High-quality phosphorus diffusion method for matching selective etching of HF/HNO3 system

A phosphorus diffusion and selective technology, applied in semiconductor devices, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of high surface area recombination, lower battery open circuit voltage, high square resistance in etching area, etc. Moderate diffusion resistance, reduced contact resistance, and improved fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

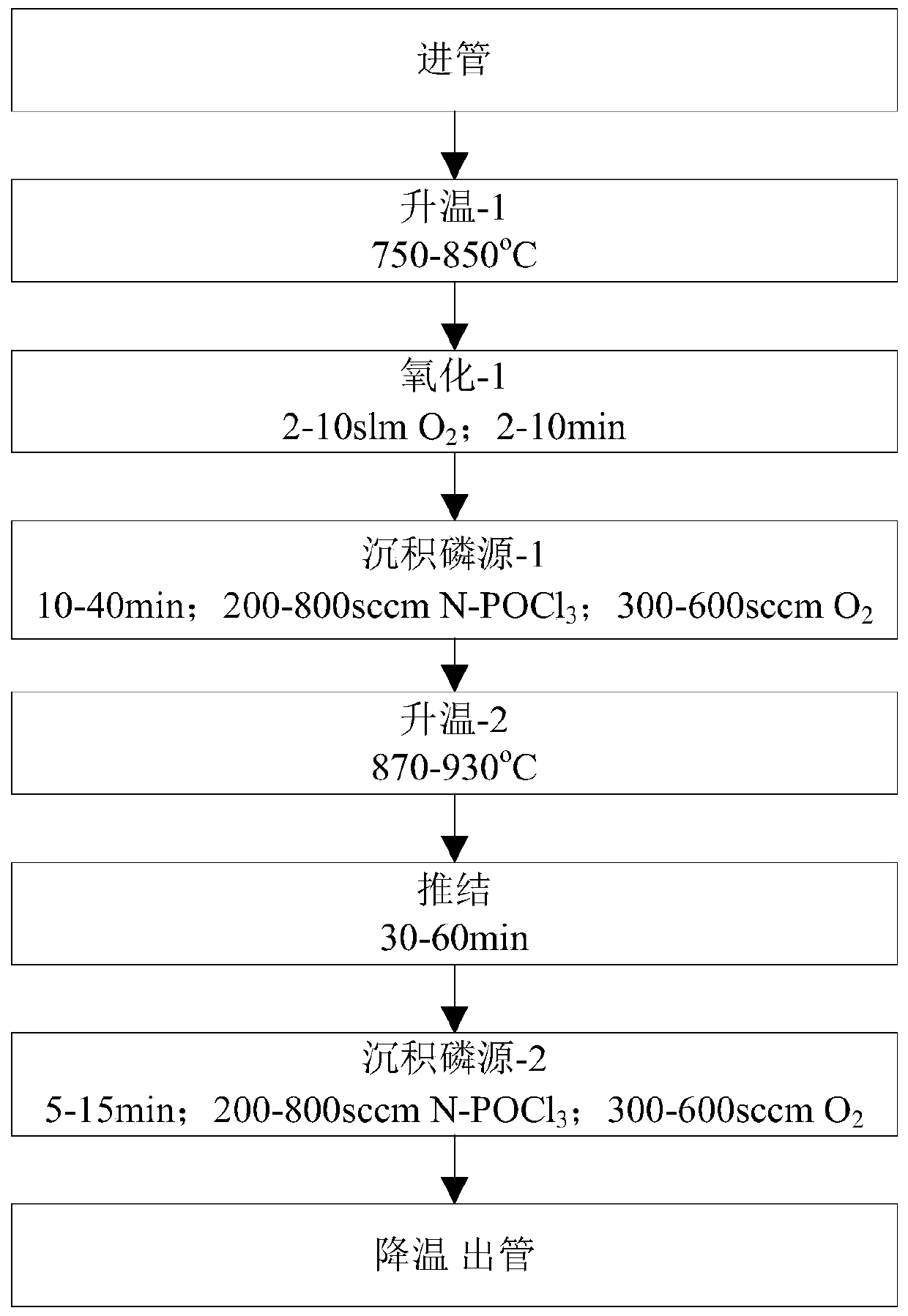

[0032] A matching HF / HNO 3 A high-quality phosphorus diffusion method for system selective etching, the process flow chart of this method is as follows figure 1 As shown, the method specifically includes the following steps:

[0033] (1) Inlet tube: put the silicon wafer to be diffused into the diffusion furnace tube,

[0034] (2) Heating up to the first temperature: under the condition of nitrogen atmosphere, the temperature of the diffusion furnace tube reaches the set temperature of 800°C at a heating rate of 10°C / min, and the flow rate of nitrogen gas is 9000 sccm.

[0035] (3) Oxidation: Oxygen was passed into the diffusion furnace tube for oxidation, and the oxidation time was 6 minutes; the gas flow rate of the oxygen was 450 sccm.

[0036] When the temperature of the diffusion furnace tube reaches the set temperature -1, the oxidation -1 step is first carried out to form a thin oxide layer on the surface of the silicon wafer to be diffused, the purpose of which is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com