Microsphere laminated lithium-enriched manganese-based solid solution anode material and preparation method thereof

A lithium-rich manganese-based, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of difficult control of material consistency, harsh control conditions, low energy density, etc., and achieve low cost, good morphology and structure. , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

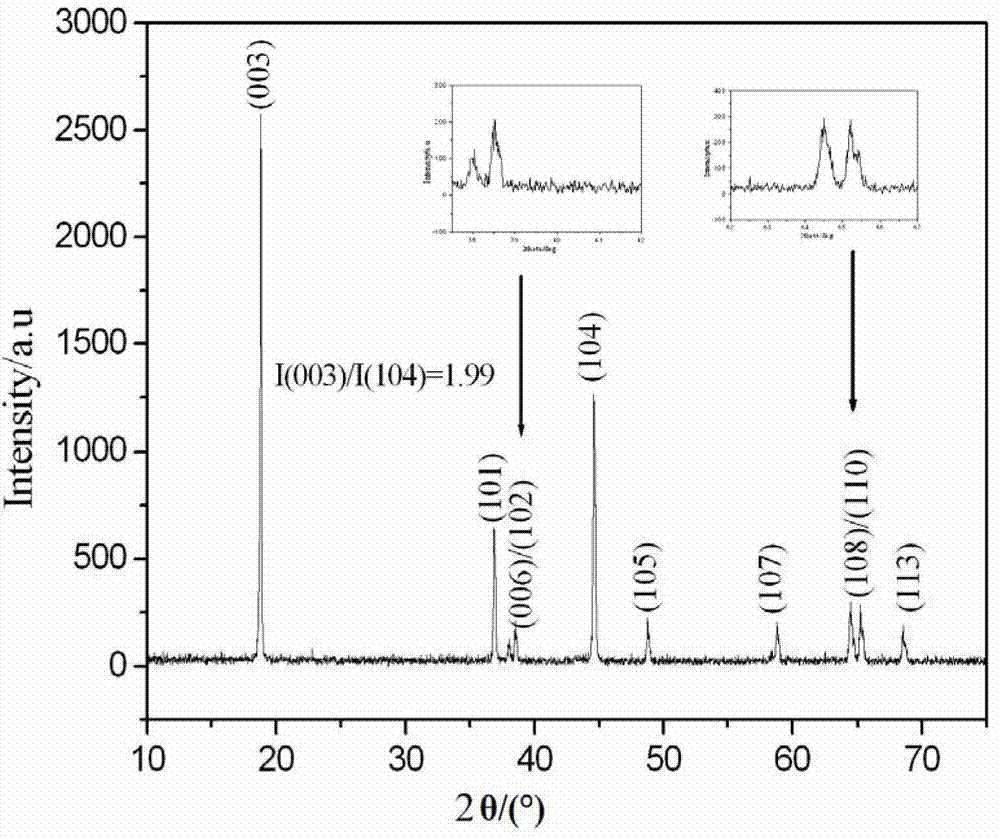

[0039] The molecular formula of the lithium-rich manganese-based solid solution cathode material of this embodiment is 0.3Li 2 mn 0.9 Cr 0.1 o 3 0.7LiMn 0.34 Ni 0.33 co 0.33 o 2 .

[0040] The preparation method of the lithium-rich manganese-based solid solution positive electrode material in this embodiment has the following steps:

[0041] 1) Preparation of precursor ①:

[0042] a) Preparation of solution:

[0043] Solution A: Mn(NO 3 ) 2 , Ni(NO 3 ) 2 , Co(NO 3 ) 2 Weigh according to Mn:Ni:Co molar ratio 0.34:0.33:0.33, add deionized water to make a total concentration of 1.0mol / L metal salt solution;

[0044] Solution B: Prepare a LiOH solution with a concentration of 1.0mol / L as a precipitant;

[0045] Solution C: Prepare ammonia water with a concentration of 1.0mol / L as a complexing agent;

[0046] b) Co-precipitation:

[0047] Add 100mL of deionized water into the reaction kettle, the temperature of the water bath is 40°C, and nitrogen gas is introduce...

Embodiment 2

[0061] The molecular formula of the lithium-rich manganese-based solid solution cathode material of this embodiment is 0.2Li 2 mn 0.95 Fe 0.05 o 3 0.8LiMn 0.7 Ni 0.2 co 0.1 o 2 .

[0062] The preparation method of the lithium-rich manganese-based solid solution positive electrode material in this embodiment has the following steps:

[0063] 1) Preparation of precursor ①:

[0064] a) Preparation of solution:

[0065] Solution A: MnSO 4 、C 4 h 6 NiO 4 、C 4 h 6 CoO 4 Weigh according to Mn:Ni:Co molar ratio 0.7:0.2:0.1, add deionized water to make a total concentration of 3.0mol / L metal salt solution;

[0066] Solution B: Prepare a KOH solution with a concentration of 6.0mol / L as a precipitant;

[0067] Solution C: Prepare ammonia water with a concentration of 0.1mol / L as a complexing agent;

[0068] b) Co-precipitation:

[0069] Add 100mL of deionized water into the reaction kettle, the temperature of the water bath is 50°C, and after argon gas is introduced to...

Embodiment 3

[0082] The molecular formula of the lithium-rich manganese-based solid solution cathode material in this embodiment is 0.1Li 2 mn 0.9 Mg 0.05 Al 0.05 o 3 0.9LiMn 0.5 Ni 0.5 o 2 .

[0083] The preparation method of the lithium-rich manganese-based solid solution positive electrode material in this embodiment has the following steps:

[0084] 1) Preparation of precursor ①:

[0085] a) Preparation of solution:

[0086] Solution A: MnCO 3 、NiSO 4 Weigh according to Mn:Ni molar ratio 0.5:0.5, add deionized water to make a total concentration of 4.0mol / L metal salt solution;

[0087] Solution B: Prepare a NaOH solution with a concentration of 4.0mol / L as a precipitant;

[0088] Solution C: Prepare ammonia water with a concentration of 2.0mol / L as a complexing agent;

[0089] b) Co-precipitation:

[0090] Add 100mL of deionized water into the reaction kettle, the temperature of the water bath is 60°C, and nitrogen is introduced to make the reaction environment oxygen-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com