Rolled membrane static mixed flow screen

A roll-type membrane and screen separation technology, applied in the field of membrane separation, can solve the problems of increasing pressure drop and pump consumption, achieve the effects of reducing pressure drop and pump consumption, reducing membrane fouling, and changing hydrodynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

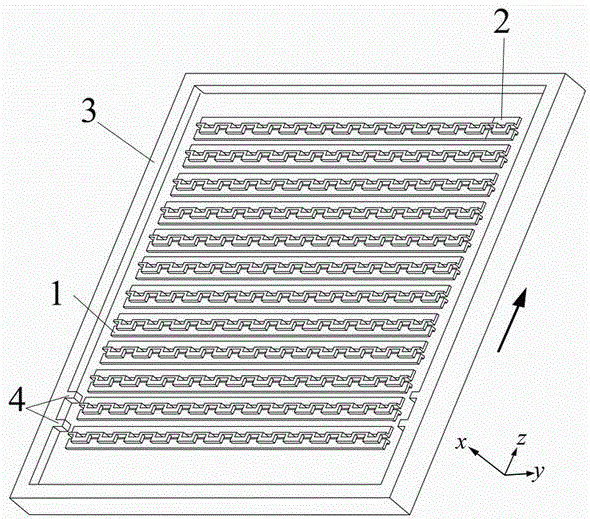

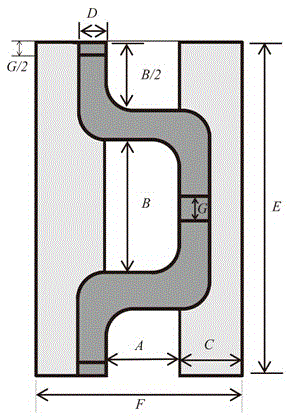

[0031] Select a screen unit size as shown in the table:

[0032] A(mm) B / A C / A D / A E / A F / A G / A 1 4 3 1 10 7 0.5

[0033] The size of 13 mesh units constitutes a mesh strip, and 13 mesh strips form a mesh. The mesh is installed on a polyethersulfone ultrafiltration membrane with a length of 19cm and a width of 14cm. Glycans (important raw materials in medicine, food, cosmetics and other industries) are tested as solutes. The test pressure is 120kPa, and the concentration of dextran is 5.0kg / m 3 , and compared with conventional grids. The experimental results show that in the membrane process under the same pump consumption, the static mixed flow partition has similar or higher mass transfer performance than the conventional partition, and in the membrane process under the lowest pump consumption, compared with the conventional partition Compared with that, the mass transfer coefficient increased by nearly 36% after adopting the static mixe...

Embodiment 2

[0035] Select a screen unit size as shown in the table:

[0036] A(mm) B / A C / A D / A E / A F / A G / A 1 5 2 1 12 5 0.5

[0037] The size of 13 mesh units constitutes a mesh strip, and 13 mesh strips form a mesh. The mesh is installed on a polyethersulfone ultrafiltration membrane with a length of 19cm and a width of 14cm. Glycans (important raw materials in medicine, food, cosmetics and other industries) are tested as solutes. The test pressure is 120kPa, and the concentration of dextran is 5.0kg / m 3 , and compared with conventional grids. The experimental results show that in the membrane process under the same pump consumption, the static mixed flow partition has similar or higher mass transfer performance than the conventional partition, and in the membrane process under the lowest pump consumption, compared with the conventional partition Compared with that, the mass transfer coefficient increased by nearly 50% after adopting the static mixe...

Embodiment 3

[0039] Select a screen unit size as shown in the table:

[0040] A(mm) B / A C / A D / A E / A F / A G / A 1 4 3 2 12 7 0.5

[0041] The size of 13 mesh units constitutes a mesh strip, and 13 mesh strips form a mesh. The mesh is installed on a polyethersulfone ultrafiltration membrane with a length of 19cm and a width of 14cm. Glycans (important raw materials in medicine, food, cosmetics and other industries) are tested as solutes. The test pressure is 120kPa, and the concentration of dextran is 5.0kg / m 3 , and compared with conventional grids. The experimental results show that in the membrane process under the same pump consumption, the static mixed flow partition has similar or higher mass transfer performance than the conventional partition, and in the membrane process under the lowest pump consumption, compared with the conventional partition Compared with that, the mass transfer coefficient increased by nearly 47% after adopting the static mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com