Carburizing method of low-carbon alloy steel

A low-carbon alloy steel and carburizing technology, applied in the field of high-temperature direct quenching, can solve the problems of high energy consumption, low production capacity, and long medium-temperature carburizing time, so as to meet technical requirements, reduce production costs, and increase carburizing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

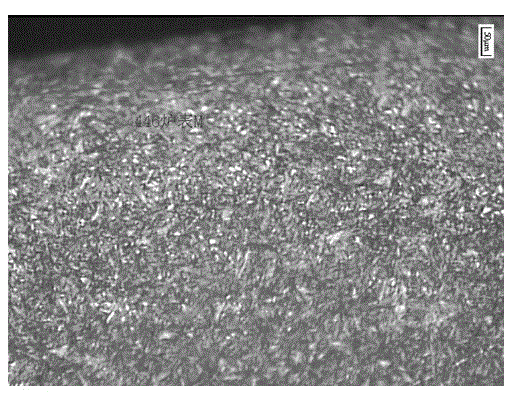

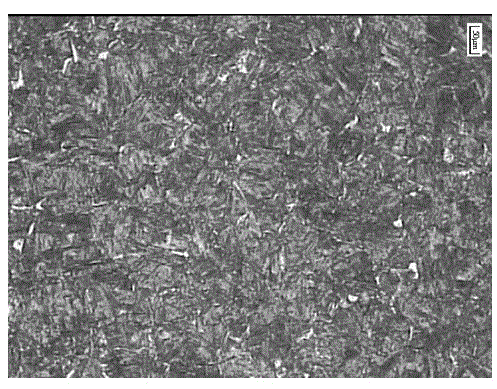

Image

Examples

Embodiment 1

[0023] (1) Preparation stage:

[0024] a. Preparation before opening the furnace: After the multi-purpose furnace starts the air infiltration or the continuous carburizing program, select the "low carbon alloy steel high temperature carburizing direct quenching process" and oil cooling method, and the furnace is loaded according to the automatic program to complete the furnace;

[0025] b, one stage (heating): set temperature (900 ℃) to start heating, feed methanol (4ml / min), adjust the atmosphere;

[0026] c. Stage 2 (determined at the temperature): the furnace temperature is raised to (900°C), set (5min), wait for time, and flow is adjusted to feed methanol (4ml / min), and the reference air pump is maintained (100ml / min);

[0027] d. The third stage (average temperature): set (10min), hold the time to make the temperature distribution in the furnace uniform, adjust the flow rate to introduce methanol (4ml / min), and keep the reference air pump (100ml / min).

[0028] (2) Strong...

Embodiment 2

[0038] (1) Preparation stage:

[0039] a. Preparation before opening the furnace: After the multi-purpose furnace starts the air infiltration or the continuous carburizing program, select the "low carbon alloy steel high temperature carburizing direct quenching process" and oil cooling method, and the furnace is loaded according to the automatic program to complete the furnace;

[0040] b, one stage (heating): set temperature (890 ℃) to start heating, feed methanol (3ml / min), adjust the atmosphere;

[0041] c. Stage 2 (determined at the temperature): the furnace temperature is raised to (890°C), set (5min), wait for time, flow is adjusted to feed methanol (3ml / min), and the reference air pump is maintained (80ml / min);

[0042] d. The third stage (average temperature): set (5min), hold the time to make the temperature distribution in the furnace uniform, adjust the flow rate to introduce methanol (3ml / min), and keep the reference air pump (80ml / min).

[0043] (2) Strong penetr...

Embodiment 3

[0053] (1) Preparation stage:

[0054] a. Preparation before opening the furnace: After the multi-purpose furnace starts the air infiltration or the continuous carburizing program, select the "low carbon alloy steel high temperature carburizing direct quenching process" and oil cooling method, and the furnace is loaded according to the automatic program to complete the furnace;

[0055] b, one stage (heating): set temperature (910 ℃) to start heating, feed methanol (5ml / min), adjust the atmosphere;

[0056]c. Stage 2 (determined at the temperature): the furnace temperature is raised to (910°C), set (5min), wait for time, flow is adjusted to feed methanol (5ml / min), and the reference air pump is maintained (120ml / min);

[0057] d. The third stage (average temperature): set (10min), hold the time to make the temperature distribution in the furnace uniform, adjust the flow rate to introduce methanol (5ml / min), and keep the reference air pump (120ml / min).

[0058] (2) Strong pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com