Fiber-reinforced composite fire door

a fiber reinforced composite and fire door technology, applied in the field of fiber reinforced composites, can solve the problems of door frame bumping, door and door frame bumping, and the appearance of traditional wooden building structures such as doors, wall panels, and windows, and may suffer from some disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0173] The following examples describe particular embodiments of fiber-reinforced composites of the present invention and particular embodiments of methods and systems of the present invention.

[0174] Fiberglass Reinforced Polyurethane Panels Door Skins

[0175] In an embodiment, the fiber-reinforced composite of the present invention is a door skin or a panel such as may be used for a wall or door unit. In an embodiment, the door skin or panel comprises lips that can at least partially wrap around the frame of the structure to be covered. For example, the lips may wrap around the rails and / or stiles used to make the door frame. The lips may be sized to completely overlap one another. Alternatively, the door skin or panel may be flat with square edges.

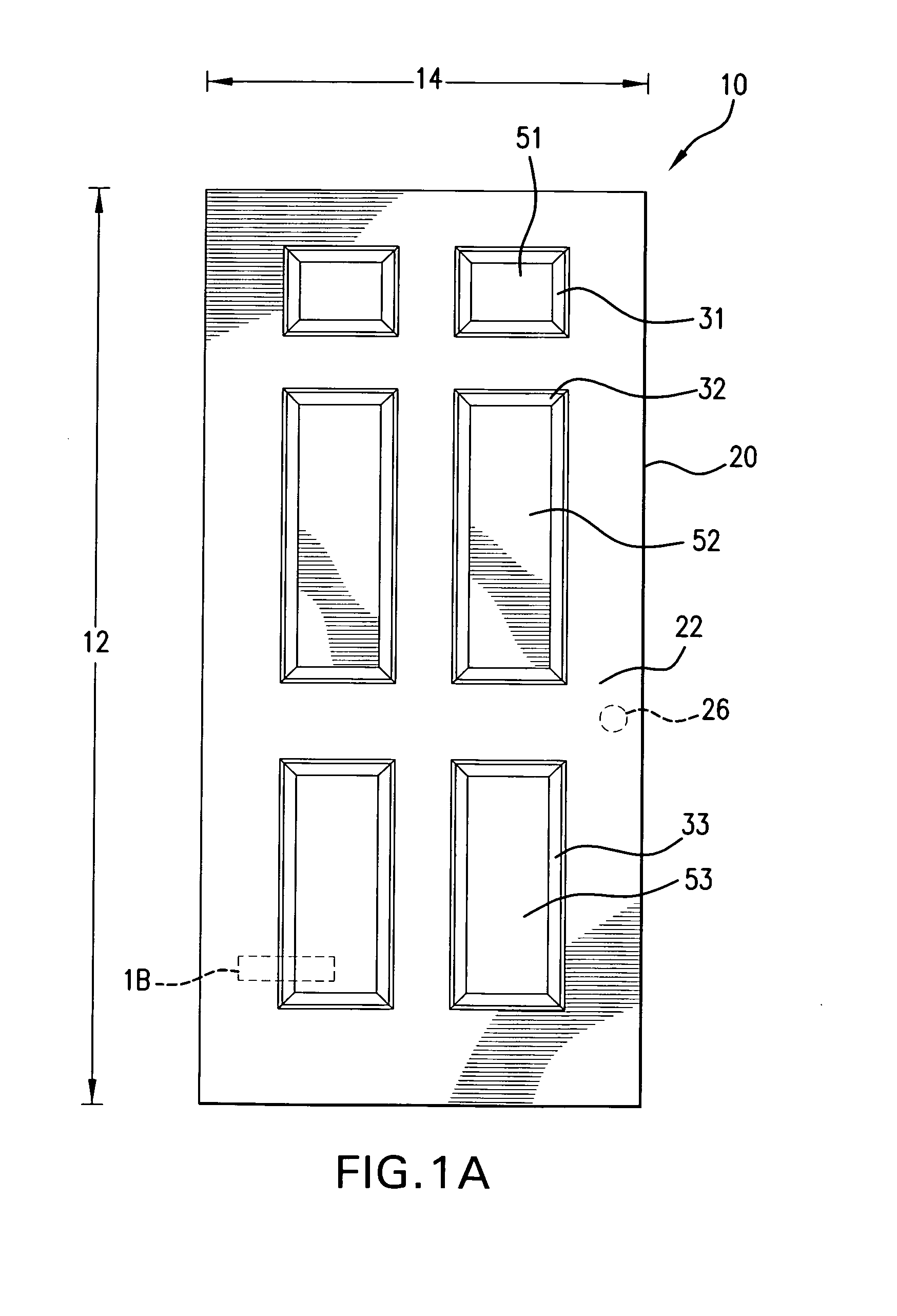

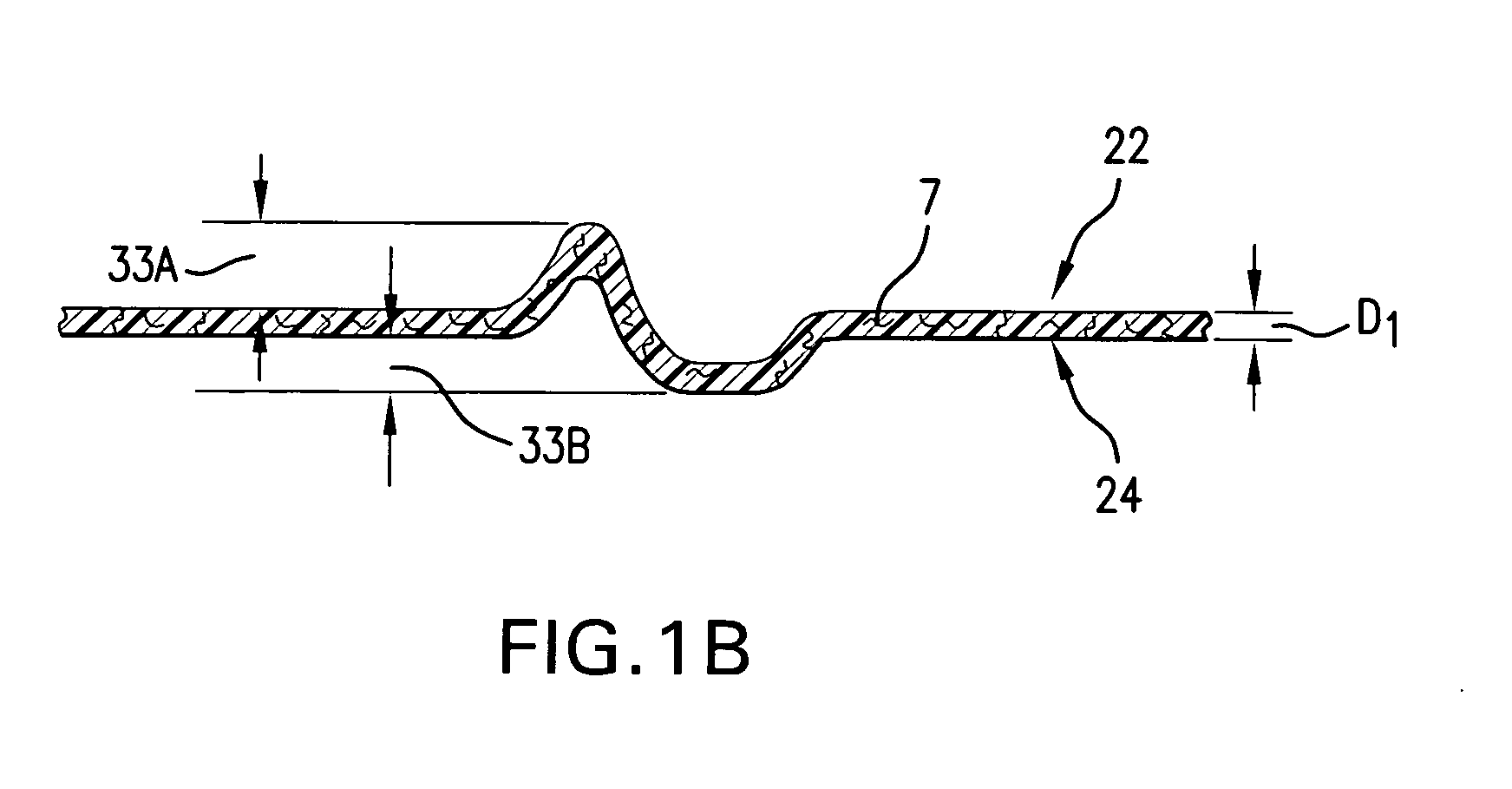

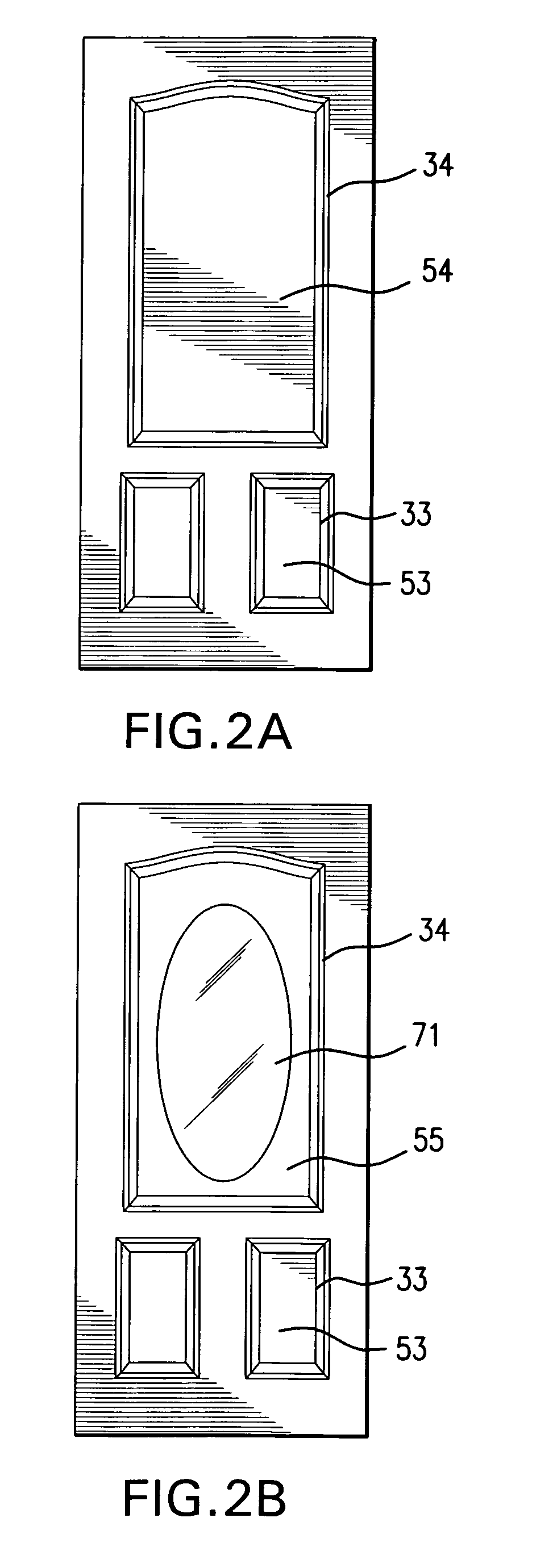

[0176] Door skins having six panels such as that shown in FIG. 1 were made with the fiber-reinforced composite of the present invention. Thus, as shown for the door skin of FIG. 1, in an embodiment, the door skins of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com