Method for making groove power semiconductor device

A device manufacturing method, power semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increasing process complexity, device performance degradation, source junction depth, etc., to improve switching characteristics, The effect of improving the breakdown strength and reducing the electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

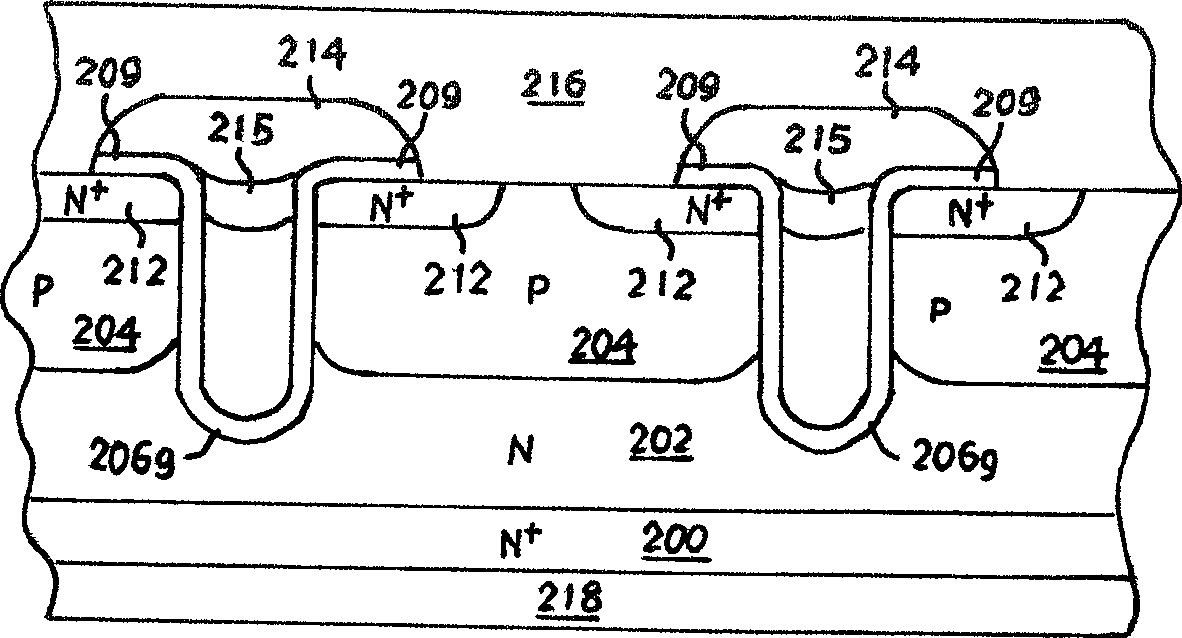

[0053] to combine Figure 2-9 , the specific steps of this embodiment are:

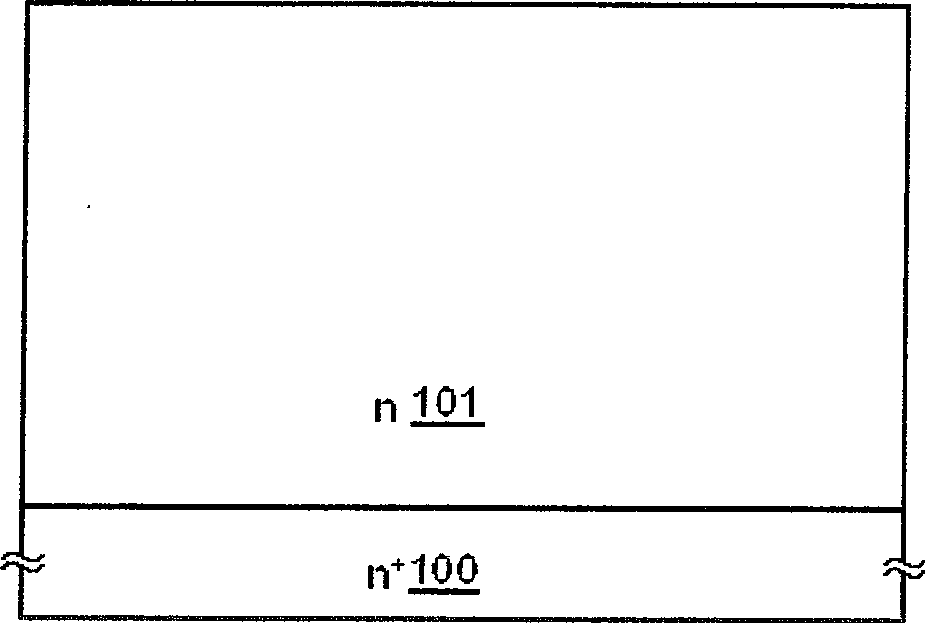

[0054] (1) Base preparation, in n + or p + Epitaxial growth on substrate n - Area;

[0055] (2) Utilize the LPCVD method to grow a thin oxide layer on the semiconductor substrate obtained in step (1), and the film thickness is controlled at 500 angstroms;

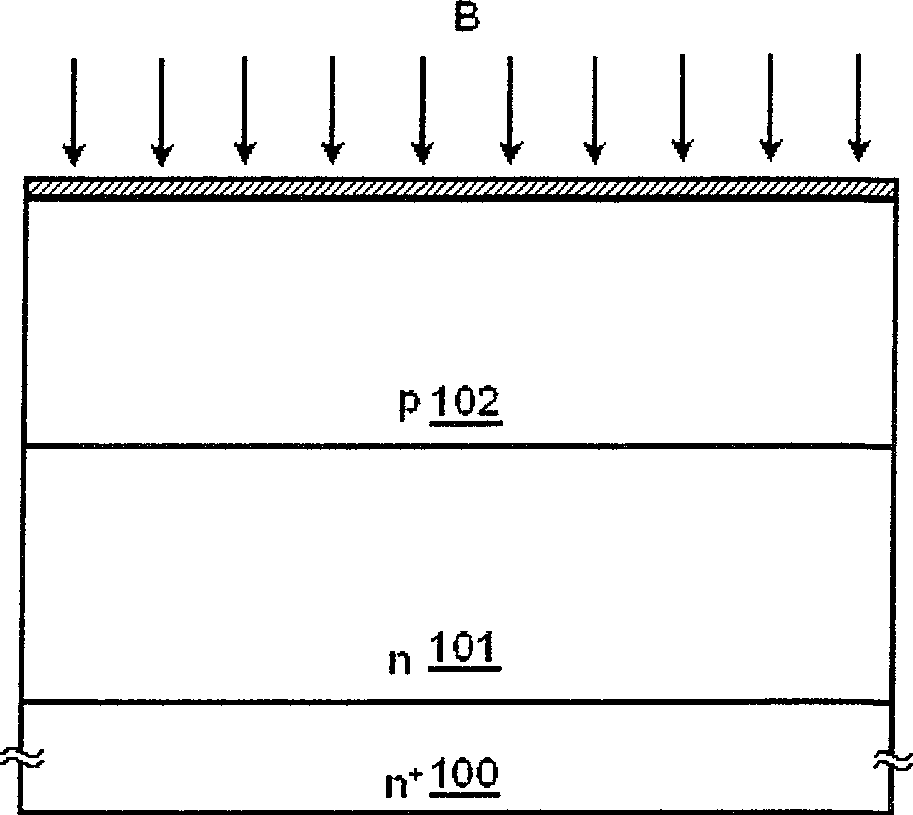

[0056] (3) Perform ion implantation of B impurities on the surface of the semiconductor substrate obtained in step (2), the ion implantation energy is typically 600KeV, and the implantation dose is controlled at 10 14 cm -2 ;

[0057] (4) utilize LPCVD method to grow Si at the semiconductor substrate surface of step (3) gained 3 N 4 , the thickness is controlled at 800 Angstroms;

[0058] (5) Spin-coat photosensitive adhesive on the surface of the semiconductor substrate obtained in step (4), obtain a groove etching window through a photolithography process, and form a groove structure by combining dry etching and wet etching;

[0059] (6...

Embodiment 2

[0073] to combine Figure 10 , an epitaxial layer 302 is grown on an n+ substrate 301 with a resistivity of 0.003Ω·cm, and the thickness of the epitaxial layer depends on the requirements of the device for withstand voltage and on-resistance. On the surface of the epitaxial layer 302, the thickness is sequentially grown by LPCVD to SiO 2 layer 303 and a thickness of Si 3 N 4 Layer 304. Form the etching window of the trench gate through the photolithography process, adopt anisotropic etching such as RIE to form the trench 305, and supplemented by wet etching (in this embodiment, dilute HNO 3 , HF and H 2 O mixture). The LPCVD growth thickness on the inner surface of the substrate groove is SiO 2 The sacrificial layer 306 is grown under the implantation energy of 100KeV, with 5*10 11 cm -2 The dose of B is injected into B, and the n-region 307 is formed by diffusion at a high temperature of 1100° C. for 100 minutes.

[0074] to combine Figure 11 , after removing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com