Method for producing PBT (Polythylene Terephthalate) color point core spun yarns

A production method and core-spun yarn technology, applied in the field of yarn production, can solve the problems of insufficient color, unsatisfactory dyeing effect, and poor bulkiness of the core-spun yarn, and achieve rich colors, good elasticity, good bulkiness and curling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

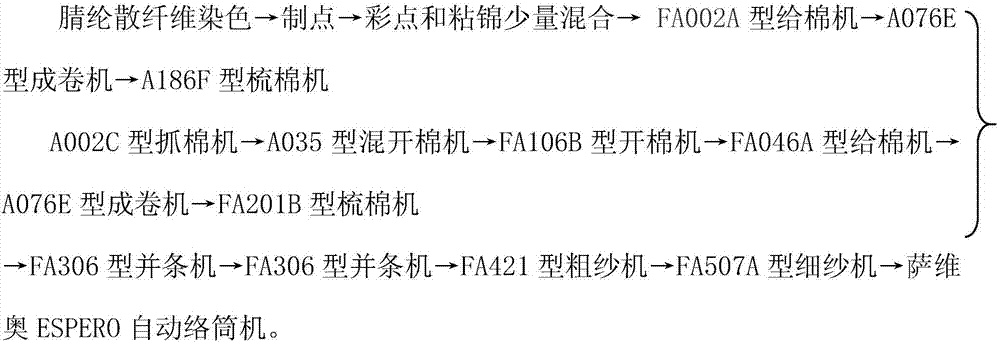

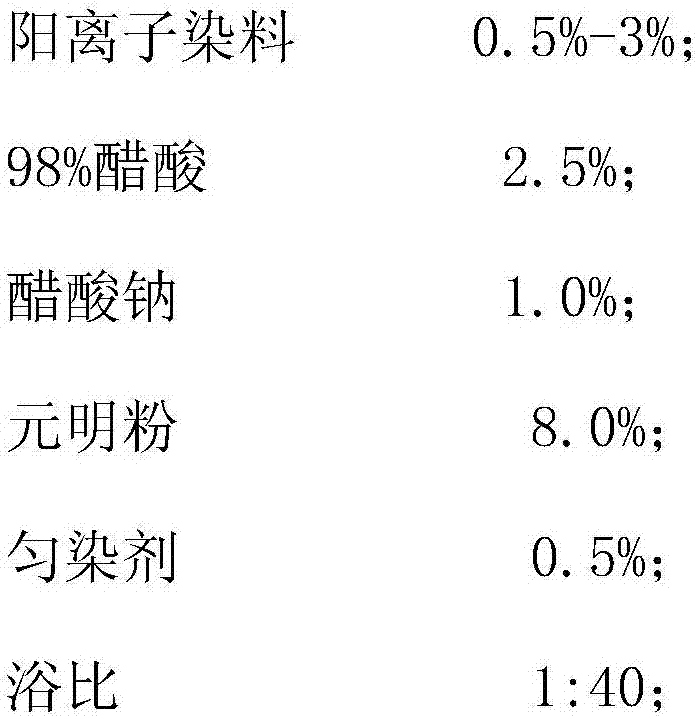

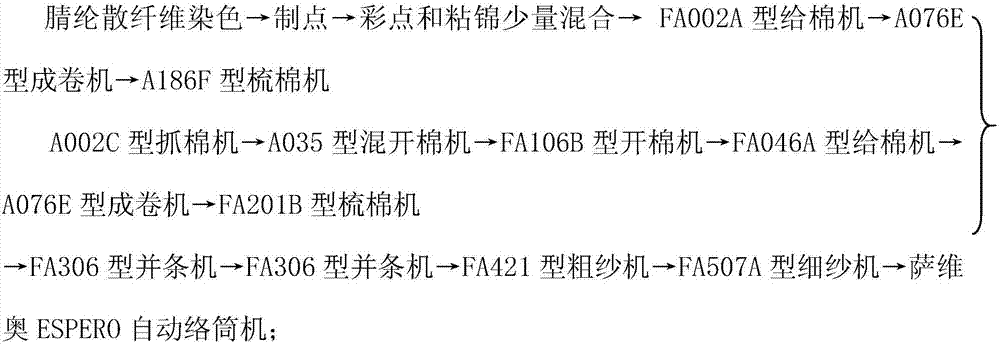

[0044] A kind of production method of PBT colored point core-spun yarn

[0045] (1) Selection of yarn raw materials

[0046] Viscose fiber: fineness 1.33dtex, length 38mm, dry breaking strength 2.3cN / dtex, elongation 20%, moisture regain 12.8%;

[0047] Nylon fiber: fineness 1.67dtex, length 38mm, dry breaking strength 35cN / dtex, elongation 45%, moisture regain 5%;

[0048] PBT polyester filament: 55dtex*24F, breaking strength 0.63cN / dtex, breaking elongation 660%, tensile strength 1.15cN / dtex, boiling water shrinkage 30%, moisture regain 0.4%.

[0049] 55 / dtex×24FPBT polyester yarn is used for production, the thicker the polyester yarn, the greater its elasticity. If PBT polyester yarn is not stretched, it will not have elasticity. The pre-drawing of polyester yarn is generally within 3 to 5 times. If it is too low, it is not suitable to take advantage of the elasticity. If it is too high, it will inevitably cause breakage and make spinning difficult. . The higher the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com