Patents

Literature

188results about How to "Avoid crosslinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

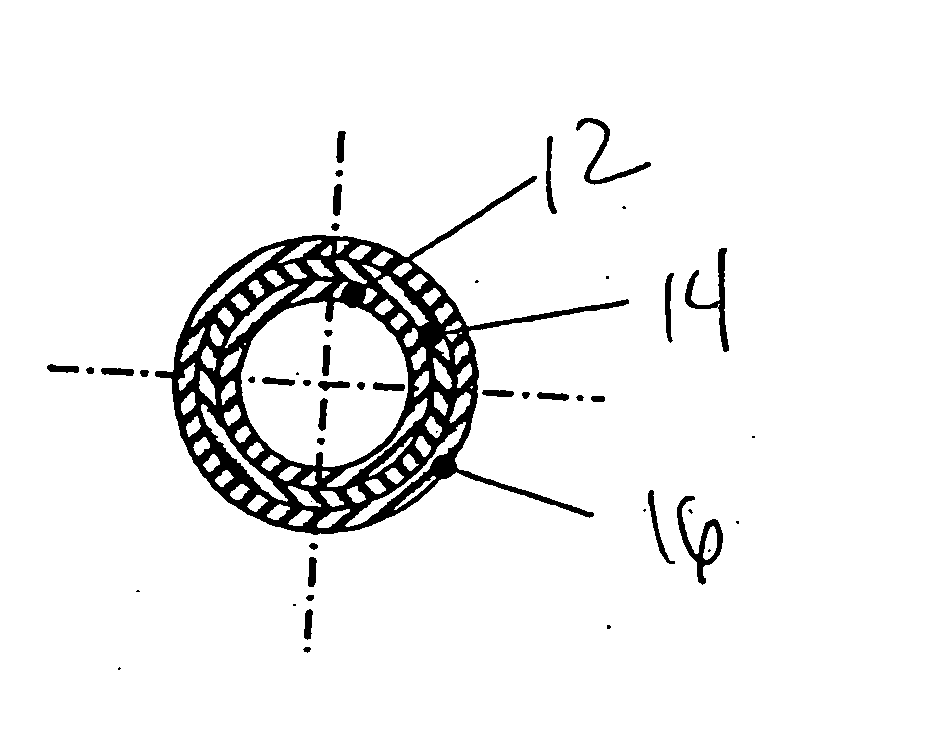

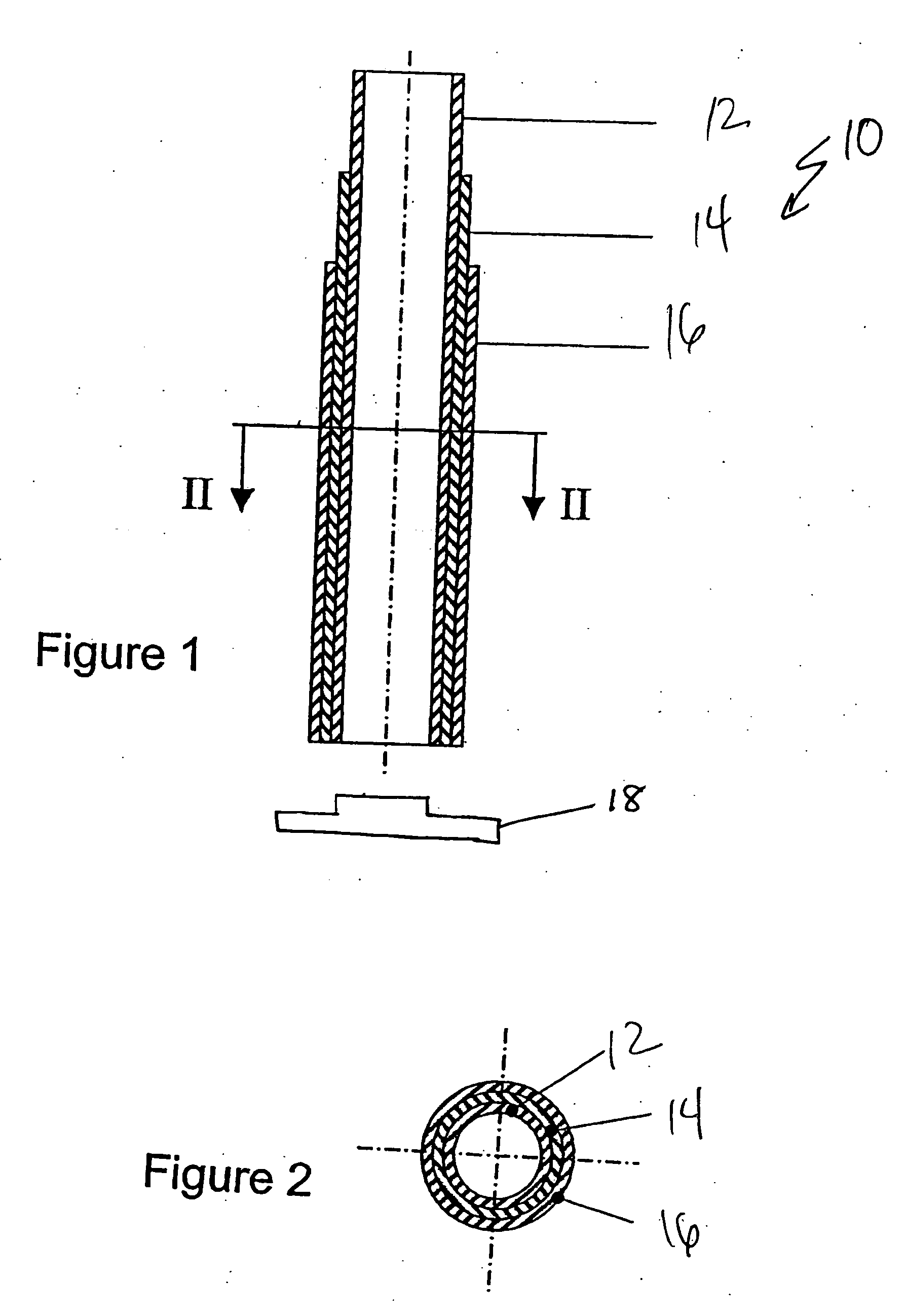

Cross-linked thermoplastic tubing

InactiveUS20050005989A1Avoid crosslinkingLayered product treatmentSynthetic resin layered productsPolyesterCross-link

A tubing includes a layer of cross-linked polyamide. The polyamide layer can include a cross-linking aid, such as triallyliscocyanurant or TAIC, to assist in cross-linking the layer. When the polyamide layer is exposed to high-level radiation, the polyamide layer cross-links to provide a layer having high temperature resistance and high glycol resistance. In another embodiment, the tubing includes a first layer of a cross-linked thermoplastic and a second layer to form a multi-layer tubing. The thermoplastic of the first layer can be polyamide, aromatic nylon, polyolefins, polyvinyl chloride or polyester.

Owner:COOPER TECH SERVICES

Graft polymers and use thereof

Solutions of graft polymers of a polymer having reactive hydrogen groups and grafted through reactive hydrogen groups an alkoxy metallic compound wherein the metal is titanium, zirconium and / or hafnium are useful as photoresist materials which are resistant to plasma. Also, compounds and graft polymers wherein the alkoxy metallic compound also contains silicon, tin or germanium are provided.

Owner:IBM CORP

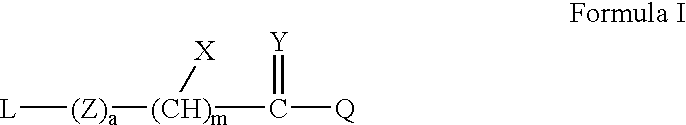

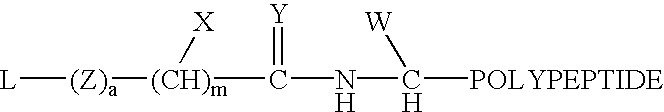

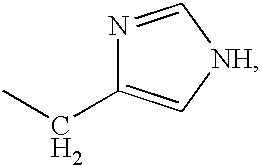

Thioester-terminated water soluble polymers and method of modifying the N-terminus of a polypeptide therewith

InactiveUS7078496B2Avoid crosslinkingDepsipeptidesPeptide preparation methodsWater solubleHistidine residue

The invention provides reagents and methods for conjugating a polymer specifically to the α-amine of a polypeptide. The invention provides monofunctional, bifunctional, and multifunctional PEGs and related polymers having a terminal thioester moiety capable of specifically conjugating to the α-amine of a polypeptide having a cysteine or histidine residue at the N-terminus. The invention provides reactive thioester-terminated PEG polymers that have suitable reactivity with an N-terminal cysteine or histidine residue of a polypeptide to produce an amide bond between the PEG molecule and the polypeptide.

Owner:NEKTAR THERAPEUTICS INC

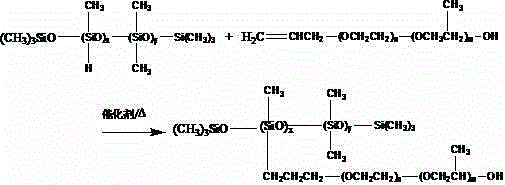

Solvent-free method for preparing polyether modified polysiloxane antifoaming agent

ActiveCN102977377AAvoid crosslinkingIncrease reaction rateInksFoam dispersion/preventionSolventMolecular sieve

Owner:KUSN ZHANGPU COLOR PRINTING FACTORY

Antioxidant-stabilized joint implants

ActiveUS20150151866A1Improve wear resistanceImprove mechanical propertiesElectric discharge tubesPackage sterilisationMedicineAntioxidant

Owner:THE GENERAL HOSPITAL CORP

Method for synthesizing solid polycarboxylic acid water reducing agent

The invention provides a method for synthesizing a solid polycarboxylic water reducing agent, comprising the following steps: using a monomer containing the nonsaturated group to react with an organic solvent, after the reaction, adding an alkaline substance for neutralization, and carrying out centrifugation to obtain a polycarboxylic acid water reducer, then drying the prepared polycarboxylic acid water reducer to obtain the solid polycarboxylic acid water reducing agent. By using a low temperature method to prepare the solid polycarboxylic acid water reducing agent , the crosslinking of the polycarboxylic acid water reducer due to high temperature spray drying is avoided, and the structure of the polycarboxylic acid water reducer is destroyed, thus the solid polycarboxylic acid water reducing agent with excellent performance is obtained.

Owner:SHANGHAI TAIJIE CHEM

Coating for elastomeric linear profiles, in particular windscreen-wiper blades, and process for production thereof

InactiveUS8575078B2High strengthIncrease resistanceOrganic chemistryPretreated surfacesElastomerHexa(methoxymethyl)melamine

The present invention relates to a coating for elastomeric linear profiles, where the coating comprises solid lubricant embedded into a polymeric matrix. It also relates to a wiper blade for windscreen wipers, comprising this type of coating, and also to a process for the production of an elastomeric linear profile coated according to the invention. The polymeric matrix with embedded solid lubricant is obtained by polymerizing, in the absence of polymeric binders, a mixture comprising the solid lubricant and low-molecular-weight crosslinking agent. In one embodiment, the matrix is obtained from the thermal polymerization of the low-molecular-weight crosslinking agent hexamethoxymethylmelamine. Examples of solid lubricants are graphite and HDPE.

Owner:ROBERT BOSCH GMBH

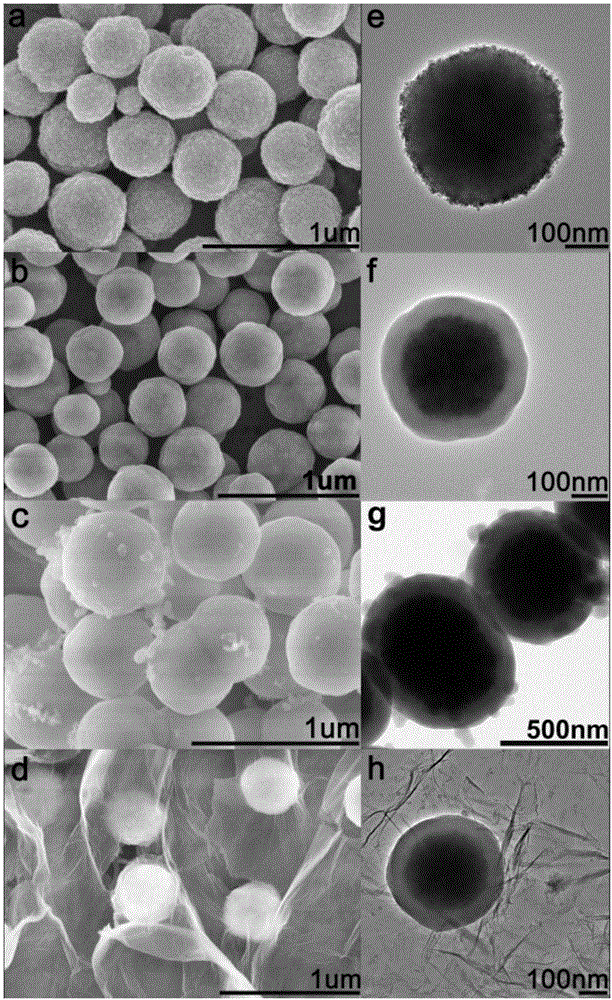

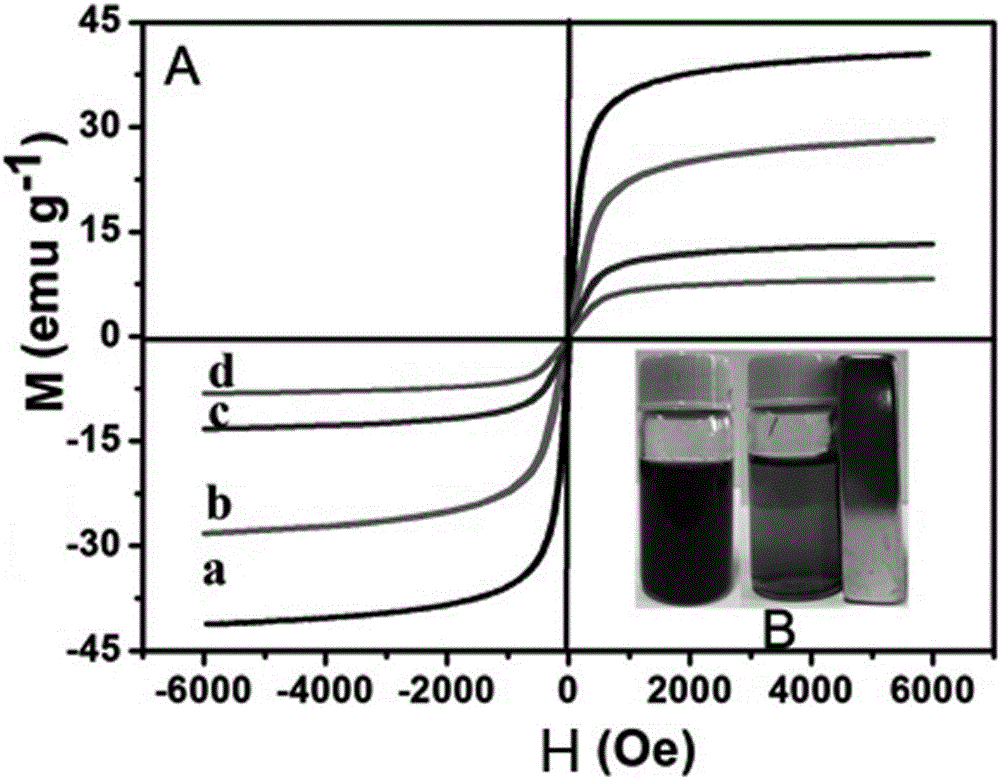

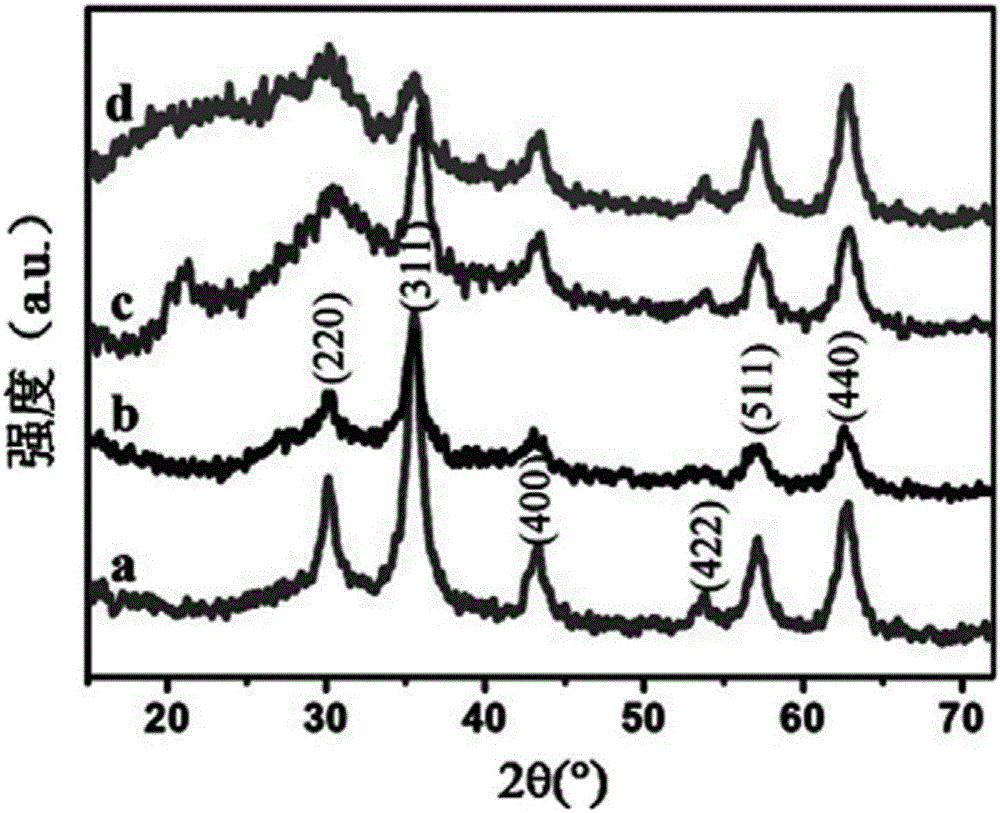

Magnetic nano composite material and a preparation method and application thereof

InactiveCN106693920ALarge specific surface areaGood shape structureOther chemical processesWater contaminantsTetramineOrganic dye

The invention discloses a magnetic nano composite material and a preparation method and application thereof. The magnetic nano composite material is obtained by firstly coating ferroferric oxide with silicon dioxide to obtain Fe3O4 @ SiO2 magnetic nano microspheres, then sequentially coating the surfaces of the Fe3O4 @ SiO2 magnetic nano microspheres with chitosan, triethylene tetramine and graphene oxide layer by layer. Experiments indicate that the magnetic nano composite material has large specific surface area, good morphology structure, strong magneticity, good adsorptive property and other advantages, can be used as a heavy metal ion and organic dye adsorbent and has a good use value and an application prospect in the environment, water treatment and other fields.

Owner:SHANGHAI UNIV OF ENG SCI

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

Preparation method for 107 silicon rubber with controllable viscosity

The invention relates to a method for producing linear hydroxyl-terminated polydimethylsiloxane, wherein the method comprises the following steps of: washing dimethyldichlorosilane hydrolysate serving as an initiative material to remove remained chloride ions; polymerizing the hydrolyzate in the presence of a basic size catalyst; after the polymerization reaches a certain degree, heating directly to decompose catalyze; ending the reaction; and removing low-boiling matters at the same time to obtain products. The linear hydroxyl-terminated polydimethylsiloxane produced by the invention has the characteristics of uniformly distributed molecular weight, controllable viscosity, good repeatability and the like.

Owner:浙江中天东方氟硅材料股份有限公司 +1

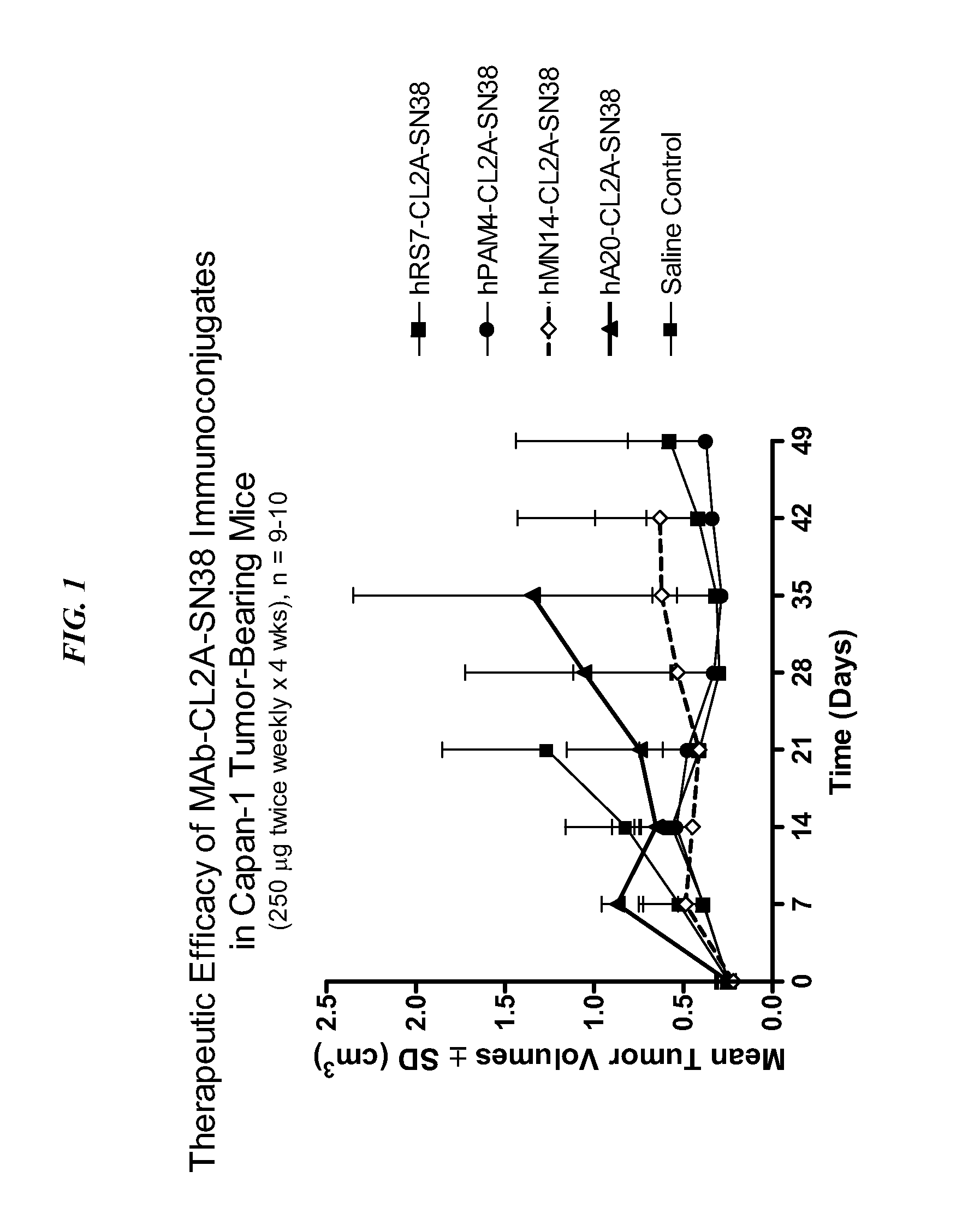

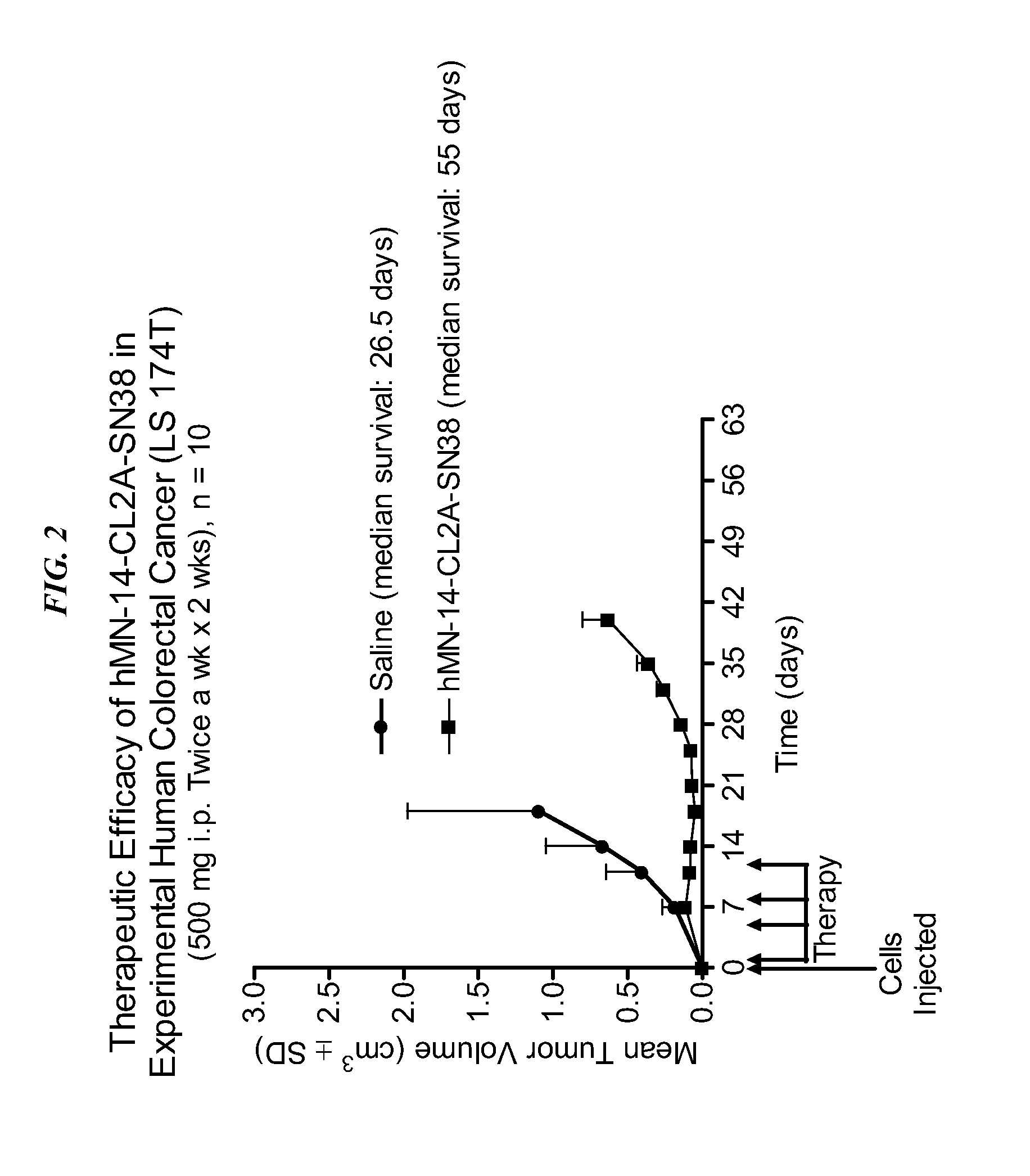

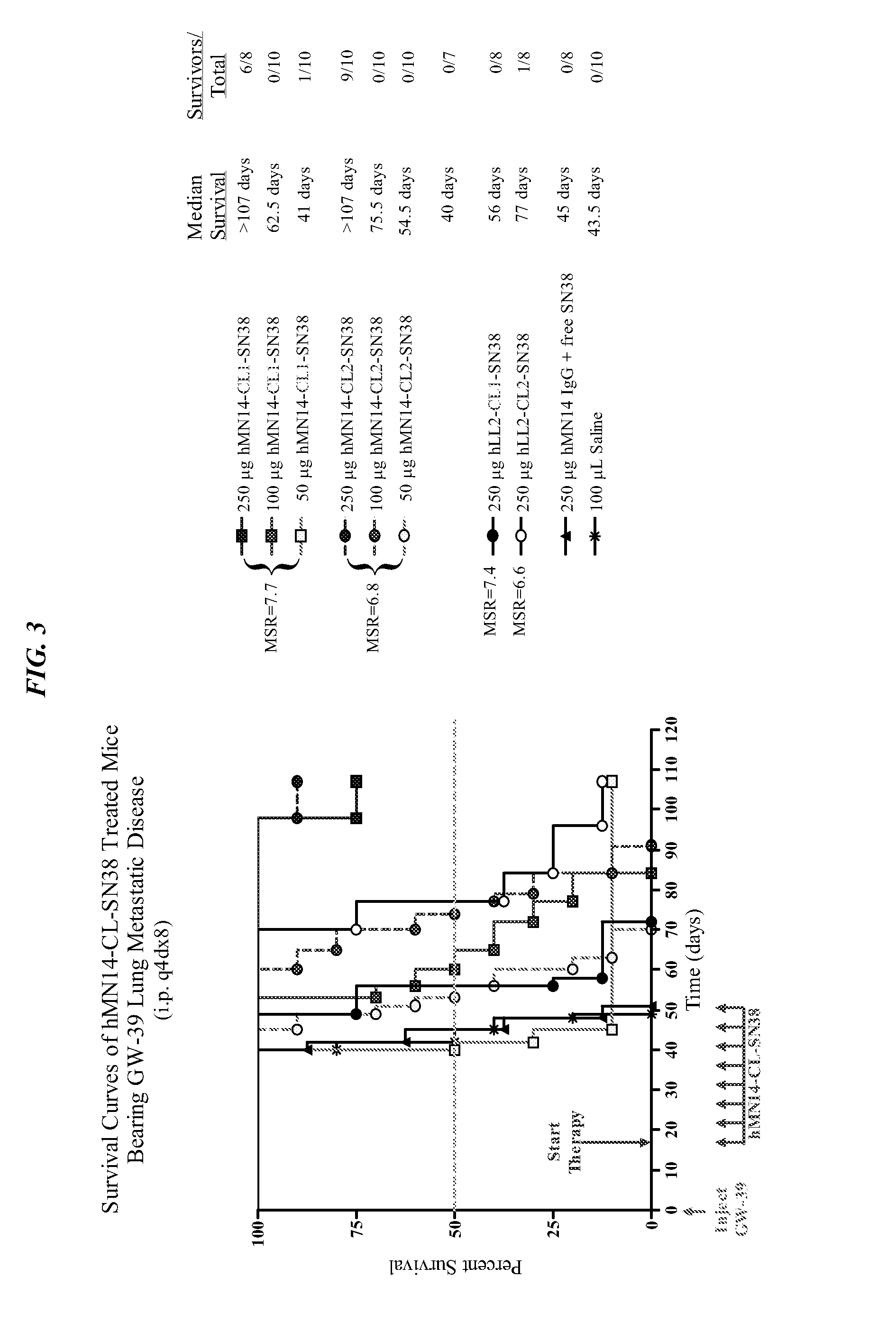

Humanized Anti-ceacam5 antibody and uses thereof

InactiveUS20150125386A1Overcome tumorImprove targetingImmunoglobulins against animals/humansRadioactive preparation carriersDrug conjugationWhole body

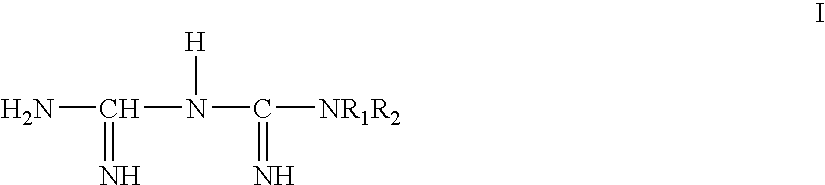

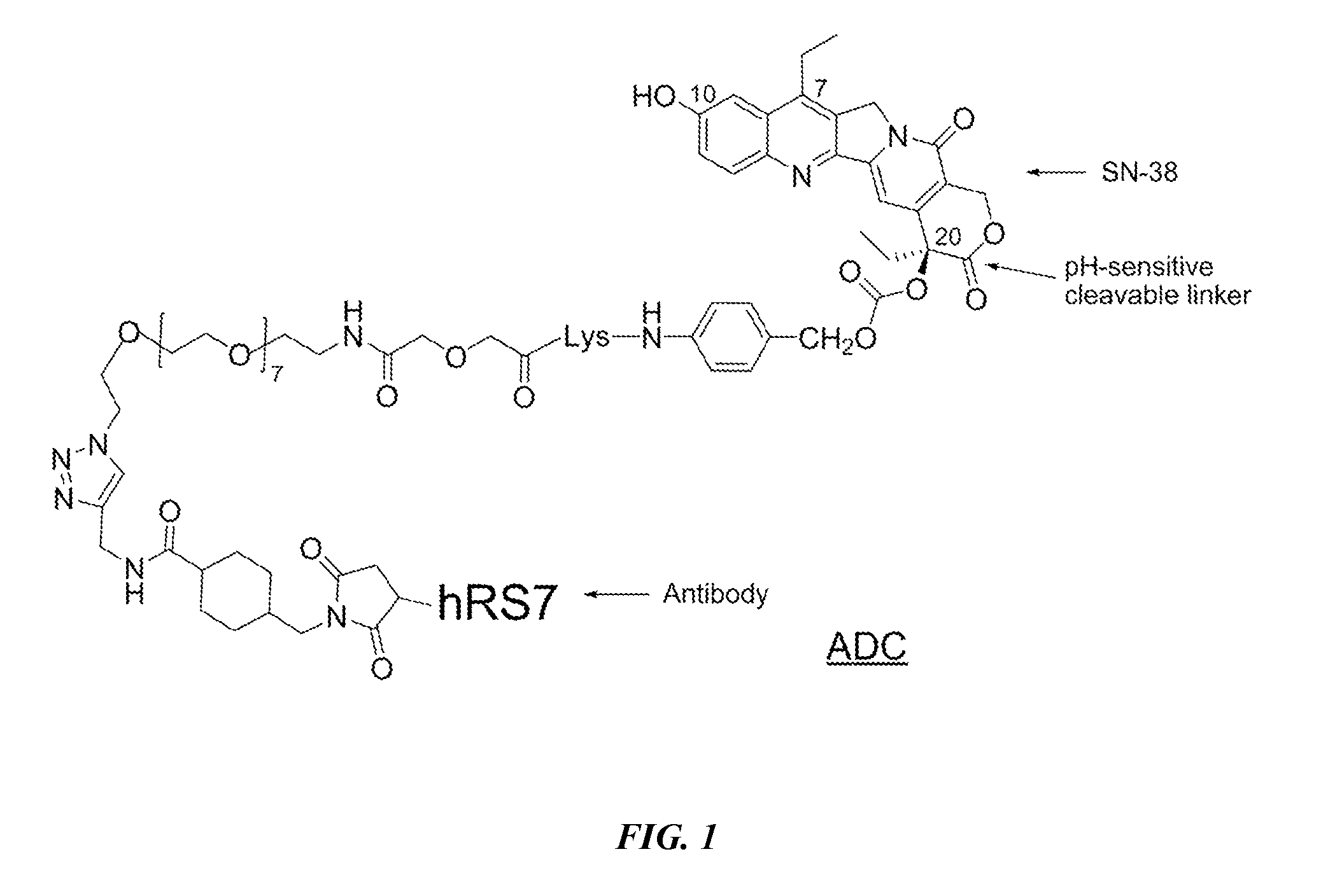

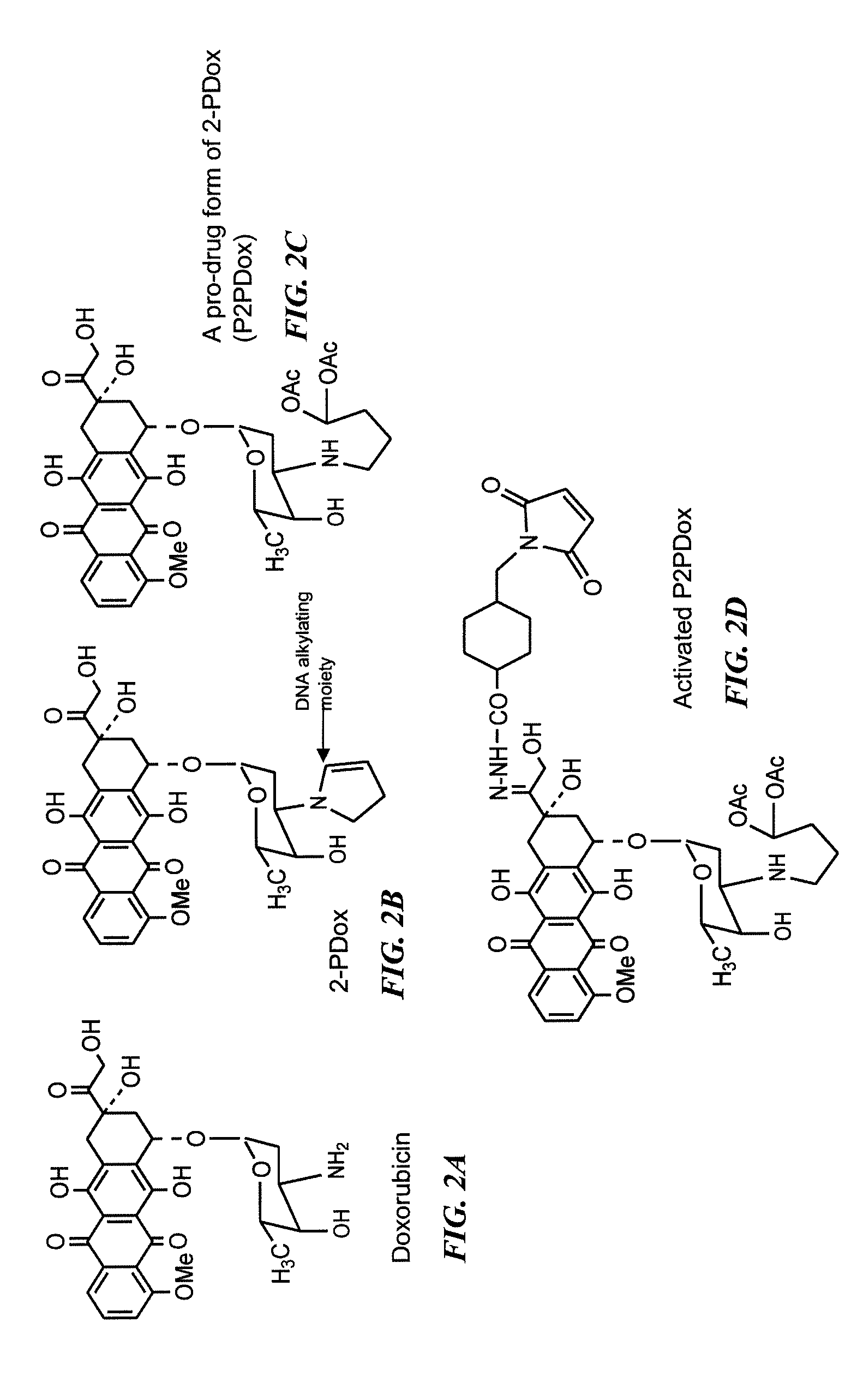

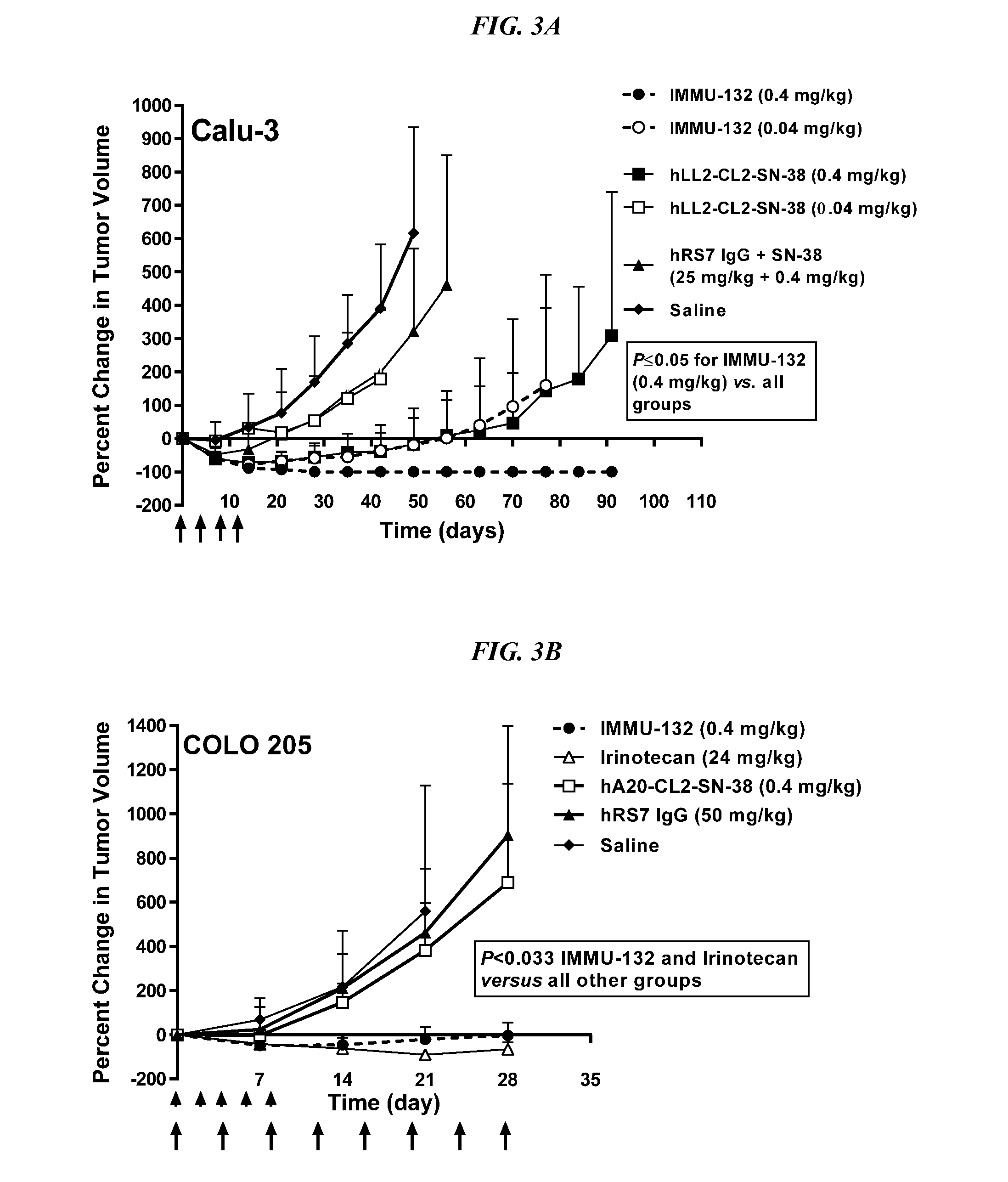

The present invention concerns compositions and methods of use of a humanized Class III anti-CEA antibody, comprising the heavy and light amino acid sequences SEQ ID NO:1 and SEQ ID NO:2. The antibody is effective to treat CEACAM5-expressing tumors, either alone or in combination with one or more therapeutic agents. Drug conjugated Class III anti-CEA antibodies, such as SN-38 or P2PDox immunoconjugates, are particularly efficacious. Surprisingly, the antibody-drug conjugates (ADCs) exhibit high anti-cancer efficacy, while exhibiting low levels of systemic toxicity that are readily treated with standard amelioration techniques. Antibodies and / or immunoconjugates comprising the amino acid sequences SEQ ID NO:1 and SEQ ID NO:2 are surprisingly efficacious for therapy of solid tumors, even when the tumor has proven resistant to standard anti-cancer therapies.

Owner:IMMUNOMEDICS INC

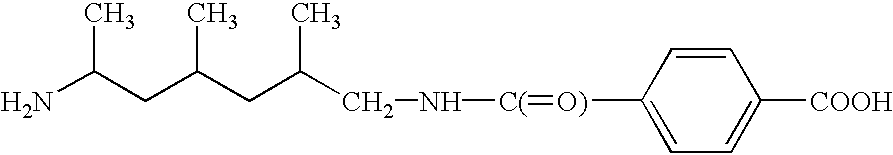

Method of fust preparing linkage type polysaccharide chiral fixed phase

A method for synthesis of linking polysaccharide chiral stationary phase, includes the following steps: 1) in the reactor with organic solvent, polysaccharide and derivative solvent of polysaccharide react with including functional group which can react with polysaccharide hydrocarbon radical, then though centrifugal separation the solid substance is collected; 2) coat the prepared polysaccharide derivative containing trihydroxyme or on the surface of silica gel matrixof chromatogram filler, then they are mixed with toluene and pyridine in reactor , cooled after reaction, then use tetrahydrofuran and carbinol separately to wash the creature, which are dried in vacuum, acquiring the linking polysaccharide chiral stationary phase. Its advantages are: wide field of use, simple and rapid preparation.

Owner:萍乡分水科技有限公司

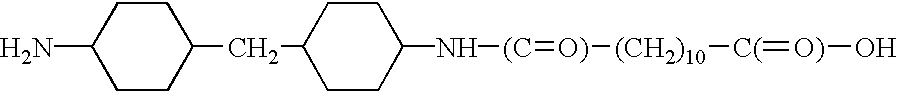

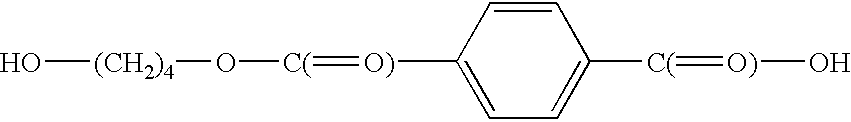

Composite and process for producing the same

InactiveUS6800372B2High bonding strengthAvoid crosslinkingLaminationPretreated surfacesPolyesterPolymer science

A composite of a resin member bonded to a rubber member is obtained by molding a resin molding element and a rubber molding element with contacting said elements each other, and vulcanizing or crosslinking the rubber molding element, wherein said resin molding element is either of a resin composition and a resin member, each comprising the thermoplastic resin; and said rubber molding element is either of a rubber composition and a rubber premolded article, each comprising at least an unvulcanized silicone rubber, and a radical-generating agent (e.g., organic peroxides) being activating on a surface to be contacted with said resin molding element. The thermoplastic resin includes a polyamide-series resin, a polyester-serires resin, a PPE-series resin, etc. The unvulcanized rubber composition may comprise a polyfunctional compound having plural polymerizable groups. Such a process can give a composite composed of a thermoplastic resin molded article bonded to a vulcanized silicone rubber molded article directly and firmly without an adhesive treatment.

Owner:DAICEL DEGUSSA

Areginine essence and preparation method thereof

InactiveCN106109302AEffective quenchingAvoid crosslinkingCosmetic preparationsToilet preparationsHydrolysateSalicylic acid

The invention discloses a hexapeptide stock solution and a preparation method thereof. A hexapeptide stock solution, the composition includes the following main components: maltooligosaccharide glucoside / hydrogenated starch hydrolyzate 0.2-0.7%, butanediol / water / peony root extract 0.1-0.5%, acetyl hexapeptide ‑80.5~1.6%, yeast extract 0.4~1.6%, salicylic acid / dextrin / xanthan gum / pullulan 0.2~0.7%, carnosine 0.1~0.21%. The hexapeptide stock solution prepared by the invention has good anti-aging and moisturizing effects.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

Material of non-woven fabric surface heavy nitrogen coupling gelatin adsorbing material and preparation method thereof

InactiveCN103263898AEasy to captureImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPolymer scienceTannin

The invention discloses a non-woven fabric surface heavy nitrogen coupling gelatin adsorbing material and a preparation method thereof. The method comprises the following steps of: grafting an unsaturated monomer with carboxy to the surface of a macromolecule non-woven fabric base material by using an ultraviolet induction technique so as to introduce the carboxy; furthermore introducing aromatic amine through catalytic condensation of aroma diamine and carboxy; subsequently, converting the aromatic amine into diazo salt; coupling and immobilizing the gelatin on the surface of the non-woven fabric through diazo coupling reaction; and finally, soaking in hot water and eliminating the uncoupled gelatin so as to prepare the non-woven fabric surface diazo coupling gelatin absorbing material. The absorbing material is good in hydrophilicity, namely, the water absorption rate is greater than 292.3%; the solid load and the absorption rate of the gelatin can be adjusted in a large range, the absorbing material has high absorption capability for tannin; and when the tannin concentration is 200-400mg / L, the balance absorption capacity is within 16.8-53.2mg / g, and the absorption balance can be achieved within 3 hours.

Owner:KUNMING UNIV OF SCI & TECH

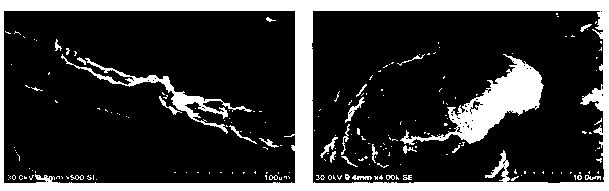

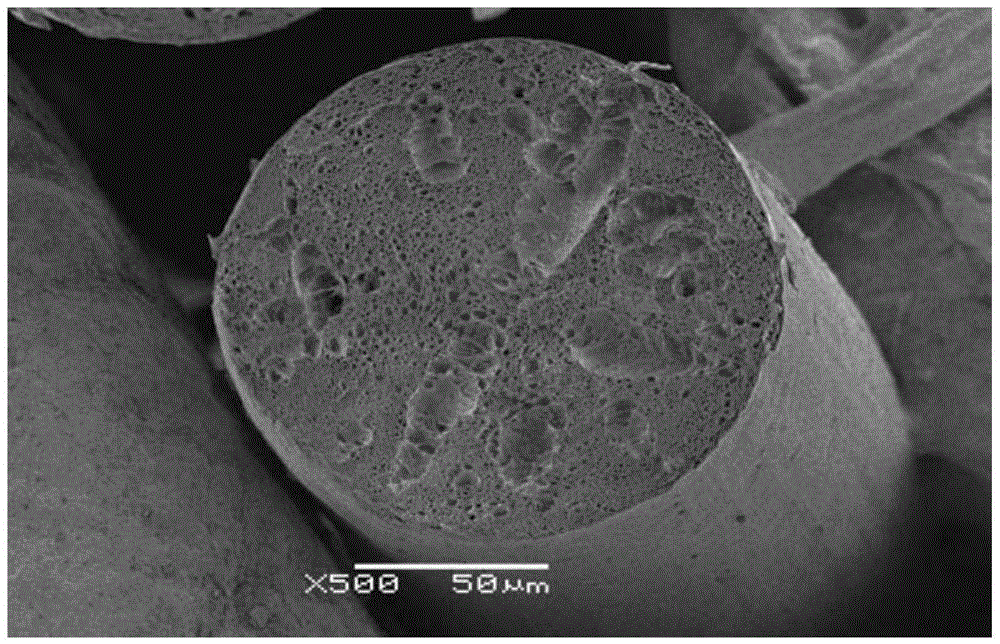

Preparation method of nascent fiber for production of carbon fiber

InactiveCN105369390ARapid preoxidationNo fusionConjugated synthetic polymer artificial filamentsCarbon fibersSolvent

A preparation method of nascent fiber for production of carbon fiber comprises the following steps: uniformly mixing modified lignin or commercialized lignosulfonate and a solvent to prepare a solution a; uniformly mixing polyacrylonitrile resin and the solution to prepare a solution b, or directly using a de-monomerized polyacrylonitrile spinning solution as the solution b; blending the solution a and the solution b; keeping the blended solution at the constant temperature of 40-80 DEG C to obtain a uniform spinning solution with solid content being 12-33 wt%; pressing the spinning solution into coagulating bath through a spinneret plate to generate polyacrylonitrile / modified lignin nascent fiber; and finally winding at constant rate to obtain the nascent fiber for production of carbon fiber. The preparation method of the invention has advantages of low cost and high quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

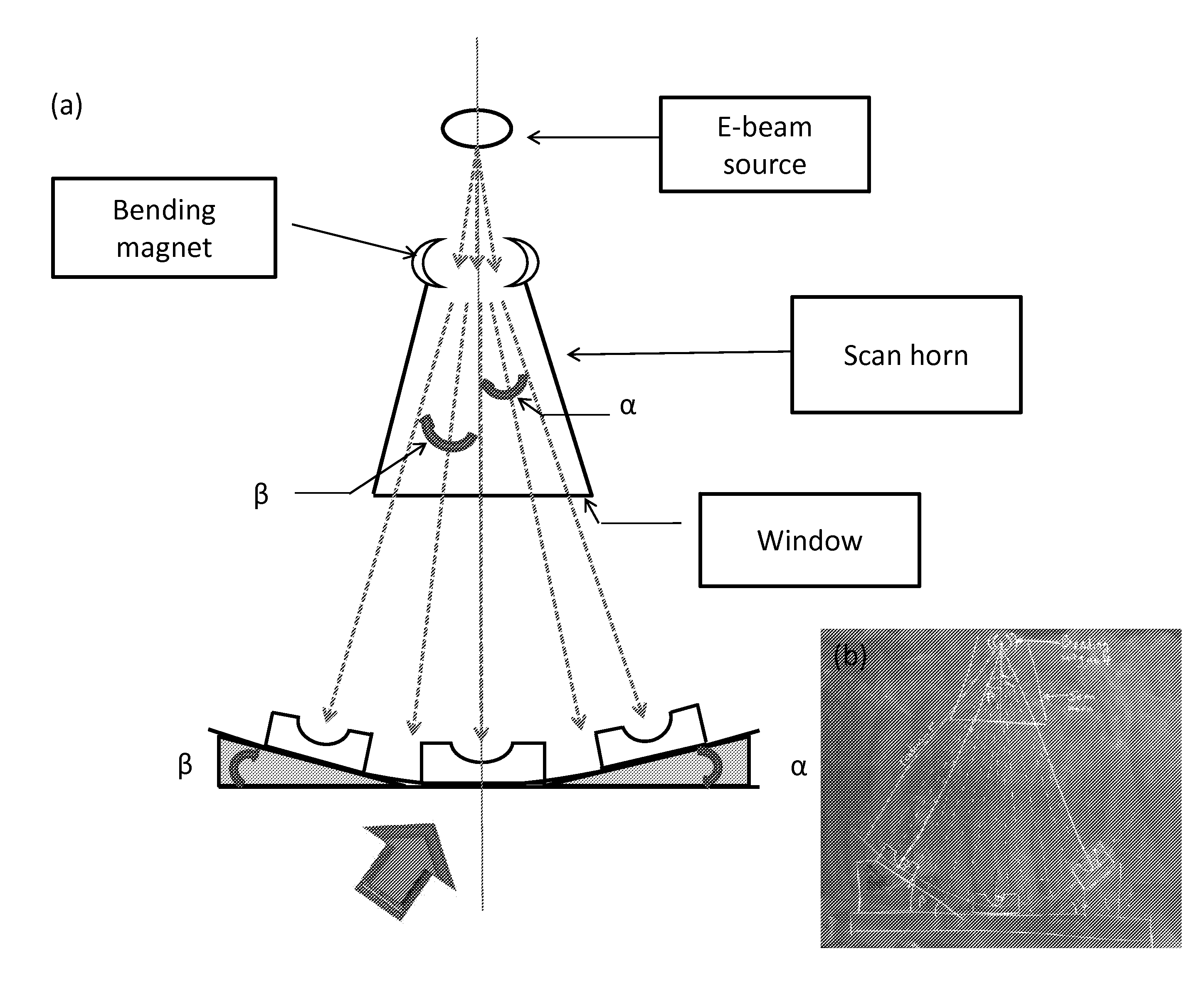

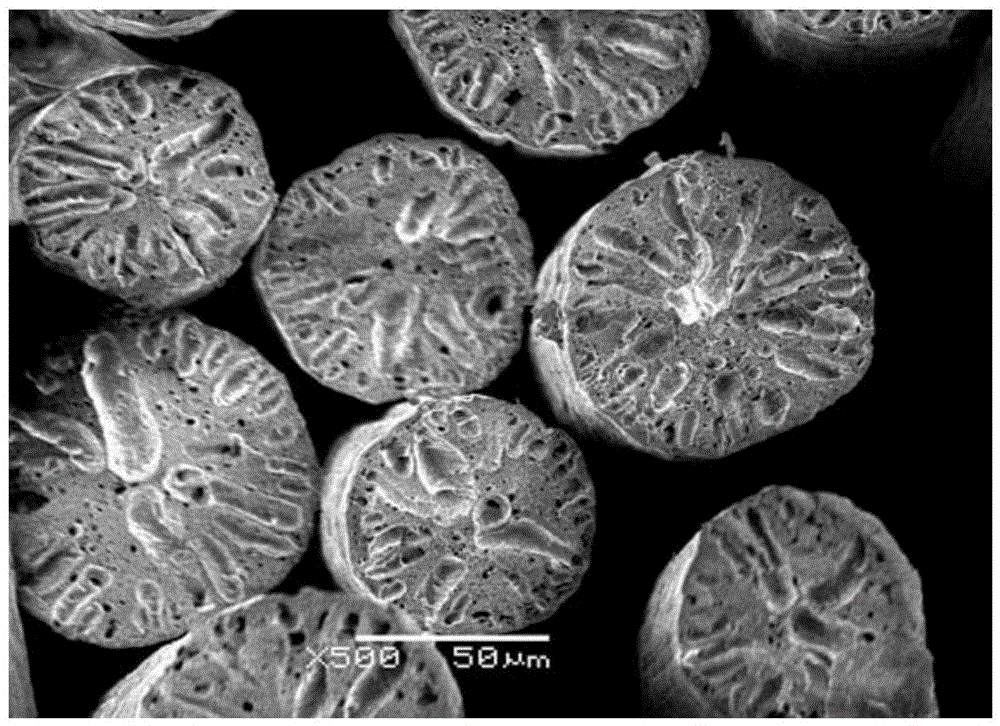

Polyethylene-polystyrene resin and preparation method thereof

ActiveCN101704929APhase separation does not occurUniform concentration distributionPre irradiationFunctional monomer

The invention relates to a polyethylene-polystyrene resin and a preparation method thereof. The preparation method comprises the following steps of: performing pre-irradiation treatment on polyethylene resin by using beta rays or gamma rays; adding the polyethylene resin after the pre-irradiation treatment, a dispersing agent, a functional monomer, an emulsifying agent, a nucleating agent and a homopolymerization inhibiting agent into a reactor to perform suspension graft polymerization reaction for a certain period of time at a certain temperature; and filtering, washing and drying a suspension graft product to obtain the polyethylene-polystyrene resin. The concentrations of macromolecular peroxides generated by the pre-irradiation are distributed evenly, so side reactions such as monomer homopolymerization, polymer crosslinking and / or degradation and the like caused by a micromolecule chemical initiator are avoided; the percent grafting ratio reaches 21 to 42 percent; the homopolymerization inhibiting agent reduces the homopolymerization of the monomer in the suspension grafting process; and the polyethylene-polystyrene resin has the tensile strength of more than 22 MPa, breaking elongation of over 90 percent and elastic modulus of more than 480 MPa, and has good mechanical properties such as strength, tenacity, impact strength and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Composite and process for producing the same

InactiveUS20030170469A1Easy to produceHigh bonding strengthPretreated surfacesLaminationPolyesterPolymer science

A composite of a resin member bonded to a rubber member is obtained by molding a resin molding element and a rubber molding element with contacting said elements each other, and vulcanizing or crosslinking the rubber molding element, wherein said resin molding element is either of a resin composition and a resin member, each comprising the thermoplastic resin; and said rubber molding element is either of a rubber composition and a rubber premolded article, each comprising at least an unvulcanized silicone rubber, and a radical-generating agent (e.g., organic peroxides) being activating on a surface to be contacted with said resin molding element. The thermoplastic resin includes a polyamide-series resin, a polyester-serires resin, a PPE-series resin, etc. The unvulcanized rubber composition may comprise a polyfunctional compound having plural polymerizable groups. Such a process can give a composite composed of a thermoplastic resin molded article bonded to a vulcanized silicone rubber molded article directly and firmly without an adhesive treatment.

Owner:DAICEL DEGUSSA

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

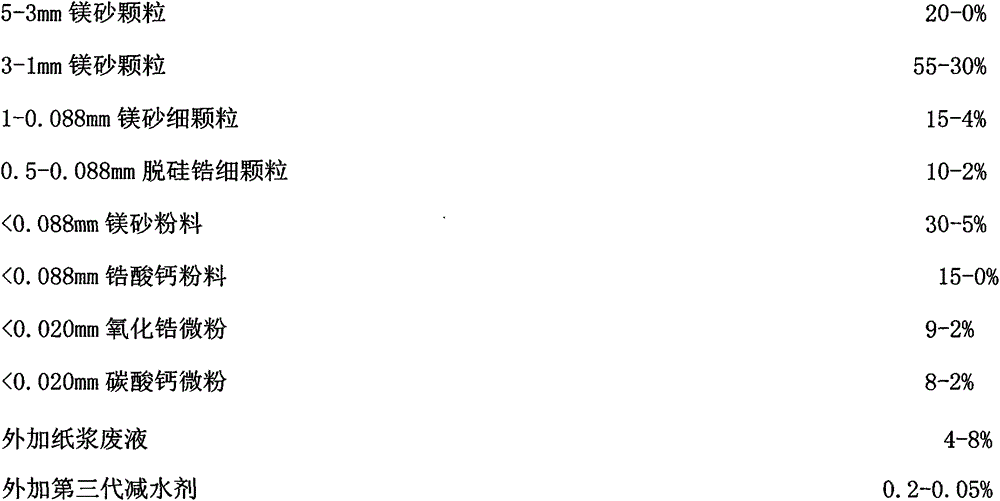

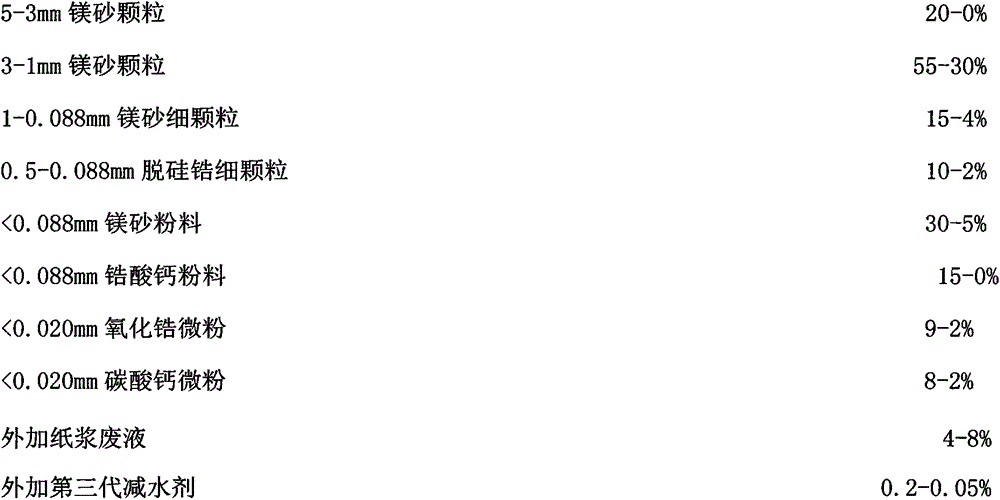

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

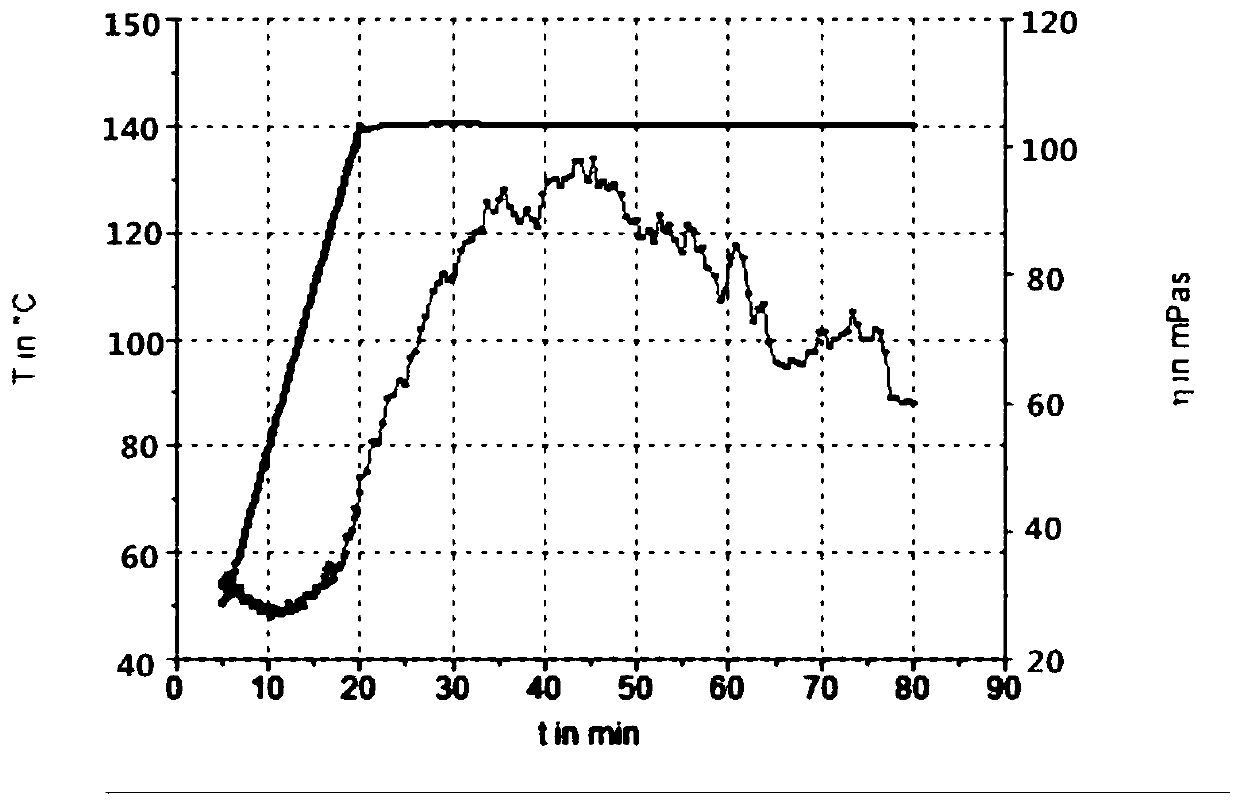

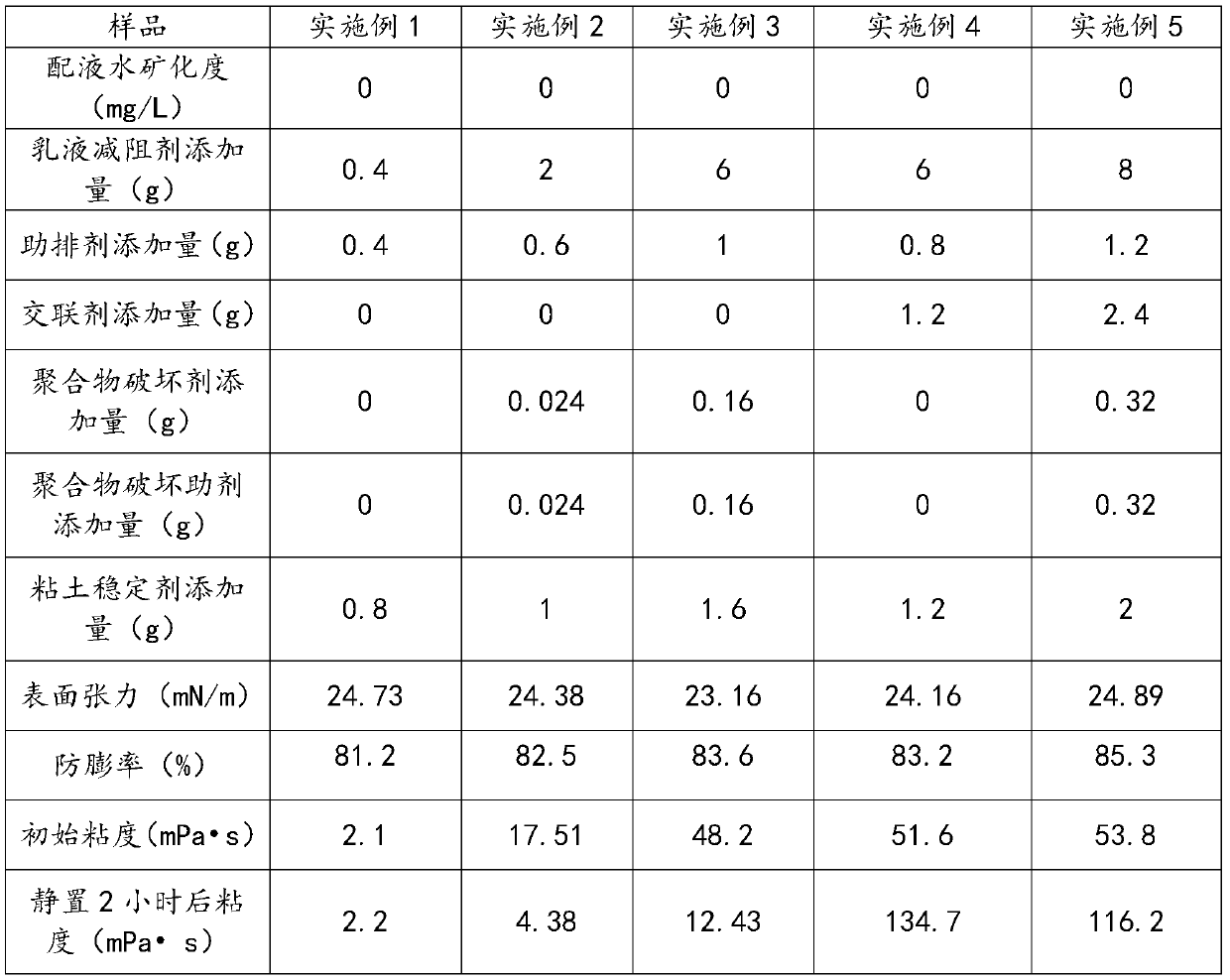

Multifunctional emulsion-type salt-tolerant fracturing fluid and production method thereof

InactiveCN110437817AMolecular structure is complexGood drag reduction effectDrilling compositionEmulsionFracturing fluid

The invention relates to the technical field of fracturing reformation of oil and gas reservoirs, in particular to multifunctional emulsion-type salt-tolerant fracturing fluid and a production methodthereof. The multifunctional emulsion-type salt-tolerant fracturing fluid comprises the following raw materials in parts by weight: 0.1-2 parts of an emulsion drag reducer, 0.1-0.3 part of a cleanup additive, 0.2-0.5 part of a clay stabilizer, 0-0.6 part of cross-linking agents, 0-0.08 part of polymer breakers, 0-0.08 part of polymer breaking assistants and 100 parts of water, wherein the emulsiondrag reducer is hyperbranched amphoteric polyacrylamide and a derivative of the hyperbranched amphoteric polyacrylamide. According to the multifunctional emulsion-type salt-tolerant fracturing fluidand the production method thereof, through synergism of the emulsion drag reducer and the components, the fracturing fluid with excellent comprehensive performance of temperature resistance, salt tolerance, shear resistance, anti-swelling performance and the like is obtained so that different requirements of a reservoir can be met.

Owner:CHINA PETROCHEMICAL CORP +3

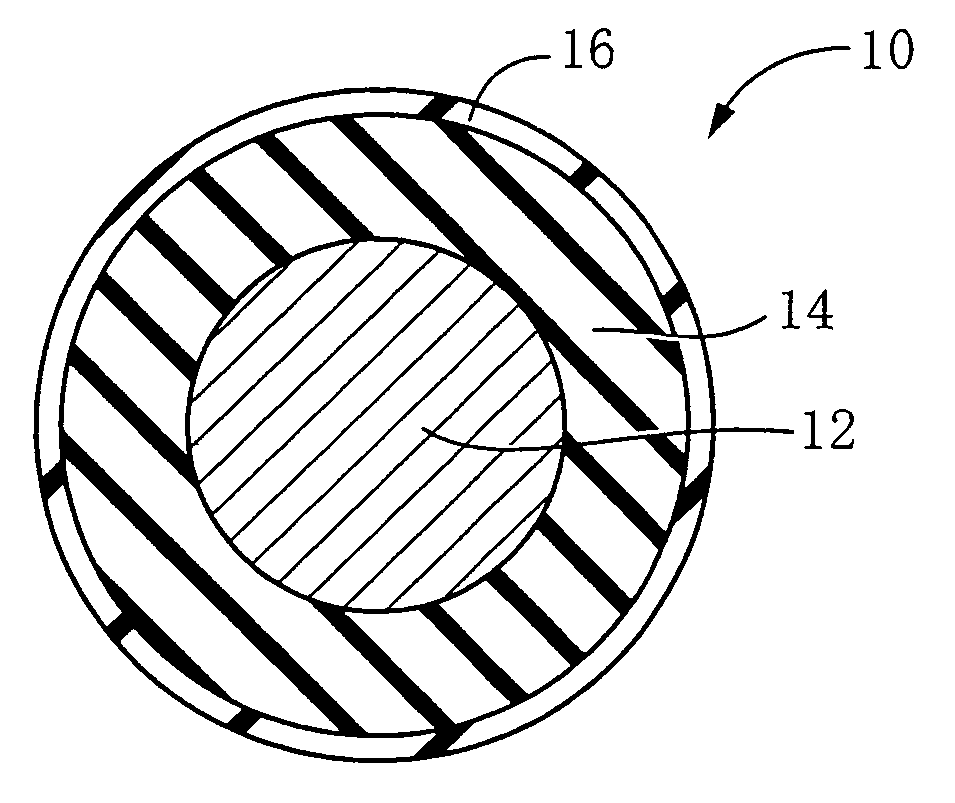

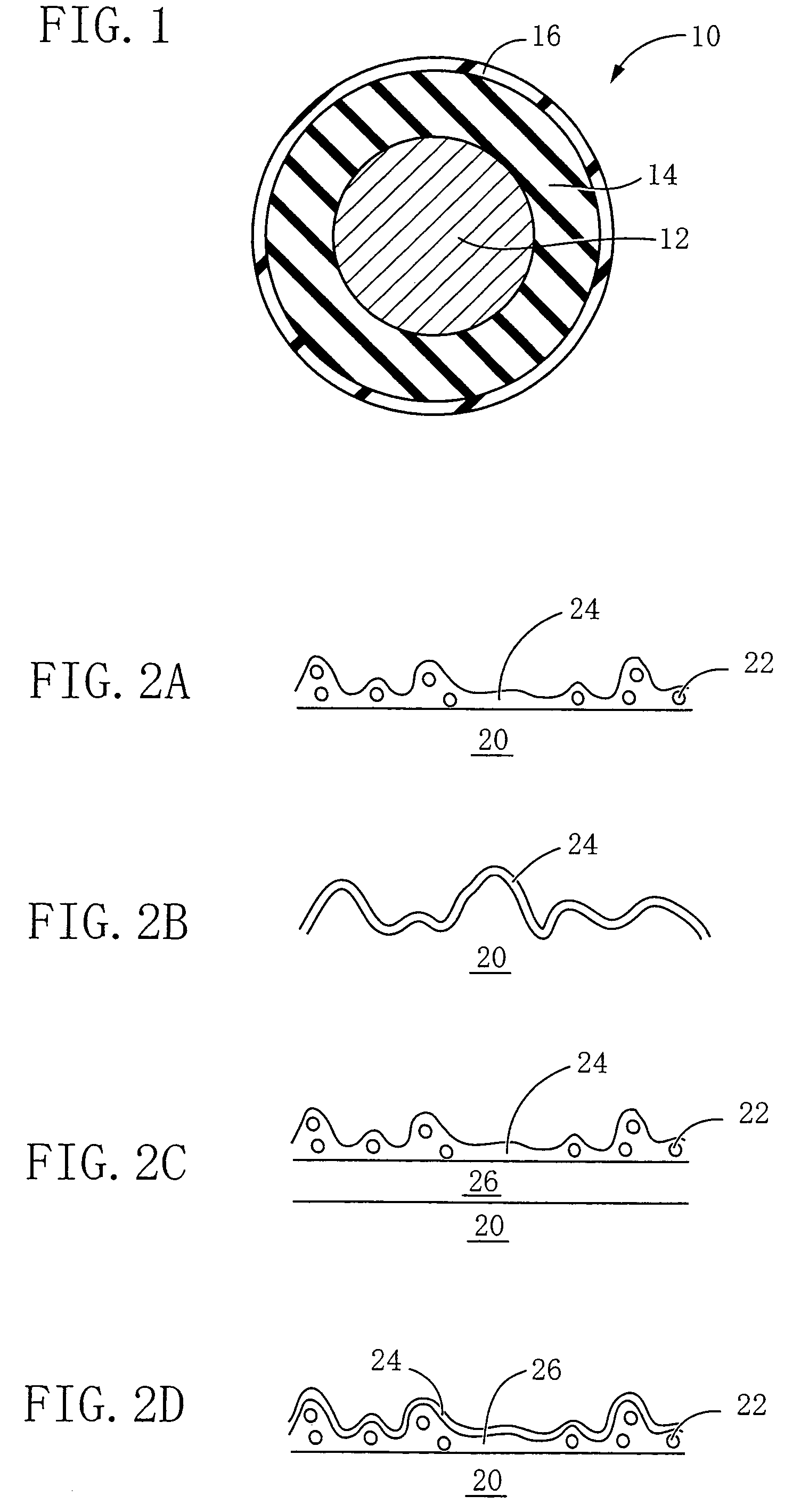

Semi-conductive roll

ActiveUS7288058B2Improve accuracyEasy to controlShaft and bearingsMetal-working apparatusRubber materialElastomer

A semi-conductive roll is provided including a shaft, a low-hardness base layer formed on an outer circumferential surface of the shaft, and a coating layer formed by coating the low-hardness base layer radially outwardly. The coating layer includes one of a rubber material and an elastomer material that is crosslinked by at least one resin crosslinking agent.

Owner:TOKAI RUBBER IND LTD

Flame retardation cladding adhesive for polystyrene prefoamed beads, and product thereof

The invention provides a flame retardation cladding adhesive for polystyrene prefoamed beads, and a product thereof, and concretely relates to a flame retardation cladding adhesive specially used for cladding polystyrene prefoamed beads, and a modified polystyrene flame retardation foam sheet made by using the flame retardation cladding adhesive. The polystyrene prefoamed bead flame retardation cladding adhesive adopting modified urea formaldehyde resin with toughening and film forming performances as an adhesion medium has excellent flame retardation characteristic, and can effectively improve the flame retardation performance of a polystyrene foam material; and the modified urea formaldehyde resin with toughening and film forming performances adopted in the invention allows a weak acidic substance to be used as a curing agent of the flame retardation cladding adhesive, so damages of a strong acid curing agent similar to phenolic resin to human bodies, environment and apparatuses are avoided.

Owner:吴福胜

Quick settling type flocculating agent and its preparation method

ActiveCN1597549AReduce degradationAvoid degradationWater/sewage treatment by flocculation/precipitationSewagePolyacrylamide

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyethylene-polystyrene foam and preparation method thereof

ActiveCN101824198AUniform concentration distributionAvoid homopolymerizationPre irradiationFunctional monomer

The invention relates to a polyethylene-polystyrene foam, which is formed in a way that polystyrene is grafted on a molecular chain of polyethylene to connect the polyethylene with the polystyrene by a covalent chemical bond, wherein the grafting ratio mass percent of the grafted polystyrene is 25-60%, and the volume density of the polyethylene-polystyrene foam is 27-208kg / m<3>. The preparation method comprises the following steps: carrying out pre-irradiation treatment on the polyethylene; and adding the polyethylene after the pre-irradiation treatment, dispersant, functional monomer, emulsifying agent, nucleating agent and homopolymerization depressor to a reaction vessel to be subject to suspension graft polymerization reaction, adding foaming agent, cooling the reaction product, filtering, washing with water, drying, and heating to obtain the polyethylene-polystyrene foam. The polyethylene-polystyrene foam has the advantages of excellent mechanical property, favorable rebound elasticity, good stress cracking resistance, high impact absorbing capacity and the like, combines the flexibility of polyethylene foam and the rigidity of polystyrene foam, and is used in the fields of vehicles, buildings, packaging, heat preservation, heat insulation and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Procyanidin capsules and process for manufacturing same

InactiveCN101642445AEasy to eatPromote absorptionOrganic active ingredientsCapsule deliveryWrinkle skinMagnesium stearate

The invention discloses a procyanidin capsules and a process for manufacturing the same. The capsules are manufactured by taking procyanidin and astragalus polysaccharide as main materials and caseinphospho peptides or D-mannitol, magnesium stearate and gelatin as auxiliary materials. The capsule has the advantages of being conveniently taken, avoiding absorbing moisture and having functions of immunoregulation, anti-ageing and radiation hardening, protecting cardiovascular health by removing free radicals in vivo, and preventing crosslinking of skin collagens, inhibiting pigmentation, dispelling wrinkles and whitening the skin, keeping skin elasticity and delaying ageing.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Descaling cleaning agent for poly-containing dirt on polymer flooding produced liquid treatment equipment

InactiveCN104293504AImprove solvencyImprove degreasing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolventIon

The invention belongs to the technical field of cleaning of polymer flooding produced liquid treatment equipment in the petroleum industry and provides a descaling cleaning agent for poly-containing dirt on polymer flooding produced liquid treatment equipment. The descaling cleaning agent comprises the following components in percentage by weight: 8-20wt% of polymer dispersant, 20-40wt% of oil scavenger, 35-55wt% of mutual solvent, 1-6wt% of metal ion chelating agent and the balance of water. The descaling cleaning agent provided by the invention has a good removal effect on the poly-containing dirt on electric dehydration systems, heat exchangers and sewage treatment systems and has stable performance, thereby being suitable for ocean transportation and long-term storage.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

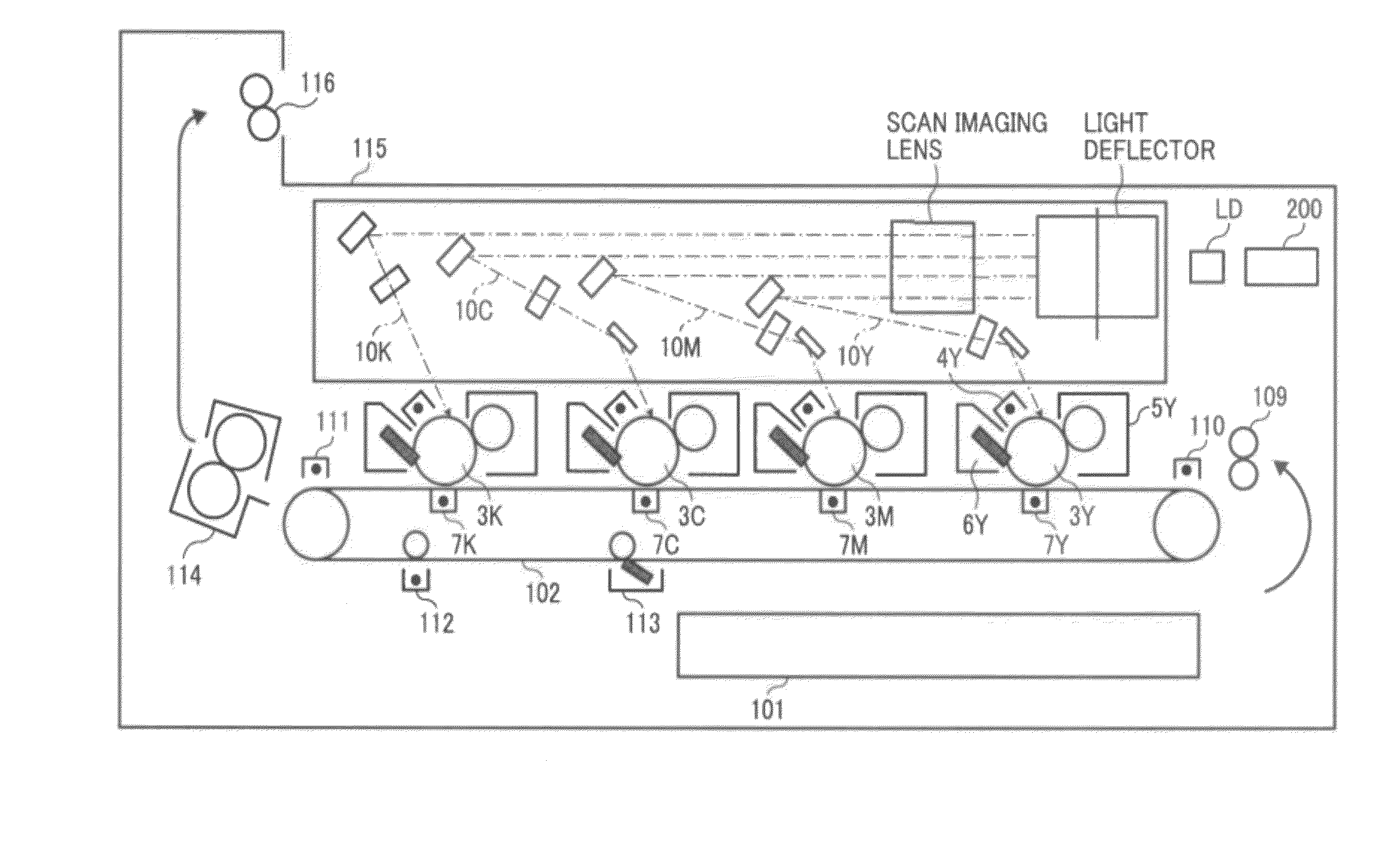

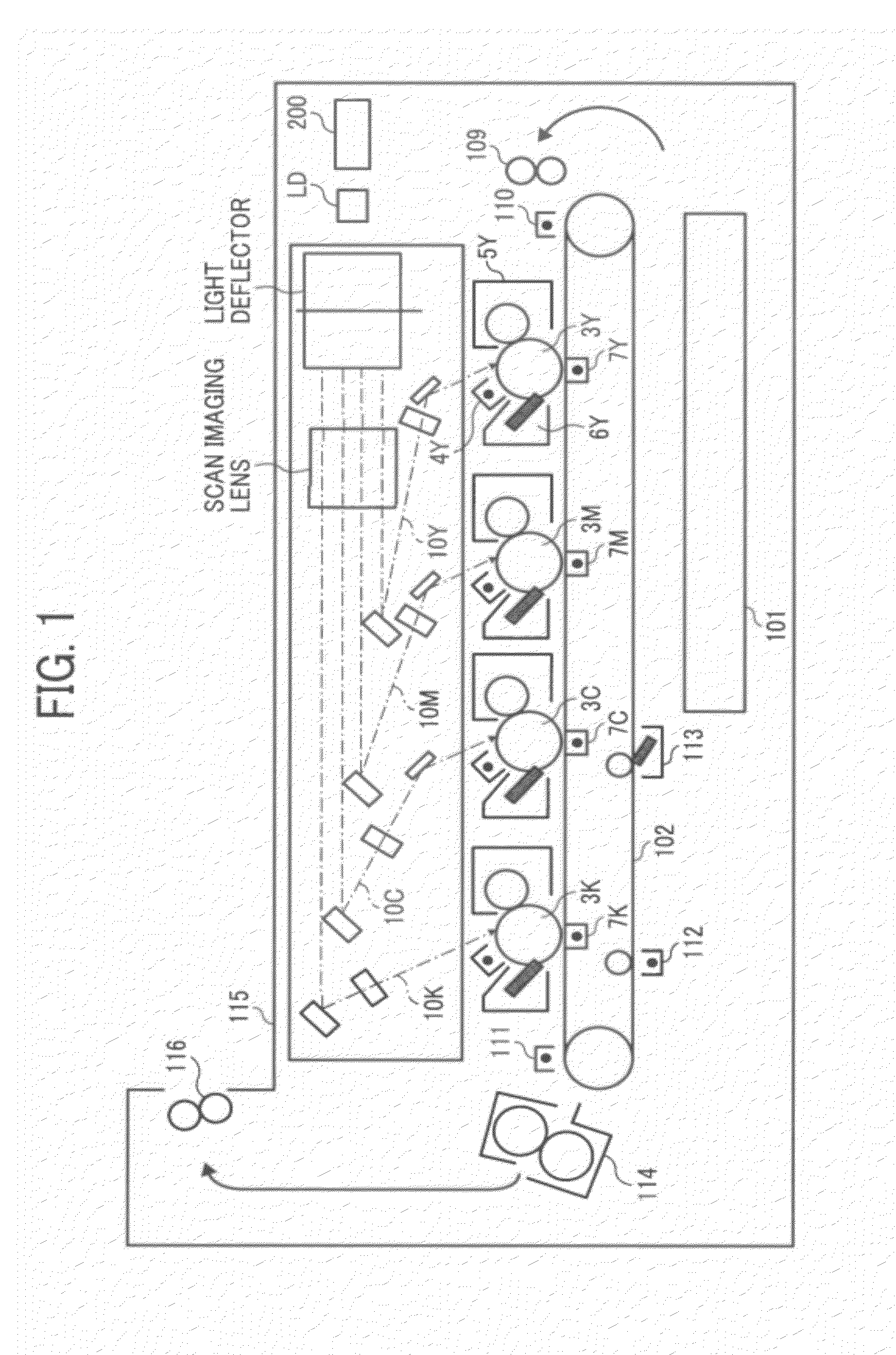

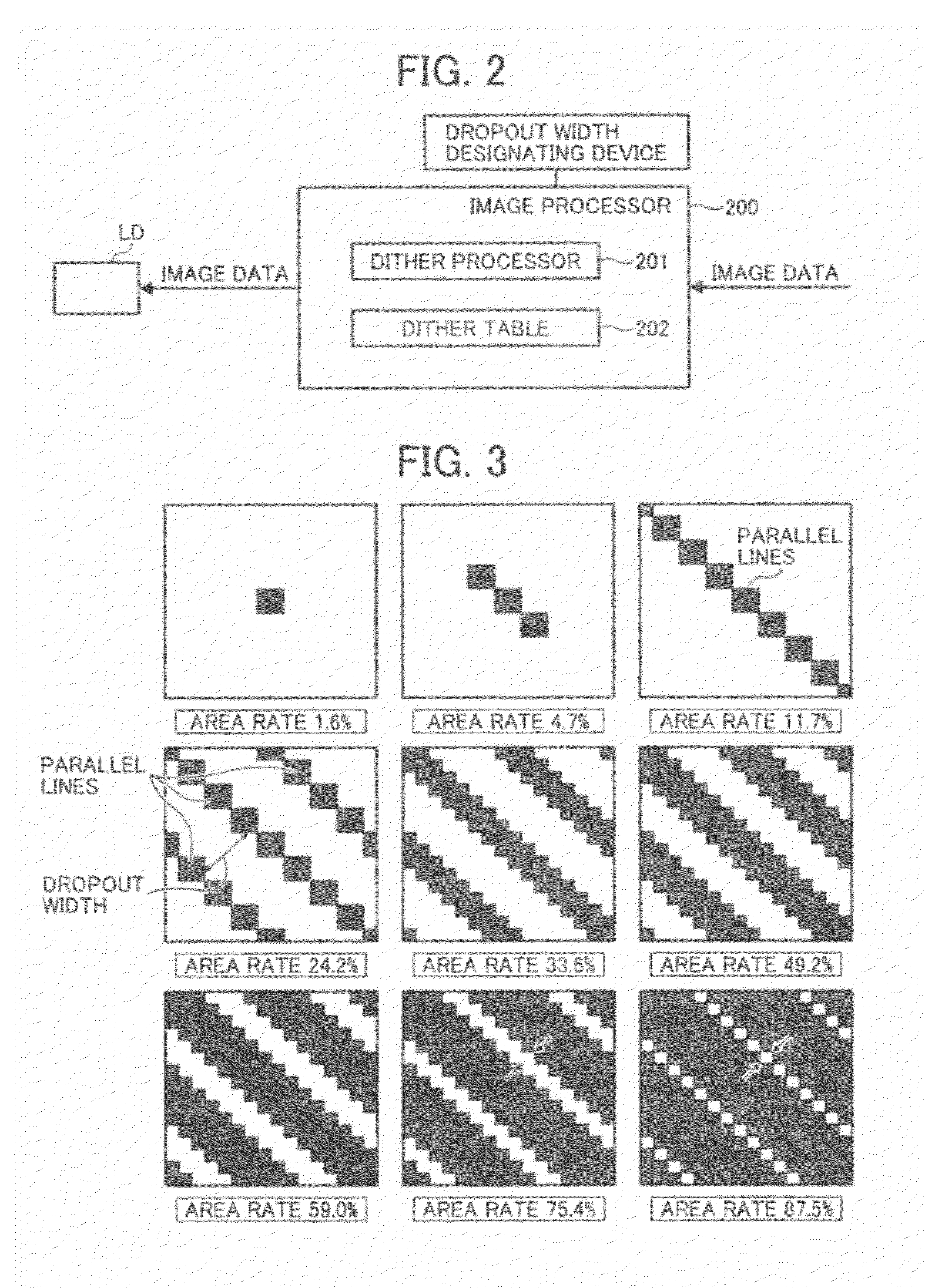

Image processing apparatus, control method, and computer program product capable of minimizing cross-linkage between line screens

InactiveUS20120120454A1Avoid crosslinkingReduce in quantityVisual presentationElectrographic process apparatusPattern recognitionImaging processing

An image processing apparatus comprises a dither processing device that applies dither processing to input image data to express halftone using line screens by increasing an area rate of the input image data and a controller that decreases the number of line screens and maintains a prescribed dropout width between the neighboring line screens when the area rate of the input image data increases and the dropout width falls below a prescribed level.

Owner:RICOH KK

3-deoxyglucosone and skin

The invention relates to the discovery that 3-deoxyglucosone (3DG) and other alpha-dicarbonyl sugars associated diseases and disorders are present and produced in the skin. Further, the invention relates to the discovery that amadorase, an enzyme that mediates 3DG synthesis, is also present in the skin. Thus, the invention further relates to methods of inhibiting production and function of 3-deoxyglucosone and other alpha-dicarbonyl sugars in skin thereby treating or prevention various diseases, disorders or conditions. Additionally, the invention relates to treatment of various diseases, disorders or conditions associated with or mediated by oxidative stress since 3DG induces ROS and AGEs, which are associated with the inflammatory response caused by oxidative stress.

Owner:DYNAMIS THERAPEUTICS

Neoadjuvant use of antibody-drug conjugates

InactiveUS20160095939A1Enhance therapyImprove efficacyOrganic active ingredientsIn-vivo radioactive preparationsStandard treatmentAntibody

Owner:IMMUNOMEDICS INC

LED coating for encapsulating quantum dots by multiple layers and preparation method thereof

PendingCN108511582ADense high barrier particlesControl glow qualityLuminescent paintsSemiconductor devicesQuantum dotHigh surface

The invention relates to an LED coating for encapsulating quantum dots by multiple layers. The LED coating comprises a traditional encapsulation material layer and a plurality of encapsulation particles of quantum dots and scattered particles, which are scattered in the traditional encapsulation material layer, wherein from inside to outside, the encapsulation particle of the quantum dot and the scattered particle comprises a quantum dot, a compatible polymer layer and a water and oxygen barrier film layer in sequence, and a plurality of inorganic nano scattered particles are scattered in thecompatible polymer layer. The compatible polymer and the quantum dot are highly compatible, so that the high surface energy property of the quantum dot is prevented from damaging colloid crosslinking,and the quantum dot is more stable. According to the LED coating, the quantum dot is wrapped in the compatible polymer and then is crushed into particles, the surface of the particle is encapsulatedby the water and oxygen barrier film layer, and finally, the obtained particles are scattered in another colloid, so as to prepare the quantum dot coating, therefore, the quantum dots are less likelyto gather so as to maintain the luminescence performance; and the multilayer encapsulation structure improves the water and oxygen blocking performance of the quantum dot coating.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com