Preparation method of nascent fiber for production of carbon fiber

A technology of primary fiber and carbon fiber, which is applied in the direction of fiber chemical characteristics, conjugated artificial filament, conjugated synthetic polymer artificial filament, etc. It can solve the problems of hydroxyl crosslinking, limit the application of carbon fiber, and cannot be quickly stabilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 0.8 L of acetic anhydride was added to 1 kg of kraft lignin (Sinopharm Group, Aldrich), the reaction temperature was 86° C., and the reaction time was 15 min to prepare acetylated kraft lignin for use.

[0035] (2) Dissolve 400g of acetylated kraft lignin in 1.6kg of dimethylformamide to make solution a, and dissolve 400g of polyacrylonitrile resin (Sinopharm Group, Aldrich) in 1.6kg of dimethylformamide under a nitrogen atmosphere. Solution b was prepared in formamide. Under a nitrogen atmosphere, solution a and solution b were mechanically stirred, the mass ratio of acetylated kraft lignin to polyacrylonitrile in the blend solution was 150:100, and the blend solution was kept at a constant temperature of 40°C to obtain a solid content of 20 wt% homogeneous spinning solution.

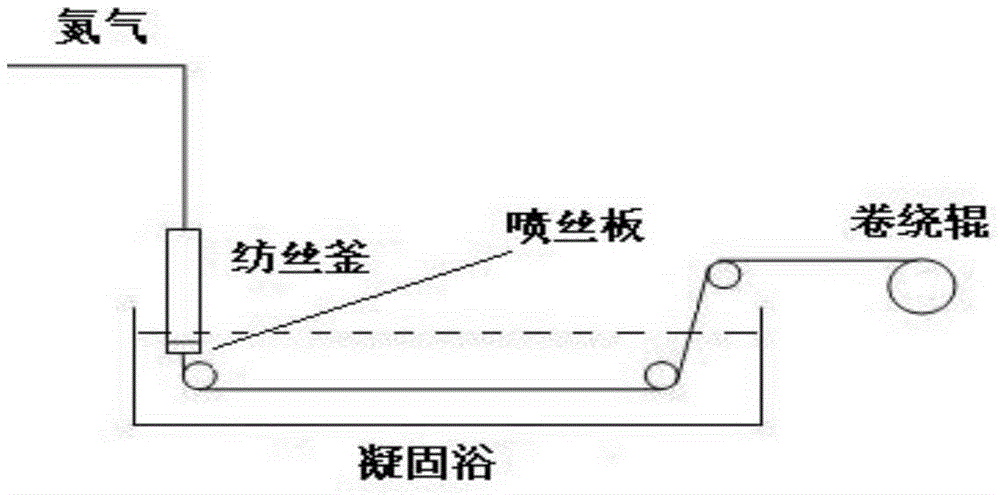

[0036] (3) Transfer the spinning solution to the spinning kettle and keep the spinning solution at a constant temperature of 40°C. Under the nitrogen pressure of 0.9MPa, the spinning solut...

Embodiment 2

[0038](1) Mix 1.2L of concentrated sulfuric acid (98%wt) and 2kg of distilled water to make a sulfuric acid solution, then add 1kg of alkali lignin (Sinopharm Group, TCI-L0082) into the sulfuric acid solution, keep the reaction temperature at 80°C, and the reaction time is 1.5 h. After the reaction, the reaction liquid is dried to prepare sulfoalkali lignin for future use.

[0039] (2) Dissolve 400g of sulfoalkali lignin in 1.6kg of dimethylacetamide to make solution a, and dissolve 600g of polyacrylonitrile resin (Sinopharm Group, Aldrich) in 1.4kg of dimethylacetamide under a nitrogen atmosphere. Solution b was prepared in amide. Under a nitrogen atmosphere, solution a and solution b were kneaded by a kneader, the mass ratio of sulfoalkali lignin to polyacrylonitrile in the blend solution was 53:100, and the blend solution was kept at a constant temperature of 50°C to obtain a solid content of 25 wt% homogeneous spinning solution.

[0040] (3) Transfer the spinning solutio...

Embodiment 3

[0042] (1) Add 100 g of concentrated ammonia water (28% wt) to 1 kg of kraft lignin (Sinopharm Group, Aldrich), stir mechanically for 1 hour, and store the ammoniated kraft lignin in a sealed container.

[0043] (2) Dissolve 440 g of ammoniated kraft lignin in 1.6 kg of dimethyl sulfoxide to make solution a, and dissolve 800 g of polyacrylonitrile resin (Sinopharm Group, Aldrich) in 1.2 kg of dimethyl sulfoxide under a nitrogen atmosphere. Prepare solution b in sulfoxide. Under a nitrogen atmosphere, solution a and solution b were extruded and mixed through a twin-screw machine, the mass ratio of ammoniated kraft lignin to polyacrylonitrile in the blended solution was 35:100, and the blended solution was kept at a constant temperature of 60°C. A homogeneous spinning solution with a solid content of 31% by weight was obtained.

[0044] (3) Transfer the spinning solution to the spinning kettle and keep the spinning solution at a constant temperature of 60°C. Under the nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com