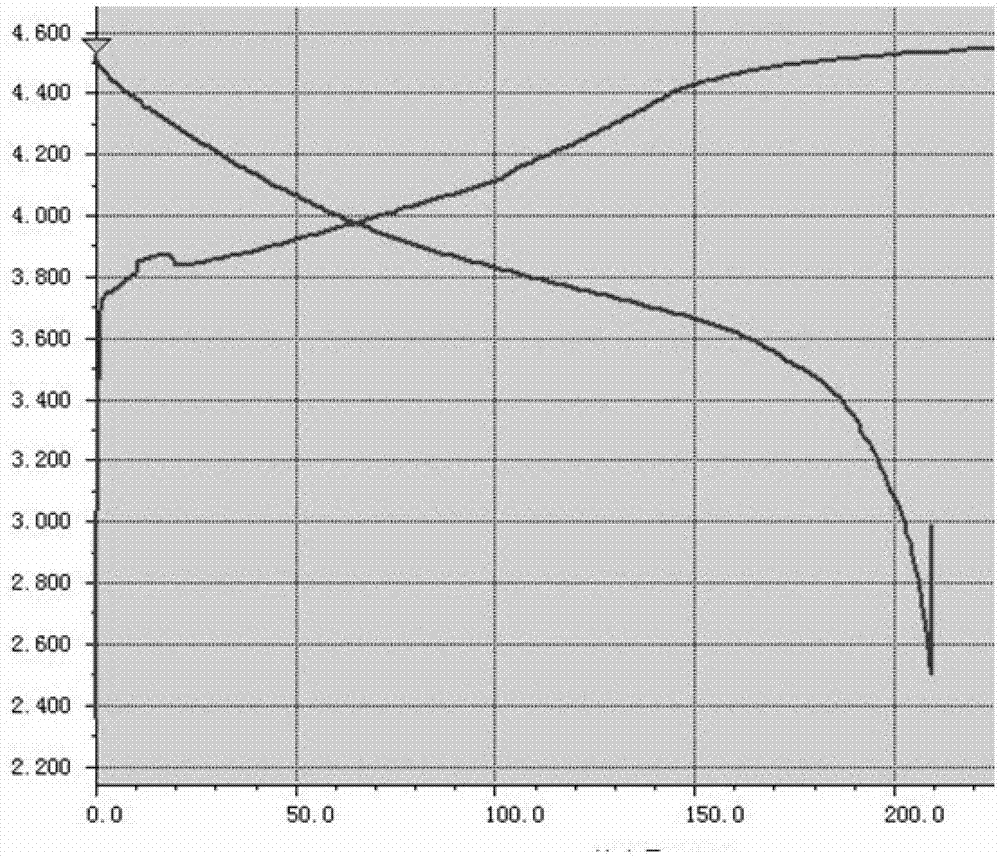

Microsphere laminated lithium-enriched manganese-based solid solution anode material and preparation method thereof

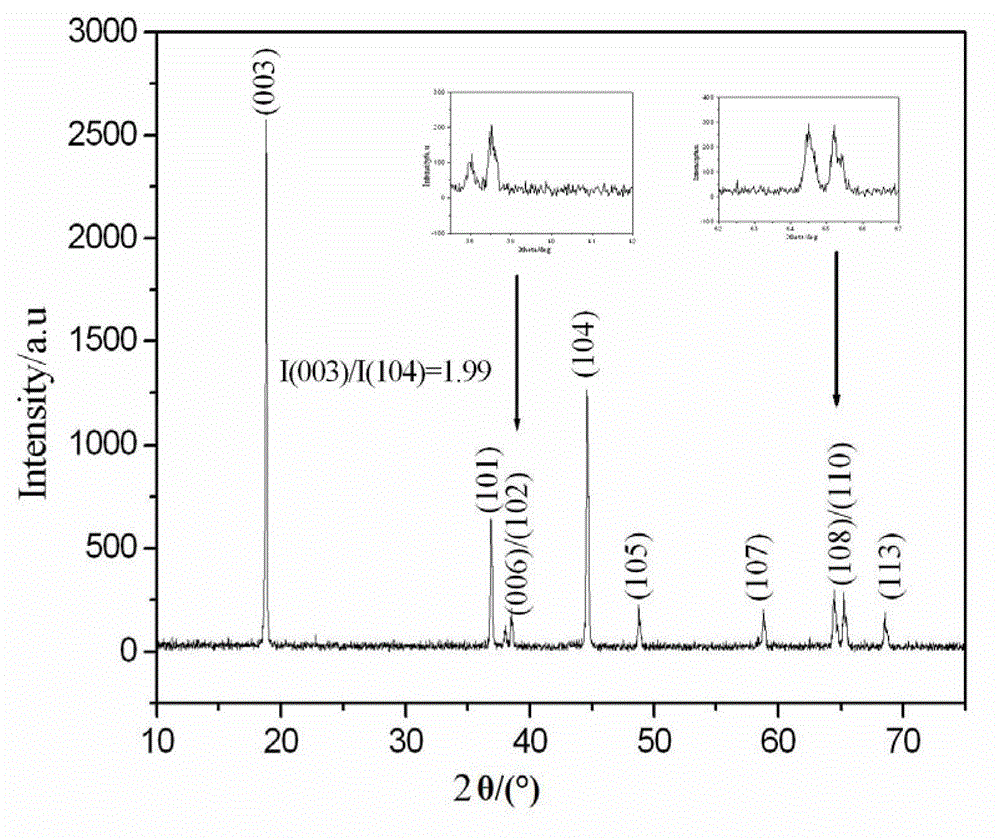

The invention discloses a microsphere laminated lithium-enriched manganese-based solid solution anode material, wherein the molecular formula is xLi2Mn1-yNyO3*(1-x)LiMn1-zMzO2; in the formula, M is one or more of Ni and Co; N is one or more of Fe, Cr, Al and Mg; x is more than 0 and less than or equal to 0.3; y is more than 0 and less than or equal to 0.1; and z is more than 0 and less than or equal to 0.7. The invention discloses a preparation method of the material at the same time. The preparation method comprises the following steps of: (1), after co-precipitating a manganese source compound and an M source compound, and sintering the manganese source compound and the M source compound with a lithium source compound in a mixed manner to obtain a precursor 1); (2), sintering the manganese source compound, the lithium source compound and an N element oxide in a mixed manner to obtain a precursor 2); and (3), mixing, acidly washing, spraying and drying the precursor 1) and the precursor 2), and sintering to obtain the lithium-enriched manganese-based solid solution anode material. The microsphere laminated lithium-enriched manganese-based solid solution anode material disclosed by the invention has the advantages of high energy density, good cycle performance, low cost, safety, excellent performance and the like and is applied to the power field with high energy and long service life.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

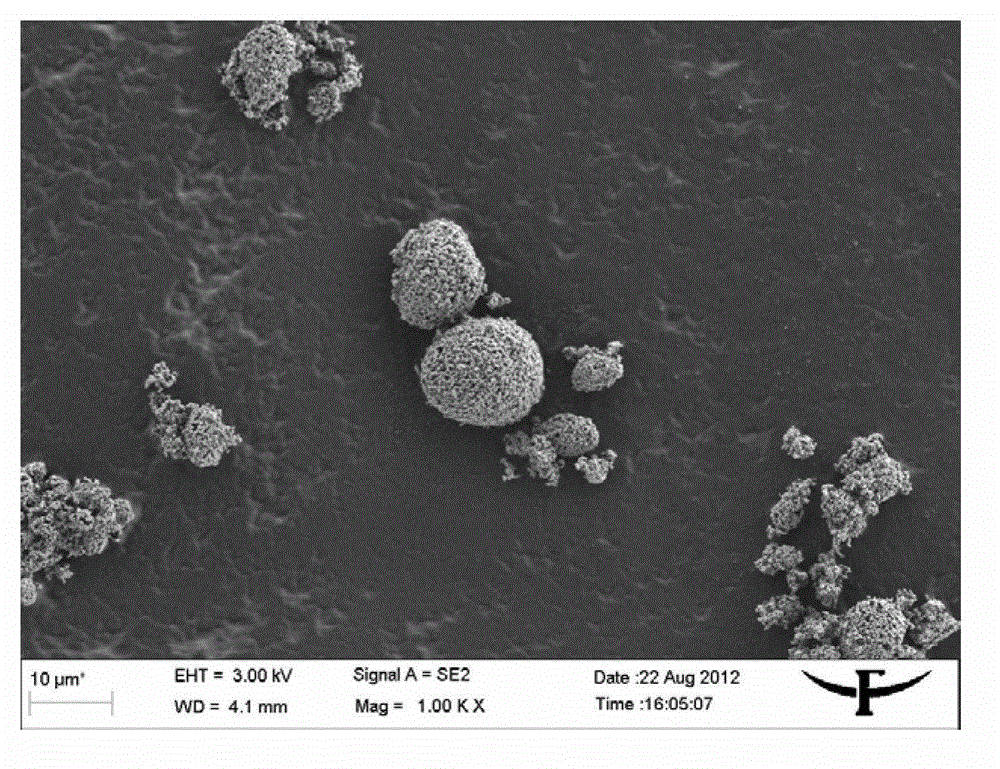

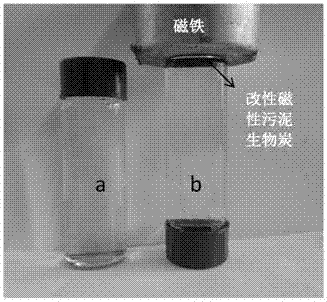

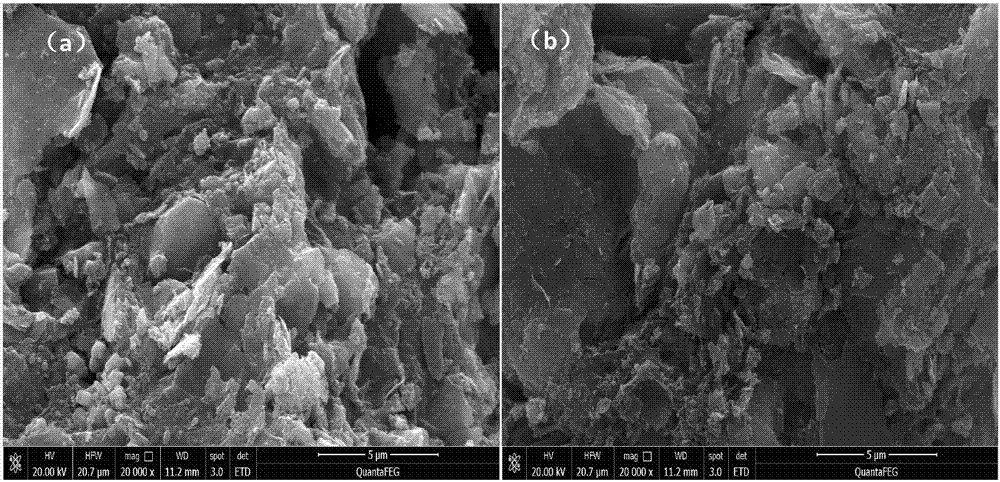

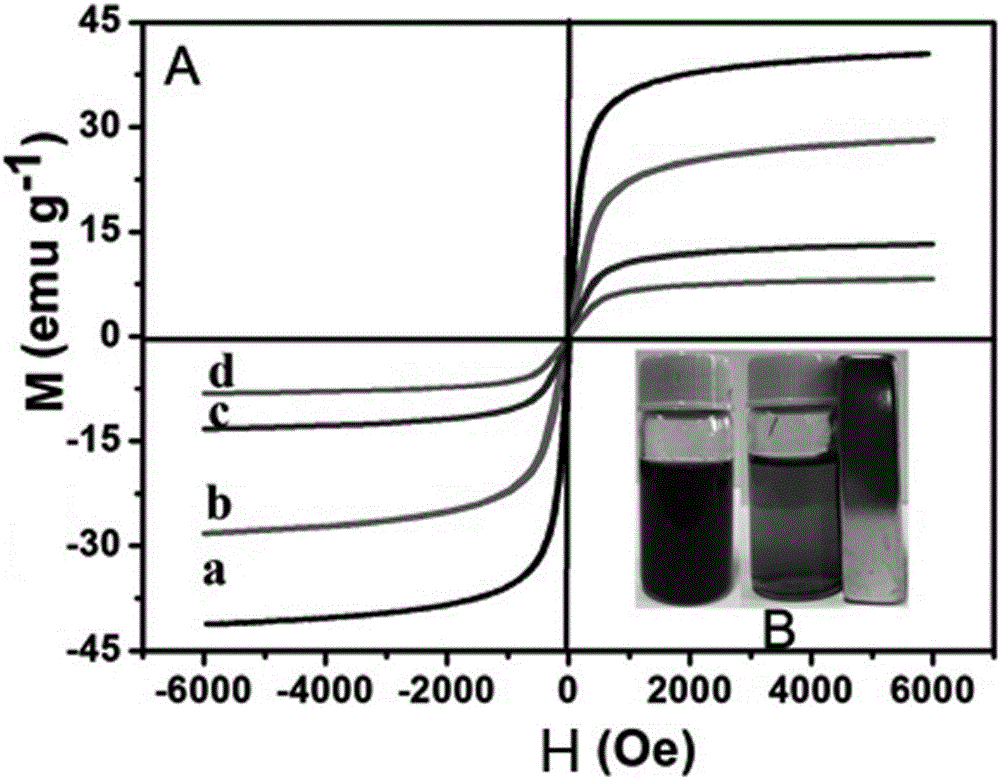

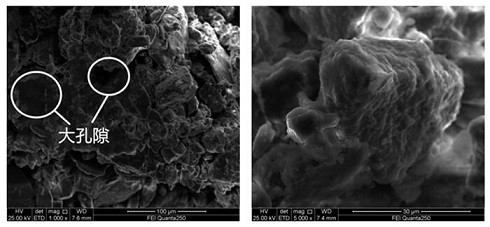

Modified magnetic sludge biological carbon and preparation method and applications thereof

ActiveCN107126924AIncrease the areaLarge hole volumeOther chemical processesWater contaminantsTetracycline HydrochlorideSludge

The invention discloses a modified magnetic sludge biological carbon and a preparation method and applications thereof. The modified magnetic sludge biological carbon is prepared by carbonizing residual sludge, modifying sludge by alkali, and modifying sludge by acid. The provided modified magnetic sludge biological carbon has the advantages of good magnetic property, large specific surface and pore volume, abundant pore structure, many surface adsorption functional groups and adsorption sites, and strong performance on removing target pollutants; and the preparation method has the advantages of simple preparation, easy operation, low cost, high production efficiency, and convenience for large scale production. The provided modified magnetic sludge biological carbon is used to remove tetracycline hydrochloride in water for the first time, has the advantages of large adsorption amount, strong adsorption performance, high adsorption efficiency, simple and convenient operation, short processing period, low processing cost, and easy separation and recovery, and has a strong performance on removing tetracycline hydrochloride. The maximal balance adsorption amount can reach 253.8 mg / g. The performance of the biological carbon is obviously stronger than that of unmodified magnetic sludge biological carbon.

Owner:HUNAN UNIV

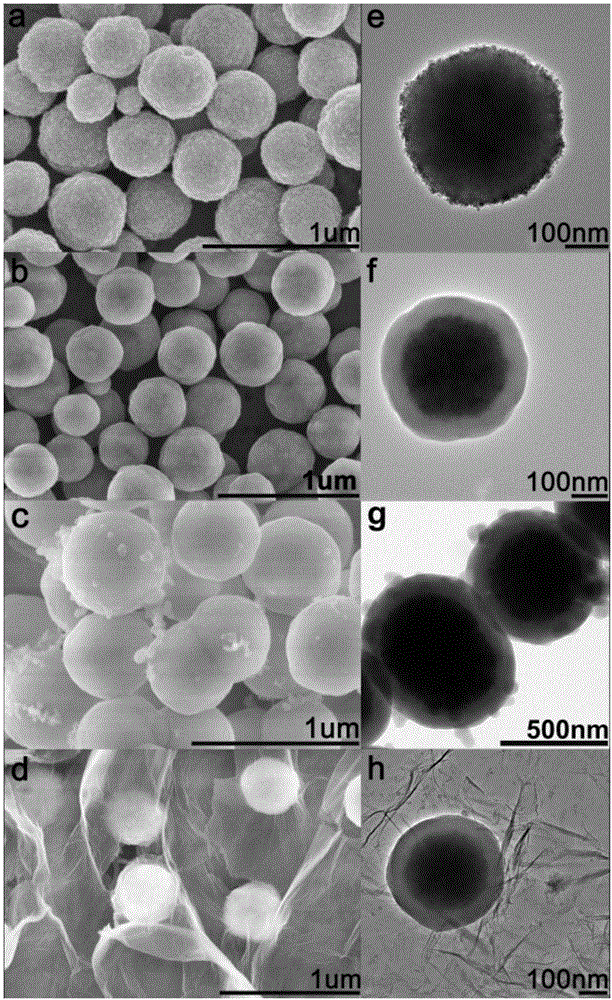

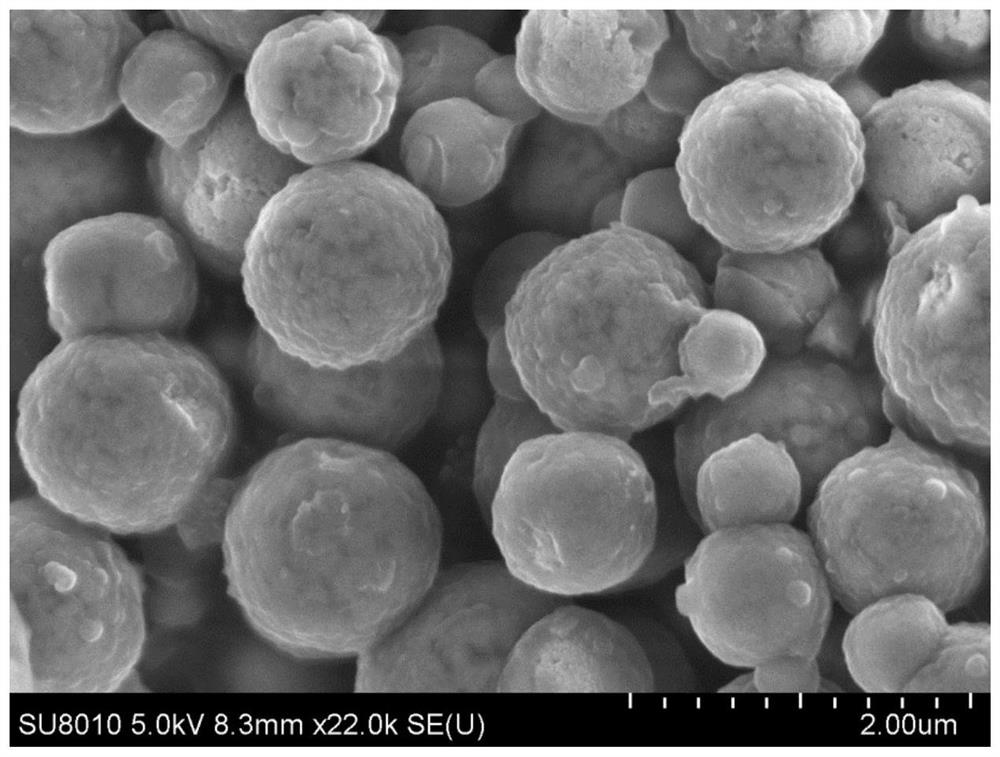

Method for preparing nanometer hollow carbon spheres with dopamine serving as carbon source

InactiveCN105502342AShort manufacturing cycleReduce energy consumptionMaterial nanotechnologyIn situ polymerizationNitrogen

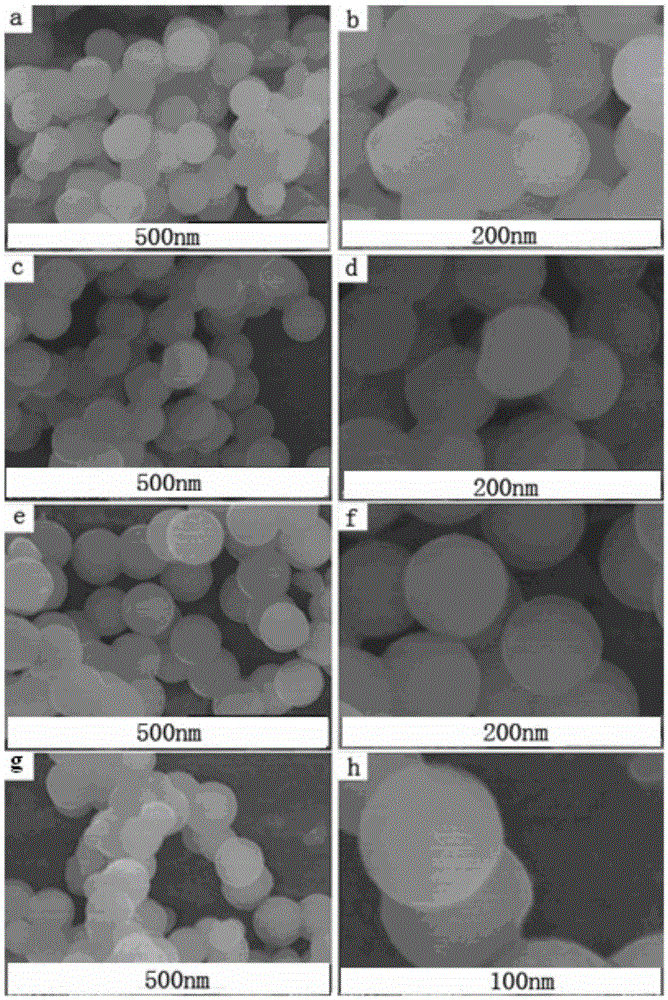

The invention discloses a method for preparing nanometer hollow carbon spheres with dopamine serving as the carbon source. The method includes the steps of firstly, preparing SiO2 nanometer spheres through a method (please see the method in the description); secondly, directly adding dopamine to a reaction system, and preparing SiO2Pdop by wrapping dopamine on the surfaces of SiO2 through in situ polymerization; thirdly, roasting the prepared SiO2Pdop under the atmosphere of nitrogen to obtain SiO2Carbon; fourthly, dispersing the prepared SiO2Carbon in an ammonia water solution to be etched. By means of the method, preparation of the SiO2 nanometer spheres and wrapping of dopamine are completed through a one-pot method, the preparation cycle is shortened, the energy consumption is saved, operation is easy, large-scale production can be easily achieved, nanometer hollow carbon spheres which are uniform in size, controllable in shell thickness and particle size and stable in morphology structure can be prepared, and application prospects are wide.

Owner:SHANGHAI UNIV OF ENG SCI

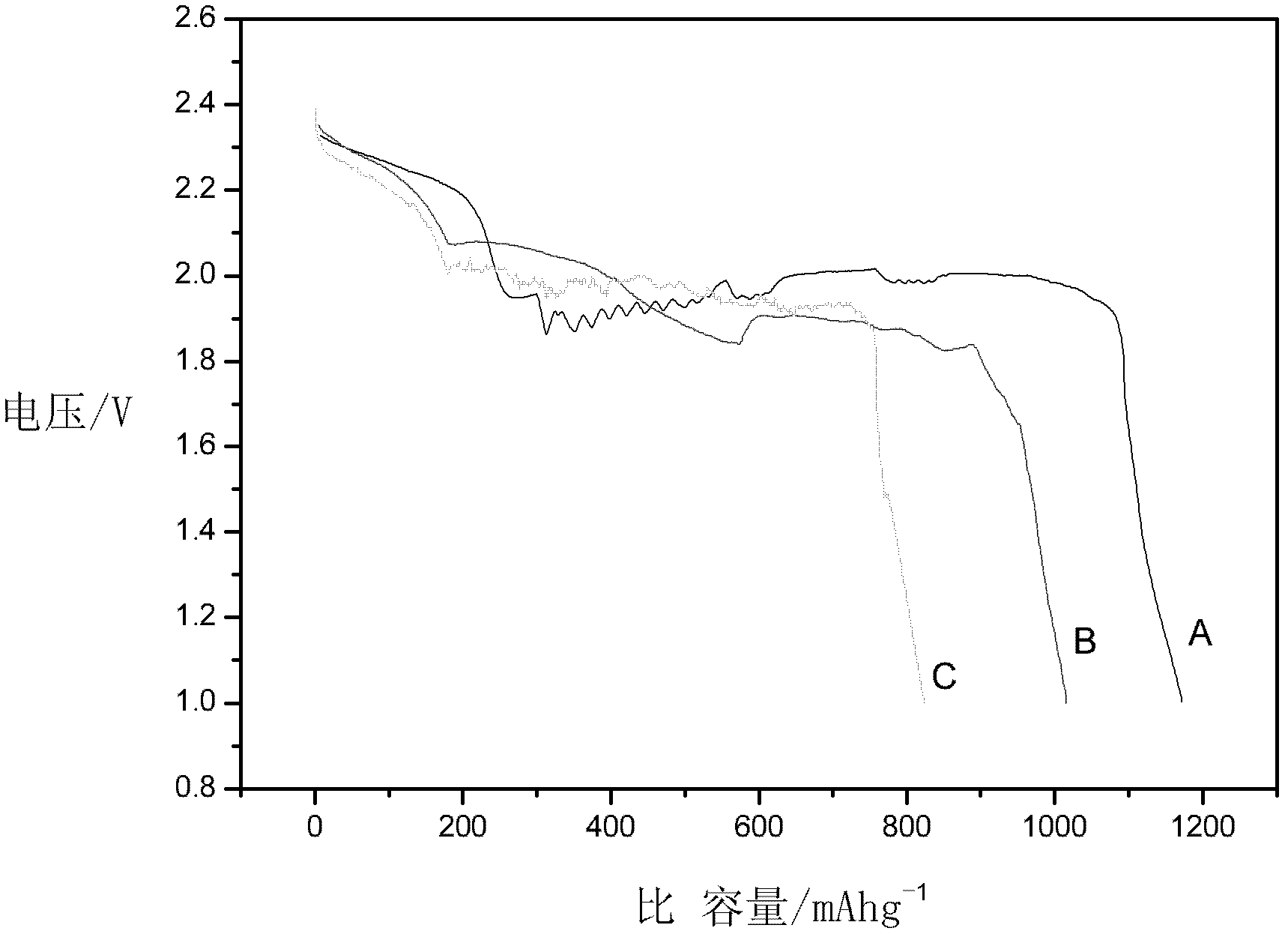

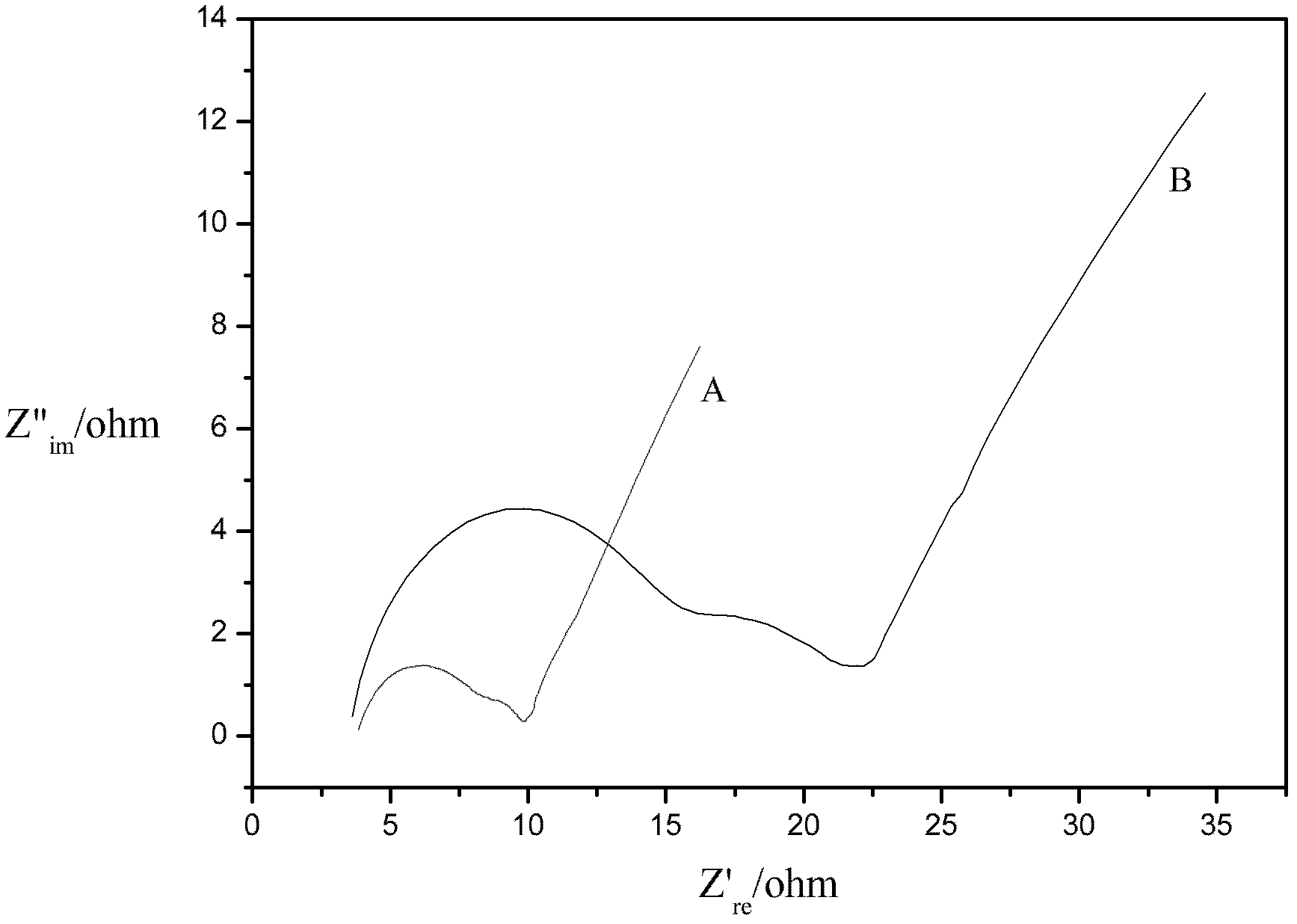

Composite material for positive pole of lithium-sulfur battery, and positive pole and battery both made of same

ActiveCN102623676AImprove cycle stabilityLow costNon-aqueous electrolyte accumulator electrodesLi-accumulatorsTube furnaceCyclic stability

The invention relates to a composite material for a positive pole of a lithium-sulfur battery, and a positive pole and a battery both made of the material. The composite material is the mixture of polynaphthylene or polynaphthylene derivative with the mass percentage of 20-34 percent, and sulfur. The preparation method for the composite material comprises the steps that firstly, the polynaphthylene or the polynaphthylene derivative is uniformly mixed with the sulfur; secondly, the mixture is placed in an electric tube furnace at the temperature of 150 DEG C for 5-8 hours, and then at the temperature of 300 DEG C for 2-3 hours; and lastly, the material is reduced to room temperature through natural cooling, so as to obtain the composite material. The invention also provides the positive pole for the lithium-sulfur battery and the battery which are made of the composite material. The lithium-sulfur battery provide by the invention has high discharge specific capacity, meanwhile, the utilization ratio of active substance is effectively improved, the cycling stability of the battery is also improved to a certain extent, and the cost of the battery is reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

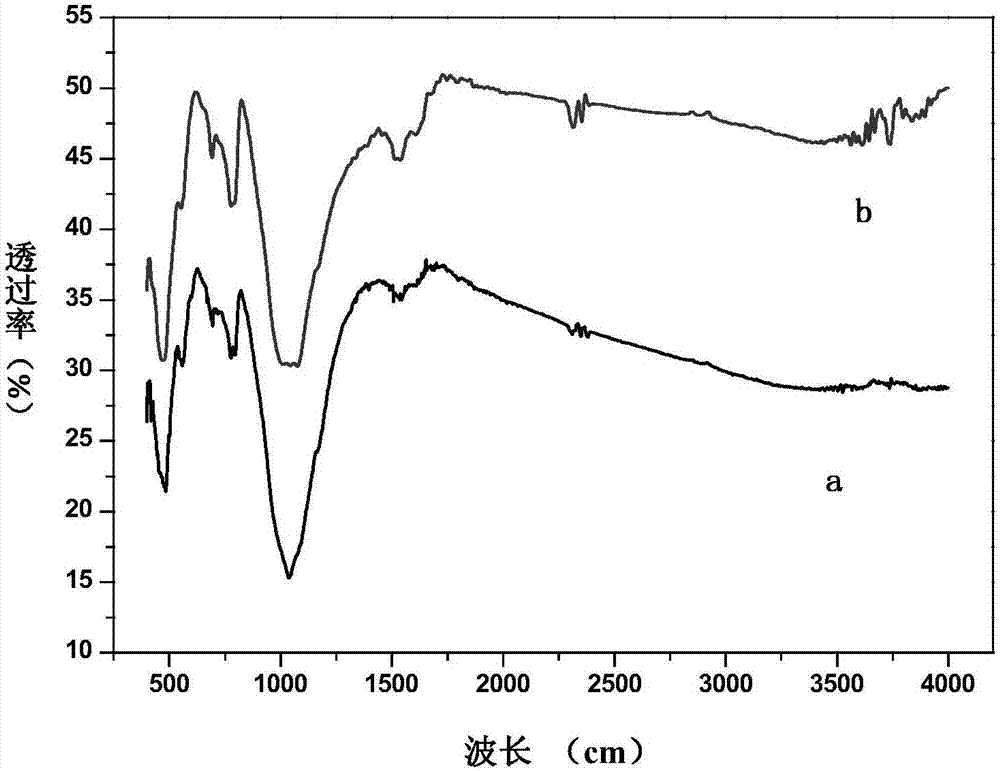

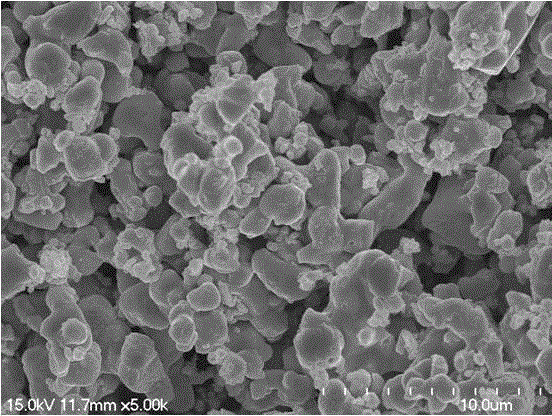

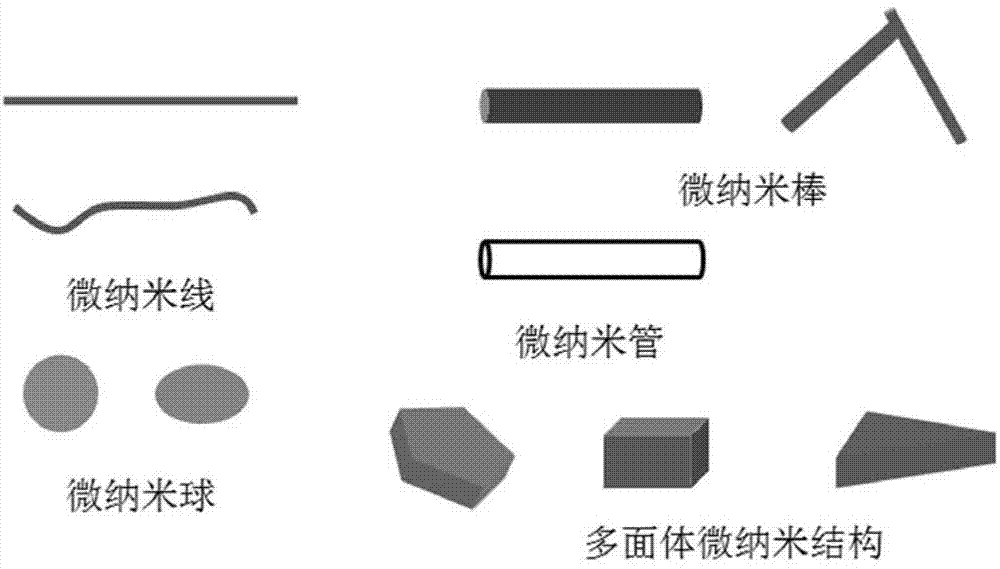

Magnetic nano composite material and a preparation method and application thereof

InactiveCN106693920ALarge specific surface areaGood shape structureOther chemical processesWater contaminantsTetramineOrganic dye

The invention discloses a magnetic nano composite material and a preparation method and application thereof. The magnetic nano composite material is obtained by firstly coating ferroferric oxide with silicon dioxide to obtain Fe3O4 @ SiO2 magnetic nano microspheres, then sequentially coating the surfaces of the Fe3O4 @ SiO2 magnetic nano microspheres with chitosan, triethylene tetramine and graphene oxide layer by layer. Experiments indicate that the magnetic nano composite material has large specific surface area, good morphology structure, strong magneticity, good adsorptive property and other advantages, can be used as a heavy metal ion and organic dye adsorbent and has a good use value and an application prospect in the environment, water treatment and other fields.

Owner:SHANGHAI UNIV OF ENG SCI

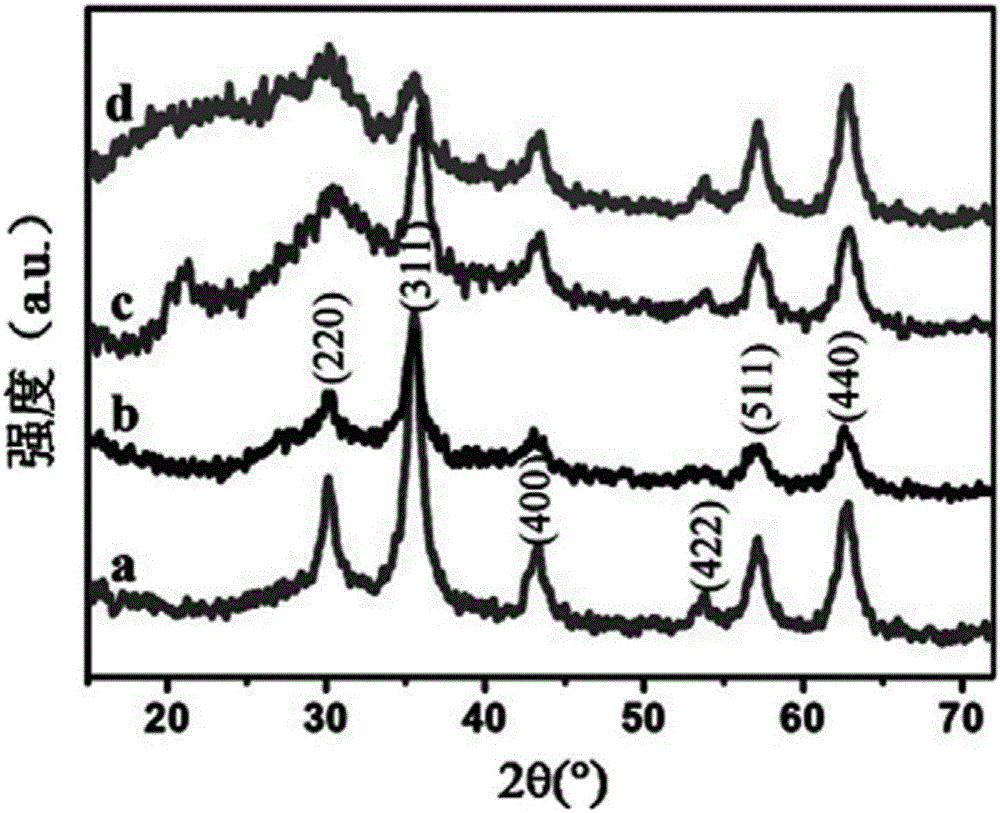

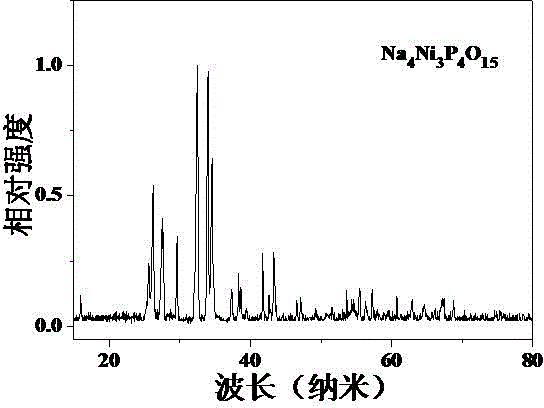

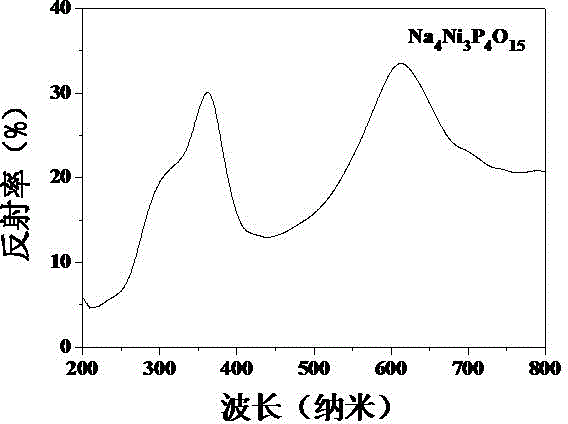

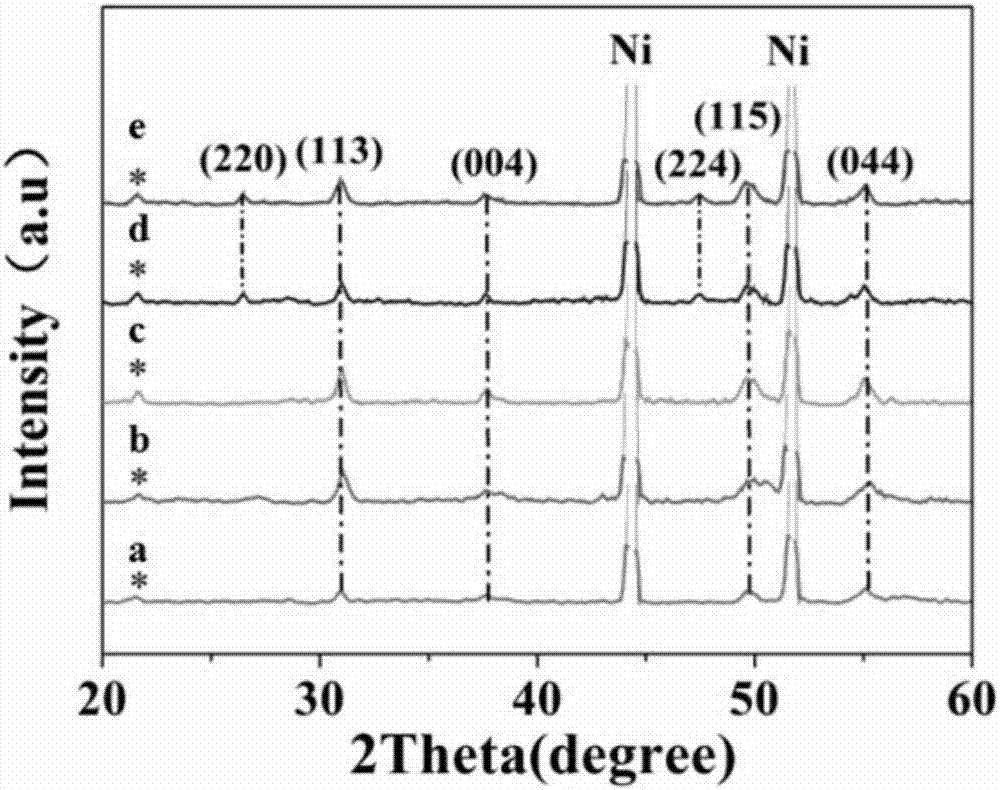

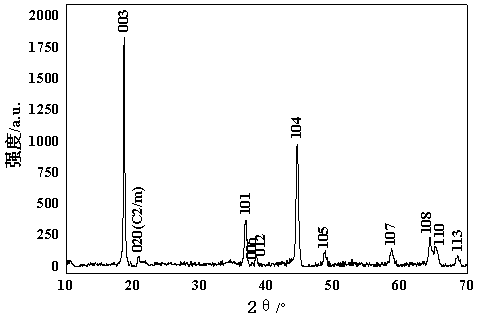

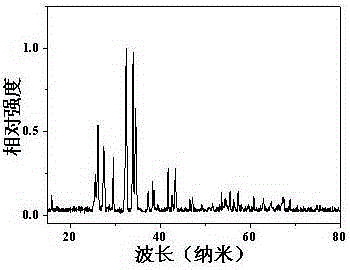

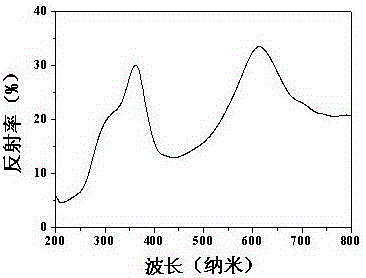

Preparation and photocatalytic application of Na4Ni3P4O15 photocatalyst

InactiveCN104888819ALow costEasy to preparePhysical/chemical process catalystsWater/sewage treatment by irradiationChemical solutionPhysical chemistry

The invention relates to a preparation method and a photocatalytic application of a novel Na4Ni3P4O15 photocatalyst and belongs to the field of inorganic photocatalytic materials. The photocatalytic material is prepared with a high-temperature solid state method or a chemical solution method, the obtained Na4Ni3P4O15 photocatalytic material is uniform in granularity and good in chemical stability and has the better photocatalytic effect, the preparation method is simple to operate and easy to implement, the production cost is low, industrial production is facilitated, organic pollutants can be well decomposed, and the photocatalytic material is ideal.

Owner:SUZHOU DEJIE MEMBRANE MATERIAL SCI & TECH

Preparation method of fluorine-containing polymer porous nano-micron fibre electrode diaphragm

ActiveCN104752663AImprove thermal stabilityGood acid and alkali resistanceCell component detailsFiberMetal oxide nanoparticles

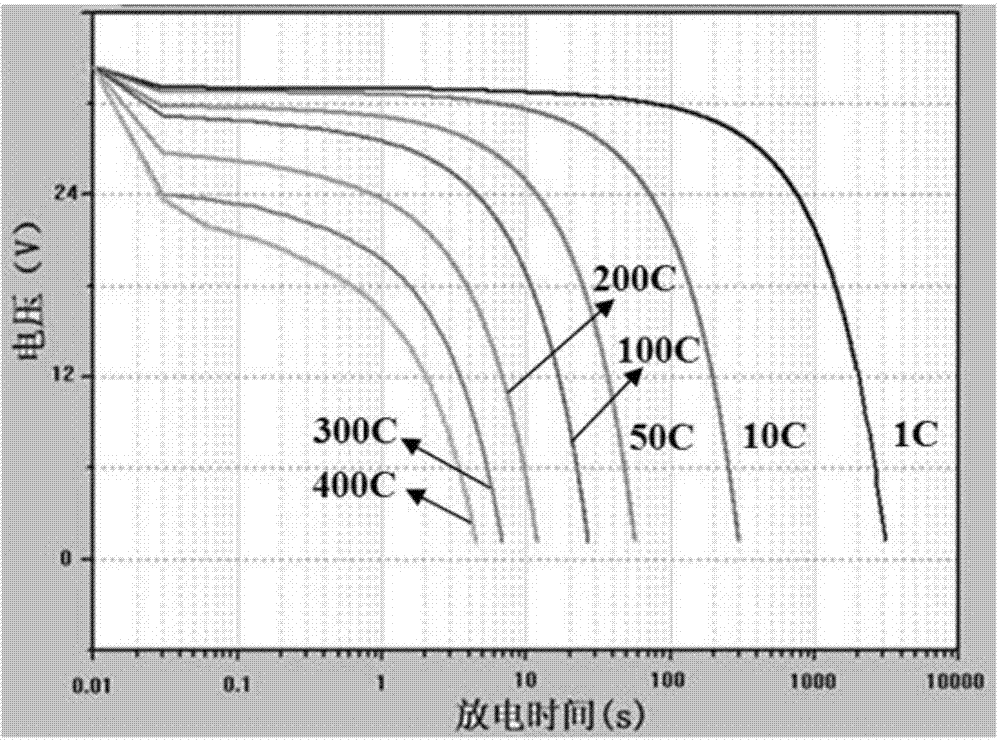

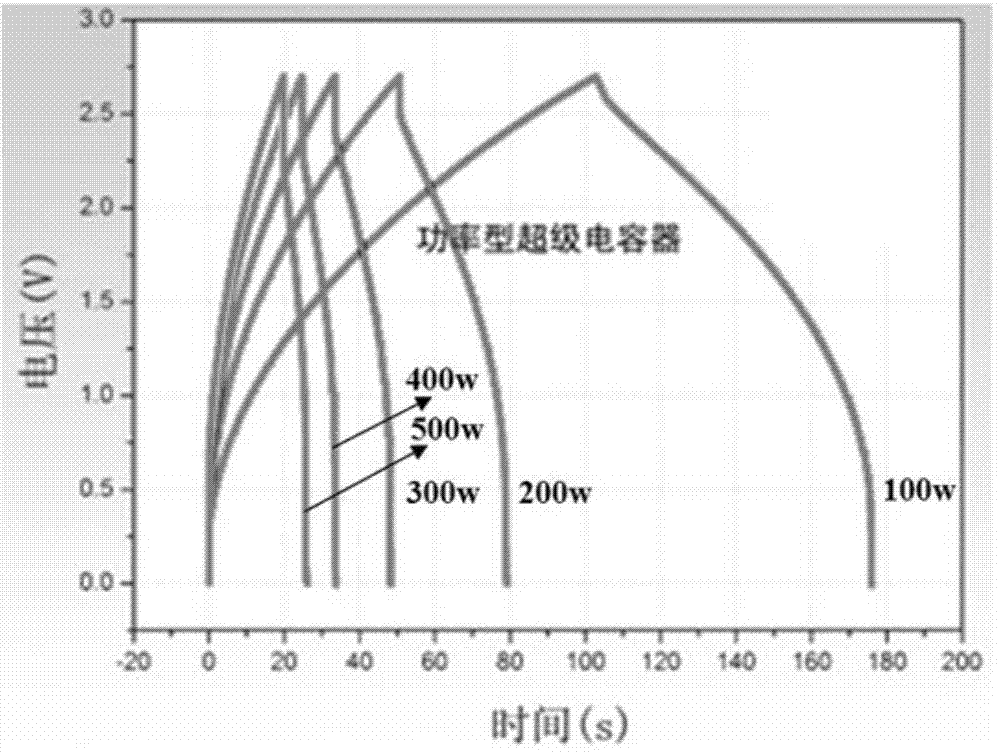

The invention relates to a preparation method of a fluorine-containing polymer porous nano-micron fibre electrode diaphragm. The preparation method comprises the following steps: dissolving a fluorine-containing polymer and soluble metal salt in an organic solvent to prepare a spinning precursor, then, preparing a fluorine-containing polymer-metal salt electrostatic spinning fibrous membrane through high-pressure electrostatic spinning, adding a mineralizing agent to carry out hydrothermal reaction so as to obtain a fluorine-containing polymer-metal oxide nano-micron fibrous membrane, carrying out acid treatment by using dilute acid aqueous solution to convert metal oxide nanoparticles in the fluorine-containing polymer-metal oxide nano-micron fibrous membrane into soluble metal salt which is dissolved in inorganic acid aqueous solution, thus obtaining the fluorine-containing polymer porous nano-micron fibre electrode diaphragm. The preparation method disclosed by the invention has the advantages that the liquid holdup, the infiltrating property and the conductive ion migration rate of the diaphragm can be effectively increased; the resistance among the diaphragm, an electrode and electrolyte is reduced; the electrochemical performances of a supercapacitor, such as the power density and the cycle service life, can be increased; and therefore, the supercapacitor having high power density can be obtained.

Owner:锦州凯美能源有限公司

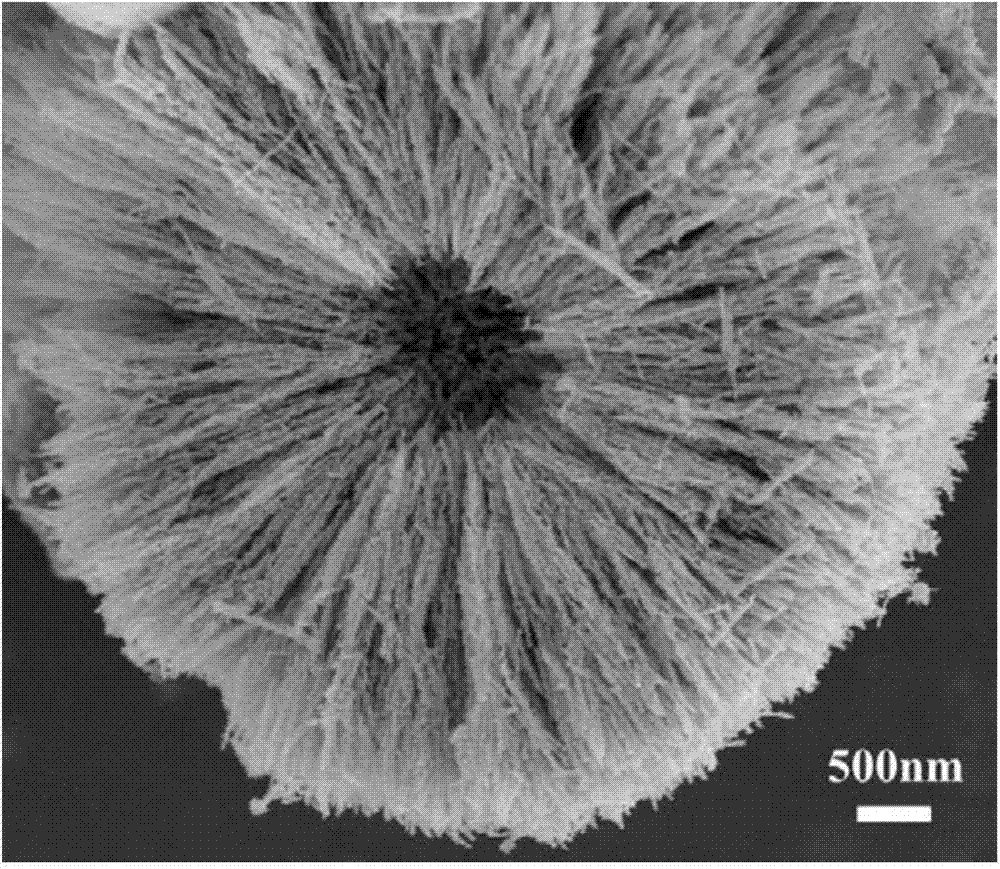

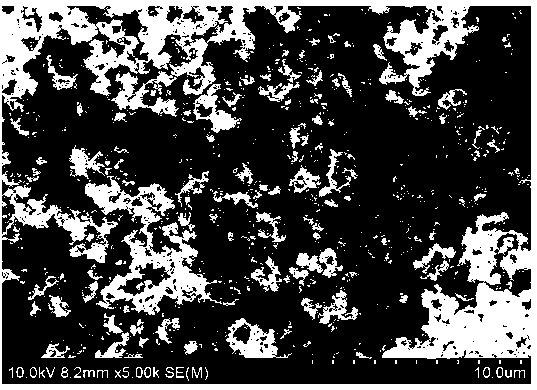

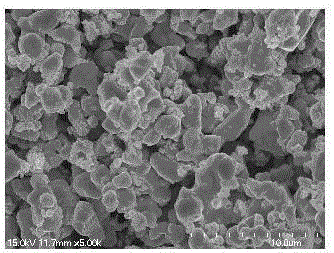

Manganese cobalt oxide hollow microsphere material and preparation method

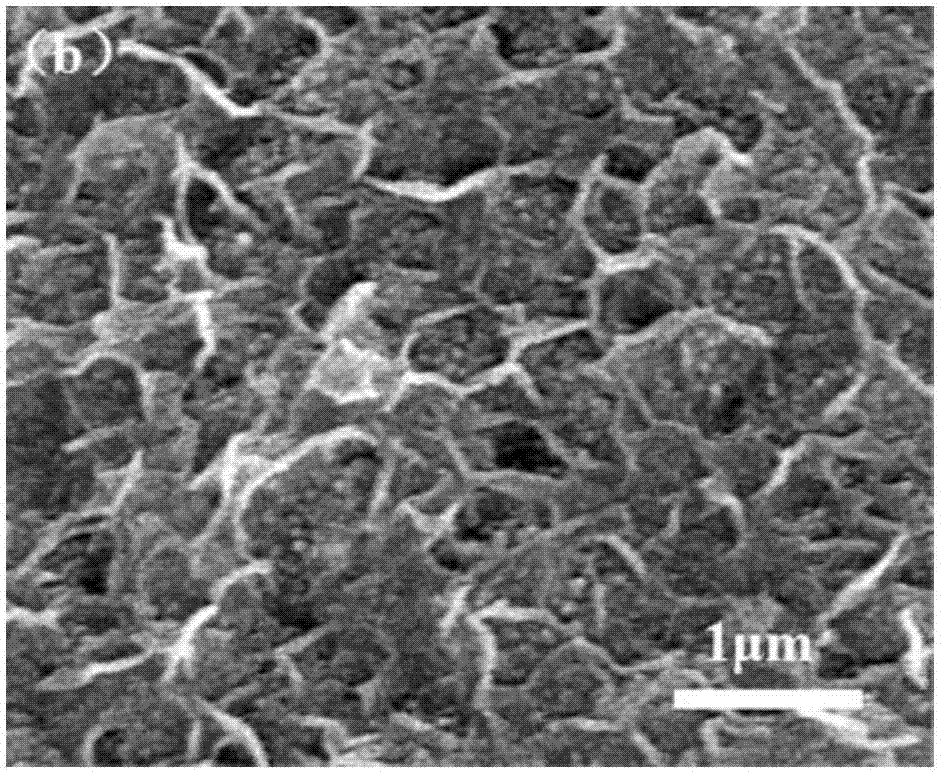

ActiveCN104733726AGood shape structureImprove cycle performanceMaterial nanotechnologyCell electrodesMicrosphereManganese

The invention provides a manganese cobalt oxide hollow microsphere material and a preparation method. The preparation method comprises the following steps: dissolving Mn(NO3)2 and Co(NO3)2.6H2O in deionized water, adding with anhydrous ethanol, and uniformly mixing the anhydrous ethanol and the deioinzed water; adding urea into the solution, transferring the mixed solution into a hydrothermal reaction kettle, and facilitating the reaction; centrifugally separating precipitates, washing the precipitates by utilizing deionized water and alcohol, and then drying the precipitates; and placing the precipitates in a muffle furnace, heating the muffle furnace to 600 DEG C, preserving the heat for 4 to 6 hours, and calcining the precipitates to obtain the hollow microsphere material assembled by manganese cobalt oxide nanoneedles. The diameter of the prepared manganese cobalt oxide nanoneedle is less than or equal to 30nm, and the diameter of the hollow microsphere is micron-sized (less than or equal to 6 micrometers). The manganese cobalt oxide hollow microsphere material is used as a lithium ion battery anode material, due to the special hollow structure, the cycling performance of the lithium ion battery can be improved, the performance is tested under the current density of 50 to 200 mAg<-1>, the primary discharging capacity can reach more than 1400mAhg<-1>, and the specific capacity still reach more than 750mAhg<-1> after the lithium ion battery is cycled for 25 times.

Owner:TIANJIN UNIV

Etching method and etching polishing liquid

The invention discloses a method for etching a flat surface of a metal product and a curved surface connected with the flat surface. According to the method, a concavo-convex continuous microstructure is formed in the surface of the metal product by controlling the size of mask blocks and mask gap on the flat surface and the curved surface of the metal product and controlling related process parameters such as etching time, etching pressure and the like in an etching process; the depth of each pit is gradually reduced from the center of the flat surface to the edge of the curved surface; the section of the pit is shaped like a trough arc of sine wave; each projection does not have an obvious edge; the adaption part of the projection is in smooth transition; the section of the projection is similar to a quadrangular shape; the whole structure is in gentle transition; the microstructure takes on gradual transition connection of from existence to null and has good visual and tactile effects; and the requirements on higher anti-skid performance and attractive appearance can be met.

Owner:GUANGDONG UNIV OF TECH

Electrocatalyst for efficiently decomposing water into hydrogen and oxygen and preparation method of electrocatalyst

InactiveCN107321366AImprove performanceHigh catalytic activityPhysical/chemical process catalystsElectrode shape/formsElectronic transmissionHydrogen

The invention discloses an electrocatalyst for efficiently decomposing water into hydrogen and oxygen and a preparation method of the electrocatalyst. With the adoption of a two-step hydrothermal method, NiCo2S4 nanosheets with different thicknesses are constructed by regulating and controlling concentration of growth-promoting media. The nanosheets with the thicknesses being 70-80 nm have good electrochemical surface area, excellent electronic transmission capacity and more reaction active sites, and show excellent performance in the reaction of decomposing water into hydrogen and oxygen with GaAs solar cells. Meanwhile, the catalyst is high in element content, low in cost and good in catalysis performance, adopts a simple preparation technology and provides basic application research for the field of direct light-to-hydrogen conversion.

Owner:UNIV OF SCI & TECH BEIJING

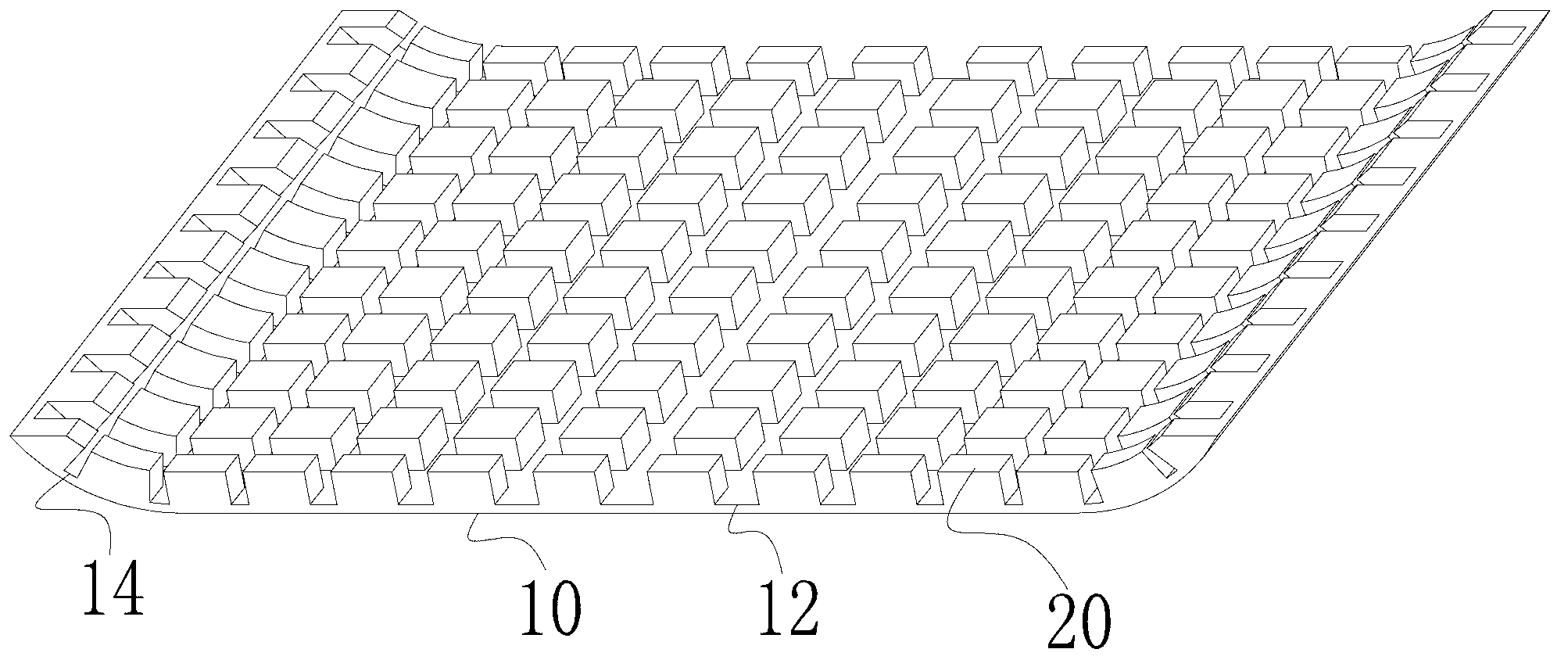

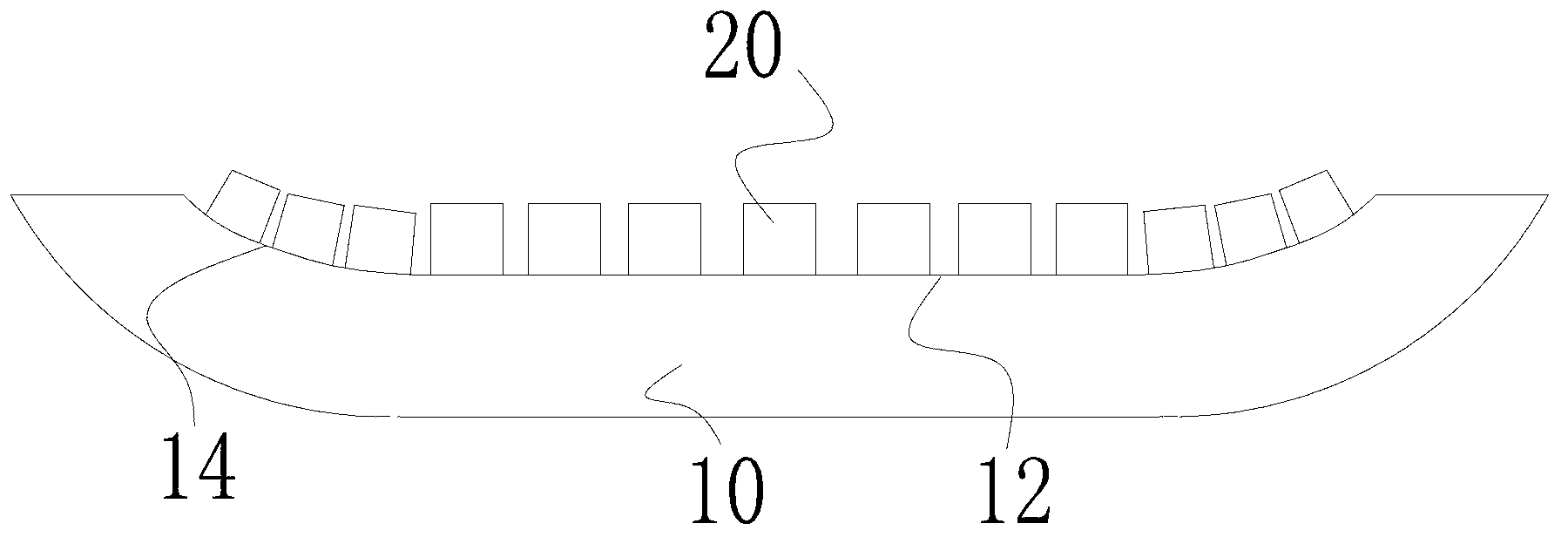

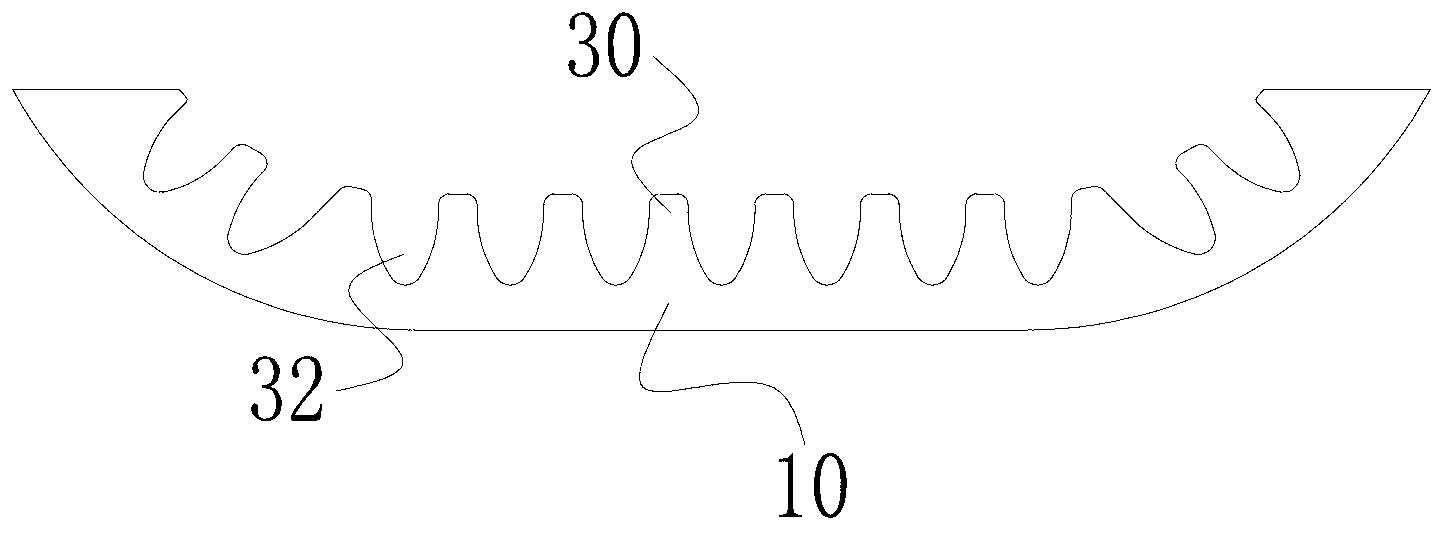

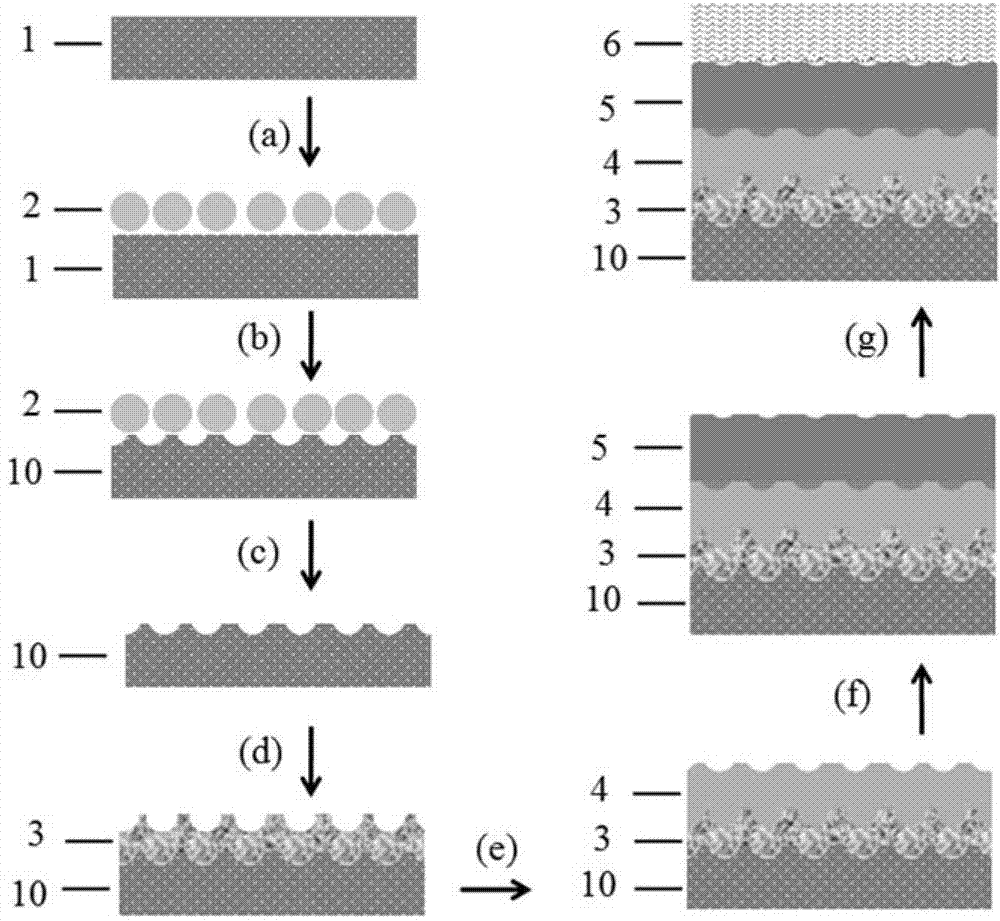

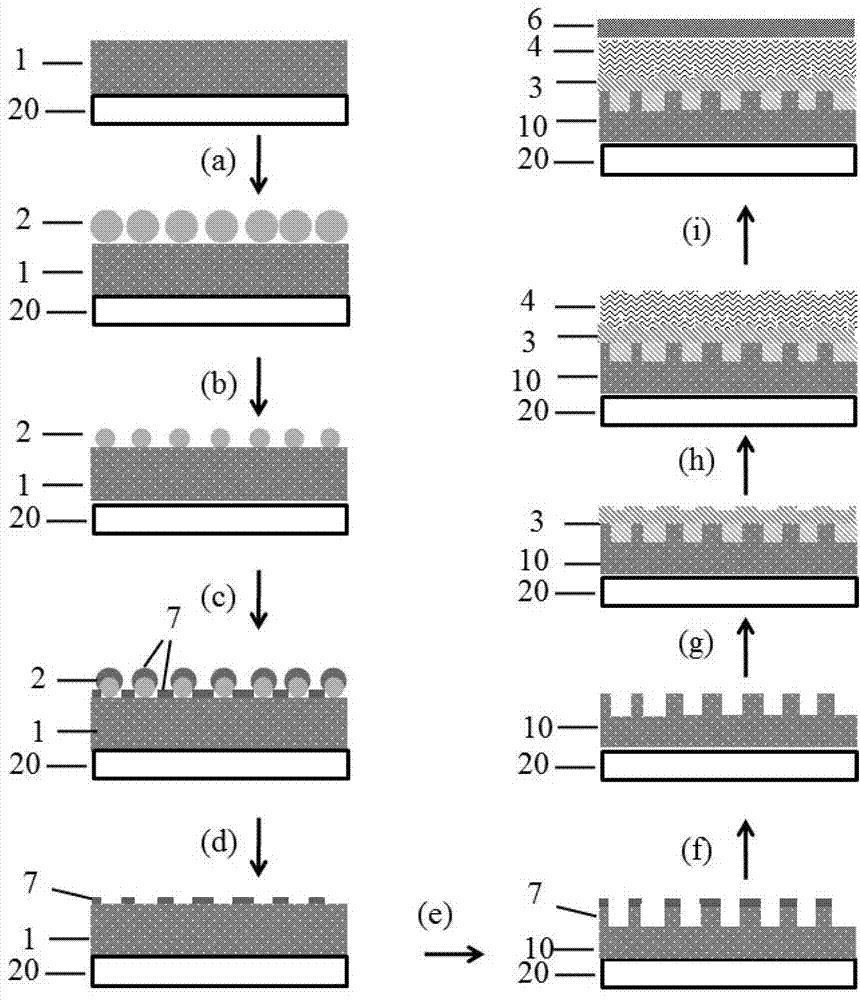

Patterned electrode, preparation method and organic solar cell

ActiveCN102832348AImprove PCEPromote absorptionFinal product manufactureSolid-state devicesOrganic solar cellNano structuring

The invention discloses a preparation method for a patterned electrode. The preparation method comprises the following steps of: (1) covering the surface of the electrode by using a nano-structured layer, wherein the coverage rate of the nano-structured layer on the surface of the electrode is 15 to 100 percent; (2) corroding the electrode by using the nano-structured layer as a template; and (3) removing the nano-structured layer to obtain the patterned electrode. The preparation method is simple, and nicks on the surface of the patterned electrode are easy to control. The invention discloses the patterned electrode obtained by the preparation method. By the patterned electrode, the optimization of the morphological structure of an organic light active layer can be induced in the preparation process of an organic solar cell, so that the performance of the organic solar cell can be improved, and the photoelectric energy conversion efficiency of the solar cell can be improved. The invention also discloses the organic solar cell. The organic solar cell can be efficiently manufactured, and the cost is low.

Owner:ZHEJIANG UNIV

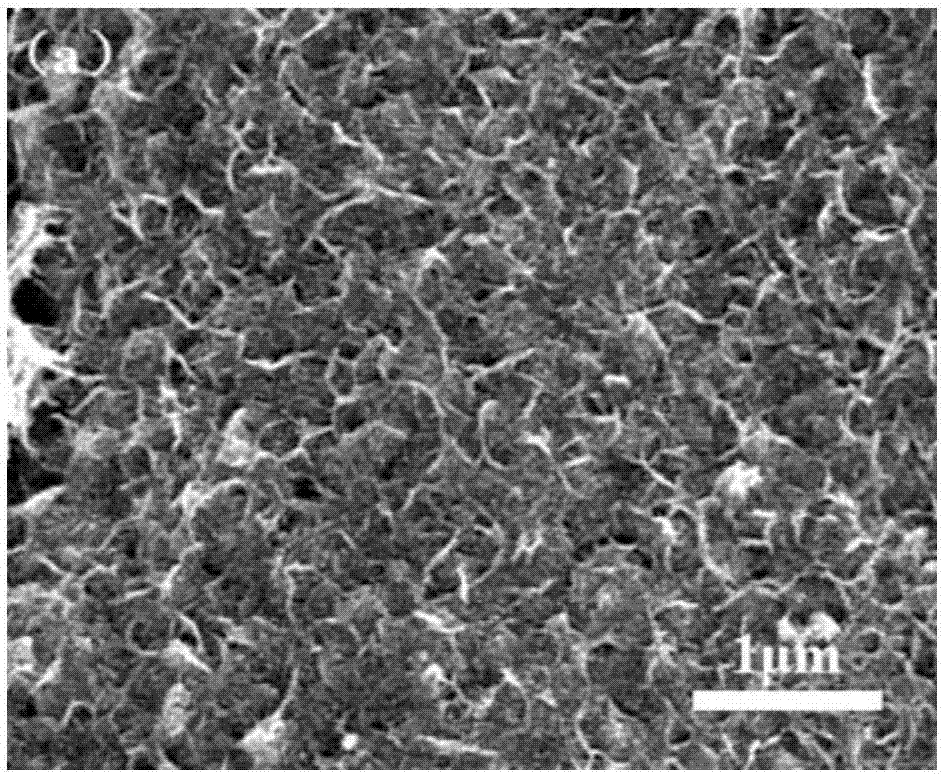

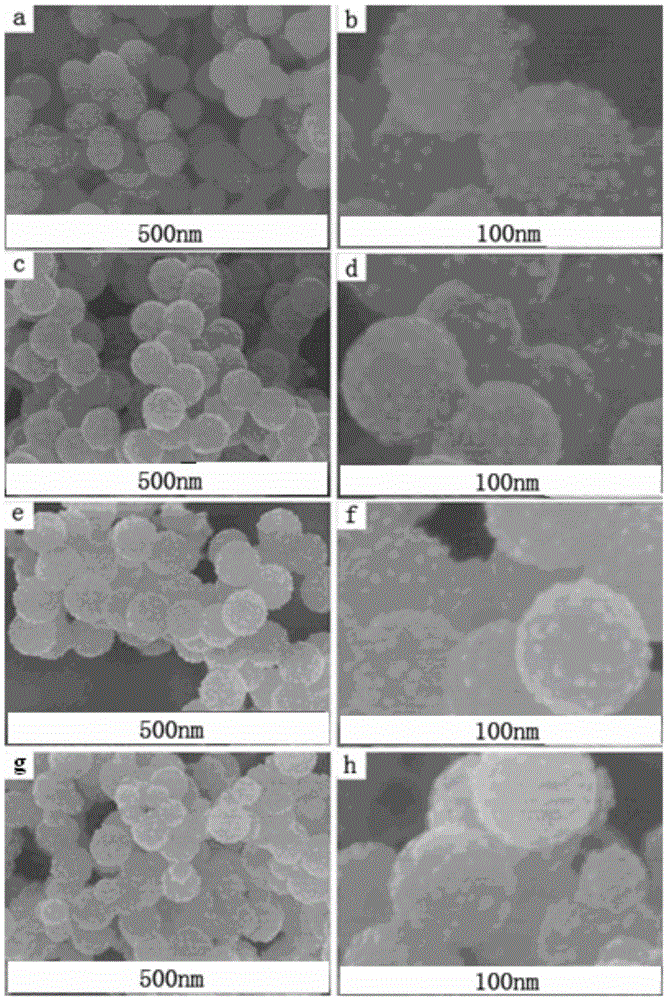

Magnetic core-shell-structured nano-material, preparation method therefor and application of magnetic core-shell-structured nano-material

InactiveCN105521772ALarge specific surface areaGood shape structureOther chemical processesOrganic compound preparationNitro compoundNickel salt

The invention discloses a magnetic core-shell-structured nano-material, a preparation method therefor and application of the magnetic core-shell-structured nano-material. The magnetic core-shell-structured nano-material is prepared through coating silicon dioxide nanospheres by a chelate of dopamine and a nickel salt so as to obtain a Ni<2+>-PDA@SiO2 core-shell-structured nano-material, subjecting the Ni<2+>-PDA@SiO2 core-shell-structured nano-material to roasting or etching and then carrying out roasting. Shown by experiments, the magnetic core-shell-structured nano-material disclosed by the invention has the advantages of large specific surface area, good morphology, relatively high magnetic property, excellent adsorption and catalysis performance and the like, can serve as a protein adsorbent and a reduction reaction catalyst of aromatic nitro compounds and has relatively good use values and application prospects in the fields of environment, energy sources and the like.

Owner:SHANGHAI UNIV OF ENG SCI

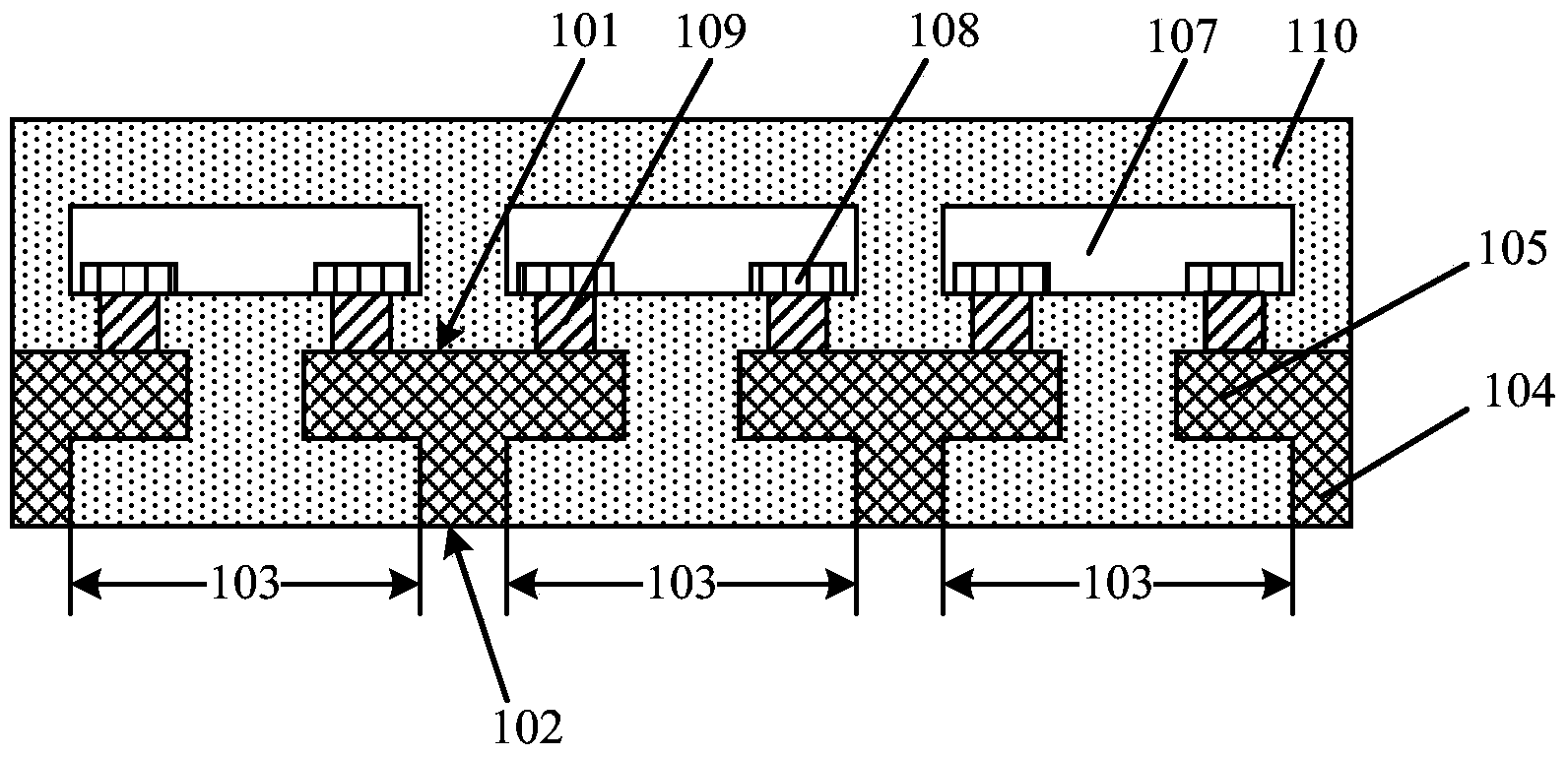

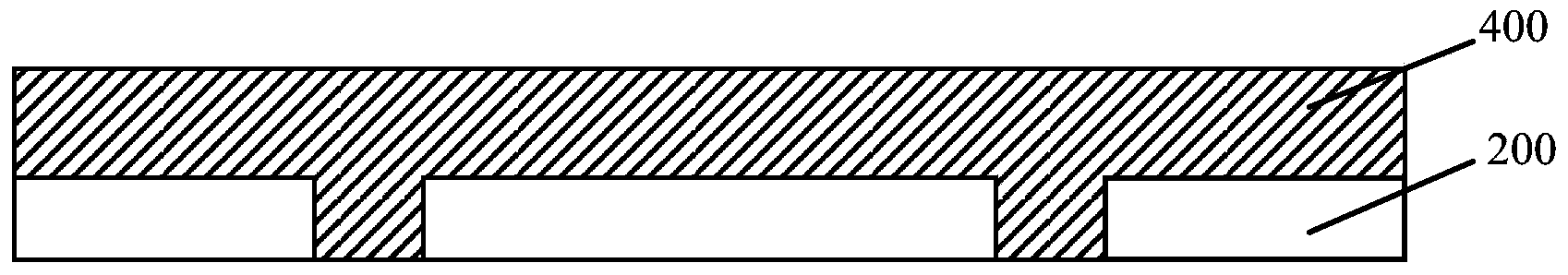

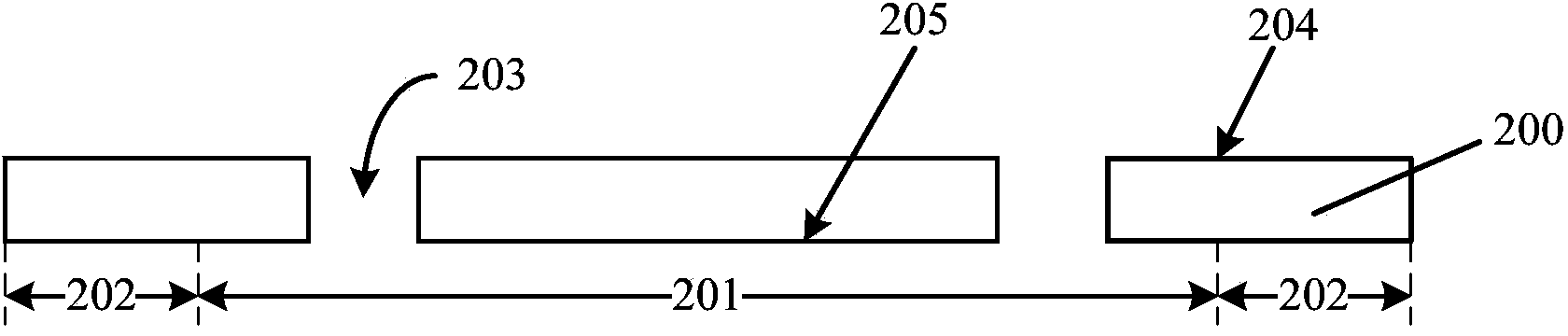

Formation method of lead frame structure

ActiveCN103972111ANice appearanceReliable electrical connectionSemiconductor/solid-state device manufacturingInsulation layerEngineering

Provided is a formation method of a lead frame structure. The formation method of the lead frame structure comprises the steps that a plastic package layer is formed, wherein the plastic package layer is provided with a plurality of supporting areas and cutting areas between the supporting areas, the supporting areas are internally provided with a plurality of first openings penetrating through the plastic package layer, and the plastic package layer is provided with a first surface and a second surface opposite to the first surface; an insulation layer is formed on the first surface of the plastic package layer, wherein the insulation layer is internally provided with second openings exposing the first openings, the second openings are greater than the first openings in size, and the second openings further expose part of the surface, around the first openings in the supporting areas, of the plastic package layer; the first openings and the second openings are filled with conductive materials, and pin structures are formed in the first openings and the second openings, wherein the insulation layer exposes the first surfaces of the pin structures, and the plastic package layer exposes the second surfaces of the pin structures. The process for forming the lead frame is simplified, cost is lowered, and the shape and the electric connection performance of the formed lead frame structure are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

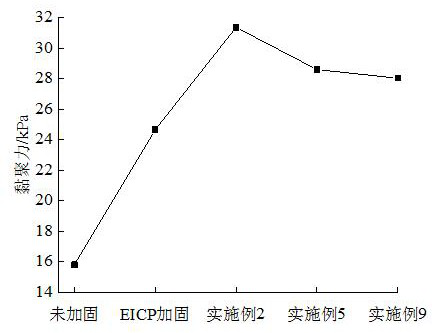

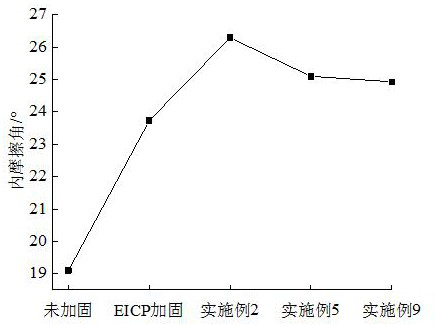

Method for reinforcing soil body by combination of organic matter and plant urease

InactiveCN111827258AImprove mineral morphology and structureIncreased strength and effectBuilding constructionsOrganic fertilisersRice flourEnvironmental chemistry

The invention provides a method for reinforcing a soil body by a combination of organic matter and plant urease. The method includes the following steps of firstly, extracting the soybean urease; secondly, mixing the organic matter such as glutinous rice flour, brown sugar or skim milk powder into a solution of soybean urease in proportion; and thirdly, sequentially injecting the organic matter and urease mixed liquid and consolidating fluid into the soil body in certain proportion. According to the method, nucleation point locations are provided for calcium carbonate precipitation by introducing the organic matter into a urease induced calcium carbonate precipitation (EICP) technology so that calcium ions can be concentratedly adsorbed to anion groups provided by the organic mater and large-grained calcium carbonate crystals can aggregate at the nucleation point locations; the growth habit of mineral crystals is affected, the morphology structure of minerals is improved, and the strength of soil body is greatly improved and enhanced; and the activity of the urease is protected, and the calcium carbonate precipitation efficiency under a high concentration is slightly improved. Themethod is efficient, economical, simple in process, friendly to the environment, convenient to popularize and suitable for large-scale treatment.

Owner:HENAN UNIVERSITY

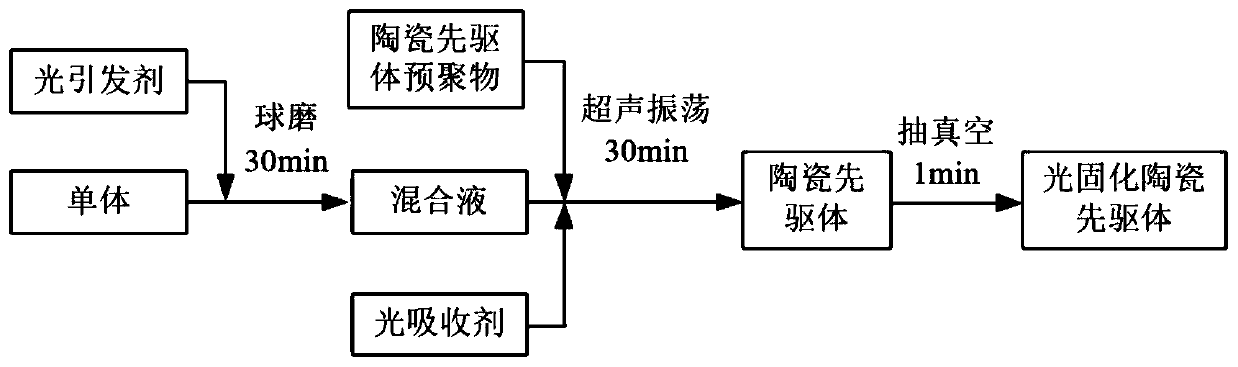

Photocuring 3D printing silicon nitride ceramic precursor and preparation and forming method thereof

InactiveCN110668824AExcellent curabilityCompact structureAdditive manufacturing apparatus3d printMethacrylate

The invention discloses a photocuring 3D printing silicon nitride ceramic precursor and a preparation and forming method thereof. The photocuring 3D printing silicon nitride ceramic precursor is prepared from a monomer, a photoinitiator, a ceramic precursor prepolymer and a light absorber, wherein the monomer is one or more from 1, 6 hexanediol diacrylate, isocyano ethyl methacrylate and ethylene1, 2-dithiocyanate; the ceramic precursor prepolymer is a polysilazane resin containing methyl, vinyl or sulfydryl groups; the photoinitiator is 2, 4, 6-trimethylbenzoyl-diphenyl phosphine oxide, IRGACURE 819 or benzoin dimethyl ether, the curing performance of the ceramic precursor is good, and the ceramic precursor is relatively simple to prepare and form.

Owner:XI AN JIAOTONG UNIV

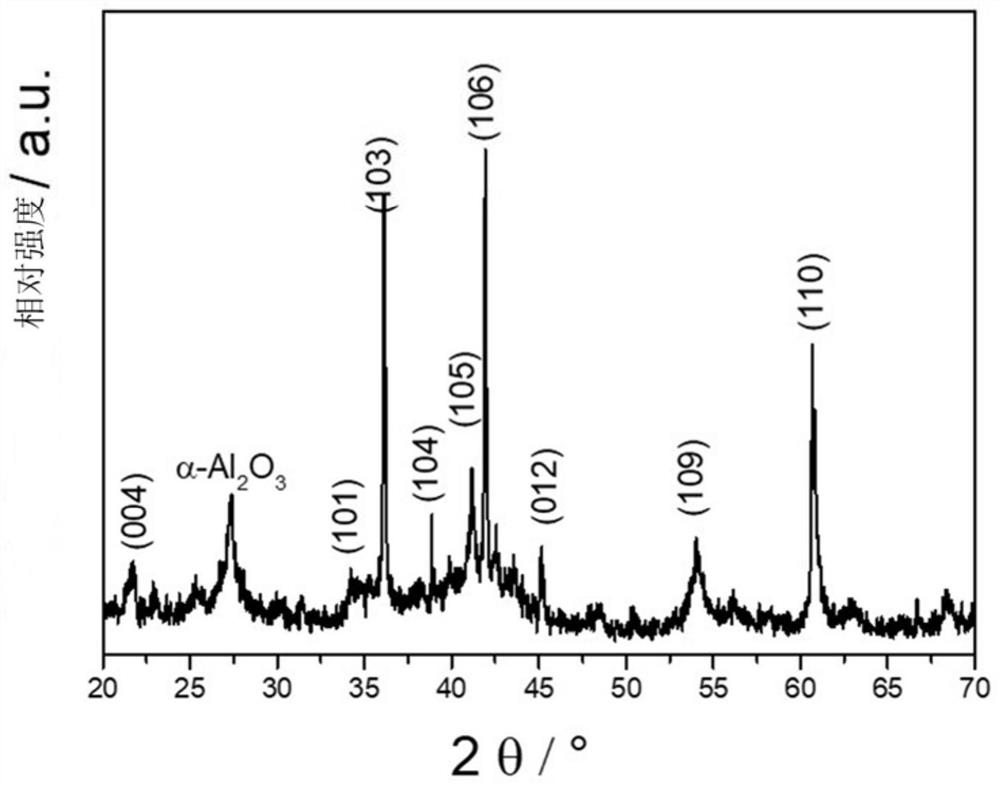

Multi-component lithium ion battery anode material rich in lithium and preparation method thereof

InactiveCN103066264ASimple preparation processReduce manufacturing costCell electrodesLithium acetateMaterials science

The invention discloses a multi-component lithium ion battery anode material rich in lithium and a preparation method thereof. The molecular formula of the multi-component lithium ion battery anode material rich in lithium is Li1.17Ni0.17Co0.17Mn0.50O2. The preparation method comprises the steps of firstly adopting an alcoholysis solid phase method, utilizing ethanol to dissolve cobalt acetate, nickel acetate, manganese acetate and lithium acetate, drying the mixture of dissolved cobalt acetate, nickel acetate, manganese acetate and lithium acetate by controlling the temperature at 120 DEG C so as to obtain transition metal acetate presoma solid powder; and finally, carrying out two times of sintering on the obtained transition metal acetate presoma powder in a high temperature pipe furnace system, and then carrying out sufficient ball milling until the particle diameter of a grain is less than 1 mum, thus obtaining the multi-component lithium ion battery anode material rich in lithium, with good morphological structure, small particle size distribution and better battery property; and the preparation method has the characteristics of being simple in preparation process, low in production cost, suitable for scale production and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for manufacturing electrochemical active material

InactiveCN101916860ASynthesis fastGood product consistencyElectrode thermal treatmentPhosphorus compoundsReaction timingCarbon dioxide

The invention discloses a method for manufacturing an electrochemical active material. The method is characterized by comprising the following steps of: (1) smashing and mixing ferric salt, lithium salt or phosphor salt compounds in a vibrating ball mill according to the molar ratio of ferrum element to lithium element to phosphor element of 1:1:1; and circulating the operation; and (2) after the uniformly mixing process in the step (1), putting a mixture into a ball milling rotary furnace and sintering the mixture in an inert atmosphere. The method has the characteristics of short processing reaction time, low energy consumption and excellent performance of processed product, simultaneously improves material purity, reduces the emission of carbon dioxide and contributes to environmental protection by adopting a carbon-free processing process.

Owner:NANOCHEM SYST SUZHOU

Roasting process of lanthanum-cerium oxide rear-earth polishing powder

InactiveCN103253694AFine granularityGood shape structureRare earth metal compoundsRoom temperatureLanthanum

The invention discloses a roasting process of lanthanum-cerium oxide rear-earth polishing powder, which belongs to the chemical field. The roasting process comprises the following temperature courses in sequence: (a), a first heat-up stage, wherein the temperature is increased to 970 DEG C from the room temperature within 180 minutes-210 minutes; (b), a first constant-temperature stage, wherein the temperature is kept within 970 DEG C+ / - 5 DEG C for 150 minutes-180 minutes; (c), a second heat-up stage, wherein the temperature is increased to 1090 DEG C from 970 DEG C within 30 minutes-60 minutes; (d), a second constant-temperature stage, wherein the temperature is kept within 1090 DEG C+ / -5 DEG C for 180 minutes-240 minutes; and (e), a cool-down stage, wherein the temperature is reduced to 60 DEG C-100 DEG C from 1090 DEG C within 20 minutes-40 minutes. The polishing powder manufactured by the roasting process is high in cutting rate, small in scratching depth to a ground object and low in proportion.

Owner:郭尧

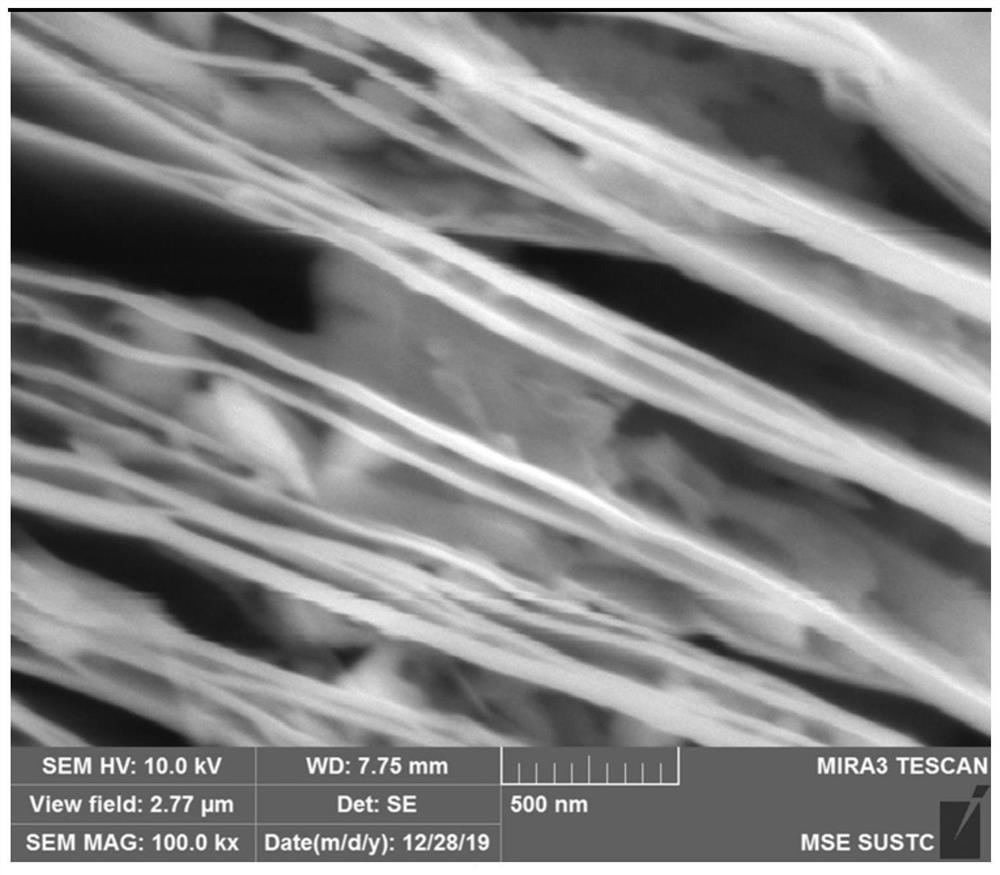

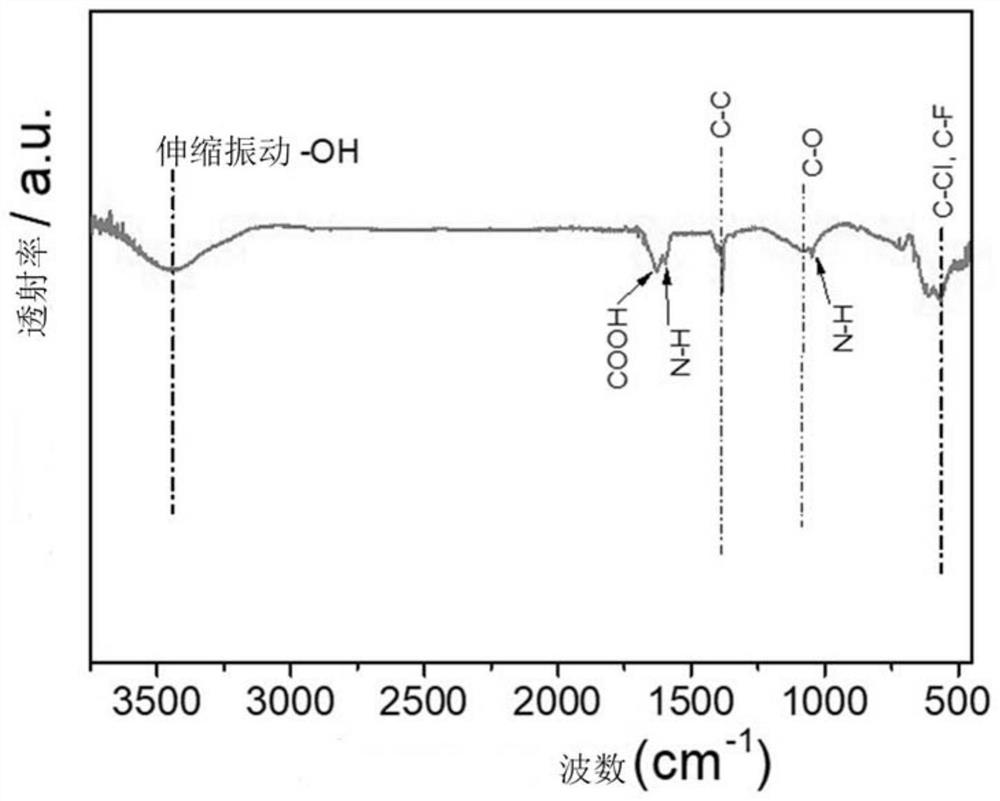

Mxene material with organic chelating functional group grafted on surface and preparation method thereof

InactiveCN113003675AHigh adsorption capacityHigh adsorption activityDispersed particle separationWater/sewage treatmentCapacitive deionizationOrganic solvent

The invention belongs to the field of modification of Mxene materials, and discloses an Mxene material with an organic chelating functional group grafted on the surface, the Mxene material is combined with a grafting agent through a silicon-oxygen bond, and the grafting agent contains amino and / or carboxyl as the organic chelating functional group. The invention also discloses a preparation method of the Mxene material. The preparation method comprises the following steps: S1, dispersing Mxene powder in an organic solvent to obtain a suspension I, and adding the grafting agent into an organic solvent to obtain a solution II; and S2, adding the solution II into the suspension I, carrying out stirring reaction under an ultrasonic condition, then separating out a solid, and carrying out cleaning and drying to obtain a product. The preparation process is controllable and simple, operation is easy and convenient, the material is good in morphology and structure, the number of chelating functional groups grafted on the surface is considerable and uniform, and the material serving as a capacitive deionization electrode material is excellent in heavy metal ion and radioactive ion removal performance, so that efficient treatment of water is achieved, the material can be regenerated and recycled, and large-scale industrial production and application prospects are achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

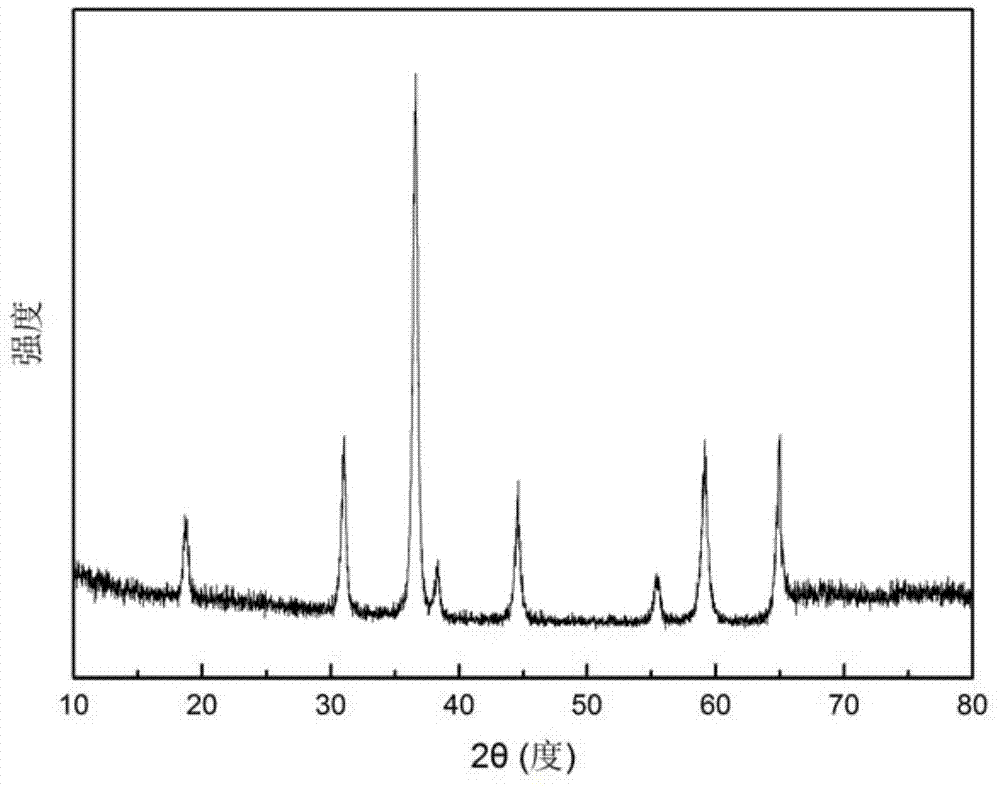

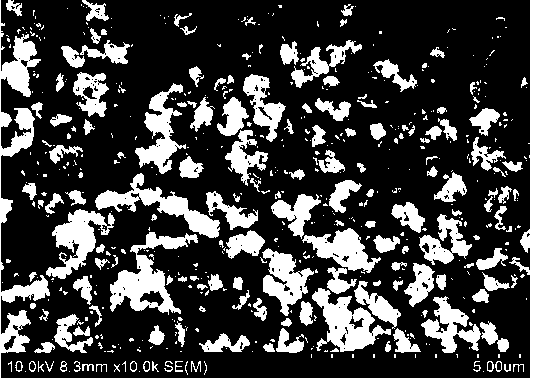

Manganese cobaltate octahedral nanomaterial and preparation method thereof

ActiveCN104779386ASmall sizeGood shape structureCell electrodesSecondary cellsPolyethylene glycolManganese

The invention provides a manganese cobaltate octahedral nanomaterial and a preparation method thereof. The method comprises the following steps: dissolving Mn(NO3)2 and Co(NO3)2.6H2O in deionized water, and adding anhydrous ethanol; adding polyethylene glycol octylphenol ether to the above obtained solution according to a molar ratio of nitrate to polyethylene glycol octylphenol ether of 1:4-1:0.25, transferring the obtained solution to a hydrothermal reaction kettle, and reacting; and opening the kettle, centrifuging, separating the obtained precipitate, washing the precipitate with deionized water and alcohol, and drying at 60-80DEG C to obtain the manganese cobaltate octahedral nanomaterial. The particle dimension of the manganese cobaltate octahedral nanomaterial prepared in the invention is not greater than 400nm. The manganese cobaltate octahedral nanomaterial can be used as a lithium ion battery. Test results show that the first discharge capacity of the manganese cobaltate octahedral nanomaterial under a current density of 50-200mAg<-1> reaches 1400mAhg<-1>, and the specific capacity of the manganese cobaltate octahedral nanomaterial after 25 cycles still reaches above 750mAhg<-1>; and the preparation method has the characteristics of simple operation and energy saving.

Owner:TIANJIN UNIV

Preparation method of rare-earth fluorescent microspheres

InactiveCN105085776AGood shape structureGood luminous effectLuminescent compositionsMethyl methacrylatePre treatment

The invention relates to a preparation method of rare-earth fluorescent microspheres, belonging to the technical field of fluorescent substance preparation. The method comprises the following steps: carrying out pretreatment to obtain a monomer refined methyl methacrylate and an initiator refined azodiisobutyronitrile, preparing a rare-earth high-luminescent-intensity three-element coordination compound with polymerization activity by a coprecipitation process, copolymerizing the three-element coordination compound with methyl methacrylate to obtain a high-molecular-weight high-polymer rare-earth metal copolymer solid material which is the rare-earth fluorescent microspheres. The example proves that the rare-earth fluorescent microspheres can be used in the aspects of biological detection, fluorescent markers, special-type inks, medical immune detection and cell markers, can not injure the human body, and has stable and efficient luminous emissivity and longer fluorescent lifetime (by 30% or above).

Owner:JIANGSU ZHENYU ENVIRONMENTAL PROTECTION TECH

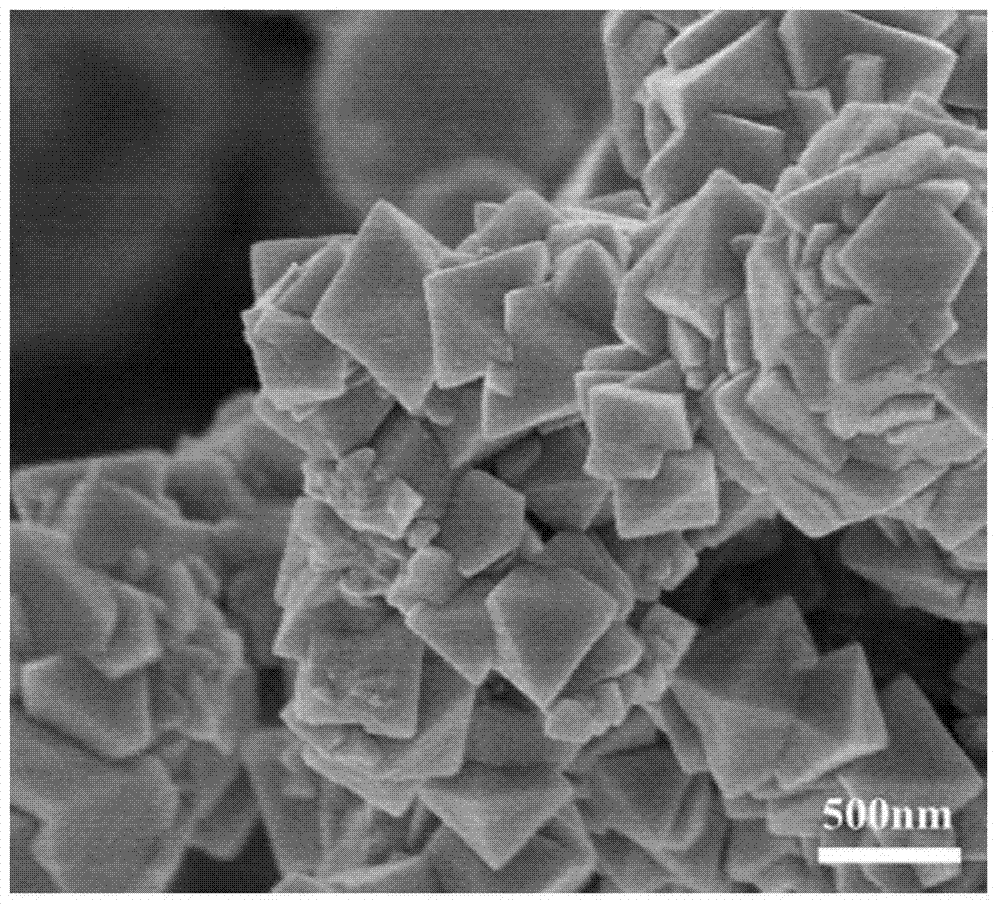

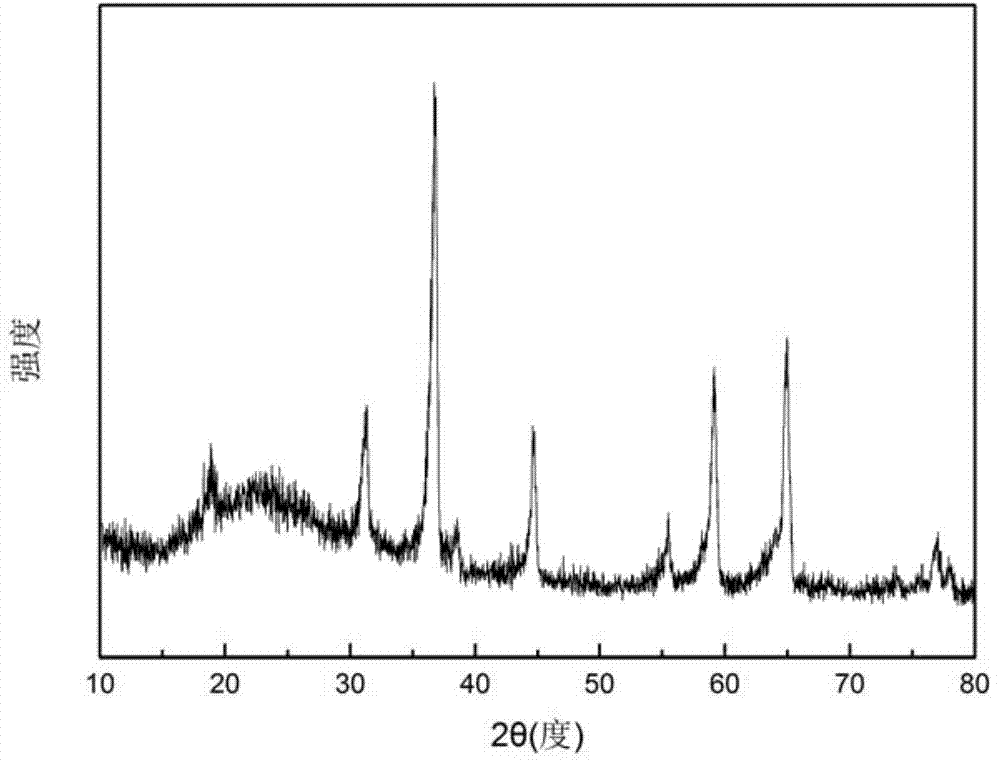

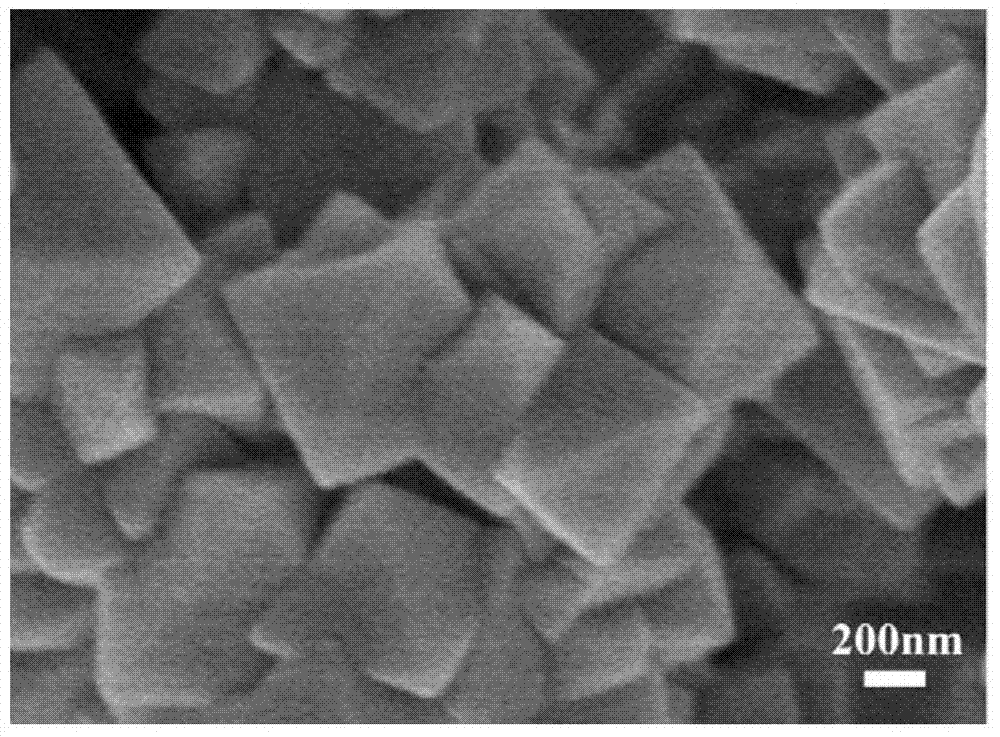

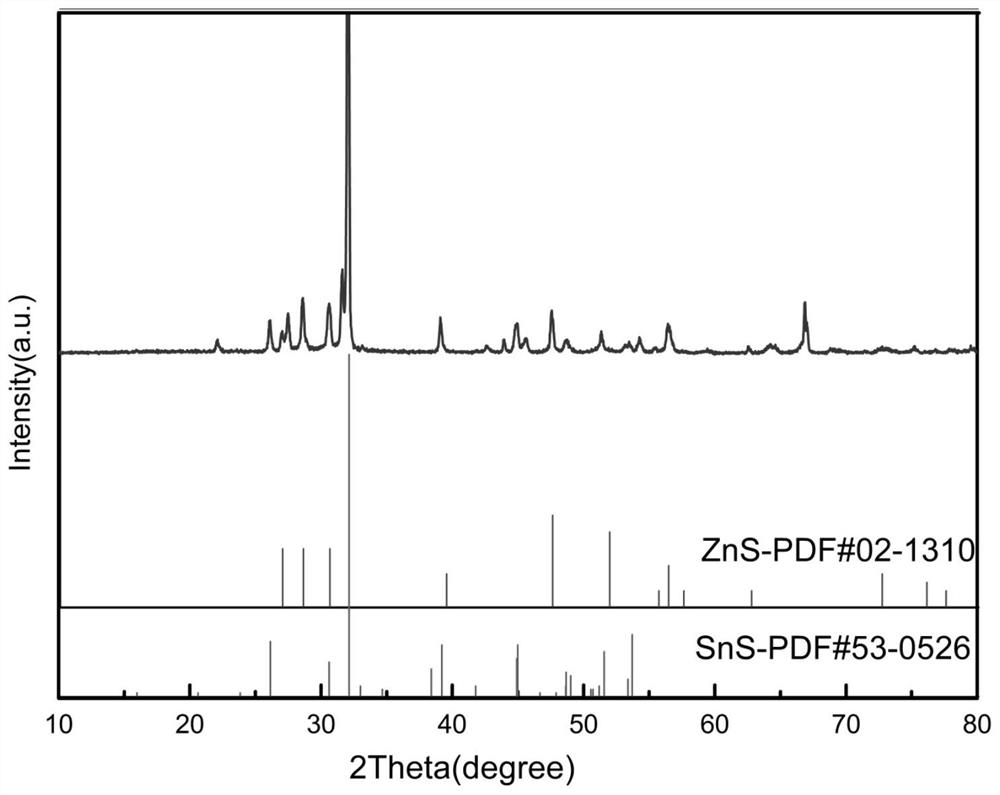

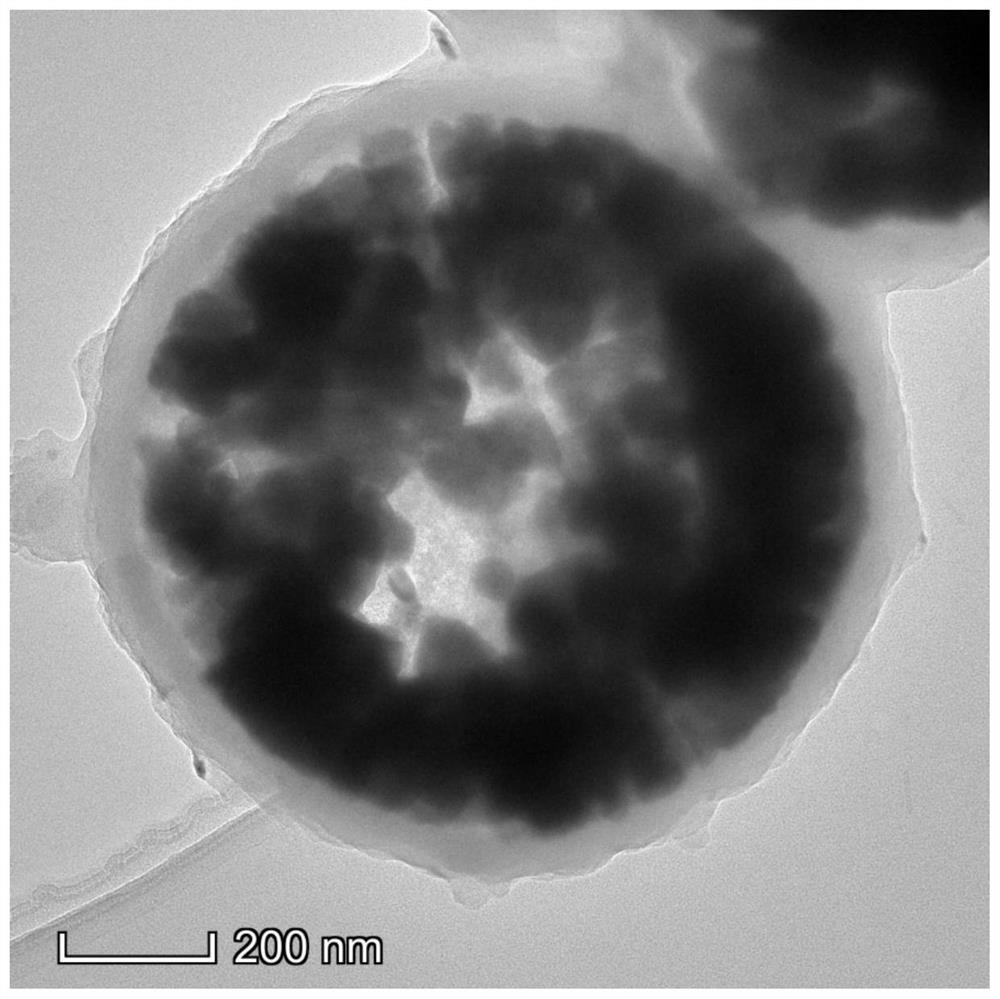

ZnS/SnS-coated NC hollow microsphere negative electrode material for lithium ion/sodium ion battery negative electrode and preparation method of ZnS/SnS-coated NC hollow microsphere negative electrode material

ActiveCN111710849AImprove electronic conductivityImprove electrochemical performanceNegative electrodesSecondary cellsCarbon layerIn situ polymerization

The invention provides a ZnS / SnS-coated NC hollow microsphere negative electrode material for a lithium ion / sodium ion battery negative electrode and a preparation method of the ZnS / SnS-coated NC hollow microsphere negative electrode material, and belongs to the technical field of lithium / sodium batteries. The method comprises the following steps that: spherical ZnSn(OH)6 is prepared; a simple hydrothermal method and an in-situ polymerization coating method are combined to prepare the ZnS / SnS-coated NC hollow microsphere composite material with the ZnSn(OH)6 is used as a precursor, and a pyrrole monomer used as a carbon source. The microstructure of the composite material is of a hollow core-shell structure; the surface of the composite material is covered with a smooth carbon layer; the hollow structure can adapt to volume expansion of ZnS / SnS in a lithium ion / sodium ion de-intercalation process; and the carbon layer on the surface of the composite material can improve the conductivity, prevent agglomeration of ZnS / SnS and guarantee the structural stability of the composite material. The lithium ion / sodium ion battery negative electrode prepared from the ZnS / SnS-coated NC hollow microsphere material shows relatively high specific capacity, excellent rate capability and cycle performance.

Owner:GUANGXI NORMAL UNIV

Preparation method of ZnO/Ag nanofiber film by electrospinning method

ActiveCN108457001ARich long-short structureGood shape structureMaterial nanotechnologyInorganic material artificial filamentsFiberNanowire

The invention provides a preparation method for obtaining a ZnO / Ag nanofiber film by an electrospinning method. Specifically, a certain proportion of the Ag nanowire sol solution is added to a mixed aqueous solution of zinc acetate and PVP, which is fully mixed to obtain a uniform mixed spinning solution of Zn (CH3COO) 2 / Ag line / PVP; the spinning solution is spun into nanoscale ZnO / Ag / PVP nanofibers by electrospinning. The nanofibers are stacked into a nanometer-scale film, and the film thickness is controlled by controlling the spinning time; the ZnO / Ag / PVP nanofiber film was calcined at a high temperature to remove the polymer PVP, and a ZnO / Ag nanofiber film with high conductivity is obtained. The preparation method is simple in process, easy to operate. The prepared nanofiber can obtain a very good topography structure. The ZnO / Ag nanofiber film prepared by the method can be used as an electron transport layer in a polymer solar cell, and the photoelectric conversion performance ofthe battery is improved by more than 10%.

Owner:QINGDAO UNIV

Microsphere laminated lithium-enriched manganese-based solid solution anode material and preparation method thereof

The invention discloses a microsphere laminated lithium-enriched manganese-based solid solution anode material, wherein the molecular formula is xLi2Mn1-yNyO3*(1-x)LiMn1-zMzO2; in the formula, M is one or more of Ni and Co; N is one or more of Fe, Cr, Al and Mg; x is more than 0 and less than or equal to 0.3; y is more than 0 and less than or equal to 0.1; and z is more than 0 and less than or equal to 0.7. The invention discloses a preparation method of the material at the same time. The preparation method comprises the following steps of: (1), after co-precipitating a manganese source compound and an M source compound, and sintering the manganese source compound and the M source compound with a lithium source compound in a mixed manner to obtain a precursor 1); (2), sintering the manganese source compound, the lithium source compound and an N element oxide in a mixed manner to obtain a precursor 2); and (3), mixing, acidly washing, spraying and drying the precursor 1) and the precursor 2), and sintering to obtain the lithium-enriched manganese-based solid solution anode material. The microsphere laminated lithium-enriched manganese-based solid solution anode material disclosed by the invention has the advantages of high energy density, good cycle performance, low cost, safety, excellent performance and the like and is applied to the power field with high energy and long service life.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Adsorption type bone apatite and preparation method and application thereof

ActiveCN110841588AWide variety of sourcesHigh specific surface areaOther chemical processesWater contaminantsO-Phosphoric AcidEngineering

The invention belongs to the field of environment-friendly materials, and particularly relates to adsorption type bone apatite and a preparation method and application thereof. The preparation methodcomprises the following steps: removing organic matters in animal bones; calcining the animal bones without the organic matters to obtain bone apatite; and carrying out surface chemical modification on the bone apatite by adopting a phosphoric acid solution to obtain the adsorption type bone apatite. The adsorption type bone apatite can be used for adsorbing heavy metal ions in industrial sewage,and the specific surface area of the adsorption type bone apatite is increased from 47.832 (m<2> / g) to 131.566 (m<2> / g) compared with the specific surface area of the adsorption type bone apatite before modification; when the initial concentration of Pb<2> is 200 mg / L, a removal rate can reach 98.3%; for Zn<2> and Cu<2> ions with an initial concentration of 200 mg / L, the removal rate of the ions can reach 70% or above; so the adsorption type bone apatite has good heavy metal ion removal capacity. The technical problem that bone apatite in the prior art is not high enough in adsorption capacityis solved.

Owner:XI AN JIAOTONG UNIV

High thermal insulation clothing material and preparation method thereof

ActiveCN110216936AWith skin-friendly fabricAvoid breakingSynthetic resin layered productsClothingsThermal insulationAramid

The invention discloses a high thermal insulation clothing material and a preparation method thereof. The high thermal insulation clothing material comprises an inner layer, a surface layer and an interlayer, wherein the interlayer is a polyimide fiber fabric, a composite aerogel material, and a camel fiber fabric from outside to inside, the composite aerogel material comprises quartz fiber and amodified aerogel, and the modified aerogel is prepared by gelation of a reinforcement material and an alcohol sol, wherein the reinforcement material is formed by nano-silica, graphene and aramid fiber pulp meal. The beneficial effects are as follows: graphene, aramid fiber pulp meal, and nano-silica free particles are used as support skeletons and the reinforcement material to match with a nano-network structure of an aerogel, and thus heat preservation thermal insulation performance, compressive strength, flexibility, elasticity and stability of the aerogel are improved; and the aerogel is compounded with the polyimide fiber fabric and the camel fiber fabric with the thermal insulation function, the breakage and particle shedding phenomenon of the composite aerogel is effectively avoided, and the heat preservation thermal insulation performance and comfort property of the heat preservation layer are further improved.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

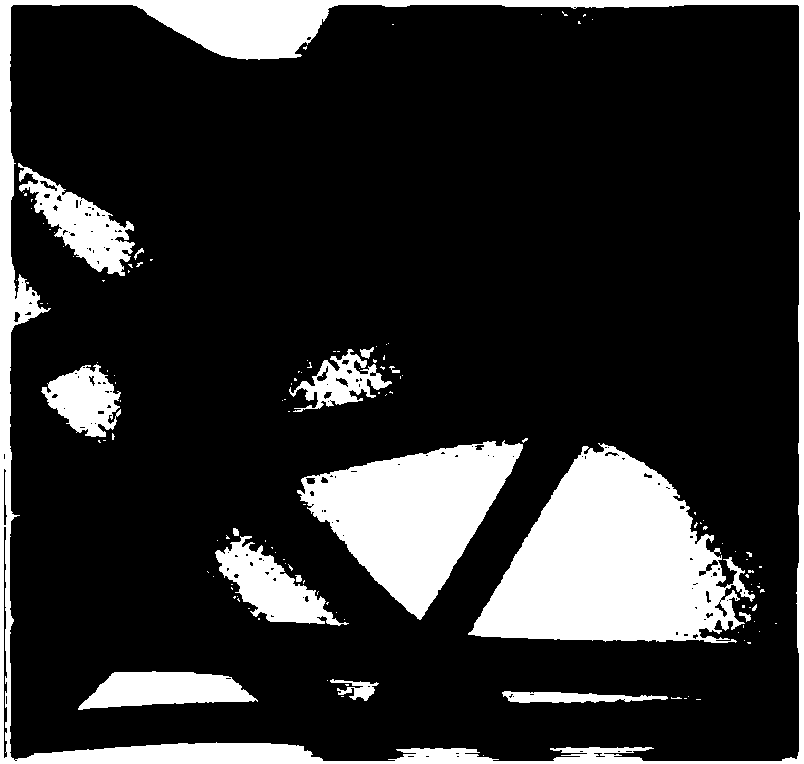

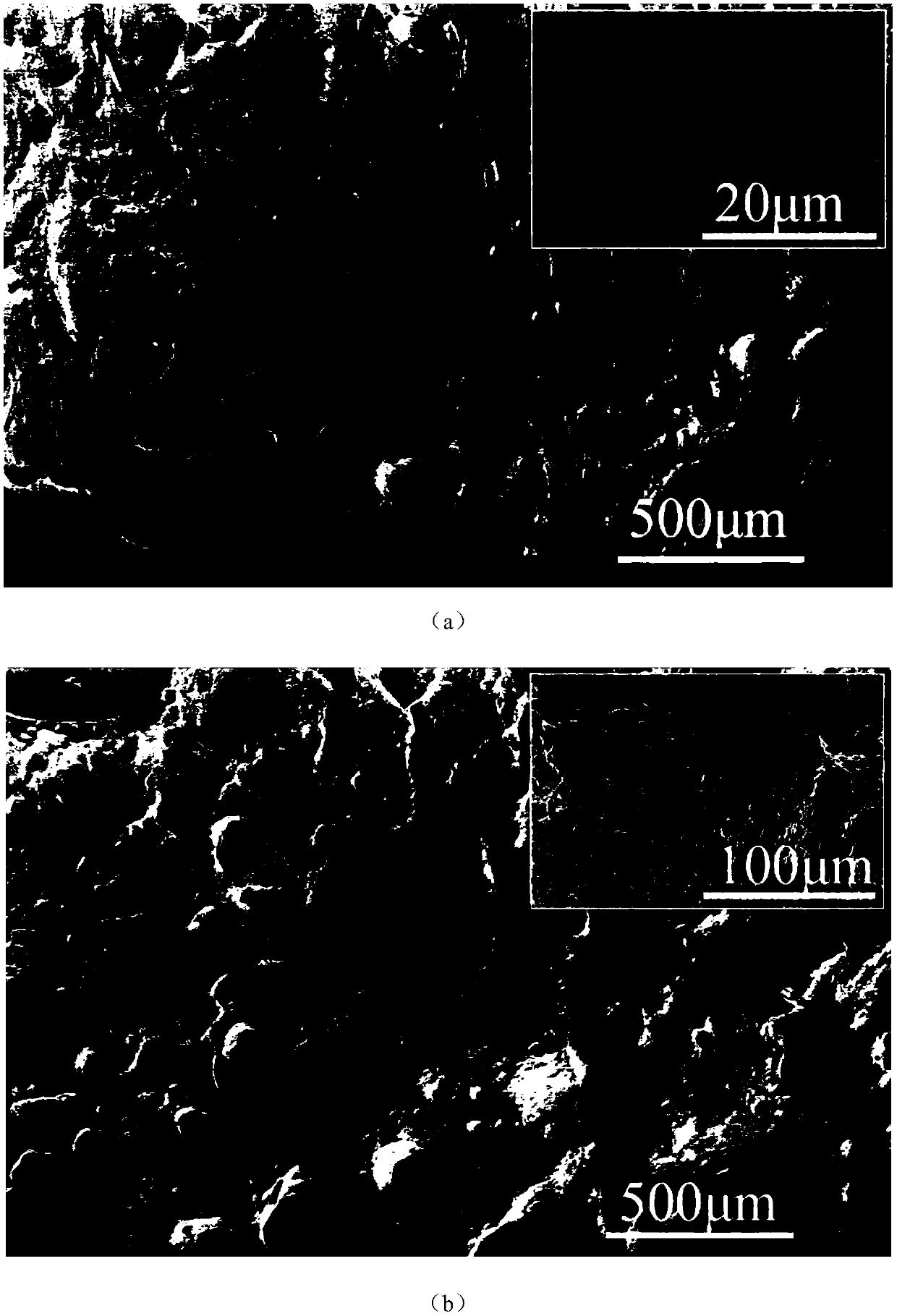

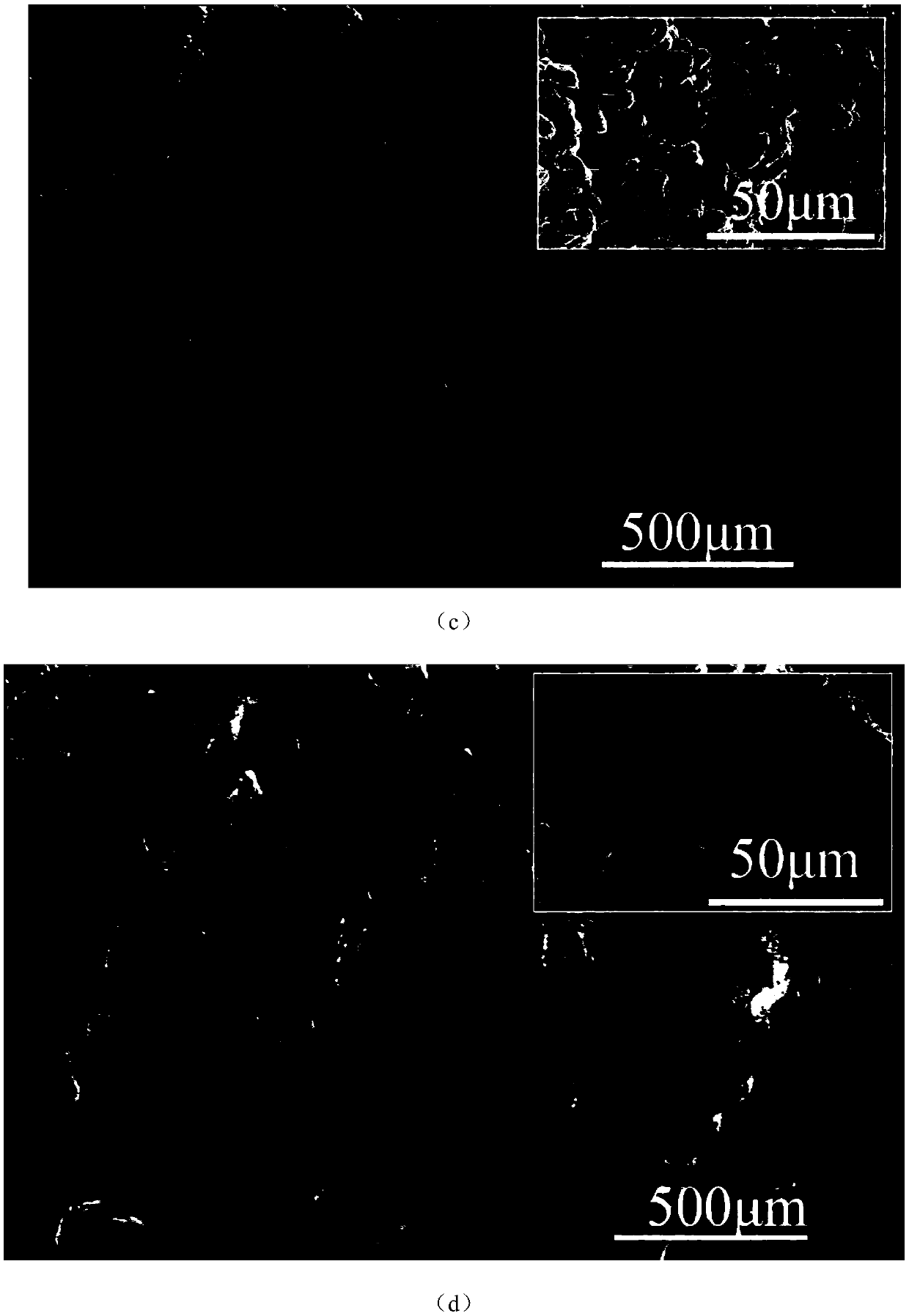

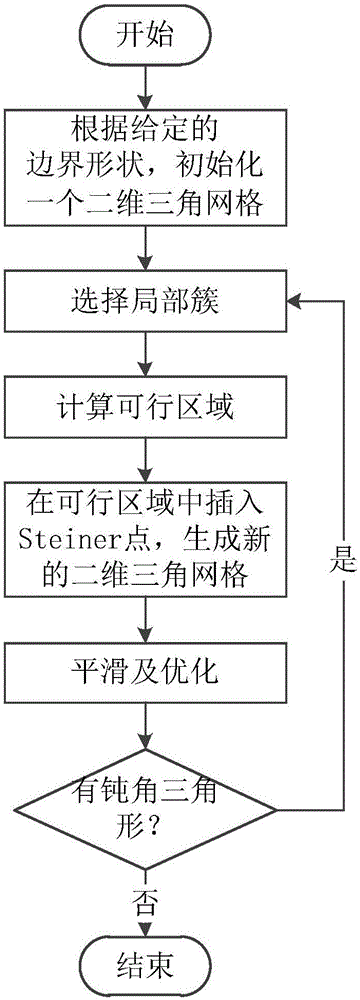

Two-dimensional triangular mesh generation method and system

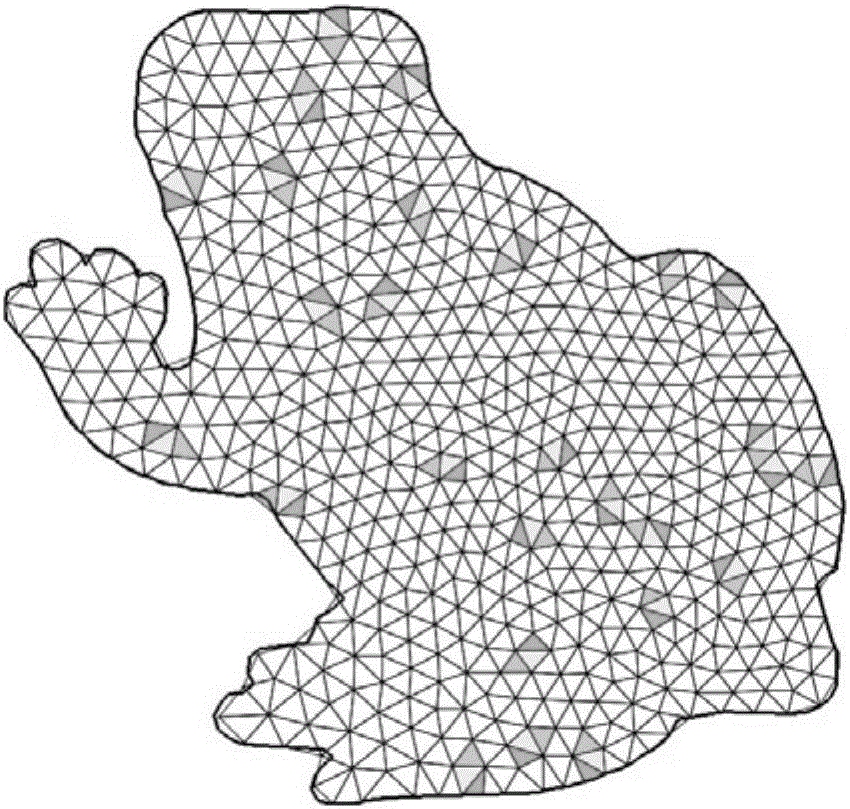

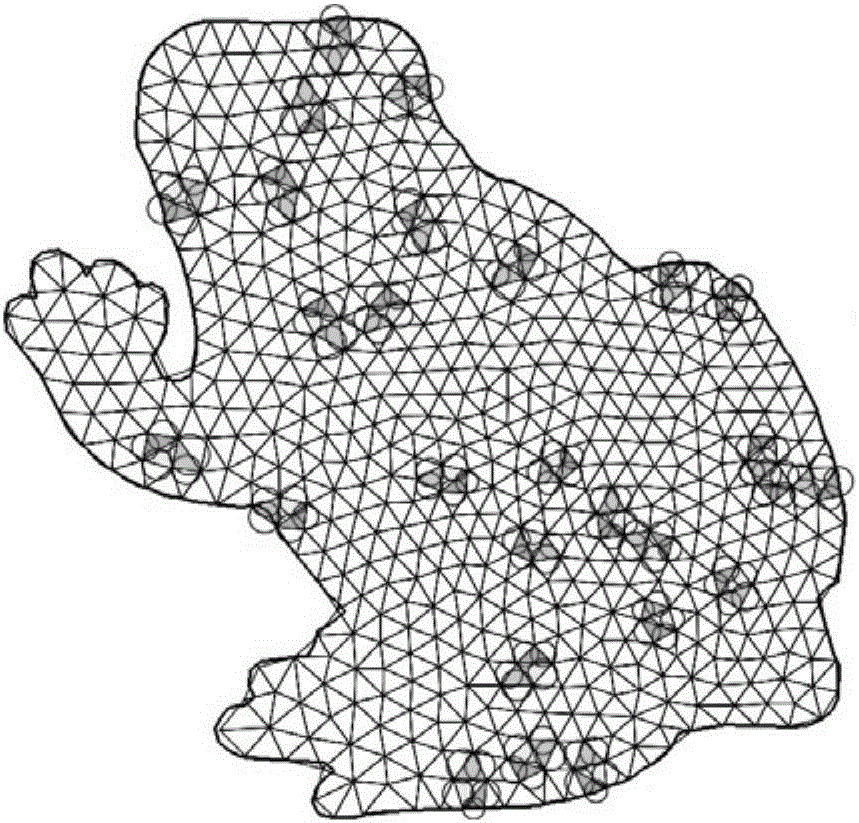

ActiveCN106652036AOptimization angleGood 2D Triangular Mesh Shape Structure3D modellingTrigonal crystal systemComputer graphics (images)

The invention relates to a two-dimensional triangular mesh generation method and system. The method comprises the following steps: generating an initial two-dimensional triangular mesh according to a given boundary shape; searching all clusters in the two-dimensional triangular mesh, wherein each cluster comprises an obtuse triangle and an integral body of two or more triangles adjacent to the obtuse triangle, and the clusters do not overlap the cluster; and inserting a Steiner point into each cluster to generate a new two-dimensional triangular mesh. According to the two-dimensional triangular mesh generation method and system, generation of a two-dimensional triangular mesh of which the angles are all acute can be guaranteed, and a relatively small angle can be optimized, so that a good two-dimensional triangular mesh-shaped structure can be kept.

Owner:北京圜晖科技有限公司

Ag/AgCl loaded sodium nickel phosphate composite photocatalytic material as well as preparation method and application thereof

InactiveCN105289671AExcellent UVImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationNickel phosphateChemical solution

The invention discloses an Ag / AgCl loaded sodium nickel phosphate composite photocatalytic material as well as a preparation method and application thereof. The chemical formula of a base material of the composite photocatalyst is Na4Ni3P4O15; and particles Ag and AgCl are loaded on the surface of the base material. The preparation method comprises the following steps: firstly, preparing the base material by adopting a high-temperature solid-phase method or a chemical solution method; then, mixing and dispersing obtained Na4Ni3P4O15 powder and AgNO3 powder; and carrying out precipitation-photoreduction treatment to finally obtain the Ag / AgCl / Na4Ni3P4O15 composite photocatalyst. The photocatalytic material has a relatively good photocatalytic effect and the preparation method is simple to operate and feasible and low in production cost; and industrial production is facilitated and organic pollutants can be degraded very well.

Owner:XUZHOU NORMAL UNIVERSITY

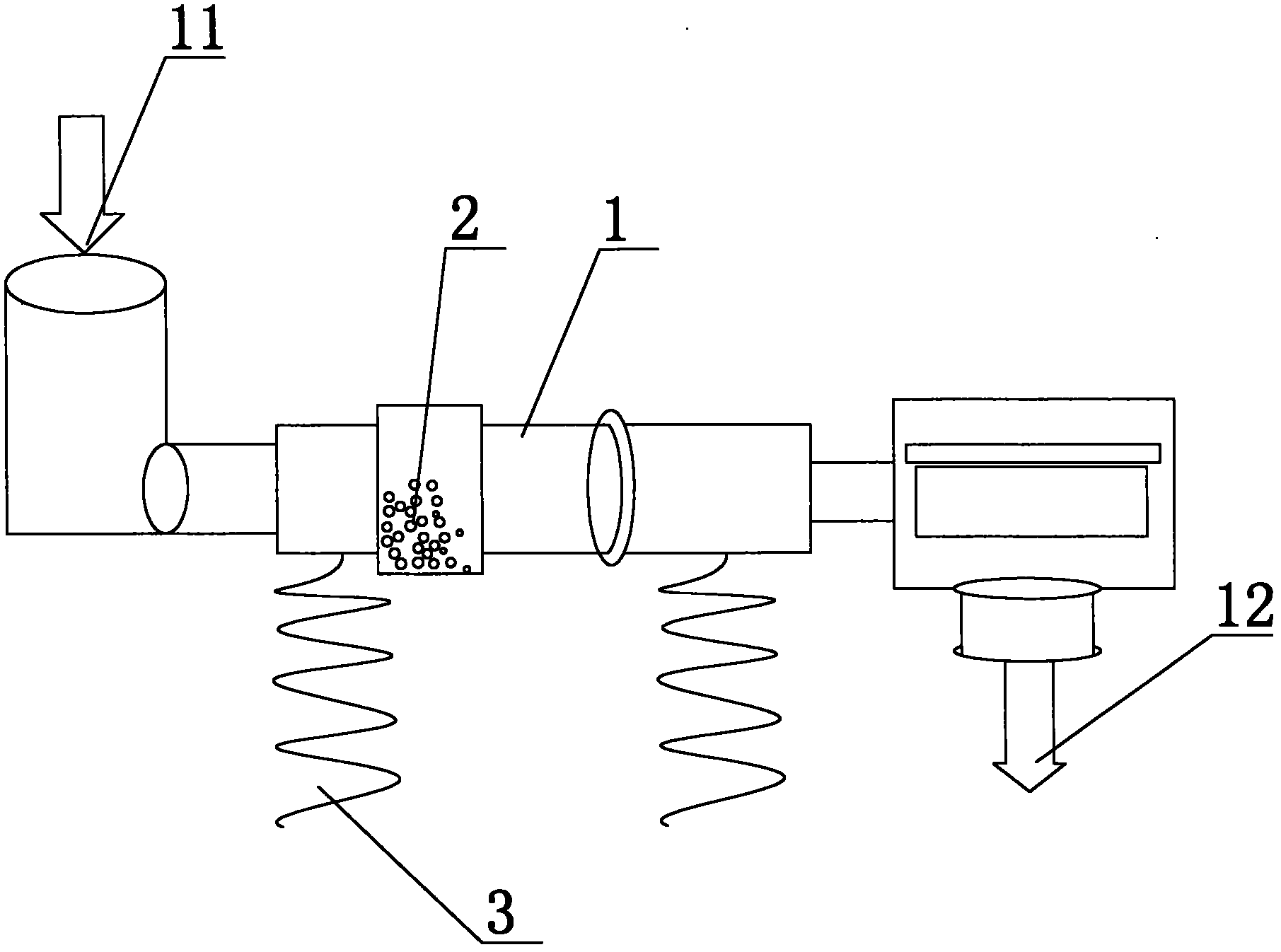

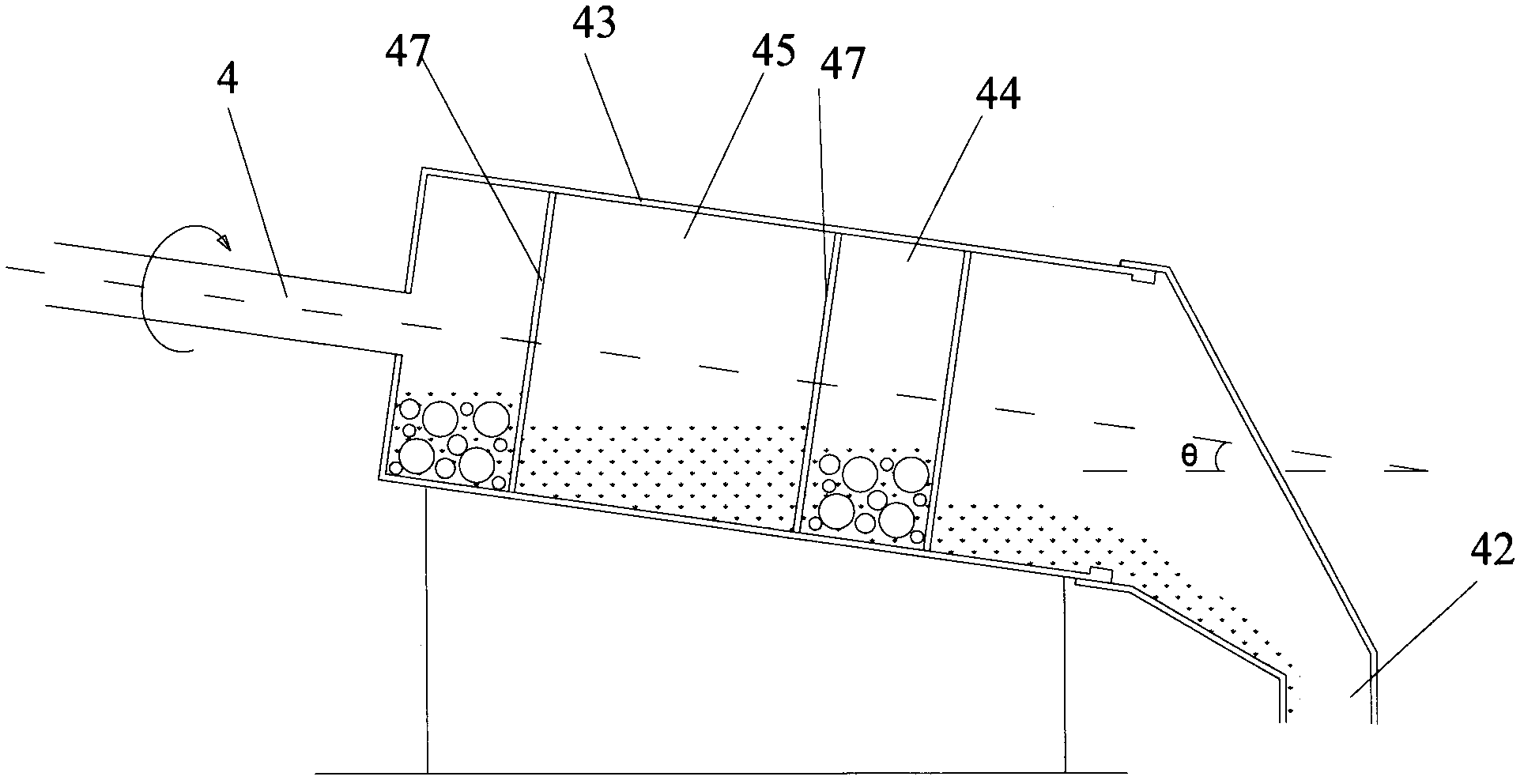

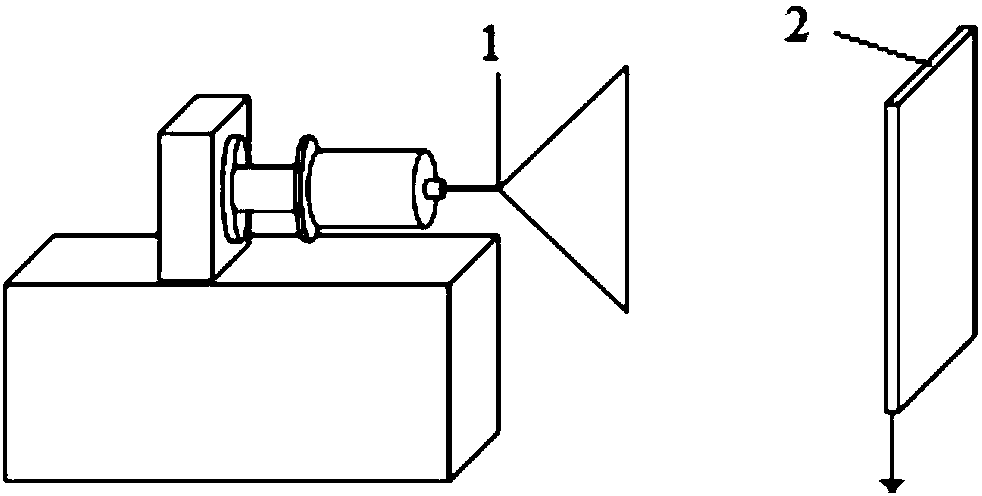

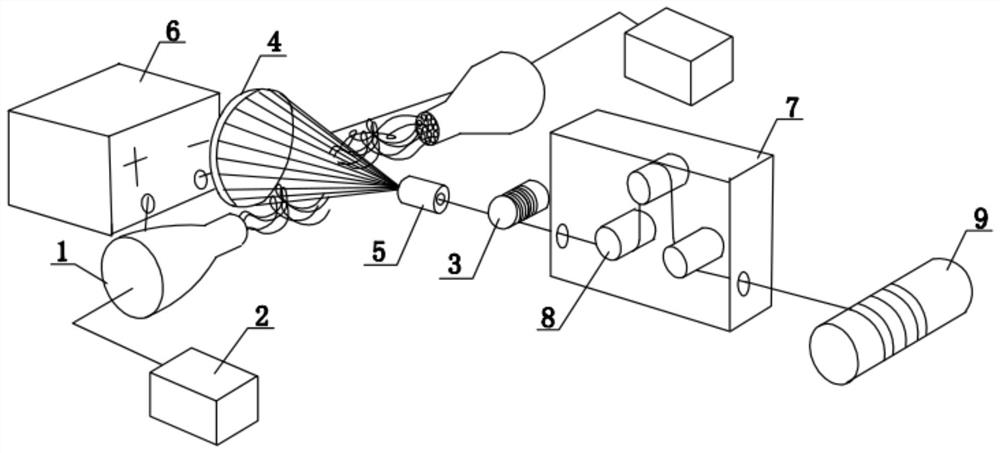

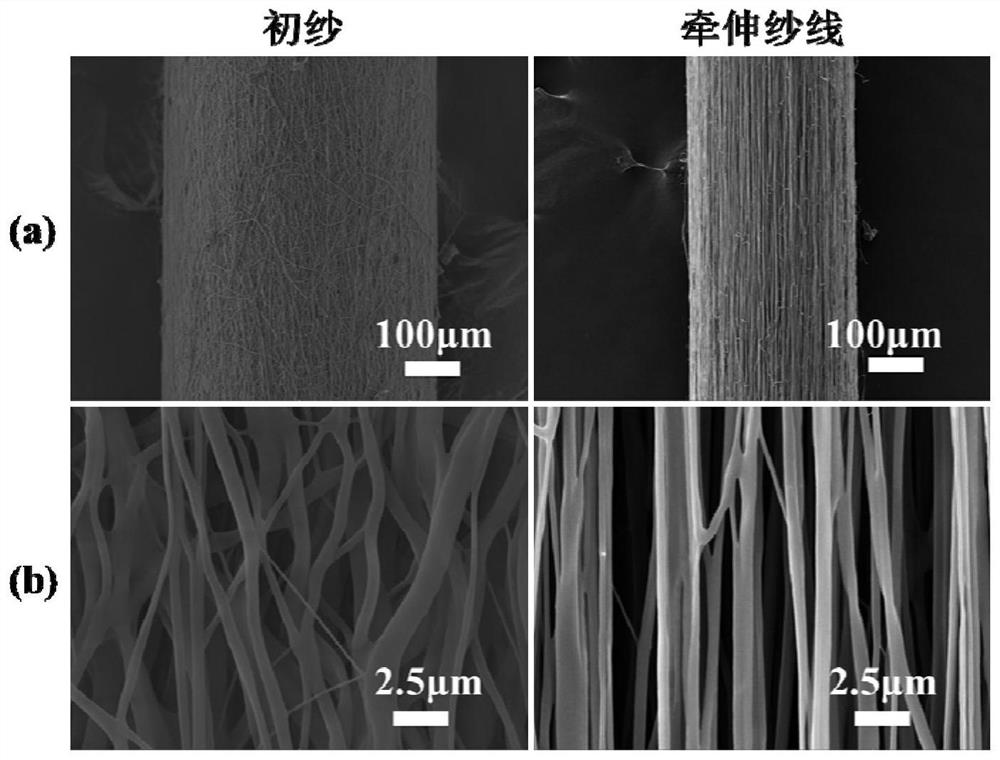

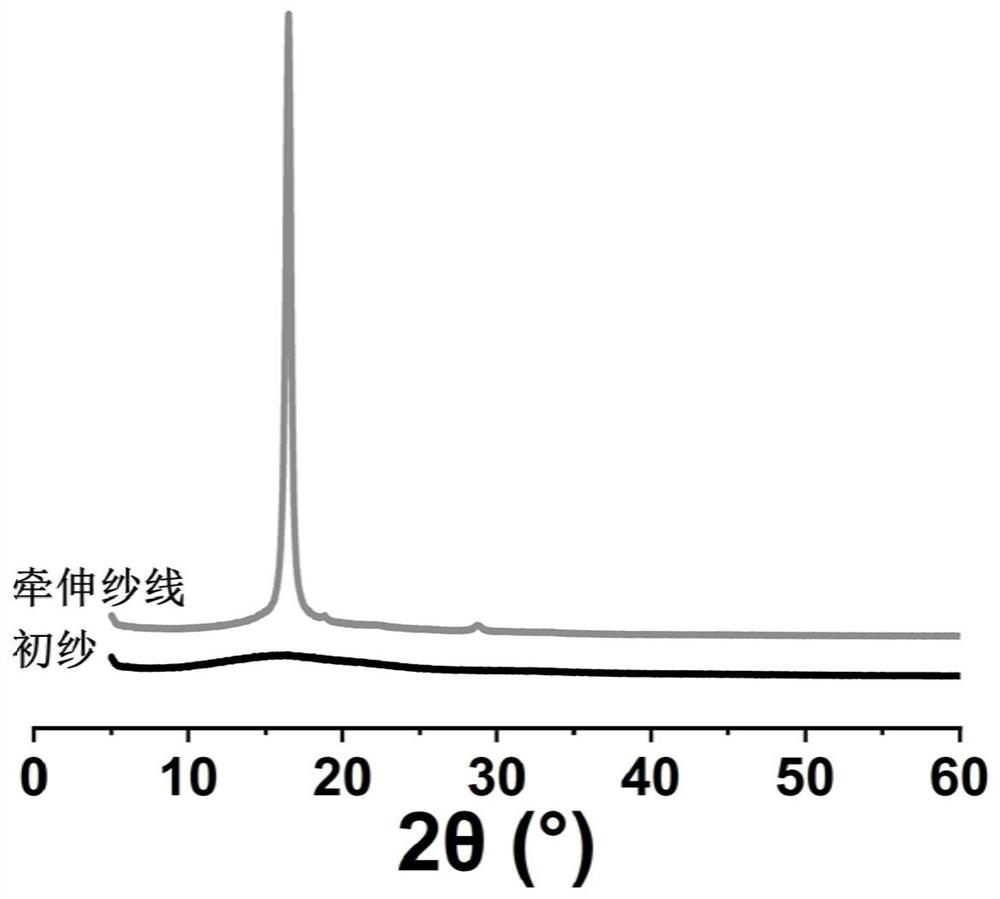

Spinning and drafting integrated preparation device and method forhigh-performance micro-nano fiber yarn

PendingCN113388928AGood orientationUniform structureDrafting machinesContinuous wound-up machinesYarnPolymer science

The invention relates to the technical field of electrostatic spinning, in particular to a spinning and drafting integrated preparation device and method for high-performance micro-nano fiber yarn. The device comprises a spinning unit, a yarn forming unit used for twisting spun yarn of the spinning unit into primary yarn, and a hot drafting unit used for heating and drafting the primary yarn of the yarn forming unit. The prepared micro-nano fiber yarn is more uniform in structure, higher in fiber orientation degree, higher in crystallinity and stronger in mechanical property, and the yield is remarkably improved.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com