Magnetic core-shell-structured nano-material, preparation method therefor and application of magnetic core-shell-structured nano-material

A technology of core-shell structure and nanomaterials, which is applied in the field of nanomaterials, can solve the problems of no application reports of core-shell structure nanomaterials, sample loss, solvent consumption, etc., achieve stable product shape, reduce reagent consumption, and easily consume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

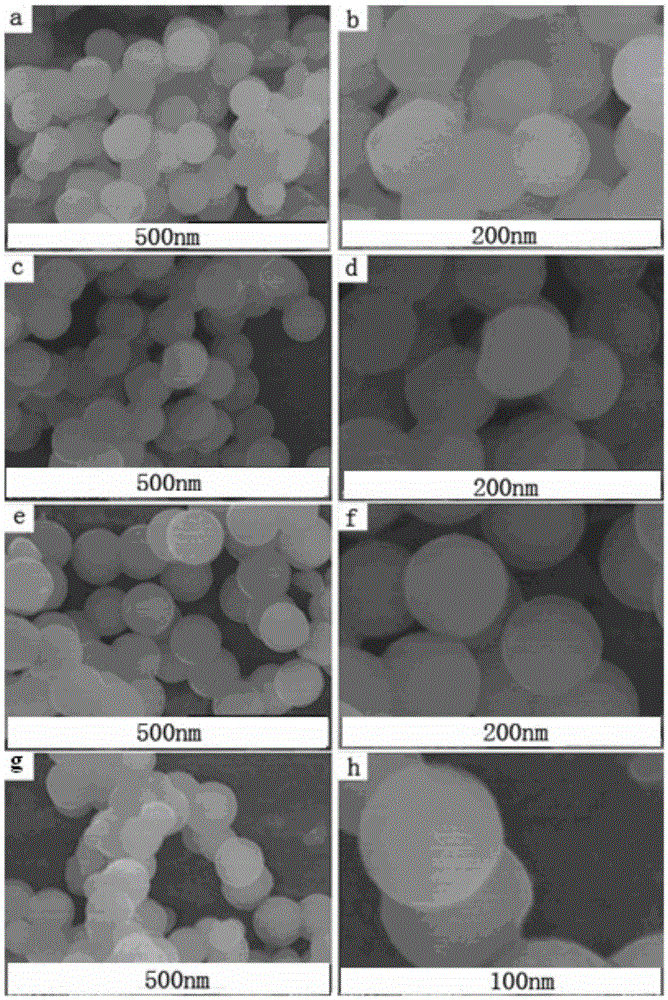

[0040] a) Add 30mL of absolute ethanol, 3mL of water (the ratio of alcohol to water is 10:1) and 1mL of ammonia water with a concentration of 32wt% into a clean beaker, stir to make it evenly mixed, and then add 1.2mLTEOS ( orthosilicate), stirred at room temperature for 6 hours, then added dropwise a mixed solution of dopamine and nickel chloride hexahydrate (2:4 in molar ratio) (wherein dopamine 250mg, nickel chloride hexahydrate 775mg), at room temperature Stirring was continued for 7 hours, and then centrifuged (6000rpm, 3min), the collected solid was washed with water and ethanol for 3 times, and then dried to obtain Ni 2+ -PDASiO 2 Core-shell nanomaterials;

[0041] b) Ni to be prepared 2+ -PDASiO 2 Under the protection of nitrogen, the core-shell structure nanomaterials were heated to 500°C at a heating rate of 10°C / min and kept at this temperature for 5 hours to obtain magnetic core-shell structure nanomaterials loaded with nickel particles.

[0042] The correspond...

Embodiment 2

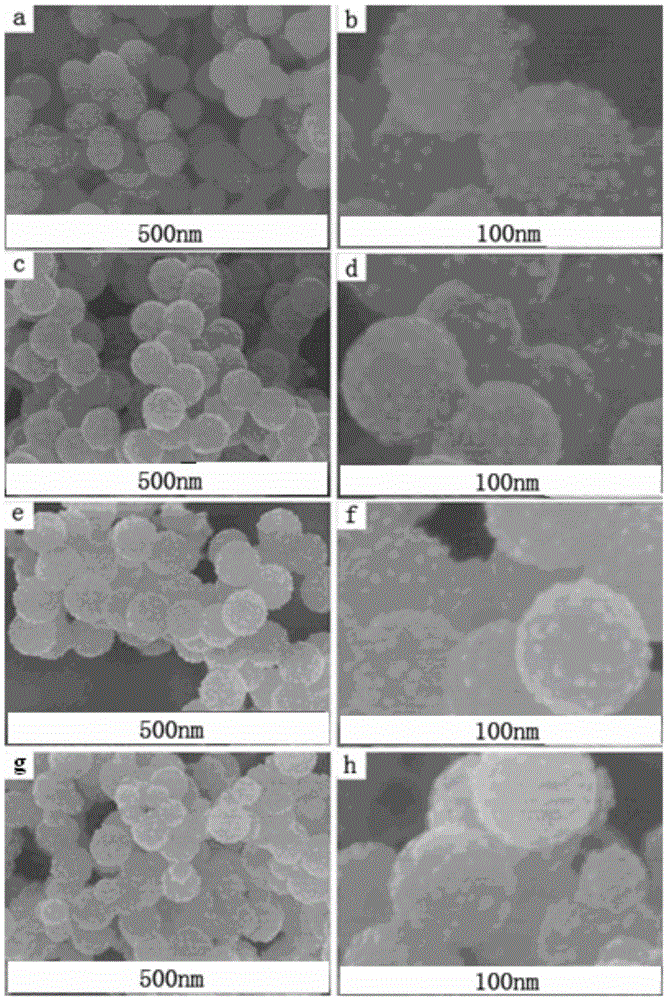

[0045] a) Add 30mL of absolute ethanol, 5mL of water (the ratio of alcohol to water is 6:1) and 1mL of ammonia water with a concentration of 32wt% into a clean beaker, stir to make it evenly mixed, and then add 1.2mLTEOS dropwise under stirring ( Ethyl orthosilicate), stirred at room temperature for 4 hours, then added dropwise a mixed solution of dopamine and nickel chloride hexahydrate (2:4 in molar ratio) (wherein 250 mg of dopamine, 775 mg of nickel chloride hexahydrate), at room temperature Stirring was continued for 24 hours, and then centrifuged (6000rpm, 3min), the collected solid was washed with water and ethanol for 3 times, and then dried to obtain Ni 2+ -PDASiO 2 Core-shell nanomaterials;

[0046] b) Ni to be prepared 2+ -PDASiO 2 Under the protection of nitrogen, the core-shell structure nanomaterials were heated to 500°C at a heating rate of 10°C / min and kept at this temperature for 5 hours to obtain magnetic core-shell structure nanomaterials loaded with nick...

Embodiment 3

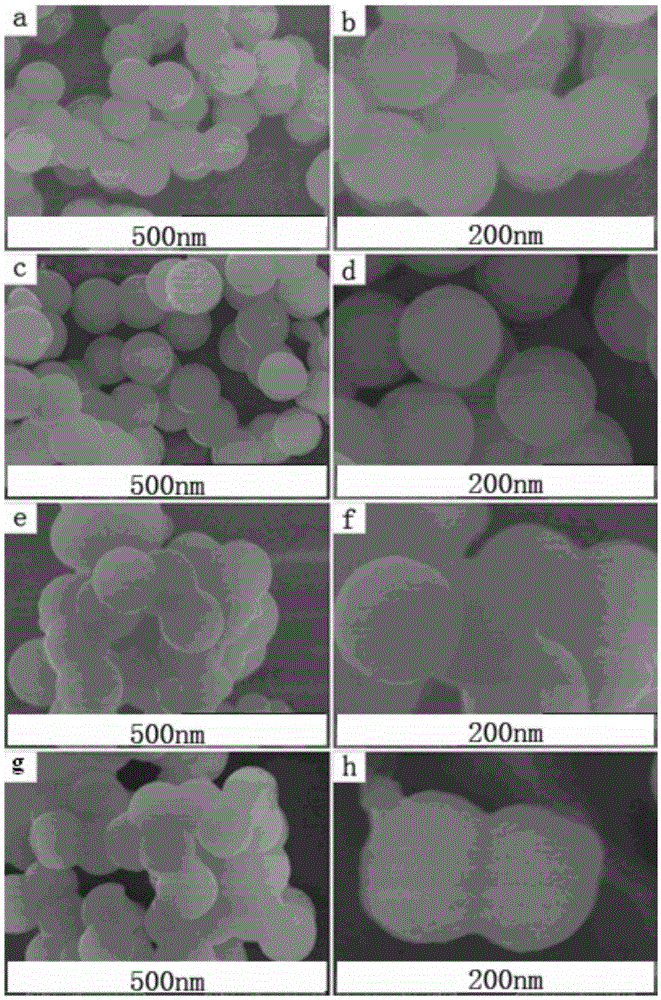

[0050] a) Add 25mL of absolute ethanol, 15mL of water (the ratio of alcohol to water is 25:15) and 3.75mL of ammonia water with a concentration of 32wt% into a clean beaker, stir to mix evenly, and then add 3.4mLTEOS dropwise under stirring (orthosilicate), stirred at room temperature for 8 hours, then added dropwise a mixed solution of dopamine and nickel chloride hexahydrate (the molar ratio was 2:6) (250 mg of dopamine, 1164 mg of nickel chloride hexahydrate), in Stirring was continued for 7 hours at room temperature, and then centrifuged (6000rpm, 3min), the collected solid was washed with water and ethanol for 3 times, and then dried to obtain Ni 2+ -PDASiO 2 Core-shell nanomaterials;

[0051] b) Ni to be prepared 2+ -PDASiO 2 Under the protection of nitrogen, the core-shell structure nanomaterials were heated to 500°C at a heating rate of 10°C / min and kept at this temperature for 5 hours to obtain magnetic core-shell structure nanomaterials loaded with nickel particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com