Composite material for positive pole of lithium-sulfur battery, and positive pole and battery both made of same

A technology of lithium-sulfur batteries and composite materials, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., which can solve the problems of active material loss, deterioration of electrolyte ion conductivity, and damage to the physical structure of electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a lithium-sulfur battery, which is prepared by the following steps:

[0044] 1. Synthesis of polynaphthalene:

[0045] Put 4 g of dried 3,4,9,10-diphenyltetracarboxylic anhydride (PTCDA) in a tube electric furnace, and after three times of vacuuming and filling with argon, adjust the argon flow rate (25mL / min), The tail gas absorption device (absorbing liquid is saturated aqueous solution of calcium hydroxide), and then under the condition that the initial temperature is room temperature, the temperature is raised at a rate of 5°C / min, and the temperature is raised to 530°C, kept at this temperature for 8 hours, and then continued to The temperature was raised at a rate of 5°C / min, the temperature was raised to 1000°C, and maintained at this temperature for 6 hours, and then the temperature was naturally lowered to obtain polynaphthalene, whose infrared spectrum was as follows Figure 6 shown.

[0046] 2. Preparation of battery cathode sheet: ...

Embodiment 2

[0052] This embodiment provides a lithium-sulfur battery, which is prepared by the following steps:

[0053] 1, the synthesis of polynaphthalene is with embodiment 1.

[0054] 2. Preparation of battery cathode sheet:

[0055] Mix the synthesized polynaphthalene and sulfur at a mass ratio of 1:4, thoroughly grind them in a mortar, and then put them into a tube electric furnace for calcination (first raise the temperature to 150°C, keep it for 5h-8h, then continue to heat up to 300°C, And keep at this temperature for 2-3h);

[0056] Mix the calcined product in a mortar, then mix it with conductive agent carbon black and PVDF in a mass ratio of 7:2:1, grind, mix well, apply it on aluminum foil, dry it at 60-70°C, and press into a positive plate.

[0057] 3. Battery assembly:

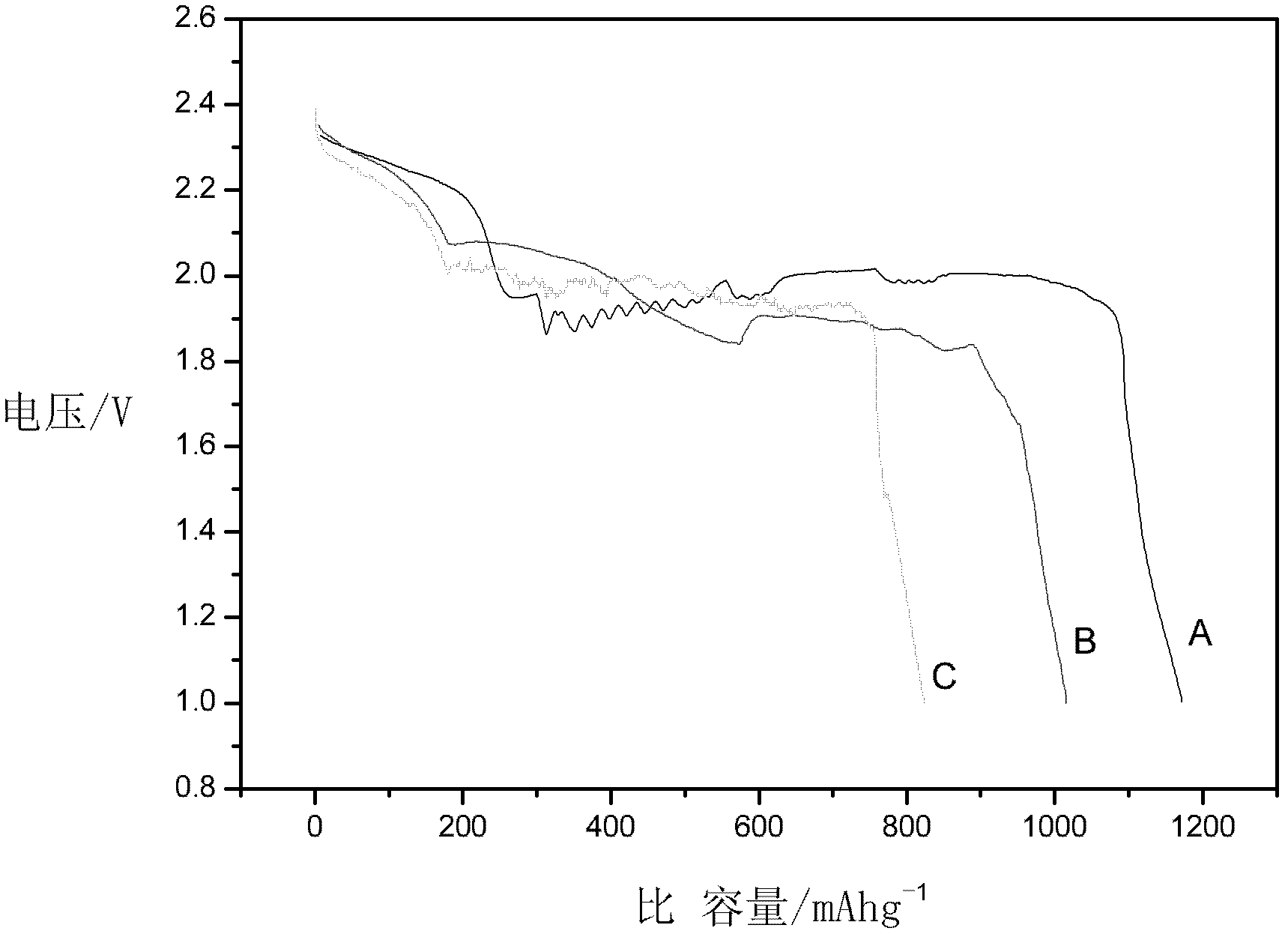

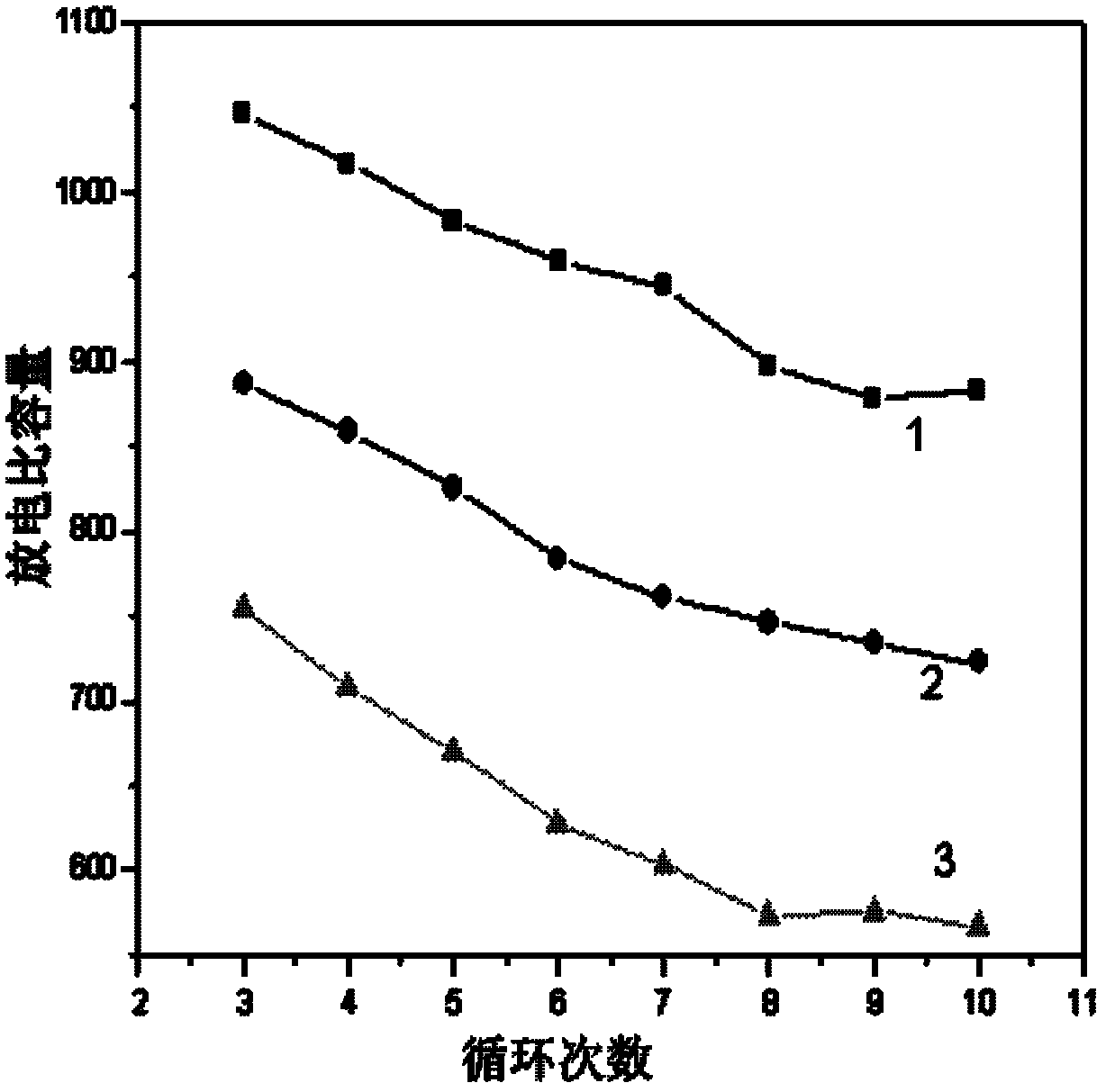

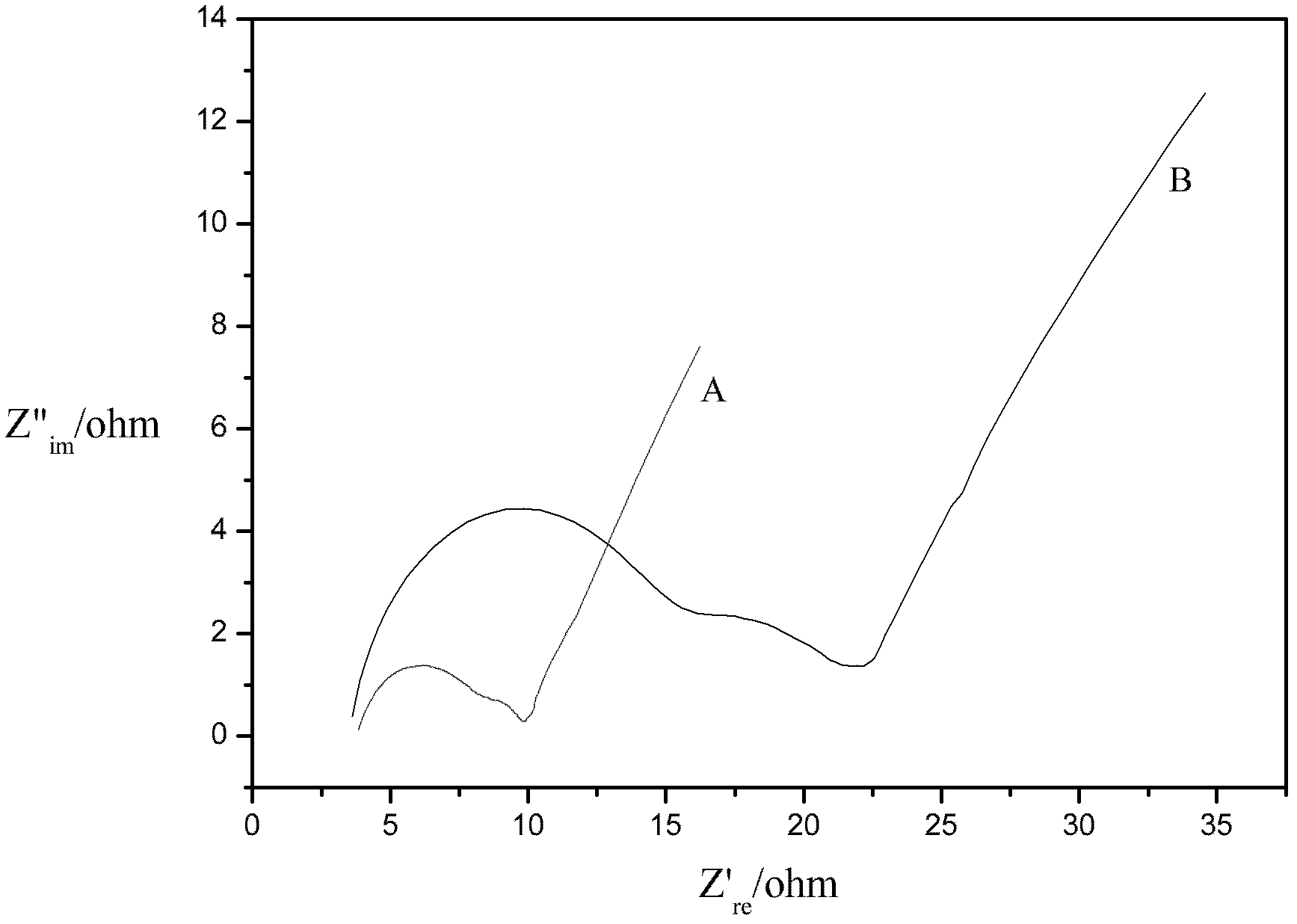

[0058] In the glove box, combine the above-mentioned positive electrode, negative electrode, diaphragm, electrolyte, and shell together to form a button battery, and let it stand for 24 hours to test; w...

Embodiment 3

[0060] This embodiment provides a lithium-sulfur battery, which is prepared by the following steps:

[0061] 1. Synthesis of nitrated compounds of polynaphthalene:

[0062] Put 2g of the polynaphthalene synthesized in Example 1 in a 250mL three-necked bottle, then add 50mL of sulfuric acid (98wt% concentration), stir, heat to 80°C, and dropwise add a concentration of 65-68wt to the there-necked bottle through a constant pressure funnel. % nitric acid (24mL) and concentration are the mixed acid of the sulfuric acid (28mL) of 98wt%, in the process of dripping mixed acid, keep internal temperature at 80 ℃ all the time, drop complete, continue to react at this temperature for 1.5 hours, then Naturally cool to room temperature, then pour the reaction liquid into 300mL ice water, stir well, add an appropriate amount of alkali to neutralize until the pH=7, filter, then wash the filtered solid with high-purity water 3 times, dry Dry, and finally obtain 2.68g product, namely the nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com