Chained diffusion process for solar cell

A solar cell and diffusion process technology, applied in the directions of diffusion/doping, circuits, electrical components, etc., can solve the problems of difficult control of surface sheet resistance, low battery life, and high surface doping concentration, reducing the surface concentration The effect of too high, increasing production capacity and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

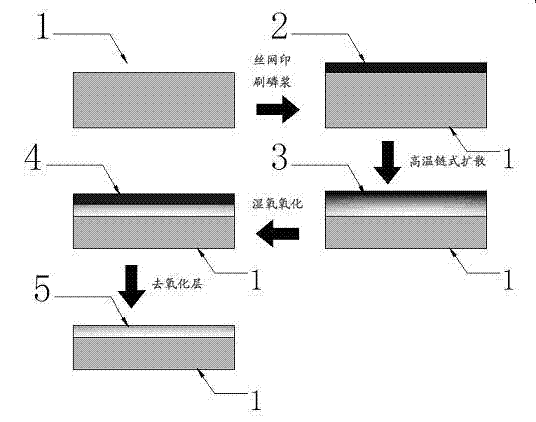

[0038] Such as figure 1 Shown.

[0039] A chain diffusion process for solar cells includes the following steps:

[0040] Step A: Use screen printing phosphor paste process for chain diffusion or spray phosphoric acid aqueous solution process for chain diffusion to form a screen printing surface phosphor paste layer 2 on the surface of the substrate silicon wafer 1;

[0041] Step B: After step A, perform high-temperature chain diffusion process to transform the screen-printed surface phosphor paste layer 2, and the formed P atoms diffuse into the surface of the base silicon wafer to form an N-type layer, and at the same time, the surface of the base silicon wafer is formed with Impurity layer, we collectively refer to the N-type layer and the impurity layer as the surface impurity distribution layer 3 after chain diffusion;

[0042] Step C: After step B, perform oxidation treatment on the surface of the surface impurity distribution layer 3 after chain diffusion, and quickly grow a un...

Embodiment 2

[0045] Such as figure 1 Shown.

[0046] Step A: Use the screen printing phosphor paste process for chain diffusion or spray the phosphoric acid aqueous solution process for chain diffusion to form a screen printing surface phosphor paste layer 2 on the surface of the substrate silicon wafer 1; the screen printing phosphor paste process performs chain diffusion The method of formula diffusion is to uniformly print the phosphor paste on the surface of the base silicon wafer 1 using a screen plate.

[0047] Step B: After step A, perform high-temperature chain diffusion process to transform the screen-printed surface phosphor paste layer 2, and the formed P atoms diffuse into the surface of the base silicon wafer to form an N-type layer, and at the same time, the surface of the base silicon wafer is formed with For the impurity layer, we collectively refer to the N-type layer and the impurity layer as the surface impurity distribution layer 3 after chain diffusion; the high temperatur...

Embodiment 3

[0051] The differences between this embodiment and Embodiment 1 and Embodiment 2 are:

[0052] The 1-square resistance of the base silicon wafer after step B is 5 ohm-30 ohm lower than the 1-square resistance of the base silicon wafer after step C.

[0053] The 1-square resistance of the base silicon wafer after step C is in the range of 60ohm-120ohm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com