Chain-type diffusion technology and chain-type diffusion device

A diffusion process and chain-type technology, applied in the direction of diffusion/doping, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problem of surface minority carrier recombination probability, increased junction leakage, high phosphorus concentration on the p-n junction surface, and internal recombination probability Increase and other problems, to achieve the effect of reducing the probability of recombination in the body, reducing the surface concentration, and various design options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

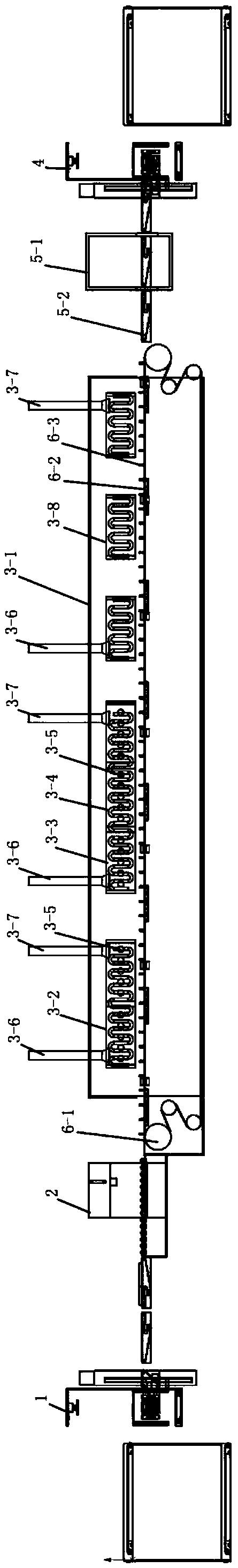

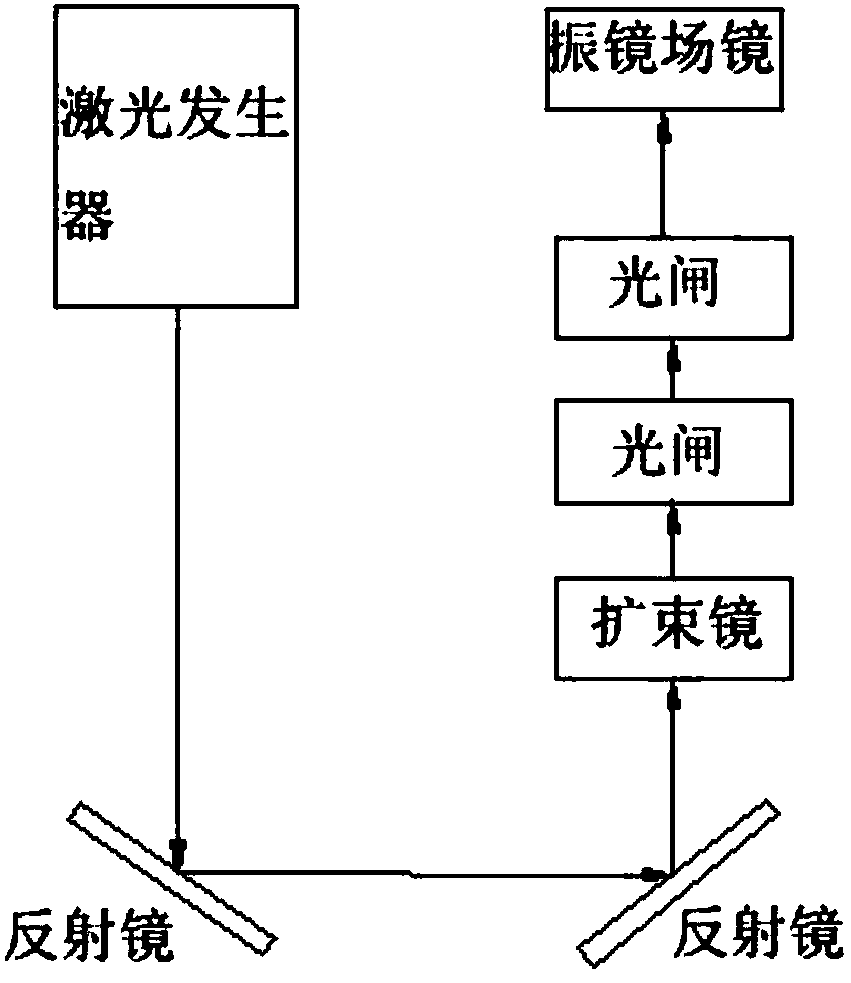

[0029] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0030] Such as figure 1 with figure 2 The chain diffusion process and chain diffusion equipment shown are the best embodiments of the present invention.

[0031] A chain diffusion process includes a spraying process, a temperature-rising dehydration process, a high-temperature diffusion process, a temperature-reducing gettering process and a laser pushing process of silicon wafers on a conveyor belt.

[0032] A. Spraying process: evenly apply a layer of phosphoric acid on the suede surface of the silicon wafer, and keep the amount of phosphoric acid on the suede surface of the silicon wafer at 1.0mol / cm 2 ;

[0033] B. Heating and dehydration process: the coated silicon wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com