Patents

Literature

68 results about "Post oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

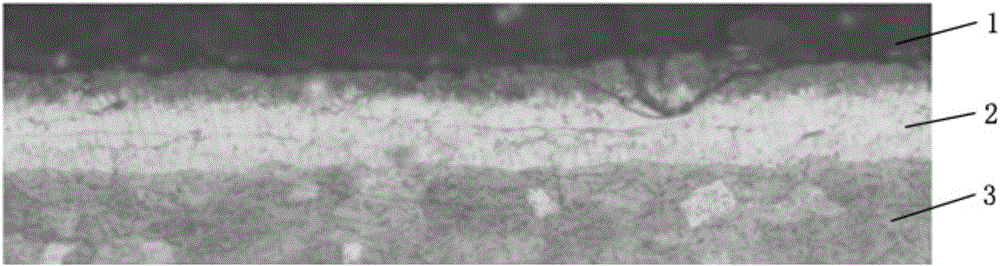

Plasma post oxidation was performed on the nitrocarburized samples with various oxygen / hydrogen ratio at constant temperature of 500°C for 1 hour. The very thin magnetite (Fe3O4) layer 1-2 μm in thickness on top of the compound layer was obtained by plasma post oxidation.

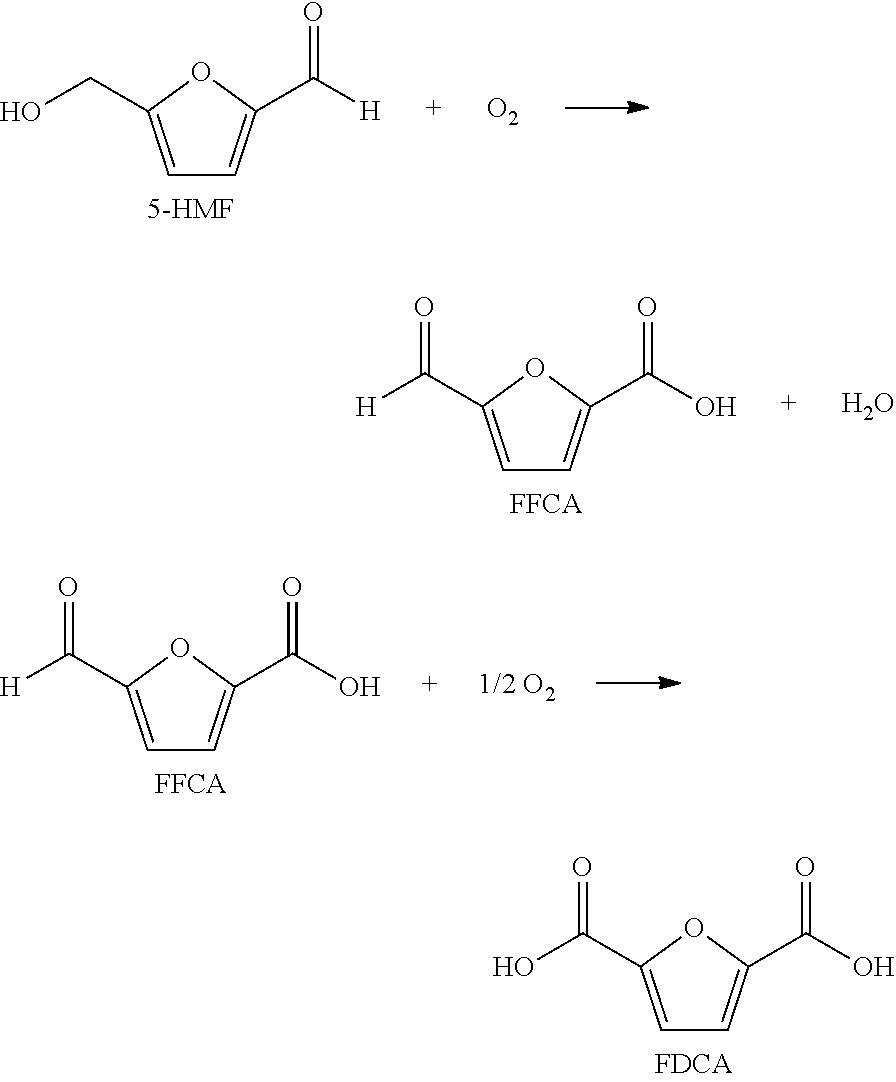

Oxidative purification method for producing purified dry furan-2,5-dicarboxylic acid

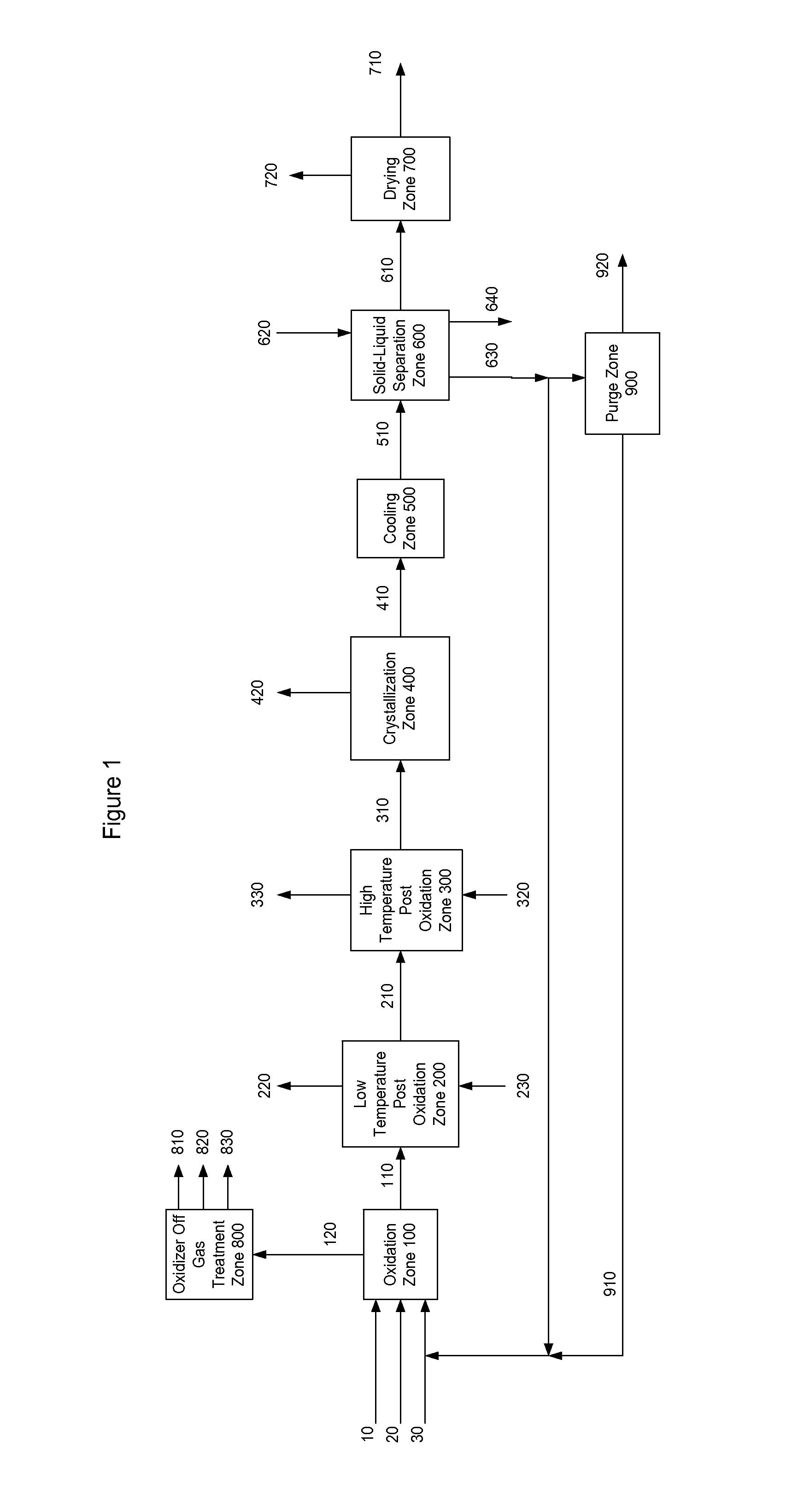

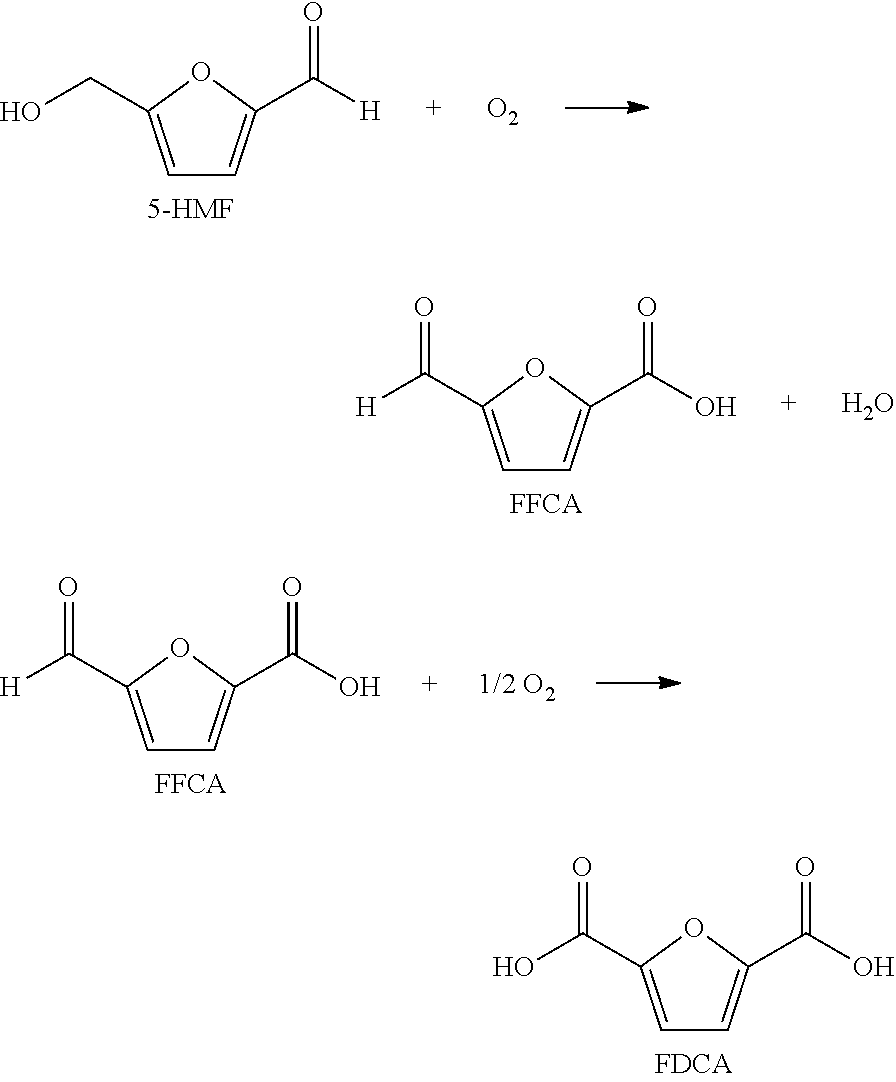

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing a feed stream comprising at least one oxidizable compound to generate a crude carboxylic acid slurry comprising FDCA, removing impurities from a crude carboxylic acid slurry via oxidative purification in a low temperature post-oxidation zone to form a low impurity slurry stream. The low impurity slurry stream is further treated in a high temperature post oxidation zone to produce a secondary oxidation slurry stream which is routed to a crystallization zone to from a crystallized slurry stream.

Owner:EASTMAN CHEM CO

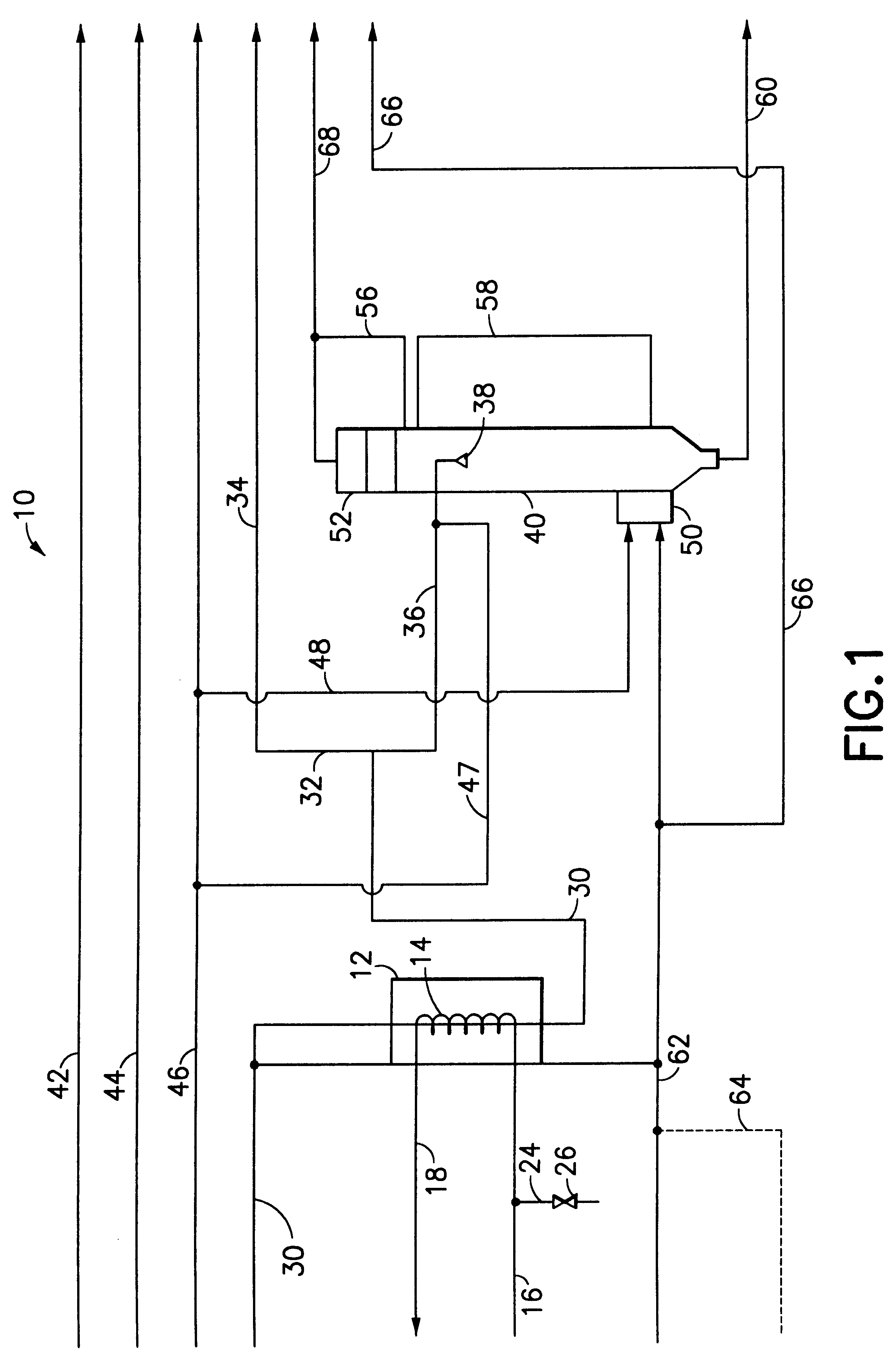

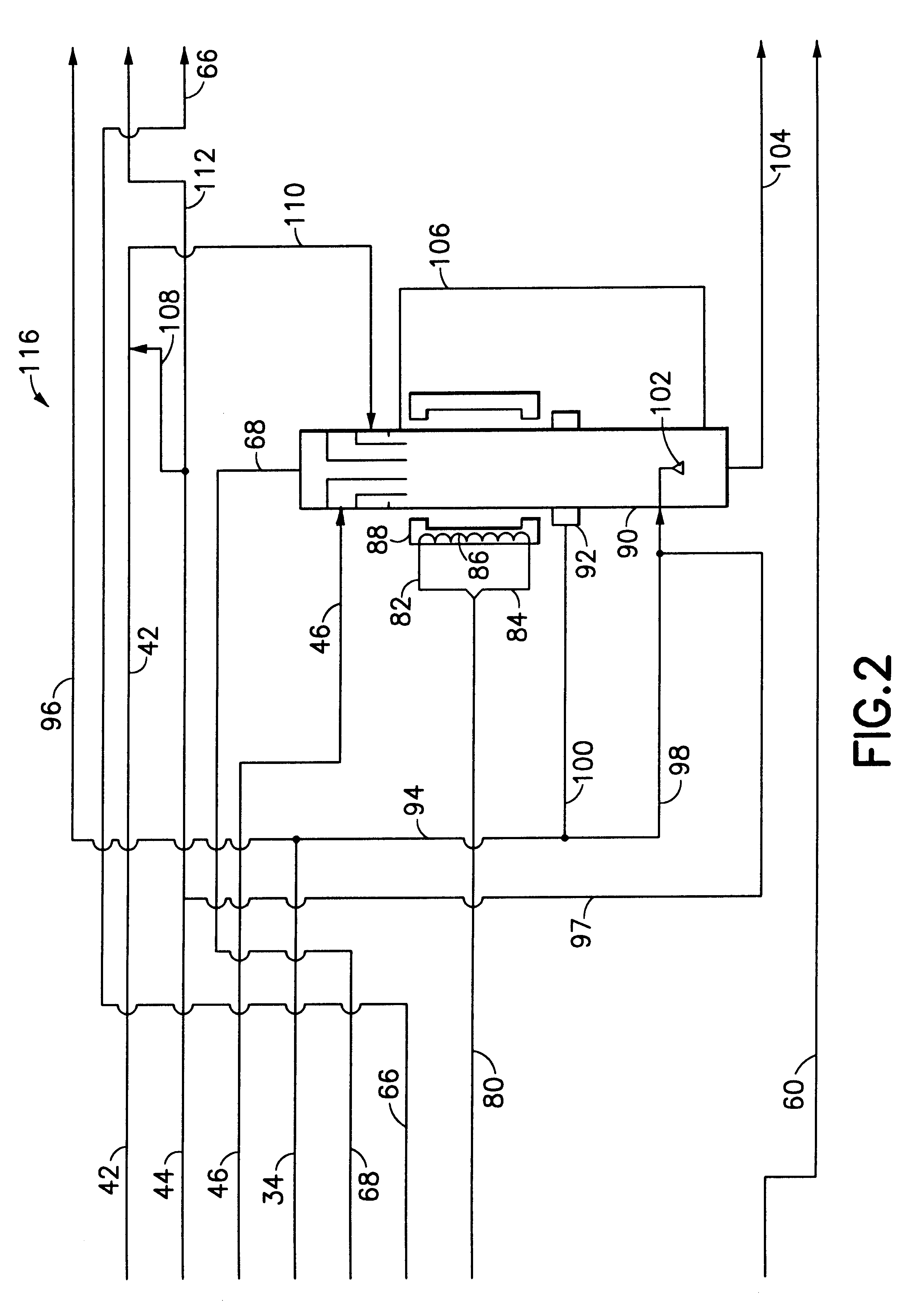

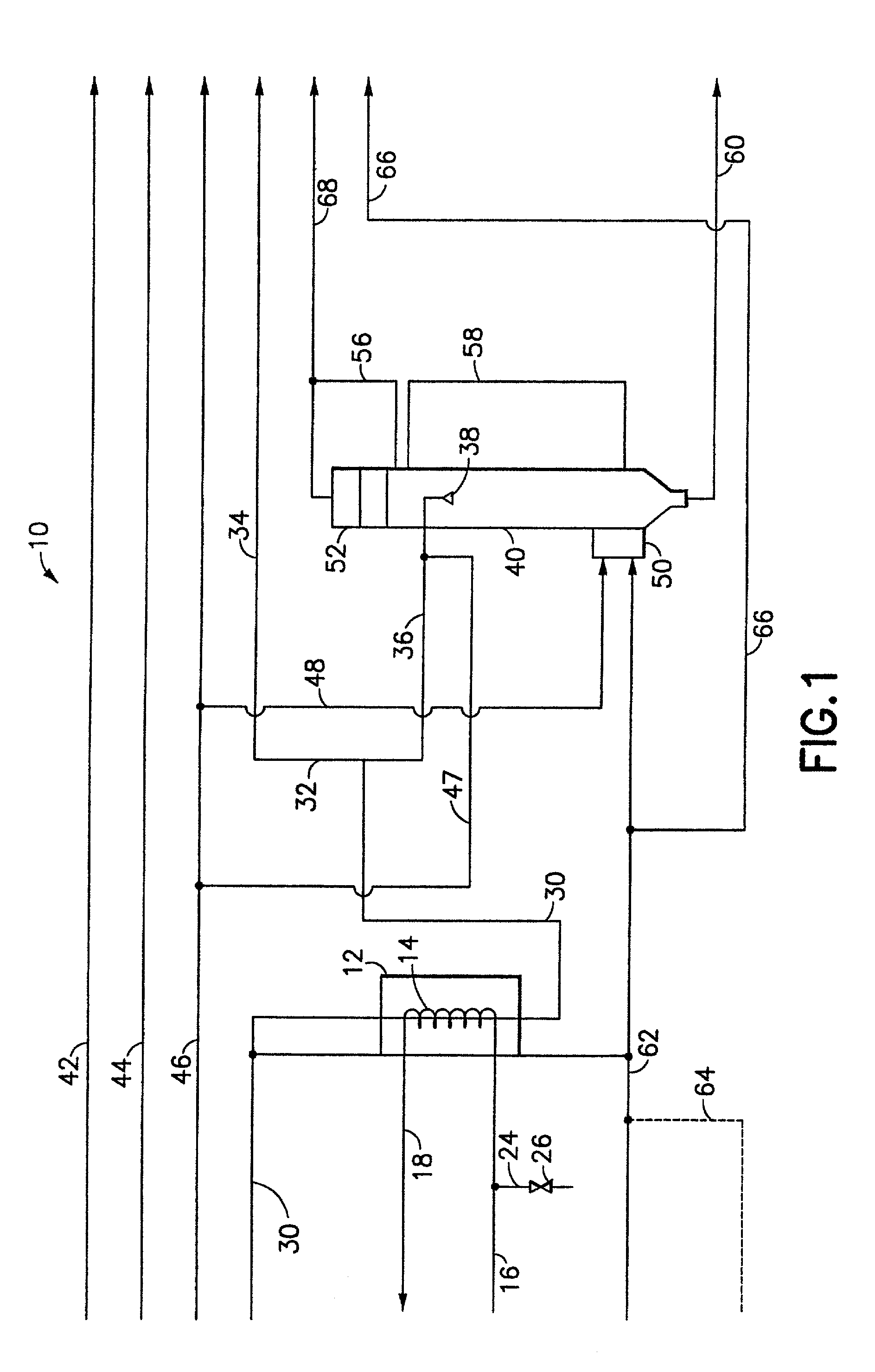

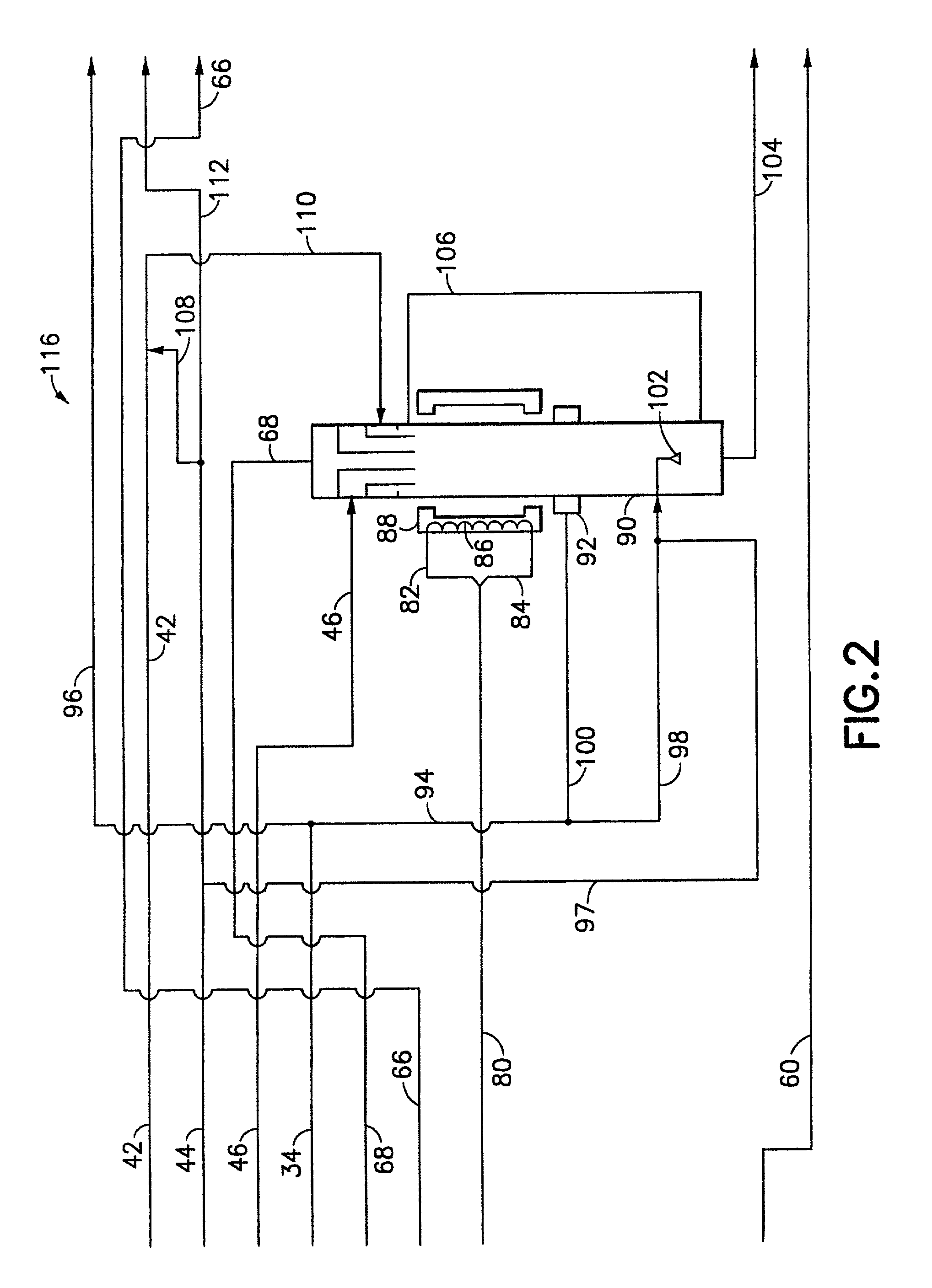

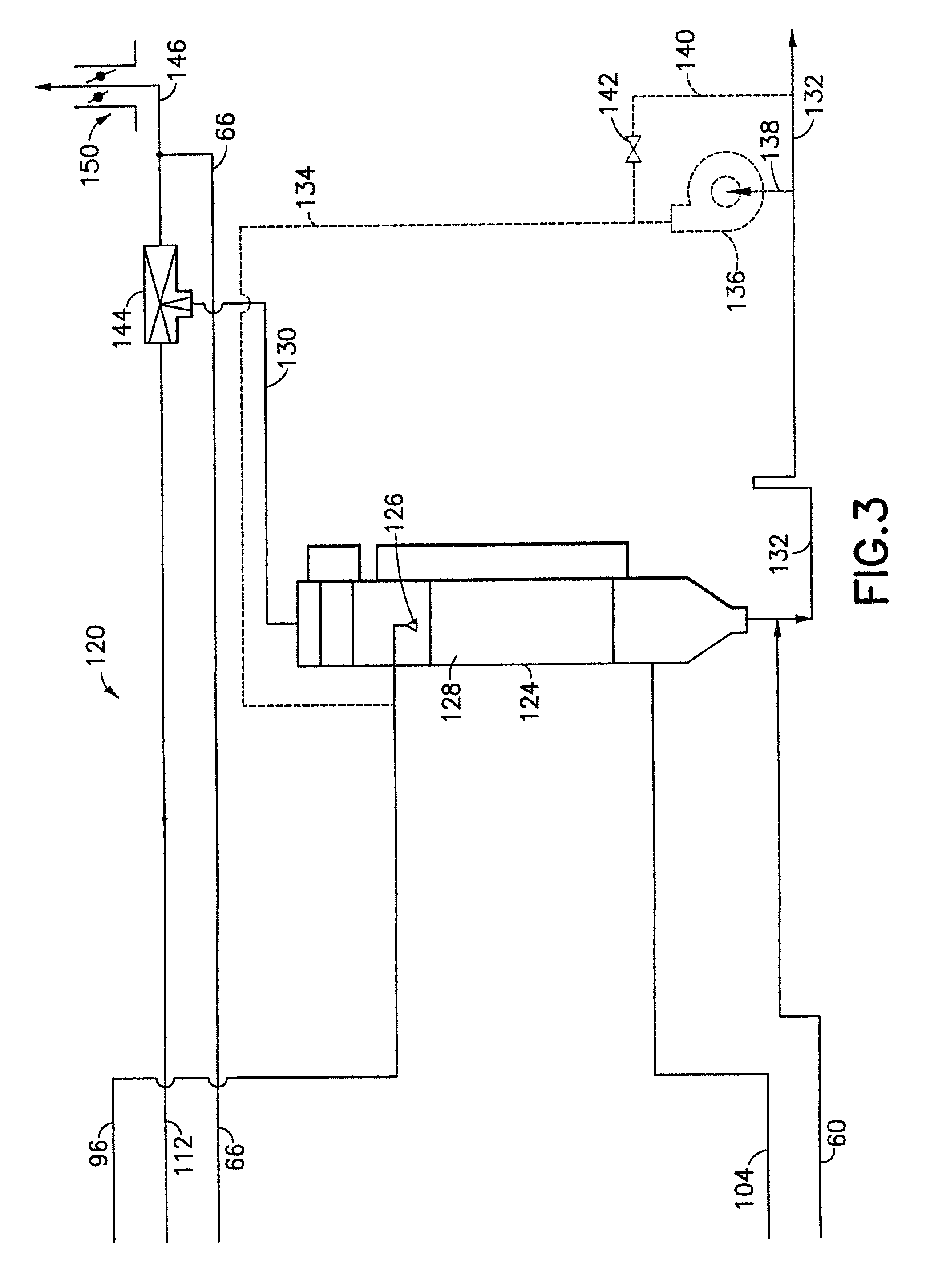

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6333010B1Reduce sensitivityReduced water requirementsCombination devicesGas treatmentEnvironmental engineeringProduct gas

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:BHT SERVICES PTE LTD

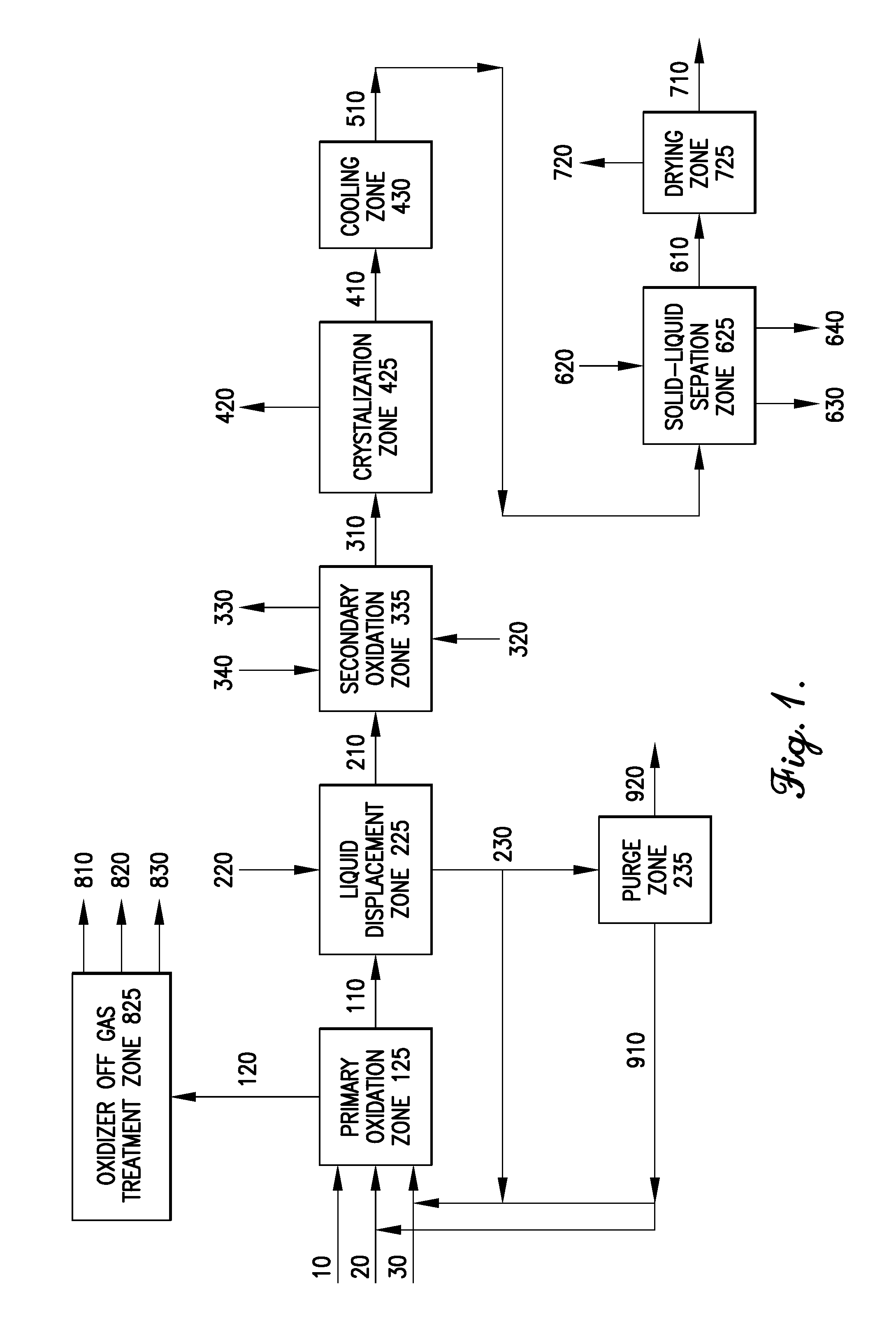

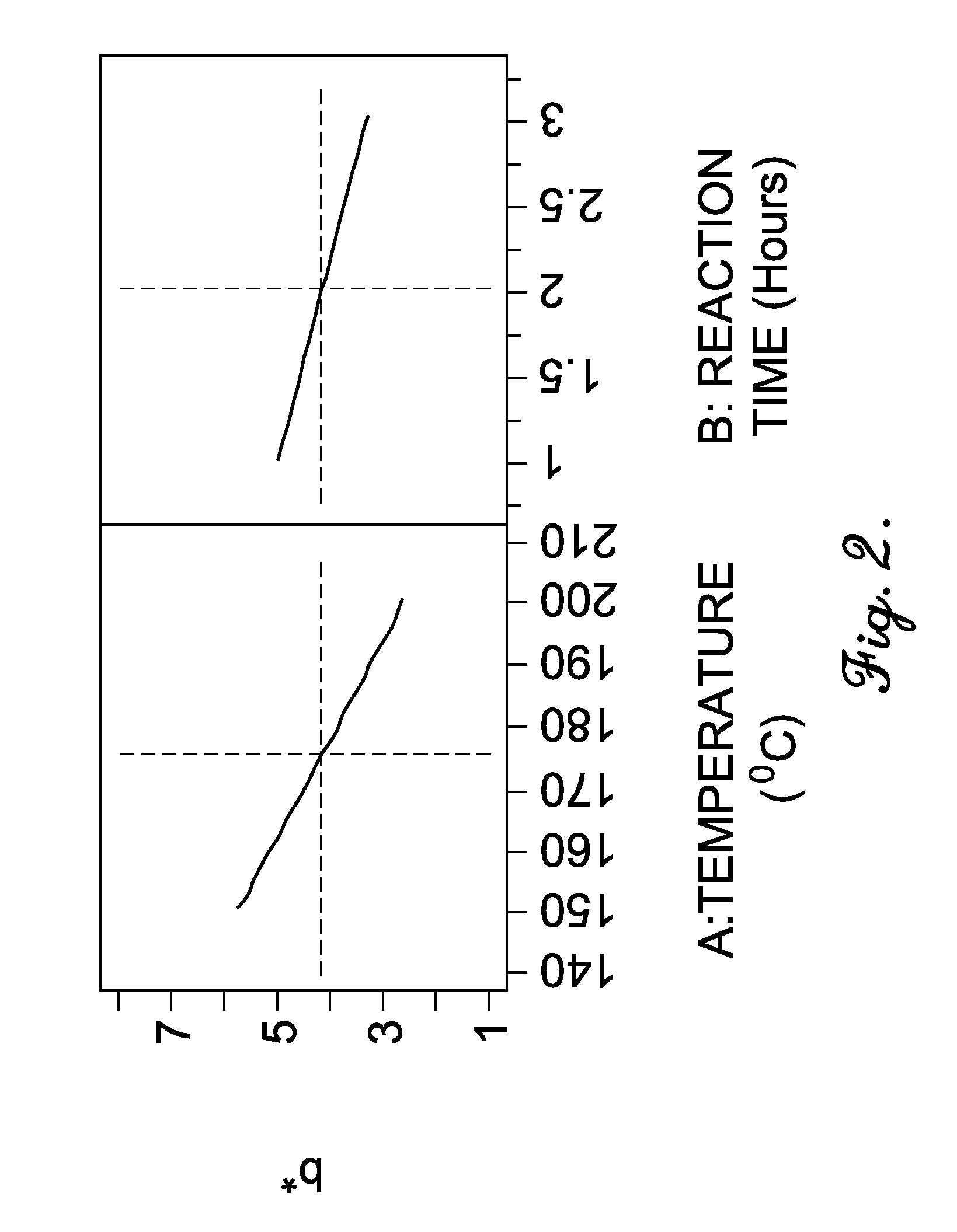

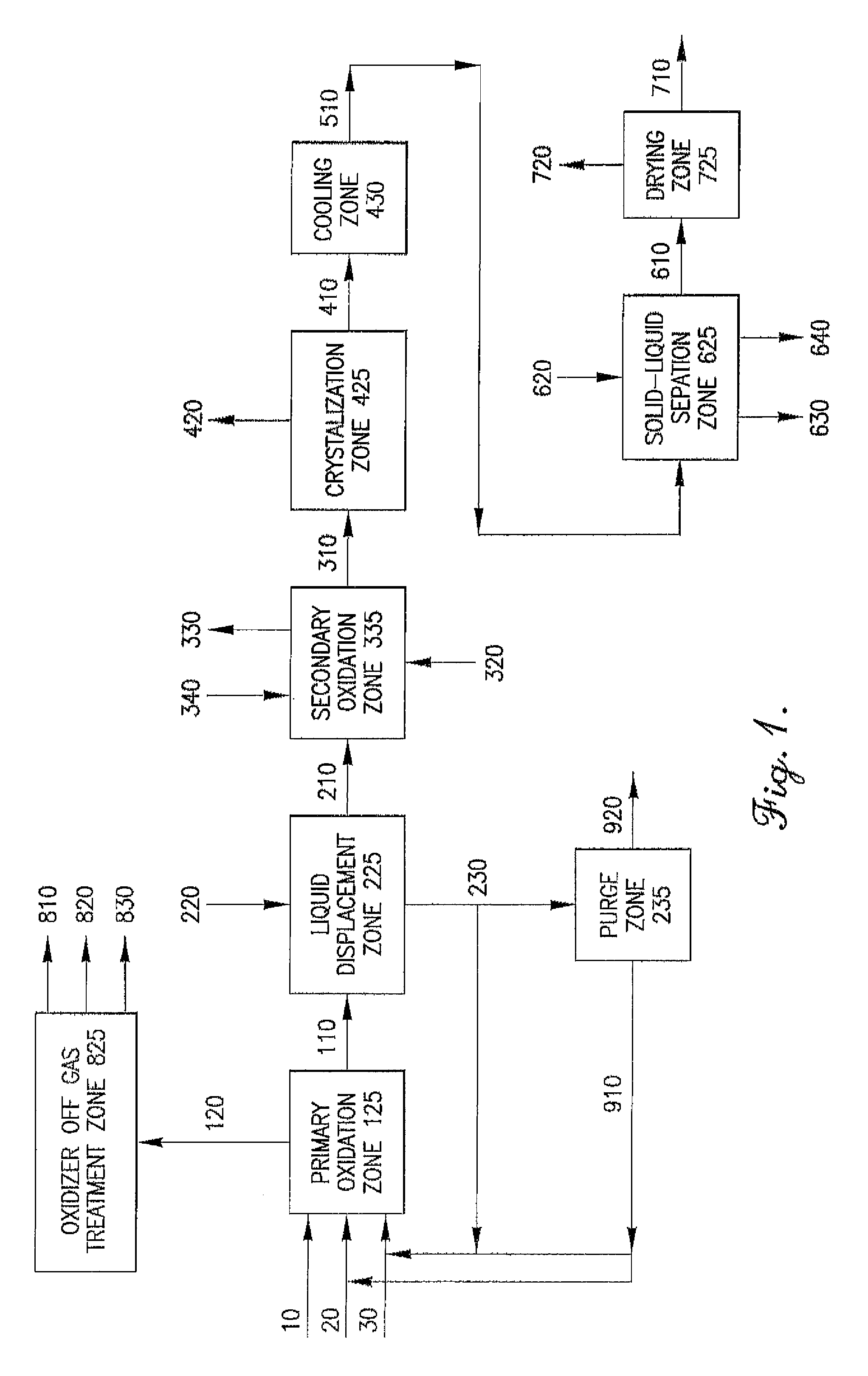

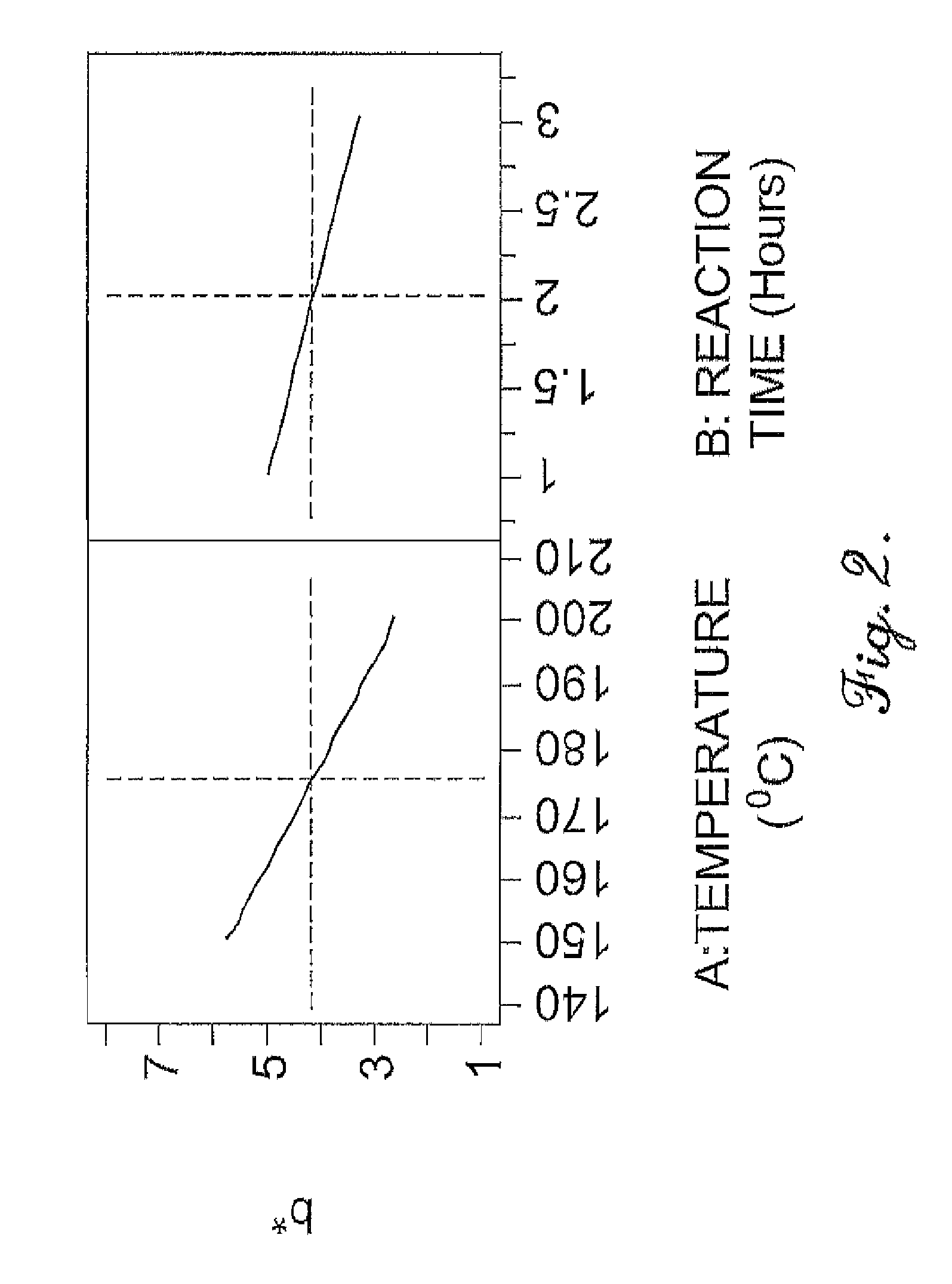

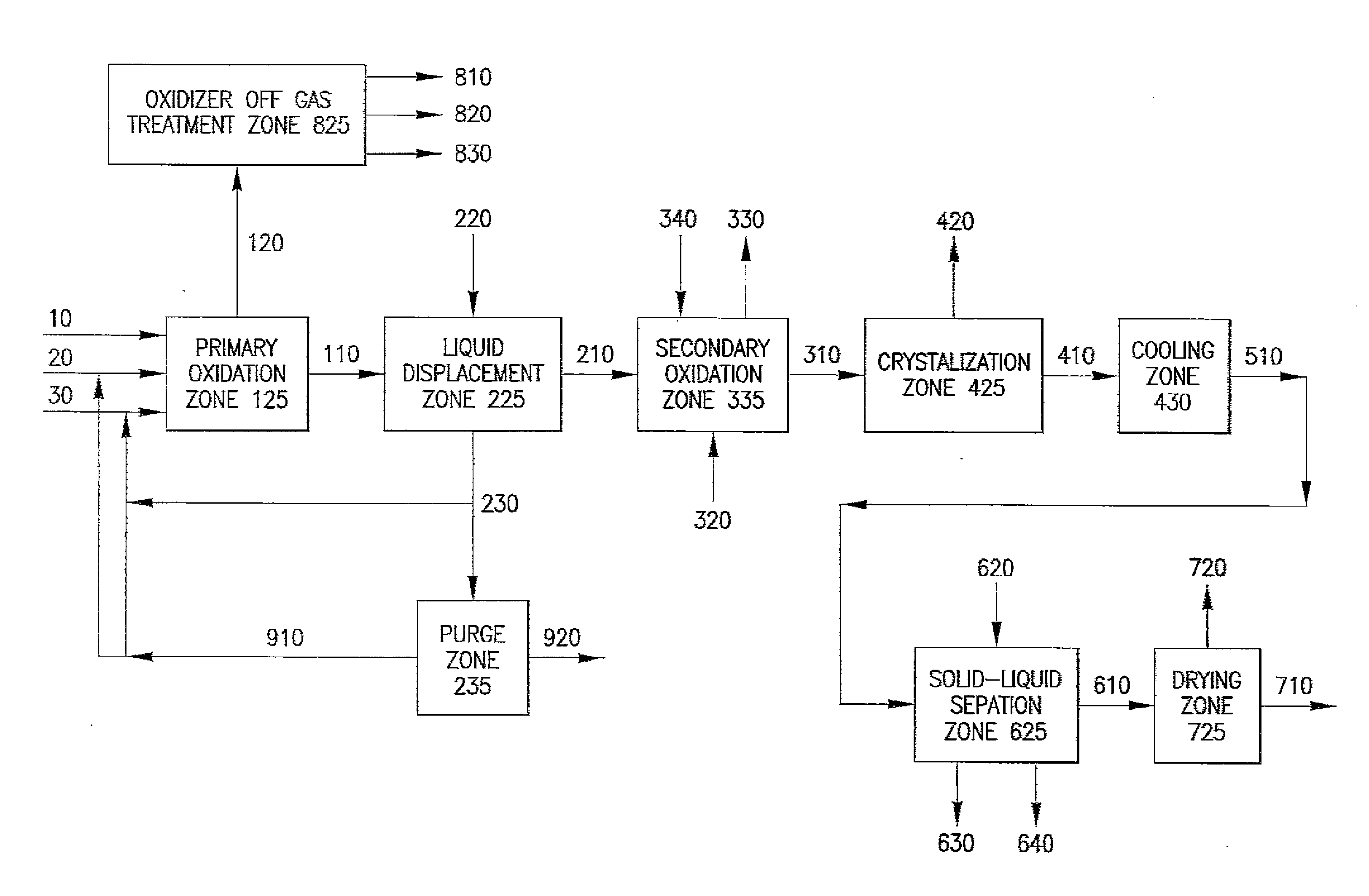

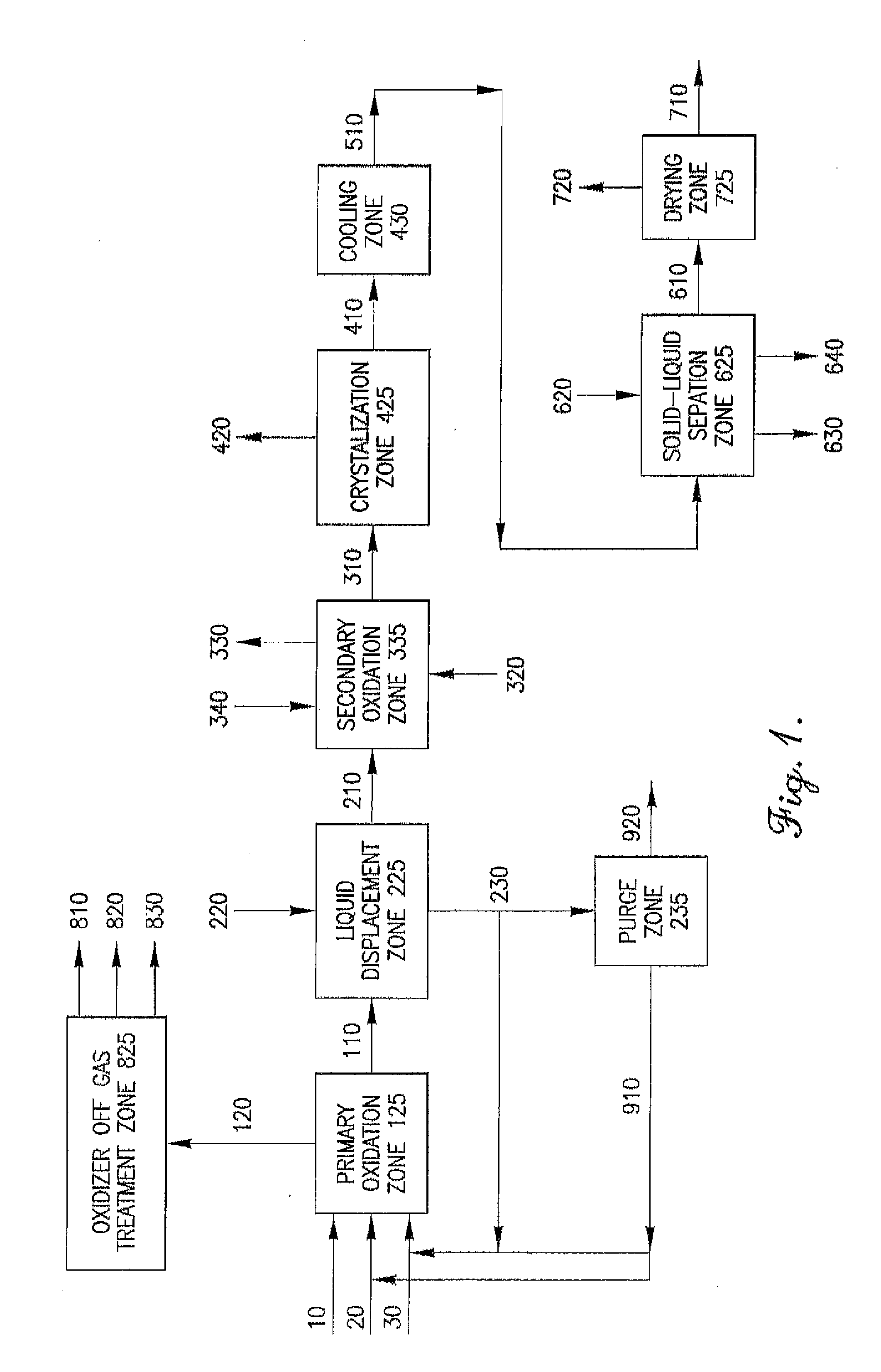

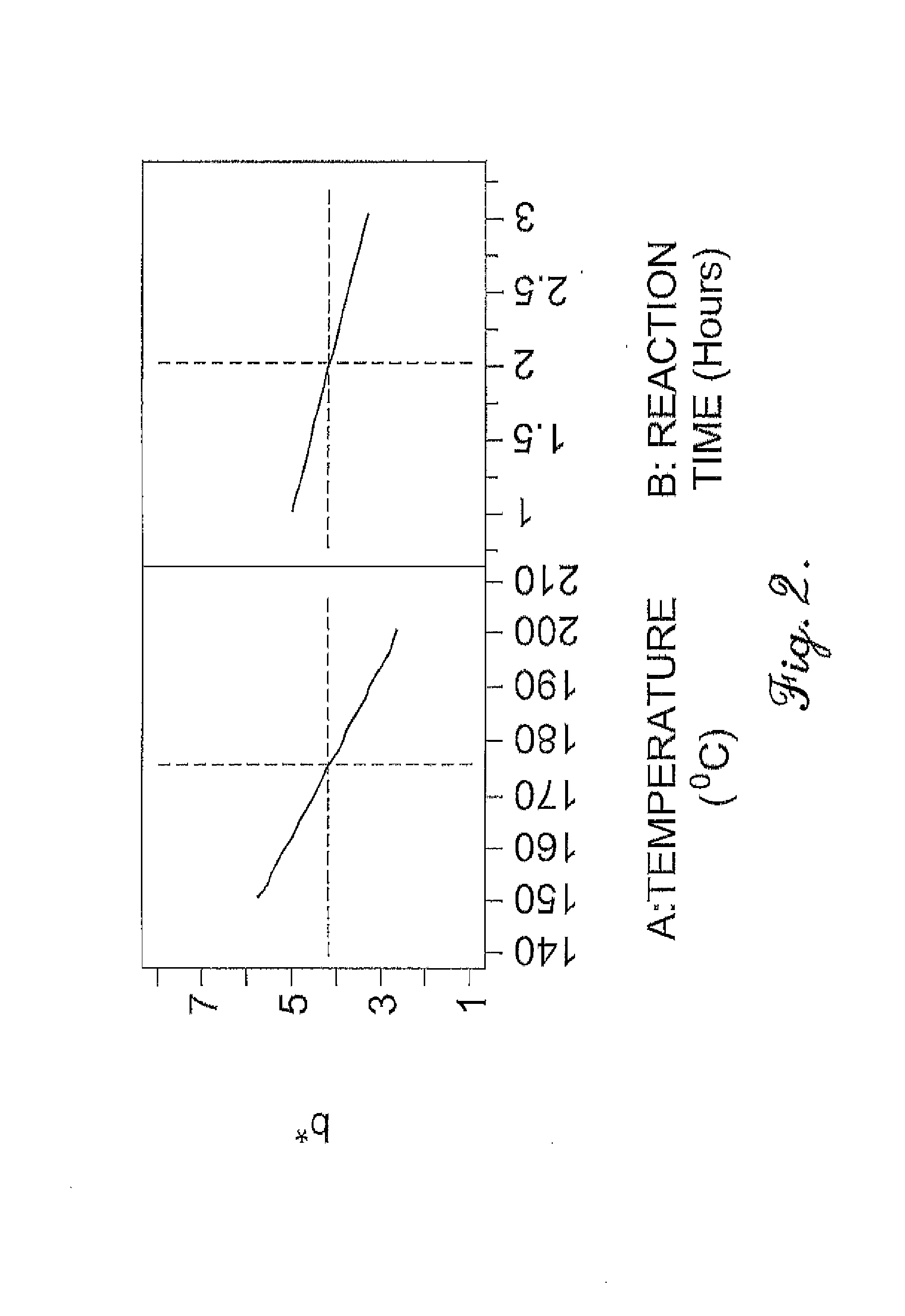

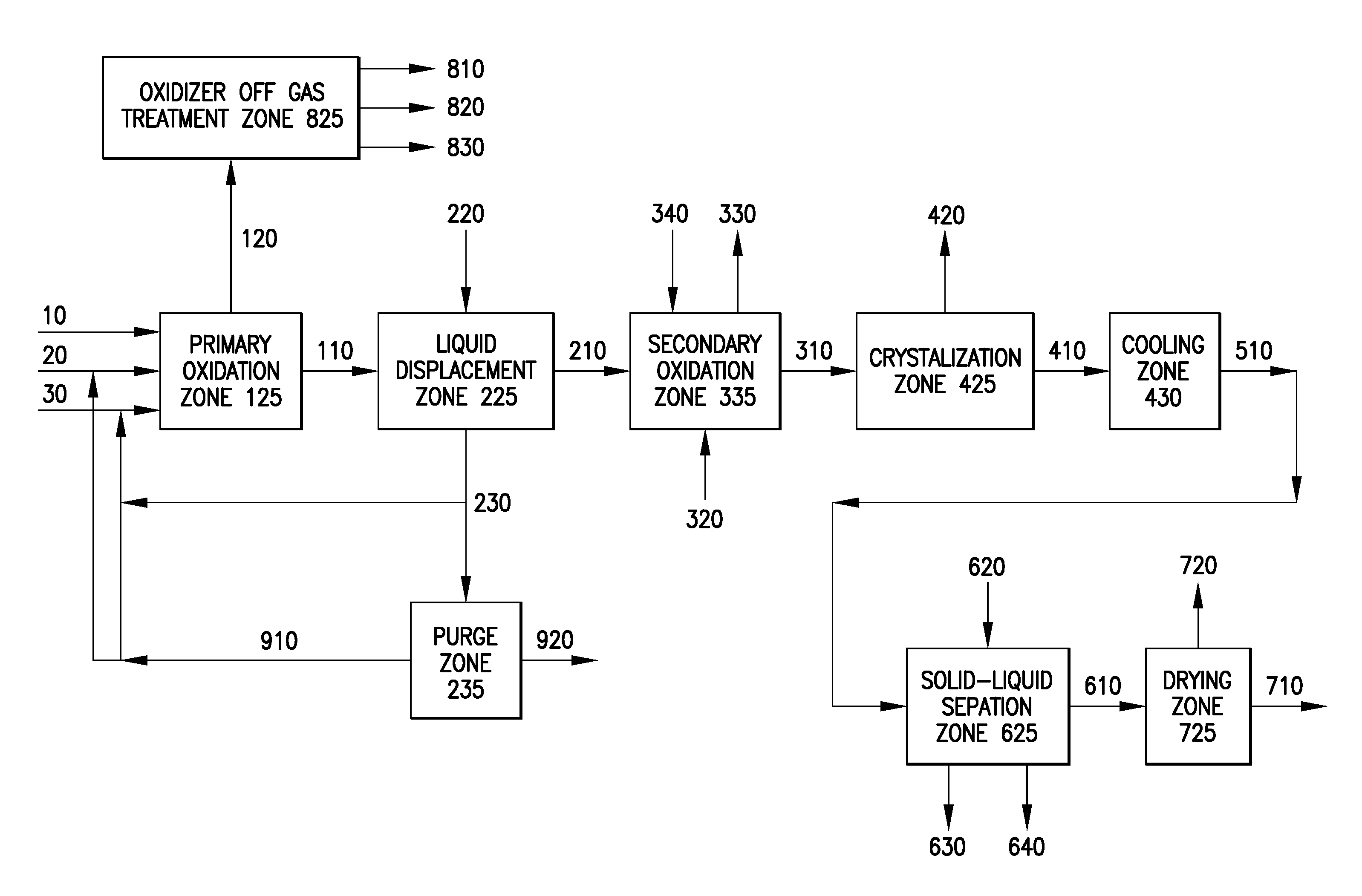

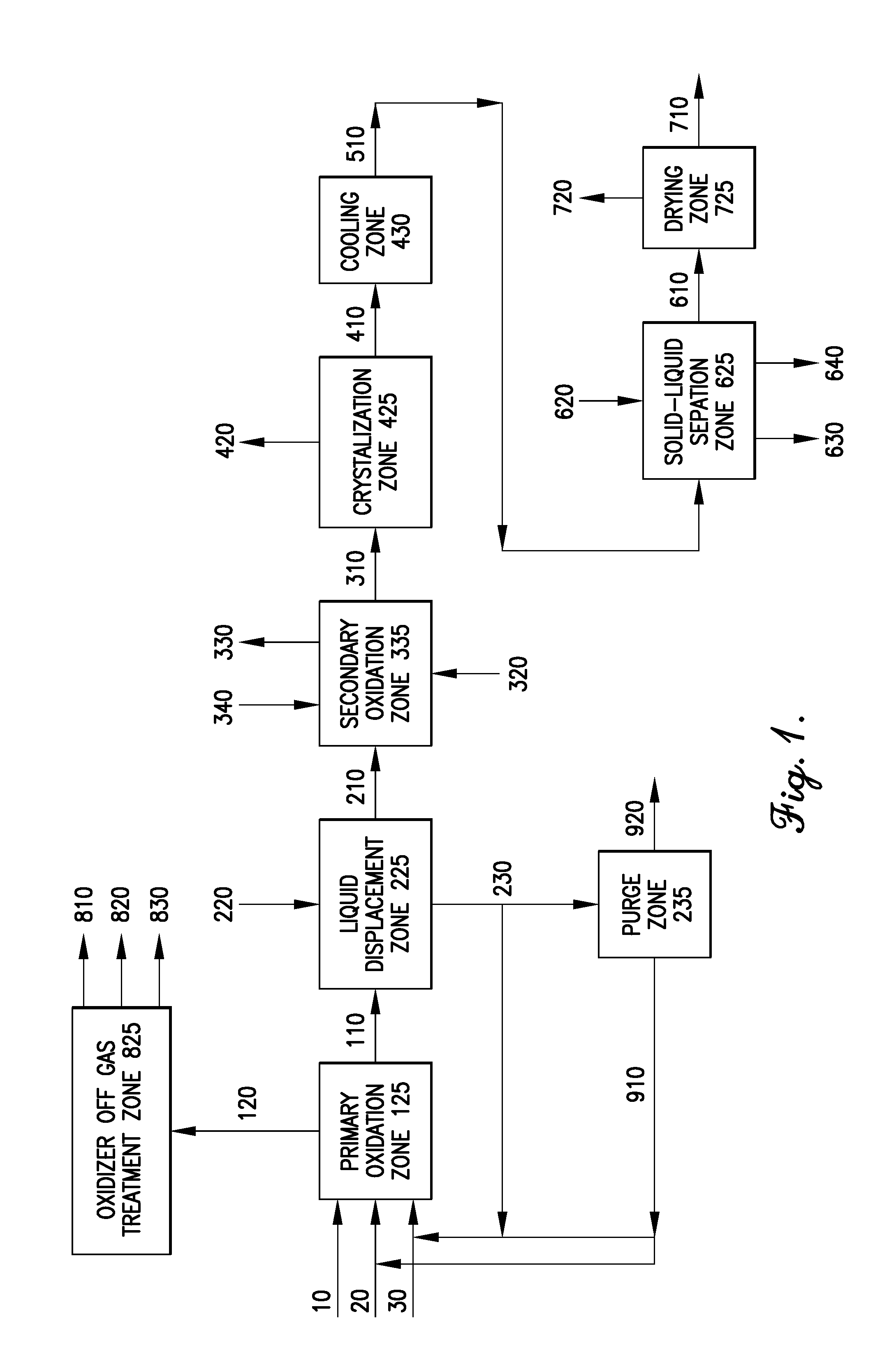

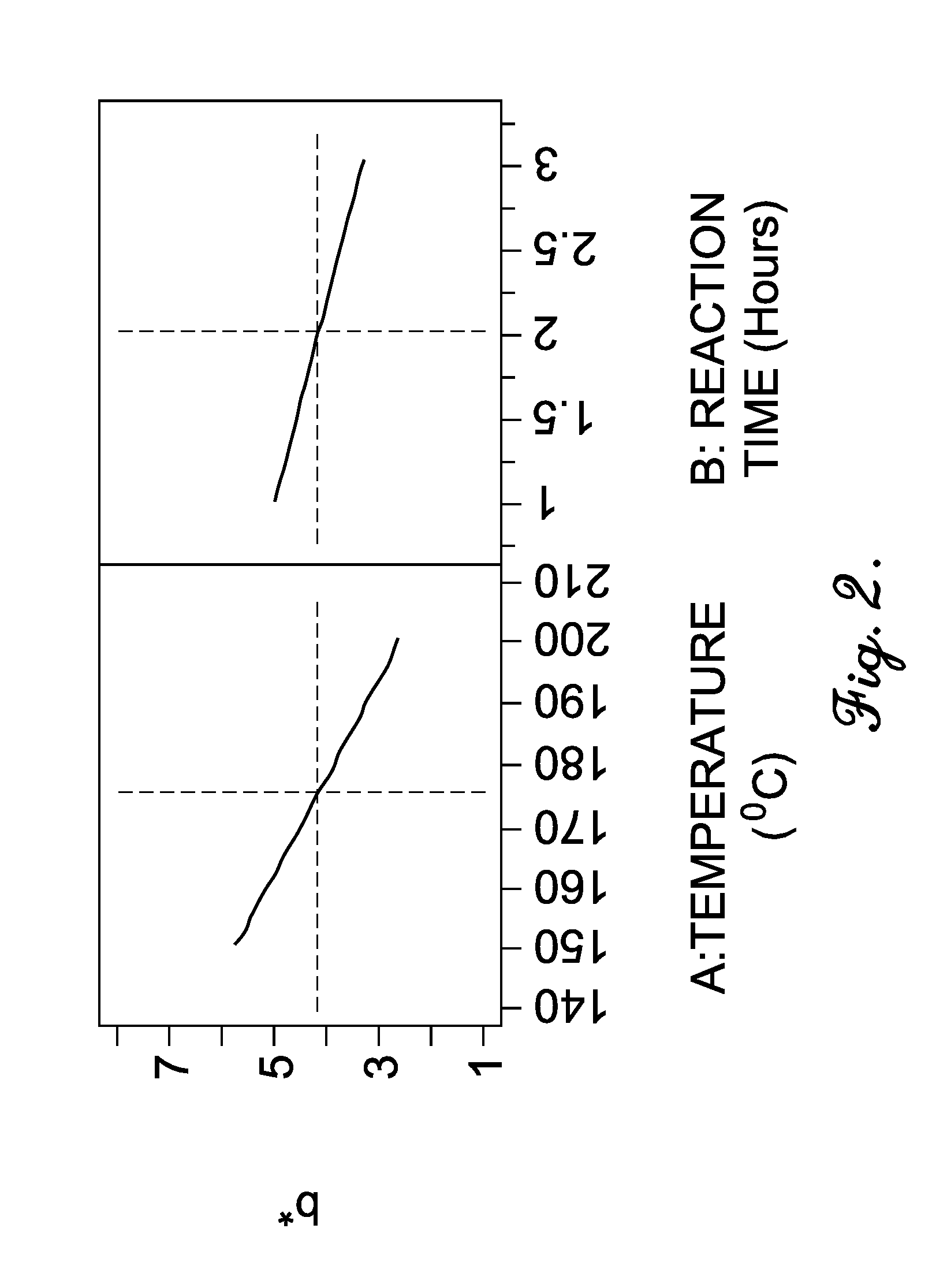

Oxidation process to produce a purified carboxylic acid product via solvent displacement and post oxidation

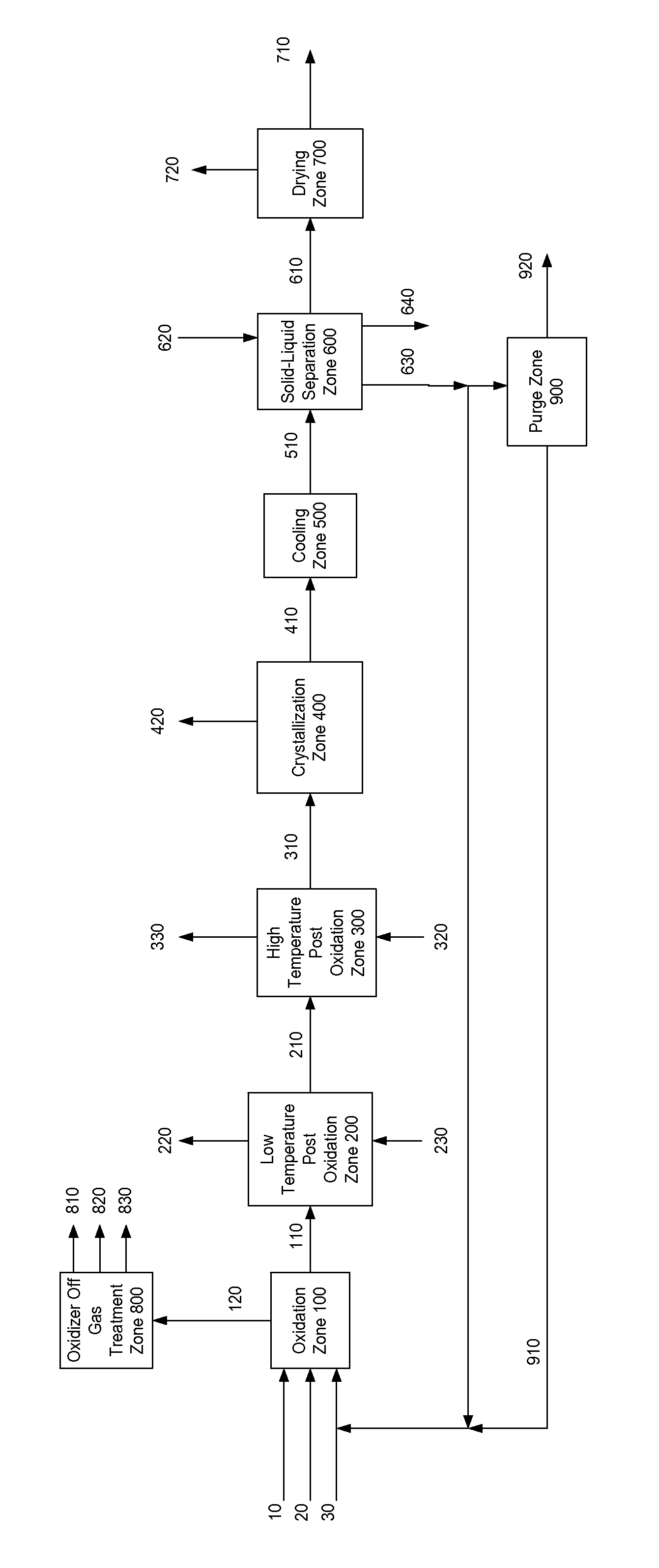

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing at least one oxidizable compound to generate a crude carboxylic acid slurry comprising FDCA, removing impurities from a crude carboxylic acid slurry in a liquid displacement zone to form a low impurity slurry stream. The low impurity slurry stream is further treated in a secondary oxidation zone to produce a secondary oxidation slurry stream which is routed to a crystallization zone to form a crystallized slurry stream. The crystallized slurry stream is cooled in a cooling zone and the resulting cooled crystallized slurry stream is routed to a solid-liquid separation zone to generate a purified wet cake stream comprising FDCA that is dried in a drying zone to generate a dry carboxylic acid product stream comprising purified FDCA (pFDCA).

Owner:EASTMAN CHEM CO

Oxidative purification method for producing purified dry furan-2,5-dicarboxylic acid

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing a feed stream comprising at least one oxidizable compound to generate a crude carboxylic acid slurry comprising FDCA, removing impurities from a crude carboxylic acid slurry via oxidative purification in a low temperature post-oxidation zone to form a low impurity slurry stream. The low impurity slurry stream is further treated in a high temperature post oxidation zone to produce a secondary oxidation slurry stream which is routed to a crystallization zone to from a crystallized slurry stream.

Owner:EASTMAN CHEM CO

Technique method of treatment for modifying surface of ferrous material

This invention relates to a method for surface modification of steel material or steel component by combined treatment of gaseous nitrocarburization and post oxidation. The method comprises: (1) performing vacuum washing of the steel material, and pre-oxidizing at 400 deg.C; (2) placing the steel material in a box-type nitrocarburization heat treatment furnace, introducing mixed gases of NH3, N2 and CO2, reacting at 550-570 deg.C, and cooling with oil; (3) polishing, placing in an oxidation furnace, performing post oxidation with high-temperature steam for 1 h, and polishing to obtain steel material with high wear resistance and high corrosion resistance.

Owner:上海上大热处理有限公司

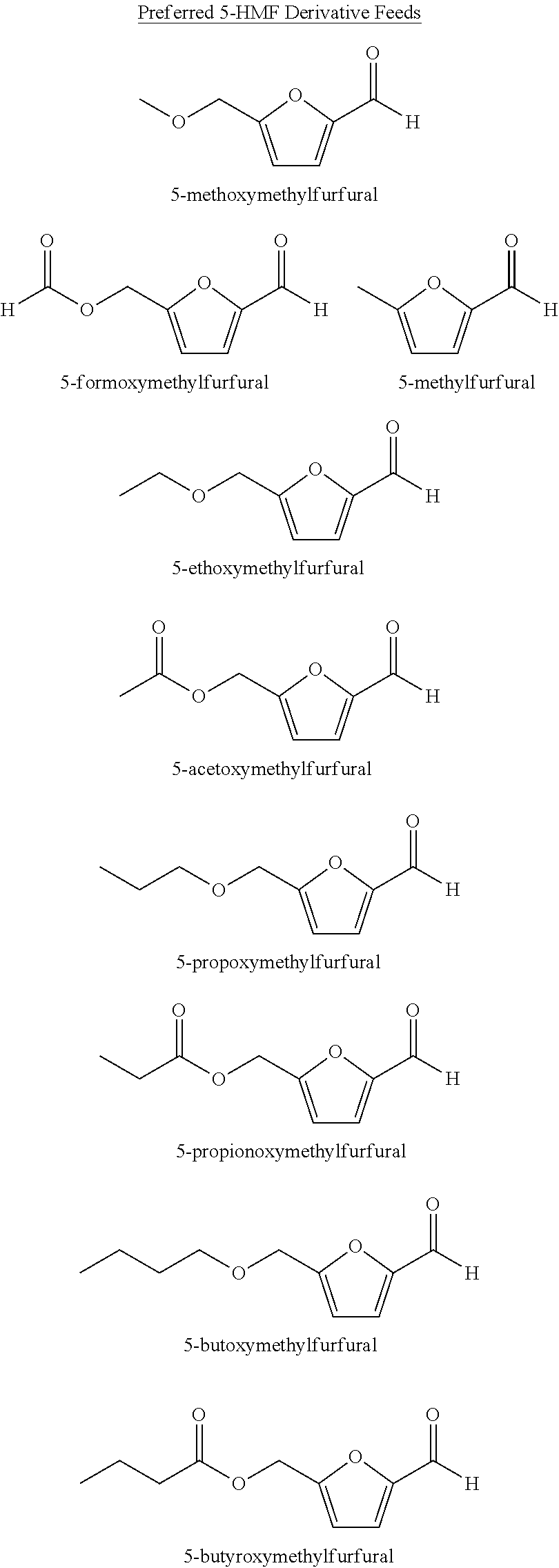

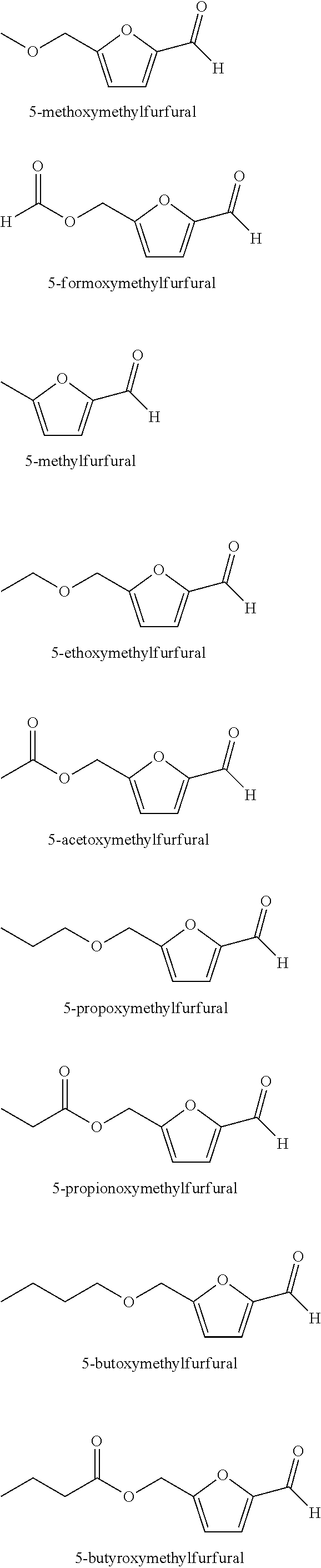

Oxidation process to produce a purified carboxylic acid product via solvent displacement and post oxidation

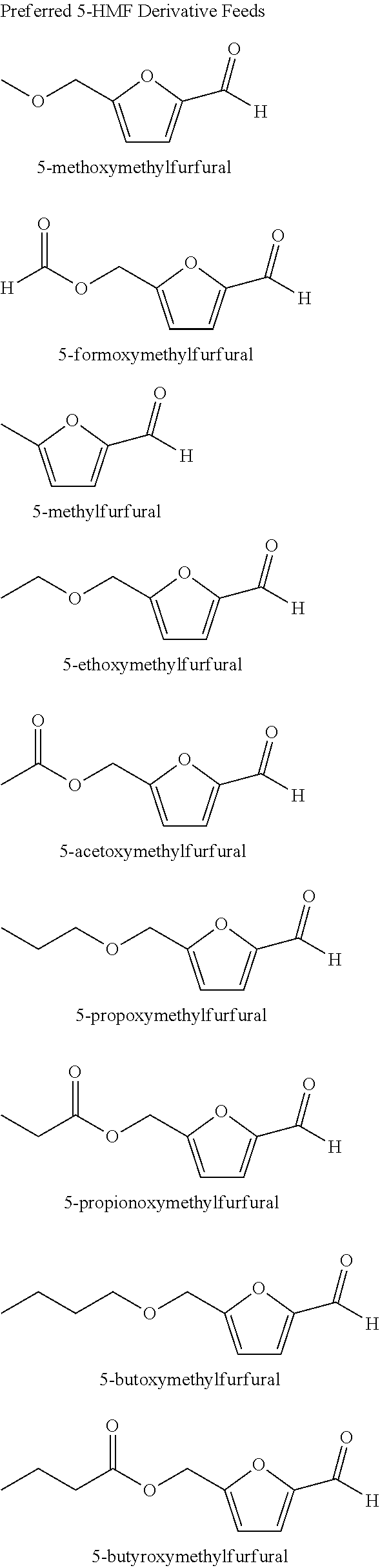

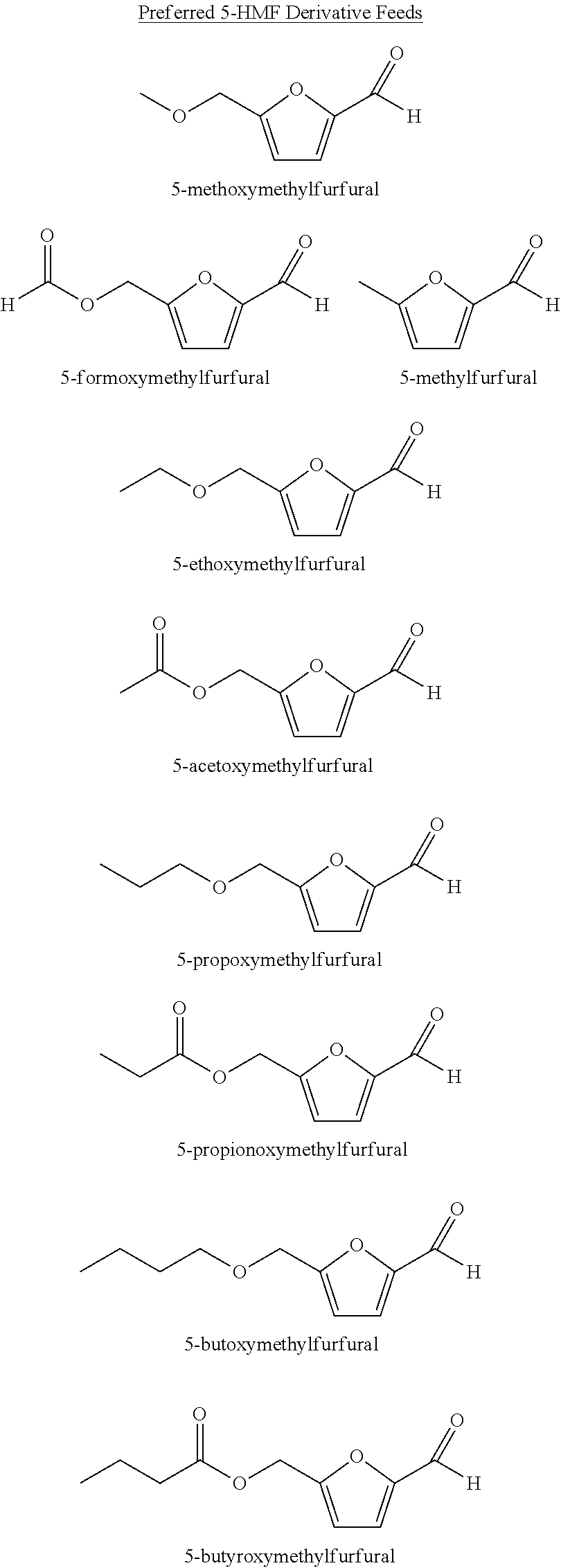

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing at least one oxidizable compound selected from the following group: 5-(hydroxymethyl)furfural (5-HMF), 5-HMF esters (5-R(CO)OCH2-furfural were R alkyl, cycloalkyl and aryl), 5-HMF ethers (5-R′OCH2-furfural, where R′=alkyl, cycloalkyl and aryl), 5-alkyl furfurals (5-R″-furfural, where R″=alkyl, cycloalkyl and aryl), mixed feed-stocks of 5-HMF and 5-HMF esters and mixed feed-stocks of 5-HMF and 5-HMF ethers and mixed feed-stocks of 5-HMF and 5-alkyl furfurals to generate a crude carboxylic acid slurry comprising FDCA.

Owner:EASTMAN CHEM CO

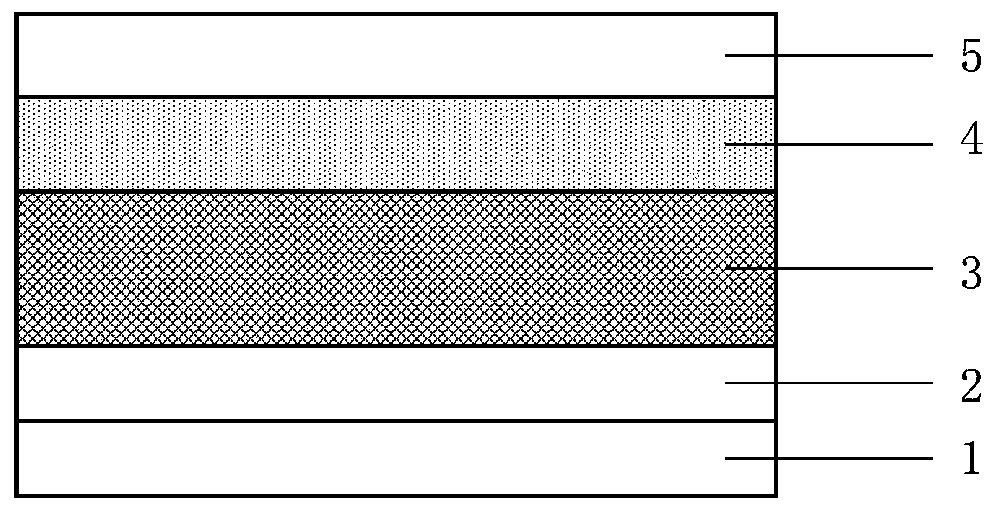

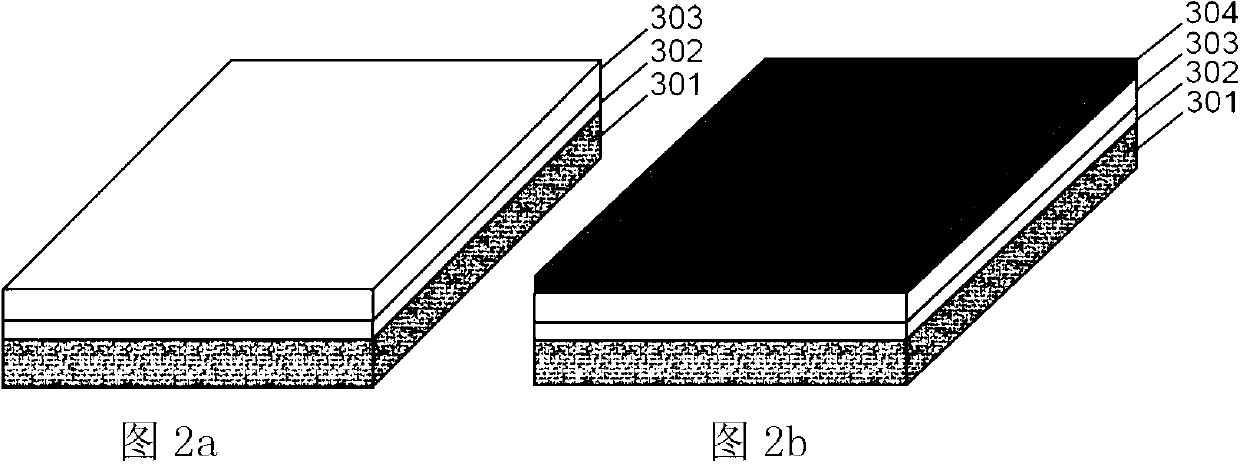

Transparent laminated film and method for producing the same

InactiveUS20110262742A1Prevent peelingReduce internal stressLamination ancillary operationsMagnetic/electric field screeningLight energyUltraviolet

A transparent laminated film is provided with which it is possible to inhibit peeling of thin film layers, even with long-term exposure to sunlight during use and exposure to UV rays during quality evaluation. The film has a thin film layer obtained by lamination of multiple thin films on at least one side of a transparent polymer film. This thin film layer has metal oxide thin films formed by a sol-gel process using light energy during sol-gel hardening and post-oxidation thin films formed by post-oxidation of at least one thin film selected from metal thin film, alloy thin film, and partially oxidized metal oxide thin film.

Owner:SUMITOMO RIKO CO LTD

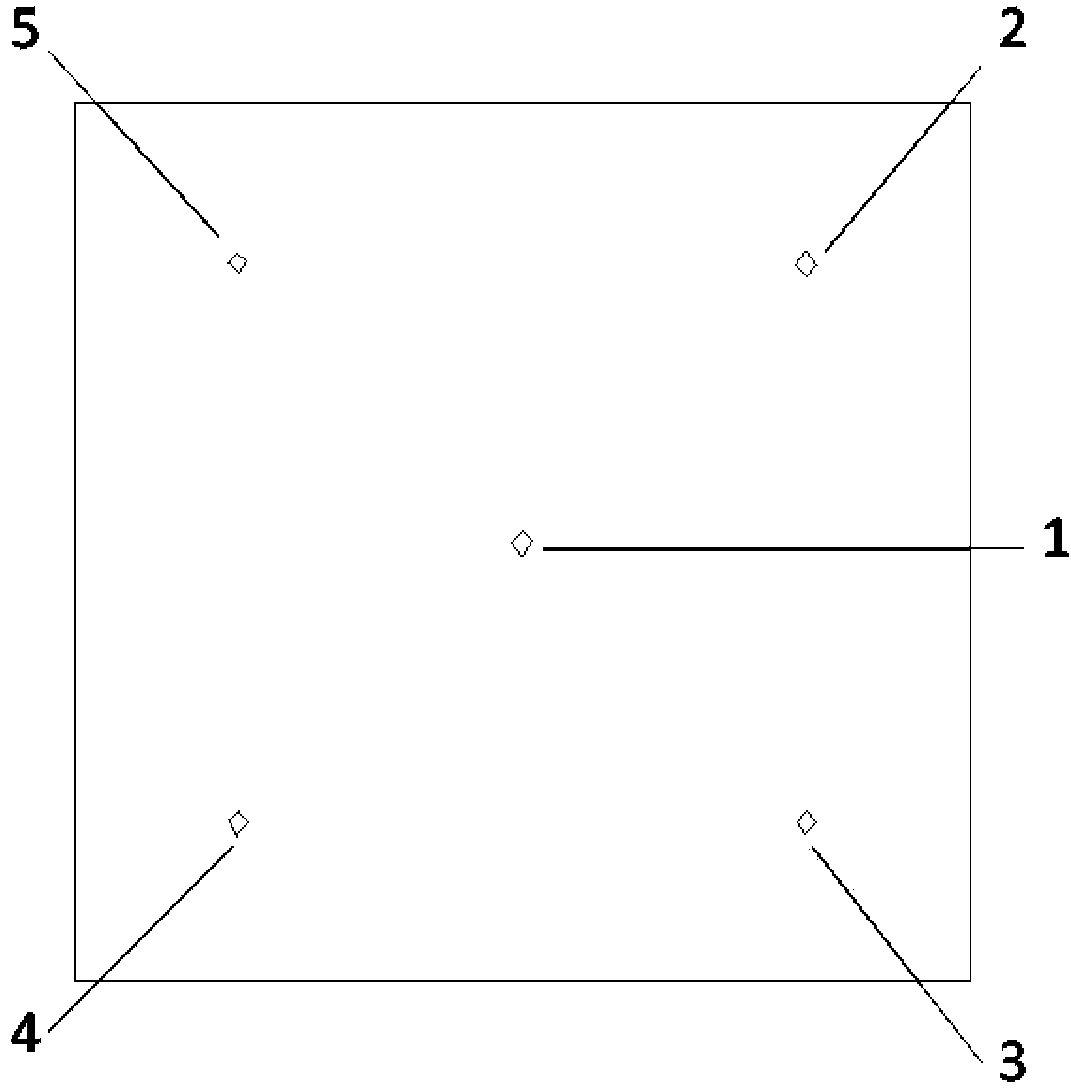

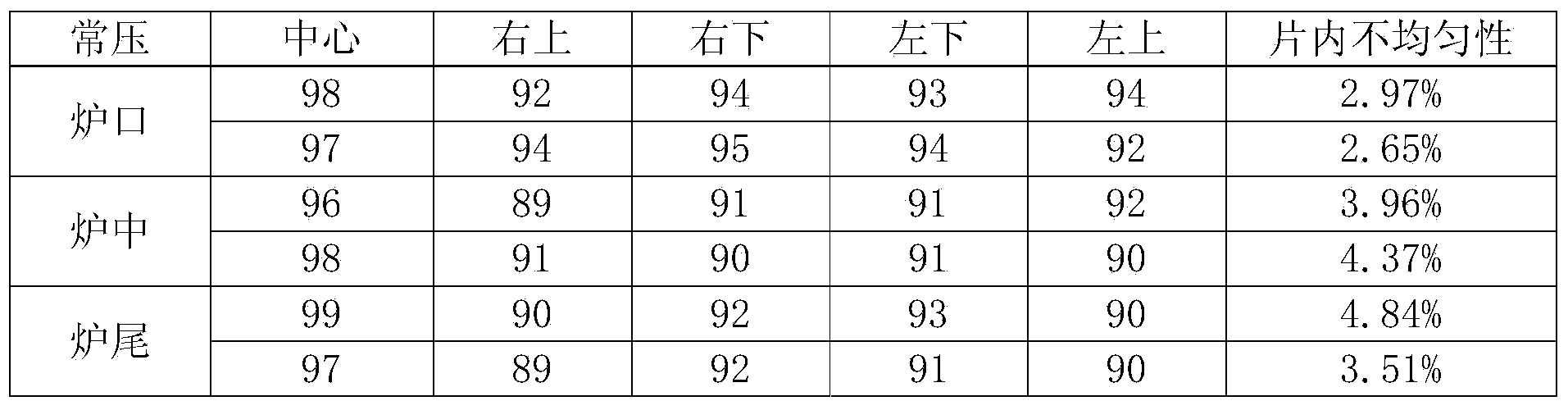

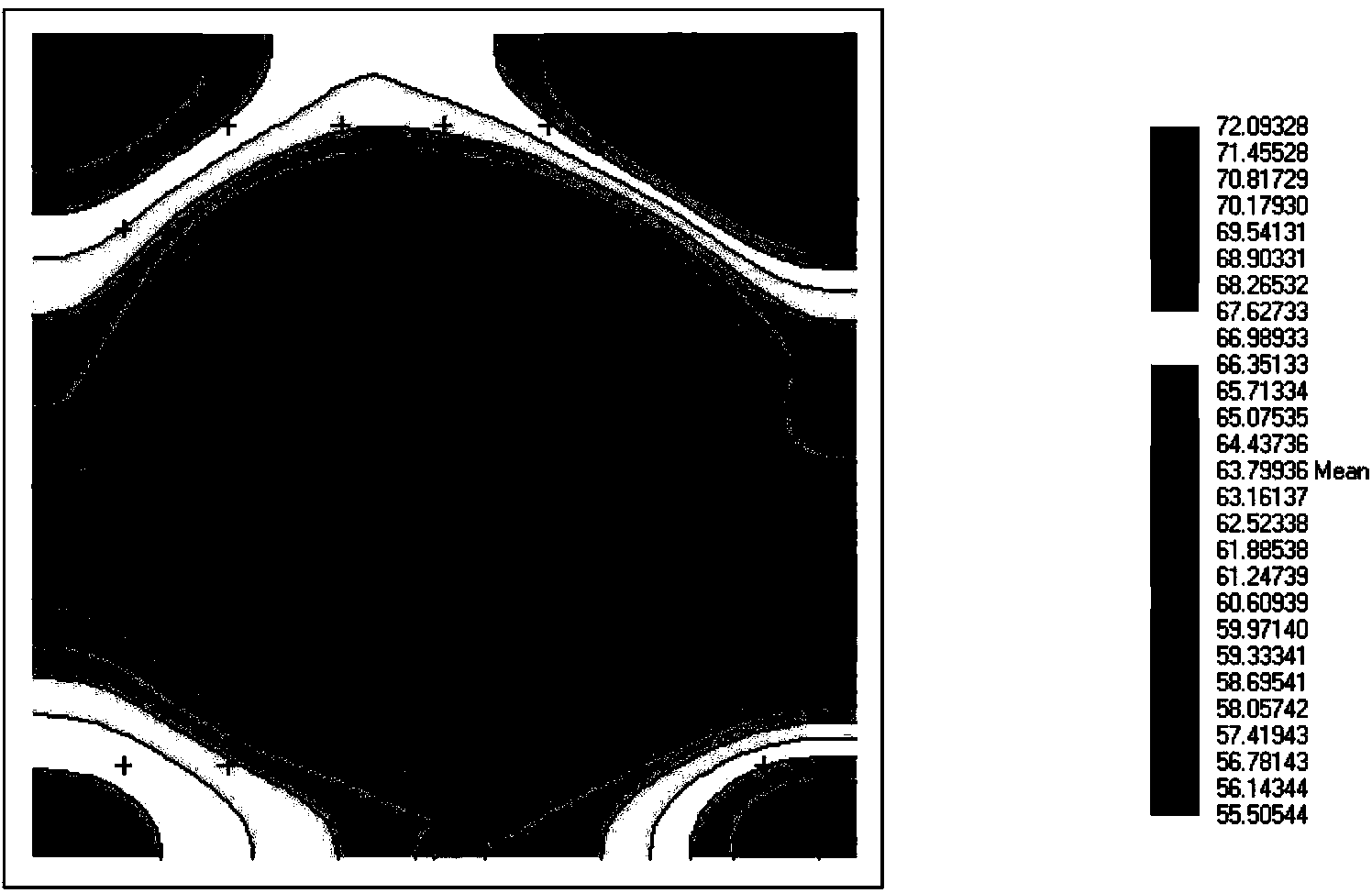

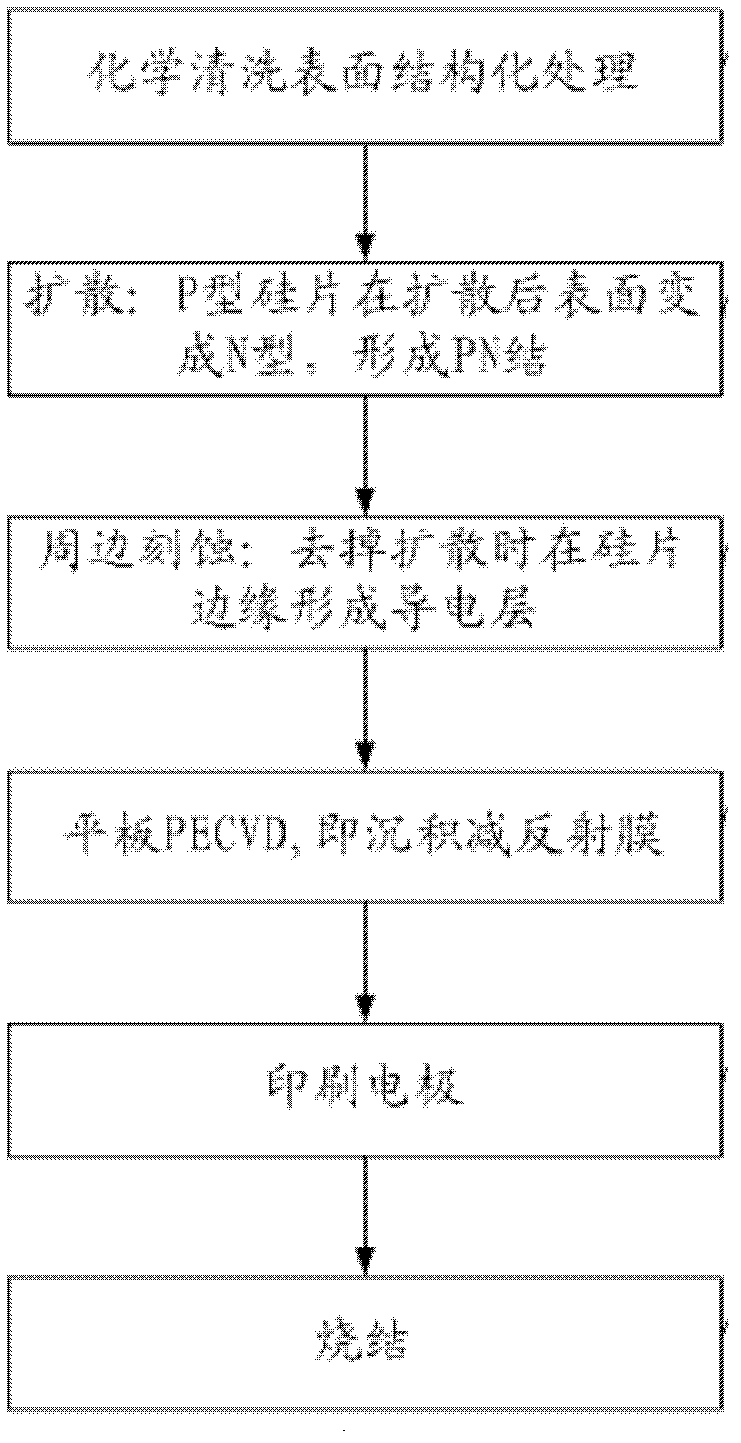

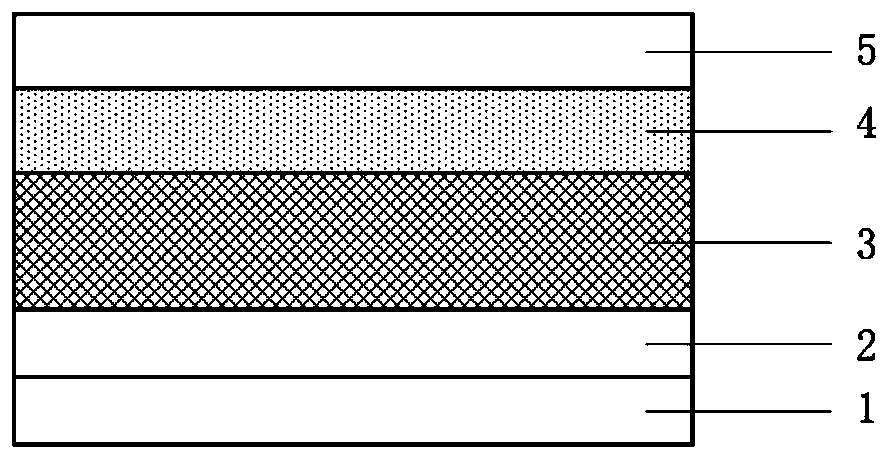

Decompression diffusion technology for manufacturing high-square-resistance battery pieces

ActiveCN104269459ARelieve pressureReduce unevennessFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductancePressure rise

The invention discloses a decompression diffusion technology for manufacturing high-square-resistance battery pieces. The technology comprises a constant-temperature decompression process, a pre-oxidation process, a temperature rise process, a deep diffusion process, a phosphorus propulsion process, a post-oxidation treatment process and a temperature drop and pressure rise process. Compared with a constant-pressure diffusion technology, the variable of pressure in the diffusion process is introduced into the decompression diffusion technology, the pressure in a diffusion furnace tube is reduced, meanwhile temperature, time and airflow are adjusted so that the uniformity of the diffusion square resistance can be better, and the photovoltaic conversion efficiency of the manufactured battery pieces can be higher; besides, the yield in unit time of equipment can be increased, and the usage amount of diffusion phosphorus sources is reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

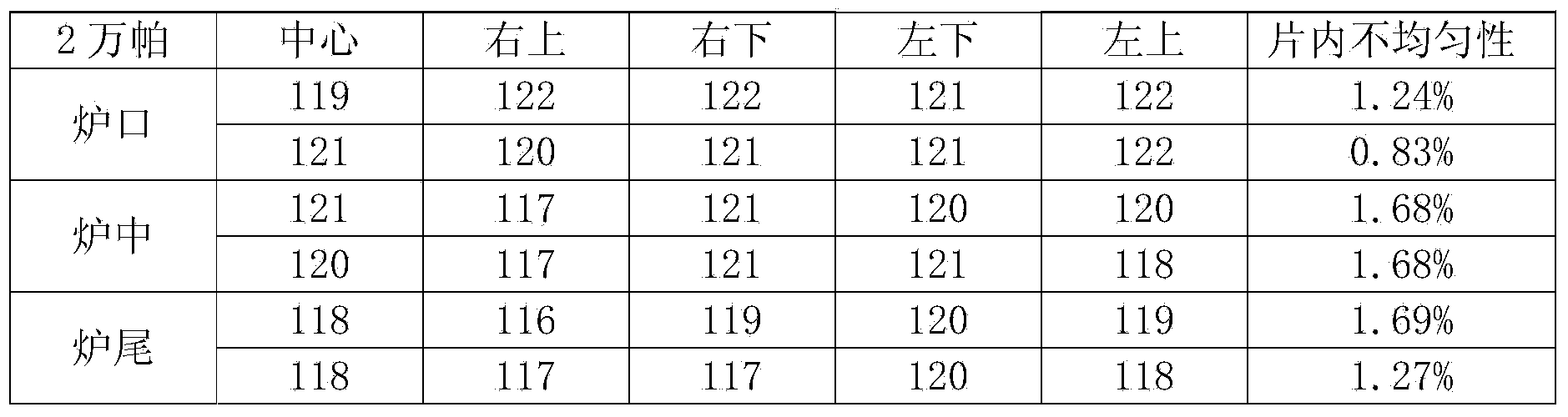

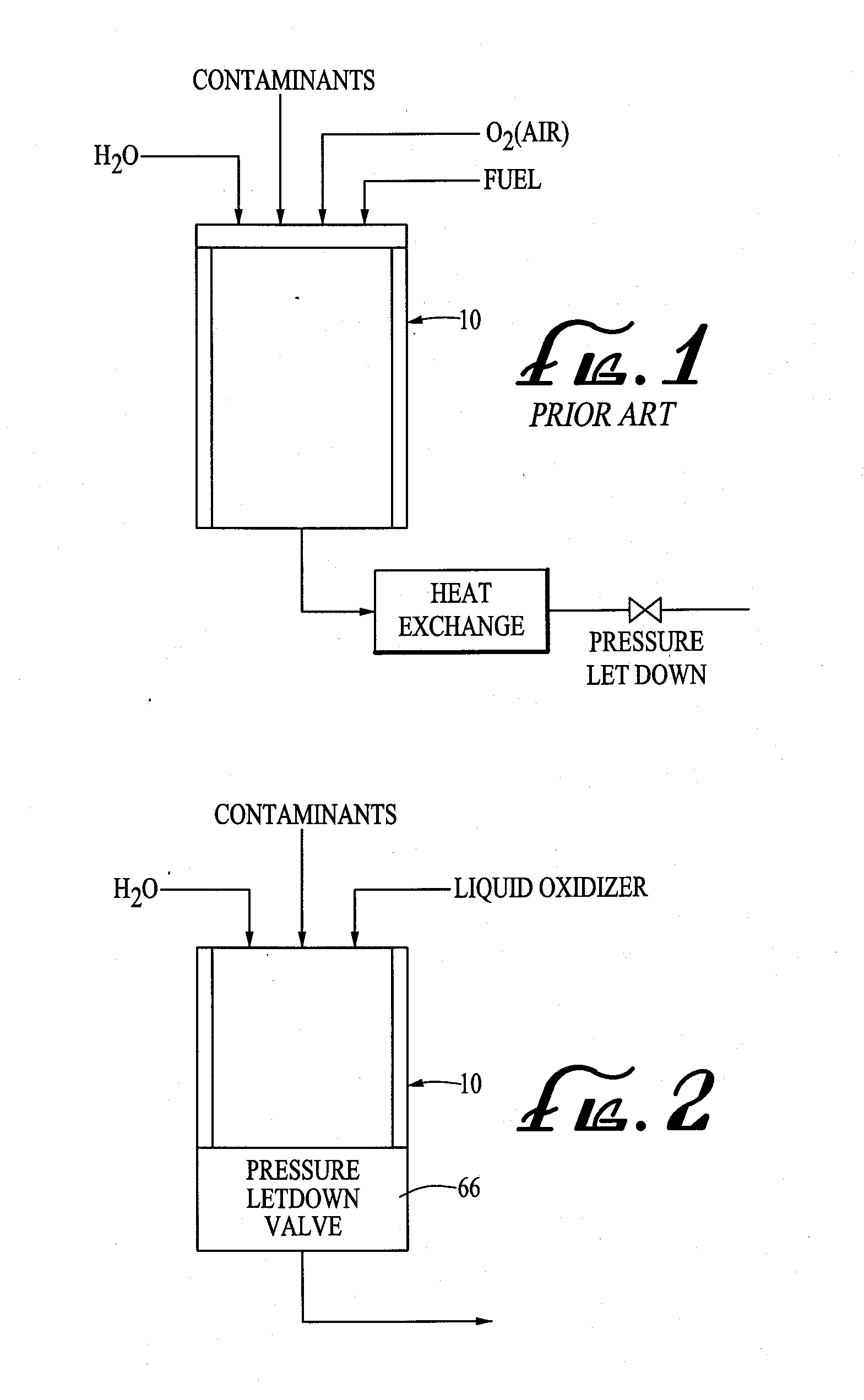

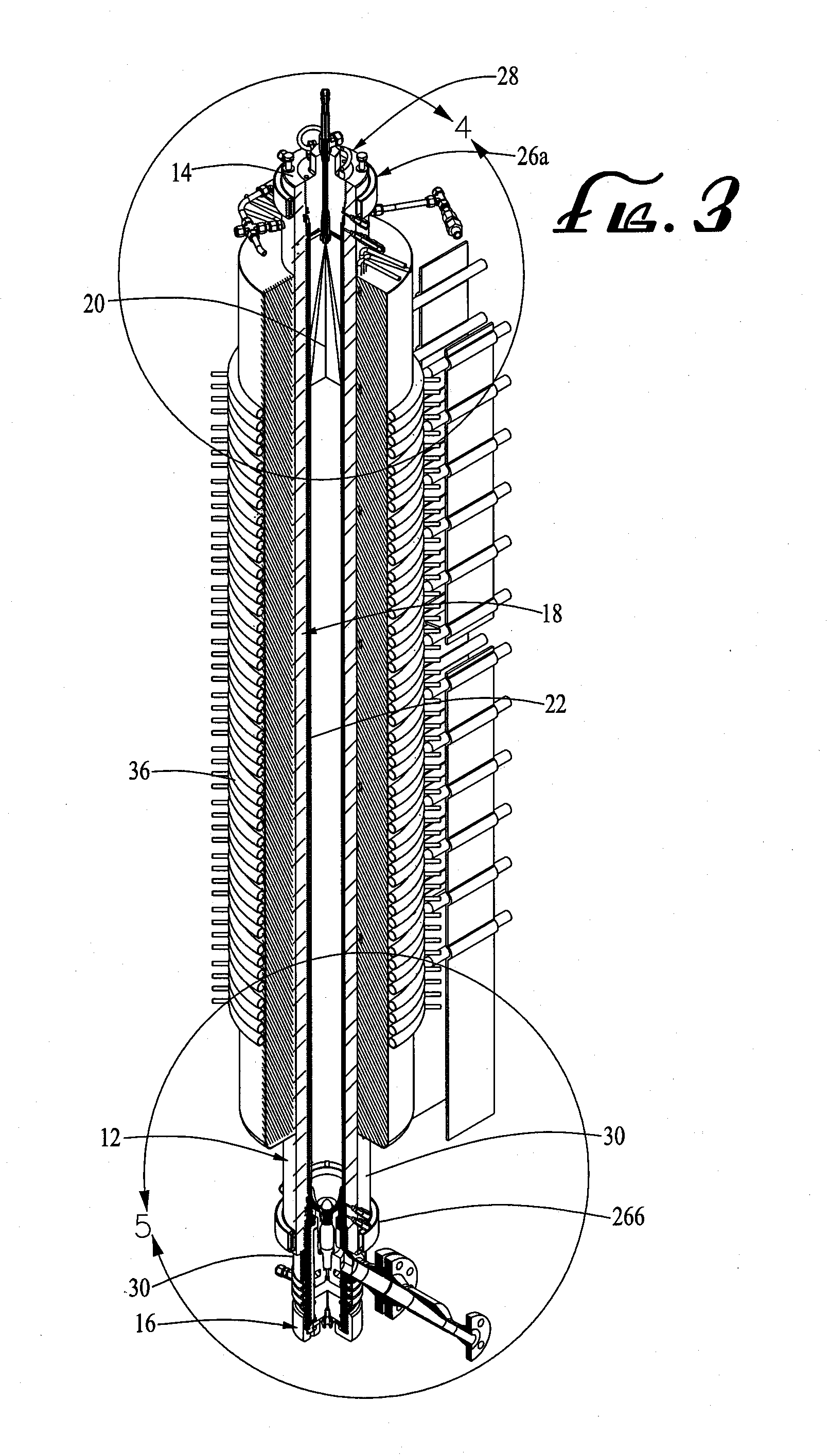

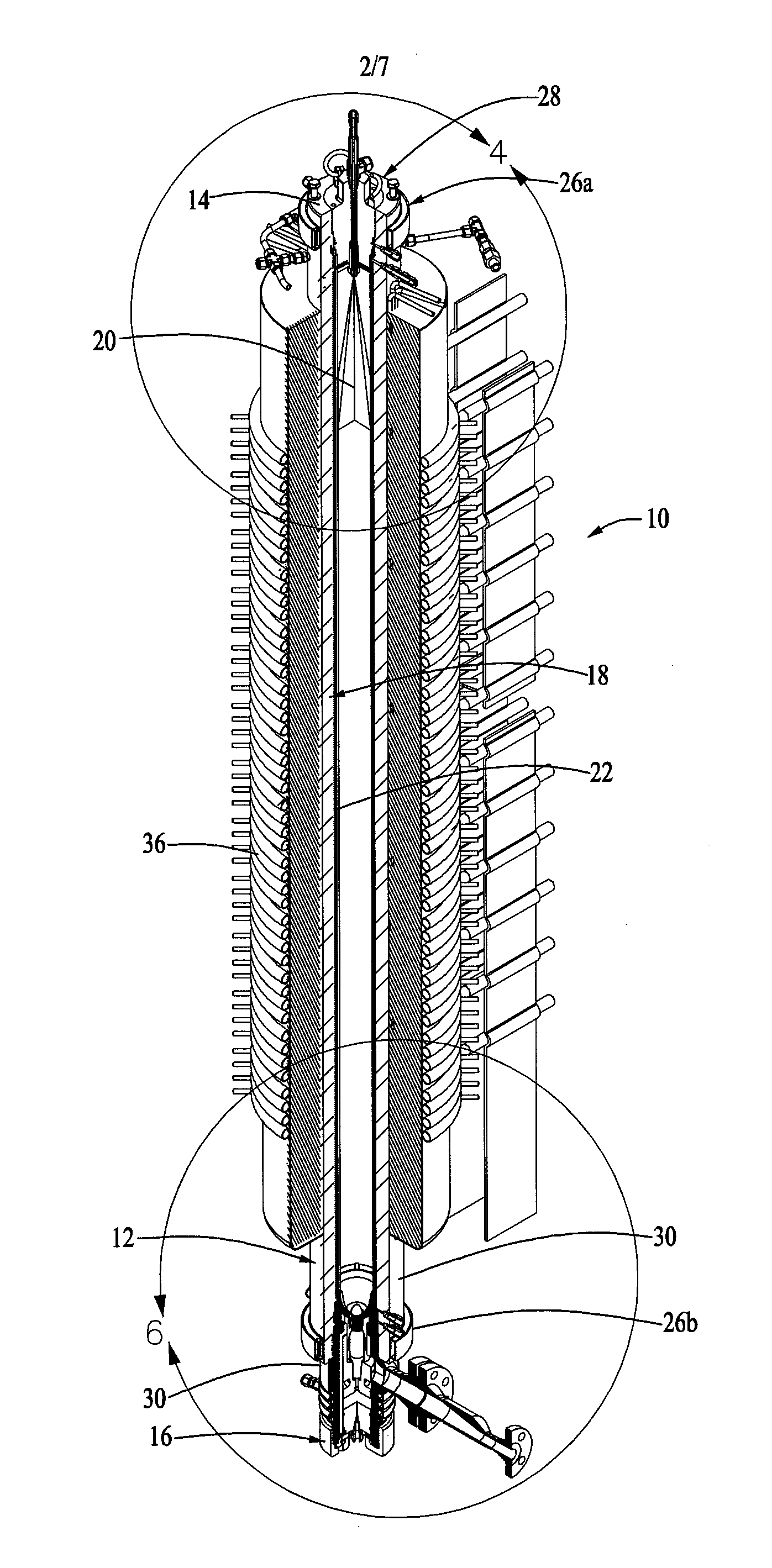

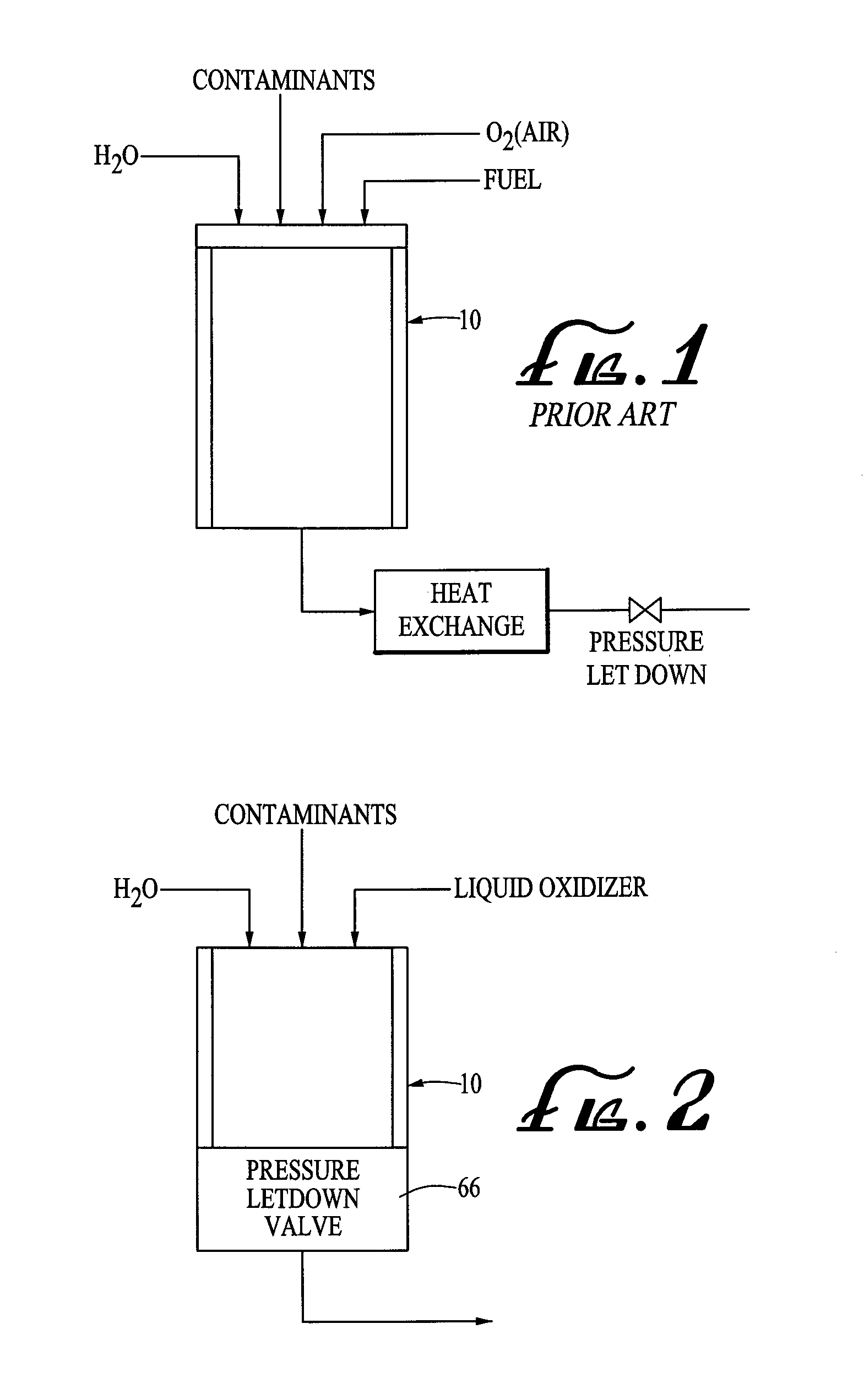

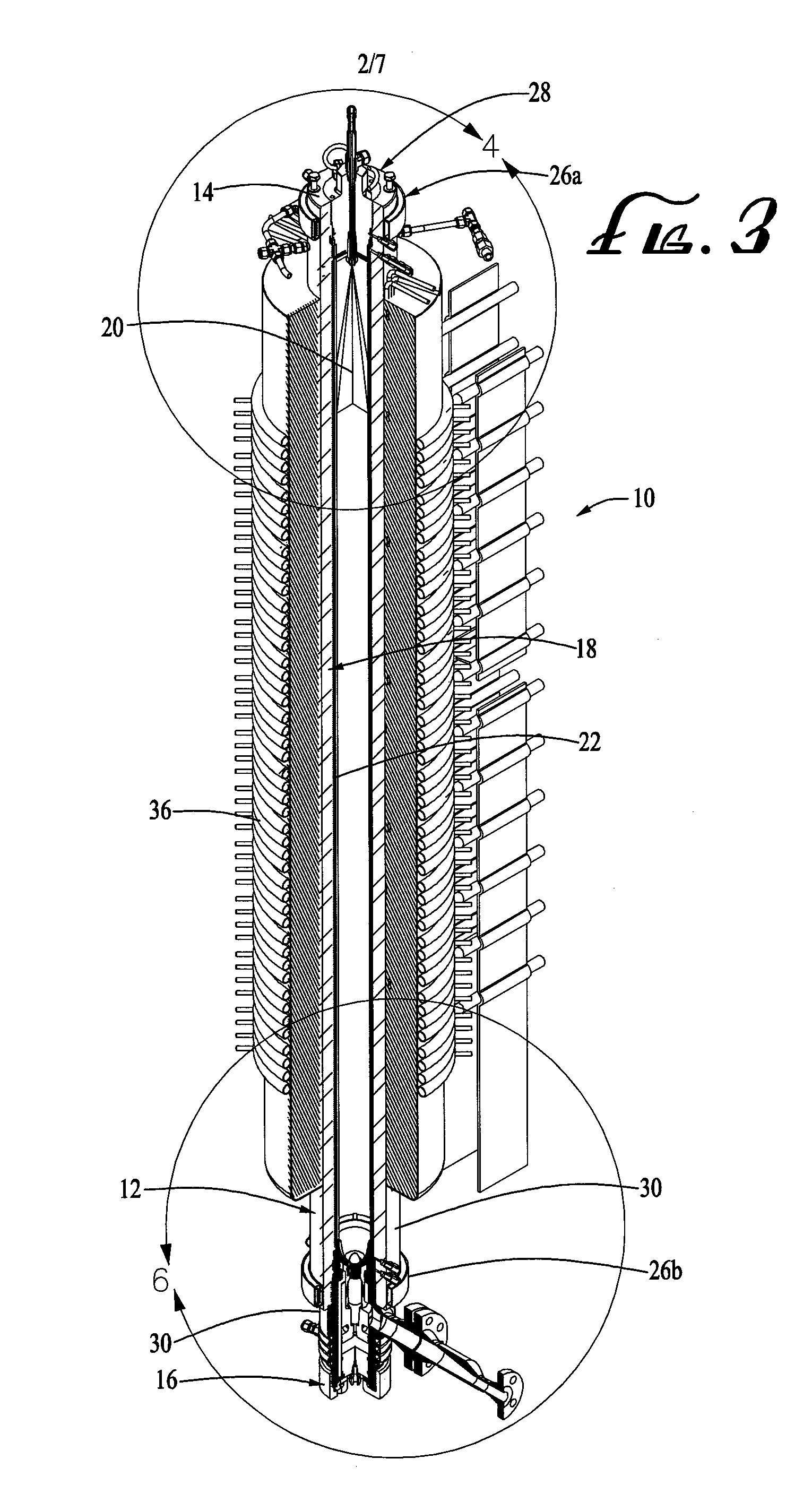

Supercritical water oxidation apparatus and process

ActiveUS20080283472A1Pressurized chemical processSludge treatmentContinuous flowSupercritical water oxidation

A method for oxidizing an organic material includes the steps of (a) forming a preoxidation mixture comprising the organic material and water, and (b) causing the preoxidation mixture to react with a liquid oxidizer in a continuous flow reactor supercritical conditions for water, including a pressure of at least 3206 psia and a temperature of at least 705° F., to form a post-oxidation mixture containing condensible material and non-condensible material, wherein substantially all of the organic material has been oxidized.

Owner:PARSONS CORPROATION

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS20020018737A1Reduce sensitivityEliminate accumulationCombination devicesGas treatmentProduct gasOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:APPLIED MATERIALS INC

Oxidation process to produce a purified carboxylic acid product via solvent displacement and post oxidation

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing at least one oxidizable compound selected from the following group: 5-(hydroxymethyl)furfural (5-HMF), 5-HMF esters (5-R(CO)OCH2-furfural were R alkyl, cycloalkyl and aryl), 5-HMF ethers (5-R′OCH2-furfural, where R′=alkyl, cycloalkyl and aryl), 5-alkyl furfurals (5-R″-furfural, where R″=alkyl, cycloalkyl and aryl), mixed feed-stocks of 5-HMF and 5-HMF esters and mixed feed-stocks of 5-HMF and 5-HMF ethers and mixed feed-stocks of 5-HMF and 5-alkyl furfurals to generate a crude carboxylic acid slurry comprising FDCA.

Owner:EASTMAN CHEM CO

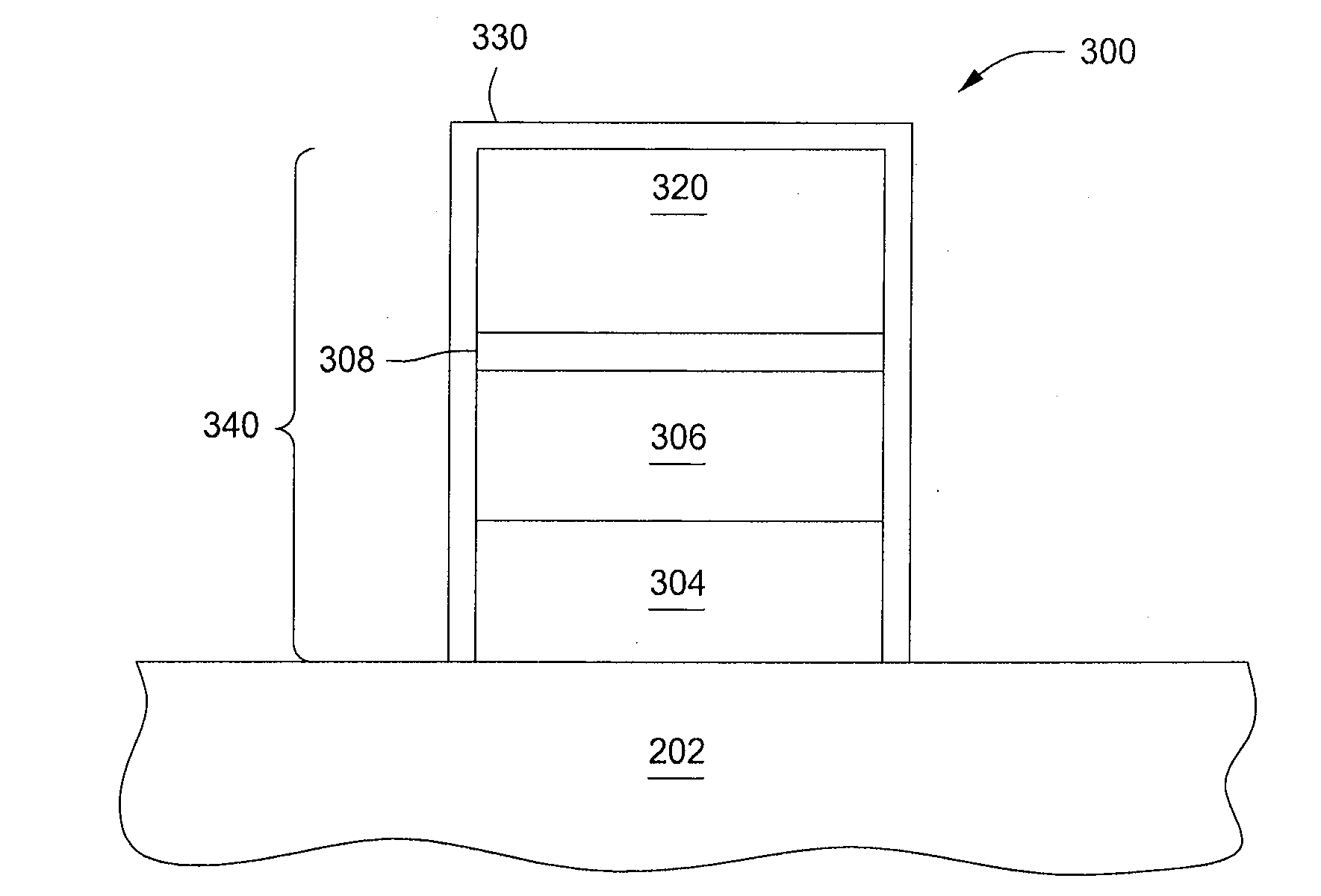

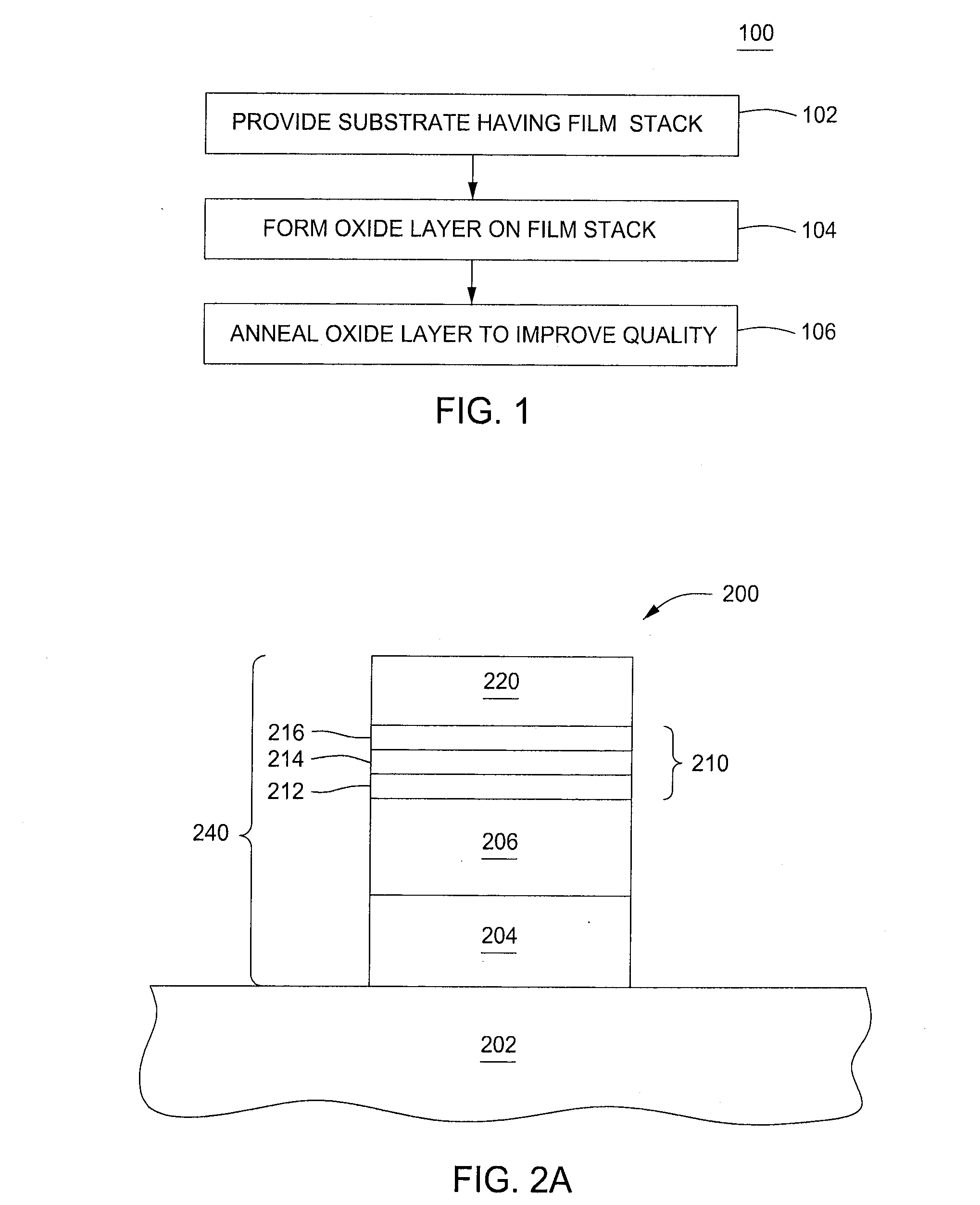

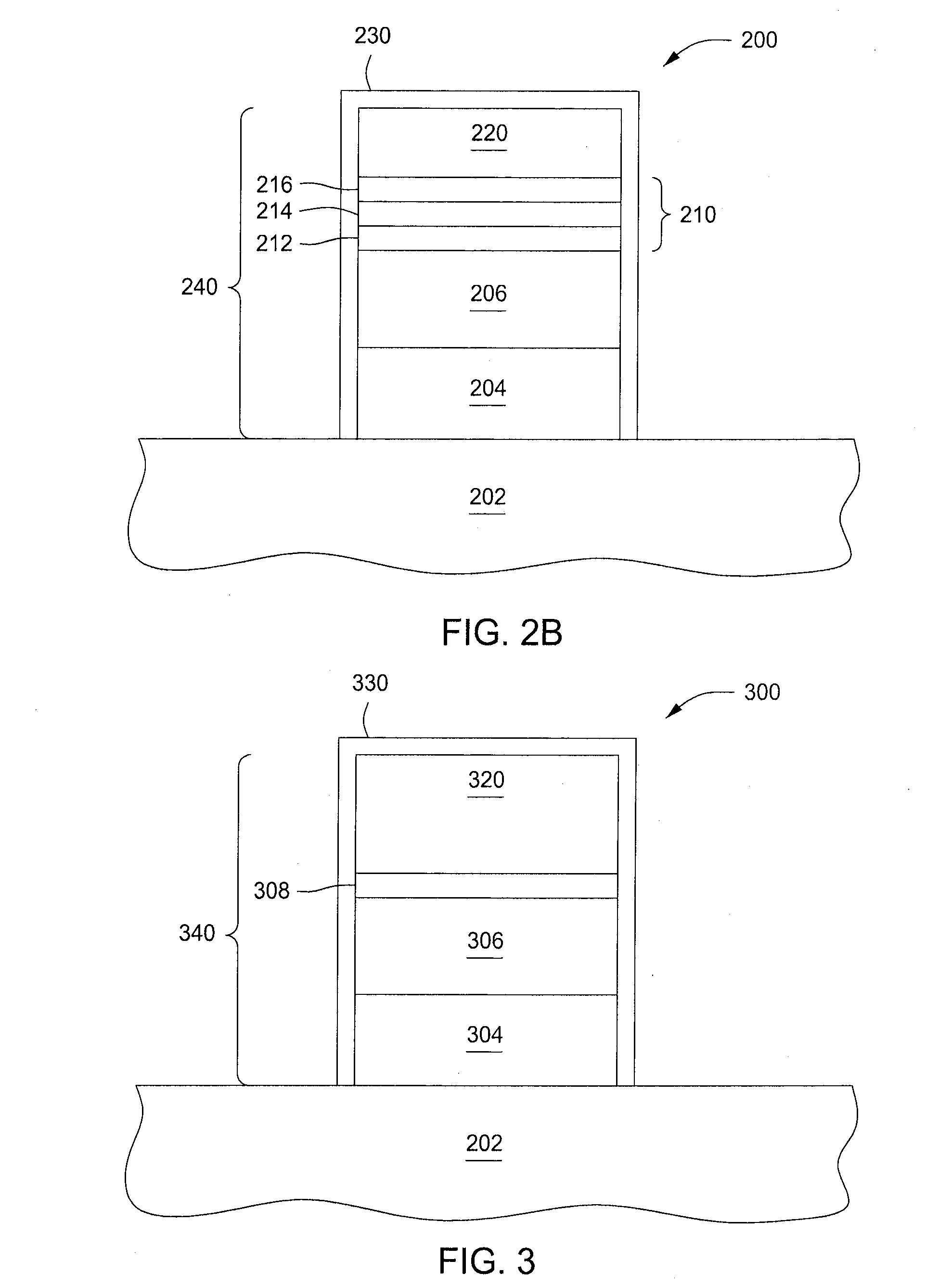

Post oxidation annealing of low temperature thermal or plasma based oxidation

InactiveUS20090311877A1Semiconductor/solid-state device manufacturingSemiconductor devicesCelsius DegreePost oxidation

Embodiments of the present invention provide methods of forming oxide layers on semiconductor substrates. In some embodiments, a method of forming an oxide layer on a semiconductor substrate includes forming an oxide layer on a substrate using an oxidation process having a first process gas at a first temperature less than about 800 degrees Celsius; and annealing the oxide layer formed on the substrate in the presence of a second process gas and at a second temperature. The oxidation process may be a plasma or thermal oxidation process performed at a temperature of about 800 degrees Celsius or below. In some embodiments, the post oxidation annealing process may be a spike or soak rapid thermal process, a laser anneal, or a flash anneal performed at a temperature of at least about 700 degrees Celsius, at least about 800 degrees Celsius, or at least about 950 degrees Celsius.

Owner:APPLIED MATERIALS INC

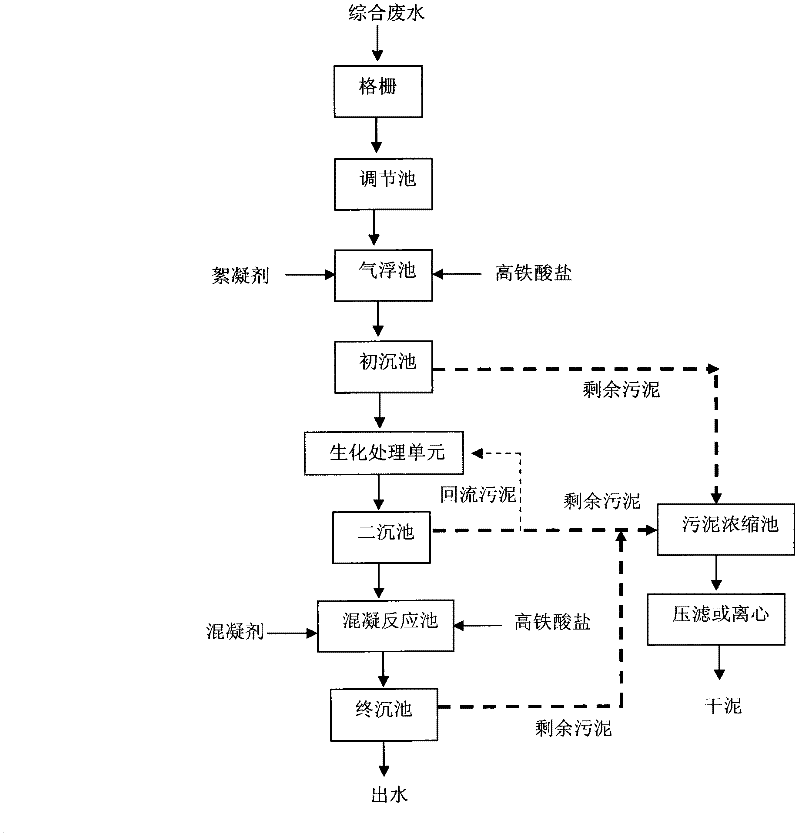

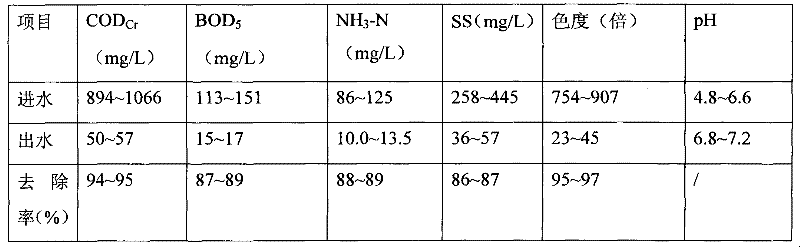

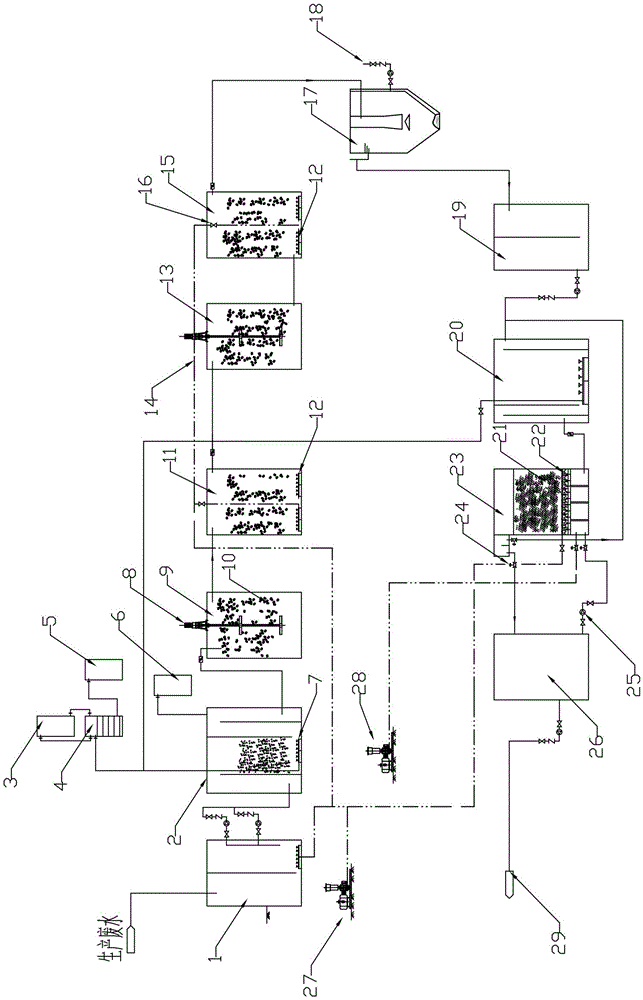

High-concentration integrated chemical organic wastewater treatment process

InactiveCN102583879AImprove biodegradabilityEasy to handleMultistage water/sewage treatmentChemical industryHigh concentration

The invention discloses a high-concentration integrated chemical organic wastewater treatment process, which comprises a pre-oxidation and physical chemical treatment unit, a biochemical treatment unit, a post-oxidation and physical chemical treatment unit and a sludge dewatering unit. Ferrate for oxidization is added in pre-physical chemical pre-treatment and is used for oxidizing organic matters in wastewater in a floatation tank, so that the content of difficult-to-biodegrade substances is reduced, the biodegradability of the wastewater is improved, and the air floatation physical chemical treatment efficacy is enhanced. In the post-oxidation and physical chemical treatment unit and, through the oxidization of the ferrate in a coagulation reaction tank, organic matters, chromaticity and SS (Standard Specification) remaining in the wastewater are further removed, and the physical chemical treatment efficacy is enhanced. The process is improved on the basis of the existing wastewater processing process, the original biochemical unit is unchanged, the equipment is simple, the investment is less, the operation management is convenient, and the operation cost is low. The water quality of outlet water of the process can stably reach primary standard of Integrated Wastewater Discharge Standard (GB8978-1996), and the process is suitable for treating wastewater of chemical industry parks and enterprises.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

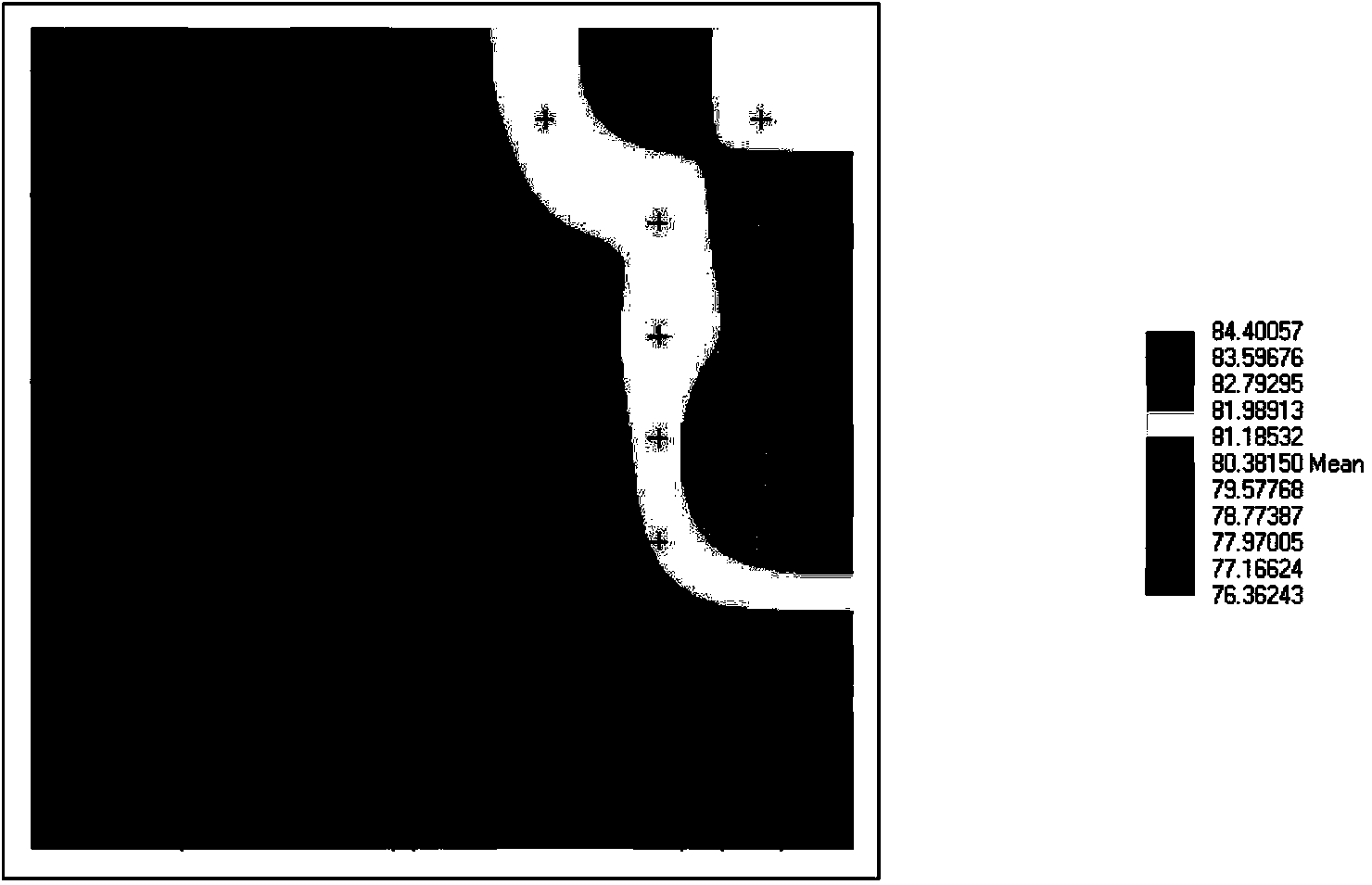

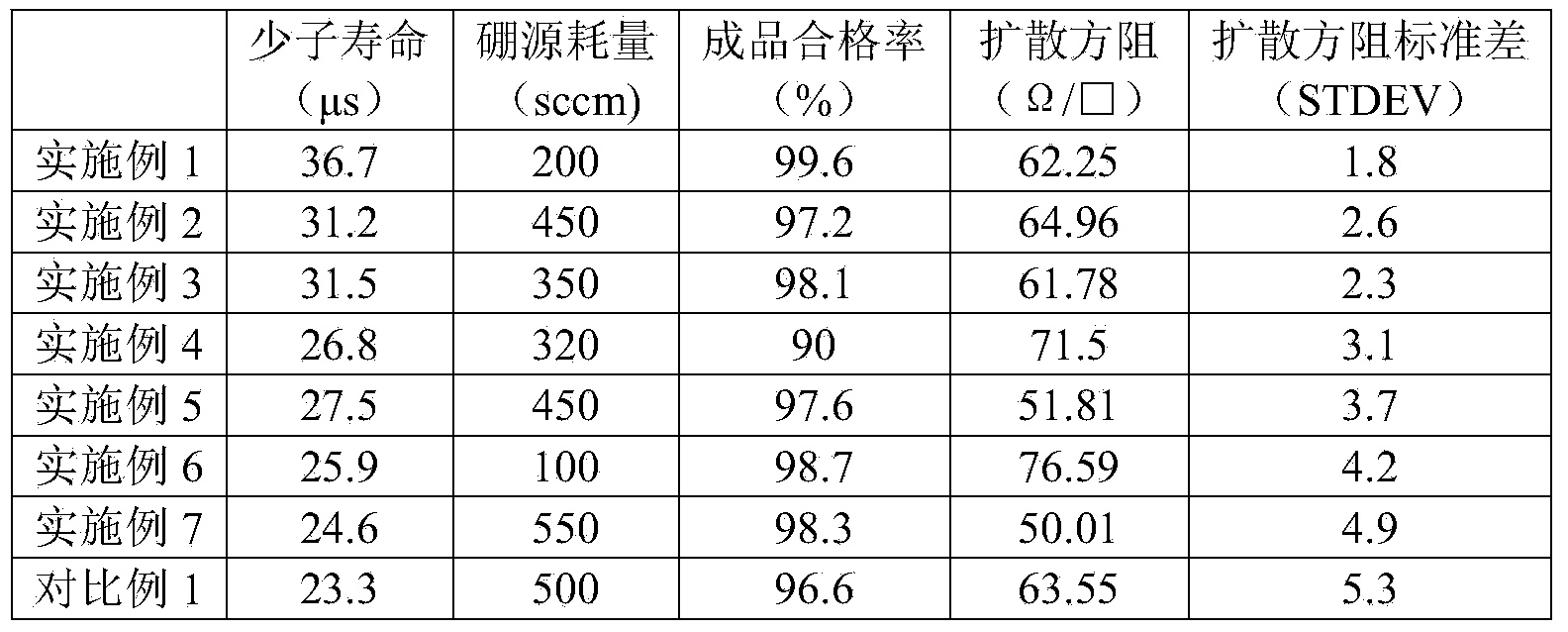

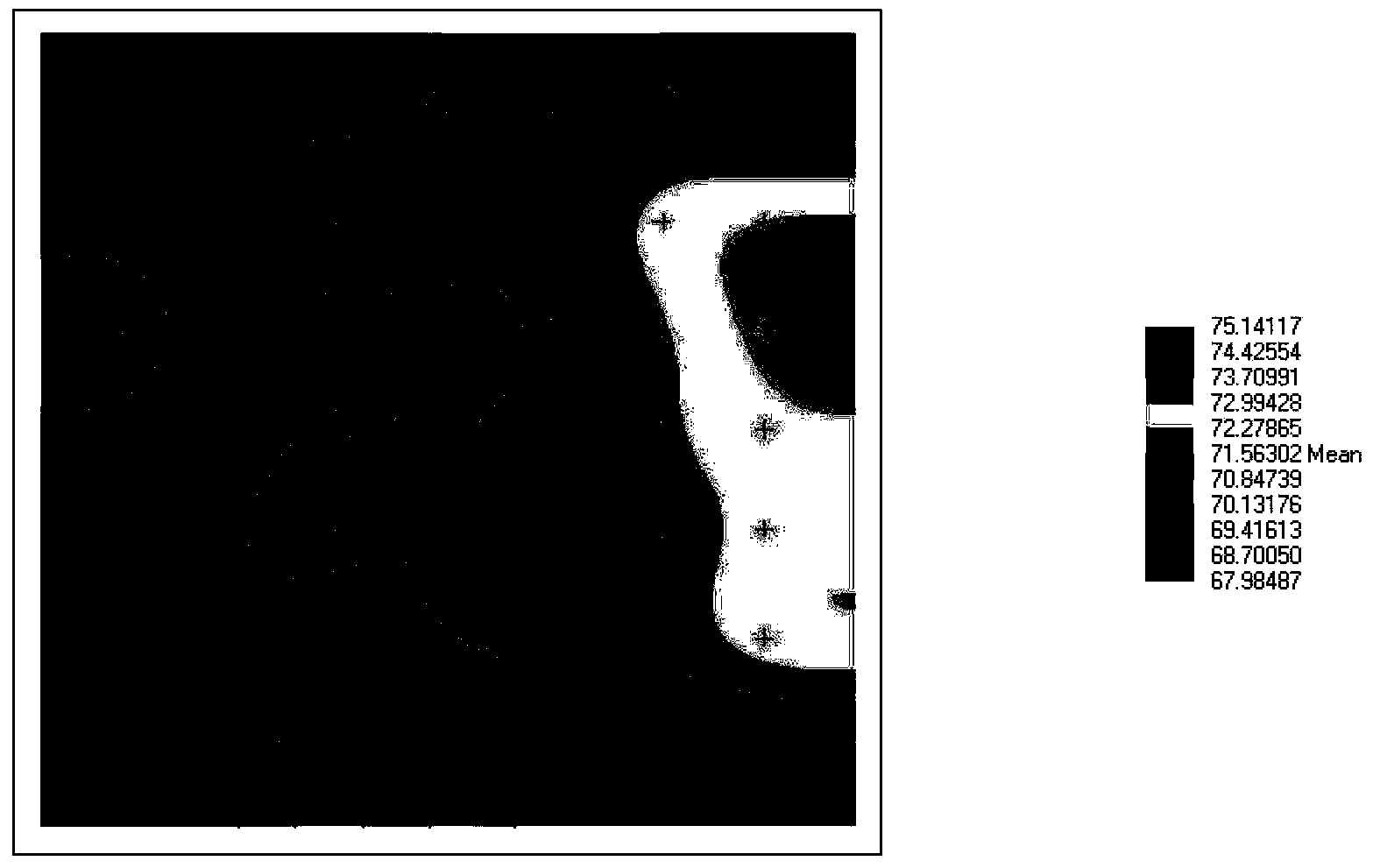

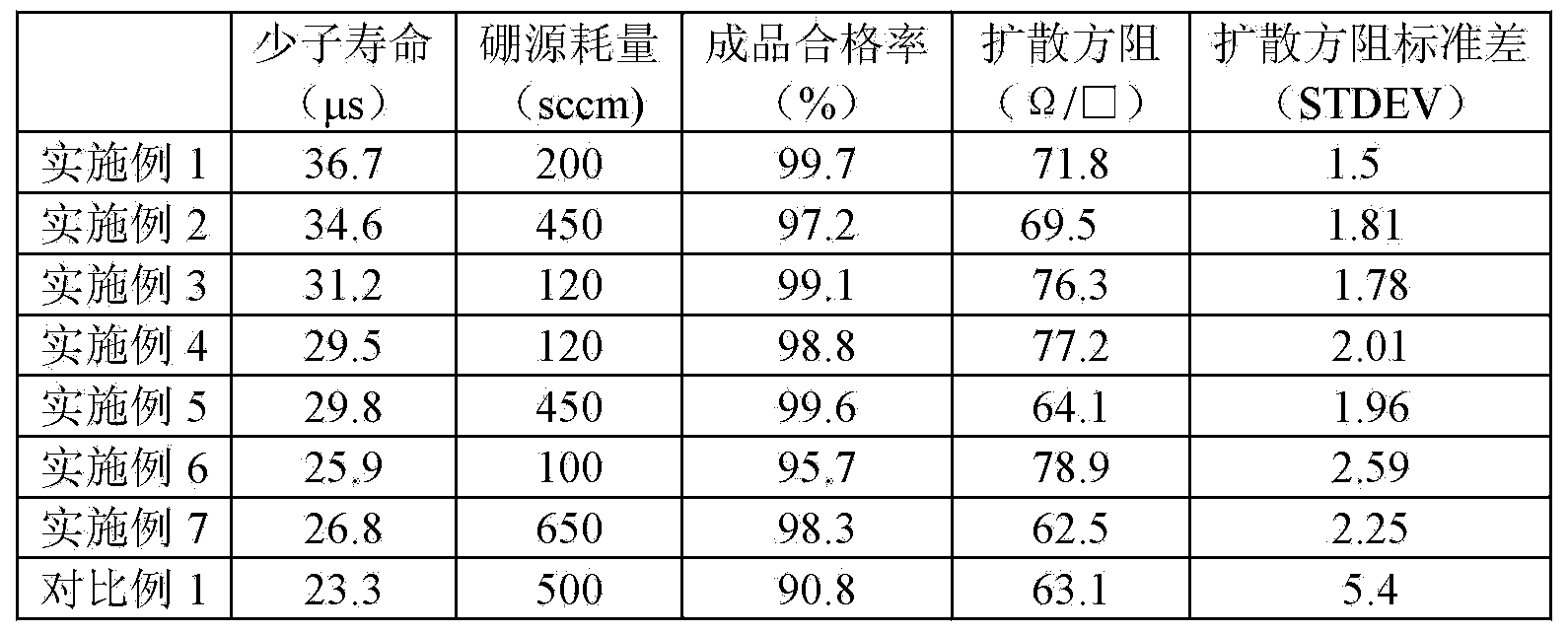

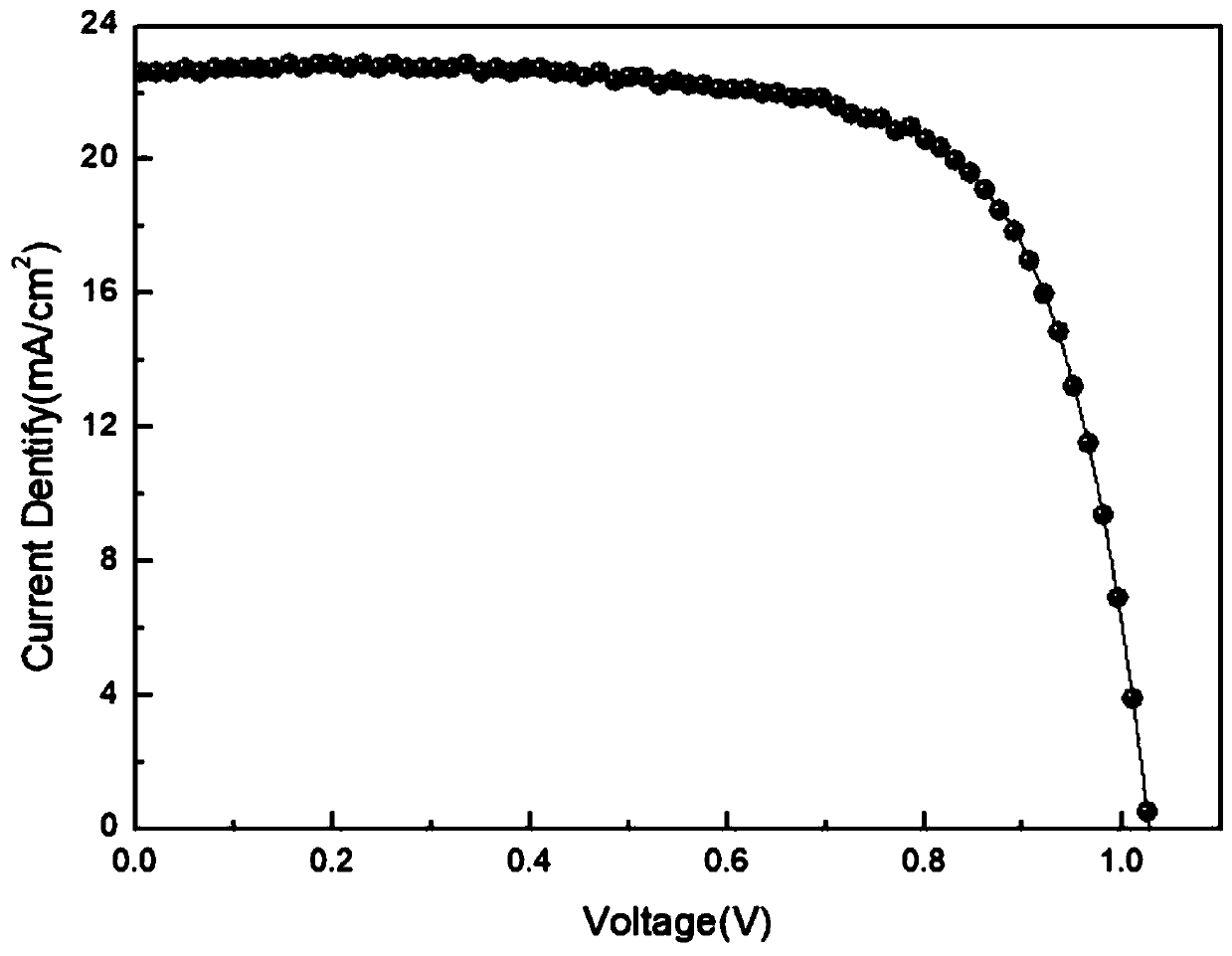

Boron diffusion method of N type silicon chip, crystalline silicon solar cell and manufacturing method of crystalline silicon solar cell

ActiveCN103632935ALower Boron Atomic ConcentrationReduce consumptionFinal product manufactureSemiconductor/solid-state device manufacturingEtchingNitrogen gas

The invention discloses a boron diffusion method of an N type silicon chip, a crystalline silicon solar cell and a manufacturing method of the crystalline silicon solar cell. The boron diffusion method comprises the following steps of a deposition stage: placing the silicon chip subjected to wet etching into a diffusion furnace, raising the temperature to 890-920 DEG C, and then introducing nitrogen, oxygen and a boron source for depositing the surface of the silicon chip; a diffusion stage: raising the temperature of the silicon chip with the surface being deposited to a preset temperature under the atmosphere of nitrogen for promoting the diffusion of boron; a post-oxidation stage: dropping the temperature of the silicon chip with the boron being diffused, and introducing oxygen and nitrogen to obtain the silicon chip with the boron being diffused. After the deposition diffusion process disclosed by the invention is adopted, the concentration of boron atoms on the surface of the silicon chip is reduced, the recombination rate and the lattice damage of the surface are reduced, the STDEV (standard deviation) of the sheet resistance is controlled to be about 2.0, the sheet resistance uniformity of boron diffusion is improved, the battery conversion efficiency is improved, the consumption of boron sources is also reduced, BGS (borosilicate glass) is prevented from being excessively generated, and the cost is reduced.

Owner:一道新能源科技股份有限公司

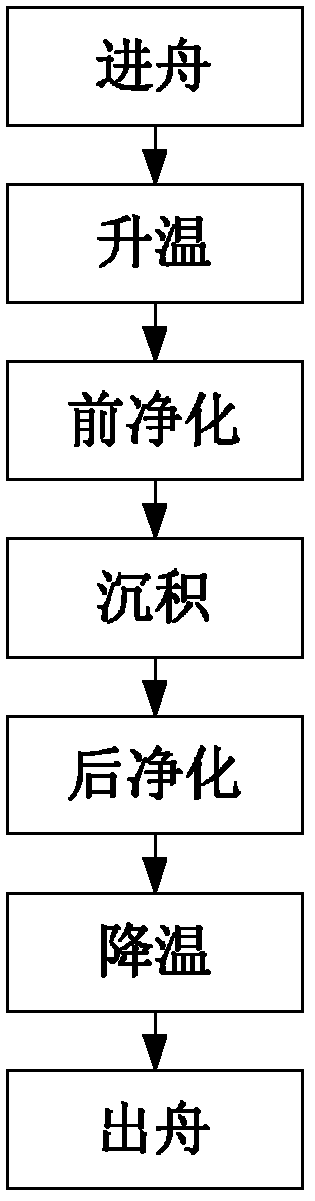

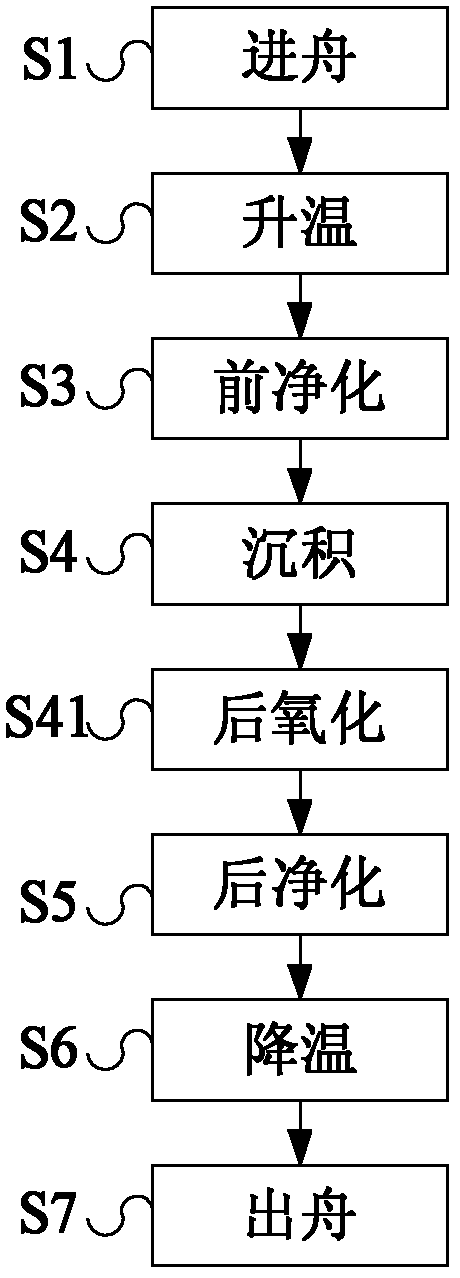

Method for reducing dead layer of solar cell

ActiveCN103367521AImprove spectral responseIncreasing the thicknessFinal product manufactureSemiconductor devicesChemical treatmentCompound (substance)

The invention provides a method for reducing a dead layer of a solar cell, and the method comprises the steps: 1) boat entering; 2) temperature rise; 3) pre-purification; 4) deposition; 5) post-purification; 6) temperature reduction; 7) boat exiting. The method also comprises: 41) post-oxidation between the step 4) and the step 5) i.e. feeding oxygen for a preset time at a preset temperature by a preset flow or carrying out the post-oxidation step during the step 5). According to the invention, the post-oxidation treatment is added and a certain amount of oxygen is let in after deposition and before the post-purification or in the process of the post-purification. Another layer of oxide film is formed between an oxide film, formed during the pre-purification, and a PN junction. The thickness of the oxide film is increased after the PN junction is formed. Phosphorus atoms react with oxygen after passing through the oxide film and diffusing towards a silicon wafer so as to further reduce the thickness of phosphorus on the surface of the PN junction and decrease the dead layer. Meanwhile, the oxide film is removed after chemical processing to reduce the thickness of the PN junction, so as to effectively improve spectrum response of a cell.

Owner:YINGLI ENERGY CHINA

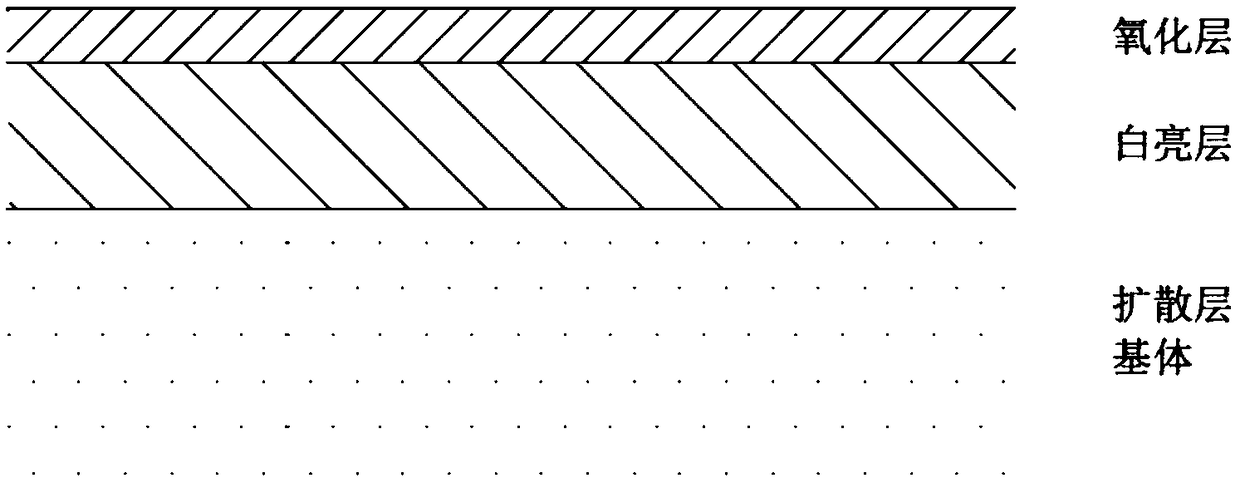

Automotive brake disc and surface modification method thereof

InactiveCN106011736AImprove wear resistanceImprove fatigue strengthBraking discsSolid state diffusion coatingNitrogenStress relief

The invention relates to an automotive brake disc and a surface modification method thereof. The surface modification method of the automotive brake disc comprises the following steps of (1) stress relief annealing, specifically, stress relief treatment is conducted on the brake disc; (2) vacuumizing for the first time, specifically, the brake disc is transferred into an oxidizing furnace, vacuumizing is conducted for the furnace pressure, and then the furnace pressure is balanced through nitrogen; (3) pre-oxidation, specifically, pre-oxidation is conducted on the brake disc; (4) tufftriding, specifically, the brake disc is transferred into a nitriding furnace, and nitrocarburizing is conducted; (5) rapid cooling for the first time, specifically, the brake disc is taken out of the nitriding furnace to be cooled rapidly; (6) vacuumizing for the second time, specifically, the brake disc is placed in the oxidizing furnace, vacuumizing is conducted for the furnace pressure, and then the furnace pressure is balanced through nitrogen; (7) post-oxidation, specifically, post-oxidation is conducted on the brake disc; (8) rapid cooling for the second time, specifically, the post-oxidized brake disc is cooled rapidly; and (9) vacuumizing for the third time, specifically, vacuumizing is conducted for the furnace pressure, then the furnace pressure is balanced through nitrogen, and the treated brake disc is taken out of the furnace. By the adoption of the surface modification method, the hardness, abrasion resistance, fatigue-resisting strength and high temperature-resisting engagement performance of the brake disc can be improved.

Owner:陈曦

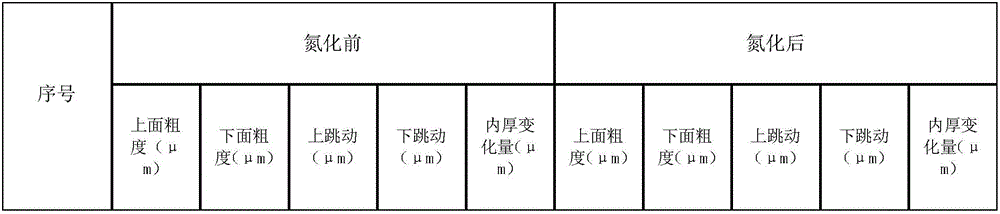

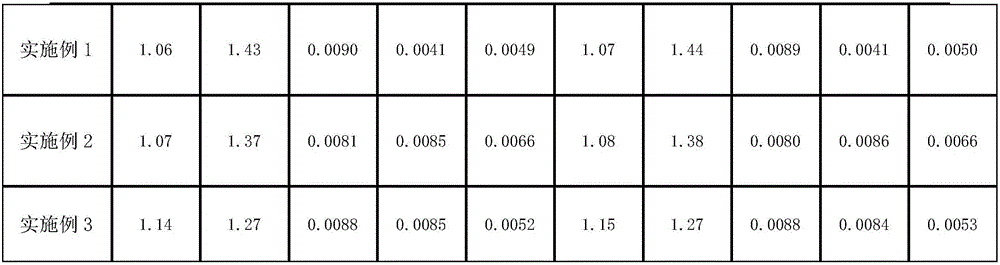

Gas nitrocarburizing and post-oxidation compounded treatment process

InactiveCN108893706AImprove corrosion resistanceImprove wear resistanceSolid state diffusion coatingWater vaporOxygen

The invention discloses a gas nitrocarburizing and post-oxidation compounded treatment process. The gas nitrocarburizing and post-oxidation compounded treatment process includes preprocessing the surface of a substrate; performing gas nitrocarburizing to form a diffusion layer on the subsurface of the substrate and a white-bright layer on the surface of the substrate; performing post-oxidation toform an oxidation layer on the surface of the white-bright layer. The technological conditions of gas nitrocarburizing comprises that applied gas is a mixture of NH3, N2 and CO2, the applied temperature is 540-600 DEG C, the treatment duration is 2-4 h and oil cooling is implemented; the technological conditions of post-oxidation comprises that applied gas is a mixture of vapor and nitrogen, the applied temperature is 400-510 DEG C, and the treatment duration is 1-3 h. compared with QPQ (quench-polish-quench) salt bath composite treatment, the gas nitrocarburizing and post-oxidation compoundedtreatment process takes nitrogen, oxygen, carbon dioxide and vapor as the raw materials, thereby being free from pollution, easy to operate and capable of reducing the production cost and greatly improving corrosion resistance and wearing resistance of materials.

Owner:上海上大热处理有限公司

Boron diffusion method of N type silicon chip, crystalline silicon solar cell and manufacturing method of crystalline silicon solar cell

ActiveCN103632934AReduce consumptionLower Boron Atomic ConcentrationFinal product manufactureSemiconductor/solid-state device manufacturingEtchingOxygen

The invention discloses a boron diffusion method of an N type silicon chip, a crystalline silicon solar cell and a manufacturing method of the crystalline silicon solar cell. The boron diffusion method comprises the following steps of a deposition stage: placing the silicon chip subjected to wet etching into a diffusion furnace, raising the temperature to a preset deposition temperature, and then introducing a boron source, oxygen and nitrogen for depositing the surface of the silicon chip; a diffusion promoting stage: raising the temperature of the silicon chip with the surface being deposited to a preset diffusion temperature for promoting the diffusion of boron, and introducing oxygen and nitrogen in the temperature raising and diffusion promoting processes; a post-oxidation stage: dropping the temperature of the diffused silicon chip, and introducing oxygen and nitrogen in the temperature dropping process. After the deposition diffusion process disclosed by the invention is adopted, the concentration of boron atoms on the surface of the silicon chip is reduced, the recombination rate and the lattice damage of the surface are reduced, the STDEV (standard deviation) is controlled to be about 2.0, the sheet resistance uniformity of boron diffusion is improved, the battery conversion efficiency is improved, the consumption of boron sources is also reduced, BGS (borosilicate glass) is prevented from being excessively generated, and the cost is reduced.

Owner:英辰新能源科技有限公司

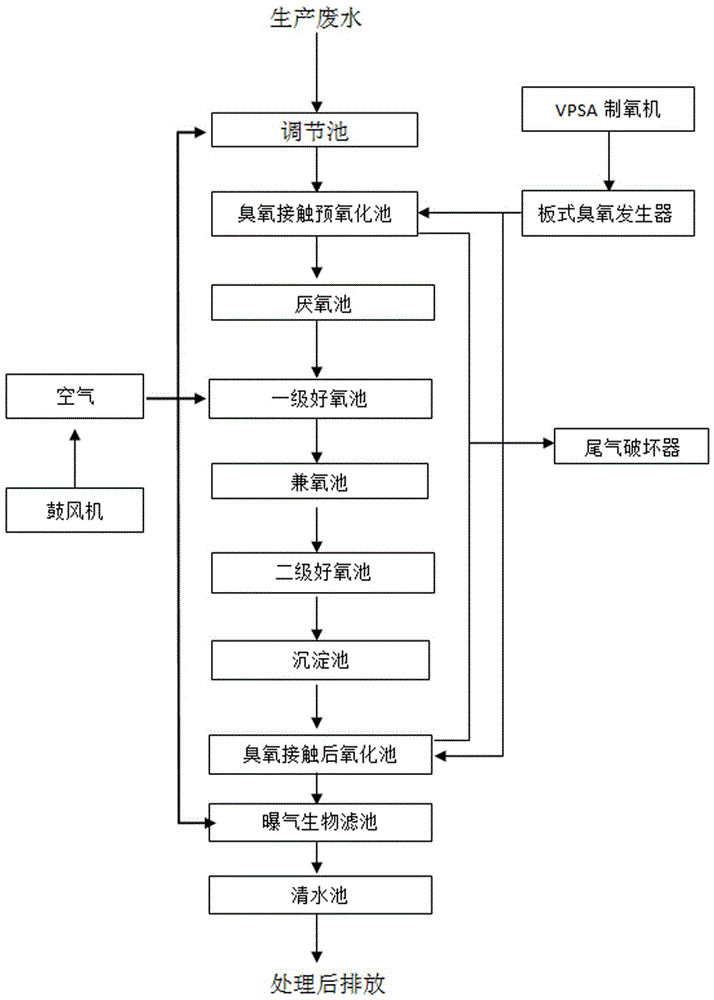

Method and system for treating toluene nitrification wastewater

InactiveCN105565614AAvoid it happening againAvoid secondary pollutionTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater qualityToluene

The invention relates to the technical field of treatment of wastewater containing nitroaromatics, and discloses a method and a system for treating toluene nitrification wastewater. The method comprises the following steps: carrying out ozone pre-oxidation treatment, anaerobic biochemical treatment, aerobiotic biochemical treatment, facultative anaerobic biochemical treatment and secondary aerobiotic biochemical treatment on the toluene nitrification wastewater in sequence; then, carrying out ozone post-oxidation treatment on the toluene nitrification wastewater, and degrading and filtering the toluene nitrification wastewater through a biological aerated filter. After the method or the system disclosed by the invention is applied to treating the toluene nitrification wastewater, the water quality can reach the discharge requirement, and the treatment cost is low.

Owner:山东彩客新材料有限公司

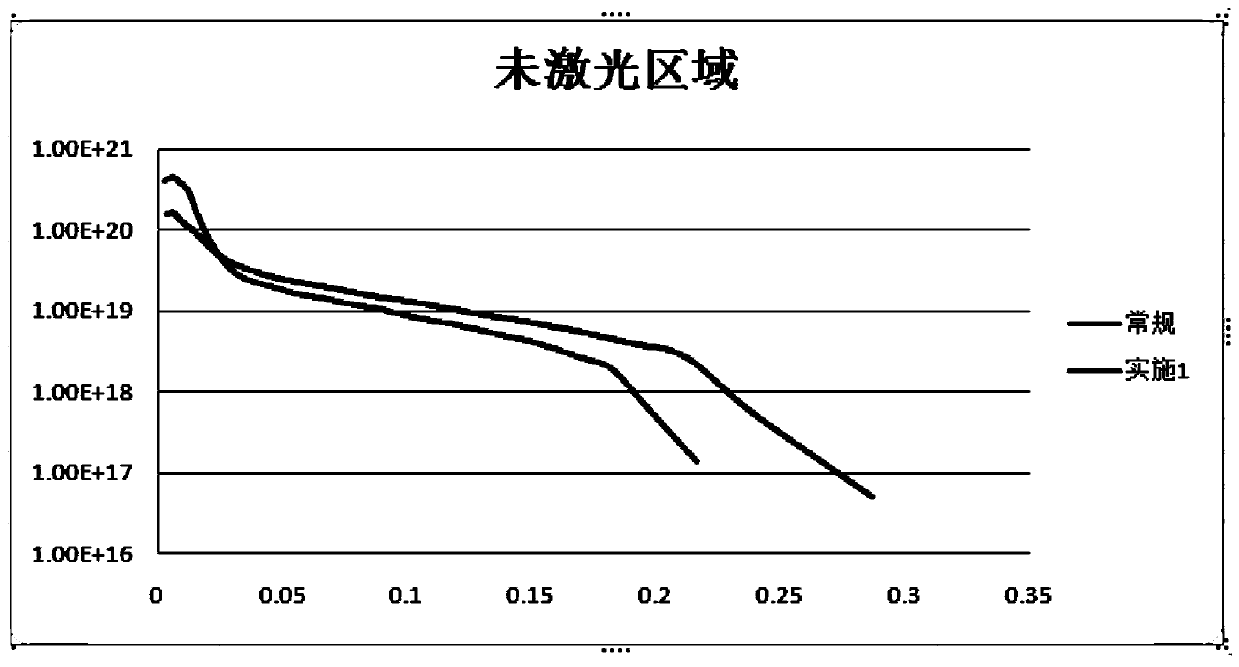

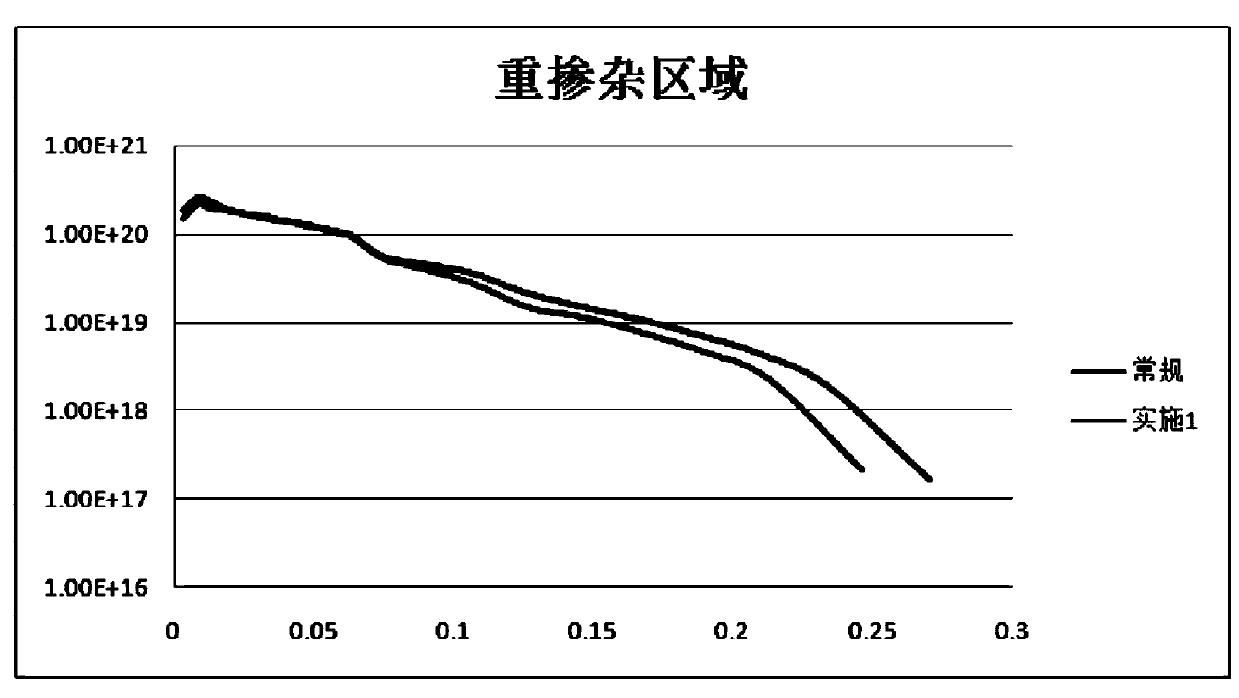

High-efficiency selective emitter solar cell diffusion process

ActiveCN110190153ASolving Compatibility Issues with High Surface ConcentrationsFix compatibility issuesFinal product manufactureSemiconductor/solid-state device manufacturingSurface concentrationHigh surface

The invention relates to a high-efficiency selective emitter solar cell diffusion process. The high-efficiency selective emitter solar cell diffusion process comprises the steps of: boat feeding, temperature rise, constant temperature, oxidization, deposition 1, propulsion 1, deposition 2, propulsion 2, oxidation, deposition 3, temperature rise, temperature reduction, deposition 4, temperature reduction and boat taking. According to the invention, high-temperature post-oxidation is added in the process, after the deposition step at the low temperature is finished, the temperature rises continuously and is kept at a certain high-temperature condition, on this basis, a phosphorus source is activated, and then the temperature reduction, oxidization and deposition are performed to perform richphosphorus gettering, the improved steps can effectively enable the phosphorus source in the formed PSG to be continuously distributed into a silicon substrate, and in addition, the PSG is enriched with a large amount of effective phosphorus sources. The improvement of the process ensures that the non-laser region keeps a low surface concentration after diffusion, and the laser heavily doped region has a high surface concentration, thereby effectively solving the problem of compatibility of the low surface concentration of the non-laser region and the high surface concentration of the laser heavily doped region; the homogeneity of sheet resistance is obviously improved after diffusion through the improvement of the process; and the sheet resistance of the laser heavily doped region is lower, and the metallization contact is better.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

Perovskite solar cell based on double-layer composite hole transport layer and preparation method

InactiveCN110246970AImprove the extraction effectLow costSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerOxygen

The invention discloses a perovskite solar cell based on a double-layer composite hole transport layer and a preparation method. An electron transport layer, a perovskite structure light absorption layer, an organic-inorganic double-layer composite hole transport layer and a top electrode are sequentially prepared on a transparent conductive substrate. The specific process for preparing the organic-inorganic double-layer composite hole transport layer comprises the following steps of: introducing oxygen into a Spiro-OMeTAD solution for oxidation, stirring, carrying out spin coating to prepare a pre-oxidization Spiro-OMeTAD hole transport layer, and preparing an inorganic hole transport layer from an inorganic hole material solution. According to the invention, based on the organic-inorganic double-layer hole transport layer, through the pre-oxidation Spiro-OMeTAD hole transport layer and the inorganic hole transport layer, the perovskite thin film degradation problem caused by the post-oxidation of a traditional hole transport layer can be effectively inhibited and the carrier transport capability and the energy band matching of the hole transport layer are remarkably improved, so that the performance of the perovskite solar cell is improved.

Owner:SOUTHWEST PETROLEUM UNIV

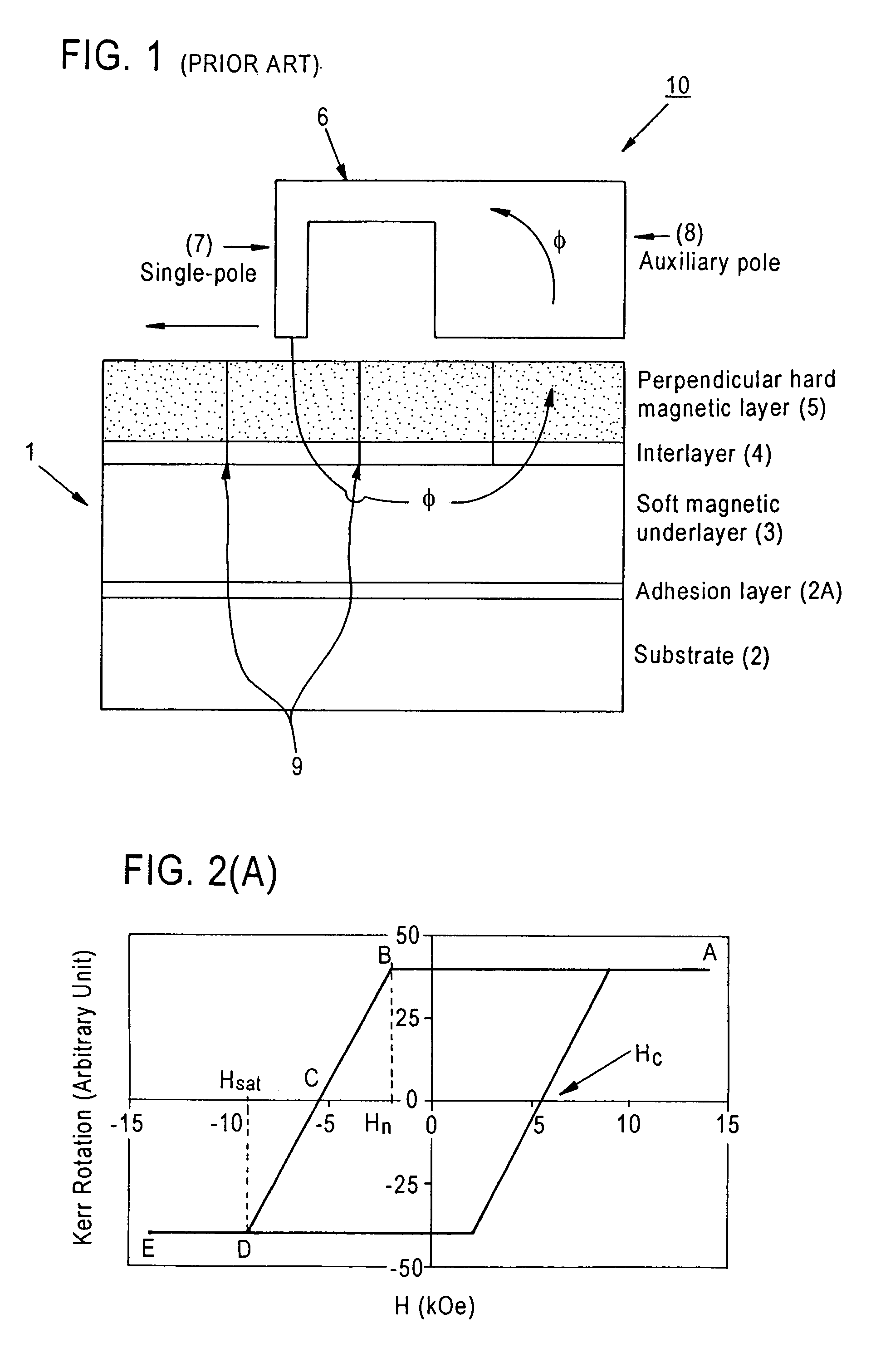

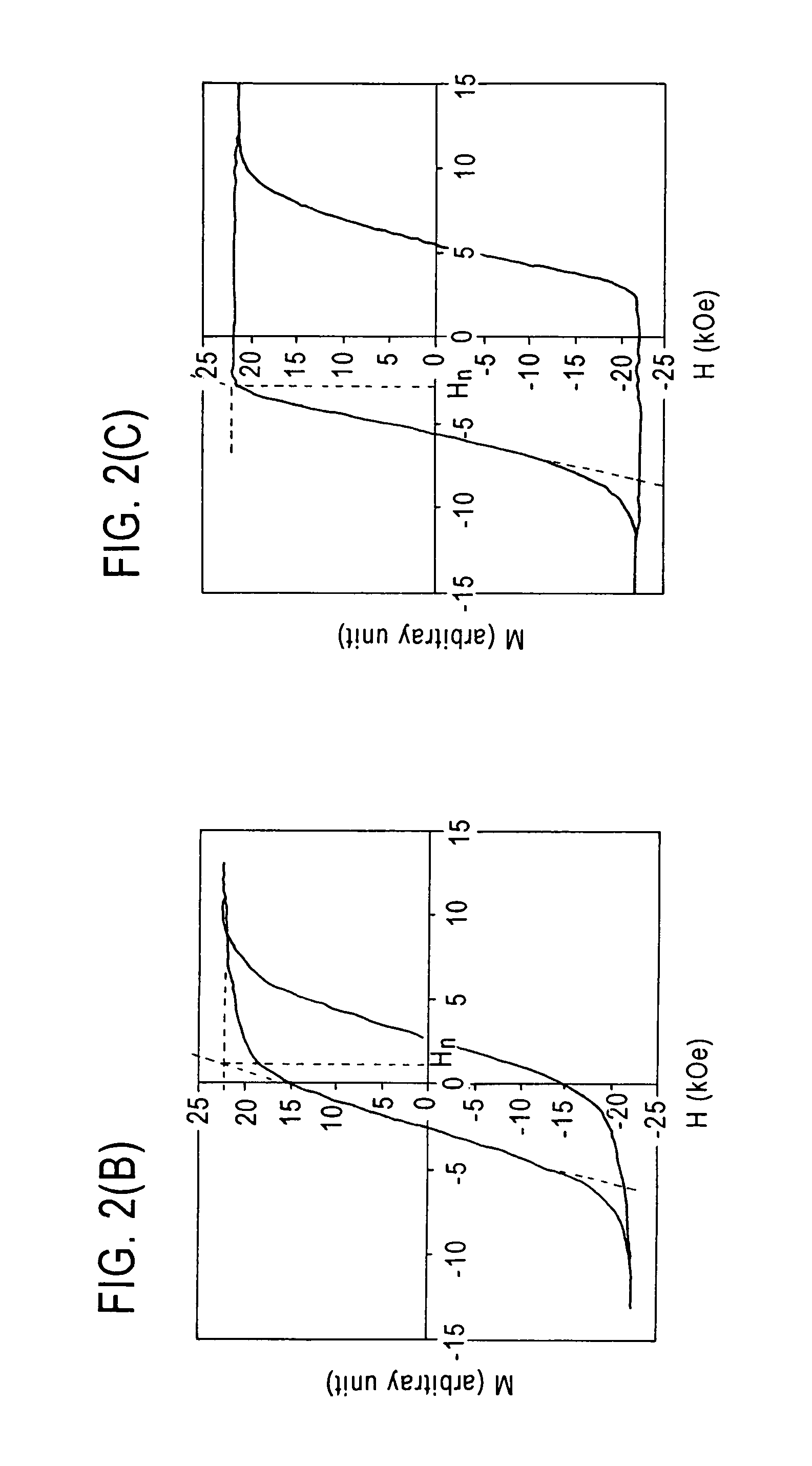

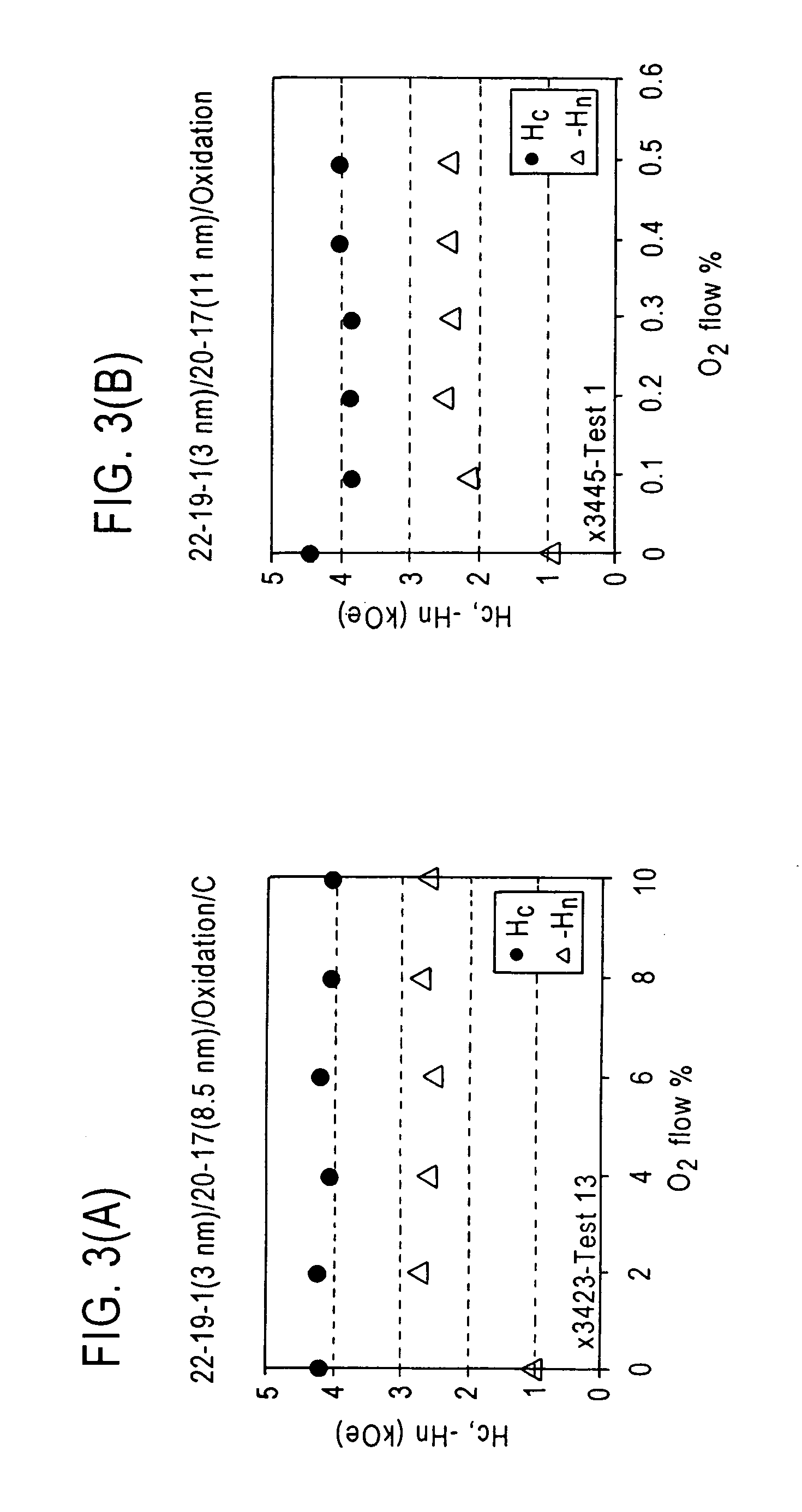

In-situ post-deposition oxidation treatment for improved magnetic recording media

InactiveUS7081268B2Easy to manufactureEasy to optimizeProtective coatings for layersRecord information storageThermal decayRecording layer

A method of manufacturing a magnetic recording medium comprises sequential steps of:(a) providing an apparatus for manufacturing the medium;(b) supplying the apparatus with a substrate for the medium;(c) forming a magnetic recording layer on the substrate in a first portion of the apparatus;(d) treating the magnetic recording layer with oxygen gas in a second portion of the apparatus at a sub-atmospheric pressure and for an interval sufficient to provide the resultant medium with at least one of the following, relative to a similar medium manufactured by a similar method but wherein the oxygen treatment of step (d) is not performed:(i) a more negative nucleation field (Hn);(ii) increased remanent squareness (Sr);(iii) increased signal-to-medium noise ratio (SMNR);(iv) narrower switching field distribution (SFD); and(v) decreased thermal decay rate; and(e) forming a protective overcoat layer on the oxygen-treated magnetic recording layer in a third portion of the apparatus.

Owner:PIONEER CORP +1

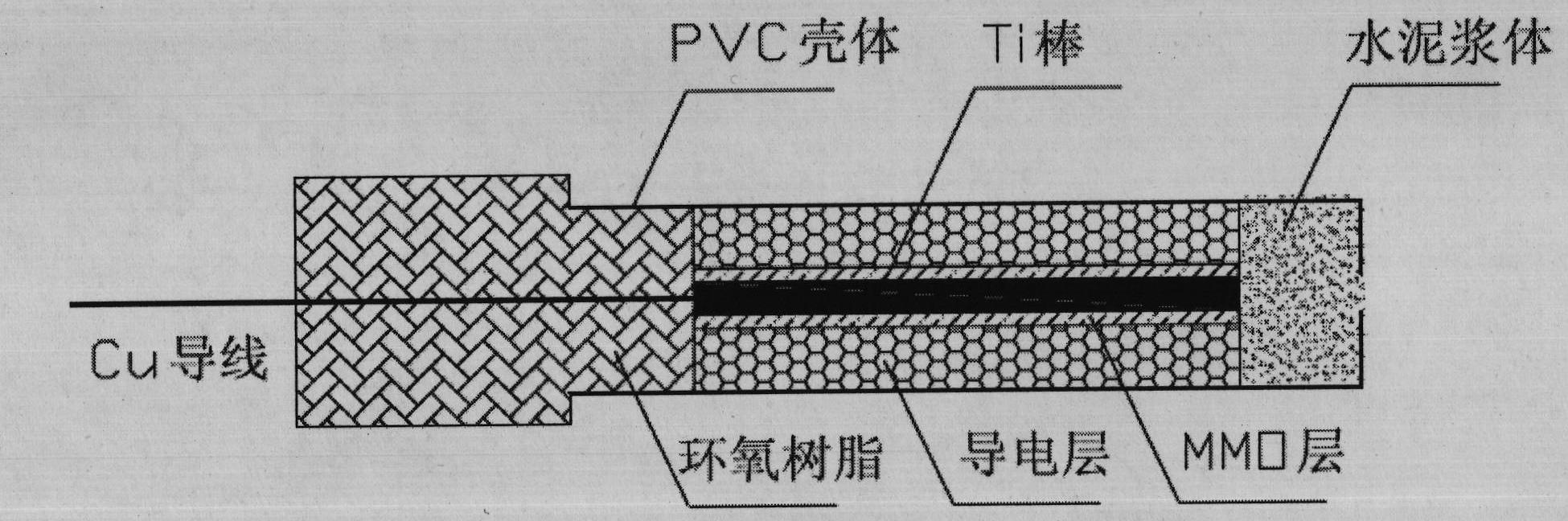

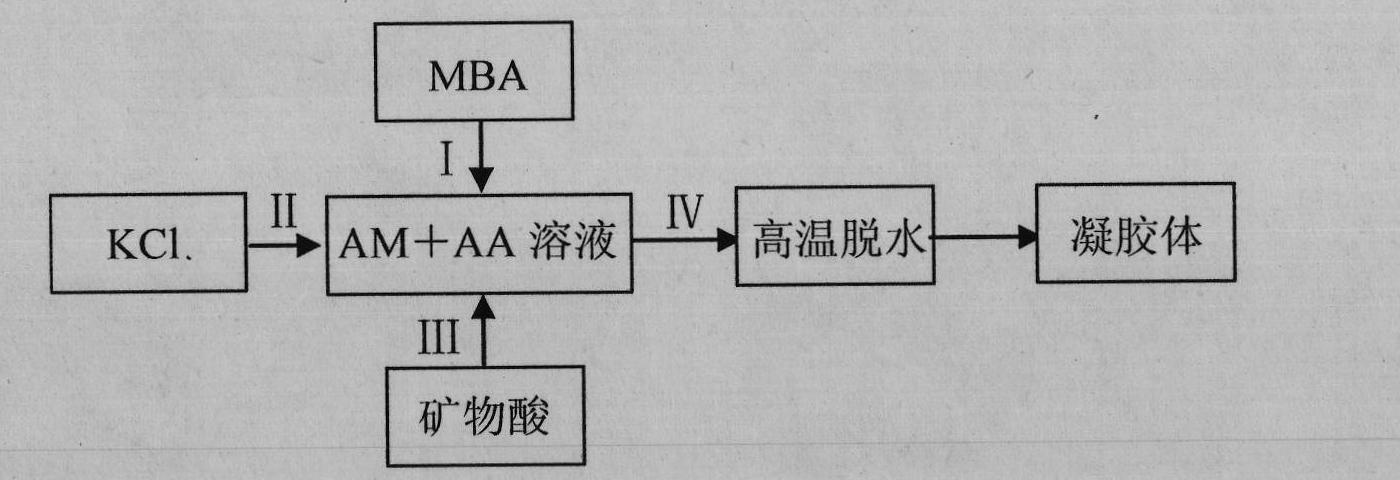

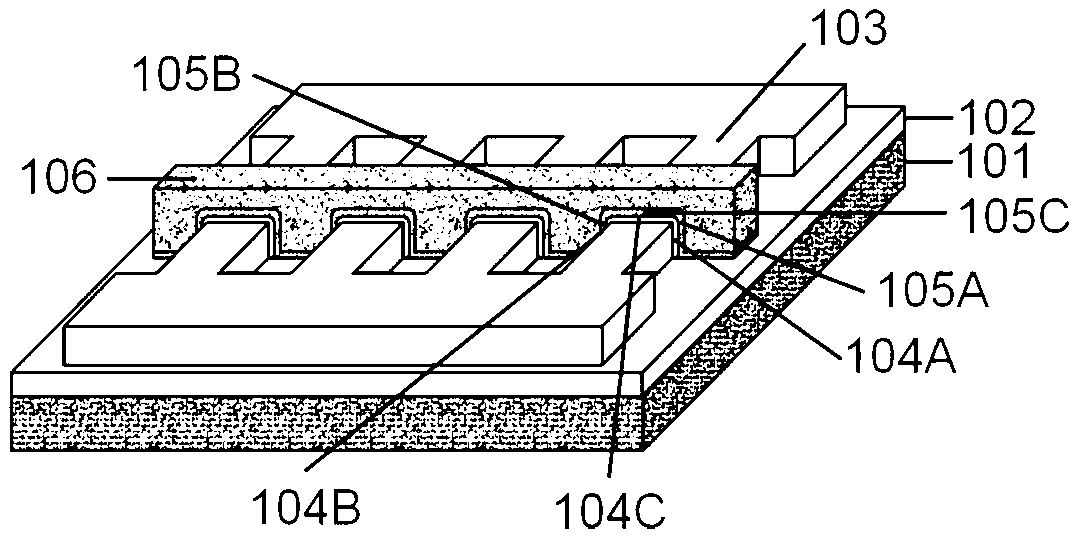

Method for preparing all-solid-state reference electrode (RE) based on EB-PVD (electron beam physical vapor deposition) and Sol-Gel

InactiveCN102087241AEnsure consistencyImprove microstructureMaterial electrochemical variablesElectrode potentialElectron beam physical vapor deposition

The invention provides a method for preparing an all-solid-state reference electrode (RE) based on EB-PVD (electron beam physical vapor deposition) and Sol-Gel. The method is characterized by depositing an Mo / Ta binary alloy thin film on a Ti substrate by adopting the EB-PVD technology satisfying large-scale industrial production, carrying out post-oxidation treatment on the thin film in the preparation state by controlling O2 atmosphere to form a mixed metal oxide layer (MMO) and ensuring a binary alloy film layer to have the function of the RE; and taking acrylamide and acrylic acid as carriers to prepare a Sol-Gel composite material conductive function layer which maintains stable electrode potential; and integrating the prepared RE function layer and the conductive layer to construct the all-solid-state RE with five layers. The method has the following beneficial effects: the EB-PVD rate is higher and hundreds of microns of function layer thin film can be deposited in 10-30 minutes, thus greatly reducing the preparation time; and the thin film in the preparation state is treated by the post-oxidation process so that the thin film has the gradient state from the unoxidized state to the complete oxidation state, thus ensuring the effectiveness of the electrochemical property.

Owner:HARBIN INST OF TECH

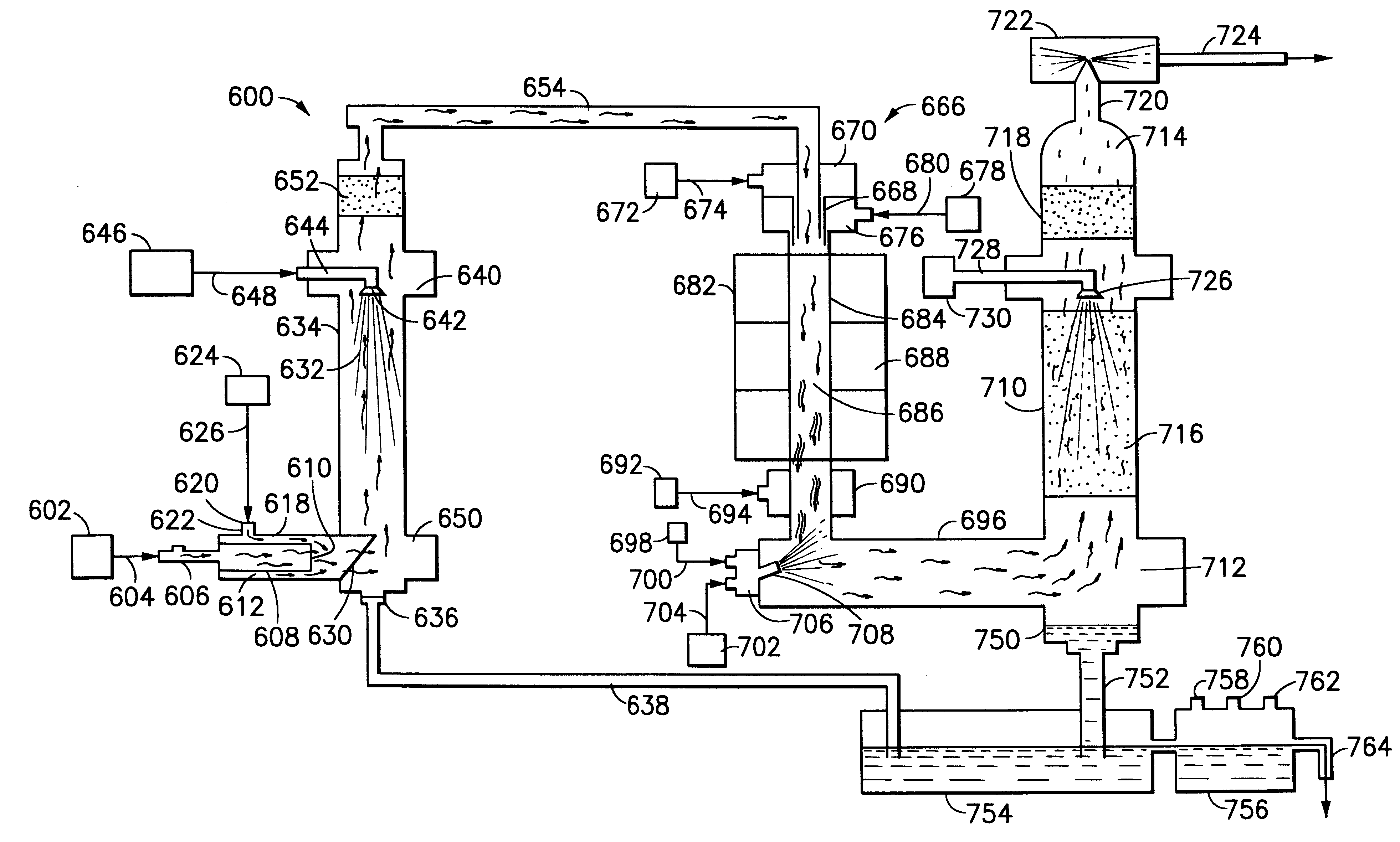

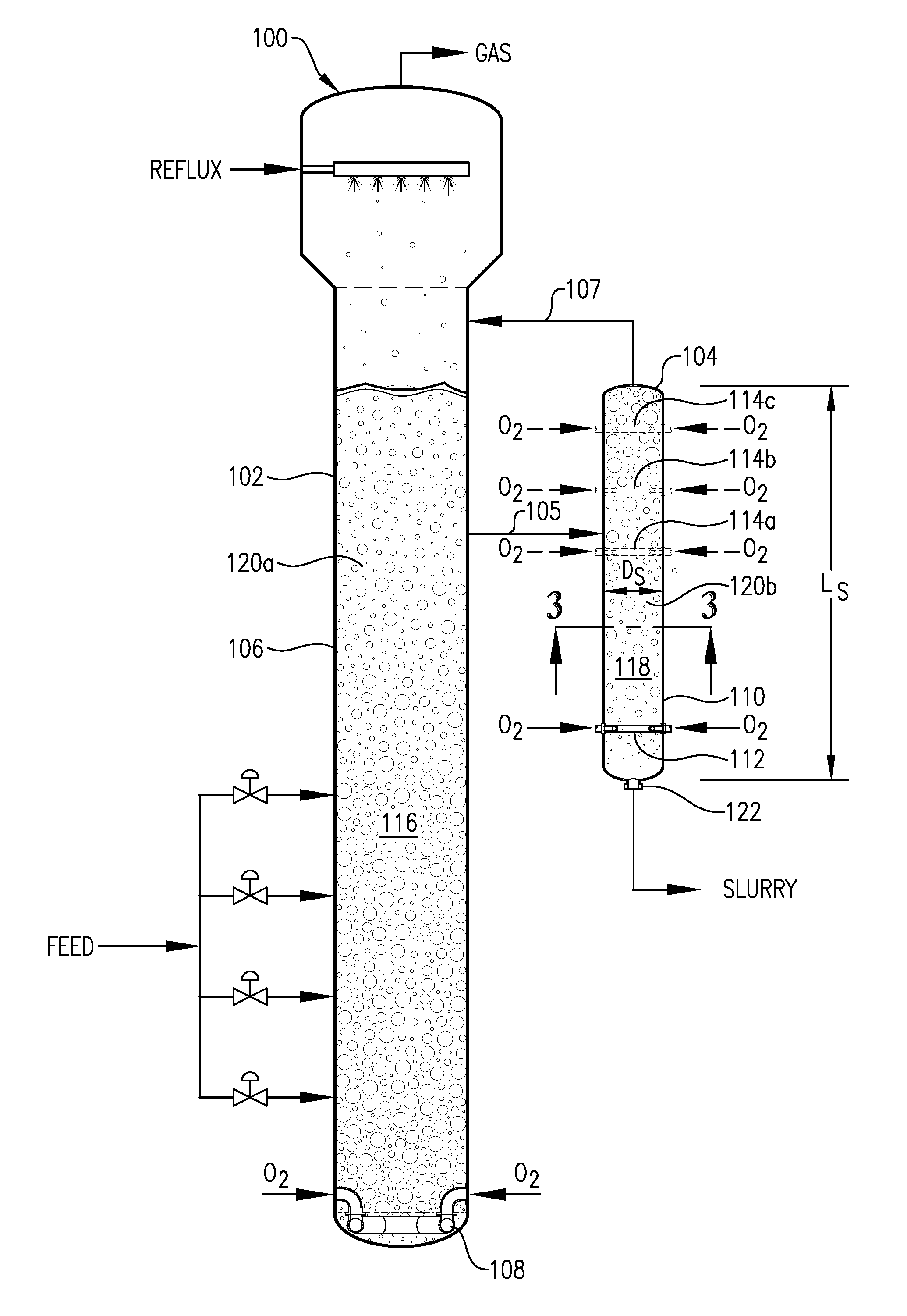

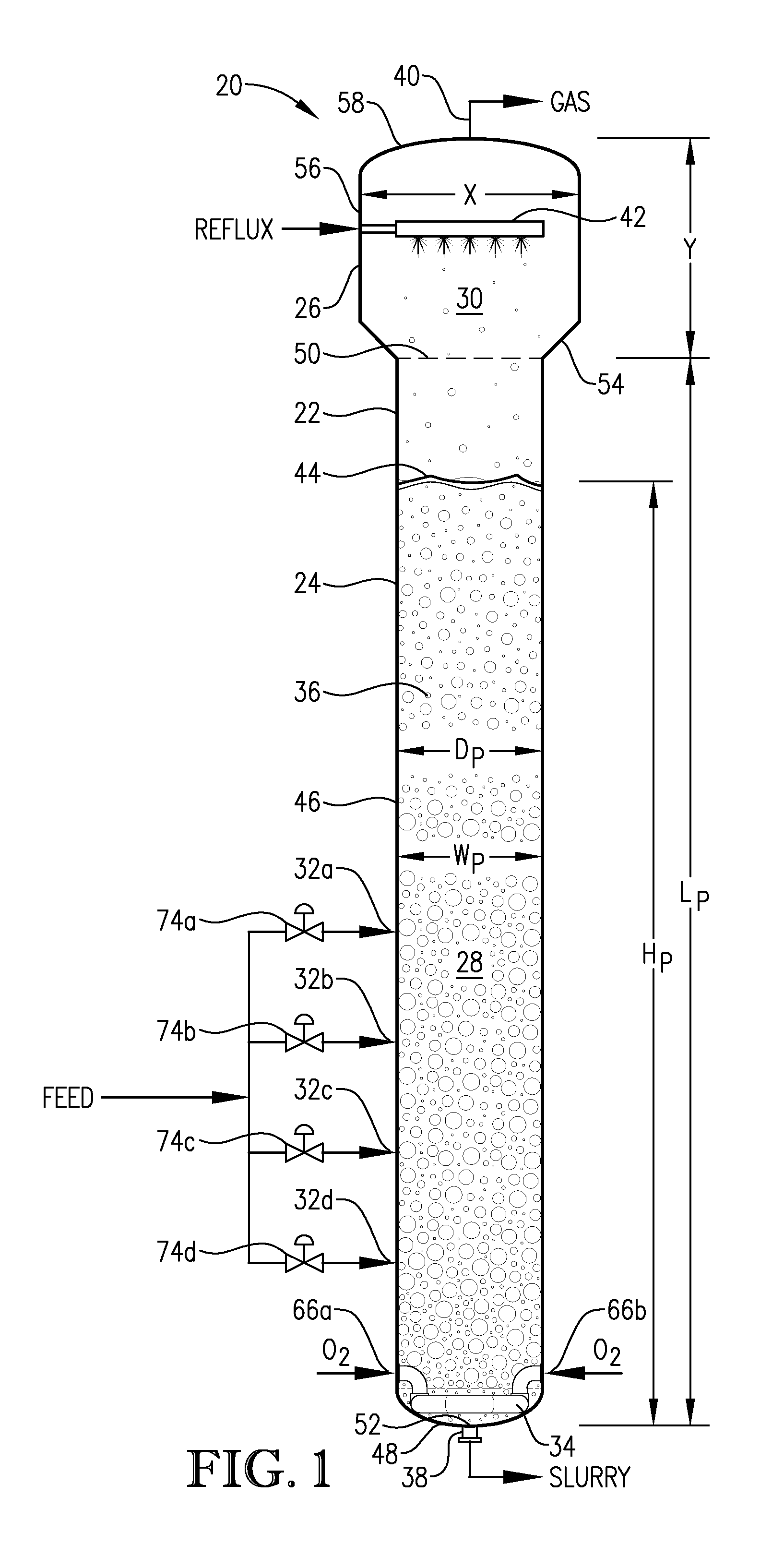

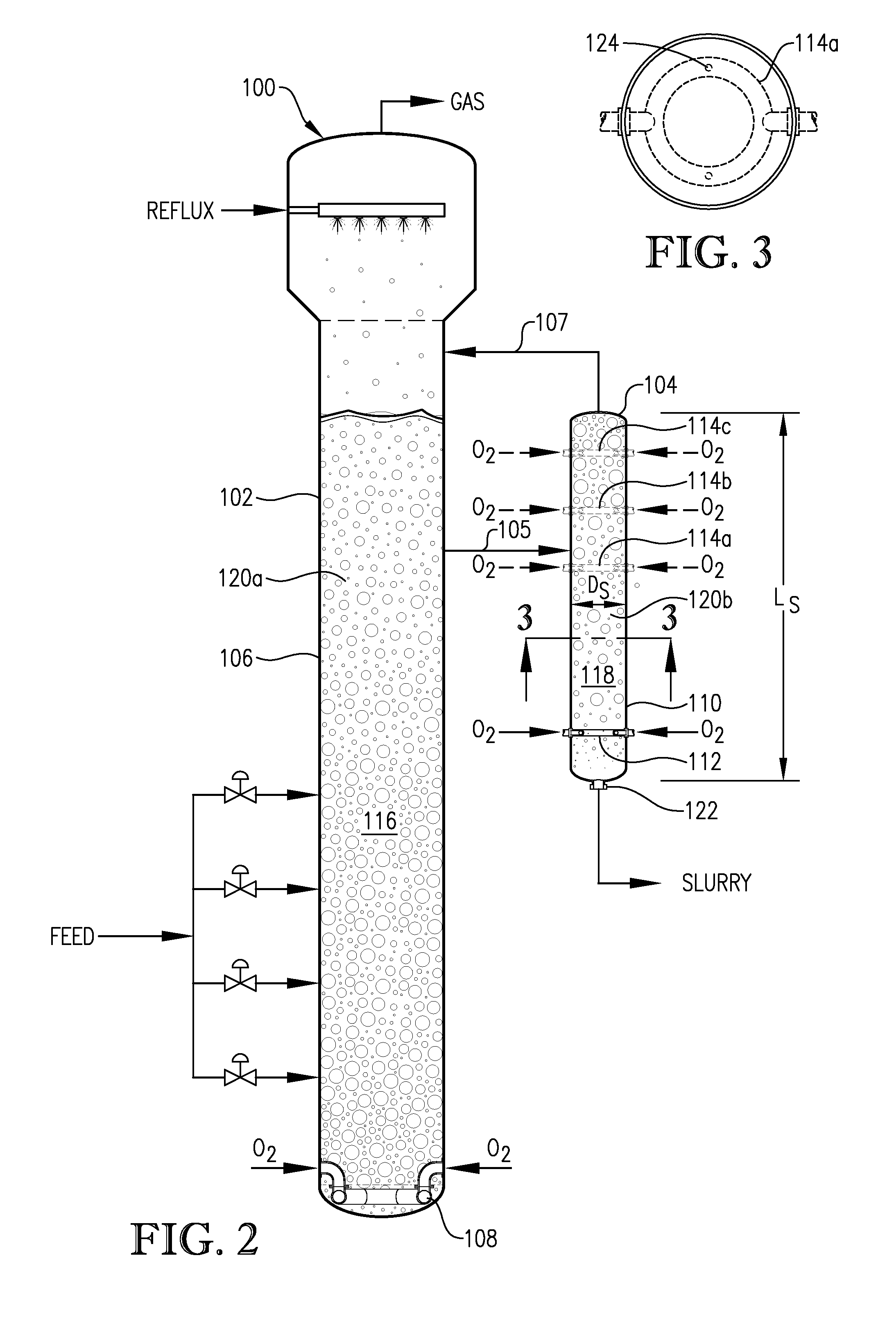

Oxidation system with sidedraw secondary reactor

Disclosed are process and apparatus for vertical splitting of the oxygen supply to a post-oxidation reactor. Further disclosed are process and apparatus for supplying reaction medium to a post-oxidation reactor at a mid-level inlet. Such apparatus and process can assist in reducing oxygen pinch throughout the post-oxidation reactor.

Owner:GRUPO PETROTEMEX DE C V

Perovskite solar cell based on pre-oxidation composite hole transport layer and preparation method thereof

InactiveCN110265552AAvoid degradationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellHole transport layer

The invention discloses a perovskite solar cell based on a pre-oxidation composite hole transport layer and a preparation method thereof.An electron transport layer, a perovskite light absorbing layer, a composite hole transport layer and a top electrode are prepared on a transparent conductive substrate in turn. The specific process of preparing the composite hole transport layer is as follows: a Spiro-OMeTAD solution oxidized by piping oxygen and an organic hole transport material solution without oxidation are mixed to prepare a precursor solution, and then the precursor solution is applied to the perovskite light absorbing layer to prepare the composite hole transport layer. The composite hole transport layer is subjected to the pre-solution oxidation process, so that that post-oxidation process of the hole transport layer thin film can be effectively replaced and the degradation of the perovskite light absorbing layer thin film can be suppressed; and the composite hole transport layer can further improve the hole transport capability, passivate the grain boundary and regulate the energy band so that the performance of the perovskite solar cell can be improved and the bottleneck of the current hole transport can be solved.

Owner:SOUTHWEST PETROLEUM UNIV

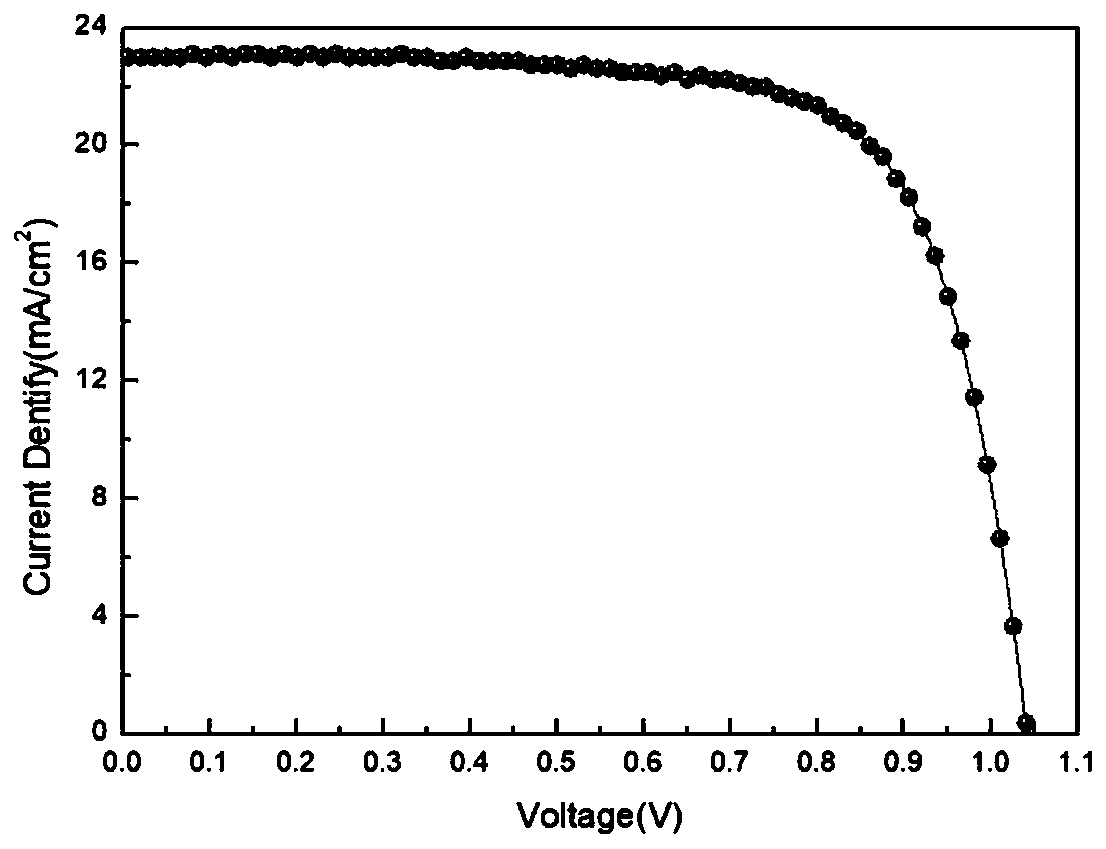

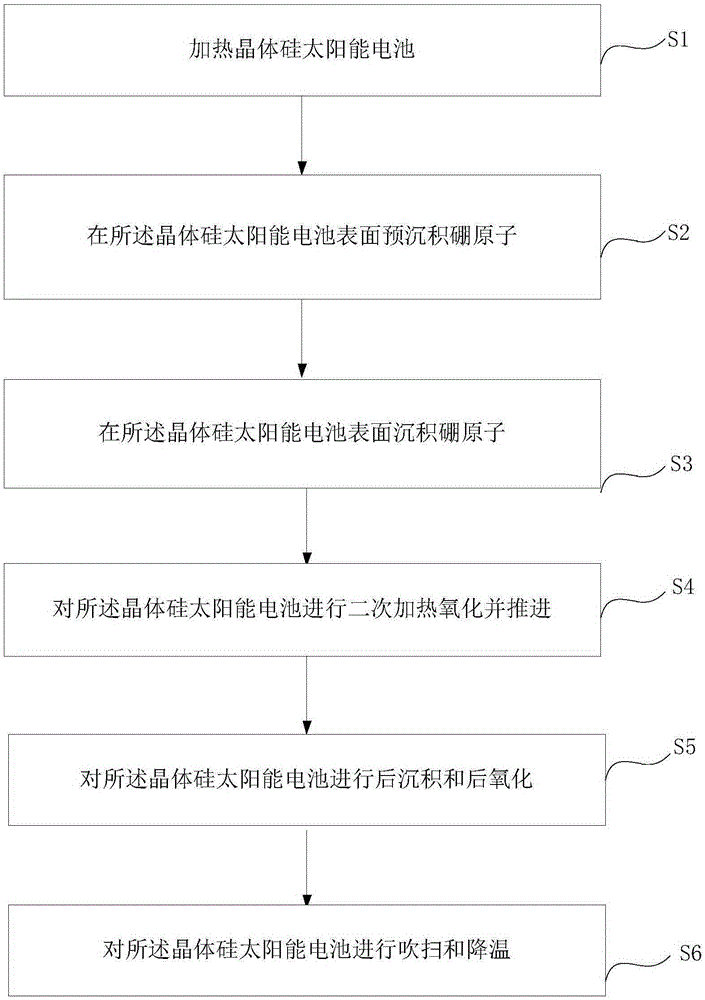

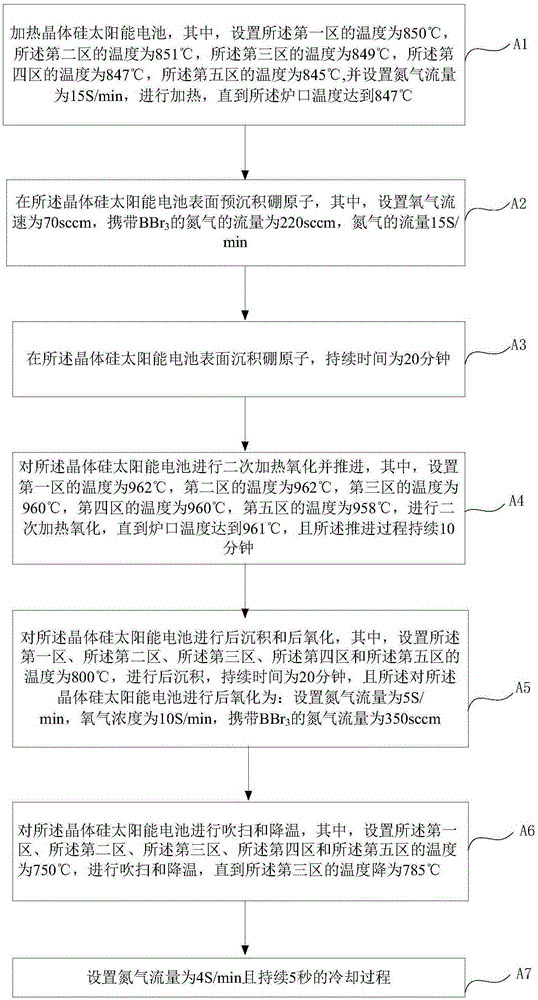

Method for boron diffusion of crystalline silicon solar cell

ActiveCN105355717AExtend your lifeImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPre depositionCrystalline silicon

The application discloses a method for boron diffusion of a crystalline silicon solar cell. The method comprises: a crystalline silicon solar cell is heated, boron atom pre deposition is carried out on the surface of the crystalline silicon solar cell; boron atom deposition is carried out on the surface of the crystalline silicon solar cell; secondary thermal oxidation and propelling are carried out on the crystalline silicon solar cell; post deposition and post oxidation are carried out on the crystalline silicon solar cell; and blowing and cooling are carried out on the crystalline silicon solar cell. According to the method provided by the application, the minority carrier lifetime can be prolonged and the cell efficiency can be improved on the premise of low cost.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Supercritical water oxidation apparatus and process

ActiveUS7682514B2Pressurized chemical processSludge treatmentContinuous flowSupercritical water oxidation

A method for oxidizing an organic material includes the steps of (a) forming a preoxidation mixture comprising the organic material and water, and (b) causing the preoxidation mixture to react with a liquid oxidizer in a continuous flow reactor supercritical conditions for water, including a pressure of at least 3206 psia and a temperature of at least 705° F., to form a post-oxidation mixture containing condensible material and non-condensible material, wherein substantially all of the organic material has been oxidized.

Owner:PARSONS CORPROATION

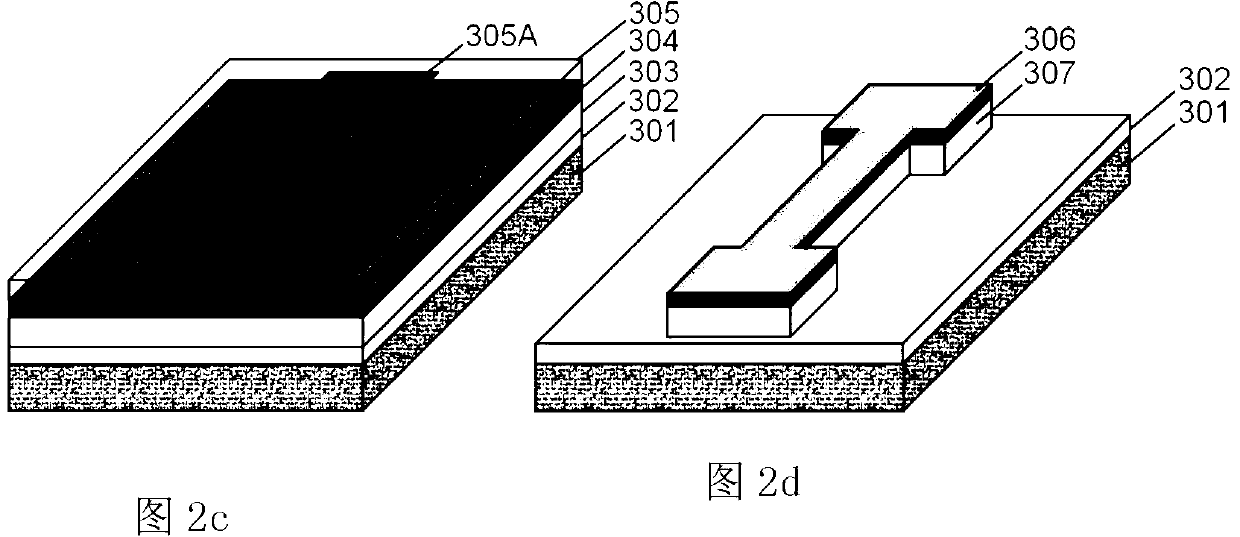

Germanium (Ge) base tri-gate device and manufacturing method thereof

InactiveCN103219381AGood insulation propertiesExcellent electrical propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessOptoelectronics

The invention provides a germanium (Ge) base tri-gate device and a manufacturing method thereof. The Ge base tri-gate device mainly comprises four functional layers including a germanium (GOI) substrate on an insulating layer, a germanium oxide transition layer, a grid electrode dielectric layer and a gate electrode layer. The high-quality and ultrathin germanium oxide transition layer achieved after ozone post-oxidation process and the high-quality grid electrode dielectric layer improved after the ozone post-oxidation are key layers to achieve high performance. The step of removing Ge, with poor quality (large surface roughness and high impurity content), on the surface of a Ge body through sacrificial oxidation process is a key step to achieve the high performance. The manufacturing process mainly comprises the step of depositing and etching on the germanium (GOI) substrate on the insulating layer to form the functional layers. According to the Ge base tri-gate device, efficiency is high, power consumption is low, the manufacturing method is simple, and the device is suitable for being widely used to actual production.

Owner:NANJING UNIV +1

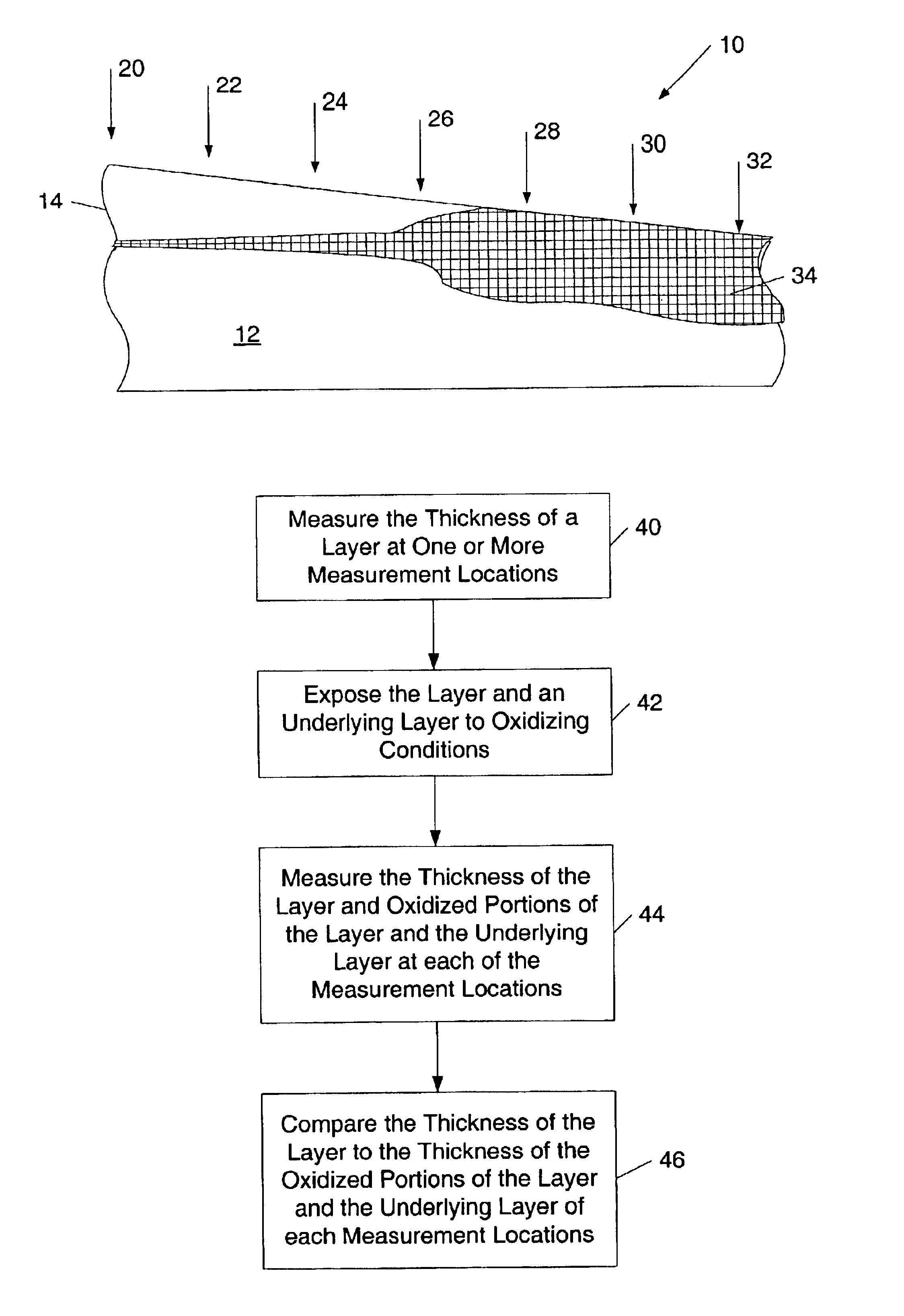

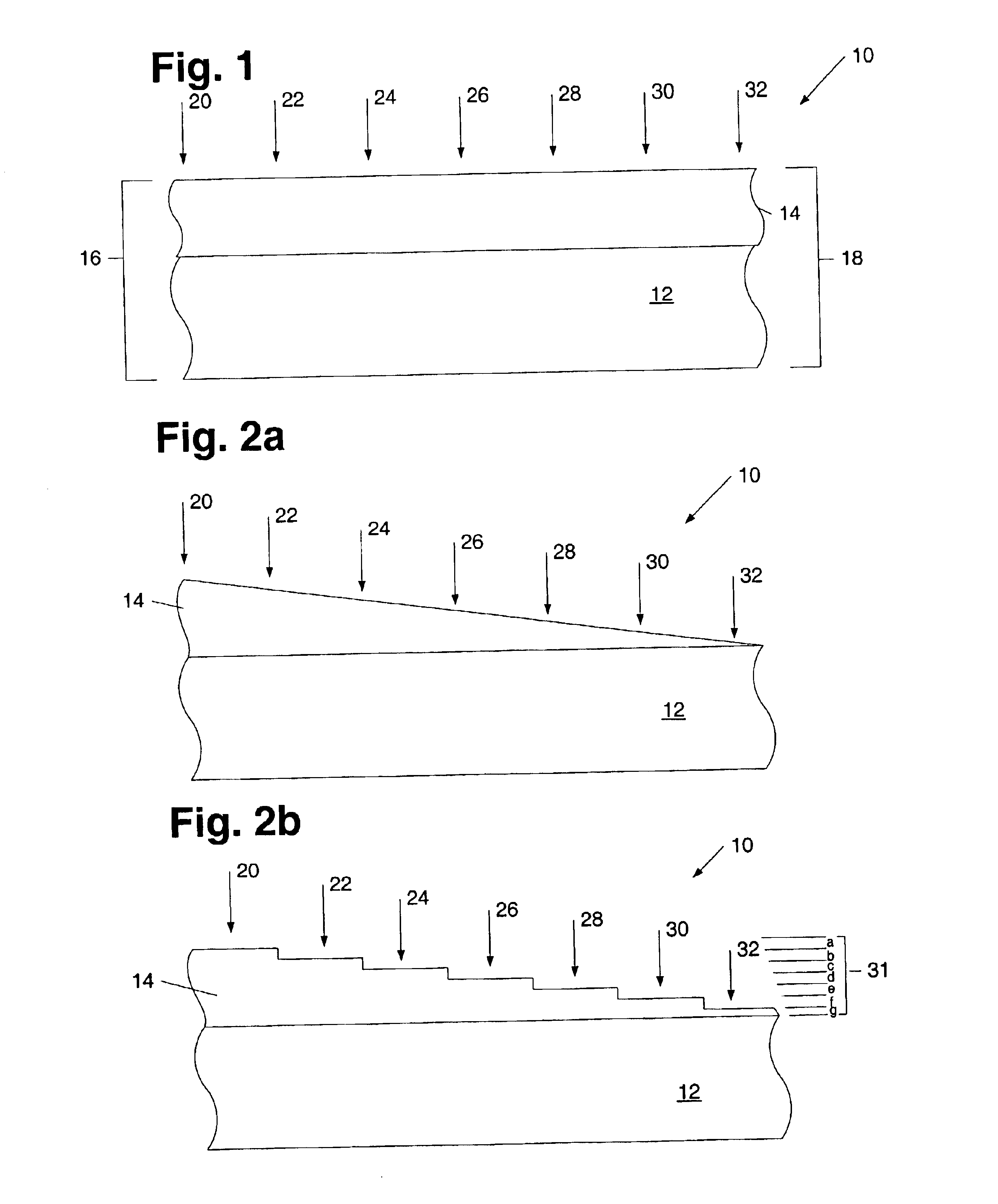

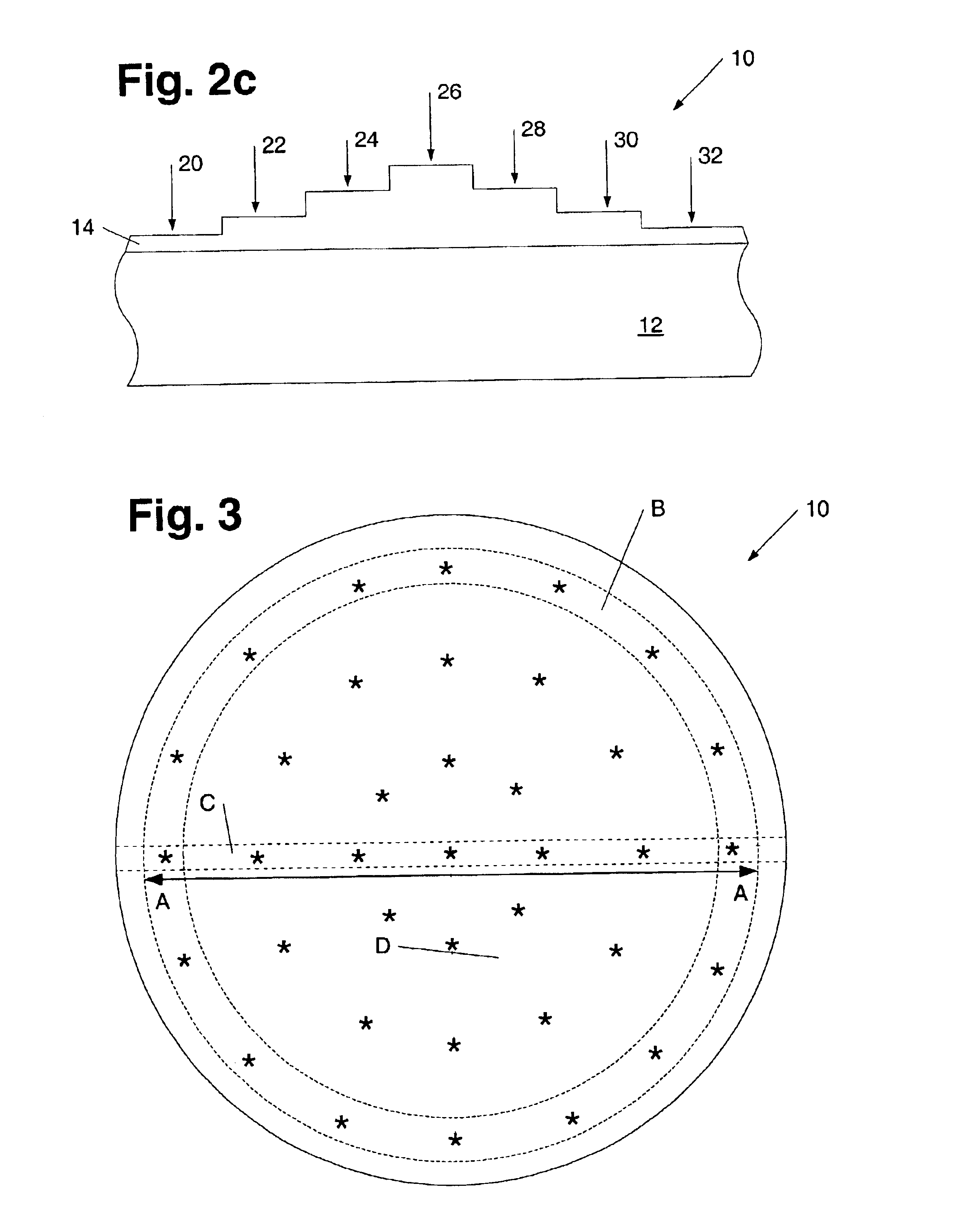

Method and structure for determining a concentration profile of an impurity within a semiconductor layer

InactiveUS6905893B1Increase productivityReduce manufacturing costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDielectricTopography

A method is provided for determining a concentration profile of an impurity within a layer of a semiconductor topography. The method may include exposing the layer and an underlying layer to oxidizing conditions. In addition, the method may include comparing thickness measurements of total dielectric above the underlying layer taken before and after exposing the topography to oxidizing conditions . In some cases, the comparison may include plotting pre-oxidation thickness measurements versus post-oxidation measurements. In other embodiments, the comparison may include determining differences between the pre-oxidation and post-oxidation thickness measurements and correlating the differences to concentrations of the impurity. In some cases, such a correlation may include subtracting a concentration of the impurity at a first location along the semiconductor topography from a concentration of the impurity at a second location along the semiconductor topography.

Owner:MONTEREY RES LLC

Oxidation process to produce a purified carboxylic acid product via solvent displacement and post oxidation

Disclosed is a process to produce a dry purified carboxylic acid product comprising furan-2,5-dicarboxylic acid (FDCA). The process comprises oxidizing at least one oxidizable compound to generate a crude carboxylic acid slurry comprising FDCA, removing impurities from a crude carboxylic acid slurry in a liquid displacement zone to form a low impurity slurry stream. The low impurity slurry stream is further treated in a secondary oxidation zone to produce a secondary oxidation slurry stream which is routed to a crystallization zone to form a crystallized slurry stream. The crystallized slurry stream is cooled in a cooling zone and the resulting cooled crystallized slurry stream is routed to a solid-liquid separation zone to generate a purified wet cake stream comprising FDCA that is dried in a drying zone to generate a dry carboxylic acid product stream comprising purified FDCA (pFDCA).

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com