Patents

Literature

71results about How to "Prolonged diffusion time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

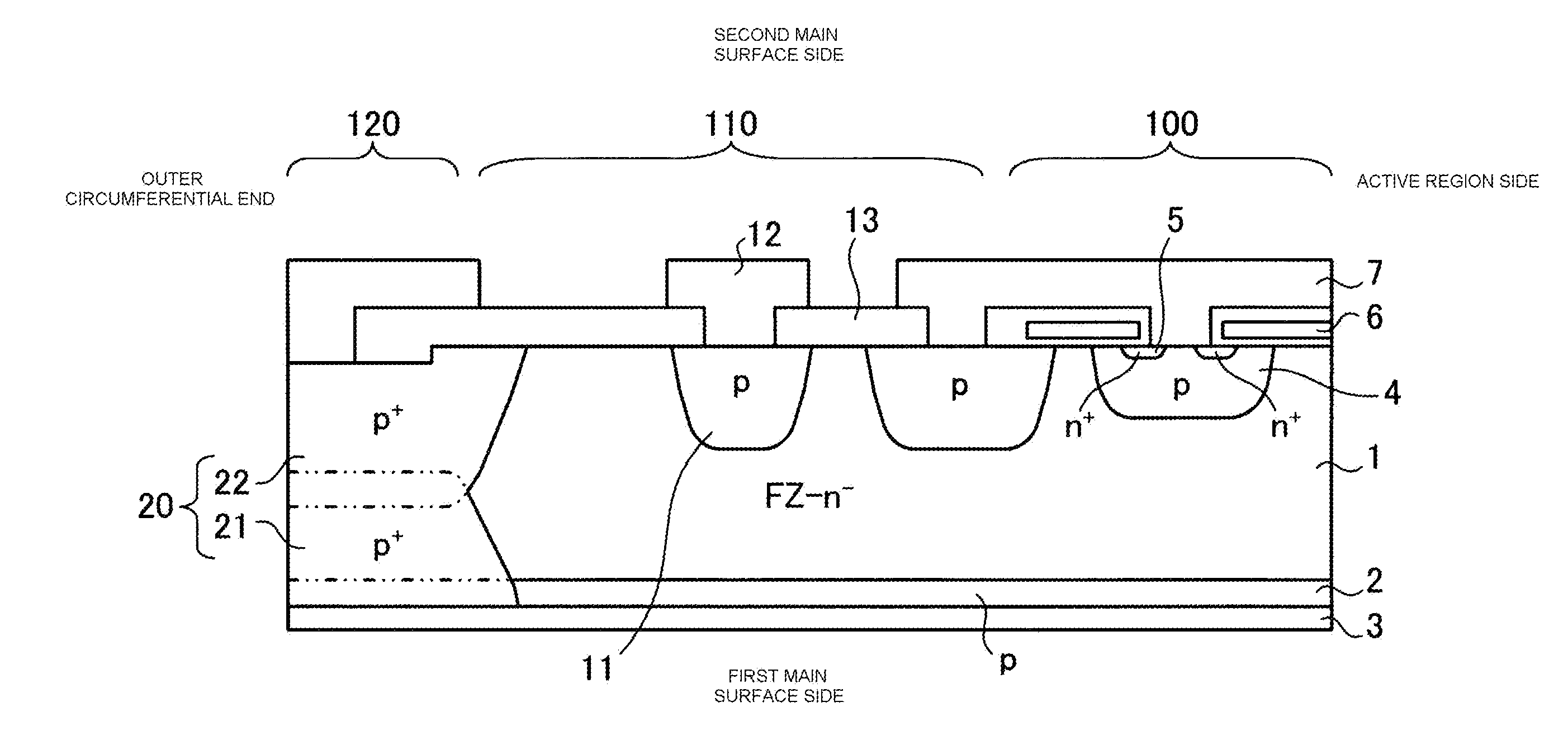

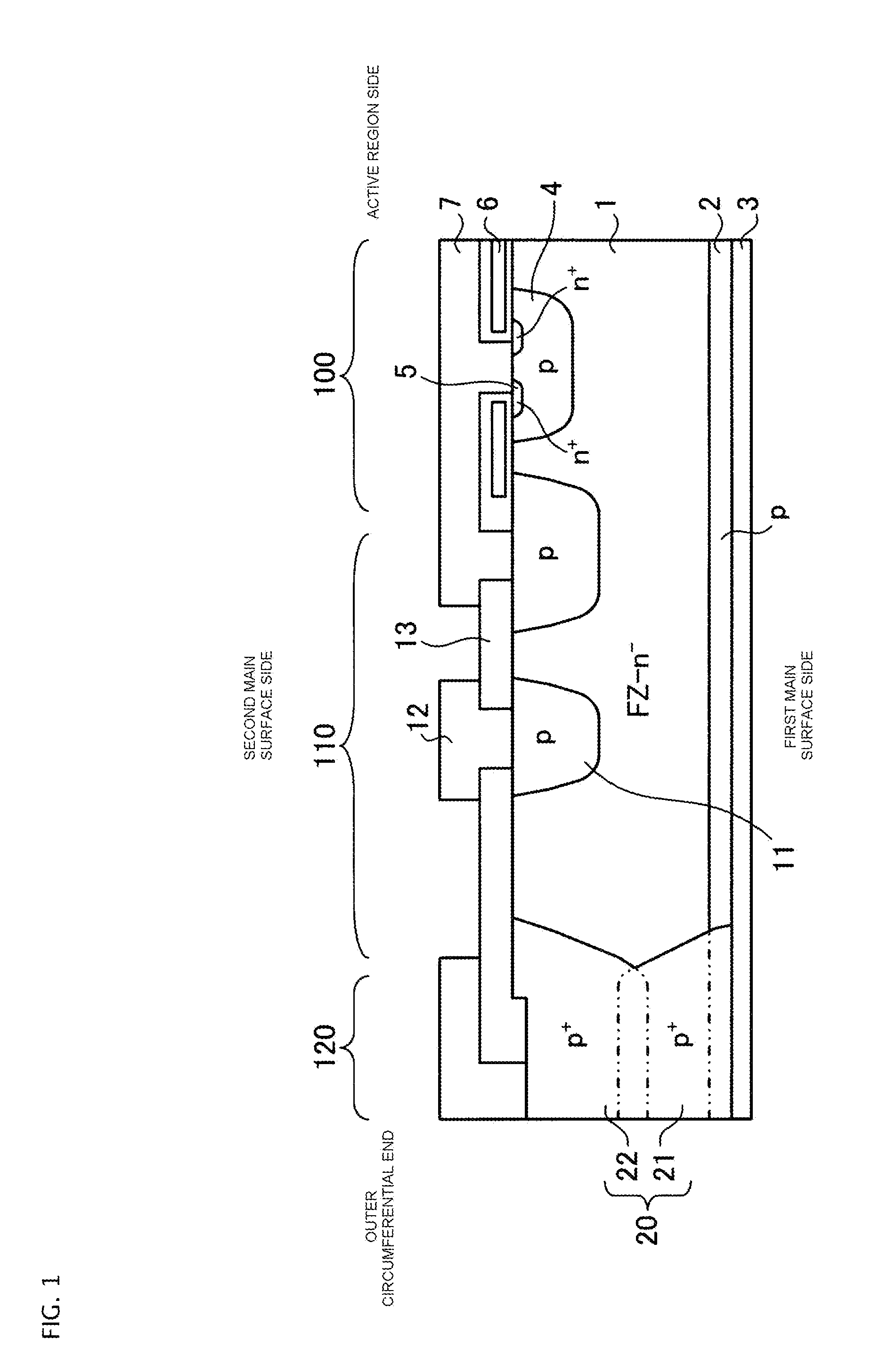

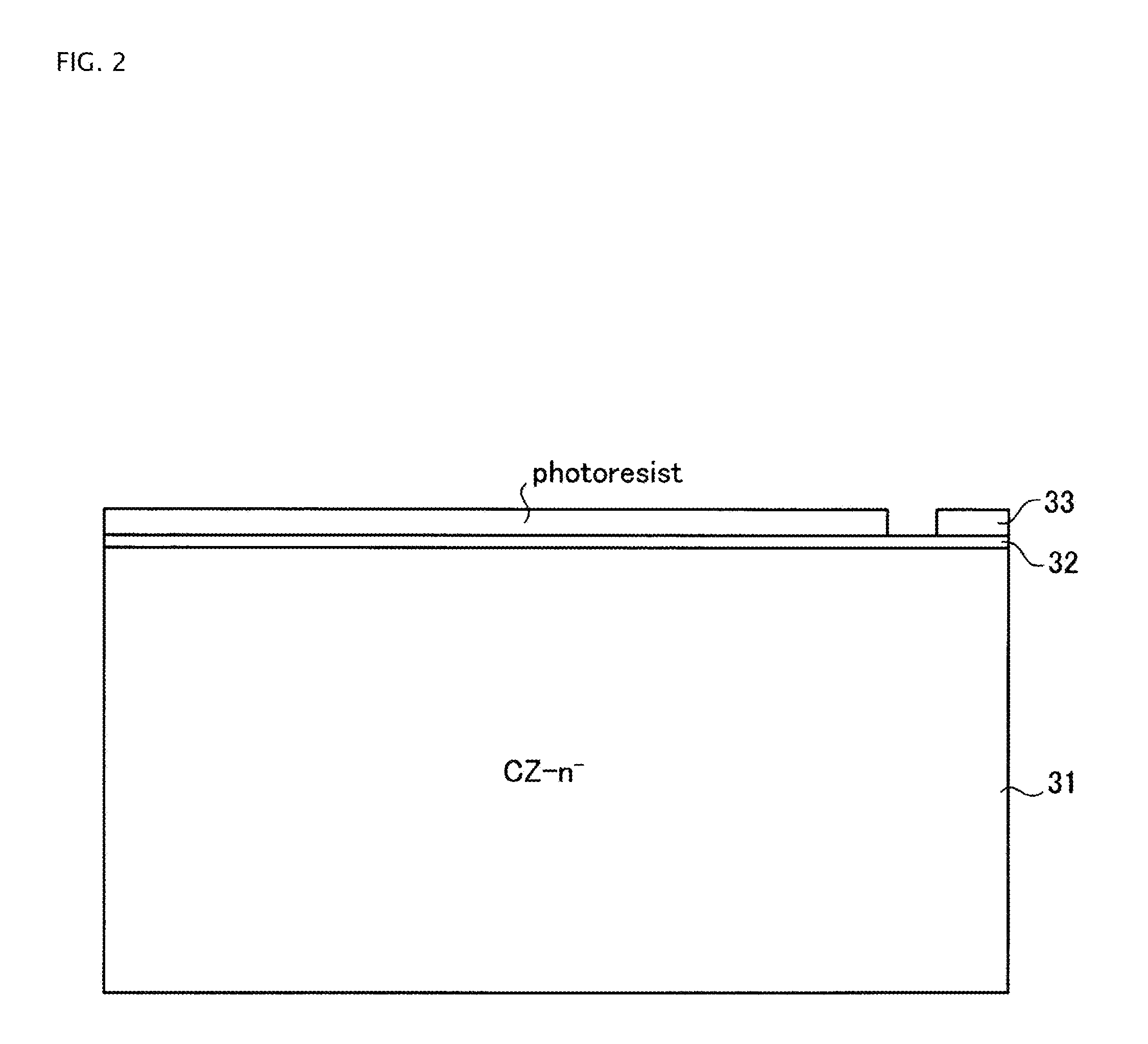

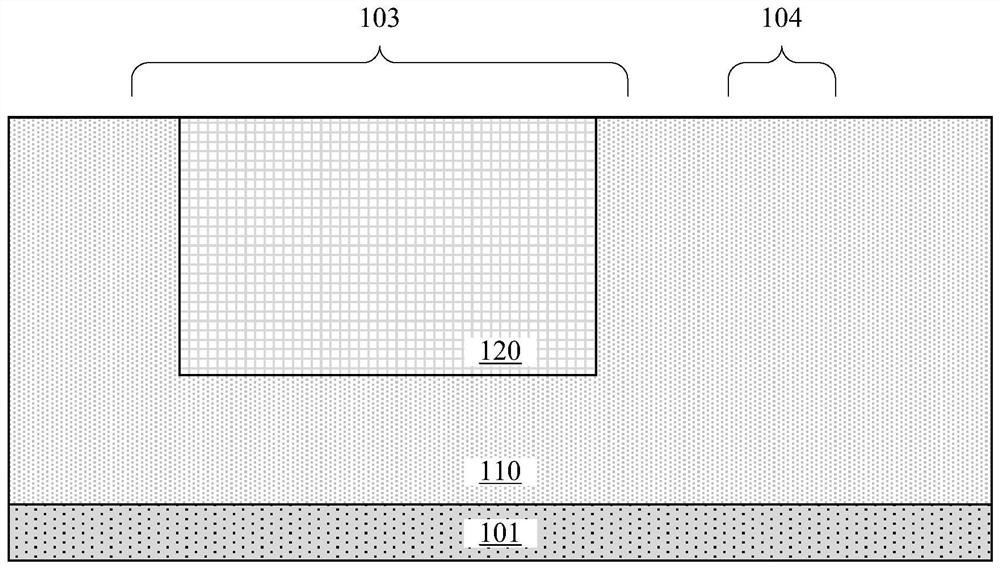

Method of manufacturing semiconductor device

InactiveUS20130122663A1Prolonged diffusion timeLower breakdown voltageTransistorSemiconductor/solid-state device manufacturingSurface layerDevice material

Mirror-polished CZ wafer and FZ wafer are prepared. A first impurity region which will be a first isolation region is formed in a surface layer of a first main surface of the CZ wafer. The first main surface of the CZ wafer and a first main surface of the FZ wafer are bonded to each other by an inter-molecular bond. A second impurity region which will be a second isolation region is formed in a surface layer of a second main surface of the FZ wafer. A heat treatment is performed to diffuse the first impurity region and the second impurity region such that the first impurity region and the second impurity region are continuous, thereby forming a through silicon isolation region.

Owner:FUJI ELECTRIC CO LTD

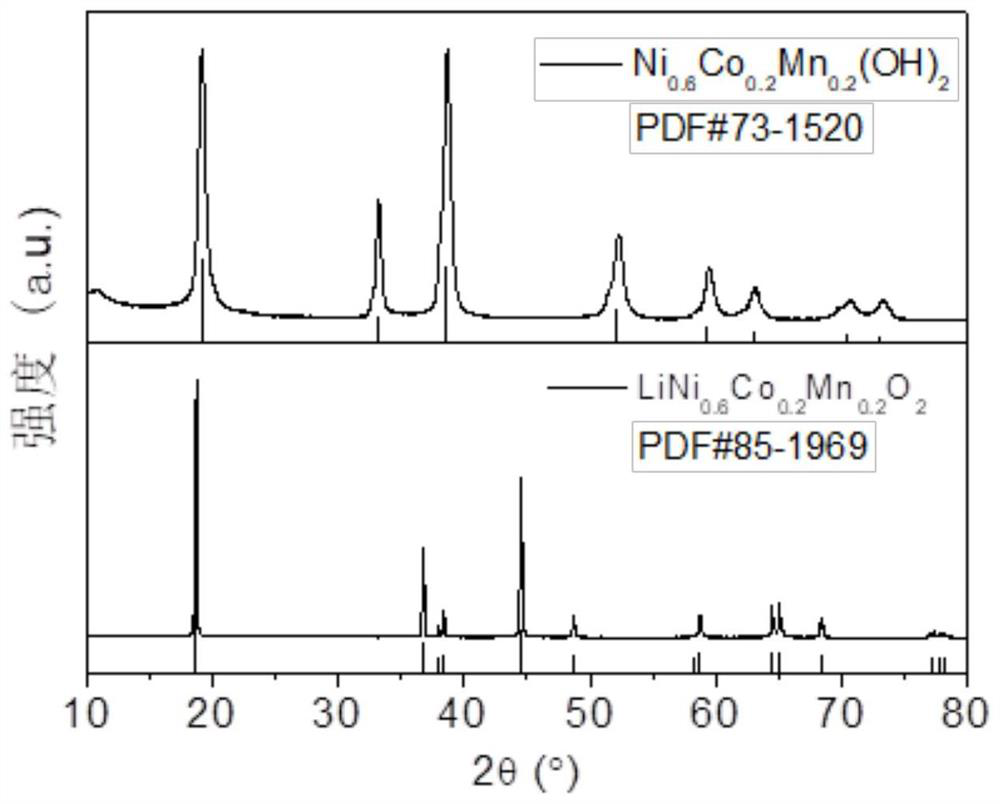

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262APromote growthSimple processCell electrodesManganese oxides/hydroxidesMANGANESE ACETATEOXALIC ACID DIHYDRATE

The invention provides an improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction. The method comprises the following steps: weighing lithium hydroxide monohydrate, nickel acetate and manganese acetate, and oxalic acid dihydrate according to the stoichiometry as follows: Li1+xMnyNi1-x-yO2, x being more than 0 and less than or equal to 1 / 3, y being more than 0 and less than 1, and x+y being more than 0 and less than 1 (wherein the mole ratio of LiOH.H2O to C2H2O4.2H2O is 1:1-1.2), and adding into a ball milling tank together for balling milling for 0.5-2h; obtaining slurry, adding deionized water in the slurry to adjust concentration, spraying and drying the slurry, and roasting the dried powder to obtain the final product -Li1+xMnyNil-x-yO2. The improved method has the following advantages: the process flow is short, the component of the material can be accurately controlled, the problems of material loss and inaccurate stoichiometry caused by repeatedly washing the product in a liquid phase method are overcome, the generation of a large quantity of waste water is avoided; simultaneously, the shape and particle size of a synthesized material can be controlled, the engineering index requirement can be achieved, the impurity pollution caused by dependence of a synthetic material by a solid phase method on crushing process can be overcome, the enriched lithium-manganese-nickel oxide has typical layered structure property, the particle size is 3-12mum, the specific capacity is high, and the cyclic performance is stable.

Owner:湖南金富力新能源股份有限公司

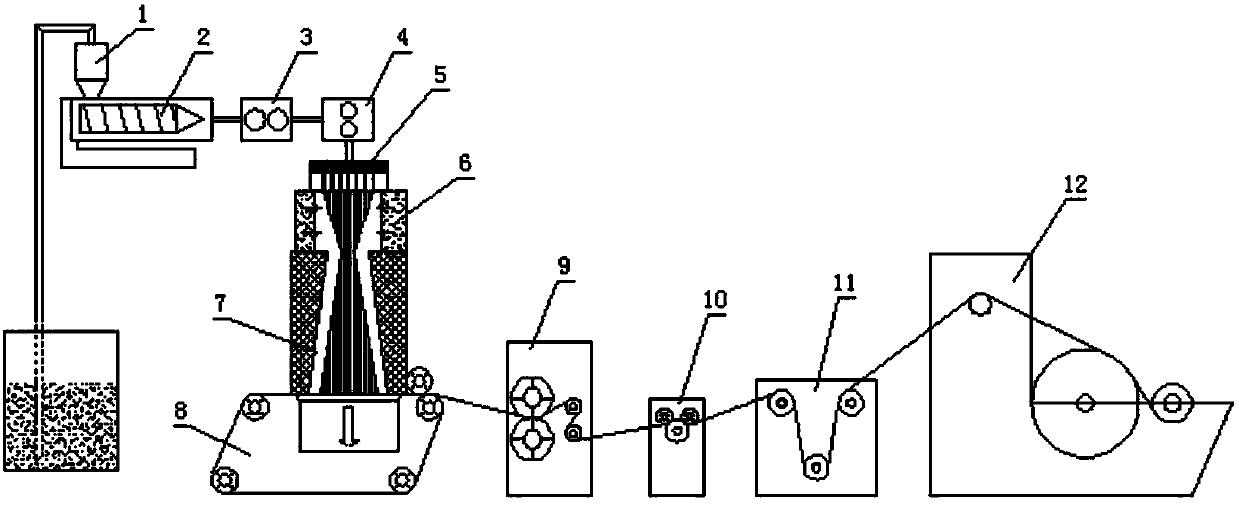

Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

InactiveCN107904787AFluffy goodExcellent suction speedNon-woven fabricsBandagesReverse osmosisEngineering

The invention discloses a spun-bonded non-woven fabric for a diaper diversion layer and a production technology of the fabric. The non-woven fabric comprises an absorption core which is formed by coarse denier fiber, the direction of the coarse denier fiber is the longitudinal direction, the pattern of the coarse denier fiber is the strip pattern, the pattern of the absorption core is the patternof the character 'yi', and the pattern direction of the absorption core is consistent with the fiber direction. Compared with the prior art, the fabric has the advantages that a hot wind non-woven fabric can be replaced, the production speed of the spun-bonded non-woven fabric is higher than that of the hot wind short fiber, the cost is low, and the effect is good; the coarse denier product is good in diversion effect, diffusion is accelerated, the diffusion length is increased, and the amount of reverse osmosis is lowered; compared with ordinary hot wind non-woven fabrics and other products,the fluffiness is better, and the liquid absorbing speed is higher.

Owner:山东恒鹏卫生用品有限公司

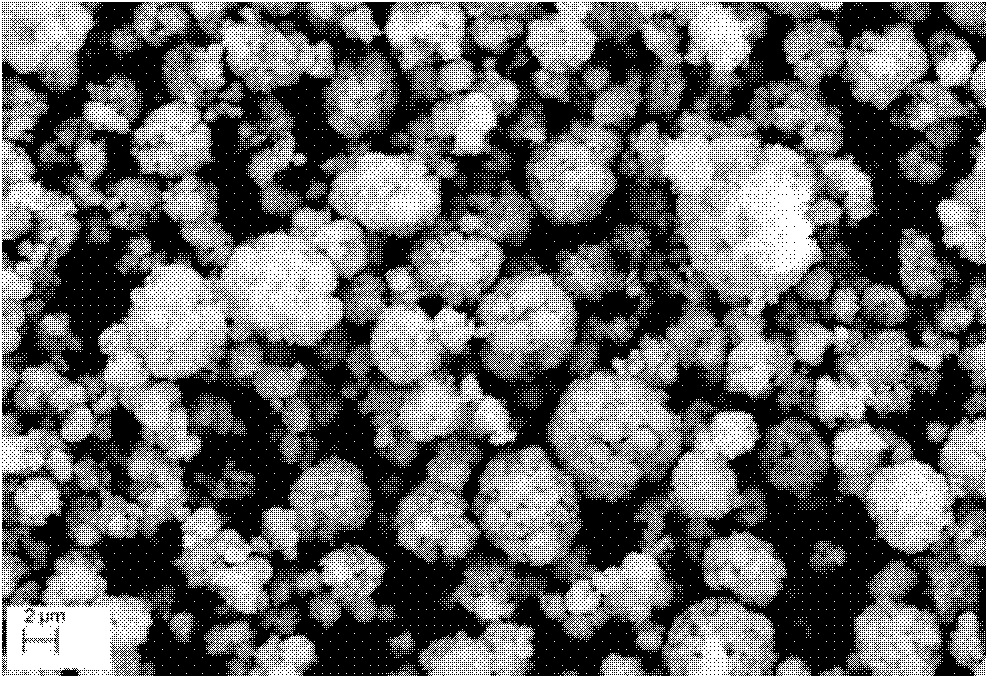

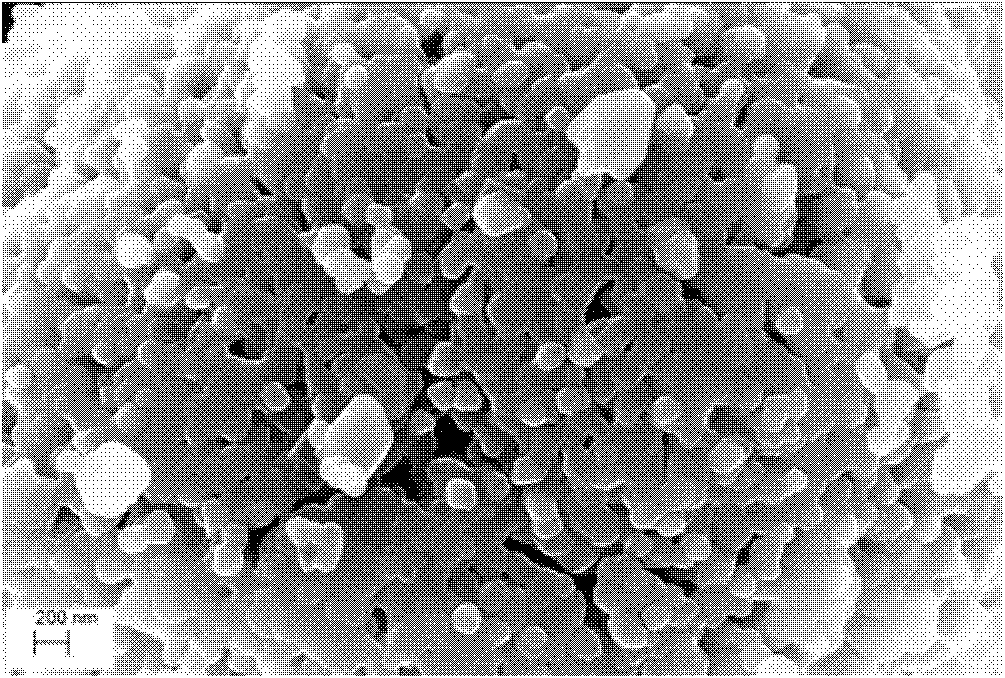

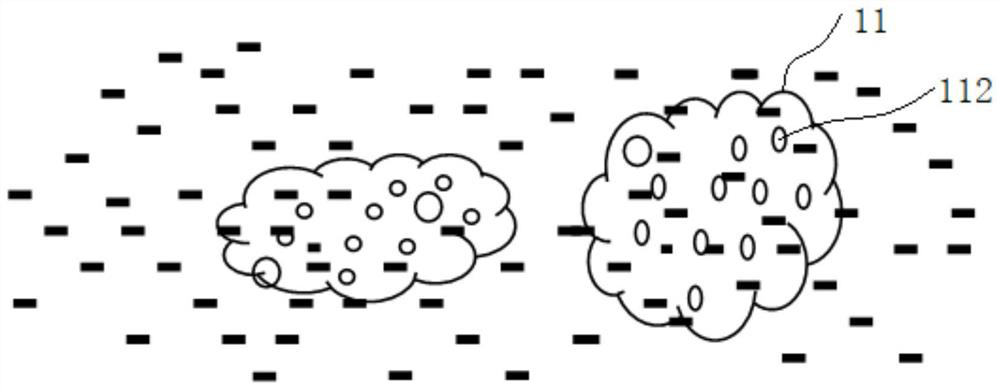

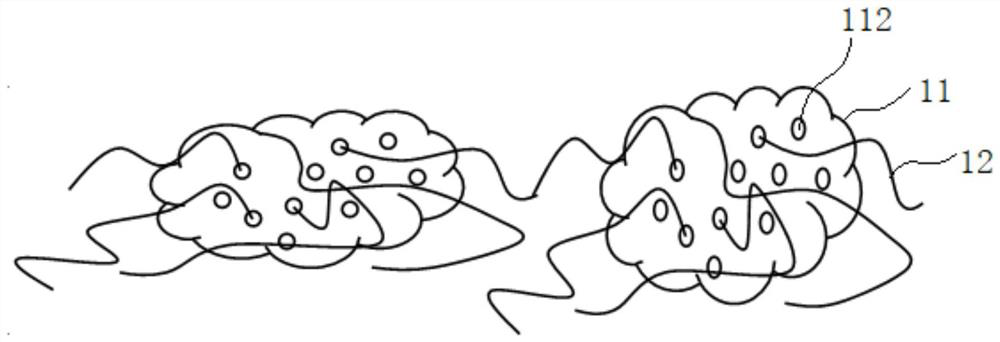

Ultra-high output power and extremely robust cycle life negative electrode material for lithium secondary battery and method for manufacturing the same, using layer structure of metal oxide nanoparticles and porous graphene

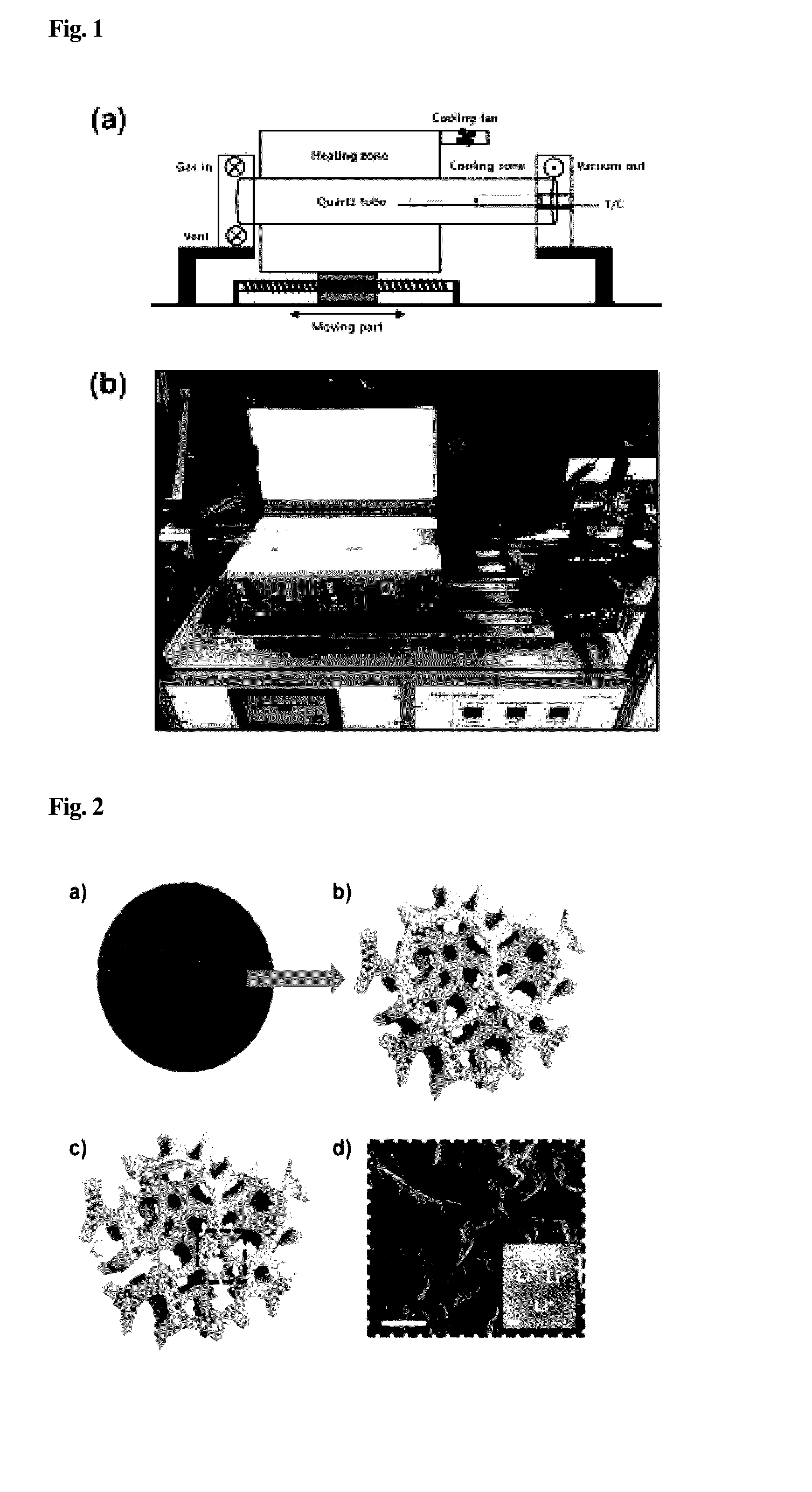

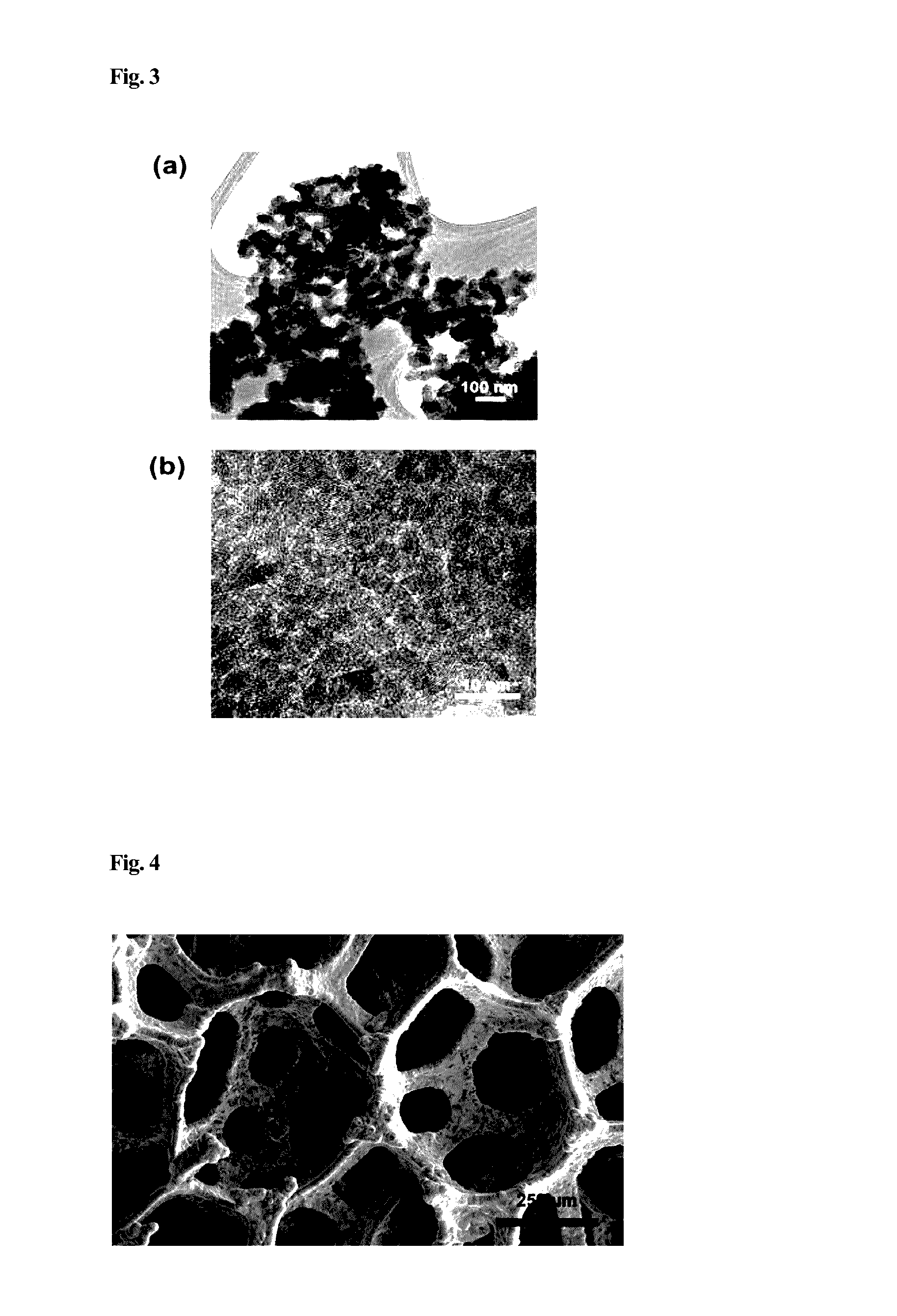

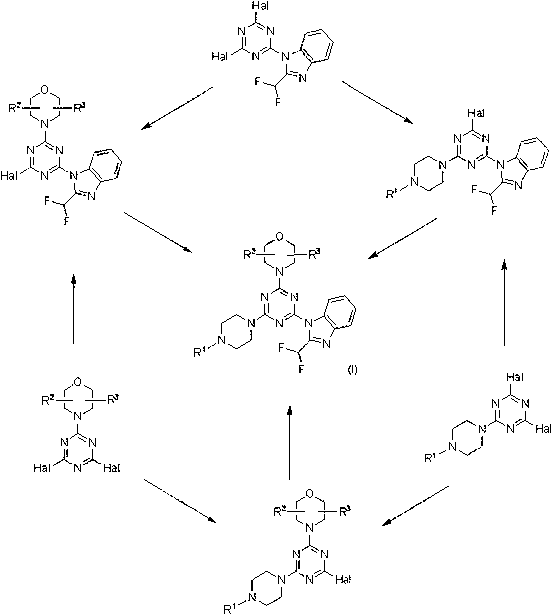

InactiveUS20170054138A1Improve conductivityLarge capacitySecondary cellsGraphenePorous grapheneMetal oxide nanoparticles

Disclosed is a negative electrode material for a lithium secondary battery, using a layer structure of porous graphene and metal oxide nanoparticles, with remarkably fast charge / discharge characteristics and long cycle life characteristics, wherein macropores of the porous graphene and a short diffusion distance of the metal oxide nanoparticles enable rapid migration and diffusion of lithium ions. The present invention may achieve remarkably fast charge / discharge behaviors and exceedingly excellent cycle life characteristics of 10,000 cycles or more even under a current density of 30,000 mA·g−1. Accordingly, the structure of the present invention may implement very rapid charge / discharge characteristics and stable cycle life characteristics while having high capacity by combining the structure with negative electrode nanostructures of the porous graphene network structure, and thereby being widely used in a variety of applications.

Owner:KOREA ADVANCED INST OF SCI & TECH

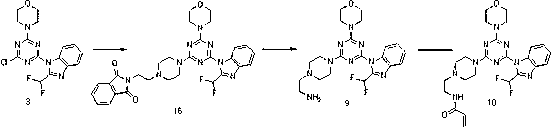

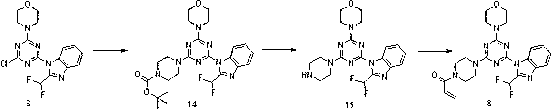

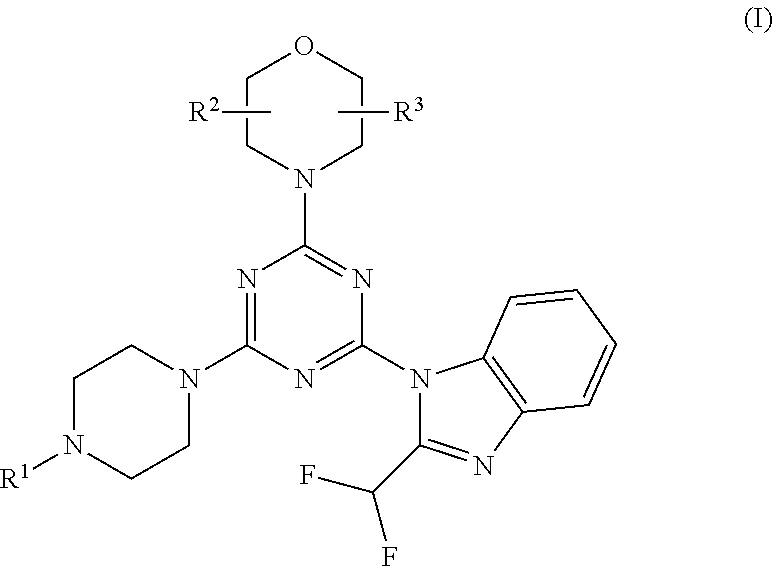

Piperazinotriazines as PI3K inhibitors for use in the treatment antiproliferative disorders

InactiveCN103002899AProlonged diffusion timeShorten Diffusion TimeNervous disorderOrganic chemistryDiseaseAcyl group

The invention relates to compounds of formula (I) R<1> is methyl, n-hexyl, aminoethyl, methylaminoethyl, ethylaminoethyl, dimethylaminoethyl, acryloylaminoethyl, methacryloylaminoethyl, methoxyethyl, ethoxyethyl, C1-C4-alkyl- sulfonyl, acryloyl, or methacryloyl; or R<1> is aminoethyl, acryloyl or acryloylaminoethyl carrying a linker and a tag, and R<2> and R<3>, independently of each other, are hydrogen or C1-C4-alkyl, or R<2> and R<3> together form a methylene or an ethylene bridge; and tautomers, solvates and pharmaceutically acceptable salts thereof. These compounds are effective in preventing or treating a disease or disorder modulated by PI3 kinases and / or mTOR, in particular treating a hyperproliferative disorder.

Owner:UNIVERSITY OF BASEL

Piperazinotriazines as pi3k inhibitors for use in the treatment antiproliferative disorders

InactiveUS20130040912A1Prolonged diffusion timeShorten Diffusion TimeBiocideNervous disorderDiseasePI3 Kinases

The invention relates to compounds of formula (I) R1 is methyl, n-hexyl, aminoethyl, methylaminoethyl, ethylaminoethyl, dimethylaminoethyl, acryloylaminoethyl, methacryloylaminoethyl, methoxyethyl, ethoxyethyl, d-C4-alkyl-sulfonyl, acryloyl, or methacryloyl; or R1 is aminoethyl, acryloyl or acryloylaminoethyl carrying a linker and a tag, and R2 and R3, independently of each other, are hydrogen or CrC4-alkyl, or R2 and R3 together form a methylene or an ethylene bridge; and tautomers, solvates and pharmaceutically acceptable salts thereof. These compounds are effective in preventing or treating a disease or disorder modulated by PI3 kinases and / or mTOR, in particular treating a hyperproliferative disorder.

Owner:UNIVERSITY OF BASEL

Disposable special rice fertilizer for crab raising rice field

InactiveCN101880194AIncrease profitGood application effectSuperphosphatesAlkali orthophosphate fertiliserFecesInorganic Chemical

The invention relates to a compound fertilizer, in particular to a disposable special rice fertilizer for a crab raising rice field. The special fertilizer consists of organic fertilizer and inorganic fertilizer in a weight part ratio of 5-7: 3-5, wherein the organic fertilizer comprises 2 to 5 weight parts of livestock and poultry dung and 1 to 2.5 weight parts of humic acid; and the inorganic chemical fertilizer comprises 9 to 11 weight parts of nitrogenous fertilizer, 2 to 4 weight parts of phosphate fertilizer and 3 to 6 weight parts of potassium fertilizer. The yield of the rice is increased obviously after one-time application, any fertilizer does not need to be applied at the later stage, and the special fertilizer does not harm river crabs.

Owner:辽宁省农业科学院环境资源与农村能源研究所

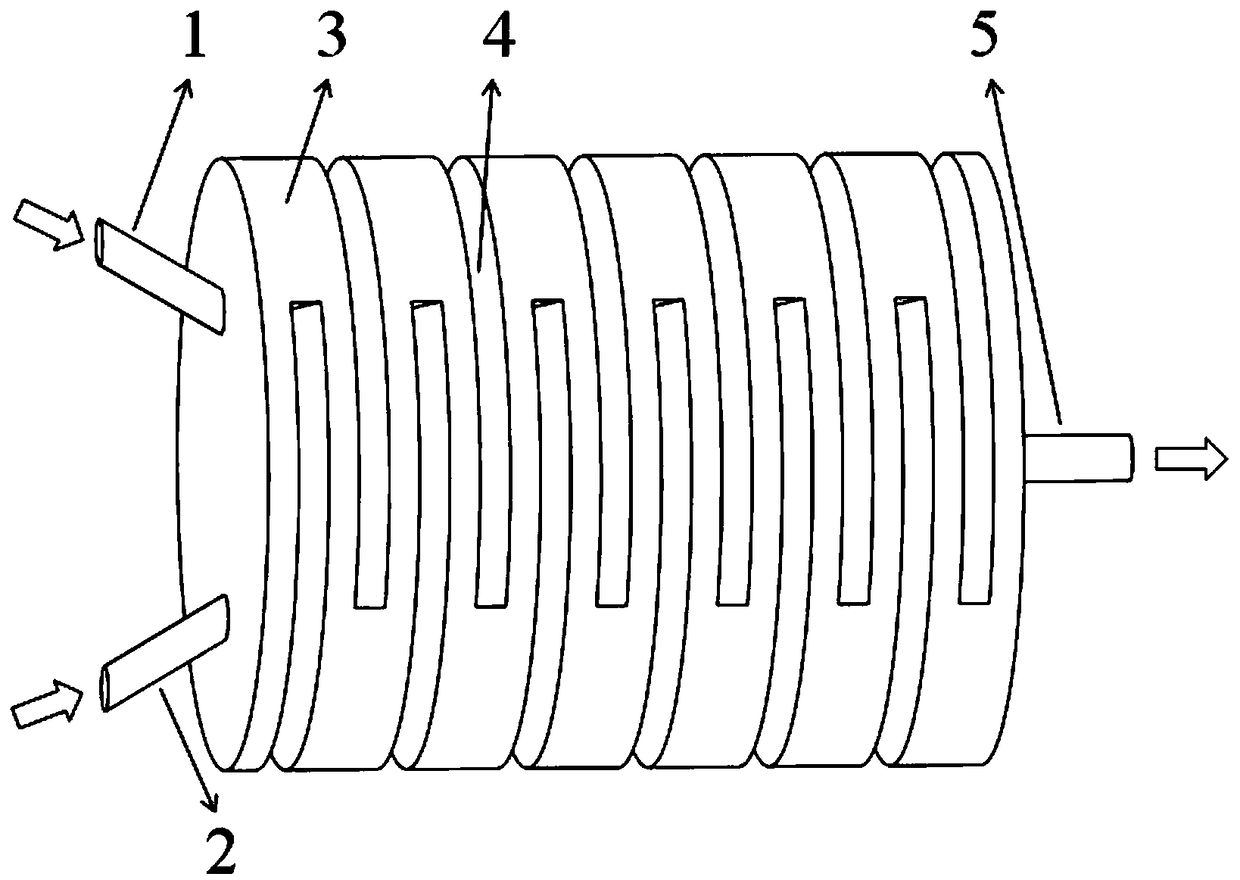

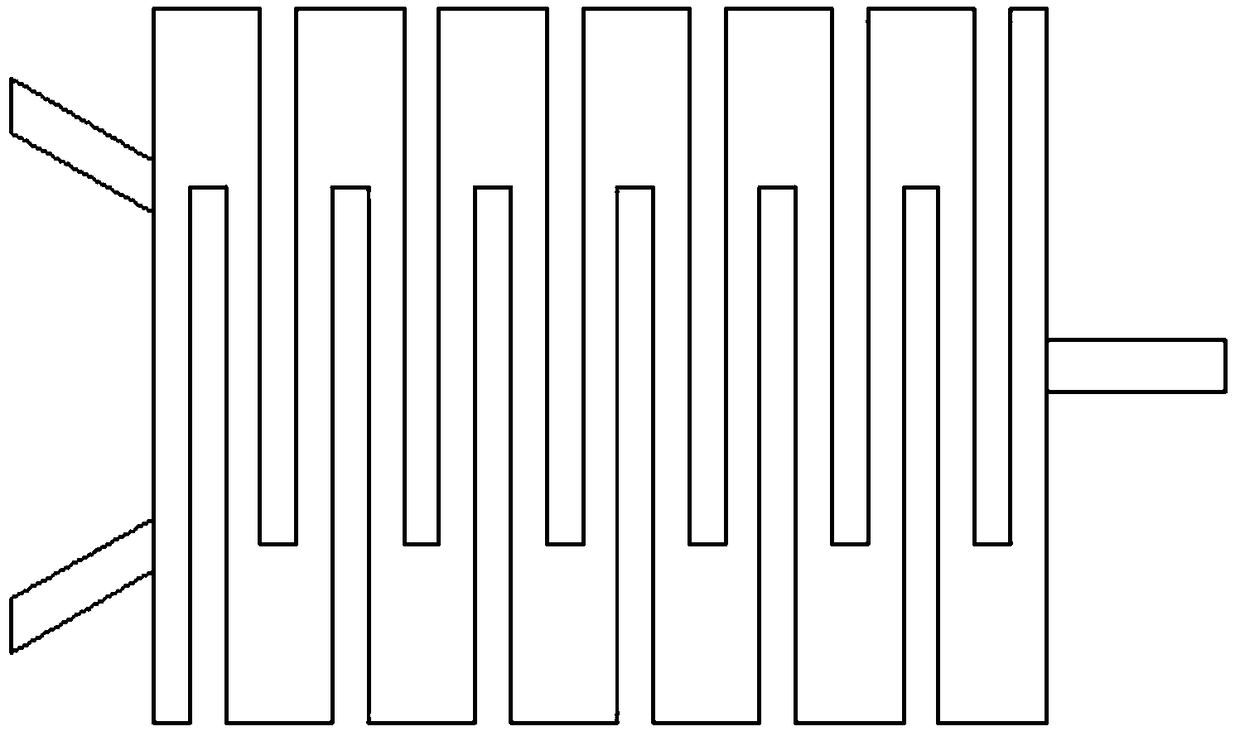

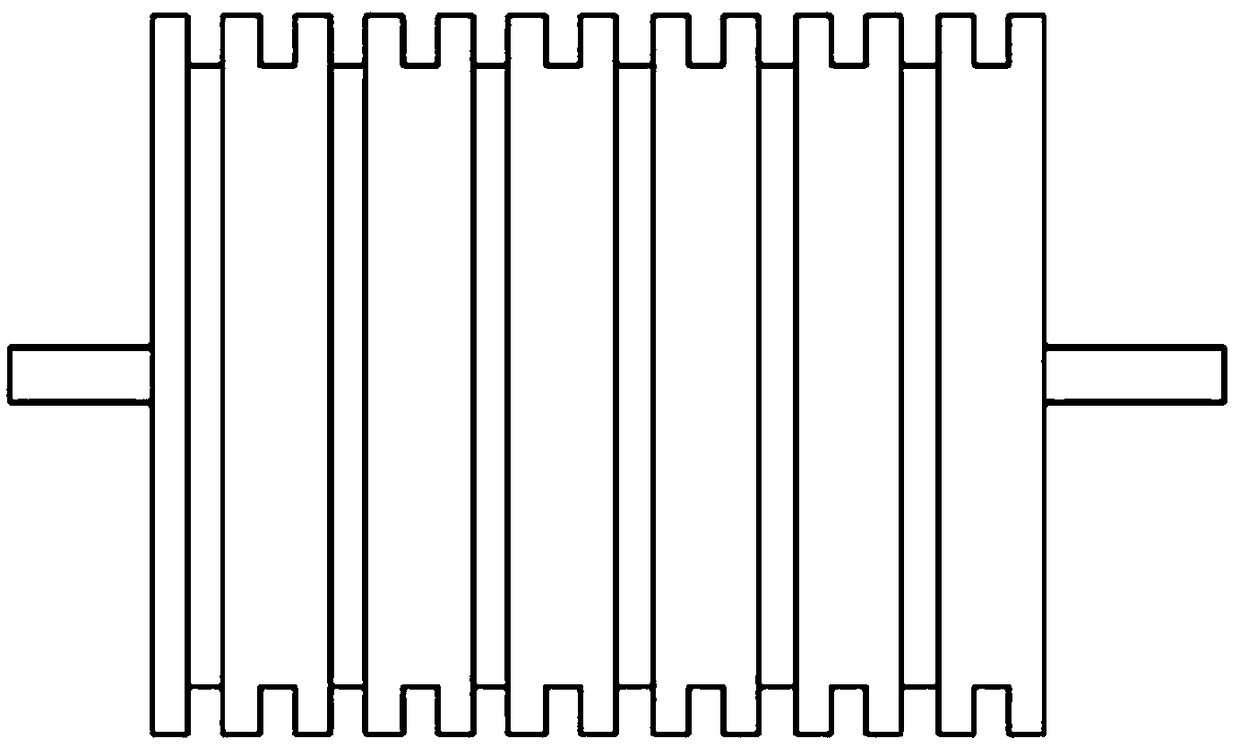

High performance micro-mixer used in ultra-high performance liquid chromatography analyzer

ActiveCN109173766AEnhanced convection effectWell mixedComponent separationFlow mixersDiffusionInlet channel

The invention discloses a high performance micro-mixer used in an ultra-high performance liquid chromatography analyzer, and belongs to the field of high grade biochemistry analysis and fluid micro mixing in micro-complete analysis systems. The high performance micro-mixer comprises two inlet channels, a mixing chamber, twelve blocking plates which are distributed in an up-down staggered manner, and an outlet channel; the blocking plates are capable of enhancing the convection effect in solvent flowing, so that it is convenient for forming of a vortex zone; and in addition, the staggered blocking plates are capable of realizing flow of mixed solvent in the mixing chamber in a square wave patter path, and vortex is easily formed at corners, the existing of vortex is capable of breaking laminar flow state of solvent in flowing, and delaying diffusion path of mixed solvent in the mixing chamber, the mixing performance of the high performance micro-mixer is improved obviously, and the precision of the ultra-high performance liquid chromatography analyzer is increased further.

Owner:BEIJING UNIV OF TECH +1

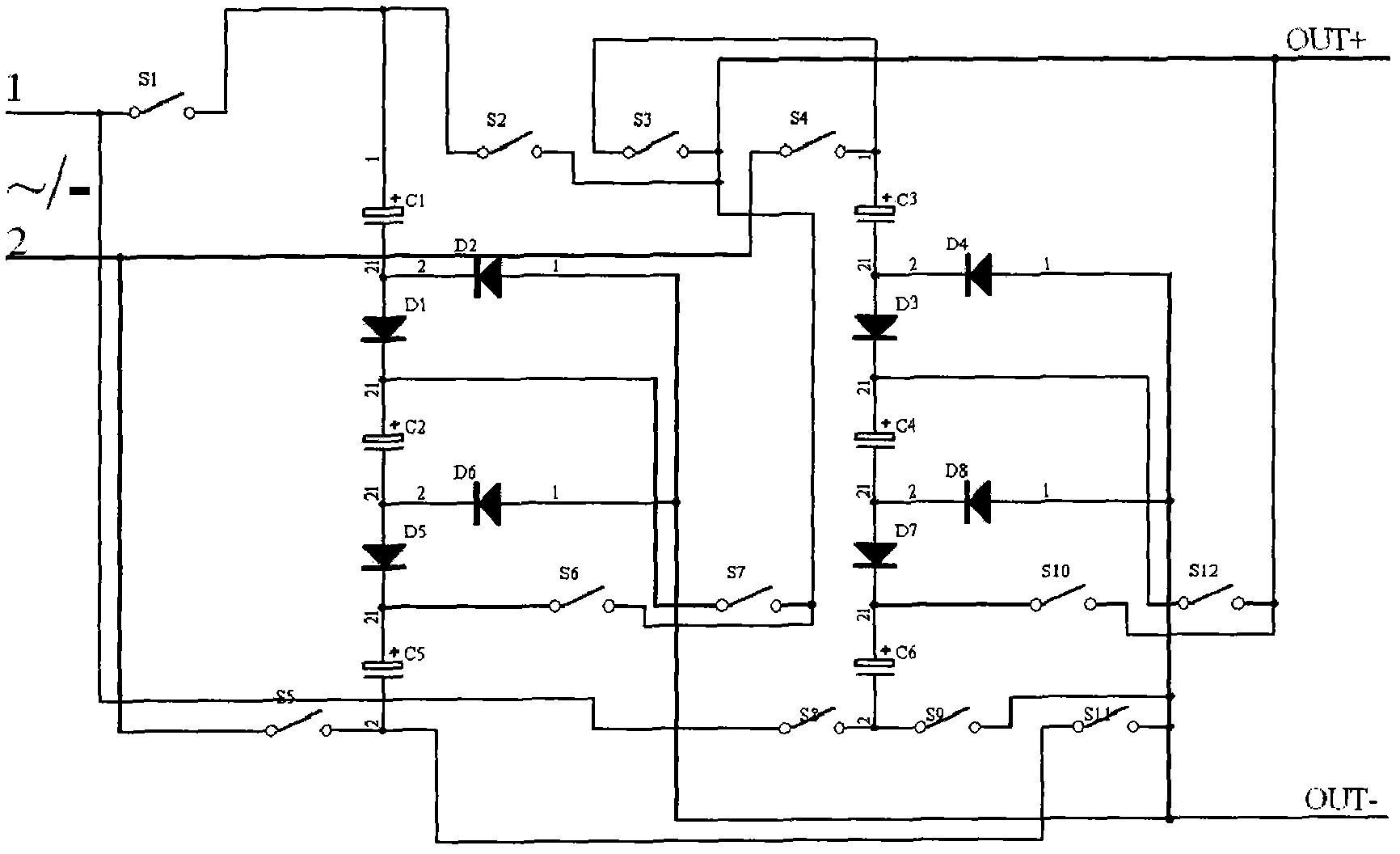

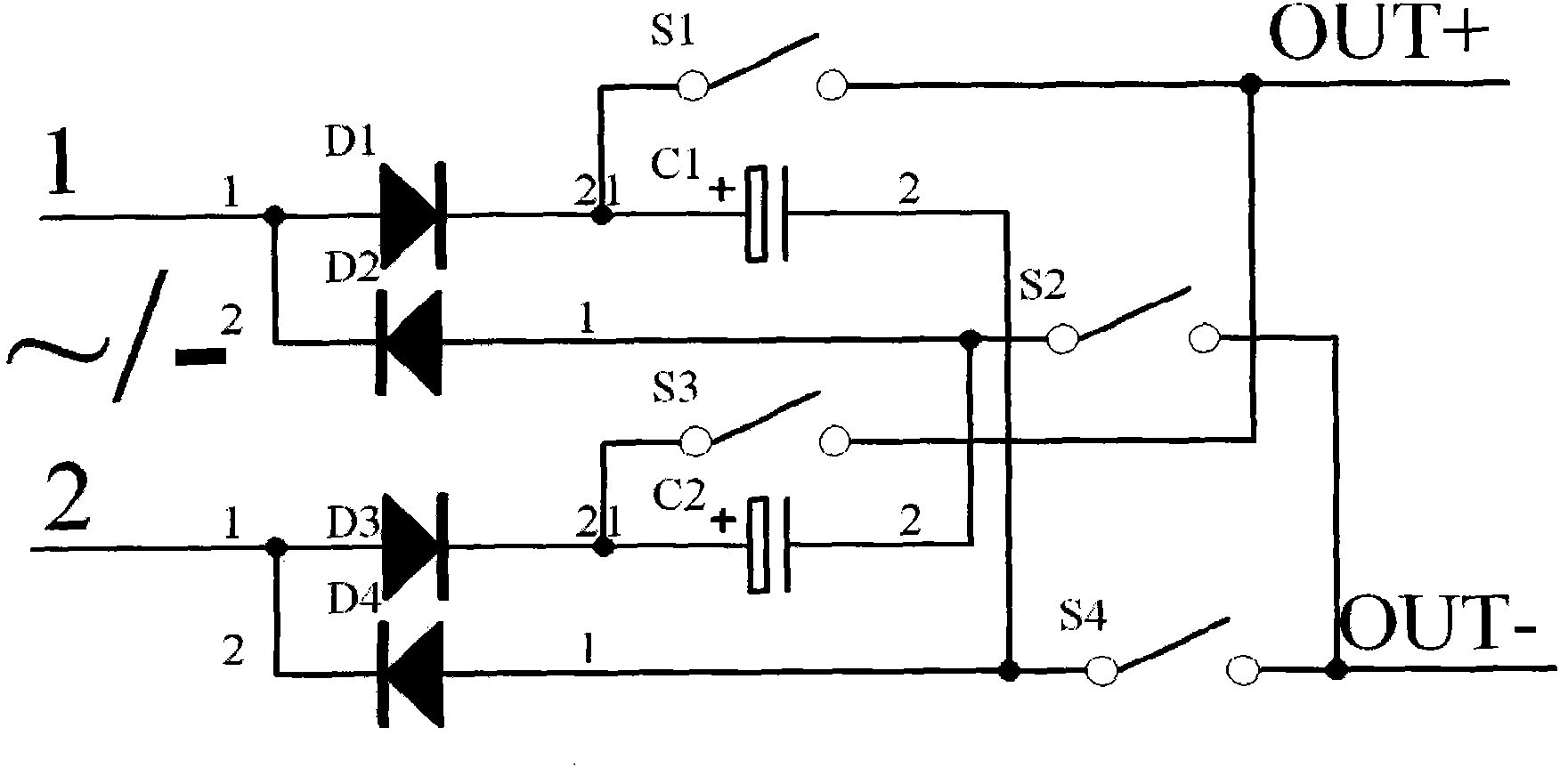

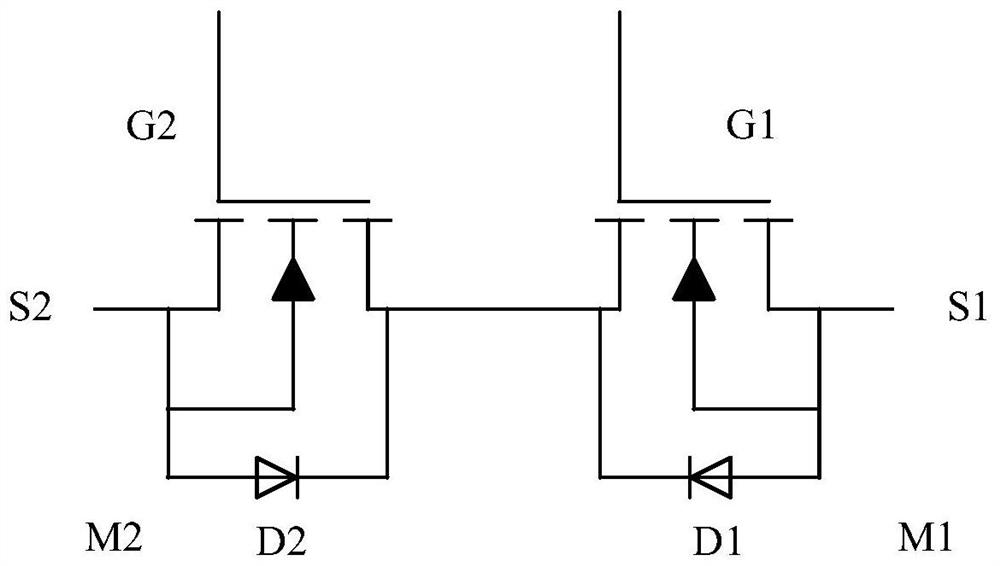

Low-frequency soft-pulse charging circuit and low-frequency soft-pulse charging method

InactiveCN103138567ASimple structureReduce lossApparatus without intermediate ac conversionCapacitanceEngineering

The invention discloses a low-frequency soft-pulse charging circuit which comprises a first switching element S1, a second switching element S2, a third switching element S3, a fourth switching element S4, a fifth switching element S5, a sixth switching element S6, a seventh switching element S7, an eighth switching element S8, a ninth sixth switching element S9, a tenth switching element S10, an eleventh switching element S11, a twelfth switching element S12, a first capacitor C1, a second capacitor C2, a third capacitor C3, a fourth capacitor C4, a fifth capacitor C5, a sixth capacitor C6, a first diode D1, a second diode D2, a third diode D3, a fourth diode D4, a fifth diode D5, a sixth diode D6, a seventh diode D7 and an eighth diode D8, wherein each of the switching elements is provided with two terminals; each of the capacitors is provided with a positive electrode and a negative electrode; and each of the diodes is provided with an anode and a cathode. The invention further discloses a low-frequency soft-pulse charging method.

Owner:ZHEJIANG YUANCHUANG ELECTRONICS TECH

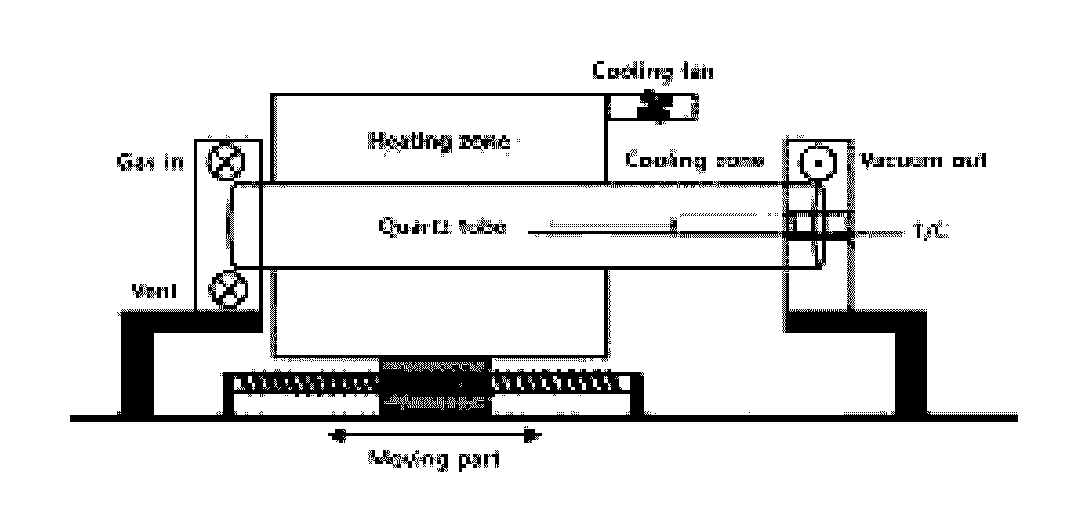

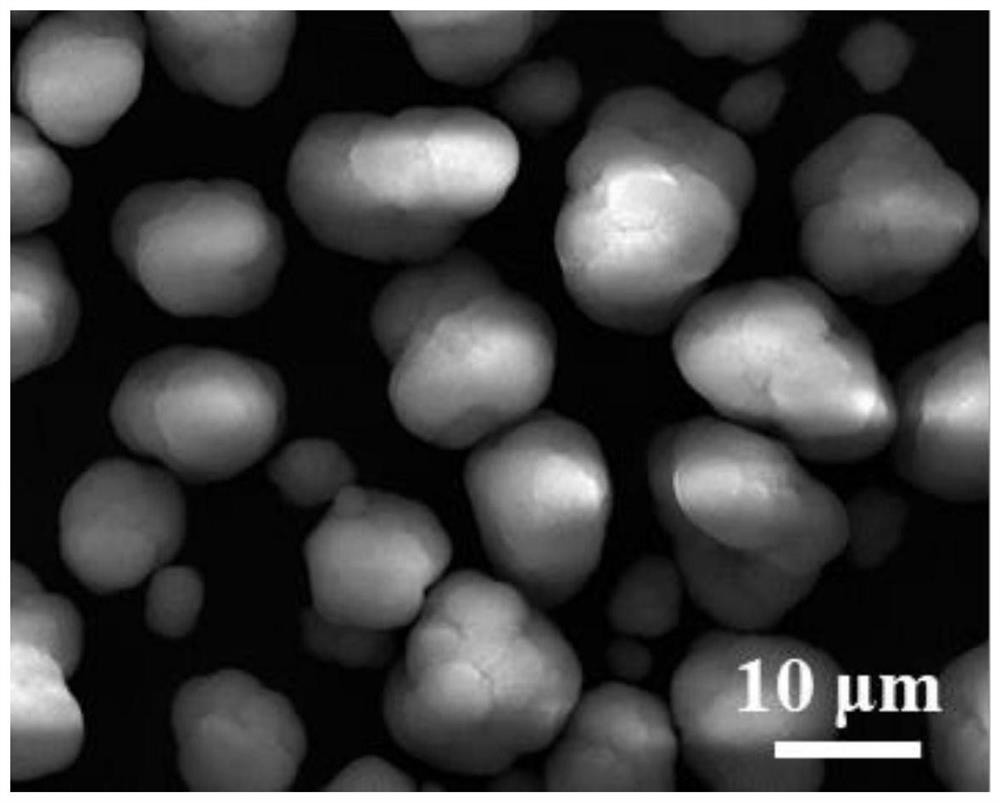

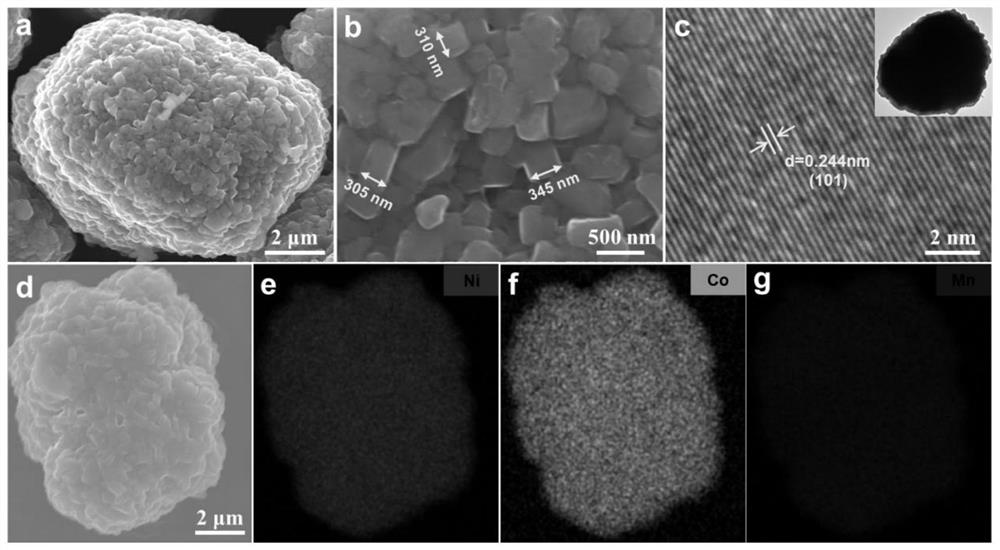

Method for preparing ternary positive electrode material of high-performance lithium ion battery at low ammonia concentration

InactiveCN111807425AReduced nucleation rateEasy reunionSecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a method for preparing a ternary positive electrode material of a high-performance lithium ion battery at low ammonia concentration, and belongs to the technical field of positive electrode materials of lithium ion batteries. The method comprises the following steps: dissolving salt containing nickel, cobalt and manganese in deionized water to prepare a mixed salt solution,adding a complexing agent into the mixed salt solution, adding acid to obtain a mixed solution; continuously pumping the mixed solution and the NaOH solution into a continuous coprecipitation reaction kettle filled with bottom liquid ammonia water respectively, enabling the total ammonia concentration of the reaction kettle to be the same as the concentration of the bottom liquid ammonia water inthe reaction process, continuously reacting to obtain a precursor material, grinding and mixing the precursor material and LiOH.H2O, and sintering to obtain the lithiated ternary material. The prepared NCM622 material is good in morphology, complete in crystal structure and uniform in element distribution, the material has high discharge capacity, good cycling stability and rate capability, and atotal battery matched with graphite and a Si / C negative electrode also has good electrochemical performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

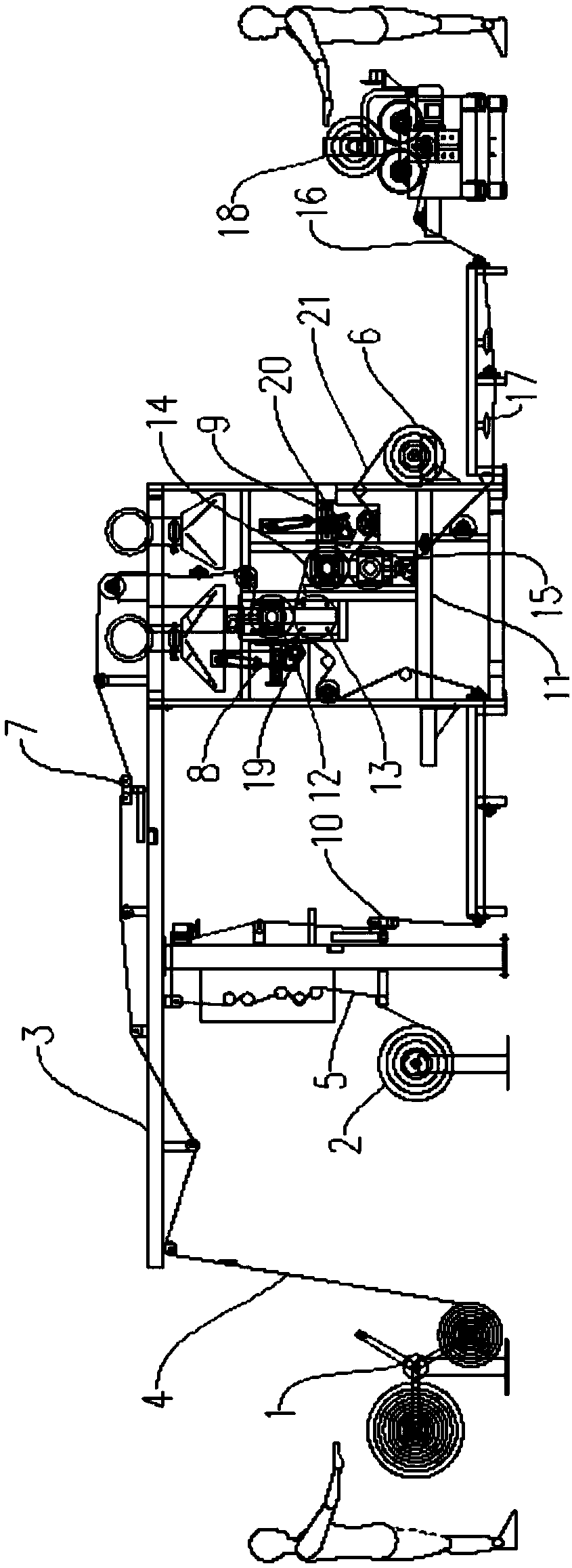

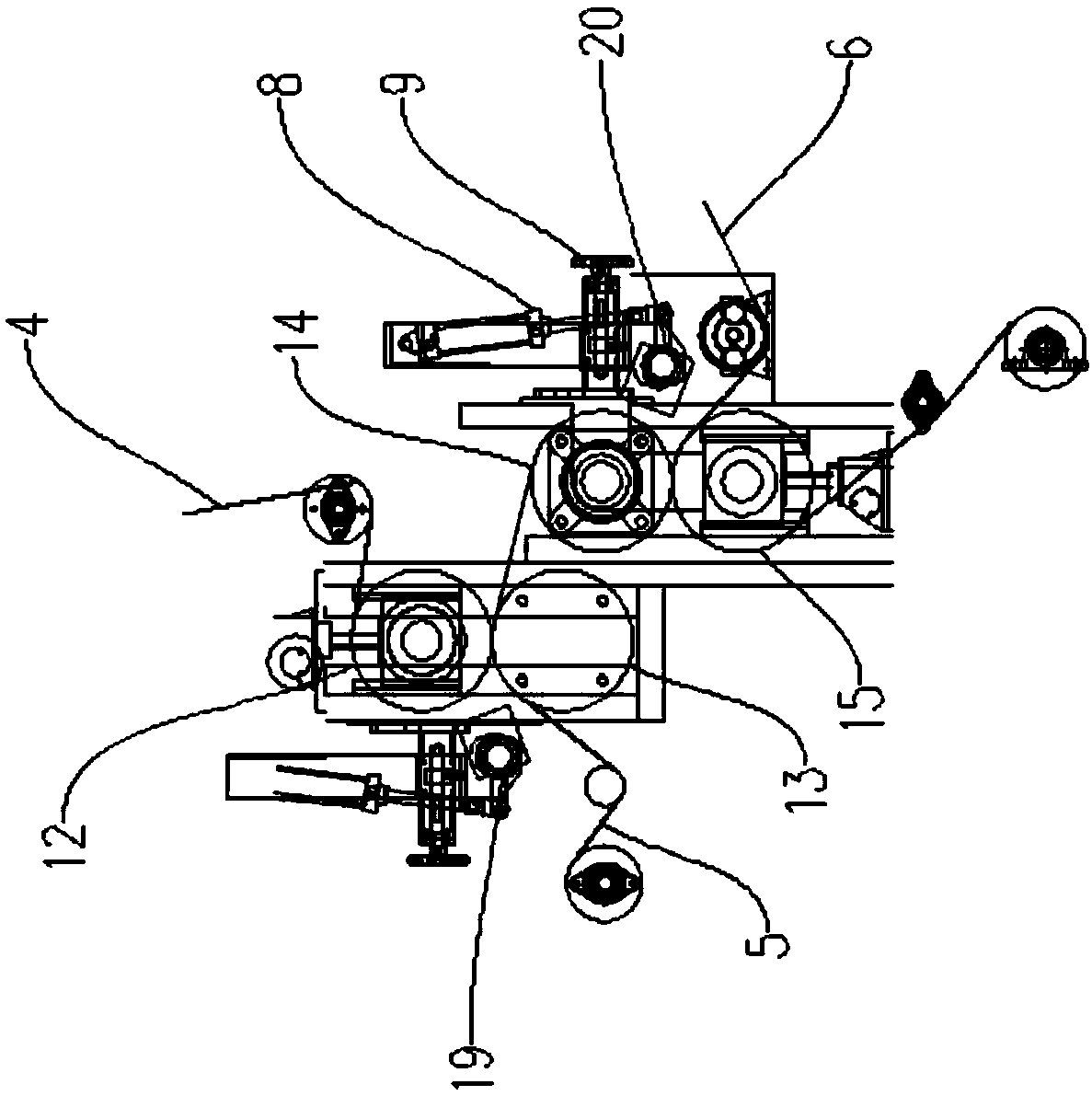

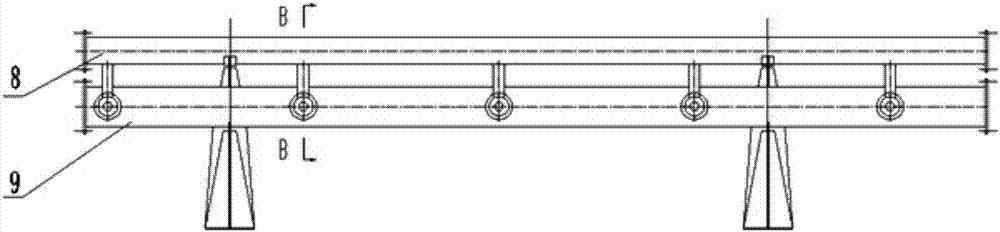

Four-roller flame laminating machine

InactiveCN109397838AProlonged diffusion timeReduce the presence of air bubblesLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses a four-roller flame laminating machine. The four-roller flame laminating machine comprises a sponge unwinding device, a fabric unwinding device, a backing material unwinding device, a rack, a four-roller laminating device, and a cooling winding device; the sponge unwinding device unwinds sponge serving as a flame laminating medium, the fabric unwinding device unwinds fabric, the backing material unwinding device is mounted on the rack, and the four-roller laminating device comprises a four-roller bracket, a first pressing roller, a second pressing roller, a third pressing roller, a fourth pressing roller, a front flame row, a rear flame row, an air cylinder overturning device, and a flame row regulator; the second pressing roller is located under the first pressingroller, the third pressing roller is located on the right lower side of the second pressing roller and is close to the second pressing roller, the fourth pressing roller is located under the third pressing roller and is close to the third pressing roller, the front flame row parallel to the first pressing roller is arranged on the lower left side of the first pressing roller, and the rear flame row parallel to the third pressing roller is arranged on the lower right side of the third pressing roller; and a three-in-one laminating material laminated by the four-roller laminating device enters the cooling winding device. According to the four-roller flame laminating machine, the laminating quality can be improved, and the four-roller flame laminating machine is suitable for laminating of various materials.

Owner:JIANGSU HONGYE MACHINERY

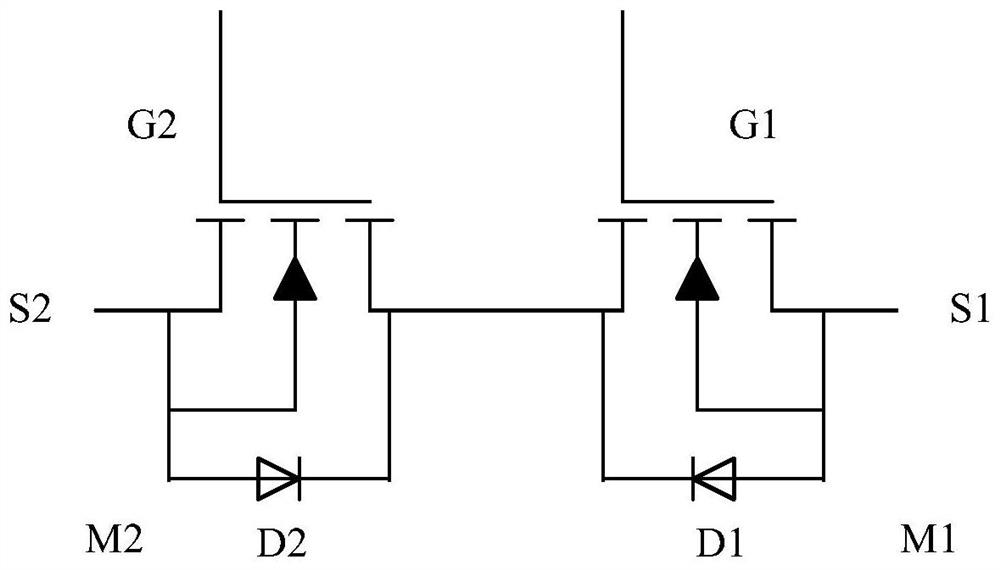

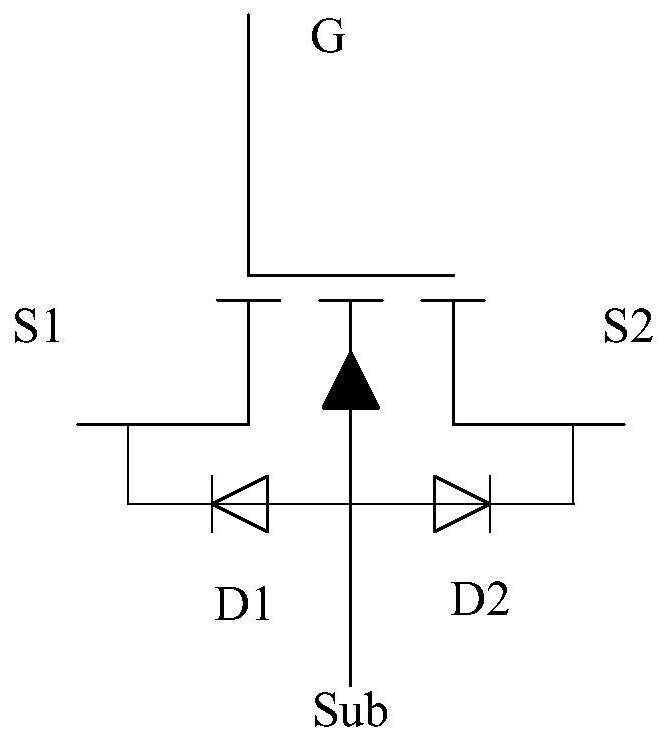

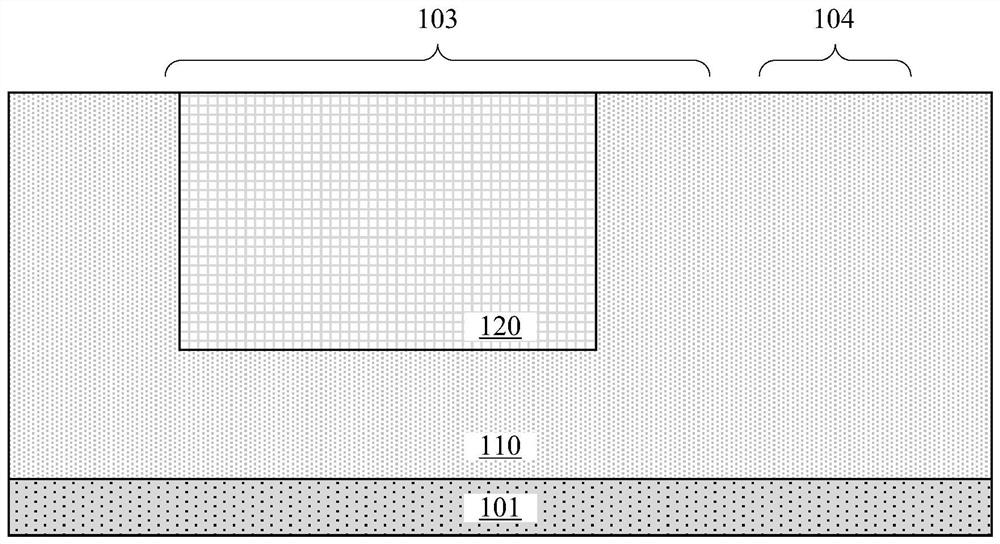

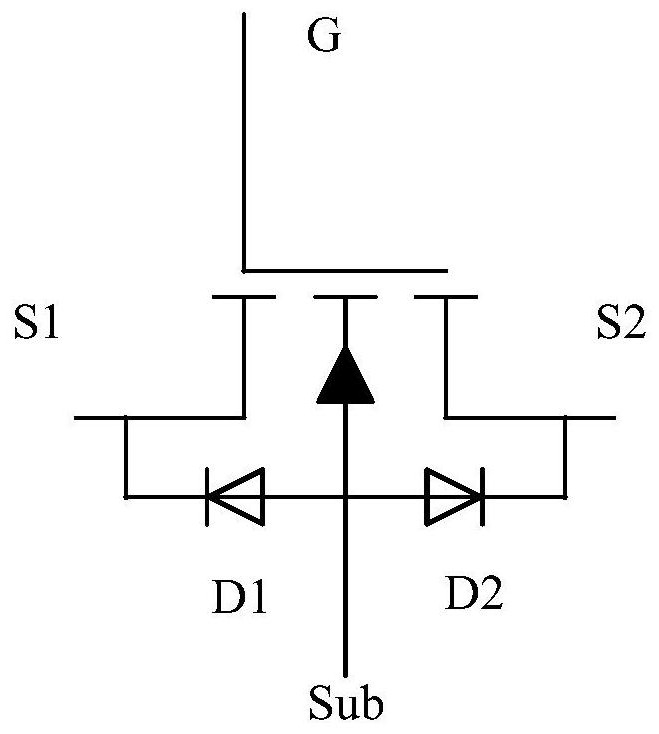

Bidirectional power device and manufacturing method thereof

PendingCN112309974AReduce areaRealize requirementsSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

The invention discloses a bidirectional power device and a manufacturing method thereof. The bidirectional power device comprises: a semiconductor layer; a first doped region, which is located in thesemiconductor layer; a plurality of trenches of a first trench region, wherein the trenches are located in the first doped region and divide the first doped region into alternating first-type sub-doped regions and second-type sub-doped regions; a gate dielectric layer, that covers the side walls of the lower parts of the plurality of trenches of the first trench region; a shielding dielectric layer, that covers the side walls of the upper parts of the plurality of trenches of the first trench region; and grid conductors, which are located in the plurality of trenches of the first trench regionand make contact with the grid dielectric layer and the shielding dielectric layer separately, wherein each grid conductor comprises a control grid and a shielding grid which are connected, the control grid makes contact with the grid dielectric layer, the shielding grid makes contact with the shielding dielectric layer, the thickness of the shielding dielectric layer is inconsistent, and the thickness of at least a part of the shielding dielectric layer is greater than the thickness of the gate dielectric layer. According to the device, the voltage withstanding performance of the device is improved through the setting that the thickness of at least a part of the shielding dielectric layer is greater than the thickness of the gate dielectric layer.

Owner:HANGZHOU SILAN MICROELECTRONICS

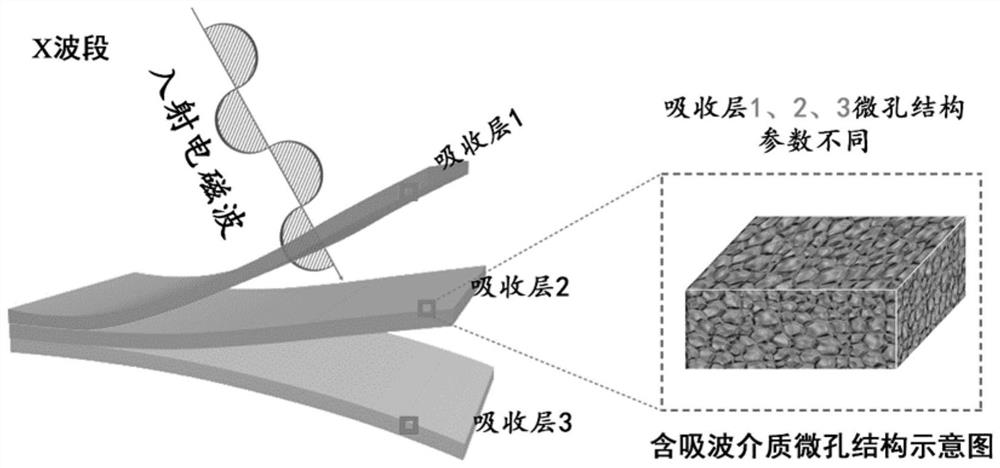

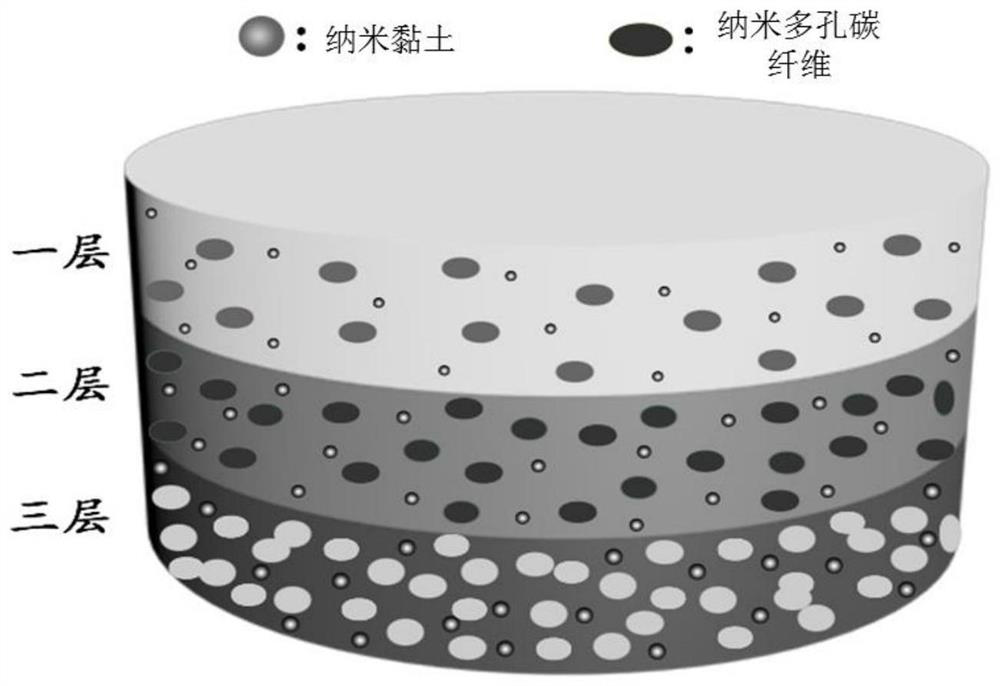

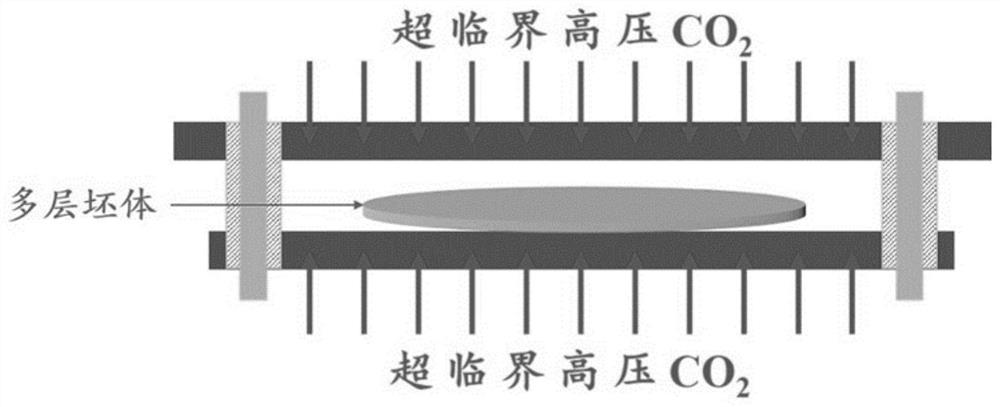

Gradient type microporous broadband wave-absorbing material and supercritical limited foaming type preparation method thereof

ActiveCN111961303AReduce weightImpede free diffusionShielding materialsSynthetic resin layered productsCompression moldingPolymer science

The invention provides a gradient type microporous broadband wave-absorbing material and a supercritical limited foaming type preparation method thereof. The gradient type microporous broadband wave-absorbing material comprises at least two layers of microporous wave-absorbing materials which are stacked, wherein the microporous wave-absorbing material is prepared from a wave-absorbing medium, a polymer base material and a nucleating agent through compression molding and supercritical carbon dioxide integrated limited foaming. According to the invention, a wave-absorbing medium, a polymer basematerial and a nucleating agent are compounded through supercritical carbon dioxide integrated limited foaming to prepare a gradient type microporous broadband wave-absorbing material, multi-band broadband absorption can be achieved by utilizing the structure and the wave-absorbing performance of the wave-absorbing medium and the synergistic effect formed by the wave-absorbing medium and the gradient type microporous structure, and the gradient type microporous broadband wave-absorbing material has the characteristics of simple preparation method, low cost, wide wave-absorbing frequency bandand good wave-absorbing frequency band regulation and control flexibility.

Owner:WUHAN TEXTILE UNIV

Dyeing process of chinlon and cotton lace

InactiveCN107740260AImprove gross effectSolve the problem that if the dye is not transparent, it will be whiteDyeing processYarnNeutral ph

The invention discloses a dyeing process of a chinlon and cotton lace. The dyeing process of the chinlon and cotton lace is mainly characterized in that a cotton pretreatment process, PH before activedyeing, a high-temperature migration temperature and time and soda ash adding time are controlled, the using amount of an auxiliary is selected, and the temperature of a dyeing bath and temperature keeping time are selected, so that a reasonable dyeing process is optimized, the problem of exposure of coarse folded yarns of the chinlon and cotton lace is solved, and a new idea and a new directionare provided for the type of products. According to the dyeing process of the chinlon and cotton lace, tea saponin, flake alkali, hydrogen peroxide and a refining agent are used for improving the wooleffect of cotton in a pretreatment process of cotton, so that the permeability of reactive dyes is enhanced. By adopting the dyeing process of the chinlon and cotton lace, the active dyeing temperature is raised to 95 to 98 DEG C, and the dye diffusion time is prolonged. After high-temperature migration, the temperature is lowered and soda ash is added fractionally to fix the dyes, so that migration of the dyes is facilitated, the permeability of the dyes is enhanced, and the problem of folded yarn exposure during dyeing is solved; moreover, high-temperature migration under a neutral PH condition does not cause hydrolysis of the reactive dyes, so that the color depth does not decline.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

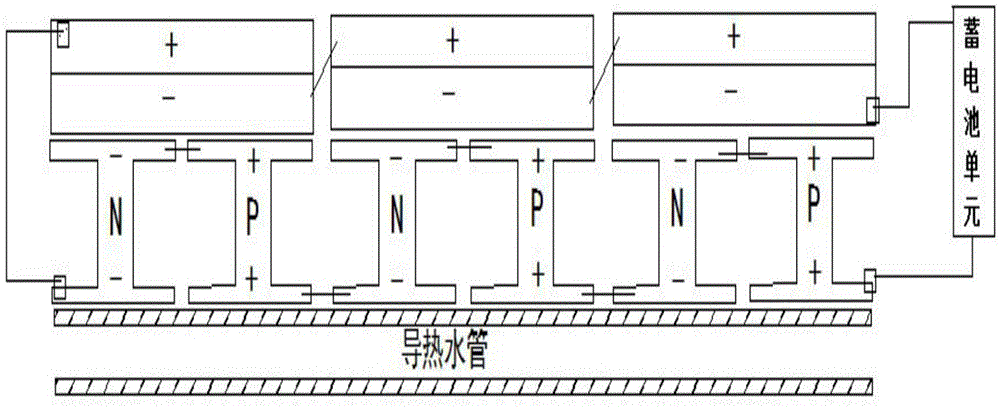

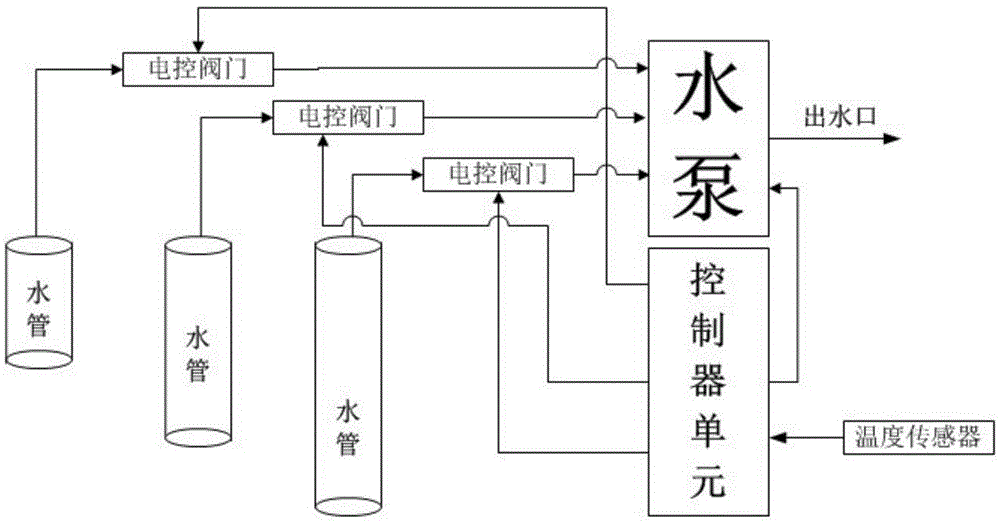

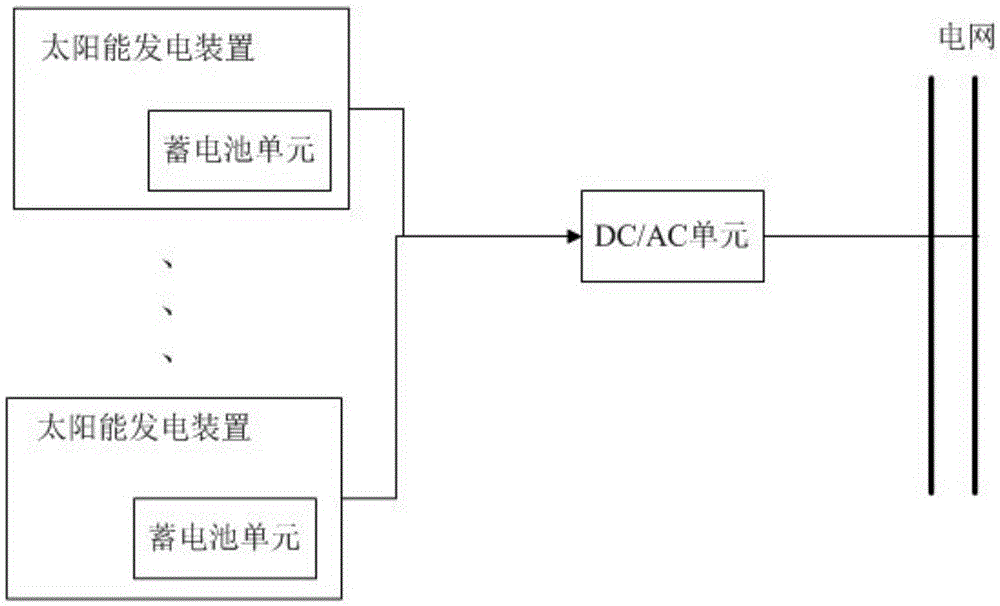

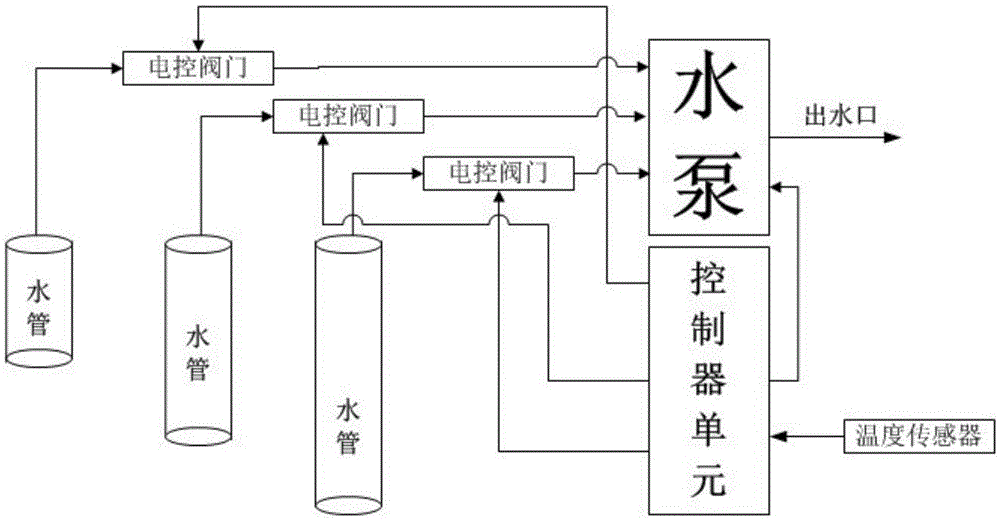

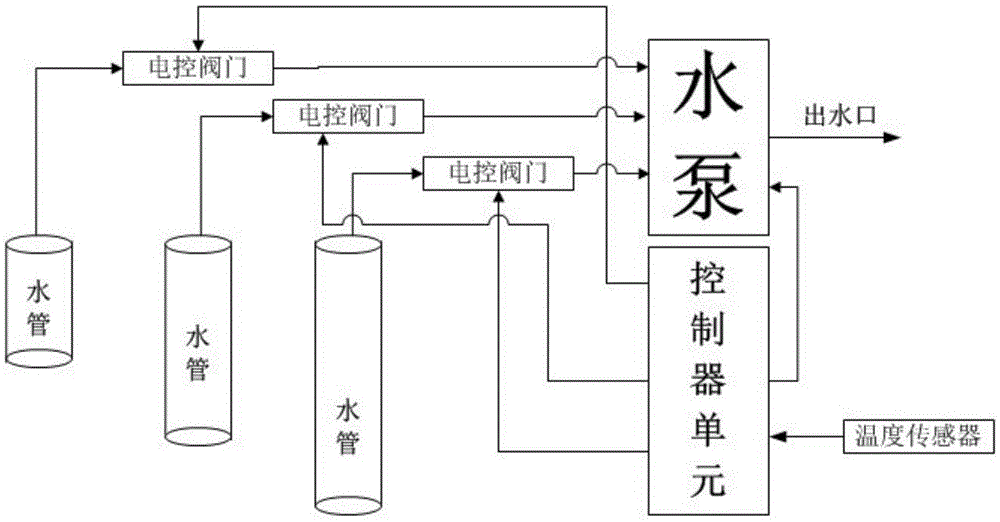

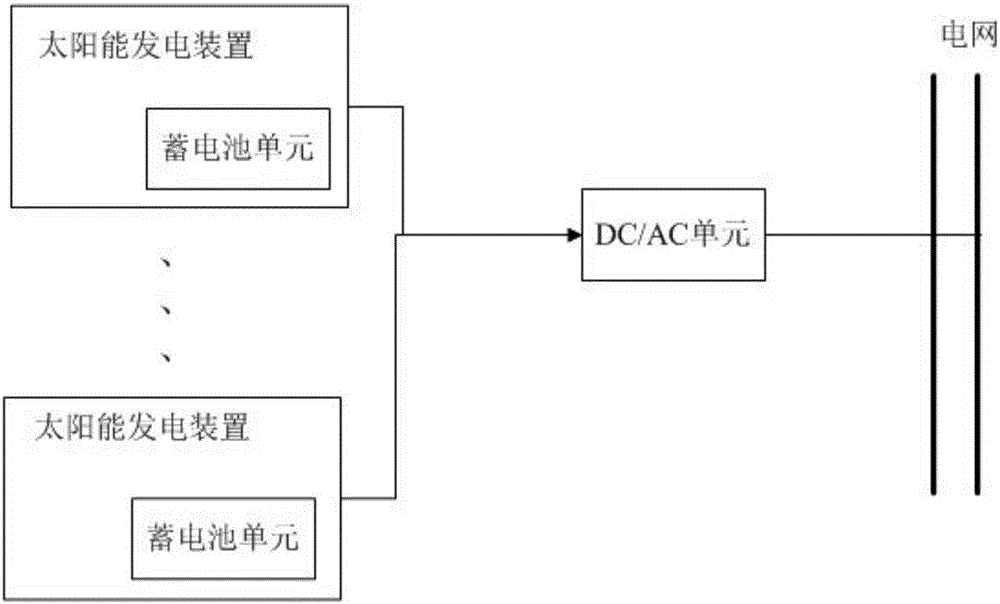

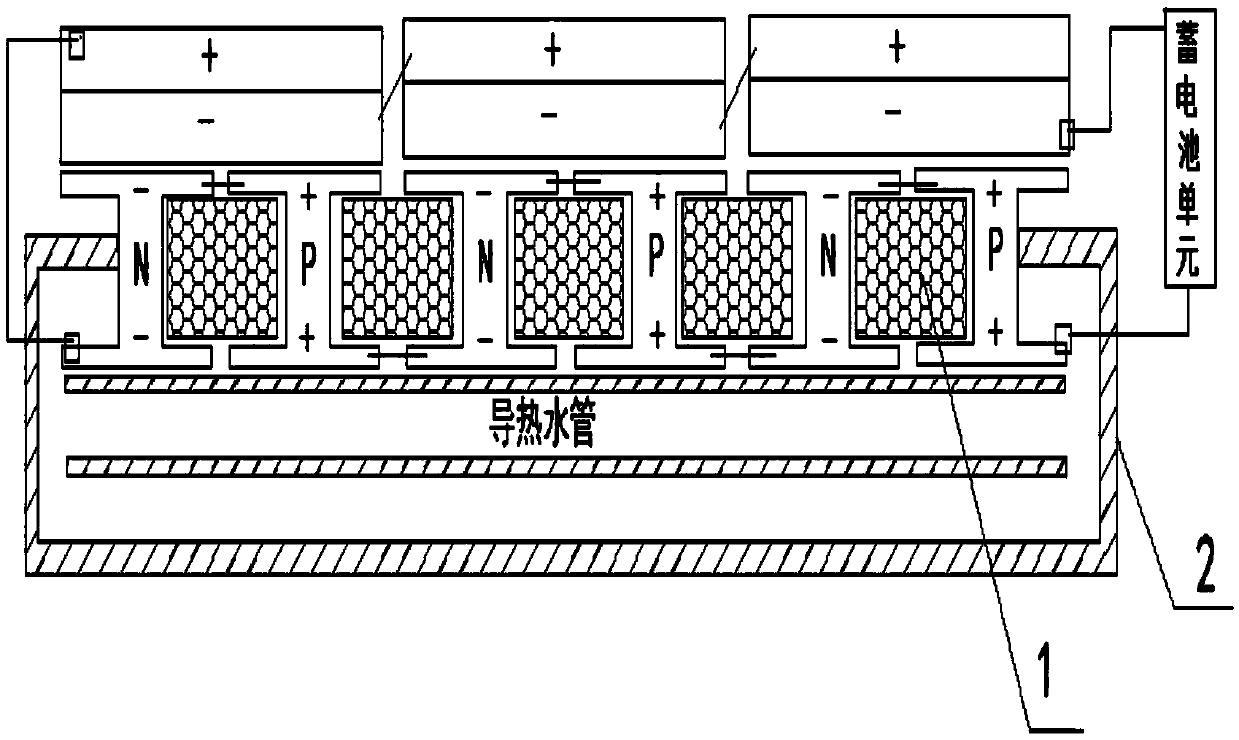

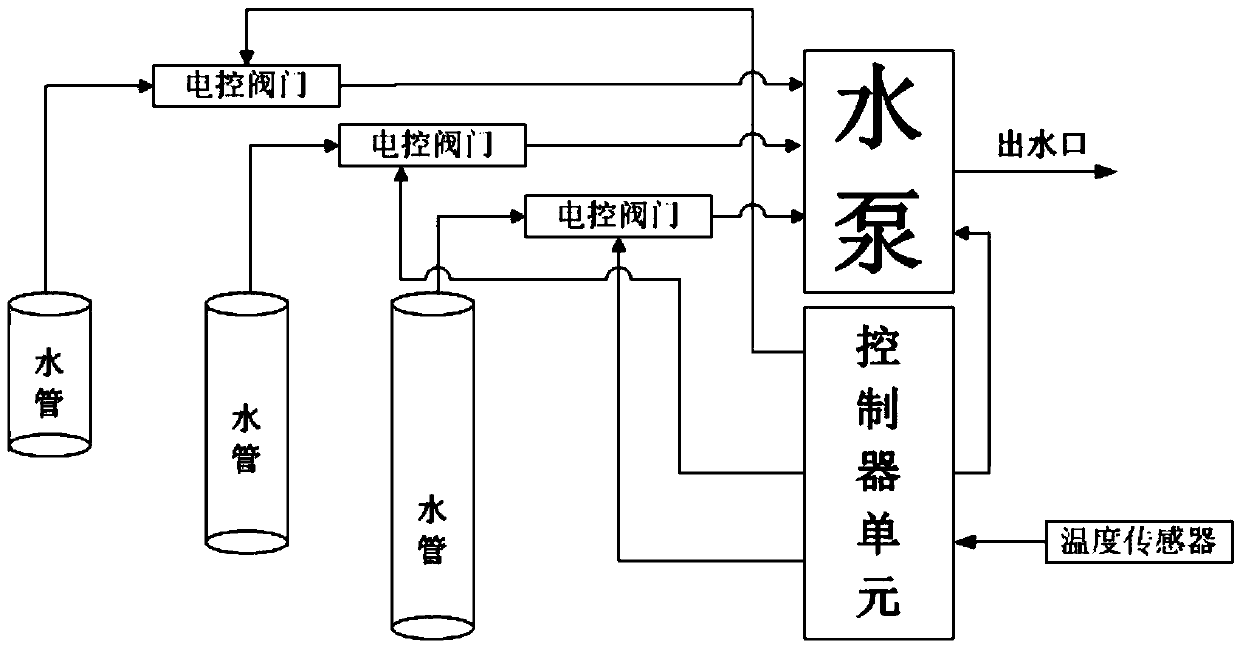

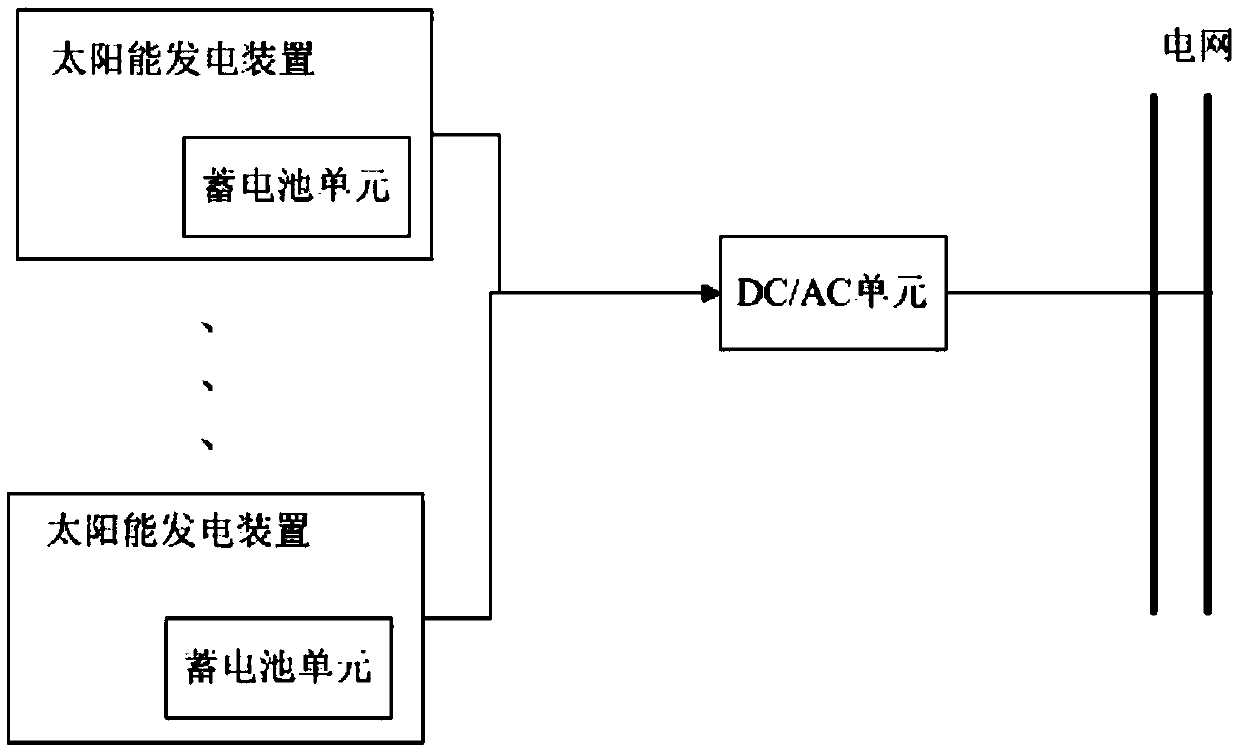

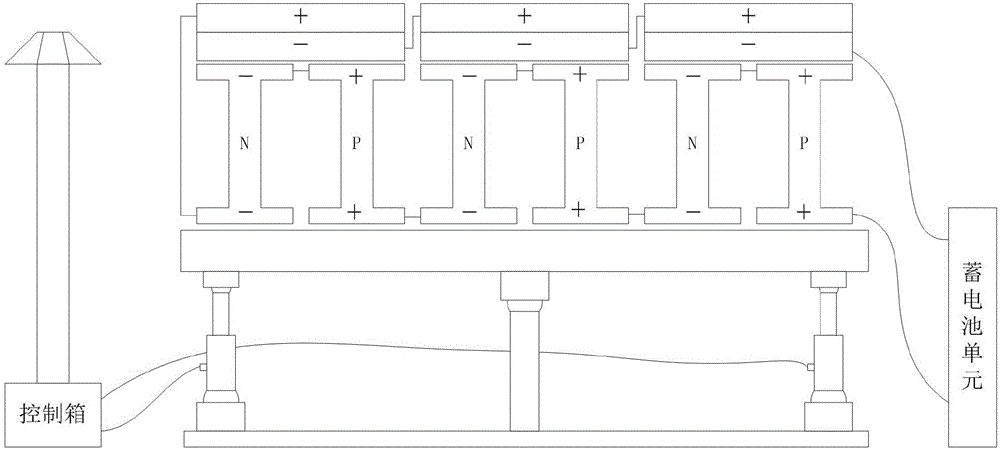

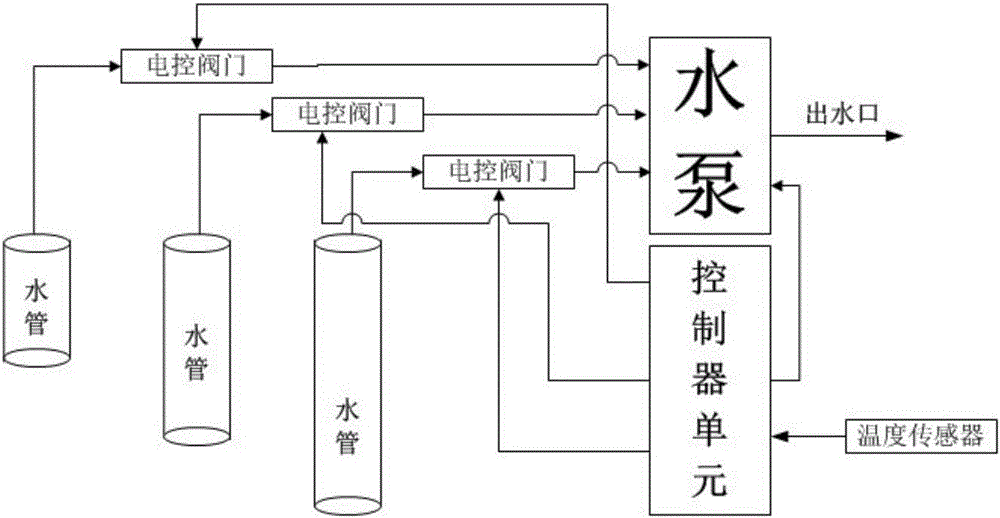

Solar power generating device

InactiveCN105553387AProlonged diffusion timeIncrease contact areaOther heat production devicesPV power plantsElectrical batteryControl valves

The invention discloses a solar power generating device, comprising a plurality of thin film solar cells, M N-type semiconductors, M P-type semiconductors, a thermal-conductive water pipe, an accumulator unit, a controller unit, 4M temperature sensors, a water pump, N electronic control valves, N water pipes and S radiating pipes, wherein the N-type semiconductors and the P-type semiconductors are all I-shaped; the section of the thermal-conductive water pipe is square in shape; the N water pipes vary in length, and the length is ranged from 5m to 200m; the N-type semiconductors and the P-type semiconductors are arranged at intervals, and the adjacent N-type semiconductor and P-type semiconductor are connected in series; the plurality of thin film solar cells are connected in series, and then connected with the N-type semiconductors and the P-type semiconductors in series, and at last used for charging the accumulator unit. According to the solar power generating device, solar power generation is effectively combined with thermoelectric power generation, a very effective technical scheme using solar energy and geothermal energy is provided, and the power generation efficiency is higher.

Owner:孙啸

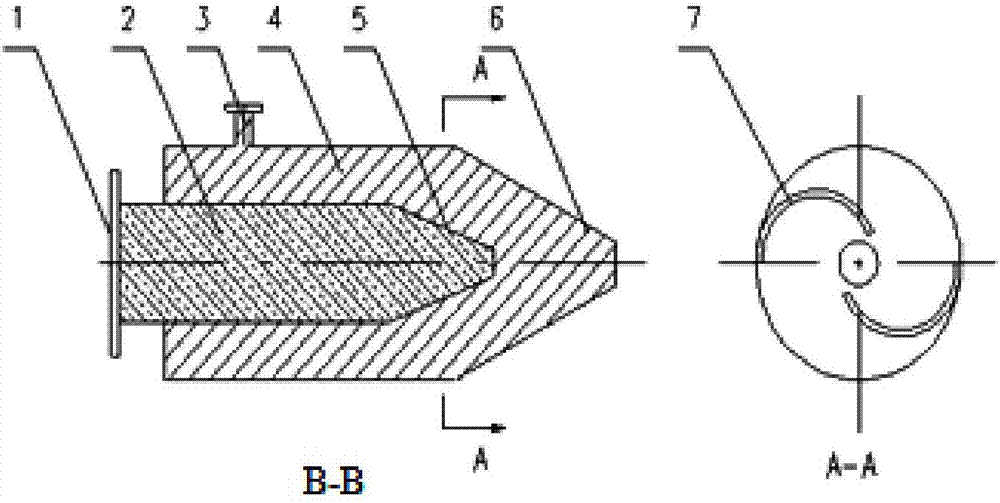

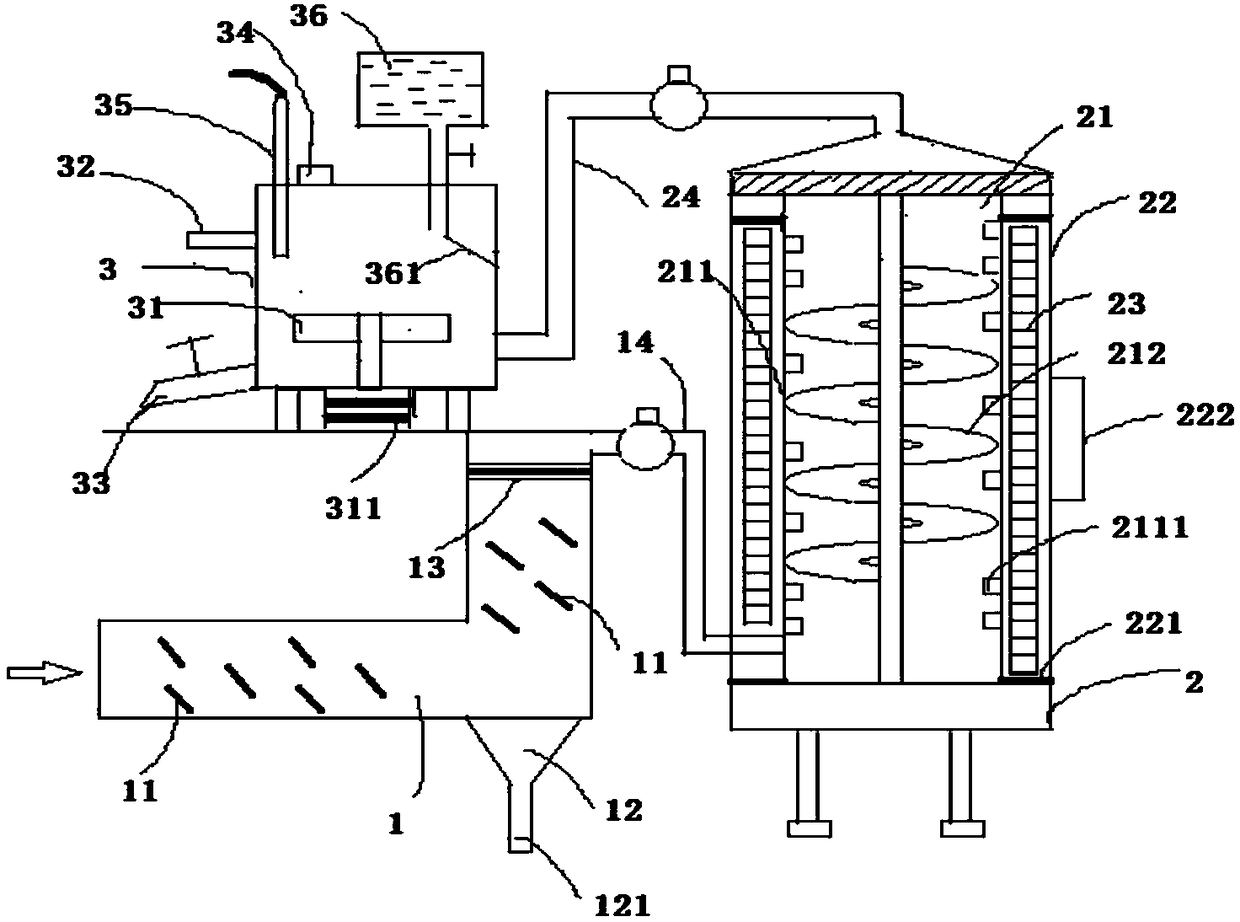

High-efficiency anti-clogging cyclone combined jet aeration device

PendingCN107226539AIncrease mass transfer rateImprove transfer rateTreatment using aerobic processesWater aerationCycloneGas chamber

The invention discloses a high-efficiency anti-clogging cyclone combined jet aeration device. The jet aeration device comprises a gaseous phase pipe, a liquid phase pipe, a water inlet end, a gas inlet end, a water chamber, a gas chamber, hydraulic ejectors, gas-liquid ejectors and a gas-liquid cyclone structure, wherein multiple groups of concentric hydraulic ejectors and gas-liquid ejectors are arranged on the side of the gaseous phase pipe and the side of the liquid phase pipe; the liquid phase pipe is connected with the water inlet end; the water inlet end is connected with the water chamber; the hydraulic ejectors are arranged at the end part of the water chamber; the gaseous phase pipe is connected with the gas inlet end; the gas inlet end is arranged on the side of the gas chamber; the gas-liquid ejectors are arranged at the end part of the gas chamber; the water chamber and the hydraulic ejectors are coaxial and are arranged in the gas chamber and the gas-liquid ejectors along the same direction. According to the high-efficiency anti-clogging cyclone combined jet aeration device disclosed by the invention, tapers and ejection orifices of the hydraulic ejectors and the gas-liquid ejectors are optimized, gas-liquid rapid mixed cutting and spiral jetting in the gas chamber are realized, the oxygenation diffusion capacity of jet flows is improved, and double functions of pushing flow and diffusion are realized.

Owner:宜兴市荣盛达环保有限公司

Carburizing method of low-carbon alloy steel

ActiveCN103014595BAccelerate decomposition and crackingIncrease carburizing speedSolid state diffusion coatingCarbon potentialMetallurgy

The invention discloses a carburizing method of low-carbon alloy steel. According to the method, through high-temperature deep seepage, the diffused carbon potential can be properly lowered, and the diffusion time can be prolonged, the time can be effectively shortened, the energy consumption can be reduced, and the carburized low-carbon alloy steel can meet the technical requirements.

Owner:金湖县常盛动力机械配件有限公司

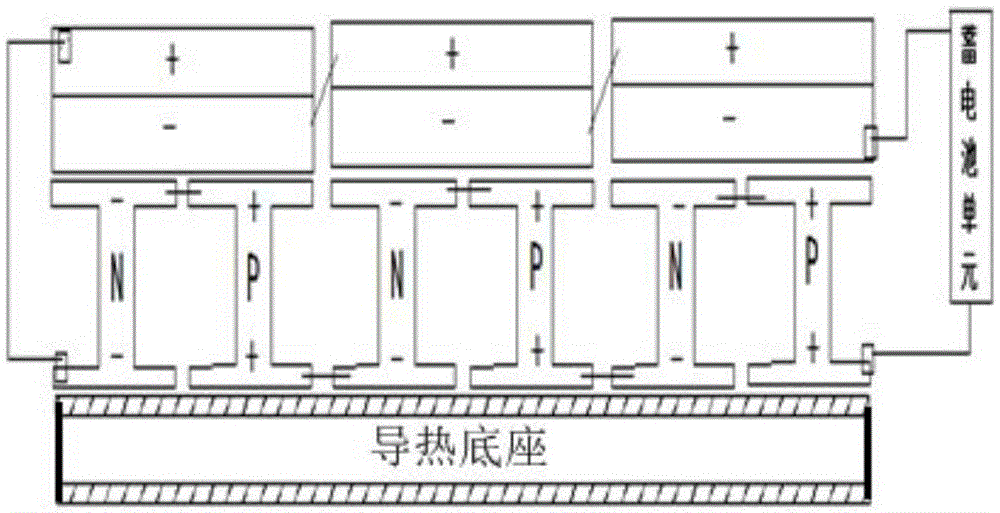

Solar power generation apparatus

InactiveCN105634402AIncrease contact areaProlonged diffusion timePhotovoltaic supportsSolar heating energyWater storageHeat conducting

The invention discloses a solar power generation apparatus. The solar power generation apparatus comprises thin film solar cells, N type semiconductors, P type semiconductors, a heat conducting base, a storage battery unit, a controller unit, temperate sensors, a water pump, electronic control valves, water pipes, electric telescopic rods, a supporting column, a control box, a threaded telescopic rod, a supporting bottom plate and a sensing head, wherein the N type semiconductors and the P type semiconductors are both I-shaped; spray headers are arranged in the water storage cavity of the heat conducting base; the two electric telescopic rods and the supporting column support between the heat conducting base and the supporting bottom plate; the N type semiconductors and the P type semiconductors are arranged at intervals, and the adjacent N type semiconductors and the P type semiconductors are connected in series; the multiple thin film solar cells are connected in series, and then are connected with the N type semiconductors and the P type semiconductors in series; and finally, the thin film solar cells charge the storage battery unit. According to the solar power generation apparatus, the solar power generation and the thermoelectric power generation are effectively combined; and a quite effective technical scheme utilizing the solar energy and the geothermal energy is provided, so that the solar power generation apparatus is higher in power generation efficiency.

Owner:孙啸

Liquid embolism composition and application thereof, medical interventional instrument and interventional therapy medicine

ActiveCN114344551ASlow diffusion rateReduce lossesSurgical adhesivesPharmaceutical delivery mechanismMedicinePharmaceutical drug

The invention relates to a liquid embolism composition and application thereof, a medical interventional instrument and an interventional therapy drug. The liquid embolism composition is a dispersed mixed solution, the dispersed mixed solution comprises a dispersing agent solution in a continuous phase and developable solid particles which are dispersed in the dispersing agent solution and are in a dispersed state, and the developable solid particles are provided with holes allowing the dispersing agent solution to enter. And the dispersing agent solution contained in the holes and the dispersing agent solution outside the developable solid particles form a continuous phase. Therefore, the loss of the developer caused by rapid diffusion of the solvent can be reduced, and the developer is effectively cured through the polymer, so that the developing and embolism performances of the liquid embolism composition are ensured.

Owner:NEULIXIR MEDICAL (SHANGHAI) CO LTD

Manufacturing method of bidirectional power device

ActiveCN112309976AReduce areaImprove withstand voltage characteristicsEfficient power electronics conversionSolid-state devicesGate dielectricEngineering

The invention discloses a manufacturing method of a bidirectional power device. The manufacturing method comprises the following steps: forming a first doped region in a semiconductor layer; forming aplurality of trenches in the first trench region, wherein the plurality of trenches of the first trench region are located in the first doped region and divide the first doped region into alternatingfirst-type sub-doped regions and second-type sub-doped regions; forming a gate dielectric layer covering the side walls of the lower parts of the plurality of trenches of the first trench region; forming control gates which are in contact with the gate dielectric layer at the lower parts of the plurality of trenches of the first trench region; forming a shielding dielectric layer, wherein the shielding dielectric layer covers the upper side walls of the plurality of trenches of the first trench region and the surfaces of the control gates; and forming shield gates which are in contact with the shield dielectric layer on the upper portions of the plurality of trenches of the first trench region, wherein the shield dielectric layer separating the control gates from the shield gates. According to the manufacturing method, the first doped region is divided into the first-type sub-doped regions and the second-type sub-doped regions which are alternated by the trenches to form a source region and a drain region of the bidirectional power device, so the area of the device is reduced.

Owner:HANGZHOU SILAN MICROELECTRONICS

High efficiency denitration equipment

InactiveCN108097041AIncreased reaction paths and diffusion timesImprove denitrification effectCombination devicesGas treatmentAirflowEngineering

The invention provides high efficiency denitration equipment. The flue gas flow enters the bottom of a denitrator tank, then slowly diffuses upwards from the bottom of a spiral air duct since the spiral air duct is vertically arranged, is continuously in contacted with a denitration catalyst plate through holes in a diffusion process so as to be subjected to catalytic purification, and is finallydischarged out from a gas outlet. The flue gas flow slowly diffuses upwards from the bottom upwards along the vertically arranged spiral air channel and is in contacted with the denitration catalyst plate through the holes in the diffusion process so as to be subjected to catalytic purification. The spiral air duct can increase a reaction path and diffusion time, and can effectively improve the denitration effect.

Owner:天津浩创节能环保设备有限公司

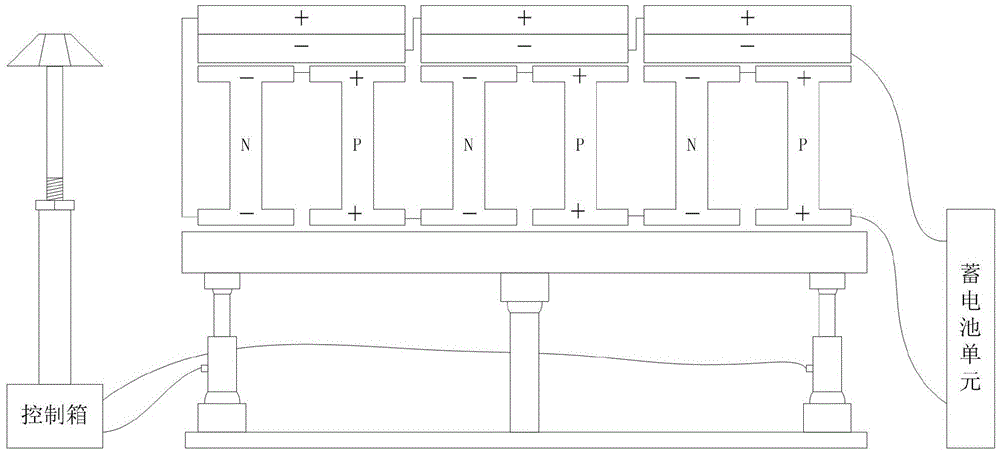

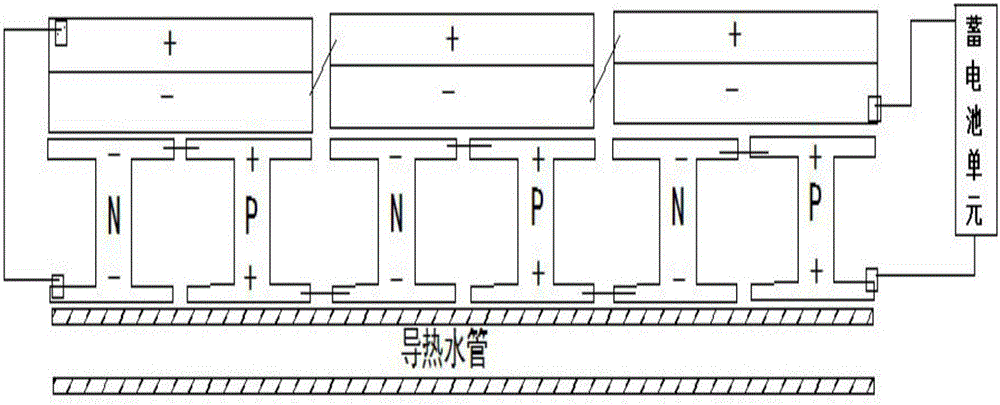

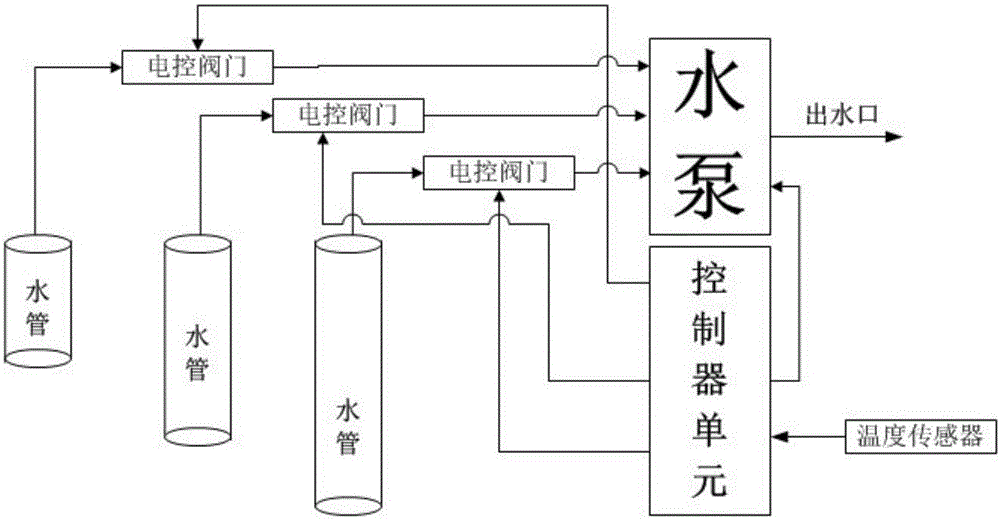

Solar generating set

InactiveCN105529984ASimple structureProlonged diffusion timeBatteries circuit arrangementsLighting and heating apparatusWater pipeEngineering

The invention discloses a solar generating set which comprises a plurality of thin film solar cells, M N-type semiconductors, M P-type semiconductors, a heat conducting base, a storage battery unit, a controller unit, 4M temperature sensors, a water pump, N electric control valves, and N water pipes. Both the N-type semiconductors and the P-type semiconductors are of an I shape; diversion baffles are arranged in a staggered manner in a water storage cavity of the heat conducting base; the N water pipes have different lengths, and have a length range of 5m to 200m; the N-type semiconductors and the P-type semiconductors are arranged at intervals, and the adjacent N-type semiconductors and P-type semiconductors are connected in series; the plurality of thin film solar cells are connected in series, then are connected in series with the N-type semiconductors and the P-type semiconductors, and finally, charge the storage battery unit. According to the solar generating set disclosed by the invention, solar power generation and temperature difference power generation are effectively combined, a very effective technical scheme which utilizes solar energy and geothermal energy is provided, and power generation efficiency is higher.

Owner:孙啸

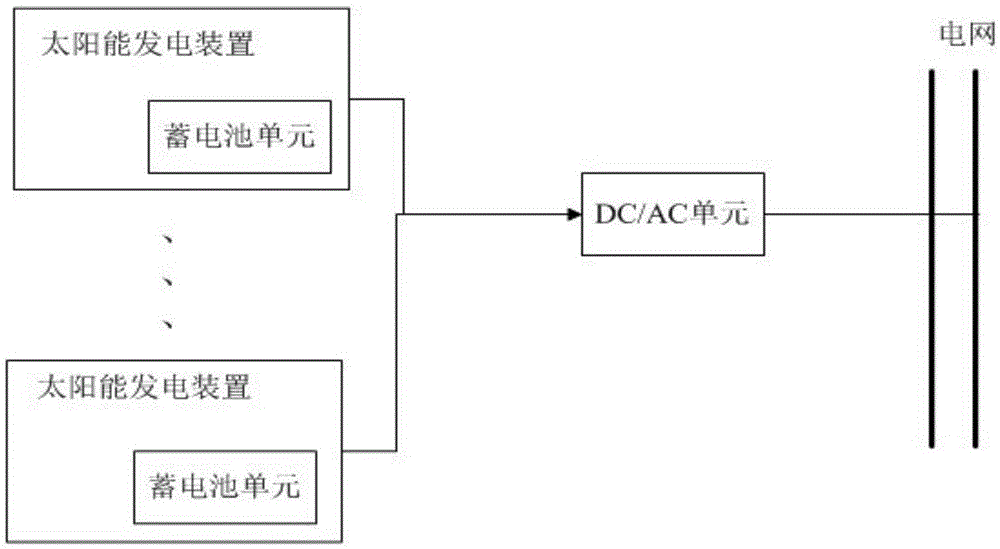

Solar energy generation device

InactiveCN105915154AProlonged diffusion timeIncrease contact areaBatteries circuit arrangementsOther heat production devicesElectrical batteryEngineering

The present invention discloses a solar energy generation device. The solar energy generation device comprises a plurality of thin-film solar cells, M N-type semiconductors, M P-type semiconductors, a heat conduction water pipe, a storage battery unit, a controller unit, 4M temperature sensors, a water pump, N electric control valves and N water pipes. The N-type semiconductors and the P-type semiconductors are I-shaped; the section of the heat conduction water pipe is in a square shape; the lengths of the N water pipes are different, and the range of the lengths is from 5m to 200m; the N-type semiconductors and the P-type semiconductors are arranged at intervals, and adjacent N-type semiconductors and P-type semiconductors are connected in series; and the thin-film solar cells are connected in series with each other and with the N-type semiconductors and the P-type semiconductors and are configured to charge the storage battery unit. Through effective combination of the solar energy generation and thermoelectric generation, the solar energy generation device provides a very efficient technical scheme by using the solar energy and the geothermal energy so as to improve the generation efficiency.

Owner:俞亮芽

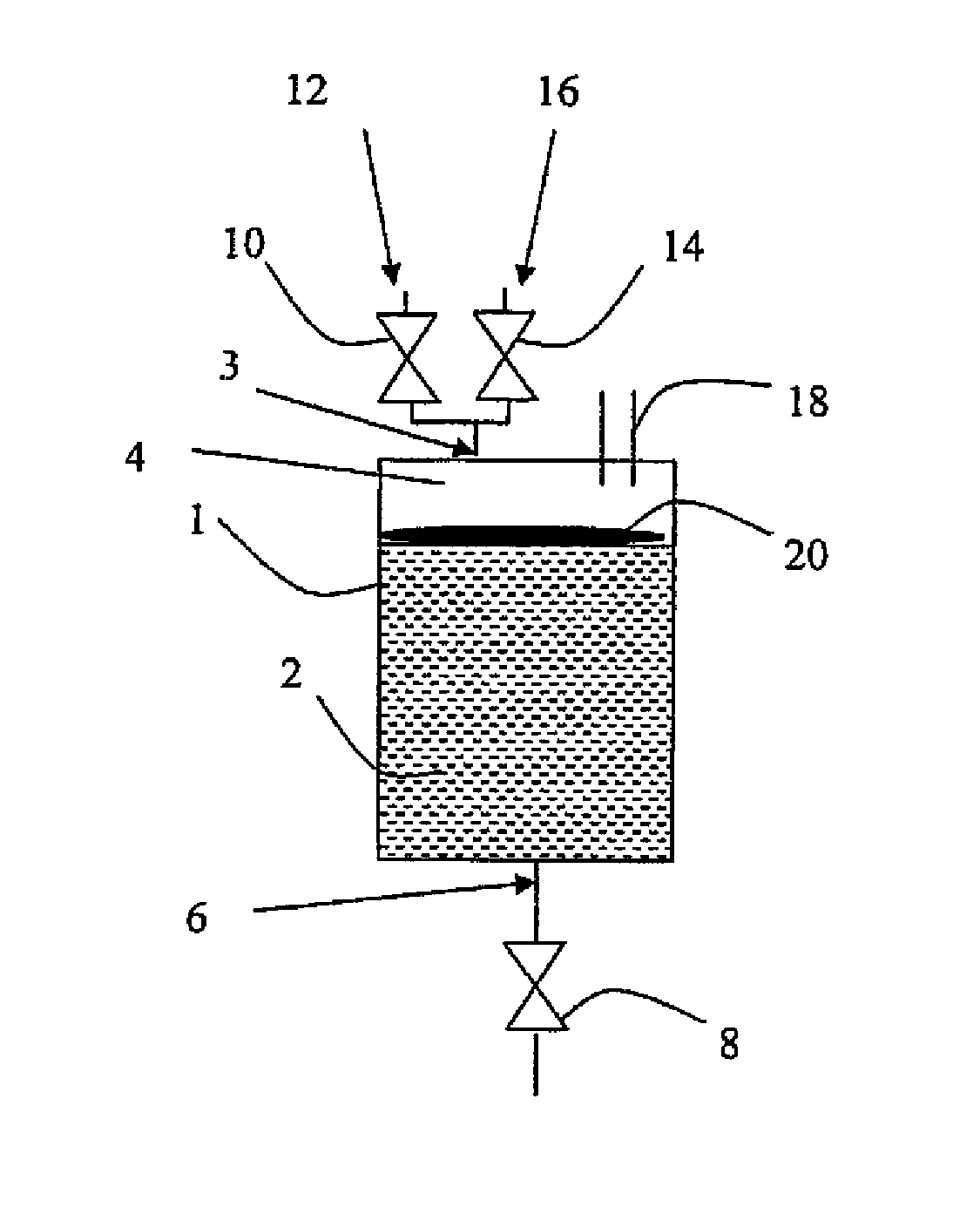

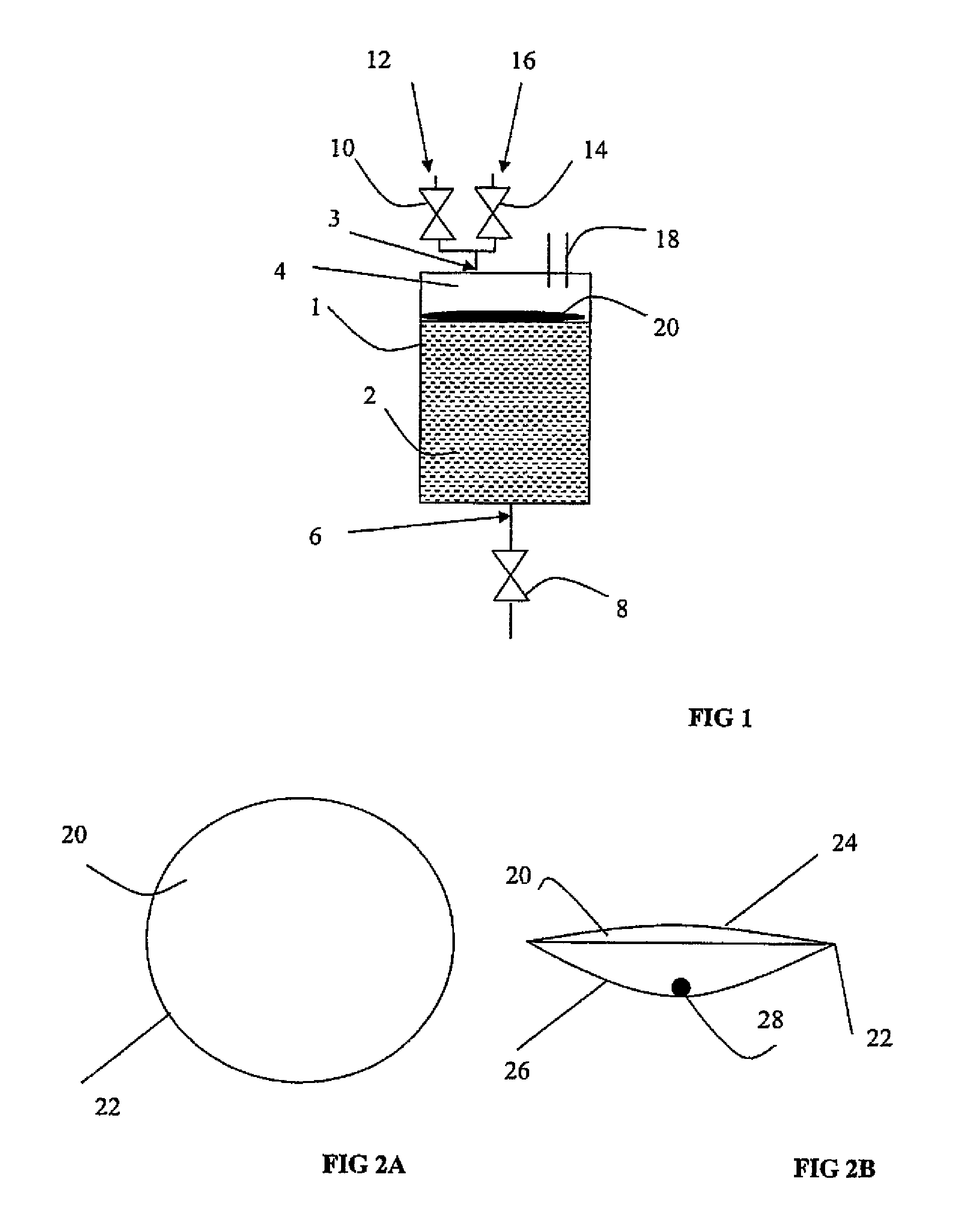

Diffusion barrier in a delivery apparatus for pressurized medical liquids

InactiveUS8205610B2Prolonged diffusion timeInhibited DiffusionRespiratorsLiquid surface applicatorsDiffusion barrierBiomedical engineering

A delivery apparatus for pressurized medical liquids has a reservoir for medical liquid and a pressurizing means configured for pressurizing medical liquid to a driving pressure; with a diffusion barrier arranged to float on medical liquid in the reservoir and disposed to cover substantially the entire surface of the medical liquid in the reservoir for the purpose of preventing diffusion of gas present in the reservoir into the medical liquid.

Owner:MAQUET CRITICAL CARE

Solar power generating device

InactiveCN105515500AIncrease contact areaSimple structurePV power plantsEnergy storageHeat conductingElectrical battery

The invention discloses a solar power generating device, which comprises a plurality of film solar batteries, M N type semiconductors, M P type semiconductors, a heat conducting water pipe, a storage battery unit, a controller unit, 4M temperature sensors, a water pump, N electric control valves and N water pipes, wherein each of the N type semiconductors and the P type semiconductors is in an I shape; the radial cross section of the heat conducting water pipe is in a square shape; the lengths of the N water pipes are different, and the length range is between 5m and 200m; the N type semiconductors and the P type semiconductors are arranged at intervals; the adjacent N type semiconductor and P type semiconductor are connected in series; the plurality of film solar batteries are connected in series and are then connected in series with the N type semiconductors and the P type semiconductors; finally, the storage battery unit is charged. The solar power generating device has the advantages that solar power generation and temperature difference power generation are effectively combined; a very efficient technical scheme using solar energy and geothermal energy is provided; the power generating efficiency is higher.

Owner:俞亮芽

Solar power device

InactiveCN105703693AIncrease contact areaProlonged diffusion timePhotovoltaic supportsSolar heating energySolar powerControl valves

The present invention discloses solar power device. The solar power device comprises solar energy cells, N-type semiconductors, P-type semiconductors, a heat conduction pedestal, a storage battery unit, a controller unit, a temperature sensor, a water pump, a electronic control valve, a water pipe, electric expansion links, a supporting column, a control box, a supporting tube, a supporting base plate and a sensing head. The N-type semiconductors and the P-type semiconductors are I-shaped; diversion baffle plates are alternately arranged in the water storage cavity of the heat conduction pedestal; the two electric expansion links and a supporting column are supported between the heat conduction pedestal and the supporting base plate; N-type semiconductor and the P-type semiconductor are arranged at intervals, and each adjacent N-type semiconductor and P-type semiconductor are connected in series; and a plurality of thin-film solar energy cells is connected in series, connected in series with the N-type semiconductors and the P-type semiconductors, and is configured to charge the storage battery unit. Through effective combination of solar power generation and thermoelectric power generation, the solar power device provides a very effective technical scheme by employing solar energy and geothermal energy so as to improve generation efficiency.

Owner:孙啸

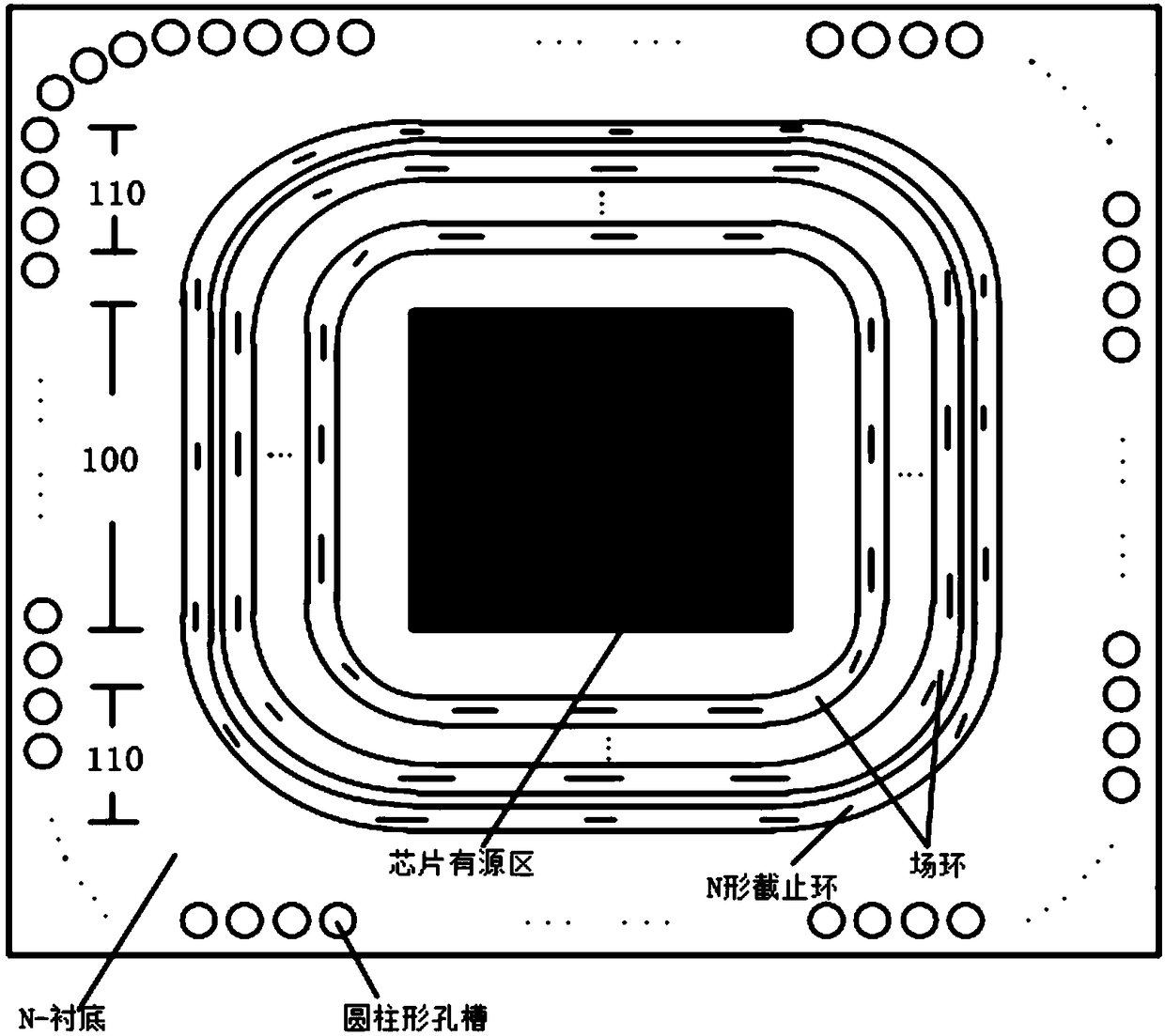

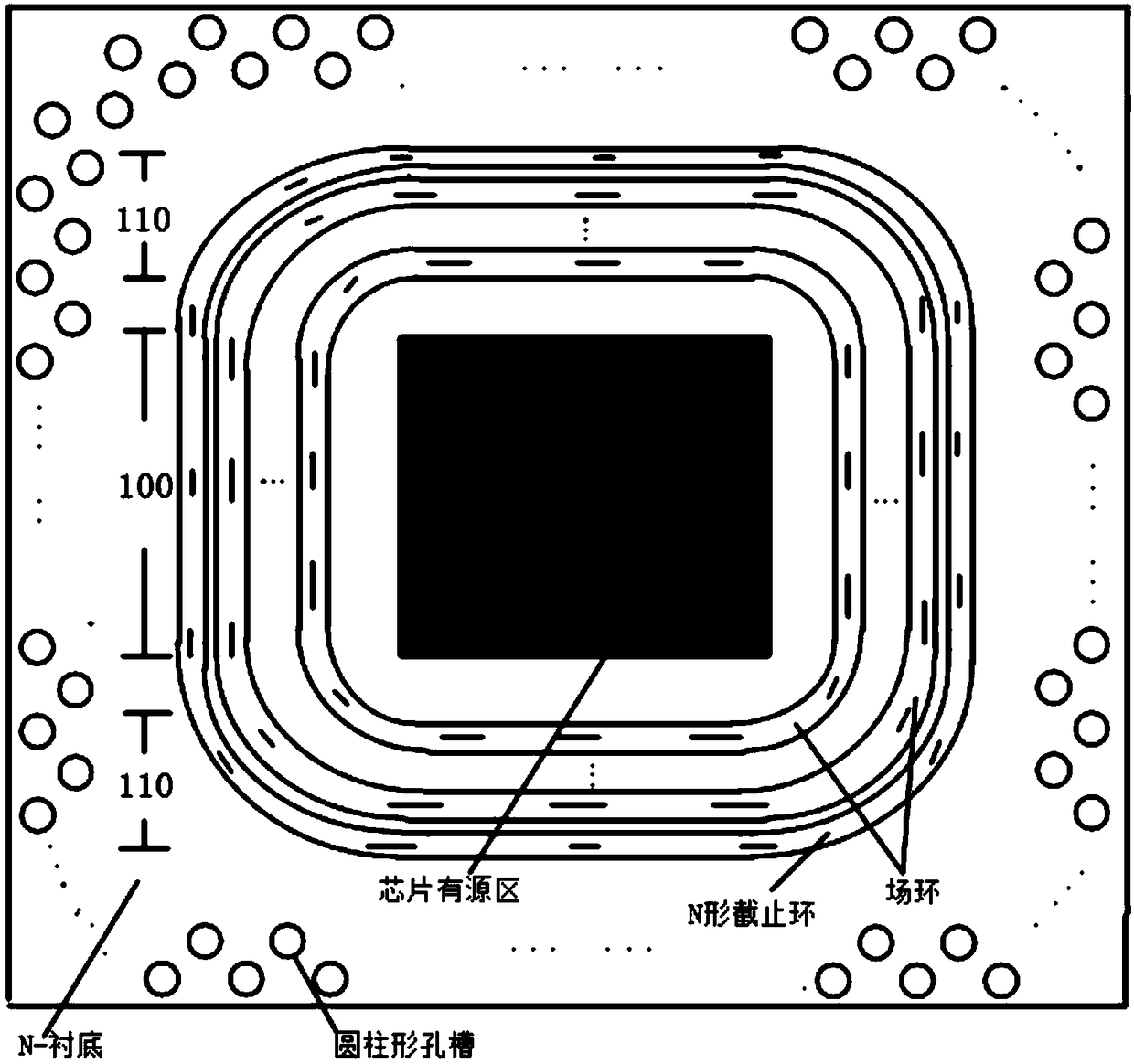

Chip of reverse blocking IGBT and manufacturing method

InactiveCN109346514AReduce chip termination area areaAvoid leakage currentTransistorSemiconductor/solid-state device manufacturingIonCurrent generation

The invention relates to a chip of a reverse blocking IGBT and a manufacturing method. According to the chip and the manufacturing method, hole grooves are formed in the edge of the chip to make contact with a collector P+ area on the back of the chip; and by adoption of physical gas deposition, the chip is put in gas which is full of boron ions to ensure that the boron ions are transversely diffused along the inner walls of the hole grooves until diffusion knots between the hole grooves make contact so as to form a diffusion and isolation area around a terminal area. Different from the conventional reverse blocking IGBT, the method adopts a diffusion method to manufacture the isolation area, so that the diffusion time is short, the operation is not influenced by the thickness of a substrate, the usable area of the isolation area is few and the chip area utilization rate is high. The bottoms of the hole grooves make contact with the collector P+ area on the back, so that the difficultythat the bottom of the diffusion and isolation area is difficult to make contact with the collector on the back as the substrate of a high-voltage device is relatively thick, and the diffusion knotsbetween the hole grooves make contact to form the overall diffusion P+ area so that the terminal area of the chip is isolated from the edge of the chip and then the edge of the chip is avoided from leakage current generation.

Owner:BEIJING UNIV OF TECH

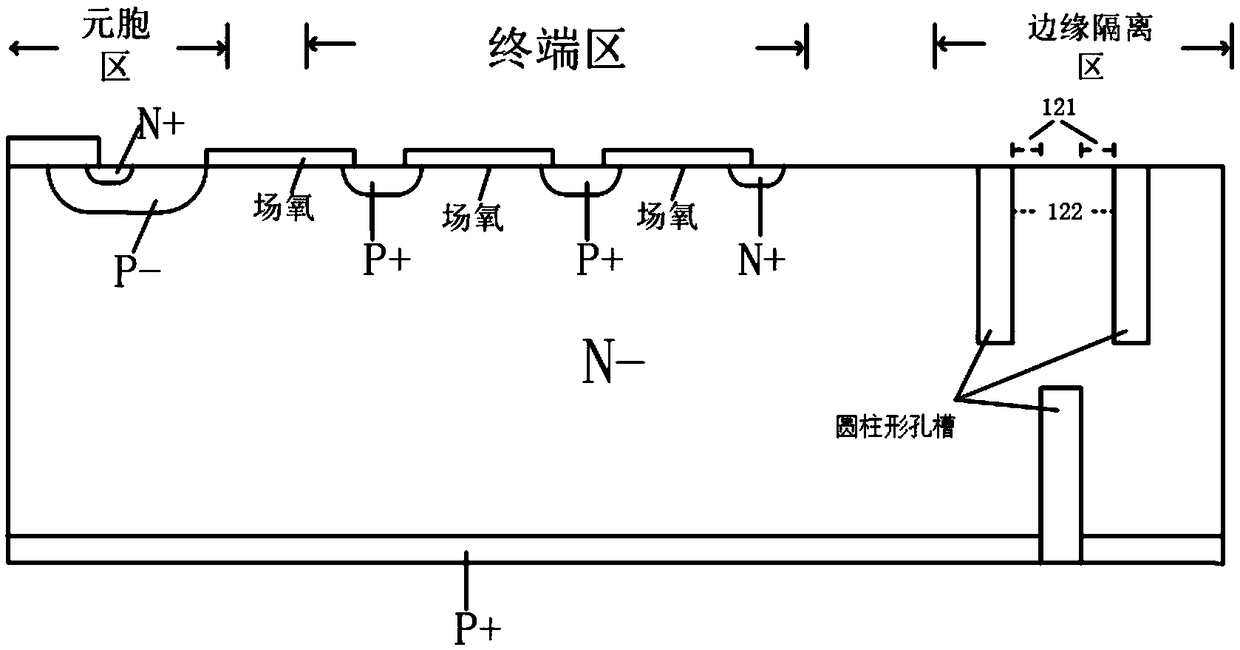

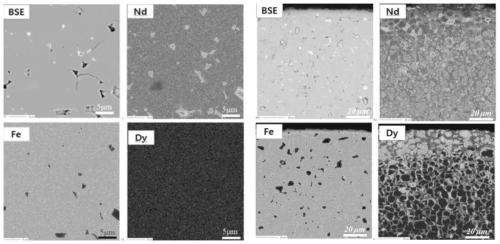

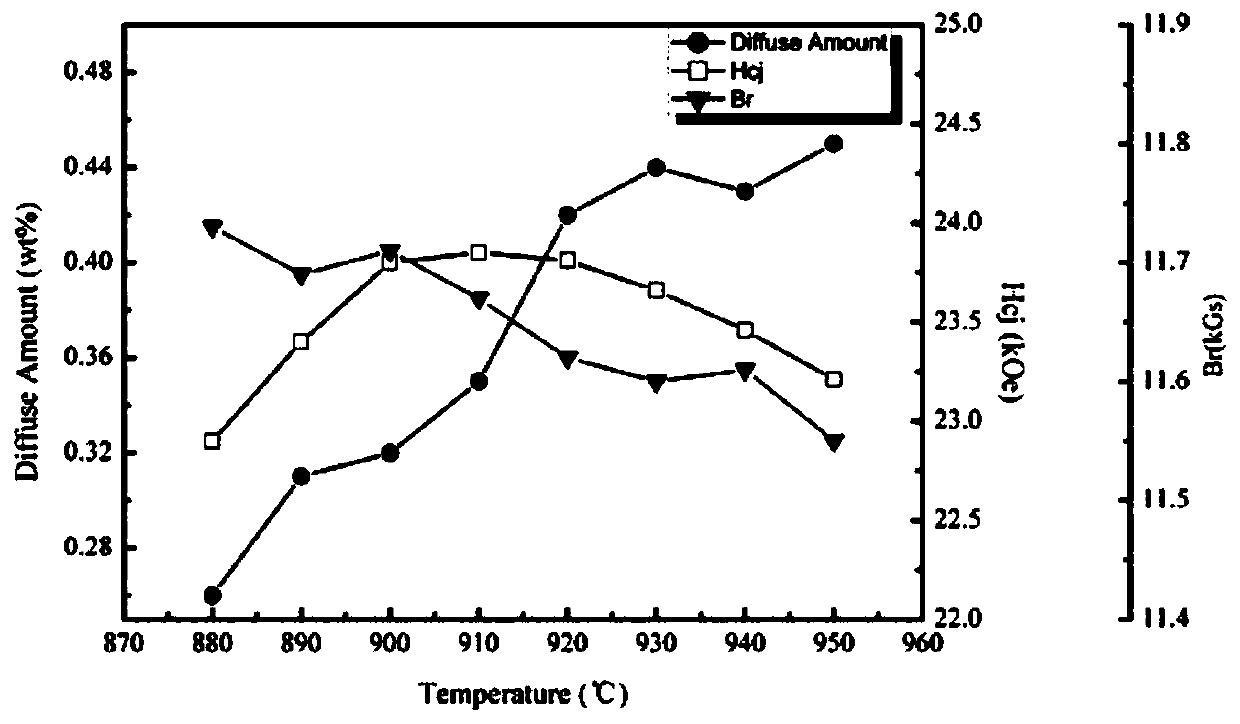

Neodymium-iron-boron permanent magnet material prepared from Dy and preparation method of neodymium-iron-boron permanent magnet material

InactiveCN111223622AExcellent diffusion synthesis performanceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsMetallurgyCurie temperature

The invention provides a neodymium-iron-boron permanent magnet material prepared from Dy and a preparation method of the neodymium-iron-boron permanent magnet material. The preparation method comprises the following steps that the surface of a neodymium-iron-boron regenerated magnet sample is coated with a layer of Dy element powder, and sintering is carried out in a vacuum sintering furnace, so that the Dy element diffuses on the Nd2Fe14B phase grain boundary, and finally, the neodymium-iron-boron permanent magnet material with a shell structure is formed. The Dy is diffused in the neodymiumiron boron grain boundary to synthesize the permanent magnet material with more excellent performance. The surface of the neodymium-iron-boron regenerated magnet is coated with the layer of Dy elementpowder; and sintering is carried out in the vacuum sintering furnace, so that the Dy element is diffused on the Nd2Fe14B phase grain boundary to synthesize the permanent magnet material with the core-shell structure in which the Nd2Fe14B phase wrapped by the heavy rare earth, and the coercive force, the magnetic energy product, the Curie temperature and the like of the neodymium-iron-boron regenerated magnet can be remarkably improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

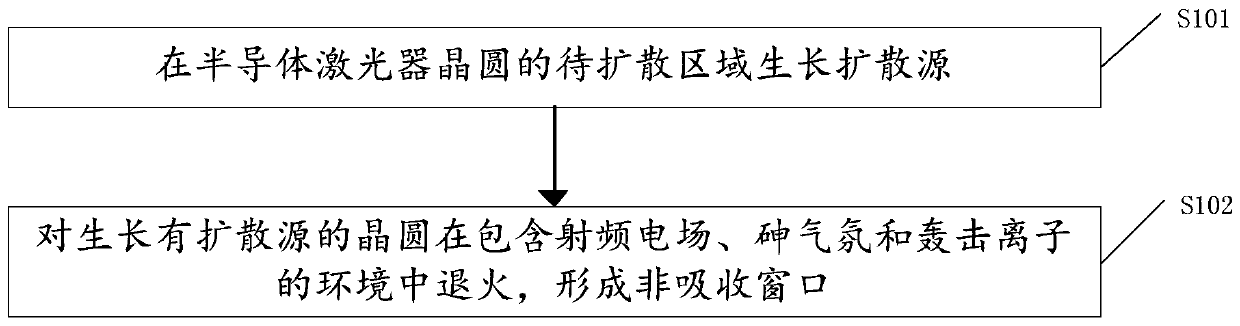

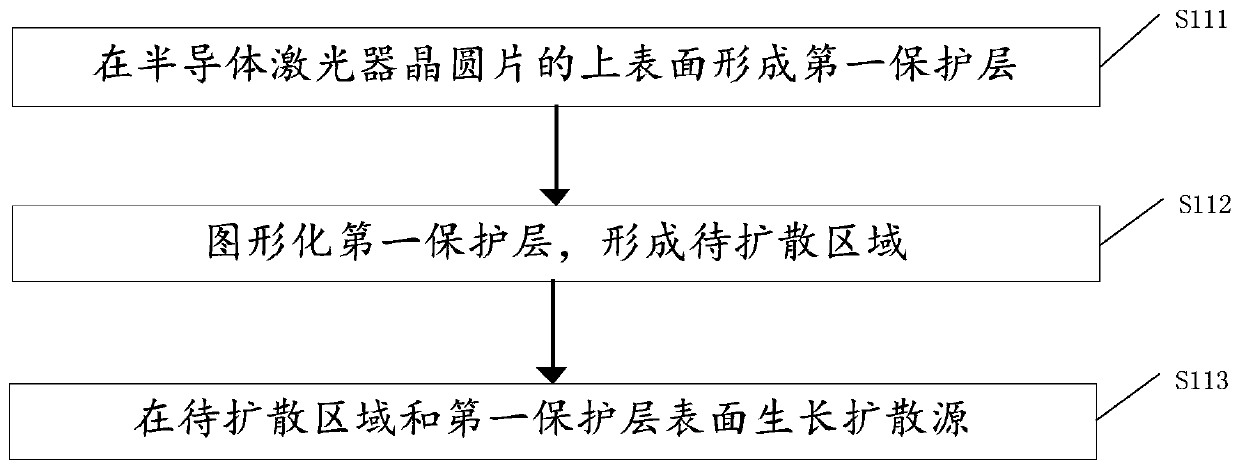

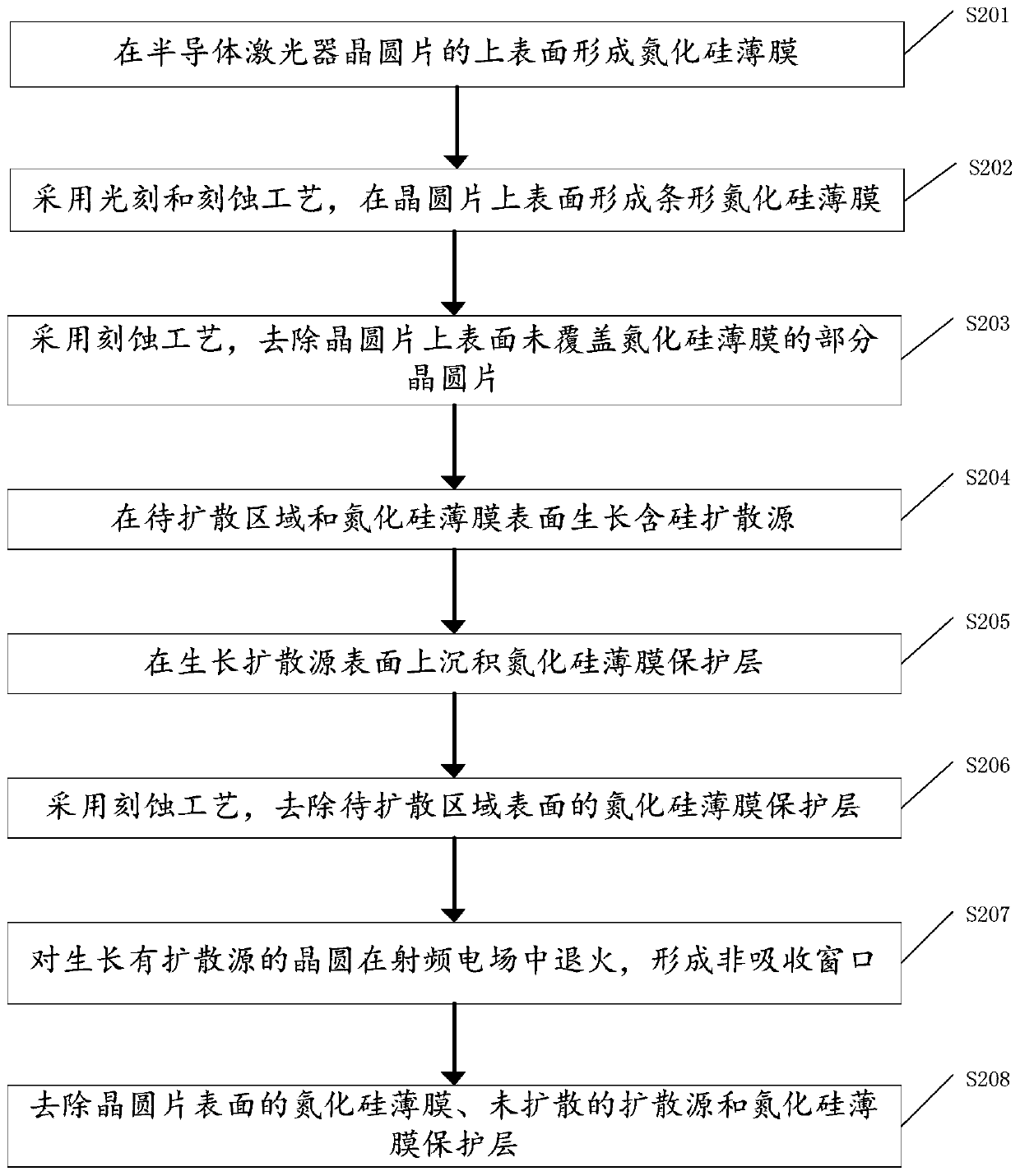

Semiconductor laser device non-absorption window and preparation method thereof, and semiconductor laser device

ActiveCN110086080AFacilitated DiffusionIncrease concentrationLaser detailsLaser active region structureVacancy defectSemiconductor

The invention discloses a semiconductor laser device non-absorption window and a preparation method thereof, and a semiconductor laser device. The preparation method comprises steps that a diffusion source is grown in a to-be-diffused region of a semiconductor laser wafer, and a wafer grown with the diffusion source is annealed in the arsenic atmosphere and bombardment ion environment containing aradio frequency electric field to form the non-absorption window. Under the action of the RF electric field, the bombardment ions bombard a surface of the wafer, vacancy defects are created inside the diffusion source without a protective layer, the rich-As atom environment facilitates diffusion of Ga and Al atoms in the epitaxial layer into the diffusion source, the Ga and Al atoms are combinedwith As atoms inside the diffusion source while vacancies are left in the epitaxial layer, increase of the vacancies in the epitaxial layer can promote downward diffusion of impurities, concentrationand depth of downward diffusion of the impurities are improved, the diffusion temperature and the diffusion time are reduced, device reliability is improved, and manufacturing cost is reduced.

Owner:SUZHOU EVERBRIGHT PHOTONICS CO LTD

Coal mine composite colloid fire preventing and extinguishing material and preparation method thereof

ActiveCN113209539AImprove liquidityImprove structural strengthFire extinguisherSodium bicarbonateCellulose

The invention discloses a coal mine composite colloid fire preventing and extinguishing material. The material is prepared from the following raw materials in parts by weight: 1-2 parts of sodium carboxymethyl cellulose, 1-2 parts of agar, 12-15 parts of coal ash, 0.1-0.2 part of polyacrylamide, 3-5 parts of a cross-linking agent, 1-2 parts of sodium bicarbonate, 3-4 parts of a flame retardant, 3-5 parts of a foaming agent and 90-100 parts of water. The material is low in cost, good in water retention and flame retardance and excellent in fire preventing and extinguishing performance.

Owner:河南中煤矿业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com