Magnetic nano composite material and a preparation method and application thereof

A magnetic nano-composite material technology, applied in the field of nano-materials, can solve the problems of low metal ion adsorption performance, single type of action, low magnetism, etc., and achieve the effect of excellent adsorption performance, strong magnetism and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

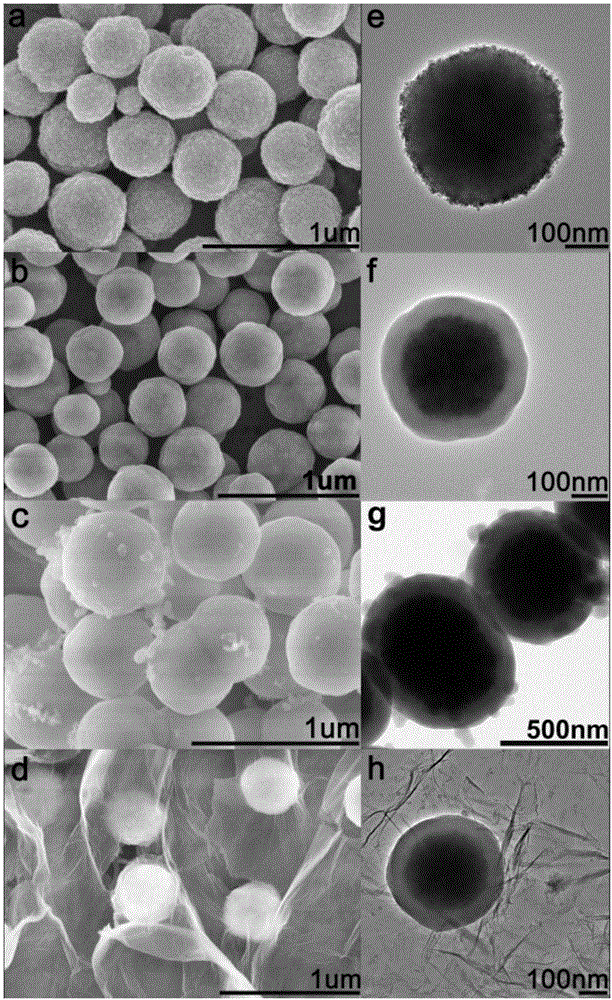

[0053] One, the preparation of ferric oxide nano-microspheres:

[0054] Add 3.13g of ferric chloride hexahydrate and 0.81g of trisodium citrate dihydrate into 70mL of ethylene glycol, stir at room temperature until completely dissolved, then add 4.81g of sodium acetate, continue stirring until dissolved, then transfer to the reaction kettle , and then kept at 280° C. for 10 hours of reaction, ended the reaction, magnetically separated, washed the collected solid with deionized water until neutral, and then dried to obtain the ferric oxide nanospheres for future use.

[0055] 2. Fe 3 o 4 @SiO 2 Preparation of magnetic nanospheres:

[0056] Disperse 0.12 g of ferric oxide nano-microspheres in 102 mL of ethanol aqueous solution (96 mL of ethanol + 6 mL of water), ultrasonicate for 20 minutes to make the dispersion uniform, then add 3 mL of ammonia water, then add dropwise the ethanol containing tetraethyl silicate under stirring. solution (300μLTEOS dispersed in 5mL ethanol),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com