Mxene material with organic chelating functional group grafted on surface and preparation method thereof

A technology of organic chelation and surface grafting, applied in the direction of separation methods, chemical instruments and methods, radioactive pollutants, etc., can solve the problems of limited adsorption capacity of materials, unfavorable large-scale application, non-renewable materials, etc., and achieve material form Good appearance structure, efficient governance, considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Follow the steps below to prepare the Mxene material grafted with organic chelating functional groups

[0034] S1, 1g, 400 mesh Ti 3 C 2 The powder was dispersed in 200mL ethanol by ultrasonic and magnetic stirring to obtain suspension I (solid content: 5g / L), and then 200mg N-(trimethoxysilylpropyl)ethylenediaminetriacetic acid was added to 10mL ethanol to obtain solution II (2.47 wt%), mixed evenly for subsequent use;

[0035] S2. Add solution II to suspension I. The volume ratio of suspension I and solution II is 1:0.05. Ultrasonic and stir to mix evenly. Stir and react at 65°C for 12 hours, then centrifuge to separate the black solid, and use ethanol and water After cleaning, it was dried in an air blast oven at 80° C. for 12 hours to obtain the final product.

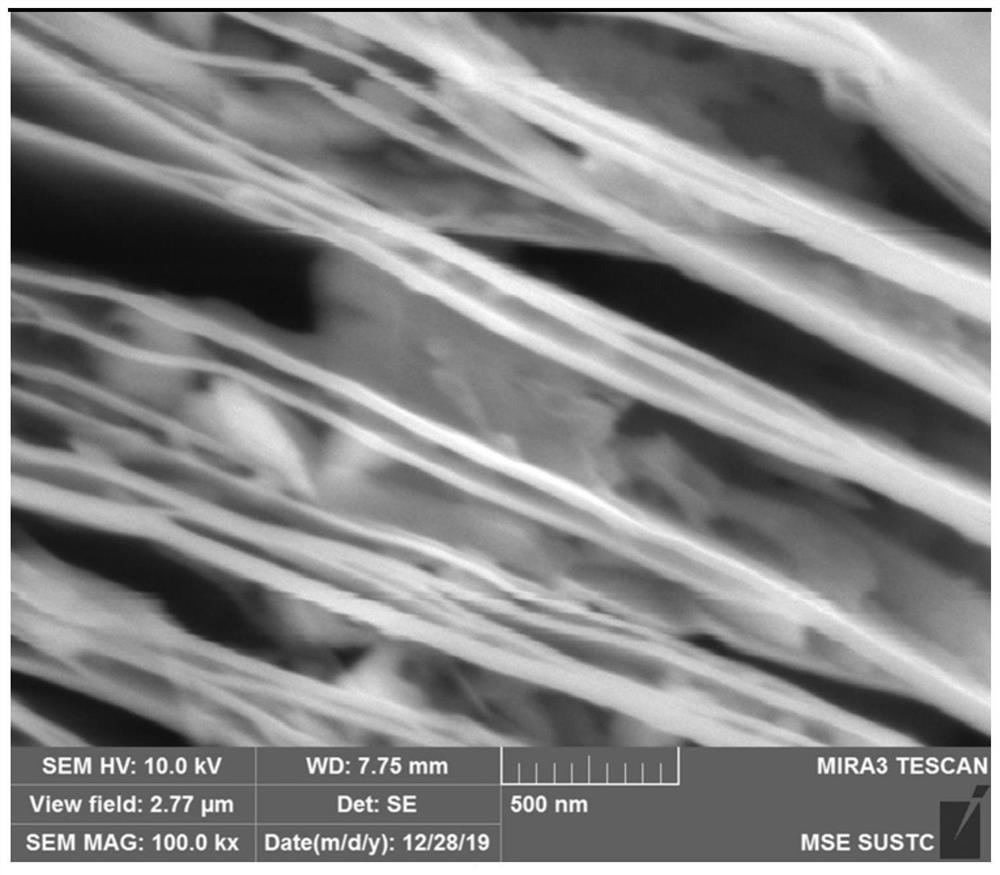

[0036] figure 1 It is the SEM picture of Mxene material, it can be seen that Mxene is in the shape of a louver stacked by two-dimensional nanosheets;

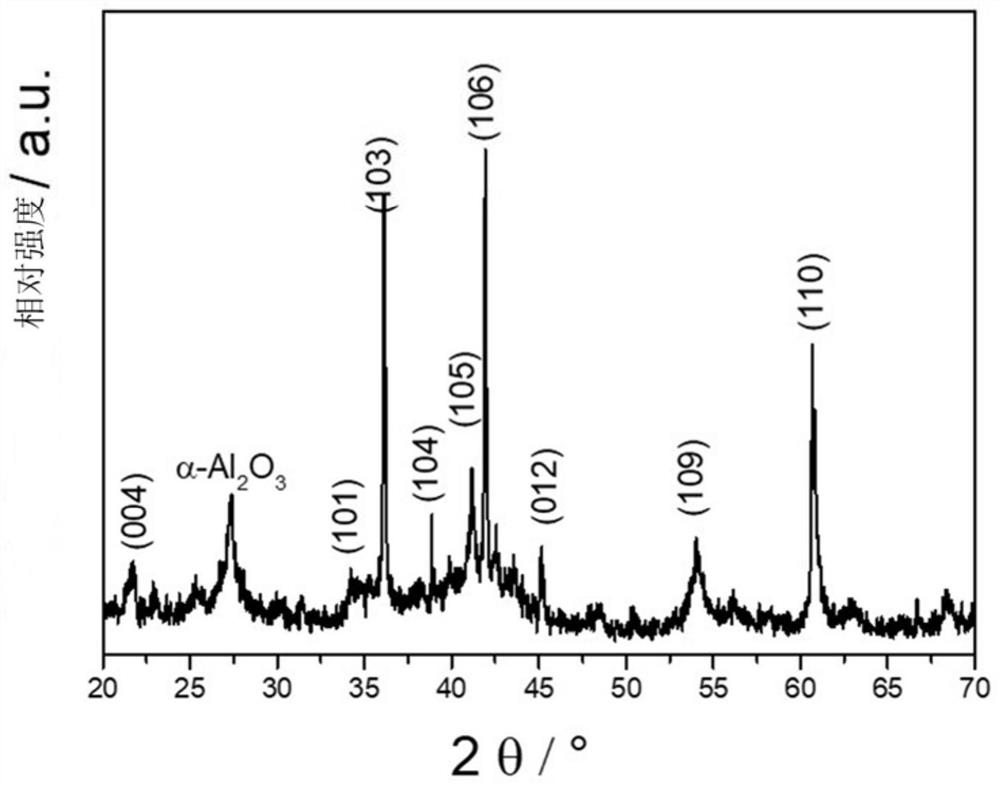

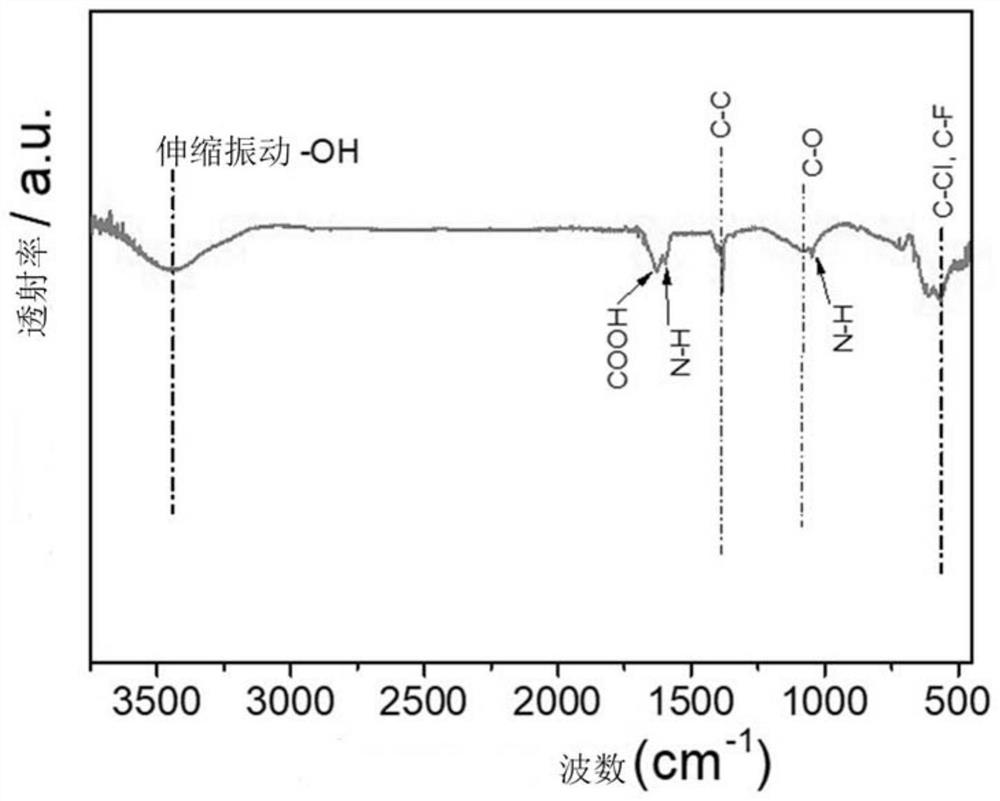

[0037] figure 2 It is the XRD pattern of the Mxe...

Embodiment 2

[0044] Prepare the Mxene material of grafted organic chelating functional group according to the following steps:

[0045] S1, 1g, 400 mesh Ti 3 C 2 The powder was dispersed in 200mL of ethanol by ultrasonic and magnetic stirring to obtain a suspension I (solid content: 5g / L), and then 300mg of N-(3-trimethoxysilylethyl)ethylenediamine was added to 10mL of ethanol to obtain a solution II ( 3.66wt%), mixed uniformly for subsequent use;

[0046] S2. Add solution II to suspension I, the volume ratio of suspension I and solution II is 1:0.05, sonicate and stir to mix evenly, stir and react at 65°C for 12h, then centrifuge to separate the black solid, and use ethanol and water After cleaning, it was dried in an air blast oven at 80° C. for 12 hours to obtain the final product.

[0047] The effective chelating functional group grafted on the surface of the Mxene material in this embodiment is an amino group, which can effectively chelate and remove heavy metal ions as a CDI elect...

Embodiment 3

[0050] Prepare the Mxene material of grafted organic chelating functional group according to the following steps:

[0051] S1, 1g, 800 mesh Ti 3 C 2 The powder was dispersed in 200mL of ethanol by ultrasonication and magnetic stirring to obtain a suspension I (solid content: 5g / L), and then 400mg of N-(3-trimethoxysilylpropyl)ethylenediamine was added to 10mL of ethanol to obtain a solution II ( 4.83wt%), mixed uniformly for subsequent use;

[0052] S2. Add solution II to suspension I. The volume ratio of suspension I and solution II is 1:0.05. Ultrasound and stir to mix evenly. Stir and react at 75°C for 10 hours, then centrifuge to separate the black solid, and use methanol and water After cleaning, it was dried in an air blast oven at 80° C. for 12 hours to obtain the final product.

[0053] The Mxene material of this example has excellent chelation removal efficiency for heavy metal ions, and the material can be regenerated. The adsorption experiment was carried out wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com