Blended yarn weaved fabric

A technology of blended fabrics and mixed strips, which is applied in textiles, textiles, papermaking, yarns, etc., can solve the problems that cannot be directly blended, and achieve the effects of improving easy pilling, good hygroscopicity, and ease of weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

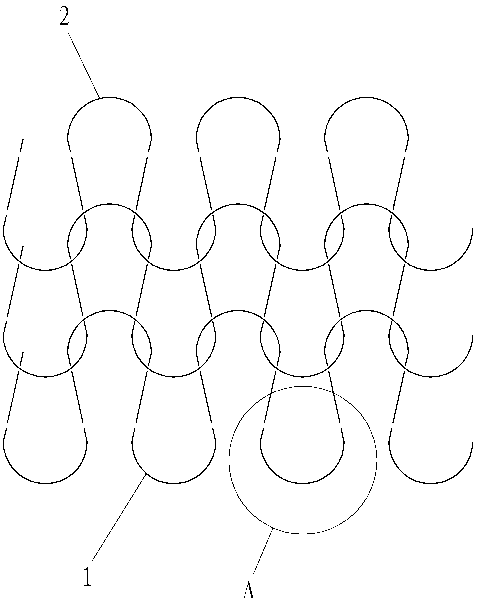

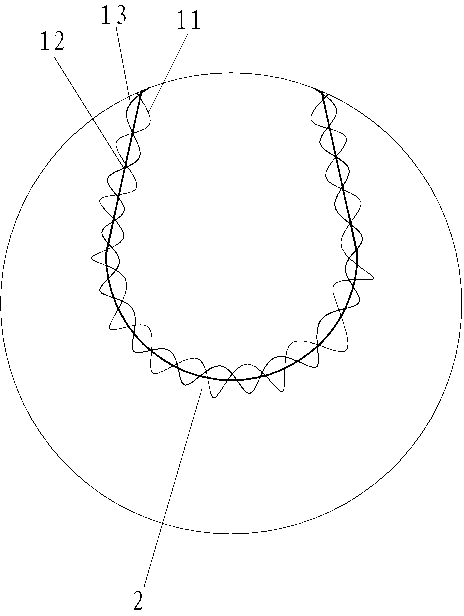

[0017] A blended fabric, comprising woolen yarn 12, spun silk yarn 11 and long-staple cotton yarn 13, the woolen yarn 12, spun silk yarn 11 and long-staple cotton yarn 13 are respectively made of strip-shaped semi-wool fiber, silk fiber Composed of long-staple cotton fibers, semi-wool fibers, silk fibers and long-staple cotton fibers are mixed and entangled with each other, and through merging and drafting processes, fiber strips 2 are formed. The fiber strips constitute a mixed strip, and the mixed strip includes 20 fiber strips 2; Among them, the counts of wool yarn 12, spun silk yarn 11 and long-staple cotton yarn 13 are all 36s, and the twist coefficients of wool yarn 12, spun silk yarn 11 and long-staple cotton yarn 13 are all metric 85 .

[0018] Then, use epoxy-terminated dimethylsiloxane, polyether amine, and synthetic quaternary ammonium salt polyether silicone ternary copolymerization finishing agent containing epoxy quaternary ammonium salt as raw materials to finis...

Embodiment 2

[0021] The difference from Example 1 is that the counts of the woolen yarn 12, the spun silk yarn 11 and the long-staple cotton yarn 13 are all 80s, and the counts of the woolen yarn 12, the spun silk yarn 11 and the long-staple cotton yarn 13 The twist coefficient is 114 in metric system.

Embodiment 3

[0023] The difference from Example 1 is that the counts of the woolen yarn 12, the spun silk yarn 11 and the long-staple cotton yarn 13 are all 50s, and the counts of the woolen yarn 12, the spun silk yarn 11 and the long-staple cotton yarn 13 Twist coefficients are metric 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com