Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

A technology of spunbond nonwoven fabric and production process, applied in the field of spunbond nonwoven fabric, can solve the problems of poor diversion effect and slow production speed of diversion layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

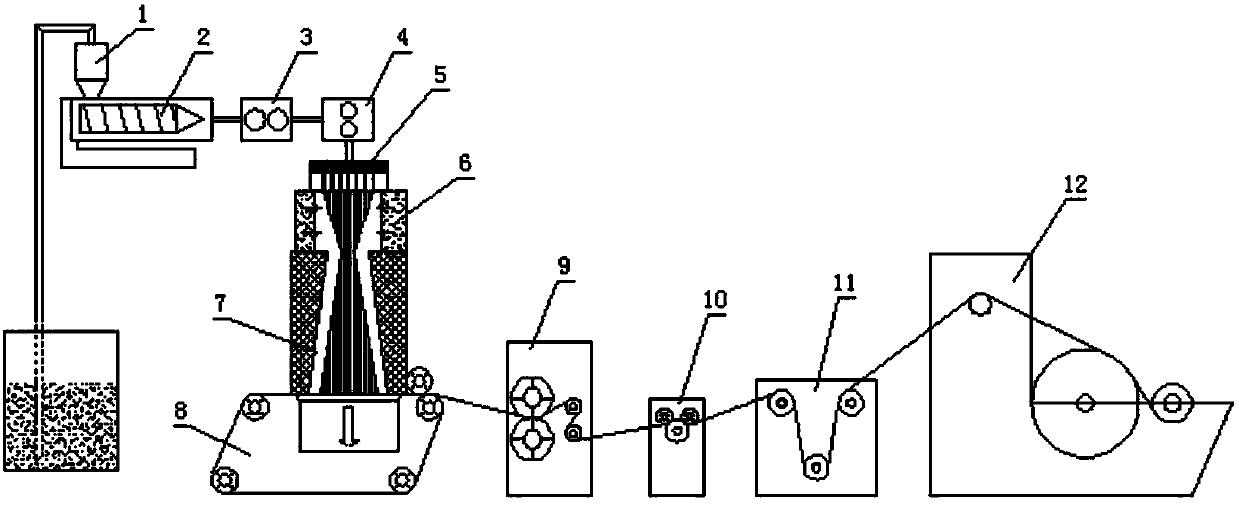

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] The invention discloses a spun-bonded nonwoven fabric product used for the flow guide layer of diapers, which comprises an absorbent core, the absorbent core is composed of coarse denier fibers, the direction of the coarse denier fibers is the longitudinal direction, and the direction of the coarse denier fibers is The pattern is a stripe pattern, the pattern of the absorbent core is a straight pattern, and the direction of the pattern of the absorbent core is consistent with the fiber direction.

[0028] The invention also discloses a production process of a spunbonded nonwoven fabric used for the diversion layer of diapers, such as figure 1 shown, including the following steps:

[0029] ①Using low melt index polypropylene raw material, spunbond raw material Z30S production, through vacuum suction into the hopper;

[0030] ② Extrude and melt the raw materials on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com