Patents

Literature

65results about How to "Reduce surface concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing fuel hose and fuel hose obtained thereby

InactiveUS6602565B1Improve bond reliabilityAdhesive strengthLayered product treatmentSynthetic resin layered productsEngineeringThermal aging

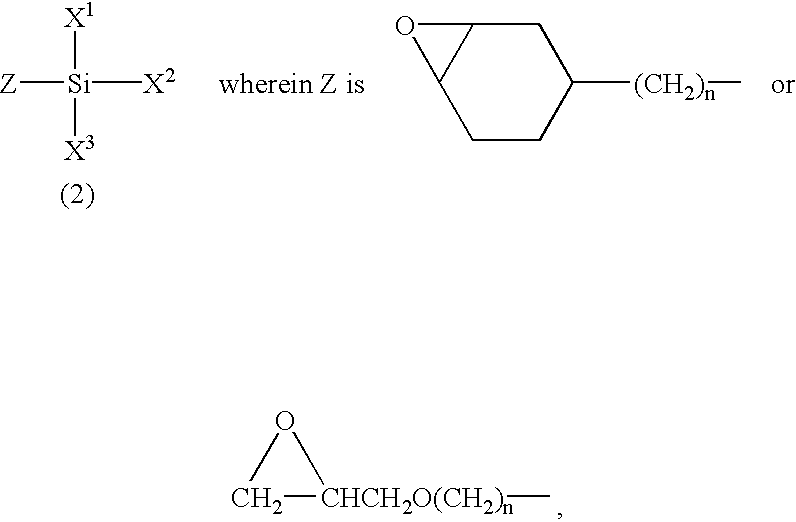

A method of producing a fuel hose having superior adhesive reliability with superior initial adhesive strength between a tubular fluororesin inner layer and a thermoplastic resin outer layer and with restrained deterioration in adhesive strength after heat aging and immersion into fuel under severe conditions such as an inside of an engine compartment. The method includes plasma treatment on a peripheral surface of the tubular fluororesin inner layer, at least one treatment of water treatment and silane coupling agent treatment on the plasma treated surface and formation of the thermoplastic resin outer layer on the treated peripheral surface.

Owner:SUMITOMO RIKO CO LTD

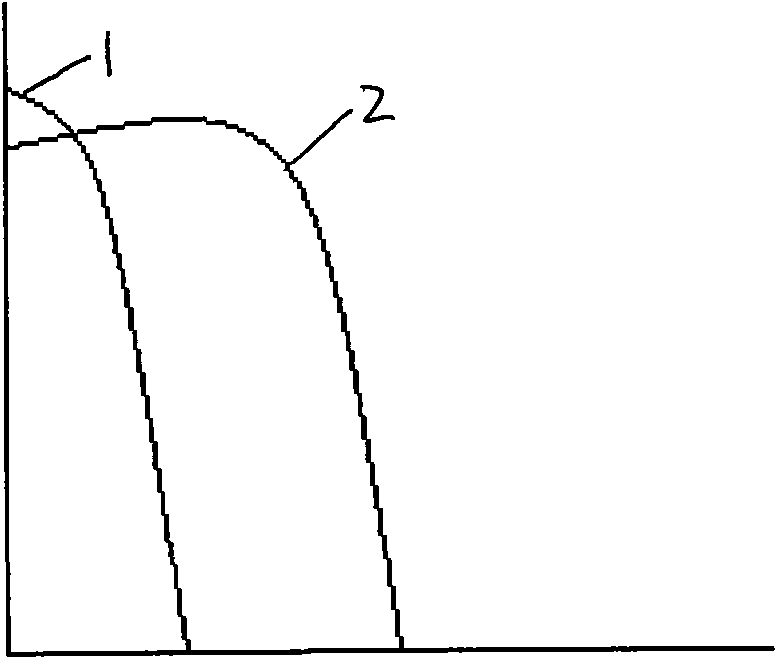

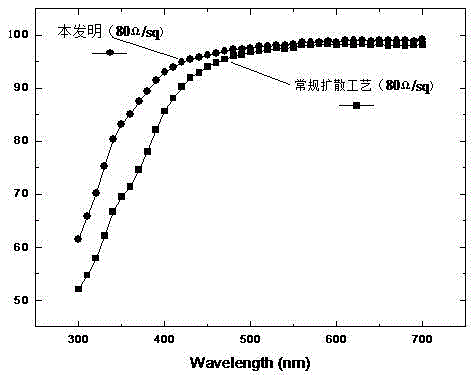

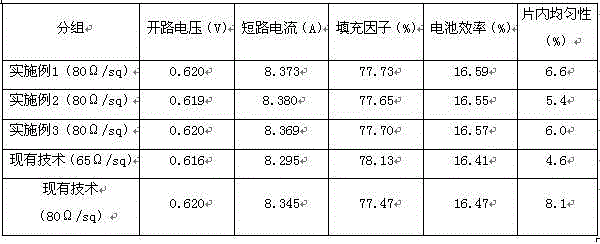

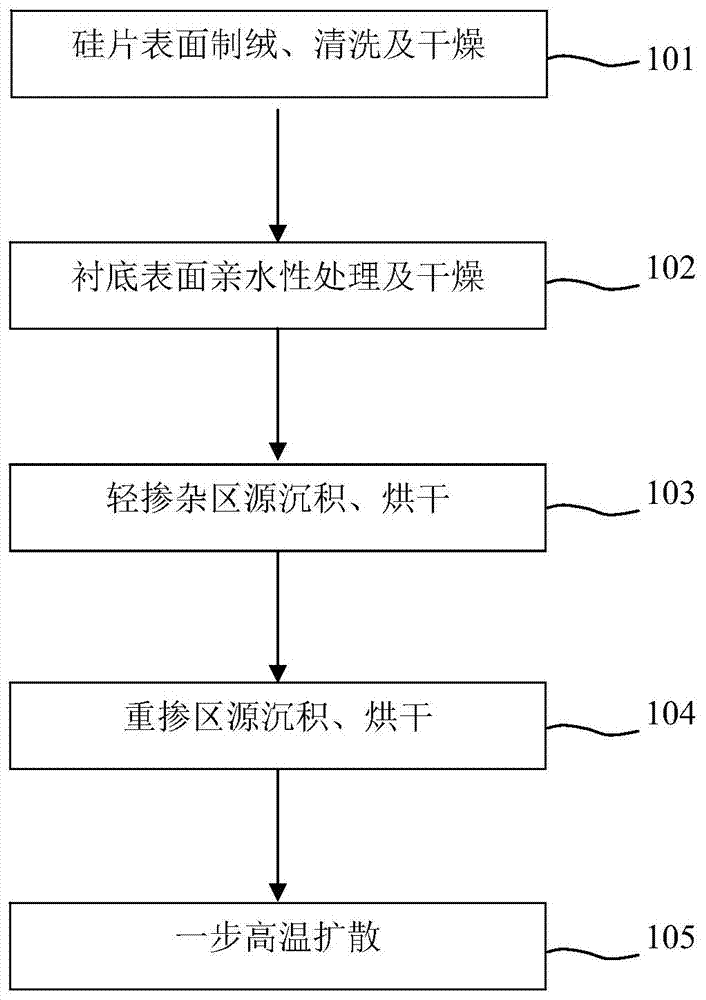

Diffusion method for solace cell with polycrystalline silicon selective emitter

ActiveCN102593262AImprove efficiencyShallow dopingFinal product manufactureDiffusion/dopingDiffusionDopant

The invention discloses a diffusion method for a solar cell with a polycrystalline silicon selective emitter. The diffusion method includes the following steps: firstly, placing a silicon chip on which a doping agent grows into a diffusion furnace and raising the temperature to 750-800DEG C, wherein the environment in the furnace is N2 with the flow being 10-30slm; secondly, after the temperature is stabilized, uniformly raising the temperature in each temperature zone in the furnace to 850-900DEG C, introducing 0.2-2slm of N2 carrying trichloroethane, 1-5slm of O2 and 10-30slm of N2 while raising the temperature so as to realize heavy doping and controlling the heavily-doped sheet resistance between 30 and 60 omega / m<2>; thirdly, reducing the temperature of each temperature zone to the diffusion temperature of 820-840DEG C and introducing N2 carrying POCl3 for diffusing; fourthly, reducing the temperature of each temperature zone to 780-800DEG C, stopping introducing the N2 carrying the POCl3 so as to realize shallow doping, wherein the propulsion time is 10-25minutes and controlling the shallow-doped sheet resistance between 70-120 omega / m<2>; and fifthly, cooling the silicon chip, taking out the silicon chip and finishing the diffusion process. According to the diffusion method disclosed by the invention, the diffusion of a doping agent is realized at high temperature and the heavy doping and shallow doping of the selective emitter are realized; and meanwhile, the gettering of a polycrystalline silicon is realized, so that the conversion efficiency is greatly increased.

Owner:CSI CELLS CO LTD +1

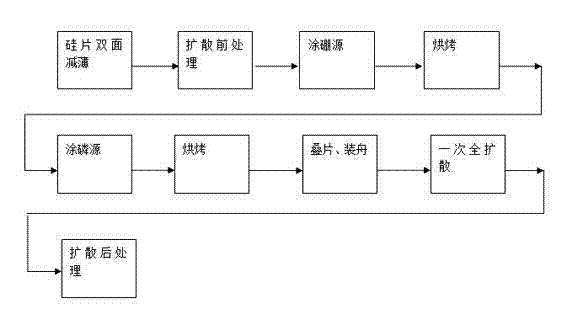

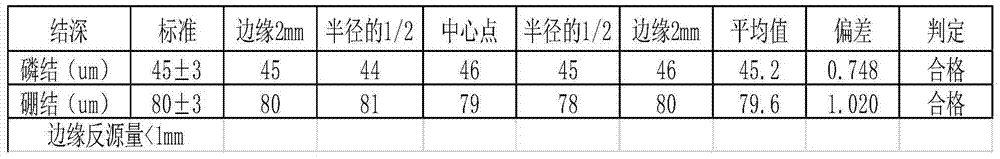

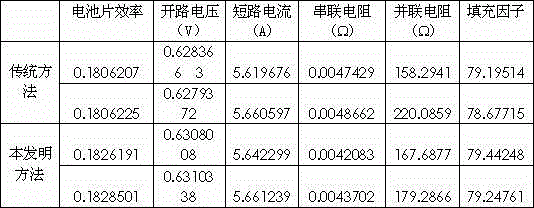

Phosphorus and boron liquid source one-shot perfect diffusion process

ActiveCN104766790ASmall amount of feedbackImprove effective area utilizationSemiconductor/solid-state device manufacturingConcentration gradientProcessing cost

The invention discloses a phosphorus and boron liquid source one-shot perfect diffusion process. The process is mainly implemented through the following steps that one surface of each silicon wafer with two thinned sides is rotated to be coated with a liquid boron source, baked and then rotated again to be coated with a liquid phosphorus source, lamination is conducted after baking, the silicon wafers are stacked on a silicon boat pairwise to be subjected to one-shot perfect diffusion in the mode that each phosphorus source surface is opposite to the corresponding phosphorus source surface and each boron source surface is opposite to the corresponding boron source surface. Diffused junction depth is even, and reverse breakdown voltage of a product can be stable and good in uniformity; the diffusion concentration gradient is reduced, PN junction field intensity can be effectively improved, discharging-resistant capacity of the product is improved, and the reverse surge capacity of the product can be effectively improved; meanwhile, the source return quantity of the edge of the silicon wafer is small, the number of intra defects is small, and product reliability is high. Processing cost is low, the process is simple, and production is easy.

Owner:SUZHOU QILAN POWER ELECTRONICS

Solar battery diffusion method

ActiveCN102723266AReduce surface recombination and defect concentrationIncrease widthSemiconductor/solid-state device manufacturingChemistryCrystalline silicon

The invention relates to a solar battery diffusion method which is characterized by comprising a step I of first oxidation, a step II of diffusion and a step III of second oxidation. The step II of diffusion comprises primary diffusion, the secondary diffusion and tertiary diffusion. In the solar battery diffusion method provided by the invention, a P-type silicon wafer is used as a diffusion source substrate; through three sub-steps of diffusion in the diffusion stage, the inlet flow of nitrogen and oxygen turns from large to small, and the inletting time turns from long to short; in the step III, the concentration of a phosphorus source is driven into the substrate from high to low, thus the surface concentration is gradually reduced, and the surface recombination and defect concentration is reduced; gradient doping is formed, the P-N junction area is widened, and the open-circuit voltage is increased; and meanwhile, through the relatively deep junction, the series resistance can be reduced, and the conversion efficiency of a solar battery is improved. The solar battery diffusion method does not need an additional process, is relatively low in cost and can be used for improving the conversion efficiency of the crystalline silicon solar battery.

Owner:JIANGSU HOYI TECH

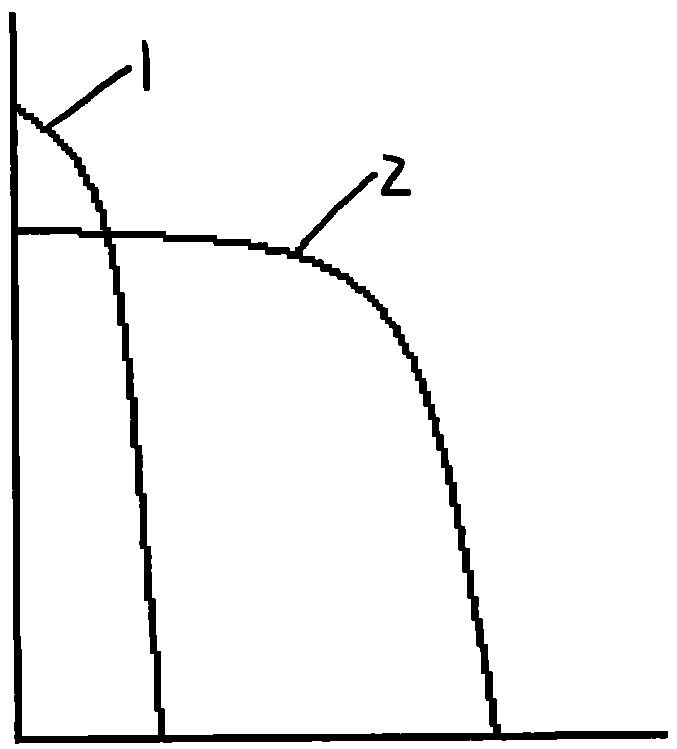

Diffusion method used for crystalline silicon solar battery

InactiveCN102157606AHigh gettering capacityIncrease short circuit currentFinal product manufactureDiffusion/dopingDiffusion methodsSurface concentration

The invention discloses a diffusion method used for a crystalline silicon solar battery. The method comprises the following steps of: (1) placing a silicon wafer into a diffusion furnace; rising the temperature from 780-810 DEG C to 840-860 DEG C; and simultaneously introducing POCL3+O2+N2 for 12 to 14 minutes; (2) simultaneously introducing O2+N2 when rising the temperature in the diffusion furnace to 840-860 DEG C and keeping the constant temperature for 2 to 5 minutes; simultaneously introducing the POCL3+O2+N2 for 8 to 12 minutes when rising the temperature from 840-860 DEG C to 870-890 DEG C; reducing the temperature from 870-890 DEG C to 800 DEG C; introducing the O2+N2 in the process of reducing the temperature; stabilizing for 2 minutes at the temperature of 800 DEG C; and introducing the POCL3+O2+N2; and (3) taking the silicon wafer out of the diffusion furnace. In the method, both the requirements on the doping concentration of an emitting region and the surface concentration of the emitting region in diffusion can be met at the same time; a gettering effect is good; and the distribution of a doping curve is more reasonable.

Owner:BAODING GUANGWEI GREEN ENERGY TECH CO LTD

Diffusing process with low temperature, low surface concentration and high sheet resistance

InactiveCN102945797AReduce surface recombination rateImprove battery efficiencySemiconductor/solid-state device manufacturingSheet resistanceChemistry

The invention relates to a diffusing process with low temperature, low surface concentration and high sheet resistance. The diffusing process with low temperature, low surface concentration and high sheet resistance comprises an entering step, a depositing step, a propelling step and an exiting step. The diffusing process with low temperature, low surface concentration and high sheet resistance is characterized in that the reaction temperatures in the entering and depositing steps are lower than 800 DEG C. Preferably, at least one of the depositing step and the propelling step is carried out by steps according to different temperatures. Furthermore, the depositing step is divided into a first depositing step and a second depositing step. The propelling step comprises a first propelling step and a second propelling step. Preferably, an oxidizing step is further carried out between the entering step and the depositing step. The oxidizing step comprises the step of: introducing oxygen into a reactor. By utilizing the diffusing process with low temperature, low surface concentration and high sheet resistance provided by the invention, the reaction temperatures in the depositing and diffusing steps are reduced compared with the that in the conventional process, so that the surface compositing rate is reduced. Meanwhile, impurities are more beneficially migrated to the impurity absorbing point at the lower diffusing temperature in the diffusing process of polycrystalline silicon, so that the battery efficiency is further improved.

Owner:TIANWEI NEW ENERGY HLDG

Boron gettering method for metallurgical N-type polycrystalline silicon chip

InactiveCN102153090AEfficient removalQuality improvementSilicon compoundsHydrofluoric acidOptoelectronics

The invention discloses a boron gettering method for a metallurgical N-type polycrystalline silicon chip, and relates to polycrystalline silicon. The invention provides the boron gettering method for the metallurgical N-type polycrystalline silicon chip, which has good gettering effect, low cost and simple operation and is suitable for industrialized production. The method comprises the followingsteps of: cleaning and drying the metallurgical N-type polycrystalline silicon chip; introducing gas to the obtained silicon chip at the temperature of between 700 and 1,200 DEG C to perform boron diffusion gettering heat treatment, and then cooling the silicon chip; soaking the obtained silicon chip into hydrofluoric acid (HF) solution; and corroding the gettering layer on the obtained silicon chip by using acid corrosive liquid, and cleaning, drying and baking the obtained silicon chip to obtain a boron gettered polycrystalline silicon chip.

Owner:XIAMEN UNIV

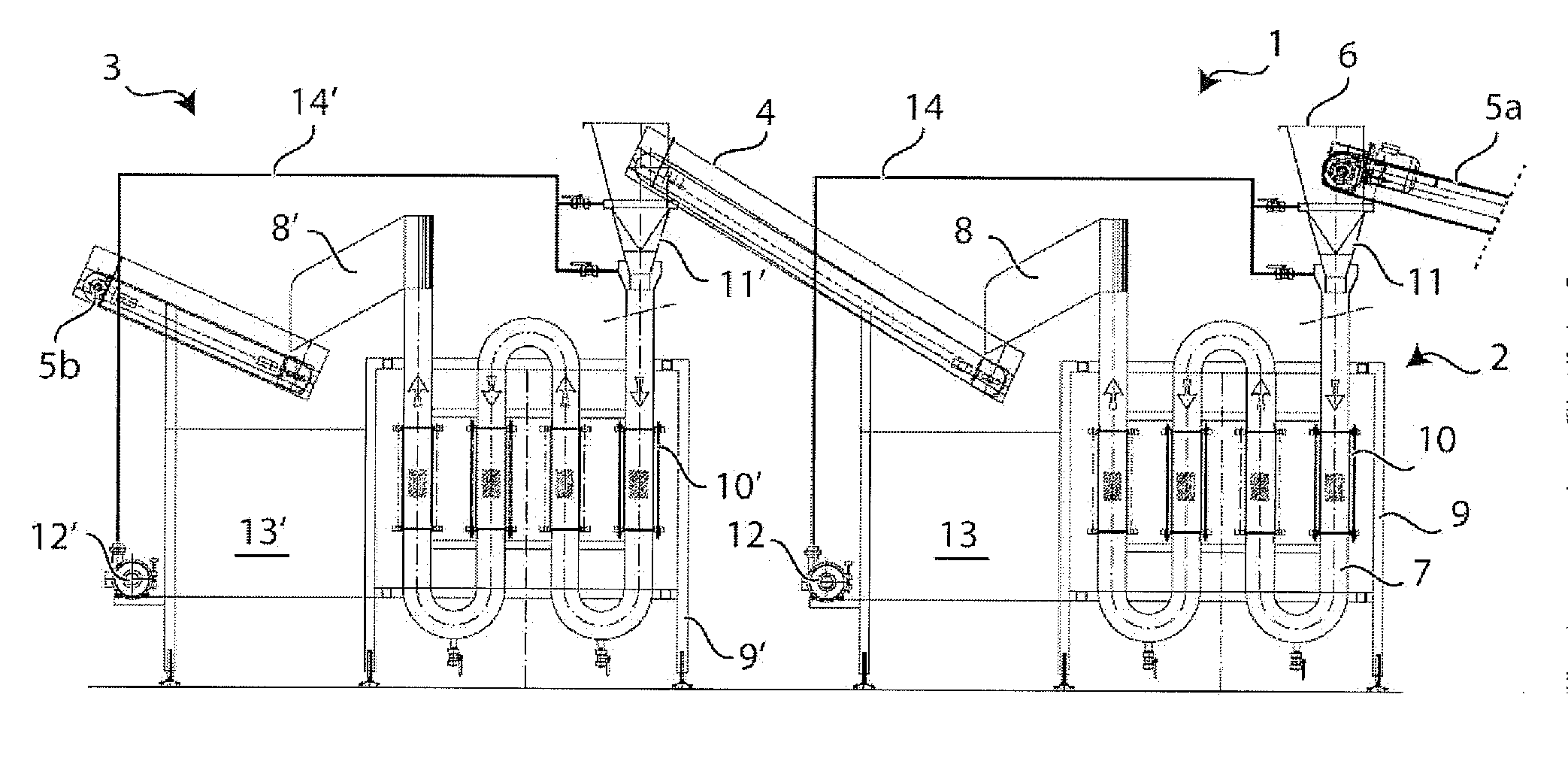

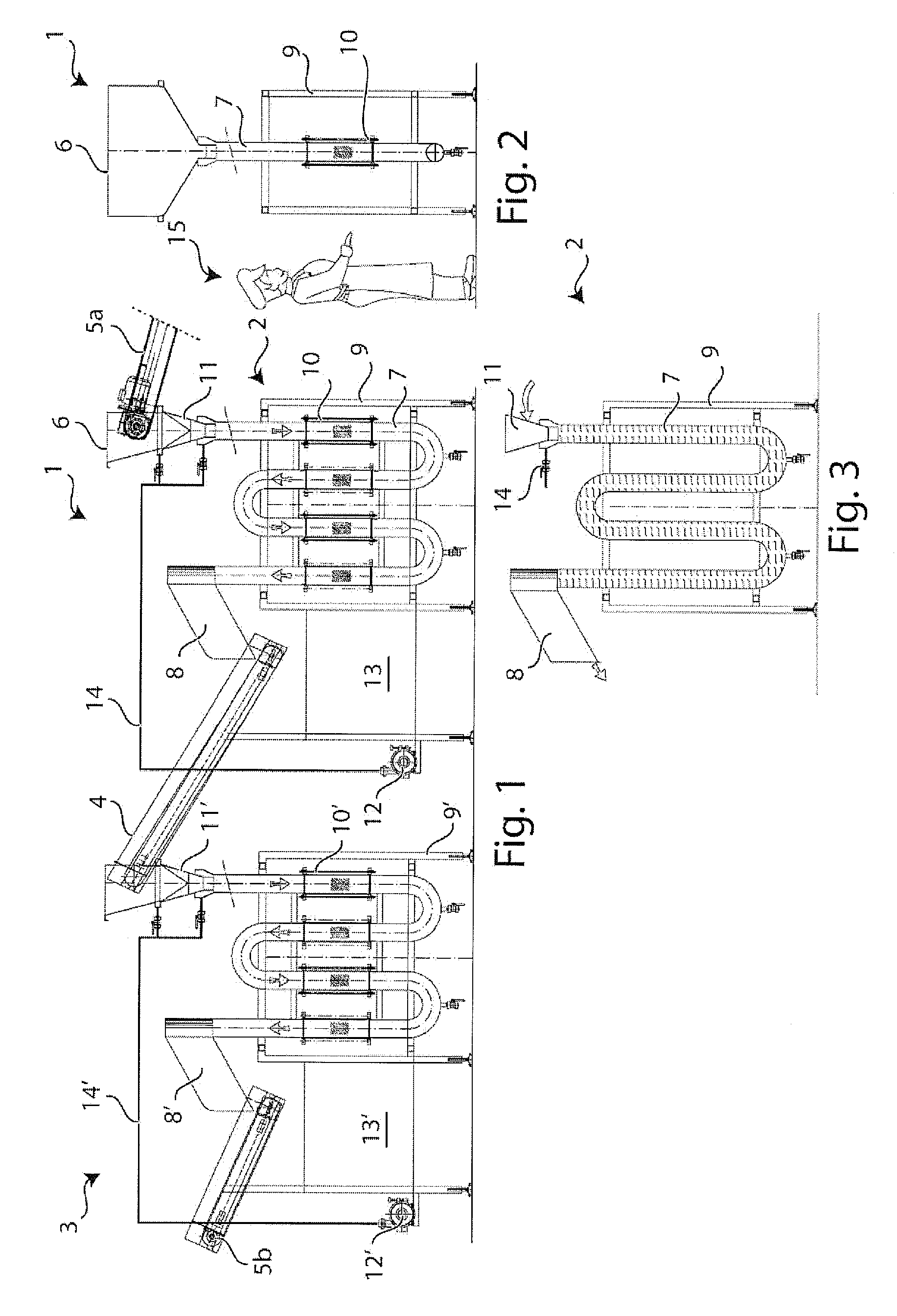

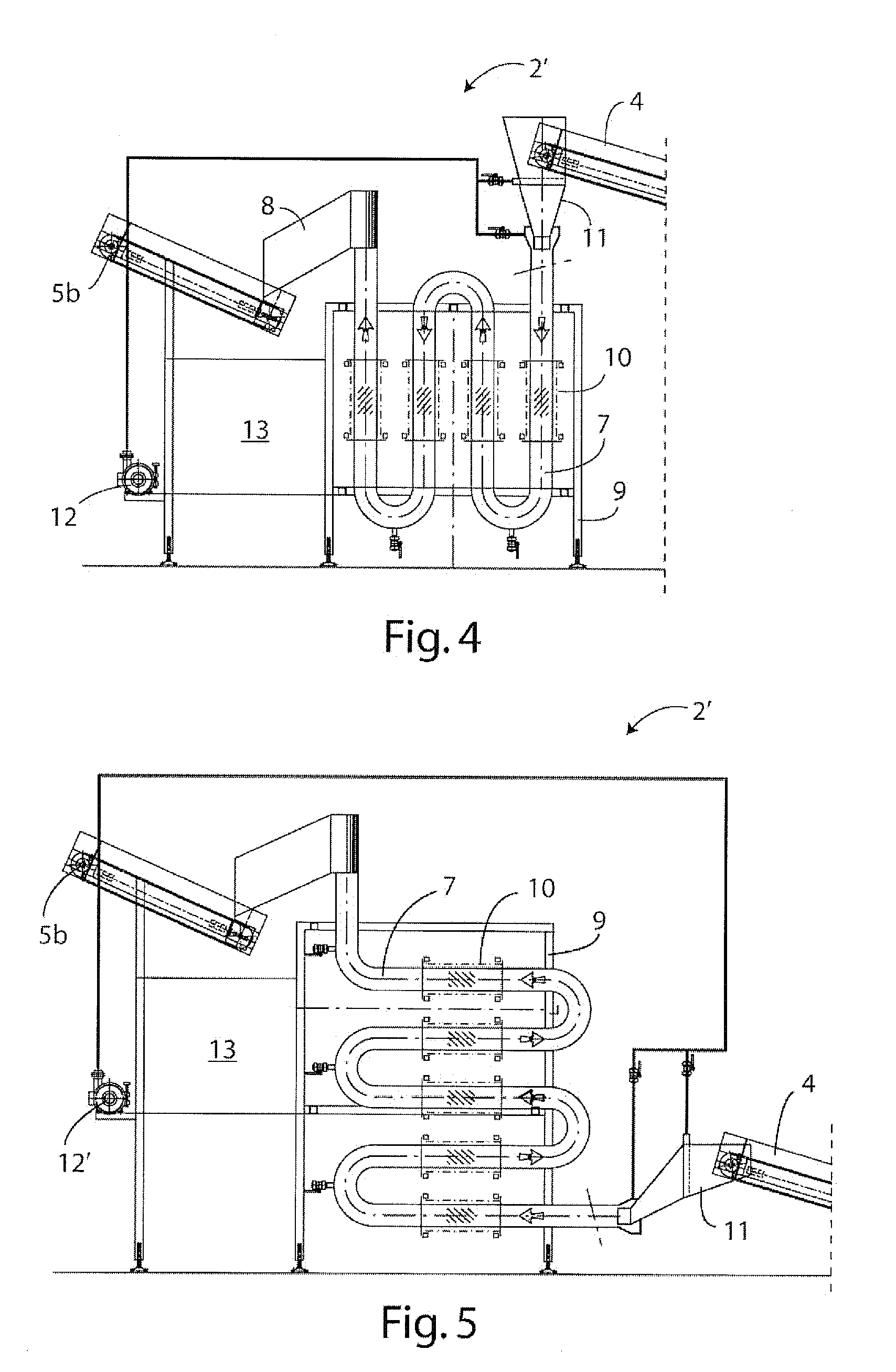

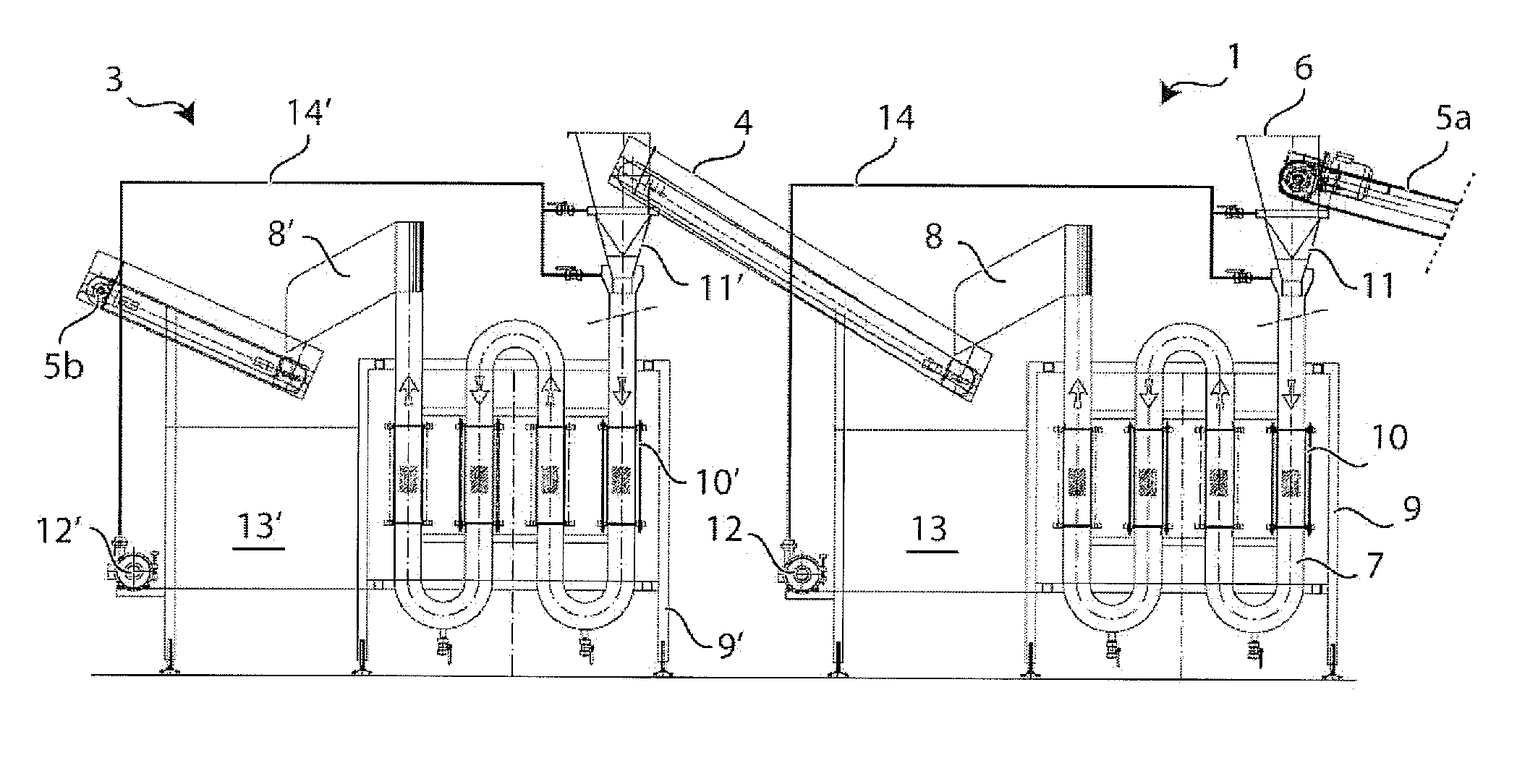

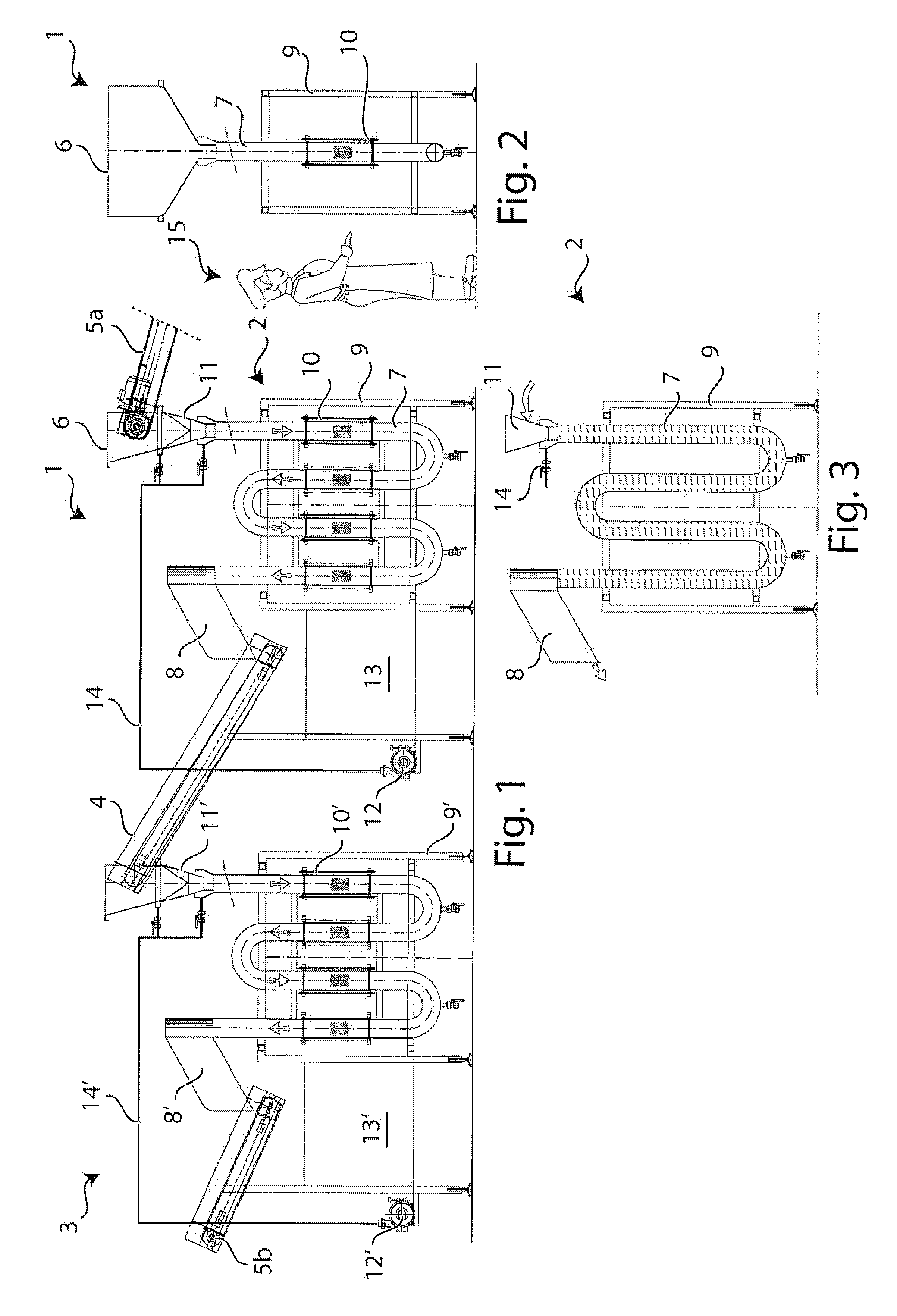

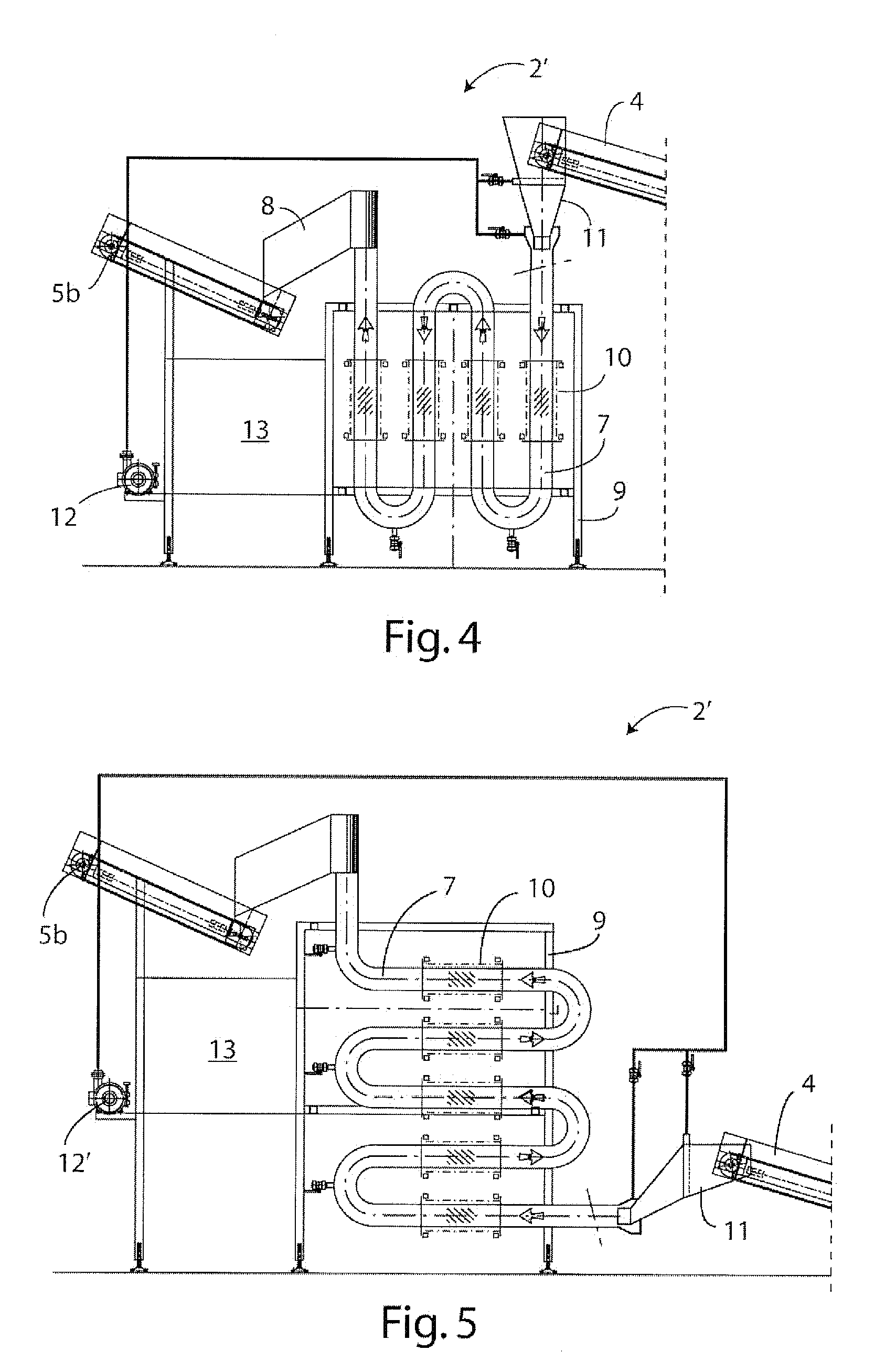

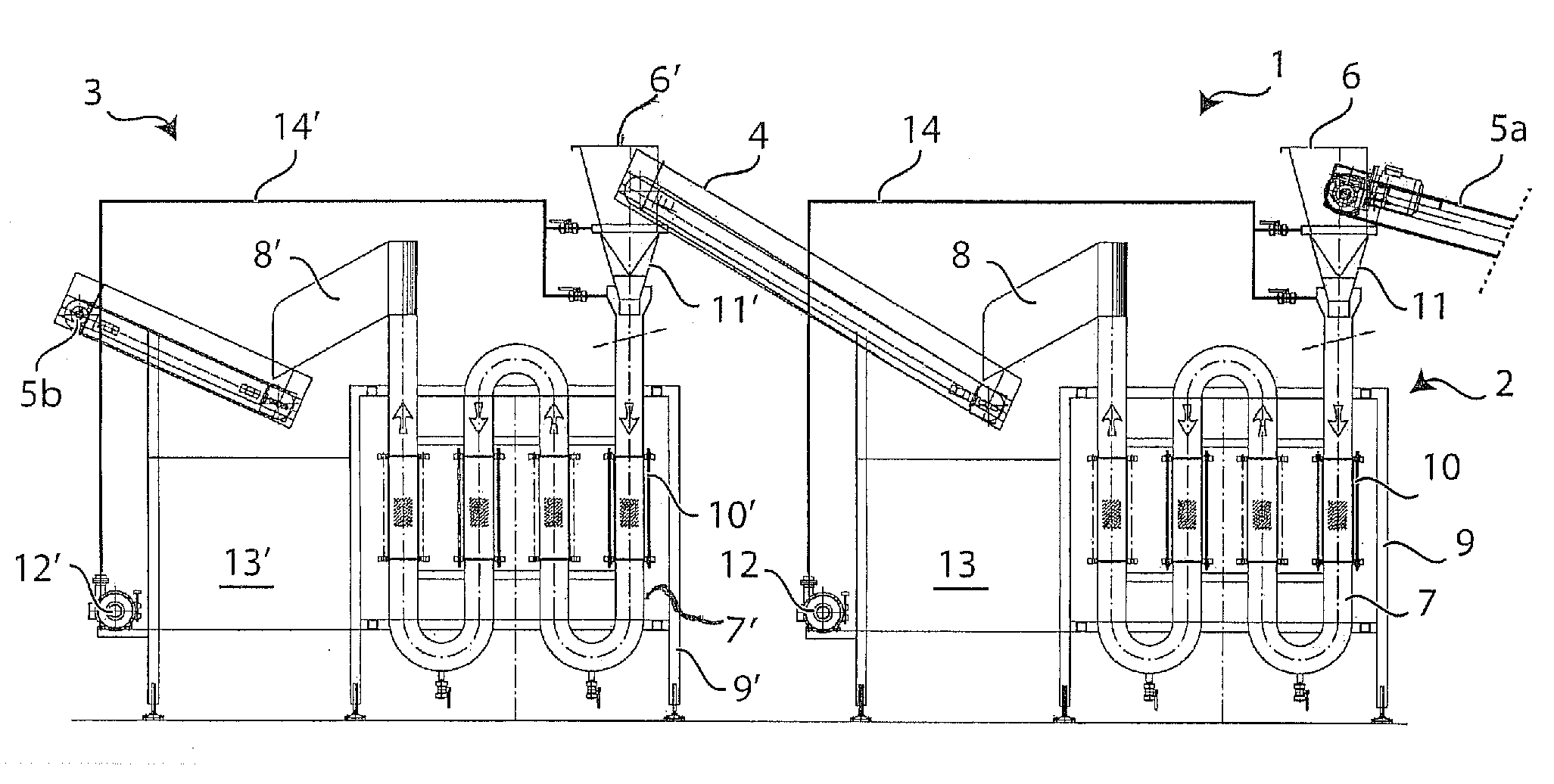

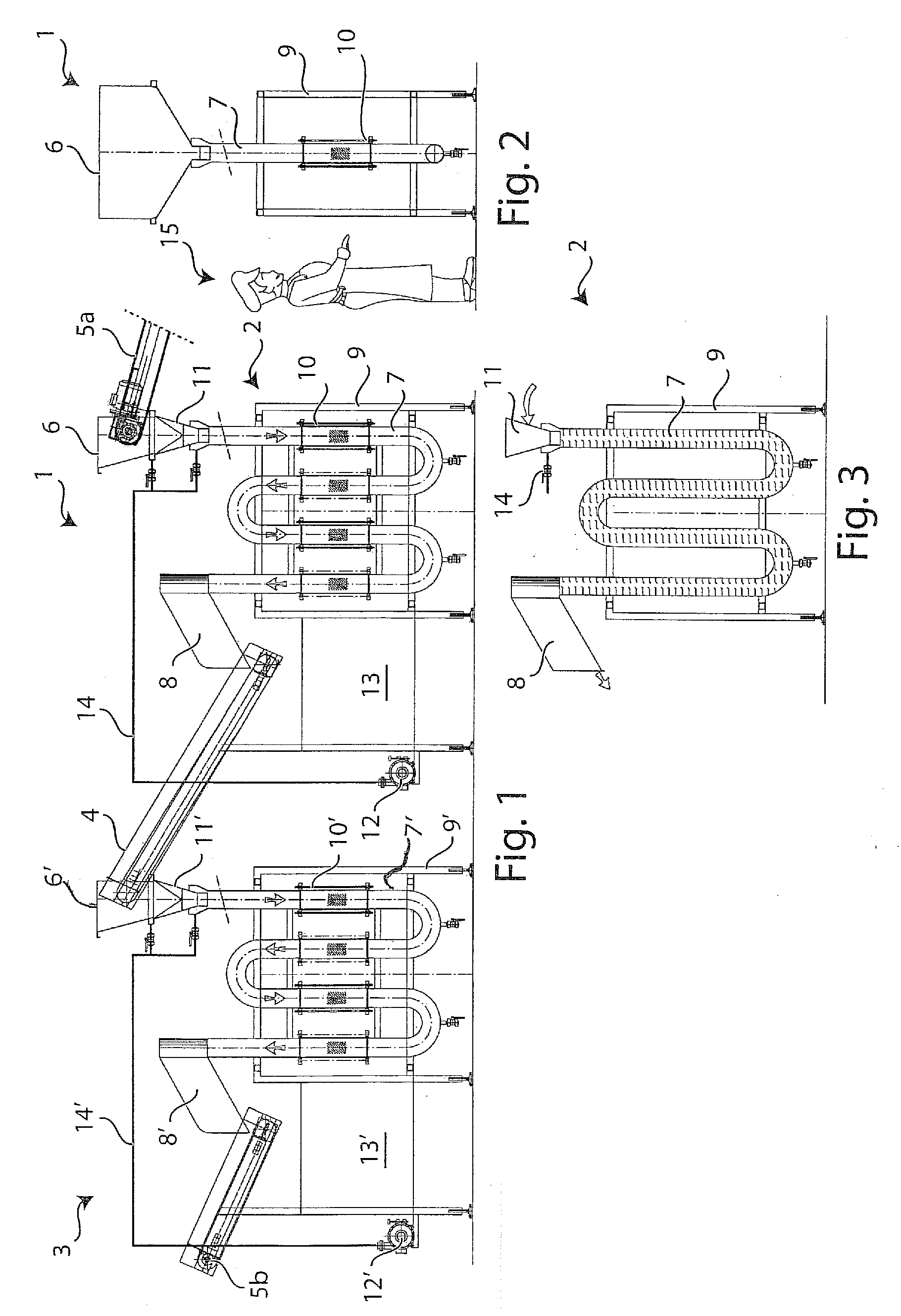

System for transporting and/or washing and/or pasteurisation thermal treatment of foodstuffs, particularly leaf products

ActiveUS20110030567A1More powerReduce surface concentrationFruit and vegetables preservationMilk preservationThermal treatmentFood products

The present invention relates to a system for transporting and / or washing and / or pasteurisation thermal treatment of foodstuffs, particularly leaf products comprising at least a treatment section. The treatment section can be comprised of one or more sections of rectilinear tubes and one or more corresponding curved tube sections, wherein products within the treatment section being conveyed by a fluid, such as water, flowing along the tubes.

Owner:TURATTI S R I

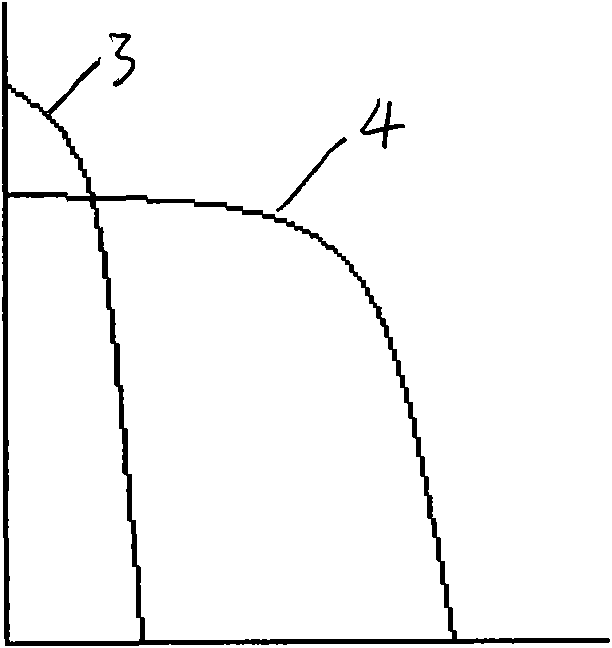

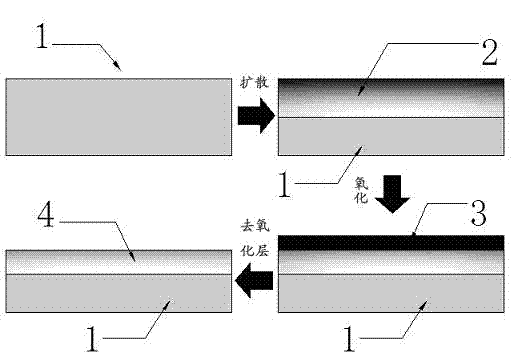

Chained diffusion process for solar cell

InactiveCN102881767AExtend your lifeImprove conversion efficiencyFinal product manufactureDiffusion/dopingSurface concentrationWater vapor

The invention discloses a chained diffusion process for a solar cell. The chained diffusion process is to remove a highly-doped area on a diffused surface and improve the minority carrier lifetime of a diffused silicon wafer by growing a thick oxidation layer on the surface of a silicon wafer subjected to chained diffusion and washing off the oxidation layer, and comprises the following steps: making a reaction between steam and the diffused surface of the silicon wafer at a high temperature to quickly grow the thick oxidation layer in a short time; and finally, removing the oxidation layer. The chained diffusion process avoids the phenomenon that the ordinary diffusion process cannot avoid generating a 'dead layer', further reduces the surface concentration, improves the minority carrier lifetime and the conversion efficiency of the cell, and reduces the production cost of the solar cell.

Owner:TIANWEI NEW ENERGY HLDG

Method for gettering phosphorus in N-type polysilicon slice by metallurgical method

InactiveCN102153089AEfficient removalQuality improvementSilicon compoundsHydrogen fluorideThermal treatment

The invention provides a method for gettering phosphorus in an N-type polysilicon slice by a metallurgical method, and relates to polysilicon. The method is good in gettering effect, low in cost and simple in operation, and is suitable for industrial production. The method for gettering phosphorus in the N-type polysilicon slice by the metallurgical method comprises the following steps of: washing and drying the N-type polysilicon slice; feeding a gas into the obtained polysilicon slice at the temperature of 700 to 1,200 DEG C, performing phosphorous diffusion gettering thermal treatment, and cooling the polysilicon slice; immersing the obtained polysilicon slice into hydrogen fluoride (HF) solution; and corroding a gettering layer on the polysilicon slice by using acid corrosive liquid, washing and drying, and baking so as to obtain the phosphorous-gettered polysilicon slice.

Owner:XIAMEN UNIV

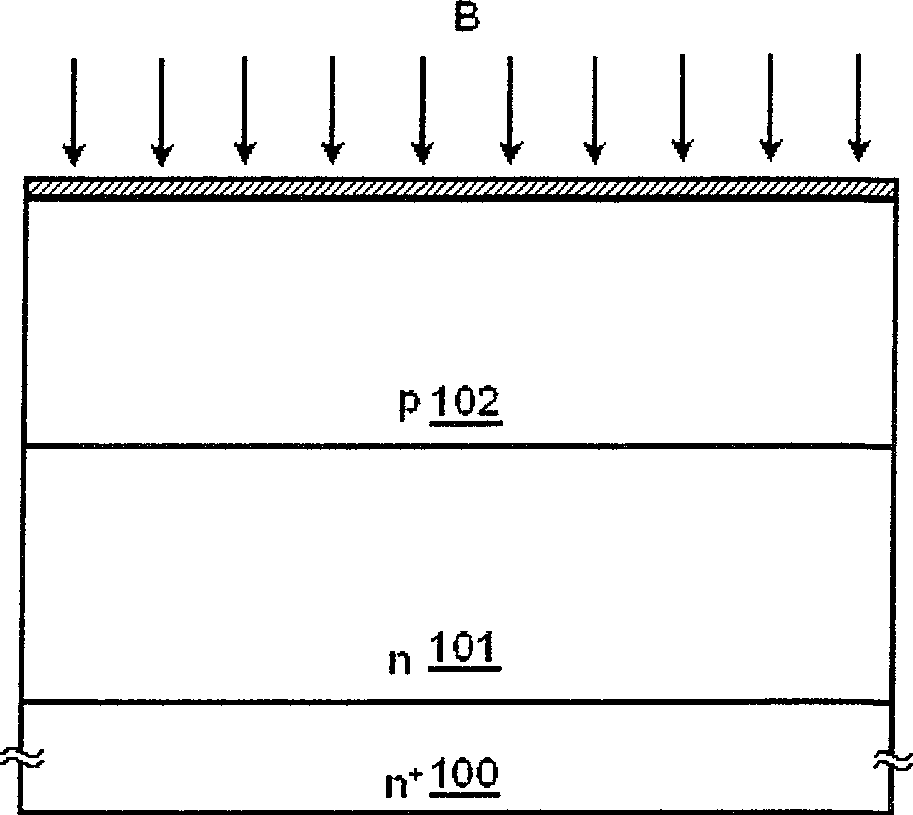

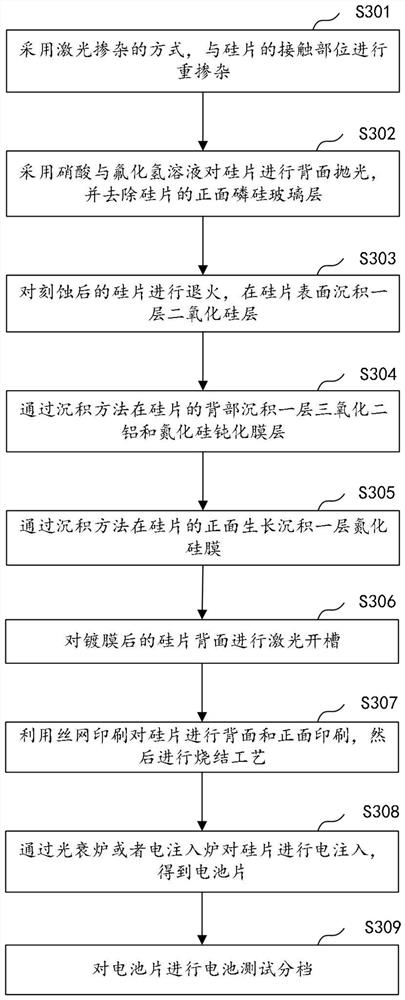

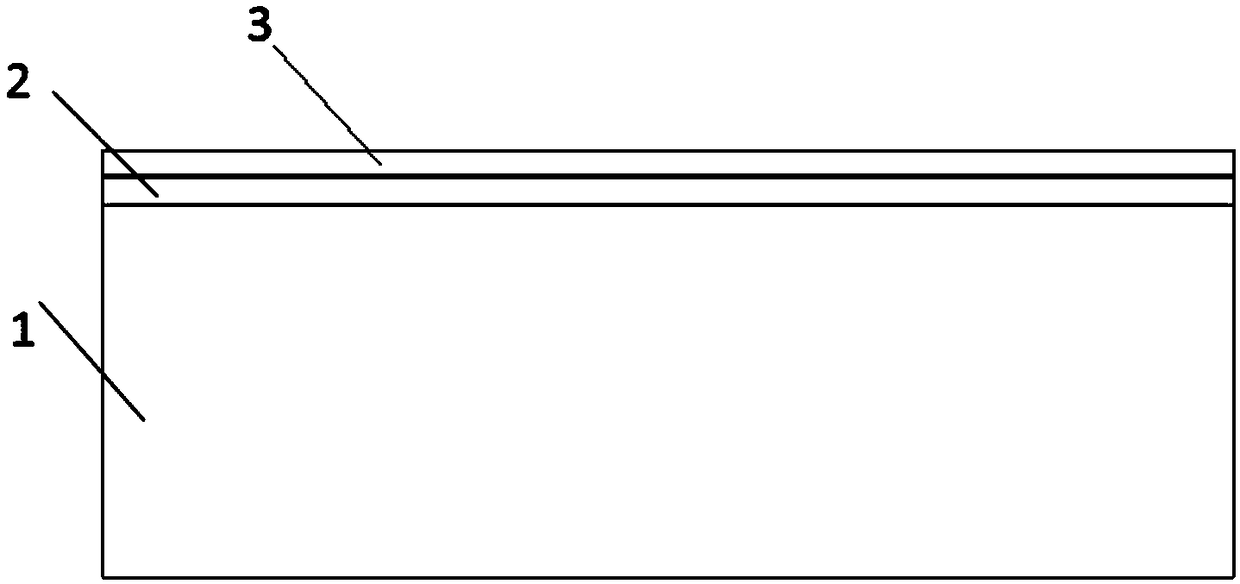

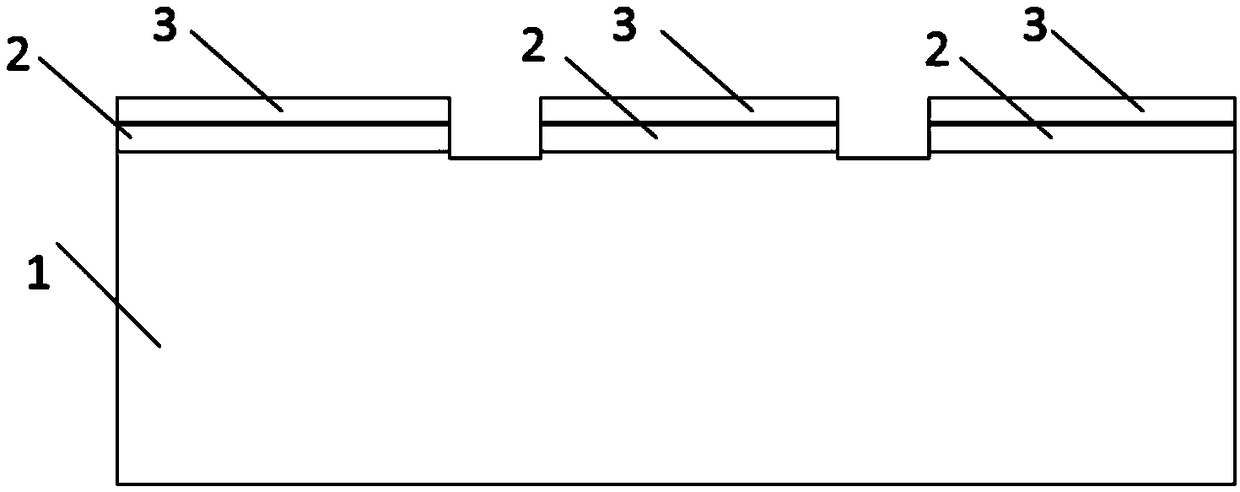

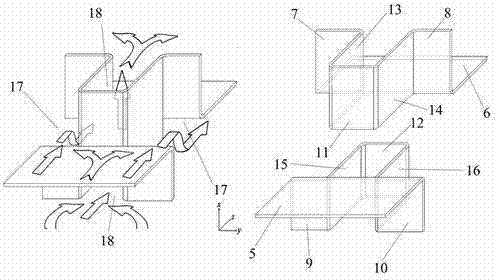

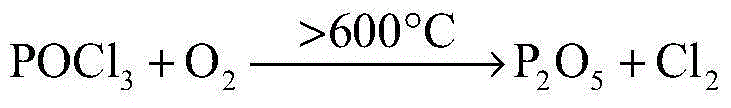

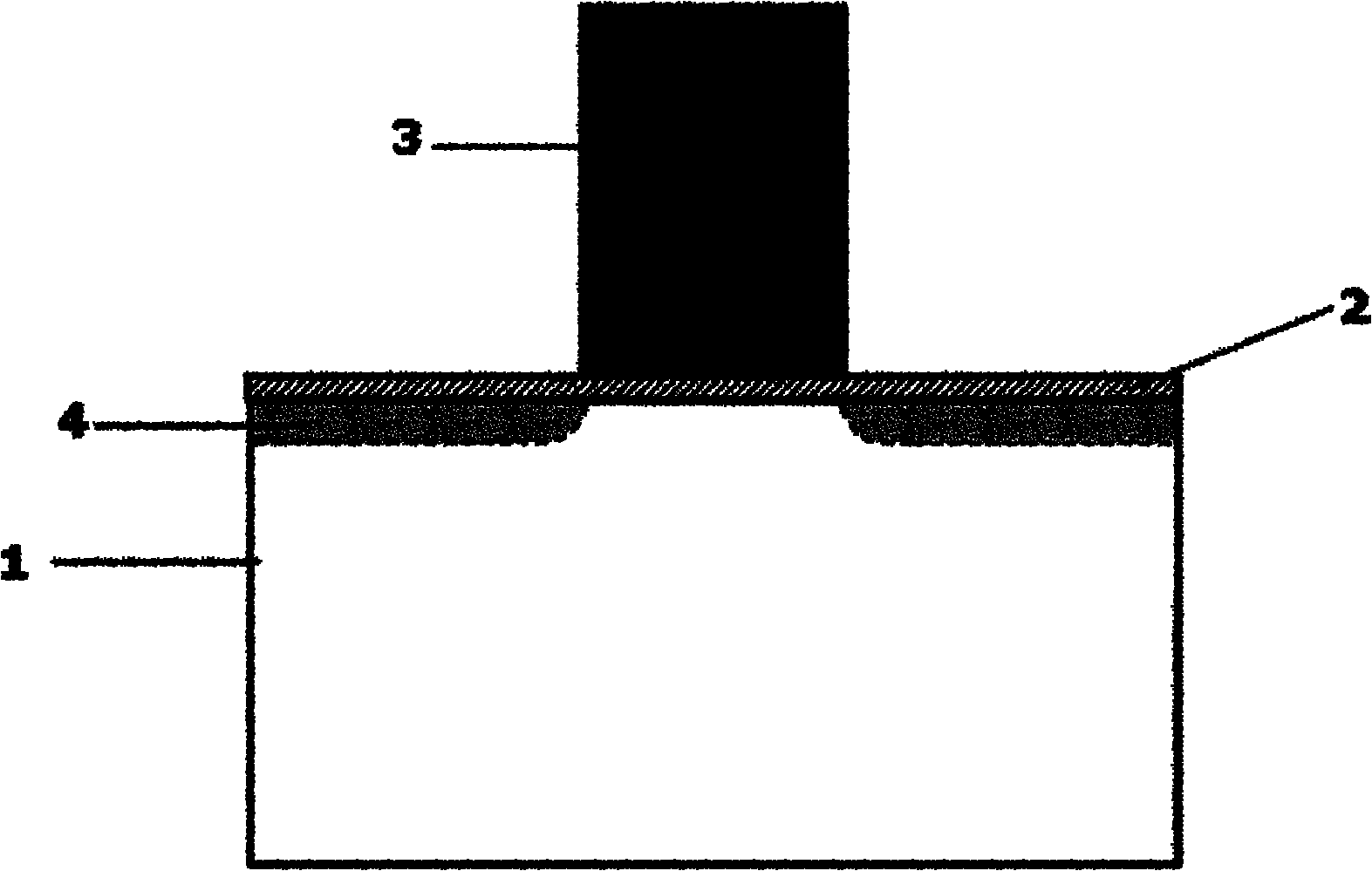

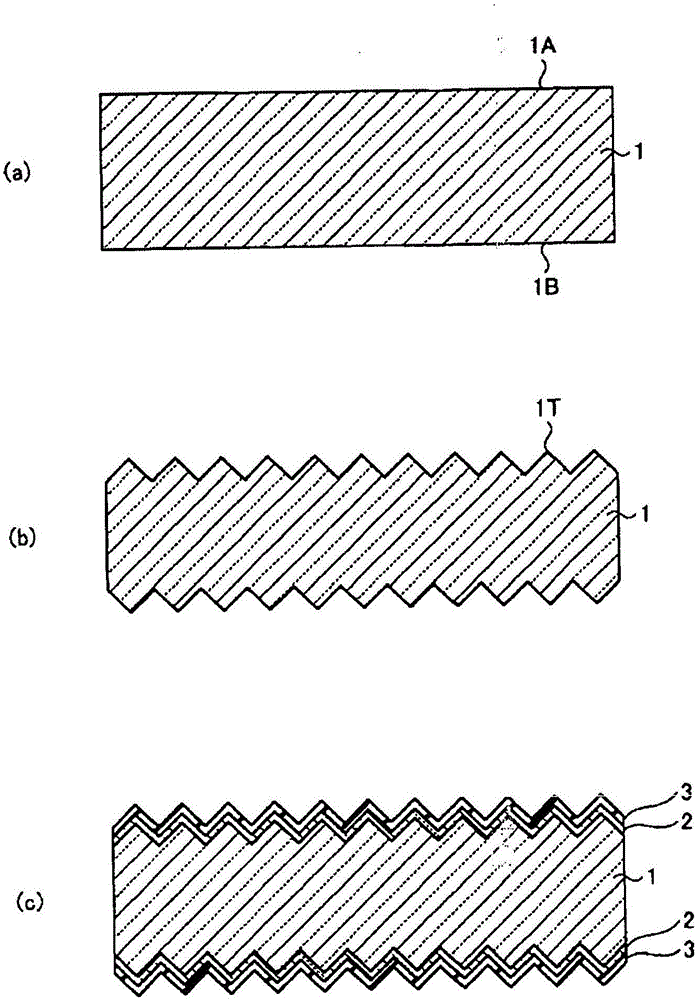

Process for manufacturing emitter of solar cell

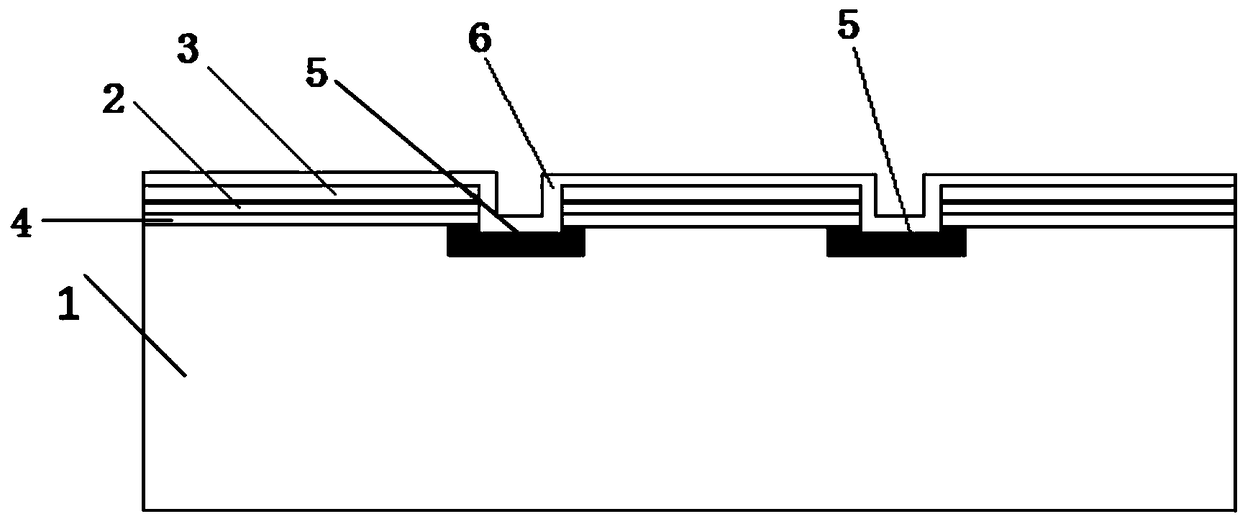

InactiveCN102881766AExtend your lifeImprove conversion efficiencyFinal product manufactureSemiconductor devicesSurface concentrationP–n junction

The invention discloses a process for manufacturing an emitter of a solar cell, which comprises the following steps: step A, manufacturing a PN junction on the surface of a matrix silicon wafer (1) by a diffusion process to form a surface impurity distribution layer (2); step B, oxidizing the surface impurity distribution layer (2) obtained in step A to quickly grow an oxidation layer (3) distributed uniformly on the surface of the surface impurity distribution layer (2); and step C, removing the oxidation layer (3) in step B. The process avoids the phenomenon that the ordinary diffusion process cannot avoid generating a 'dead layer', further reduces the surface concentration, improves the minority carrier lifetime and the conversion efficiency of the cell, and reduces the production cost of the solar cell.

Owner:TIANWEI NEW ENERGY HLDG

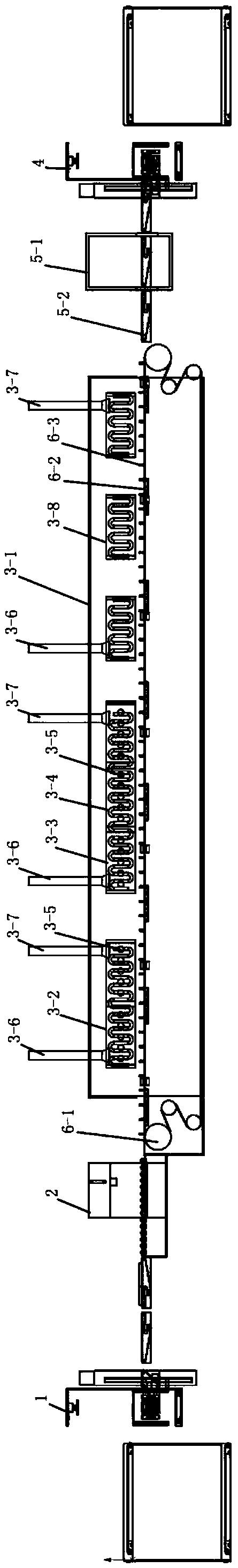

Chain-type diffusion technology and chain-type diffusion device

PendingCN108447949AReduce surface concentrationReduce the chance of recombination in the bodyFinal product manufactureDiffusion/dopingChain typeSolar cell

The invention provides a chain-type diffusion technology and a chain-type diffusion device, so as to solve the problems that the surface phosphorus concentration of a p-n junction obtained after chain-type diffusion is high and the junction depth is shallow, the surface minority carrier recombination probability is increased, serious electric leakage happens to a junction area, impurities existingin a silicon wafer substrate form a coincidence center easily, and the bulk recombination probability is increased. In the diffusion process of solar cell production, the surface phosphorus concentration of the p-n junction is reduced, the junction depth is increased, surface minority carrier recombination and junction area electric leakage are reduced, the impurities existing in the silicon wafer substrate are absorbed, and the bulk recombination probability is reduced.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

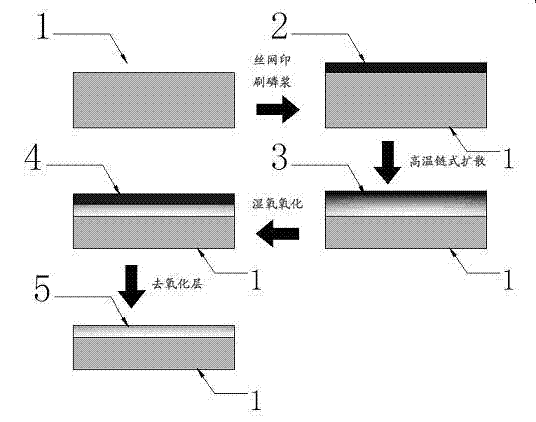

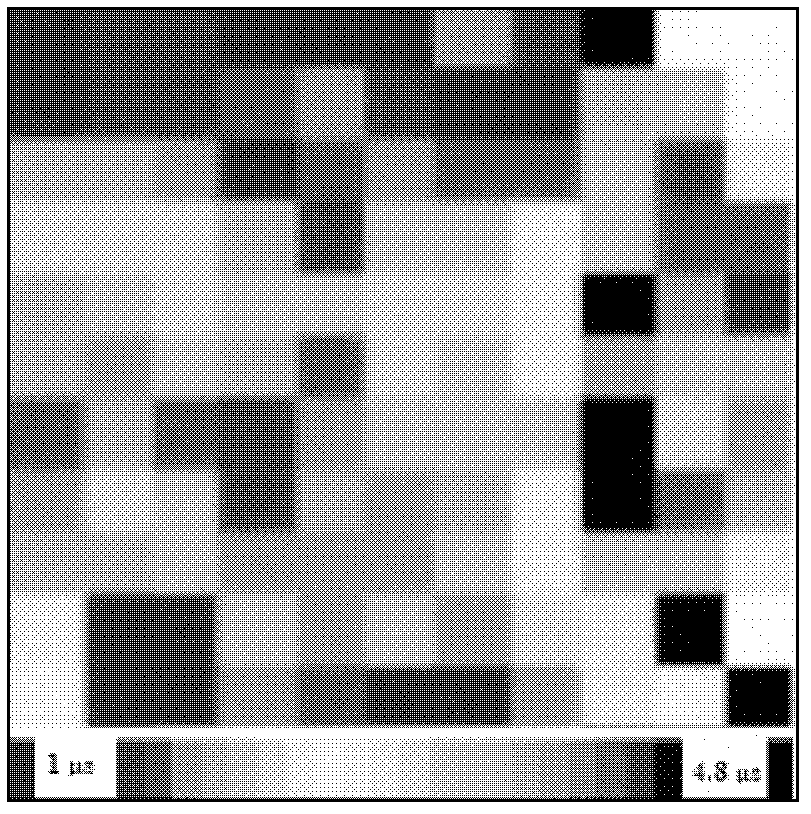

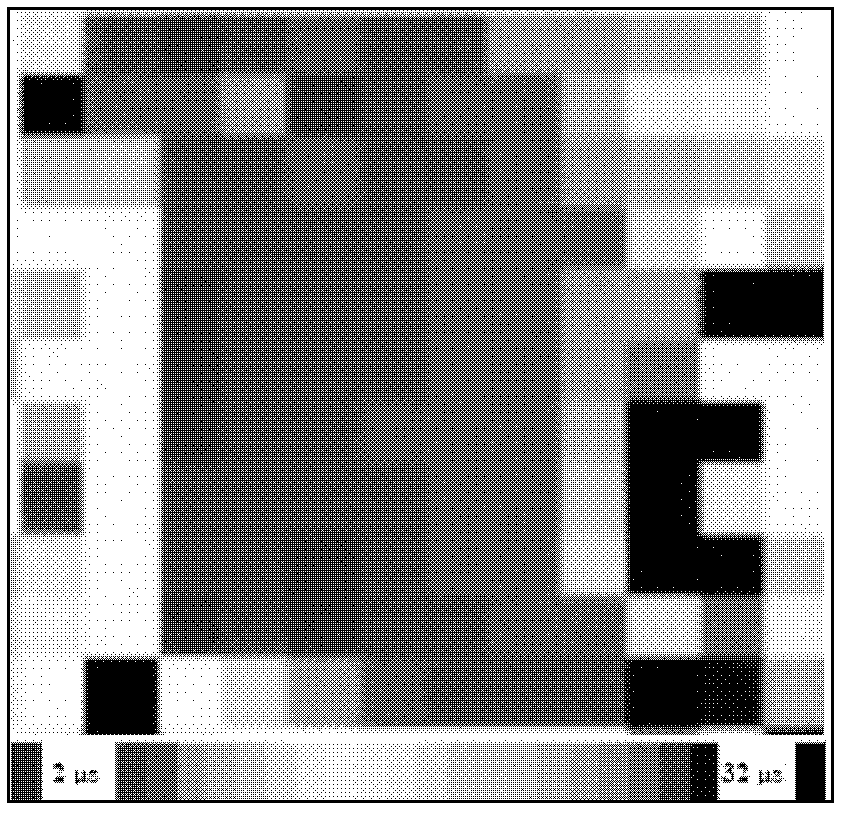

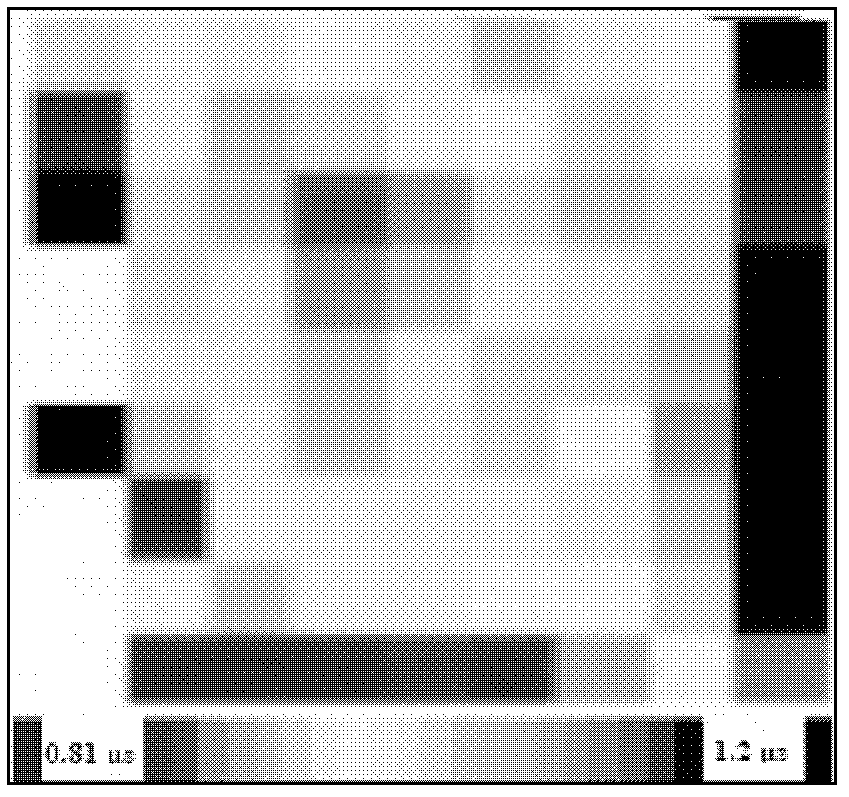

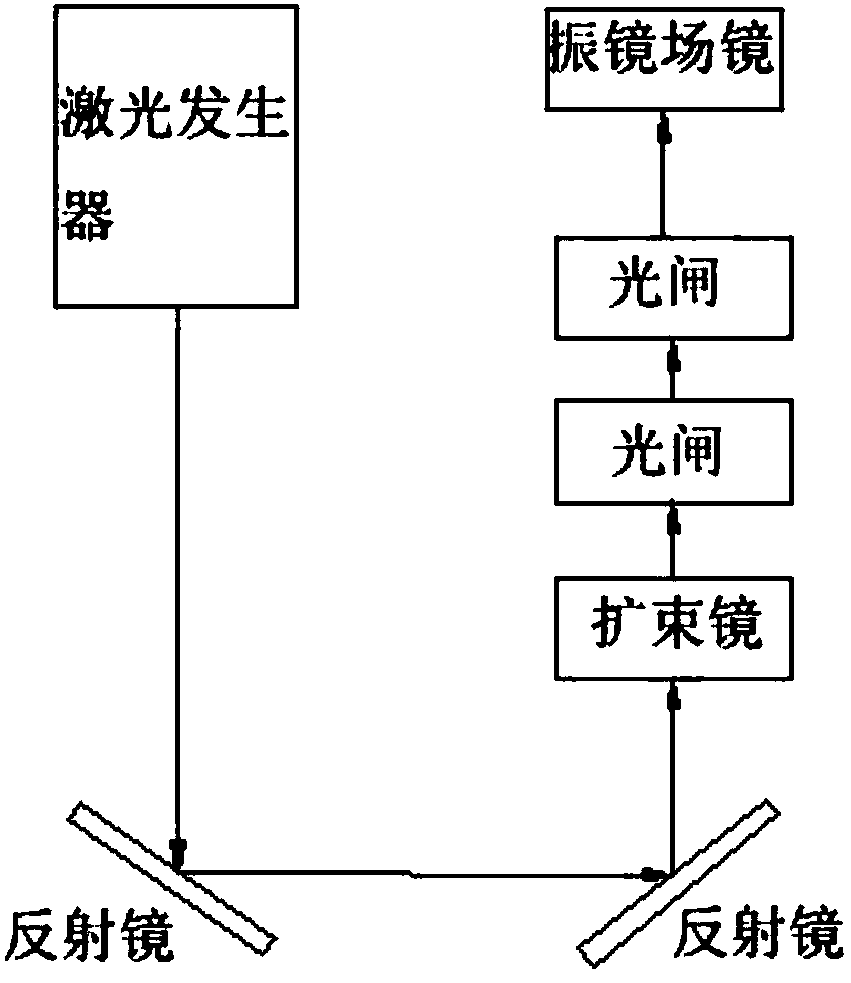

Method for manufacturing selective emitter structure with low surface concentration and soft doped zone

InactiveCN103904141AReduce surface concentrationImprove conversion efficiencyFinal product manufactureSemiconductor devicesOxygenSpin coating

A method for manufacturing a selective emitter structure with low surface concentration and a soft doped zone includes the steps that (1) the surface of a substrate to be prepared is corroded and cleaned, and the surface of the substrate is completely dried after cleaning; (2) the clean substrate prepared in the step (1) is soaked in a solution with high oxidability to carry out wet chemical oxidation on the surface of a silicon wafer, and then the surface of the substrate is completely dried; (3) a microcosmic salt aqueous solution of 0.5-20% is deposited on the surface of the substrate in a spin coating and spraying mode, and then the surface of the substrate is dried; (4) phosphorus ink or silicon ink is deposited on an electrode area on the surface of the substrate coated with a phosphorus source in the step (3) in a screen printing mode, and then the surface of the substrate is dried; (5) the temperature of a diffusion furnace rises, nitrogen is introduced into a diffusion quartz tube, when the temperature reaches 780-890 DEG C, the clean substrate prepared in the step (4) is placed into a constant-temperature area of the diffusion quartz tube, a fire door of the diffusion furnace is sealed, and after the temperature of the diffusion furnace is stable, oxygen is introduced into the diffusion quartz tube; (6) the substrate is taken out and cooled after the diffusion process is over.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

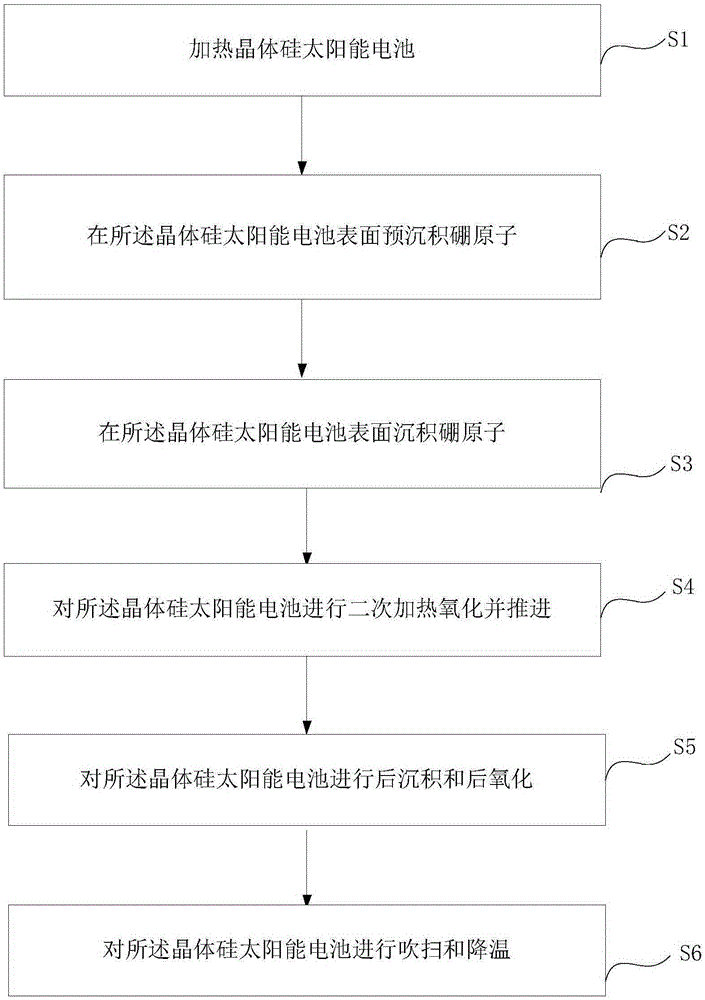

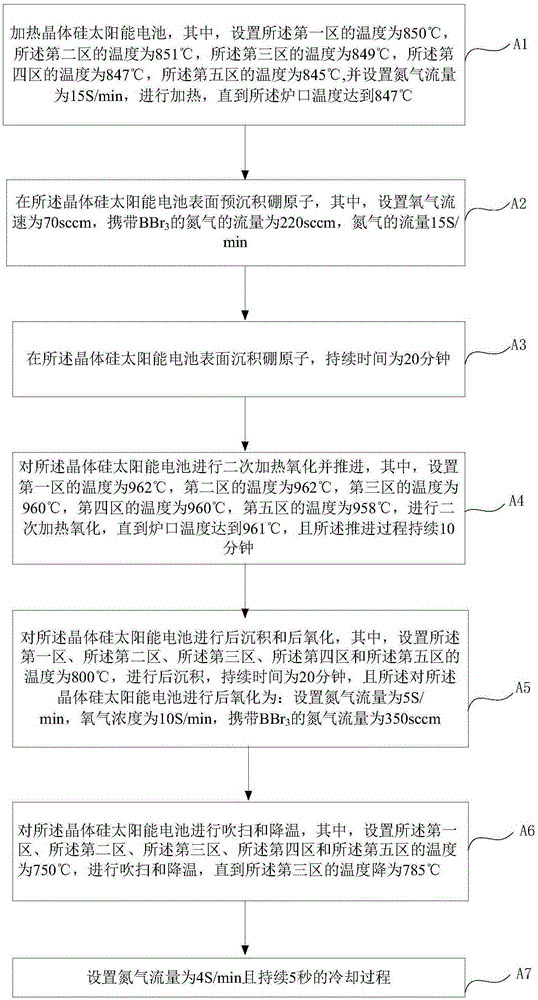

Method for boron diffusion of crystalline silicon solar cell

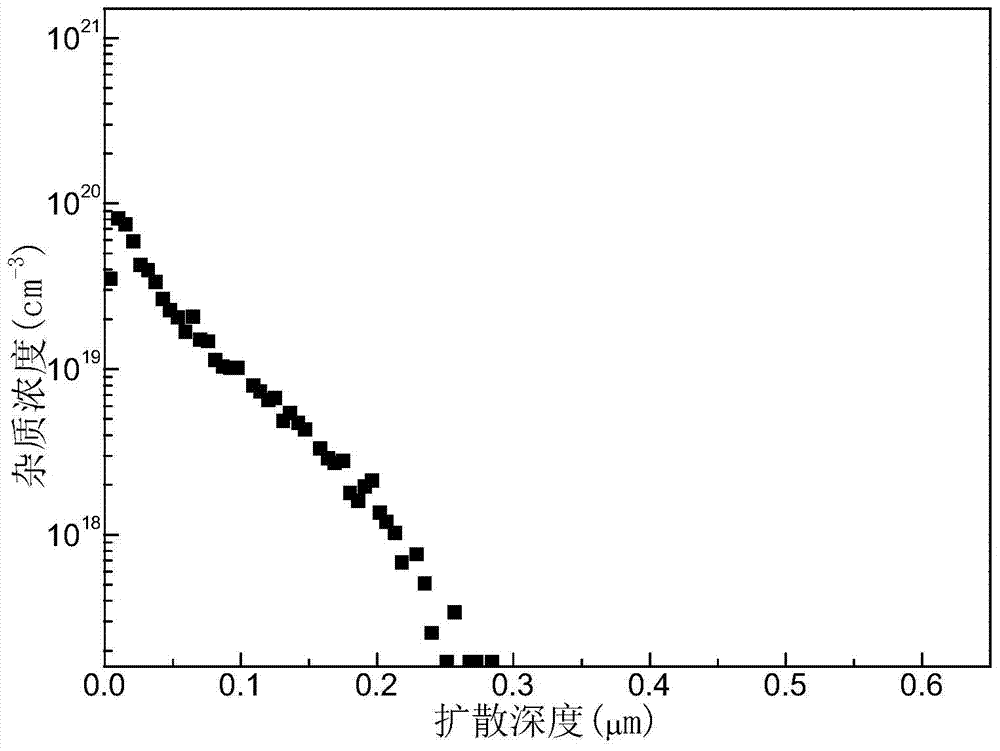

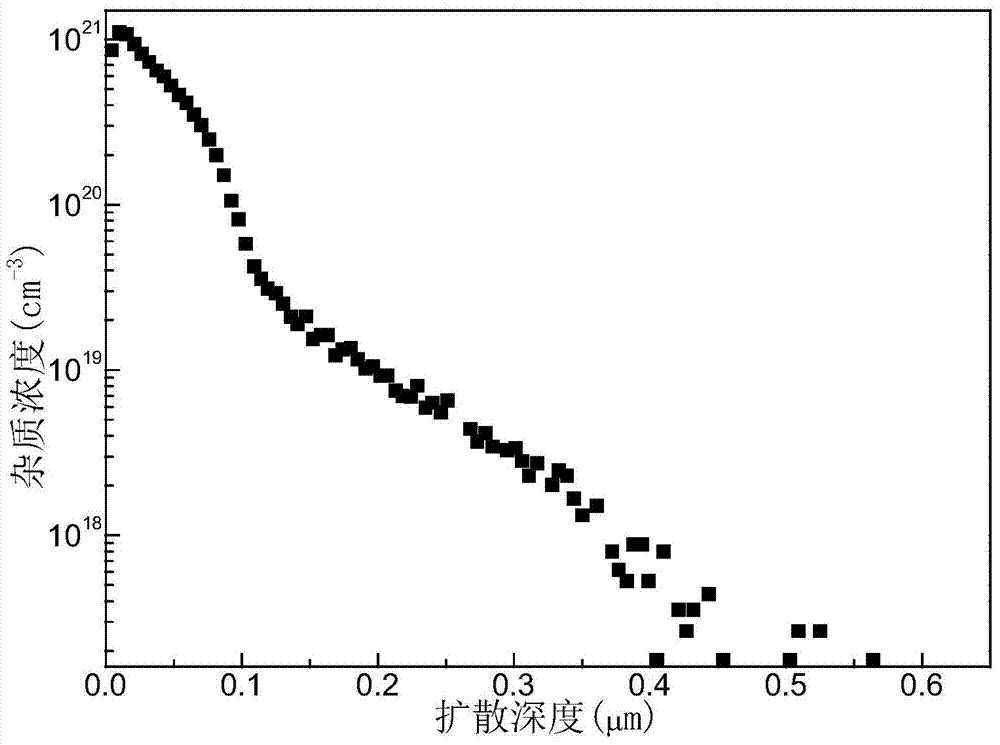

ActiveCN105355717AExtend your lifeImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPre depositionCrystalline silicon

The application discloses a method for boron diffusion of a crystalline silicon solar cell. The method comprises: a crystalline silicon solar cell is heated, boron atom pre deposition is carried out on the surface of the crystalline silicon solar cell; boron atom deposition is carried out on the surface of the crystalline silicon solar cell; secondary thermal oxidation and propelling are carried out on the crystalline silicon solar cell; post deposition and post oxidation are carried out on the crystalline silicon solar cell; and blowing and cooling are carried out on the crystalline silicon solar cell. According to the method provided by the application, the minority carrier lifetime can be prolonged and the cell efficiency can be improved on the premise of low cost.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

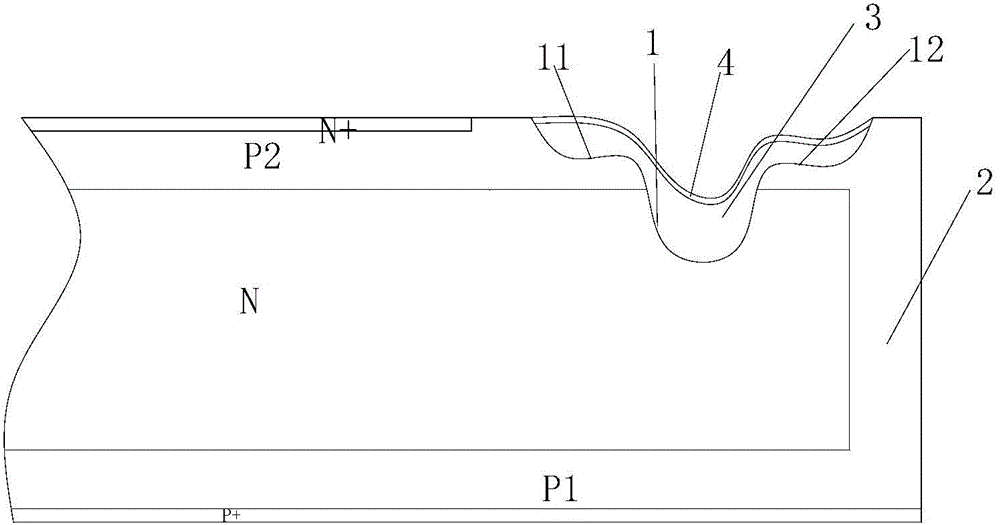

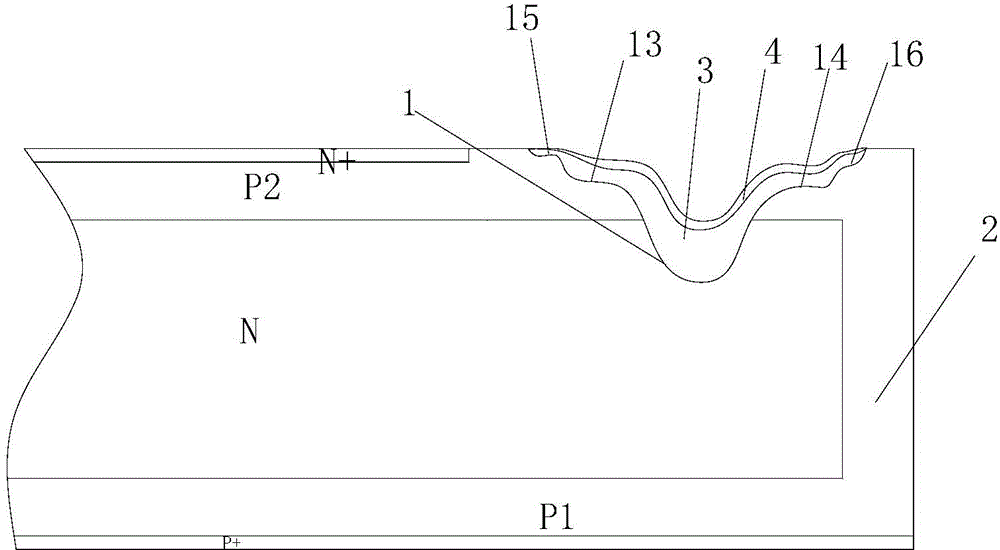

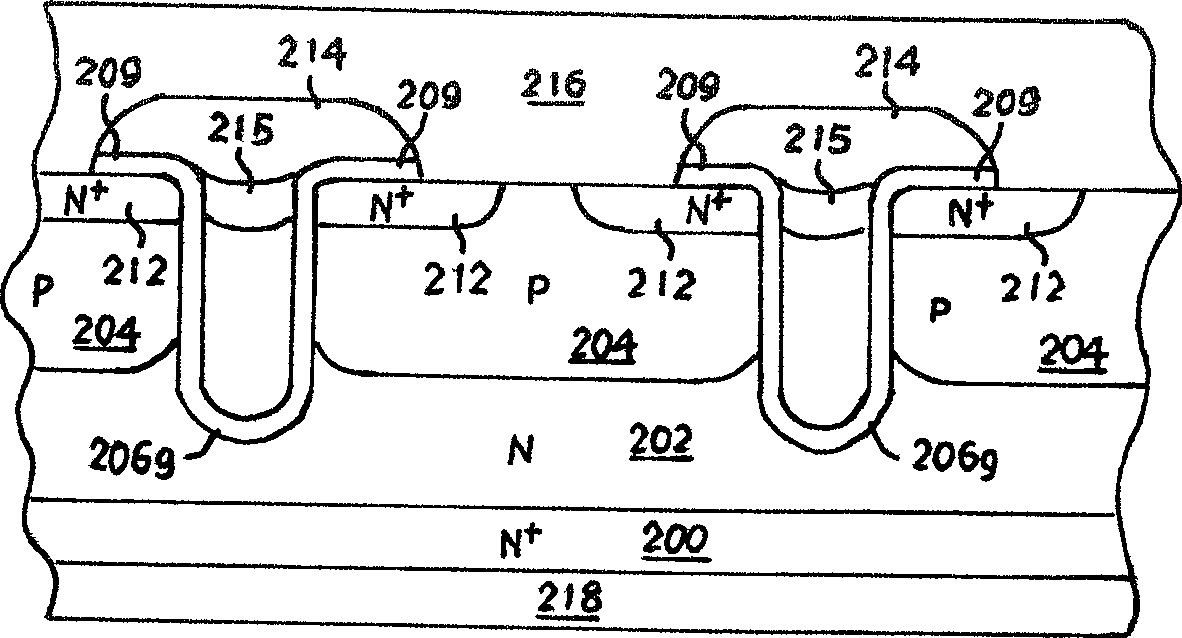

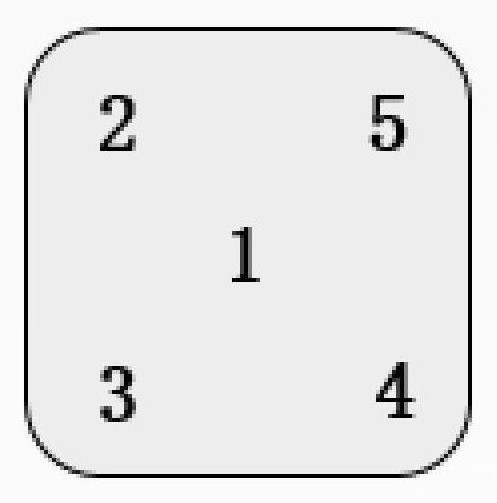

Junction termination structure of thyristor chip

The present invention discloses a junction termination structure of a thyristor chip, and the problems of low forward voltage withstand value and large leakage current of a chip in an existing thyristor single-face trench are solved. Two inner walls of the voltage groove in the thyristor single-face trench are symmetrically provided with stepped structures. The voltage trench is provided with two-stage stepped structures or three-stage stepped structures, the height is larger than a P2N junction, and the structures extend into an N area for 20um to 70 um. The junction termination structure is suitable for the semiconductor chip production field of all table top structures.

Owner:ANHUI PROVINCE QIMEN COUNTY HUANGSHAN ELECTRIC APPLIANCE

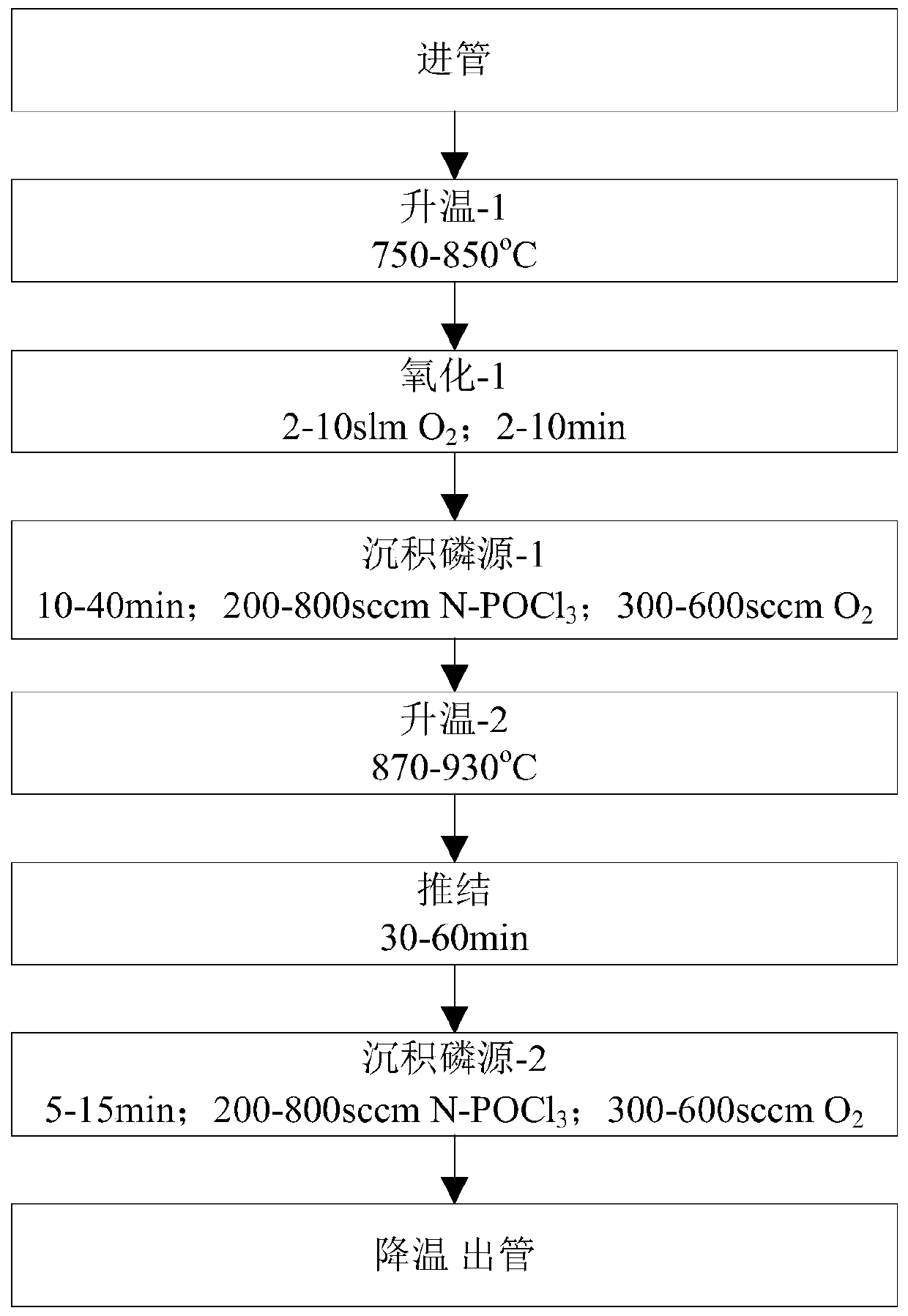

High-quality phosphorus diffusion method for matching selective etching of HF/HNO3 system

ActiveCN109860334AReduce compoundingEasy to coverFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsEtching

The invention relates to a phosphorus diffusion method, in particular to a high-quality phosphorus diffusion method for matching selective etching of an HF / HNO3 system, which belongs to the technicalfield of crystalline silicon solar cells. The method comprises the following steps of: (1) tube entering, (2) temperature rise to a first temperature, (3) oxidation, (4) phosphorus source deposition,(5) temperature rise to a second temperature, wherein the second temperature is higher than the first temperature, (6) knot pushing, (7) second-time phosphorus source deposition after knot pushing toform second phosphorus diffusion on the surface of a silicon wafer, and (8) cooling down and tube existing. According to the high-quality phosphorus diffusion method disclosed in the invention, in a condition of reducing etching weight loss, moderate sheet resistance in an etching area is ensured, the surface phosphorus doping concentration is low, and besides, steps in the etching area and a non-etching area are reduced, and passivation of a subsequent silicon nitride film is facilitated.

Owner:晶科能源(海宁)有限公司 +1

Method for making groove power semiconductor device

InactiveCN100508143CReduce surface concentrationInhibition of channel punch throughSemiconductor/solid-state device manufacturingSemiconductor devicesBreakdown strengthEngineering

The invention is concerned with the manufacture method of the ditch groove power semiconductor device. It is: provides the materials of the basal; forms the first electric transmit epitaxy layer on the basal; forms the second electric transmit zone and the ditch groove inside the epitaxy layer; forms the ebb first electric transmit area and the medium layer with the ditch groove; and then, forms the electric transmit area within the medium layer; forms the first electric transmit source area on the surface of the second electric transmit area; forms the second electric transmit contact area with higher doping PH indicator on the second electric transmit zone surface; forms the passivation layer cap on the top of the ditch groove which must with the medium layer and the electric transmit area; forms the diffusion protecting layer on the surface of the source area and the contact area; finally, forms the structure surface with good electric connection. The invention can control the threshold voltage of the device and improves the breakdown strength of the oxide layer of the device bottom area, and improves its electric connection reliability with no extra cover film printing plate and complex method request.

Owner:HARBIN ENG UNIV

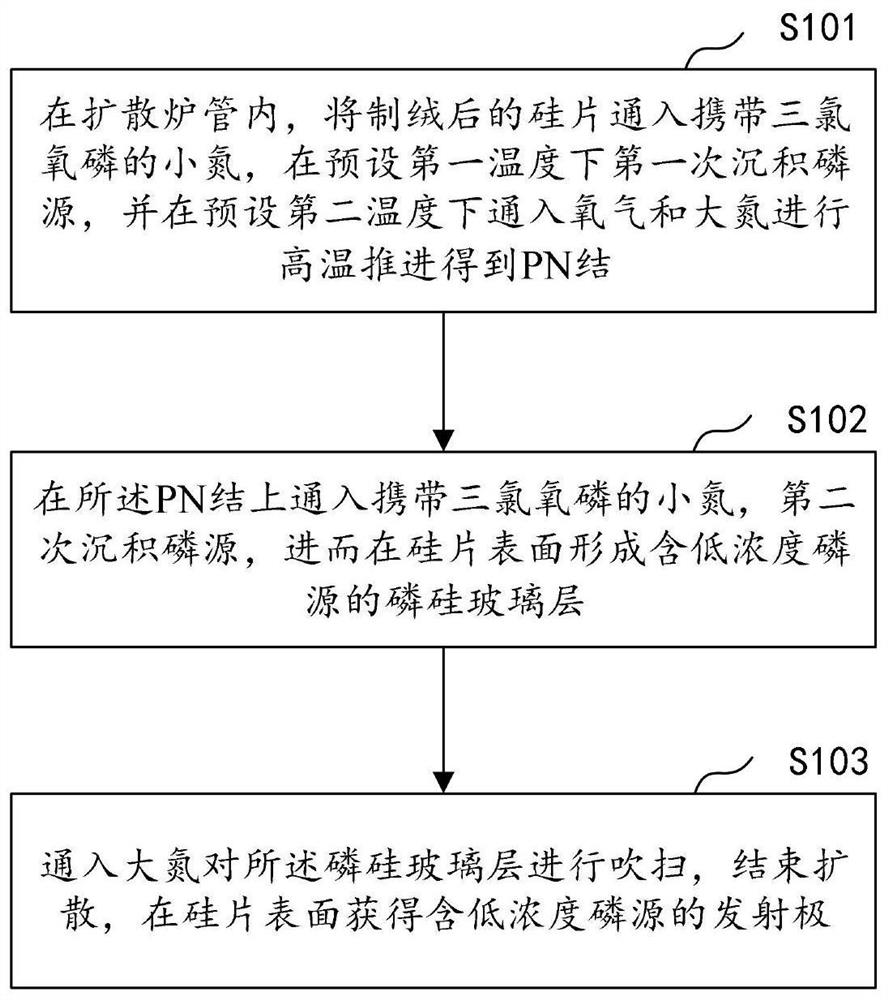

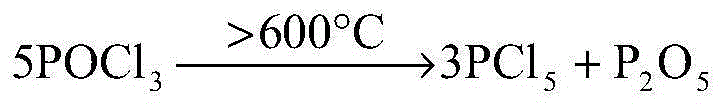

Diffusion process of solar cell, preparation method of solar cell and silicon wafer

PendingCN113437182AImprove conversion efficiencyReduce surface concentrationPolycrystalline material growthAfter-treatment detailsChemical physicsPhysical chemistry

The invention discloses a diffusion process of a solar cell, a preparation method of the solar cell and a silicon wafer, and the diffusion process comprises the steps: introducing small nitrogen carrying phosphorus oxychloride into the textured silicon wafer in a diffusion furnace tube, depositing a phosphorus source at a first temperature, and introducing oxygen and large nitrogen at a second temperature for high-temperature propulsion to obtain a PN junction; introducing small nitrogen carrying phosphorus oxychloride, secondarily depositing a phosphorus source, and further forming a phosphorosilicate glass layer containing a low-concentration phosphorus source on the surface of the silicon wafer; and introducing atmospheric nitrogen to purge, ending diffusion, and obtaining an emitter containing the low-concentration phosphorus source on the surface of the silicon wafer. According to the method, a two-step source deposition mode is adopted, phosphorus oxychloride is deposited in a low-temperature environment, the surface concentration of a silicon wafer can be fully reduced, meanwhile, the uniformity of PN junctions is guaranteed by controlling the gas flow ratio of large nitrogen, oxygen and small nitrogen deposited by a phosphorus source, and the conversion efficiency of a solar cell can be effectively improved.

Owner:CSG PVTECH +1

Preparation method of selective emitter of solar cell

InactiveCN109449251AImprove performanceLess quantityFinal product manufacturePhotovoltaic energy generationSurface concentrationSilicon thin film

The invention discloses a preparation method of a selective emitter of a solar cell. The method can obtain a lightly-doped emitter region with lower surface concentration, shallower junction depth andhigher sheet resistance, thus an emitter with better performance can be obtained. The preparation method of the selective emitter of the solar cell comprises the following steps: (1) providing a silicon substrate, wherein the surface of the silicon substrate comprises a metal contact region used for being contacted with a metal contact electrode and a non-metal contact region located outside themetal contact region; (2) arranging a doped filter layer on the non-metal contact region of the surface of the silicon substrate, wherein the doped filter layer includes a silicon thin film; and (3) doping the silicon substrate, forming a lightly doped region of the selective emitter in the non-metal contact region, provided with the doped filter layer, on the surface of the silicon substrate, andforming a heavily doped region of the selective emitter in the metal contact region, provided with no doped filter layer, on the surface of the silicon substrate.

Owner:北京晶澳太阳能光伏科技有限公司

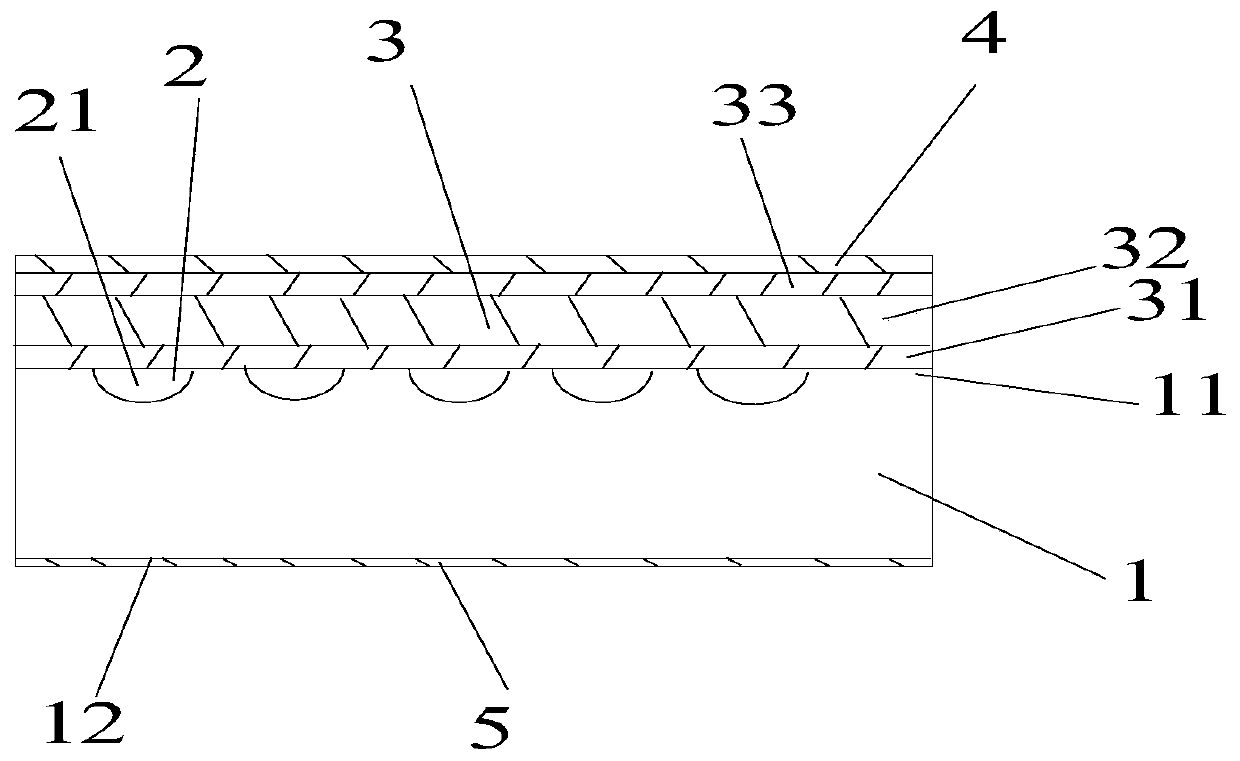

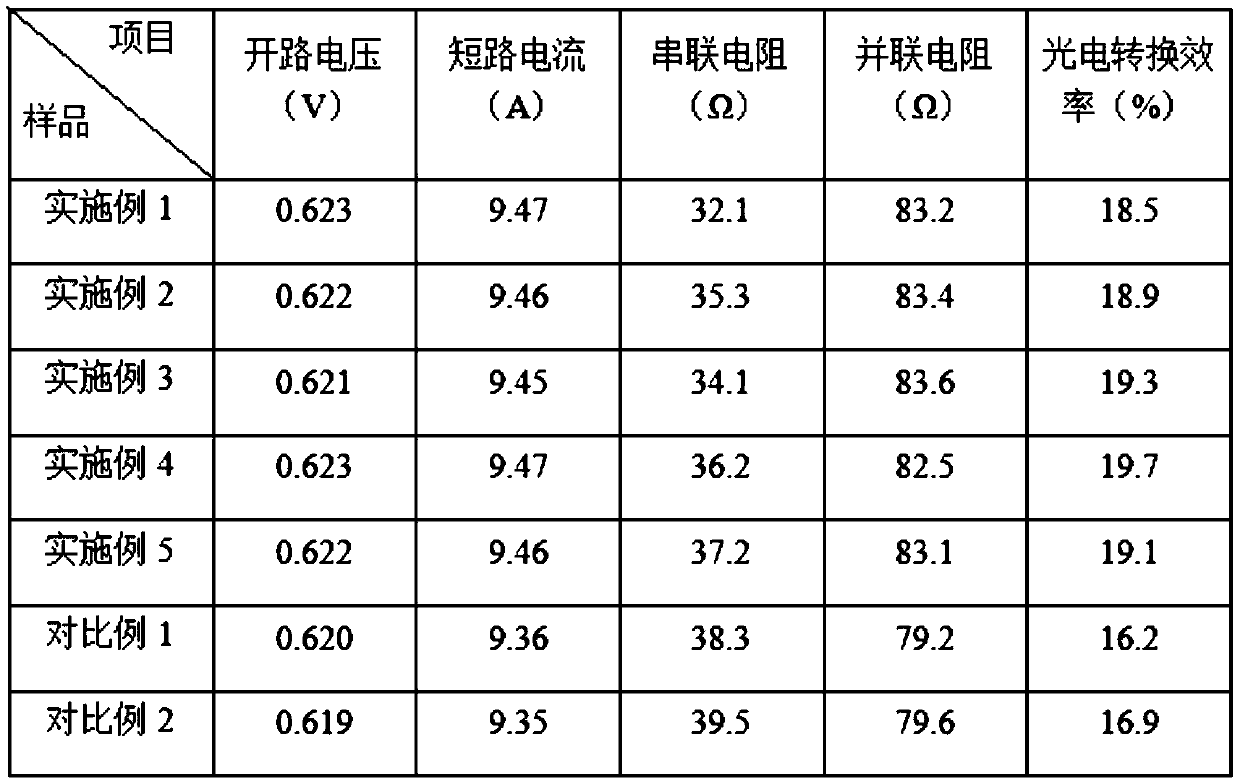

Polycrystalline silicon solar cell with high photoelectric conversion efficiency and method for preparing same

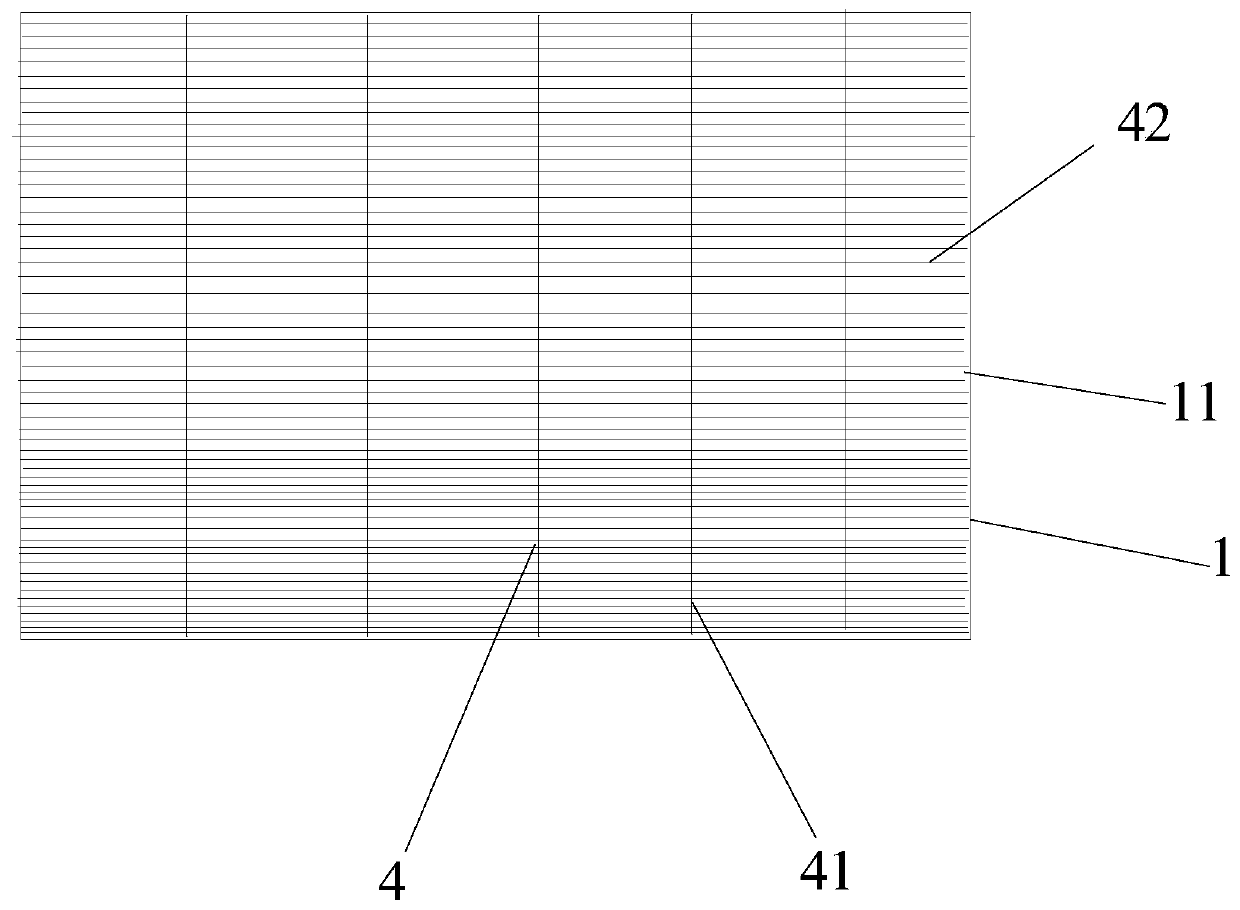

InactiveCN110544726APlay a polishing roleImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical performanceReflective layer

The invention discloses a polycrystalline silicon solar cell with high photoelectric conversion efficiency and a method for preparing the same. The polycrystalline silicon solar cell includes a polycrystalline silicon wafer, wherein the front surface of the polycrystalline silicon wafer is a textured surface, three layers of silicon nitride are deposited on the upper surface of the textured surface, a positive electrode is printed on the front surface of the polycrystalline silicon wafer, and a negative electrode is printed on the back surface of the polycrystalline silicon wafer. The method for preparing the polycrystalline silicon solar cell comprises performing detection and cleaning; performing texturing; performing diffusion knotting; performing a dephosphorized silicon glass treatment; preparing a silicon nitride reflective layer; printing positive and negative electrodes; and performing sintering. A uniform textured surface can be formed on the surface of the polycrystalline silicon wafer by texturing twice, thereby contributing to improvement in the photoelectric conversion efficiency of the polycrystalline silicon wafer. The three layers of silicon nitride are deposited onthe surface of the polycrystalline silicon wafer so as to achieve a good passivation effect on the surface of the polycrystalline silicon wafer and improve the photoelectric conversion efficiency ofthe polycrystalline silicon wafer. An electrical performance test result shows that the polycrystalline silicon solar cell prepared by the method has high photoelectric conversion efficiency.

Owner:浙江利博能源有限公司

Carburizing method of low-carbon alloy steel

ActiveCN103014595BAccelerate decomposition and crackingIncrease carburizing speedSolid state diffusion coatingCarbon potentialMetallurgy

The invention discloses a carburizing method of low-carbon alloy steel. According to the method, through high-temperature deep seepage, the diffused carbon potential can be properly lowered, and the diffusion time can be prolonged, the time can be effectively shortened, the energy consumption can be reduced, and the carburized low-carbon alloy steel can meet the technical requirements.

Owner:金湖县常盛动力机械配件有限公司

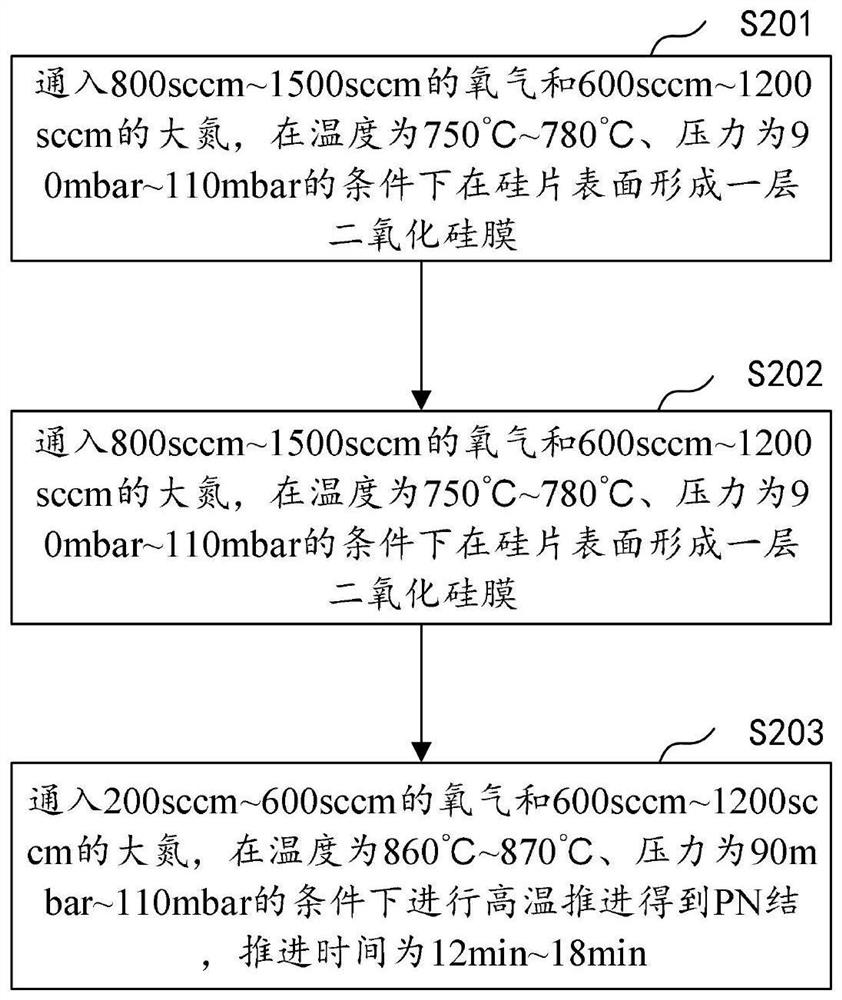

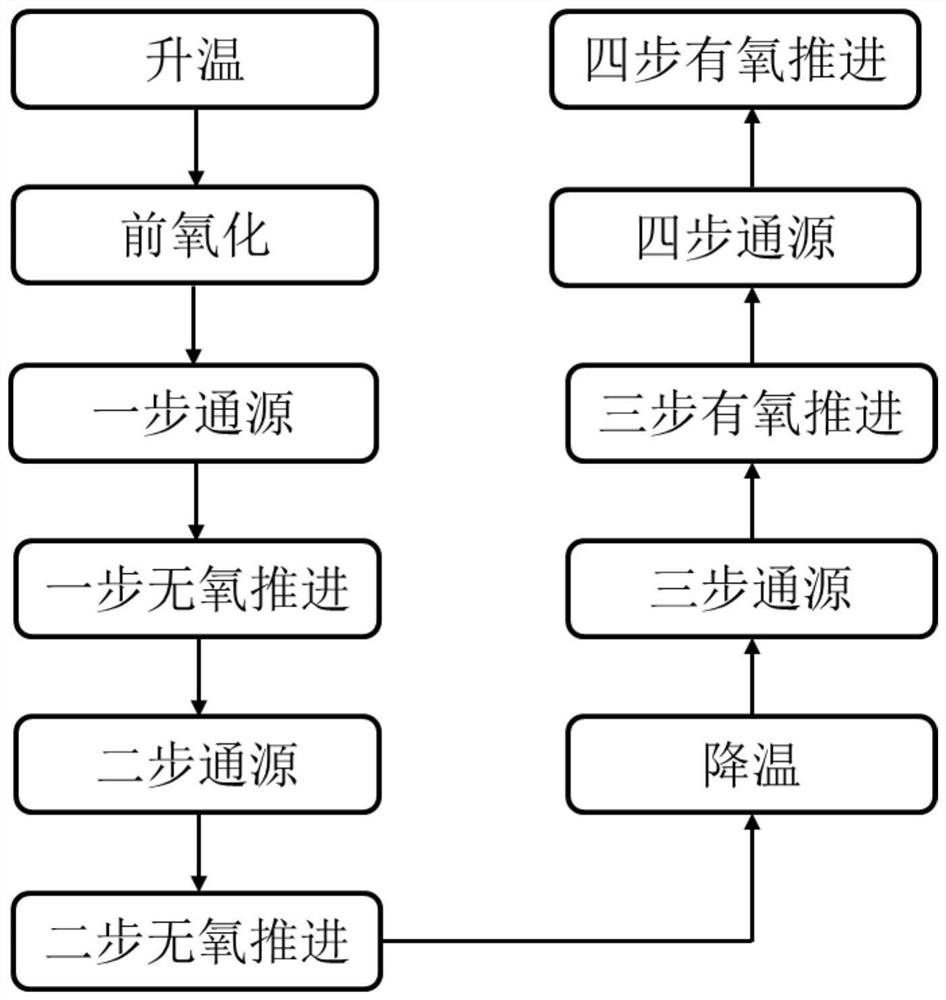

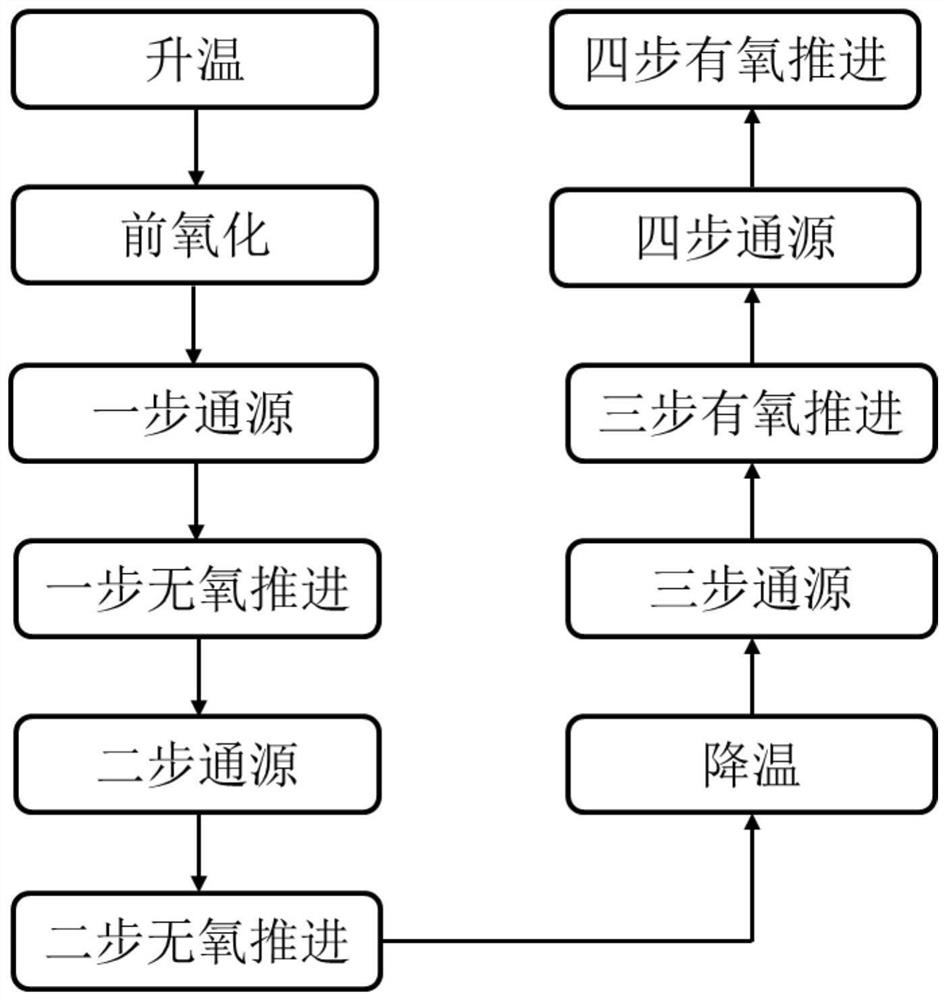

Low-pressure diffusion process of solar single crystal PERC

ActiveCN113964239AReduce surface concentrationIncrease the diffusion lengthFinal product manufactureSemiconductor/solid-state device manufacturingSingle crystalSolar cell

The invention provides a low-pressure diffusion process of solar single crystal PERC. The low-pressure diffusion process comprises one-step source introduction, one-step oxygen-free propulsion, two-step source introduction, two-step oxygen-free propulsion, three-step source introduction, three-step aerobic propulsion, four-step source introduction and four-step aerobic propulsion which are carried out in sequence. According to the method, four-step source introduction, two-step anaerobic propulsion and two-step aerobic propulsion are combined, the two-step anaerobic propulsion is firstly carried out after early-stage source introduction so that the surface concentration can be reduced, and the two-step aerobic propulsion is carried out after later-stage source introduction so that the diffusion length can be increased, and then the sheet resistance uniformity is improved; according to the low-voltage diffusion technology, the solar cell piece which is low in surface concentration, small in junction depth and high in uniformity can be manufactured, high open-circuit voltage and short-circuit current are achieved, and the conversion efficiency is high.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

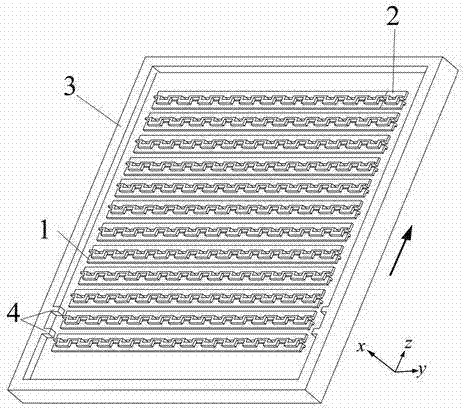

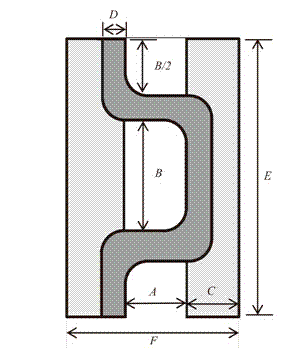

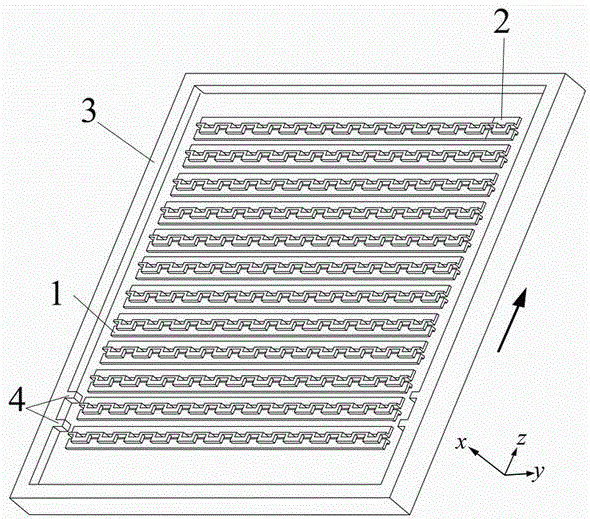

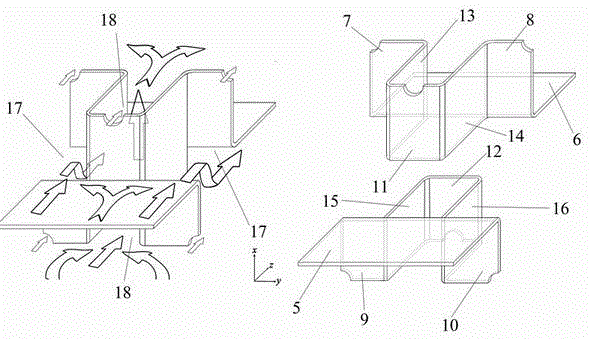

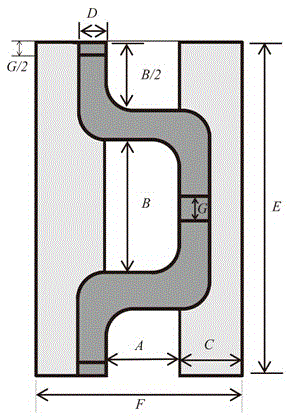

Spiral-wound membrane static-state mixed flow filtering net

The invention discloses a spiral-wound membrane static-state mixed flow filtering net. The spiral-wound membrane static-state mixed flow filtering net is composed of a plurality of filtering net strips and is fixed by a filtering net frame, and the filtering net strips are uniformly distributed at the same distance in a feeding direction, each filtering net strip is composed of a plurality of filtering net units, each filtering net unit is provided with three fluid passages perpendicular to the feeding fluid direction, fluid is statically mixed in the filtering net unit, no vortex and turbulent flow are caused, and no fluid dead angle is generated when the fluid passes through the filtering net. According to the spiral-wound membrane static-state mixed flow filtering net, fluid near the surface of the membrane and at the center of the fluid passage is inter-migrated, the fluid mechanical condition of the surface of the membrane is changed, no vortex and turbulent flow are generated, the above technical scheme is different from the various existing schemes, the surface concentration of the substance intercepted by the membrane can be reduced, the mass transfer rate is increased, the fluid mixing effect is improved, while the concentration polarization and the membrane pollution can be effectively reduced, the increased pressure drop and the pumping loss during membrane operation due to the arrangement of the filtering net can be reduced, and the energy utilization rate is improved.

Owner:CENT SOUTH UNIV

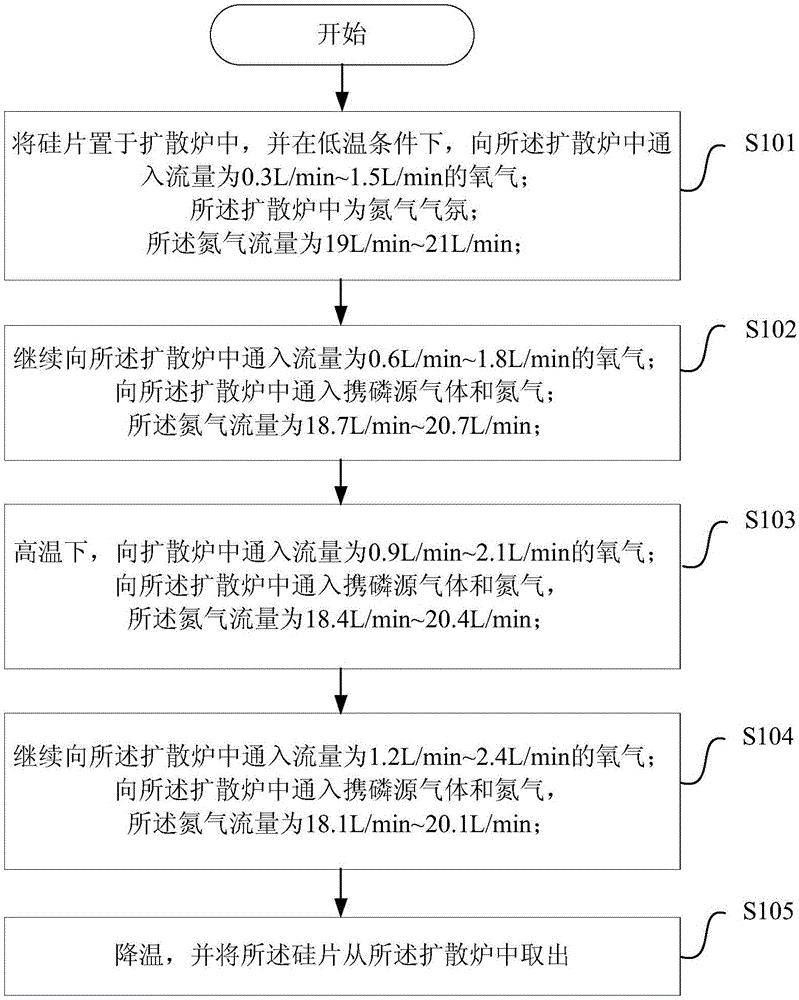

High-sheet resistance cell slice diffusion preparation method

ActiveCN105161574AImprove current efficiencyImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSurface concentrationNitrogen atmosphere

The invention discloses a high-sheet resistance cell slice diffusion preparation method. The method comprises steps: a silicon wafer is placed in a diffusion furnace in a nitrogen atmosphere, and in a low temperature condition, low concentration oxygen is inlet to the diffusion furnace; an oxygen flow is enhanced afterwards, a gas carrying a phosphorus source and the nitrogen with a reduced flow are inlet to the diffusion furnace; after temperature rise, the oxygen with the enhanced flow, the nitrogen with the reduced flow and the gas carrying the phosphorus source are inlet continuously to the diffusion furnace; the oxygen flow is enhanced continuously, and the nitrogen flow is reduced; and temperature falls, and the silicon wafer is taken out from the diffusion furnace. A four-step gradient oxygen inletting method is adopted, the silicon wafer surface concentration can be effectively reduced, surface recombination of carriers is reduced, the diffusion sheet resistance is enhanced through reducing the silicon wafer surface concentration, and the solar cell efficiency is further improved.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

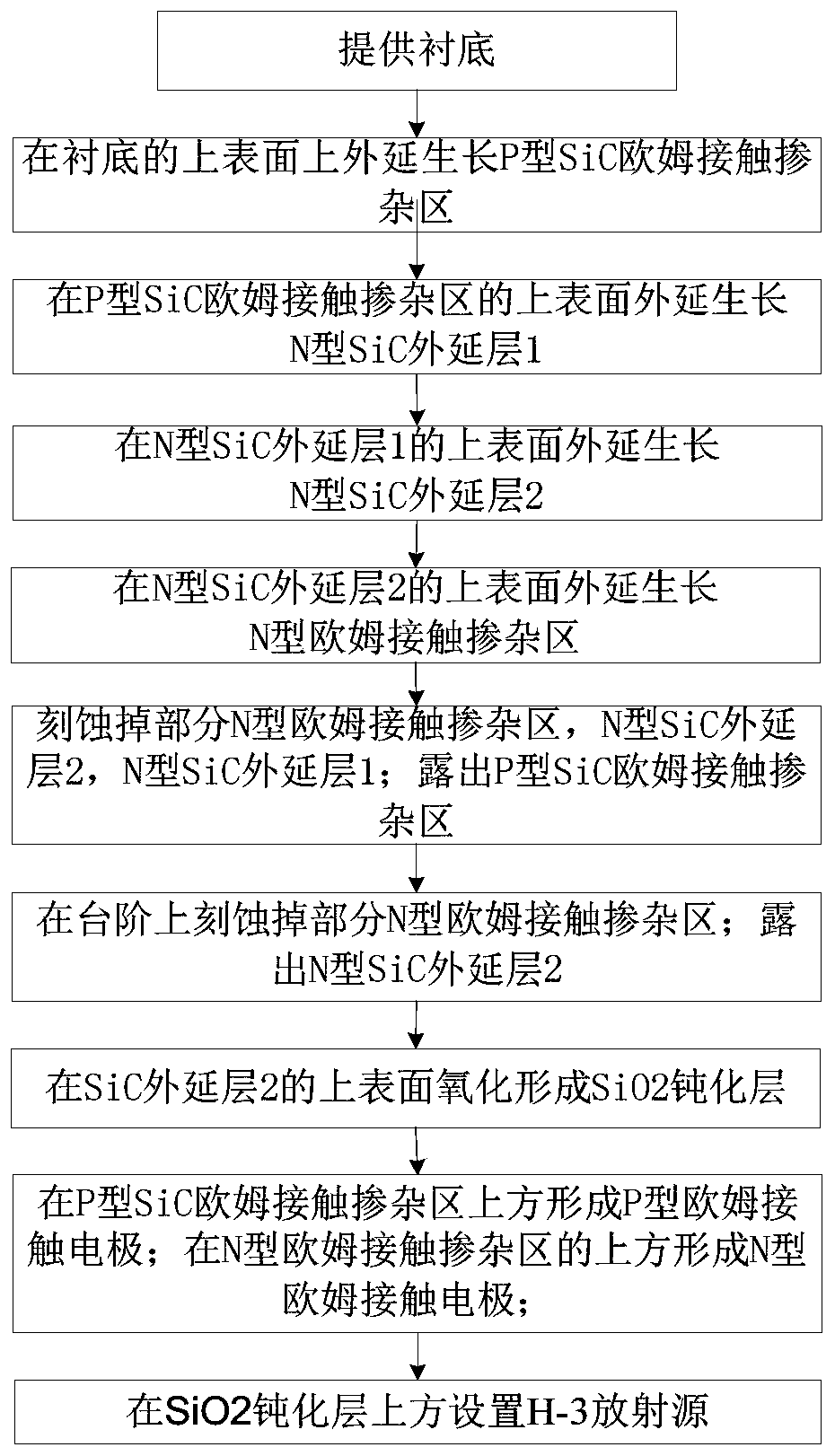

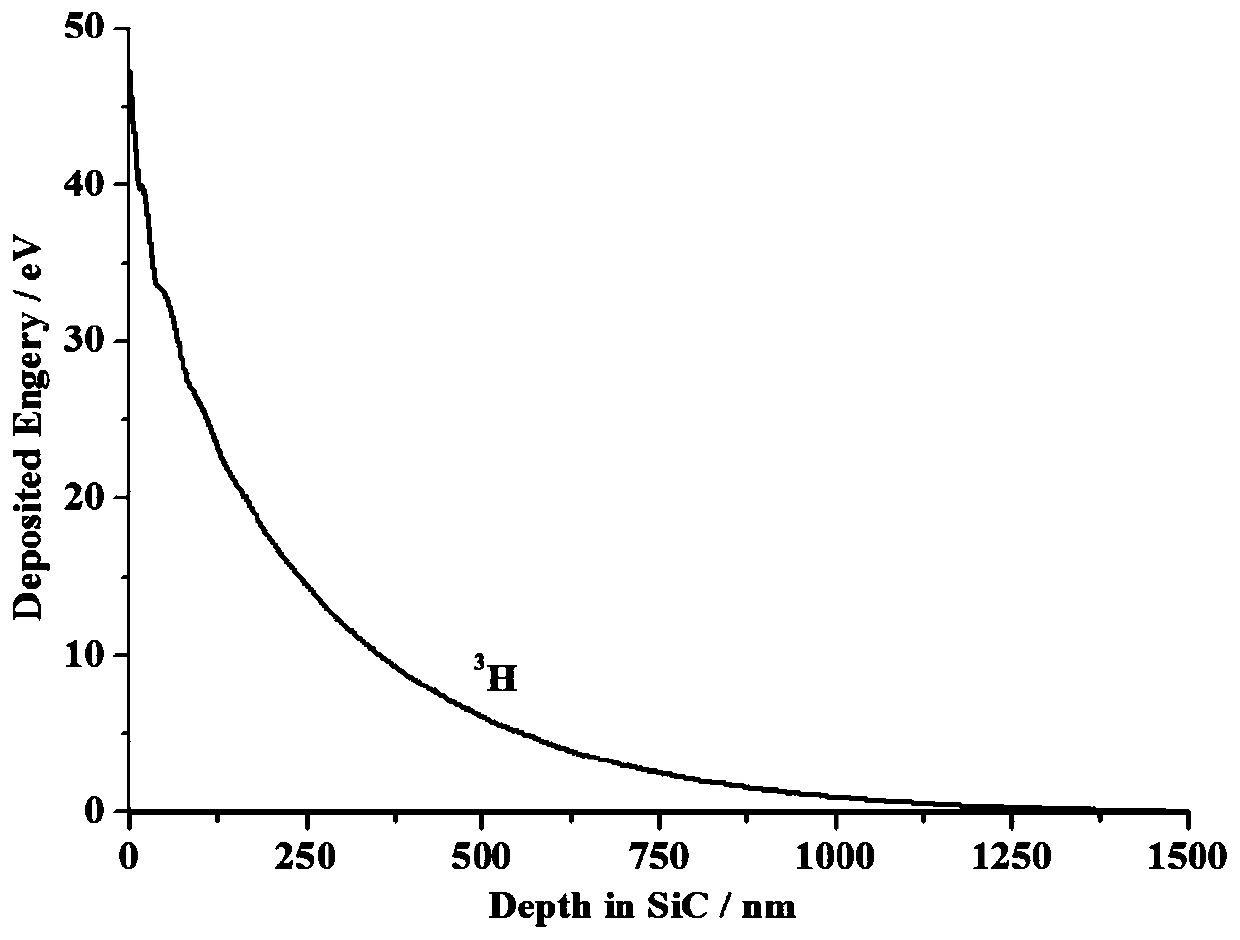

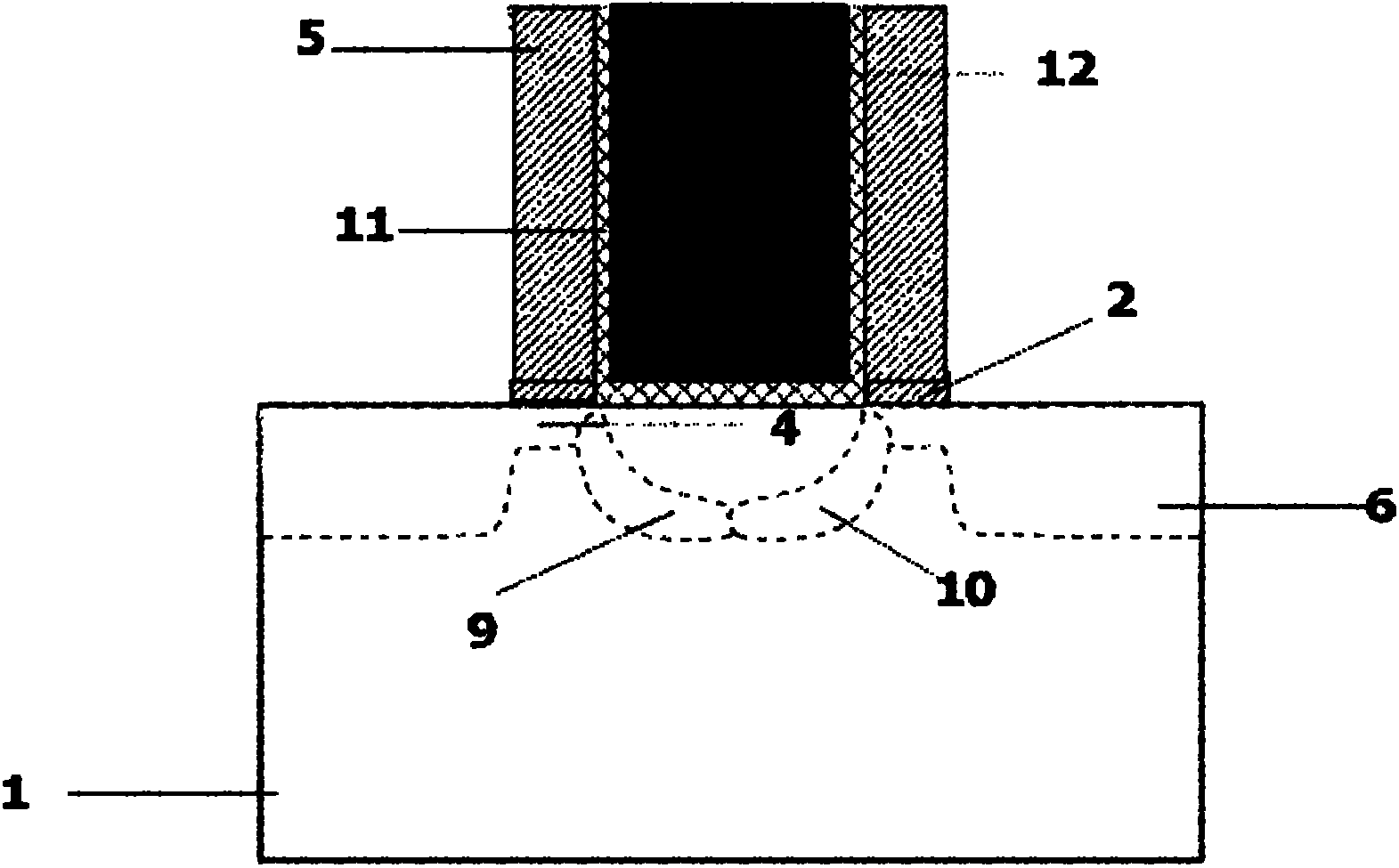

H-3 silicon carbide isotope battery and manufacturing method thereof

ActiveCN110491541AIncrease output powerReduce recombination lossFinal product manufacturePhotovoltaic energy generationOhmic contactIsotope

The invention discloses an H-3 silicon carbide isotope battery and a manufacturing method thereof. The isotope battery comprises an N-type highly-doped SiC substrate and a P-type SiC ohmic contact doped region from bottom to top, wherein a first N-type SiC epitaxial layer is arranged in a partial region on the P-type SiC ohmic contact doped region; a second N-type SiC epitaxial layer is arranged on the first N-type SiC epitaxial layer; a P-type ohmic contact electrode is arranged in a region, except the first N-type SiC epitaxial layer, on the P-type SiC ohmic contact doped region; an N-type ohmic contact doped region is arranged partially in a region on the second N-type SiC epitaxial layer; an N-type ohmic contact electrode is arranged on the N-type ohmic contact doped region; a SiO2 passivation layer is arranged in a region, except the N-type ohmic contact doped region, on the second N-type SiC epitaxial layer; and an H-3 radioactive isotope source is arranged on the SiO2 passivation layer. The design is novel and reasonable, the problem of irradiation generated carrier recombination loss of H-3 on the surface can be effectively solved, and the output power and the energy conversion efficiency of the isotope battery are effectively improved.

Owner:CHANGAN UNIV

Manufacturing method of high-K metal gate MOS (Metal Oxide Semiconductor) transistor

ActiveCN102110614ASuppression of short channel effectsReduce surface concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentSurface concentration

The invention discloses a manufacturing method of a high-K metal gate MOS (Metal Oxide Semiconductor) transistor, which comprises the following step: injecting corresponding impurities to the space right above a channel region of the MOS transistor, so that the bottom of the channel region of the MOS transistor and the junction between the channel region and a source drain region are heavily doped with impurities which are of the same type with the impurities doped on a substrate, the source drain region of the MOS transistor is doped with impurities of which the type is opposite to that of the impurities doped on the substrate, and the doping of the channel region can not cause impurity compensation to the source drain region. Thus, the manufactured transistor has an inversely doped channel which has a low surface concentration and a high bulk concentration, and can simultaneously satisfy the requirement for high drive current and the requirement of inhibiting the short-channel effect.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

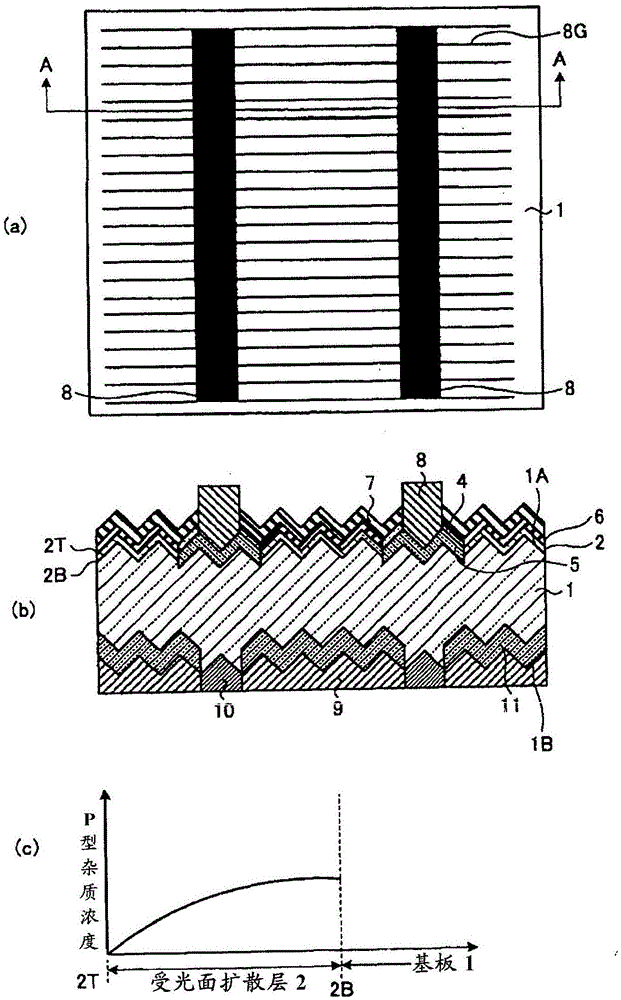

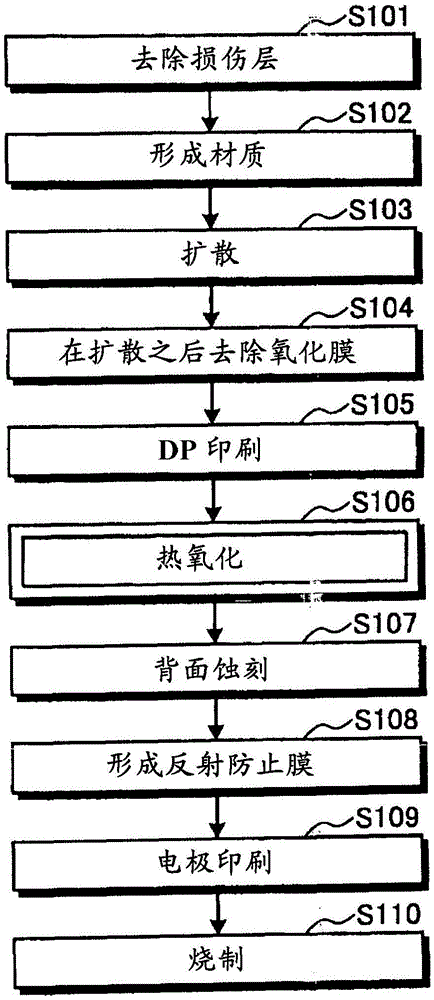

Solar cell manufacturing method and solar cell

InactiveCN106133922AReduce transmittanceLow interface reference densityFinal product manufacturePhotovoltaic energy generationHigh concentrationSurface concentration

The purpose of the present invention is to achieve high efficiency by reducing surface concentration of a light receiving surface and increasing impurity concentration under electrodes, while facilitating concentration control of a diffusion layer. At the time of forming a high concentration diffusion layer (5) on a part of a first surface (1A) of a substrate (1) having formed thereon a diffusion layer (2) of a light receiving surface, an impurity in the outermost surface of the diffusion layer (2) of the light receiving surface is taken into a thermally oxidized film (6) by performing thermal oxidation in a state wherein a diffusion source is formed. Consequently, an impurity concentration of the outermost surface of the diffusion layer (2) of the light receiving surface is set lower than the impurity concentration of the inner side.

Owner:MITSUBISHI ELECTRIC CORP

System for transporting and/or washing and/or pasteurisation thermal treatment of foodstuffs, particularly leaf products

ActiveUS8146489B2More powerReduce surface concentrationFruit and vegetables preservationMilk preservationThermal treatment

The present invention relates to a system for transporting and / or washing and / or pasteurization thermal treatment of foodstuffs, particularly leaf products comprising at least a treatment section. The treatment section can be comprised of one or more sections of rectilinear tubes and one or more corresponding curved tube sections, wherein products within the treatment section being conveyed by a fluid, such as water, flowing along the tubes.

Owner:TURATTI S R I

Rolled membrane static mixed flow screen

ActiveCN104524979BReduce pollutionLower overall pressure dropSemi-permeable membranesSurface concentrationMixed flow

The invention discloses a static mixed flow separating screen for a spiral-wound membrane. The screen is composed of a plurality of separating screen strips which are fixed through a separating screen strip frame and uniformly distributed in the feeding direction at equal intervals. Each separating screen strip is composed of a plurality of separating screen units. Each separating screen unit is provided with three fluid channels perpendicular to the fluid inlet direction. Fluid carries out static flow mixing in the separating screen units and does not generate vortexes or turbulence, and fluid dead space does not exist when the fluid flows through the separating screen. According to the static mixed flow separating screen for the spiral-wound membrane, the fluid close to the surface of the membrane and the fluid in the centers of the fluid channels can be transferred mutually, the mechanical condition of the fluid on the surface of the membrane is changed, the vortexes and the turbulence are avoided, the separating screen is different from various existing schemes, the surface concentration of materials held back by the membrane is reduced, the mass transfer rate is increased, and fluid mixing is strengthened; moreover, pressure drop and pump consumption increased in the operating process of the membrane due to adding of the separating screen are reduced while concentration polarization and membrane pollution are effectively reduced, and the energy utilization ratio is increased.

Owner:CENT SOUTH UNIV

System for pasteurisation thermal treatment of foodstuffs, particularly leaf product

ActiveUS8082840B2Reduce surface concentrationConservation periodMilk preservationFruit and vegetables preservationPasteurizationEnvironmental engineering

The present invention relates to a system for pasteurization thermal treatment of foodstuffs, particularly leaf products, comprised of means for loading the product to be subjected to treatment and means for discharging the treated product. The system is comprised of a first treatment section in which the product to be subjected to treatment is conveyed by the loading means and wherein the first treatment section heats the product by a treatment fluid, so as to reduce starting concentration of thermo sensitive bacterial flora present in the same. A second treatment section is provided in cascade with the first treatment section. The second treatment section cools the product by the treatment fluid, so as to stop growing of residual bacterial flora present.

Owner:TURATTI S R I

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com