Fiber with modified cross section and fiber for artificial hair formed of the same

A special-shaped cross-section and fiber technology, which is applied in fiber processing, textiles and papermaking, and single-component halogenated hydrocarbon artificial filaments. It can solve the problems of reduced softness and bulkiness, and achieve excellent bulkiness and stable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

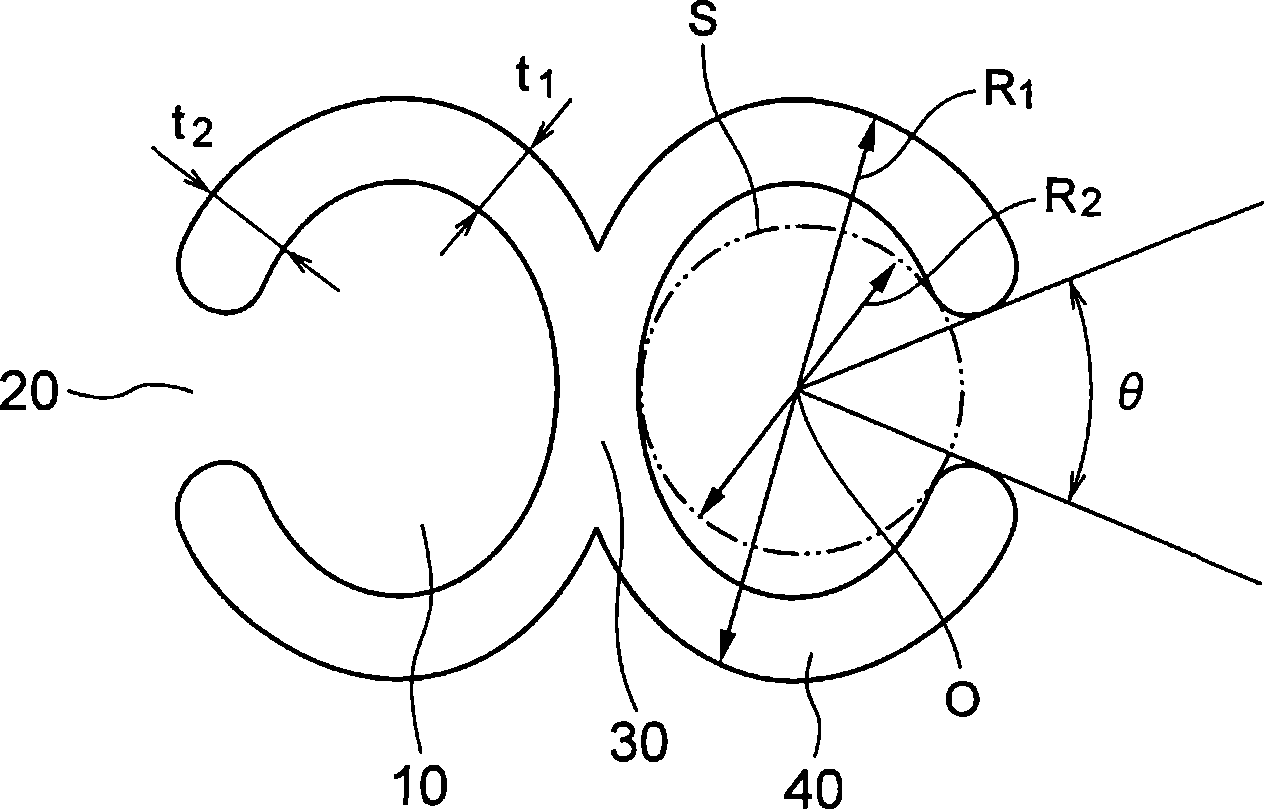

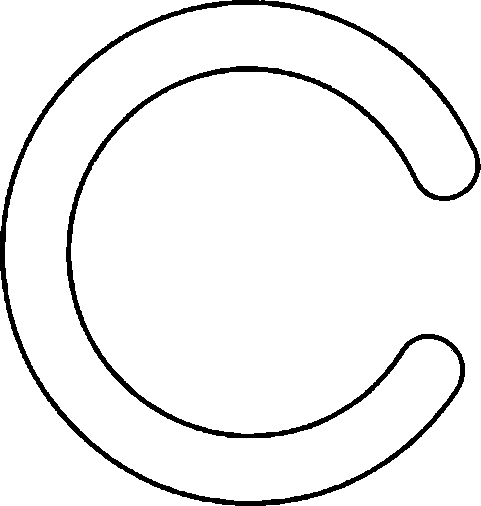

[0086] Through the following steps in sequence, the size (R) shown in Table 1 is obtained 1 and R 2 The unit of θ is μm, the unit of θ is degree), and the cross-sectional shape of the special-shaped cross-section fiber with a fineness of 67 dtex: (a) use a ribbon mixer to mix vinyl chloride resin (TH-1000 manufactured by Dayang Shibi Co., Ltd.) 100 by mass 3 parts by mass, hydrotalcite-based composite heat stabilizer (CP-410A manufactured by Nissan Chemical Industry Co., Ltd.) (the heat stabilizer component is 1.5 parts by mass), epoxidized soybean oil (O-130P manufactured by Asahi Denka Industry Co., Ltd.) 0.5 parts by mass, an ester lubricant (EW-100 manufactured by Riken Vitamin Co., Ltd. EW-100) and 0.8 parts by mass of a vinyl chloride resin composition are mixed; (b) using figure 1 The nozzle shape shown is "approximately C-shaped back close", and the nozzle cross-sectional area is 0.06mm 2 and a spinning die with 120 nozzle holes, melt-spinning the above-mentioned mix...

Embodiment 2~7

[0089] In Examples 2 to 7, except that the shape of the nozzle in the step (b) of Example 1 was changed to have the cross-sectional shape of the dimensions shown in Table 1, the rest was performed in the same manner as in Example 1 to obtain fibers with special-shaped cross-sections.

Embodiment 8

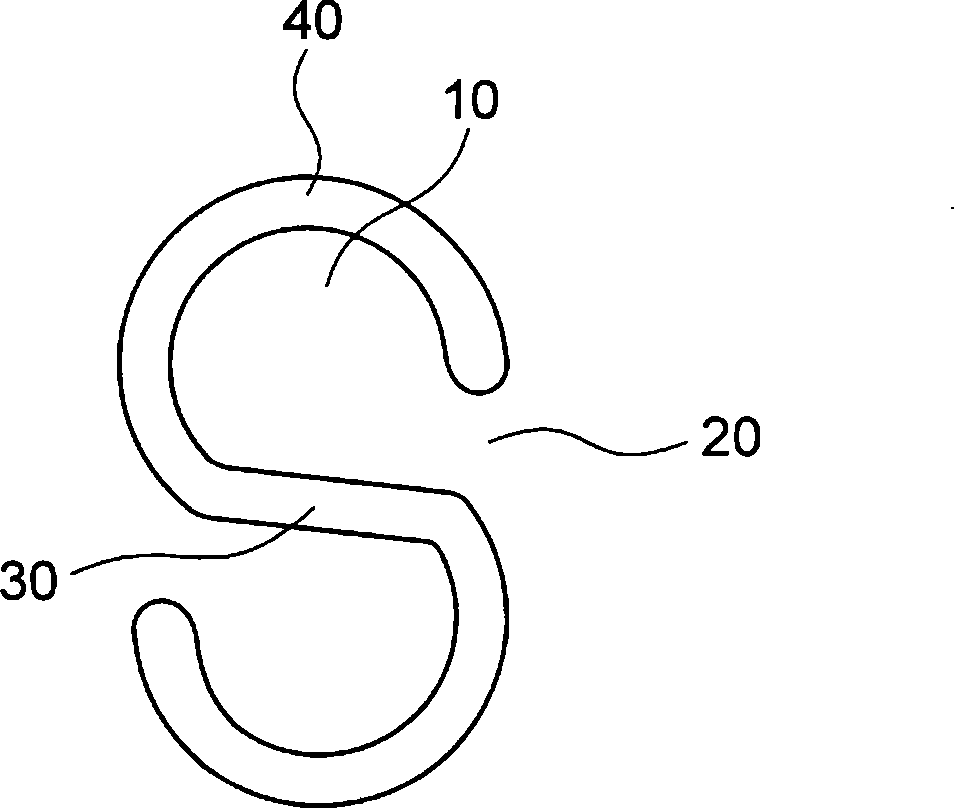

[0091] In addition to changing the nozzle shape of the (b) step of Example 1 to figure 2 Except for the "S shape" shown, the other operations were performed in the same manner as in Example 1 to obtain fibers with special-shaped cross-sections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com