Patents

Literature

120results about How to "Improve spectral response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

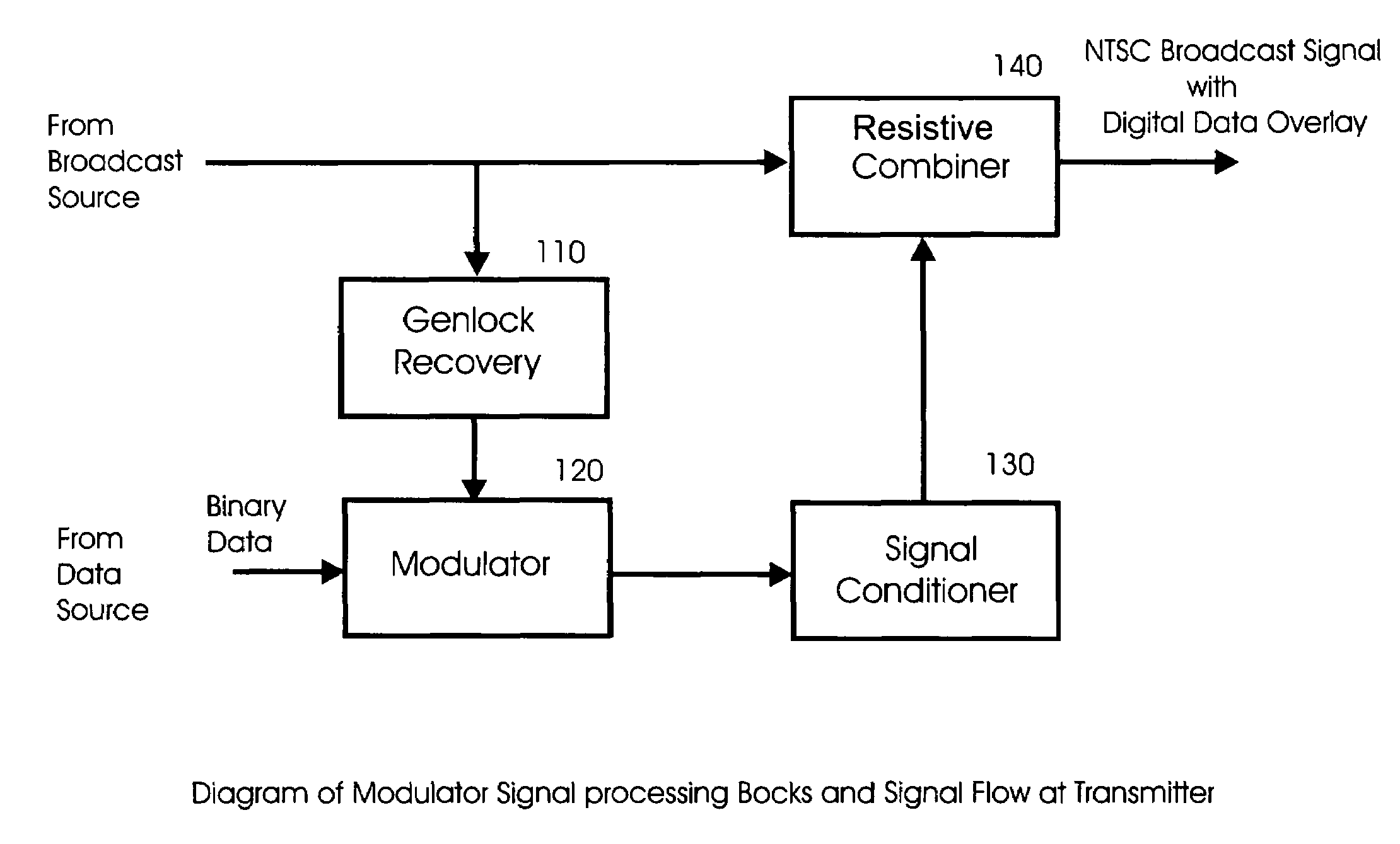

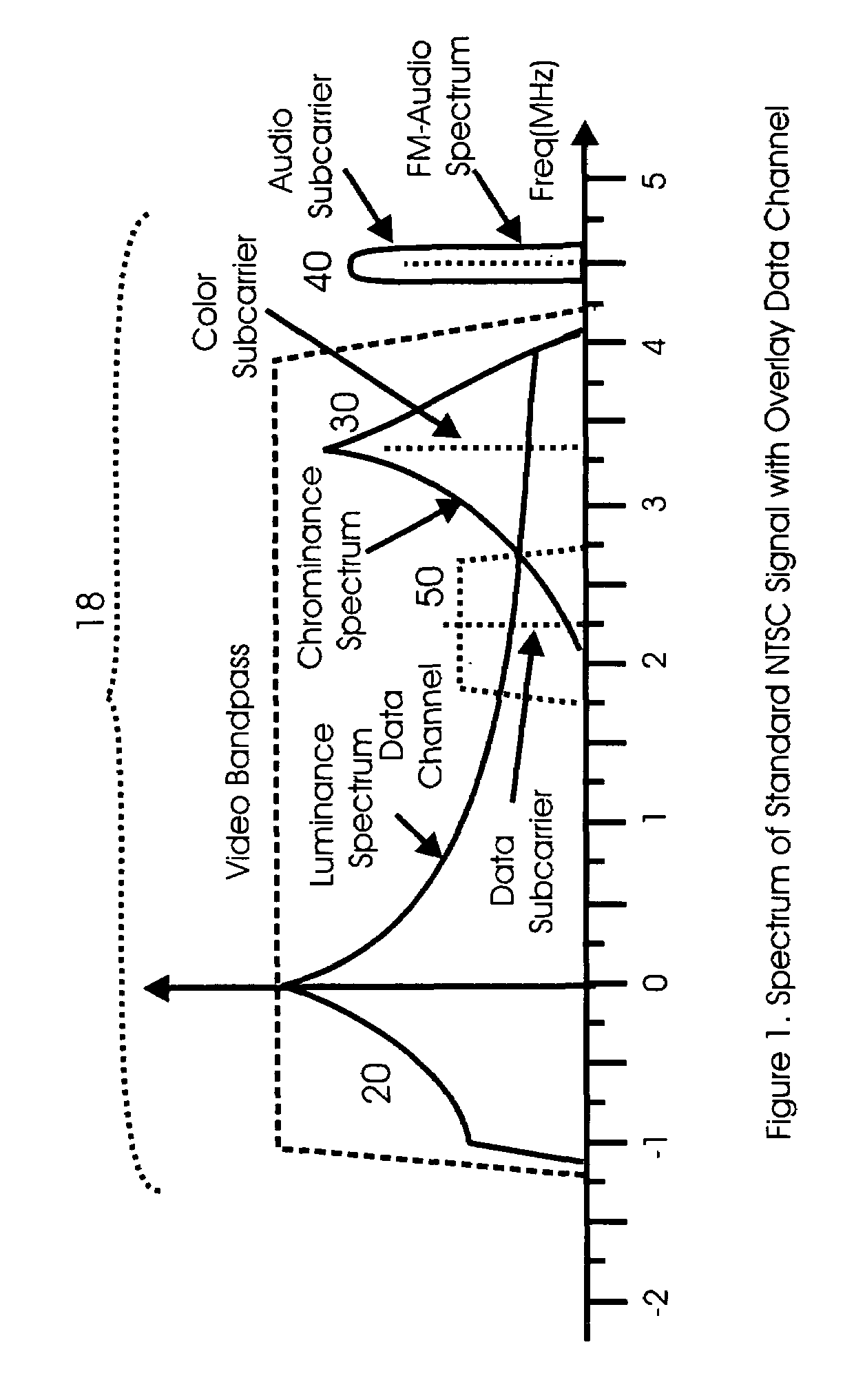

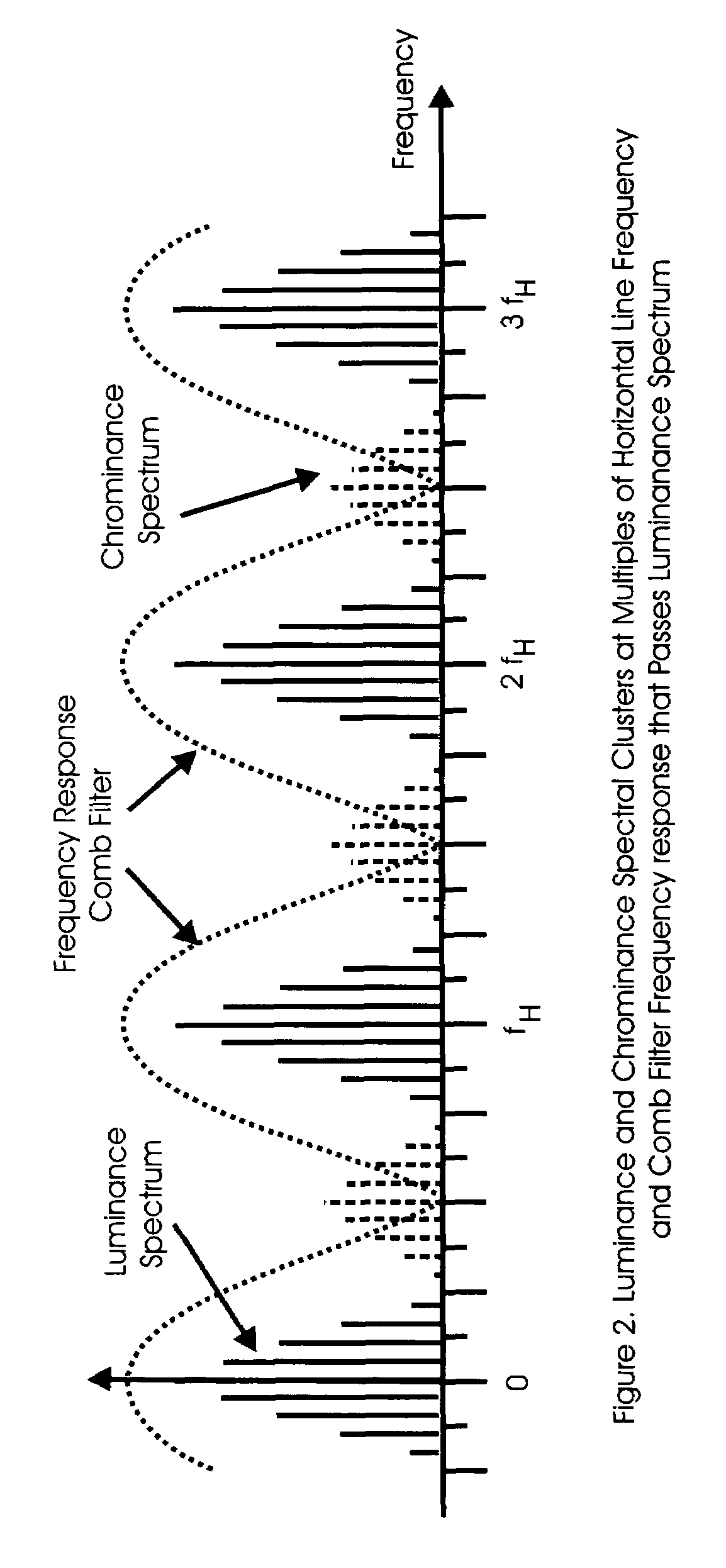

System and method for nondisruptively embedding an OFDM modulated data signal into a composite video signal

InactiveUS7071994B2Minimizes locally correlated temporal componentImprove spectral responsePlural information simultaneous broadcastSimultaneous/sequential multiple television signal transmissionIntermediate frequencyQuadrature amplitude modulation

A method and system for sending and receiving binary bit stream in a composite video signal, such as a NTSC signal. The binary bit stream is modulated according to quadrature amplitude modulation, converted to analog and translated to an intermediate frequency relative to the composite video signal and the associated sync pulses, and combined with the composite video signal. At reception of a composite video signal that includes the modulated bit stream, the sync pulses of the composite video signal are determined by extracting the composite video signal from the modulated bit stream. Also, the modulated bit stream is extracted from the composite video signal, separated into its component parts based on the sync pulses, and combined into a binary bit stream.

Owner:TELISAR CORP

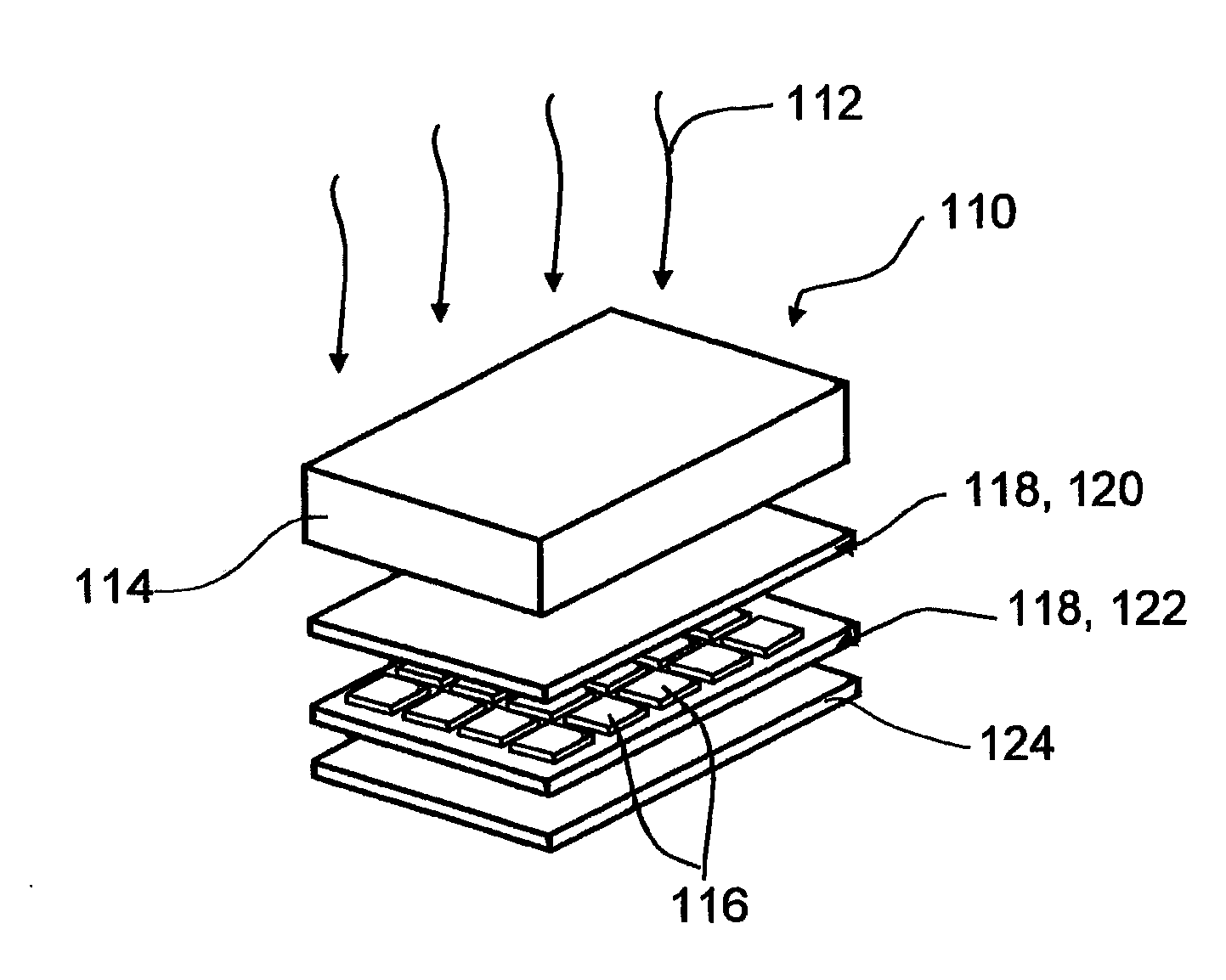

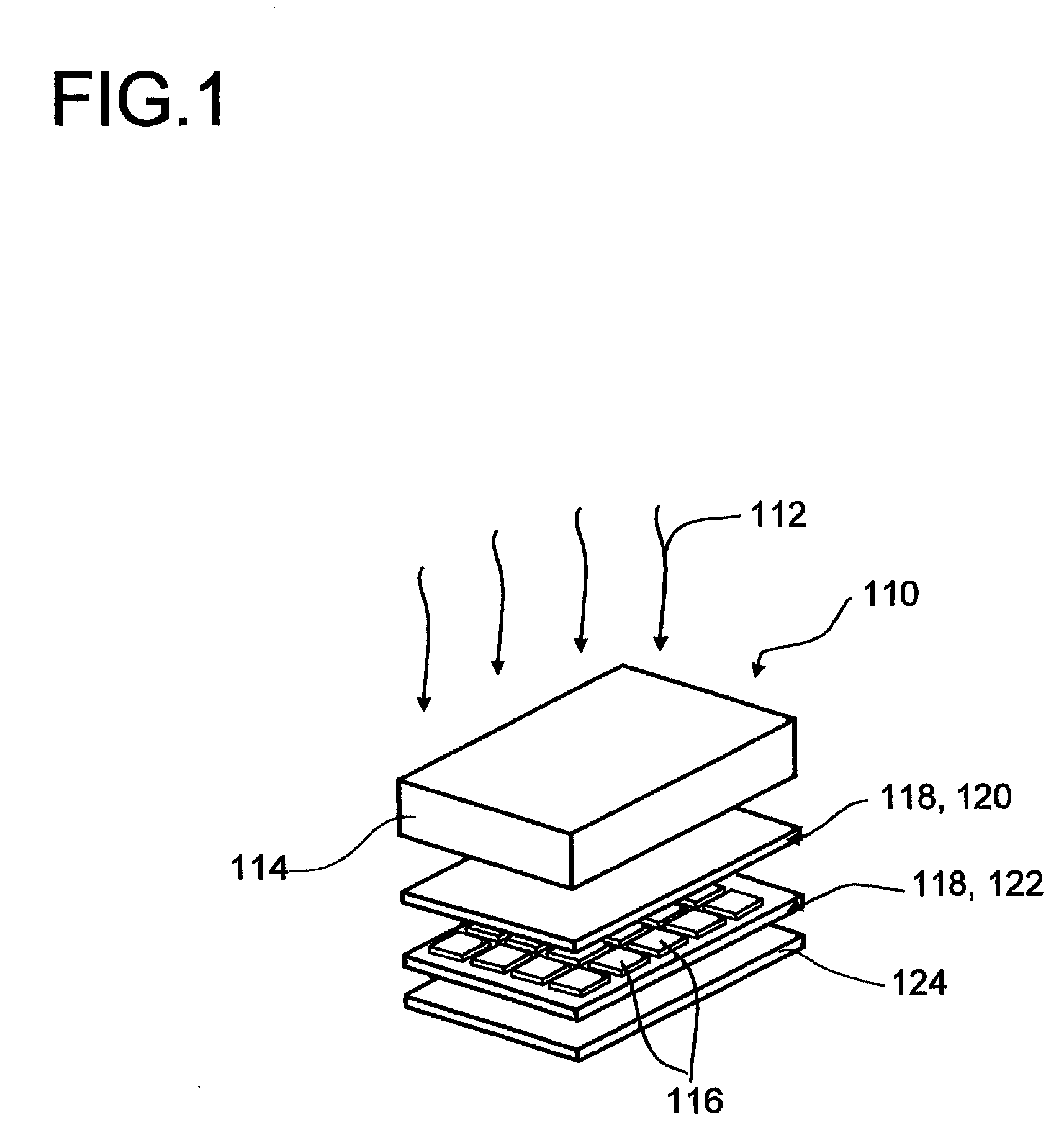

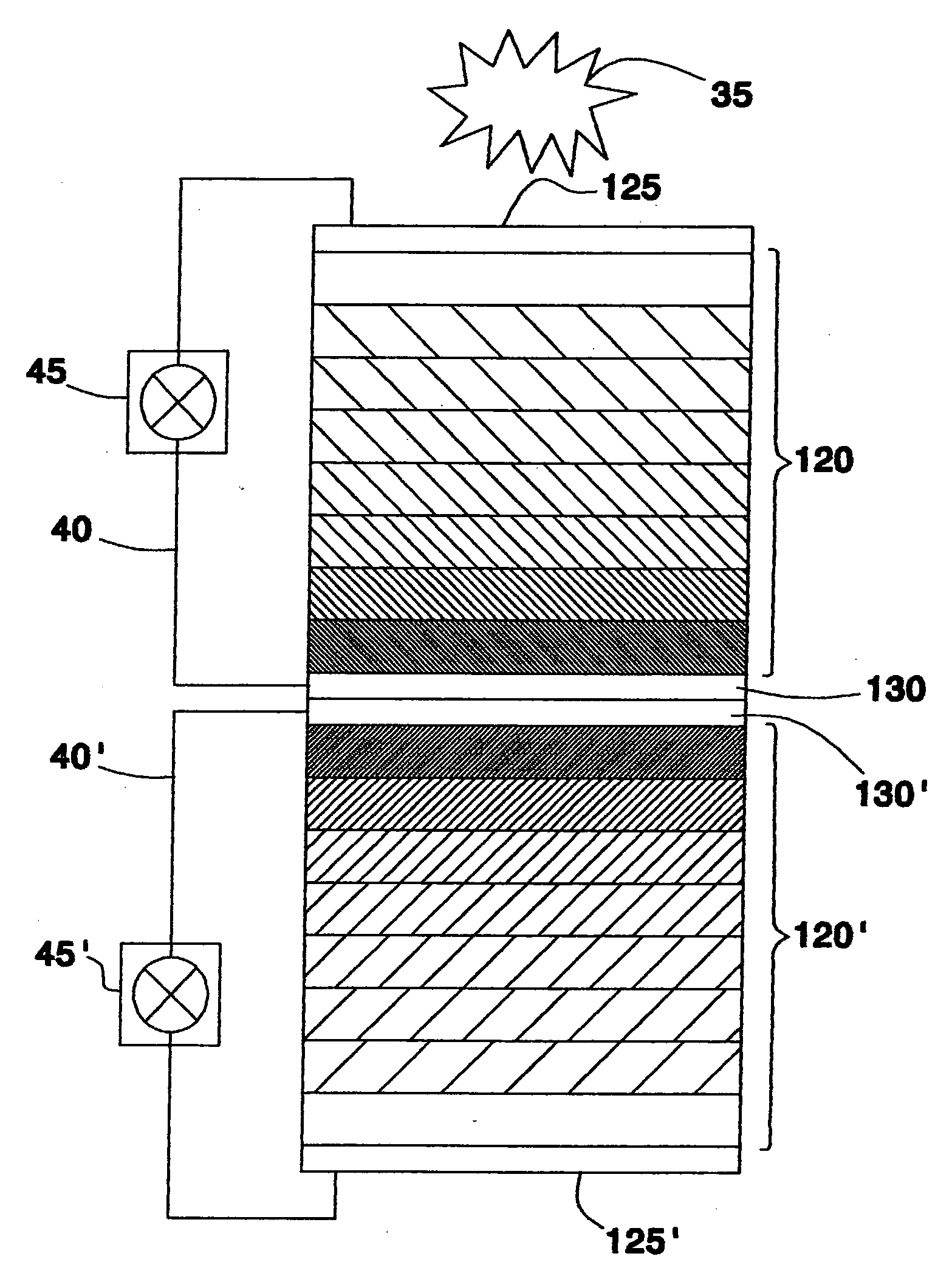

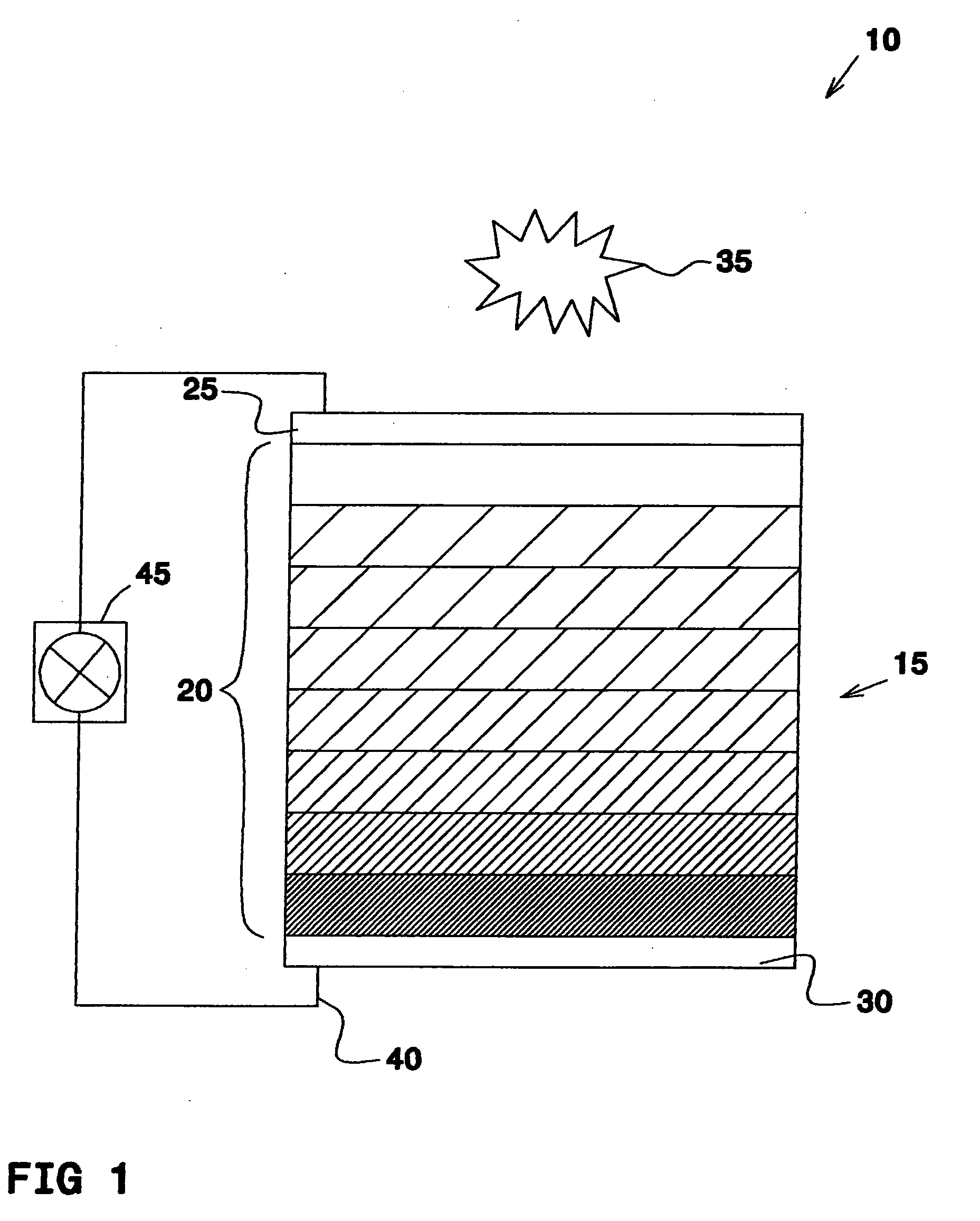

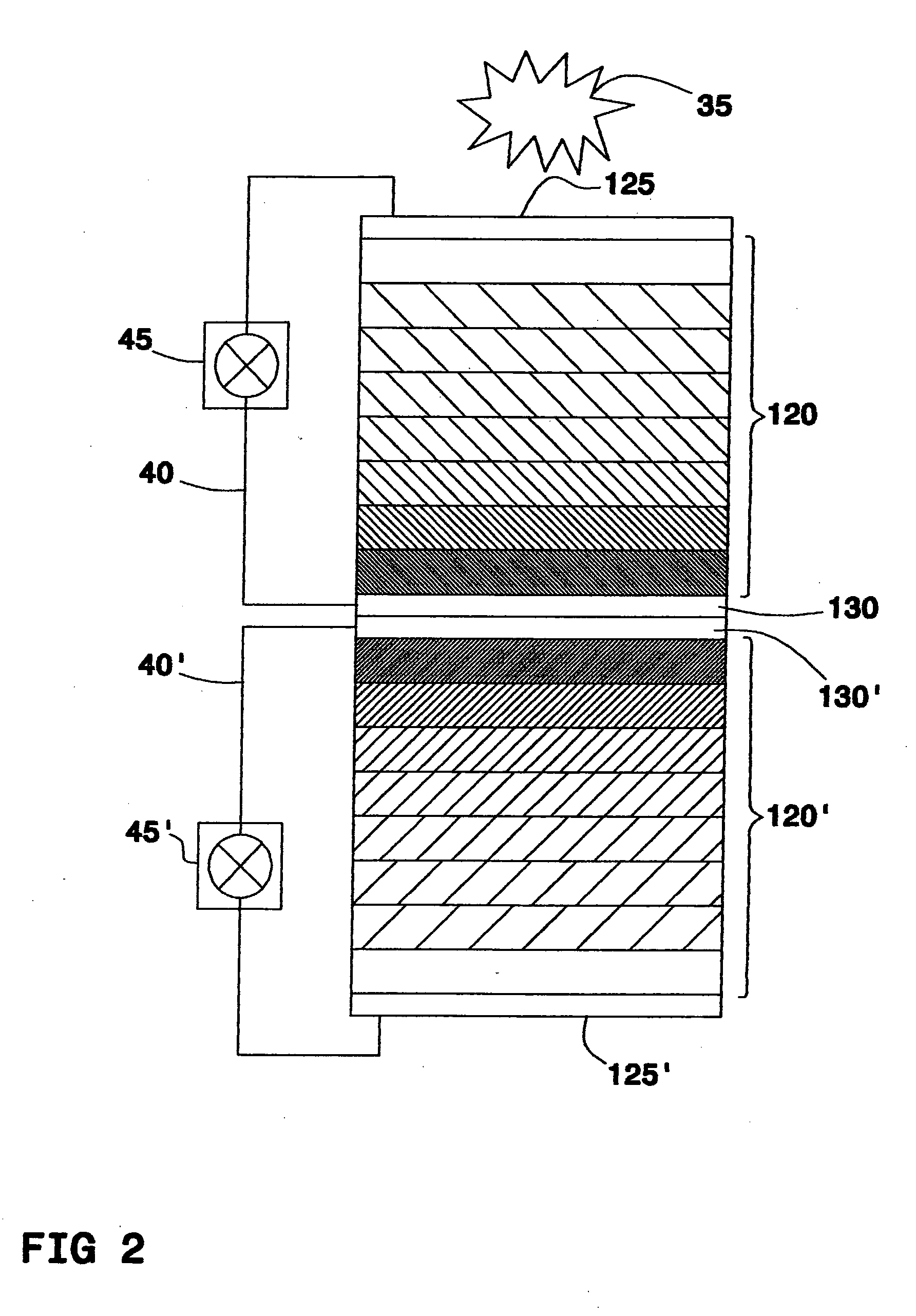

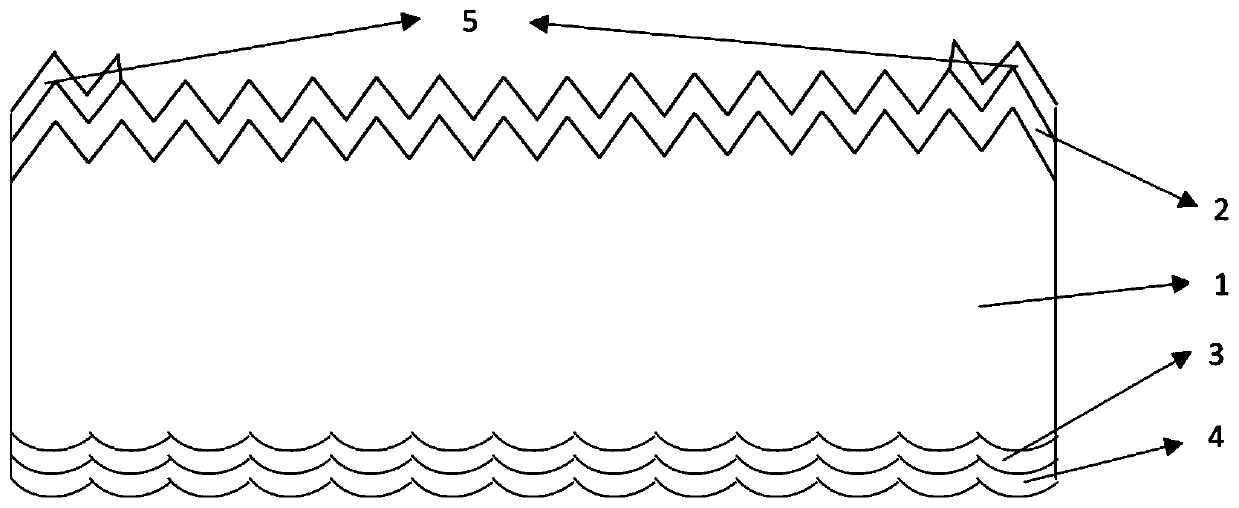

Photovoltaic modules with improved quantum efficiency

InactiveUS20100186801A1Improve quantum efficiencySuitable spectral responseSemiconductor/solid-state device manufacturingGlass/slag layered productsElectromagnetic radiationLuminescence

A photovoltaic module (110) is disclosed, which is suited for conversion of incident electromagnetic radiation (112) into electric energy. The photovoltaic module (110) comprises in order: a transparent cover sheet (114); and—at least one photovoltaic cell (116), wherein the at least one photovoltaic cell (116) is adapted to convert electromagnetic radiation (112) passing through the transparent cover sheet (114) into electric energy and wherein the photovoltaic cell (116) is accommodated within at least one encapsulation element (118) providing protection from environmental influence. The encapsulation element (118) comprises at least one luminescence downshifting material, which is adapted for at least partially absorbing the incident radiation (112) and for re-emitting radiation (112) at a longer wavelength.

Owner:BASF AG

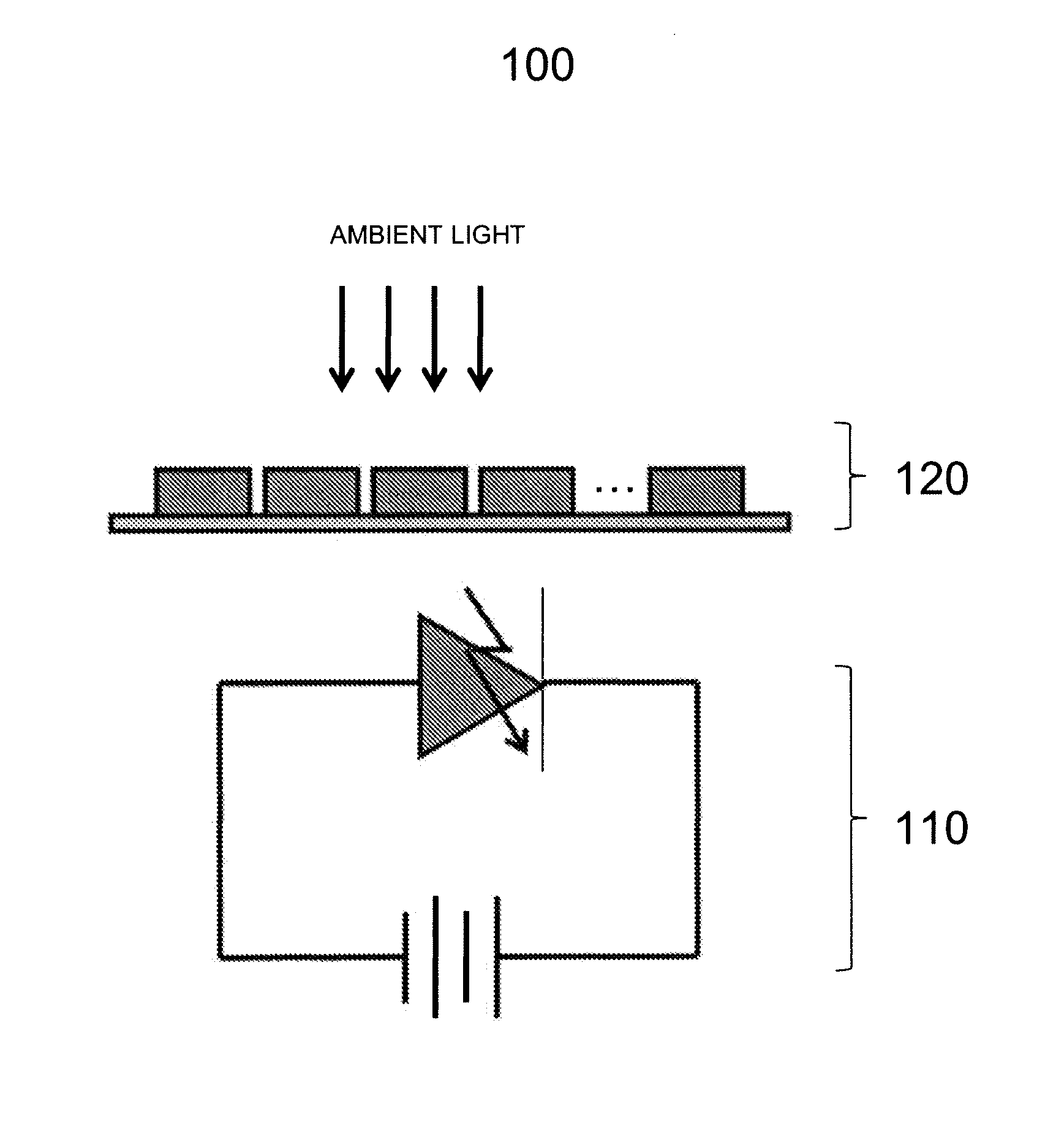

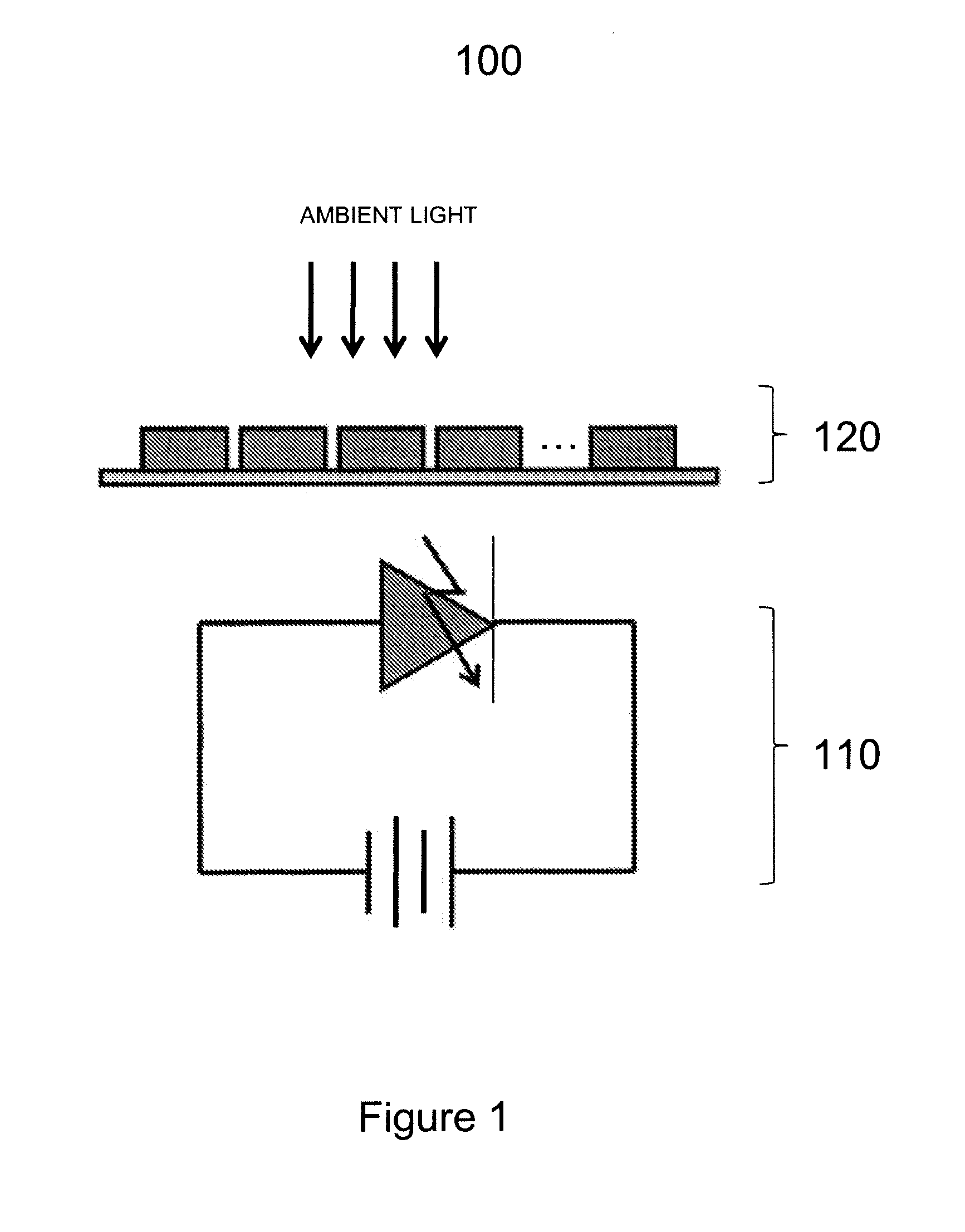

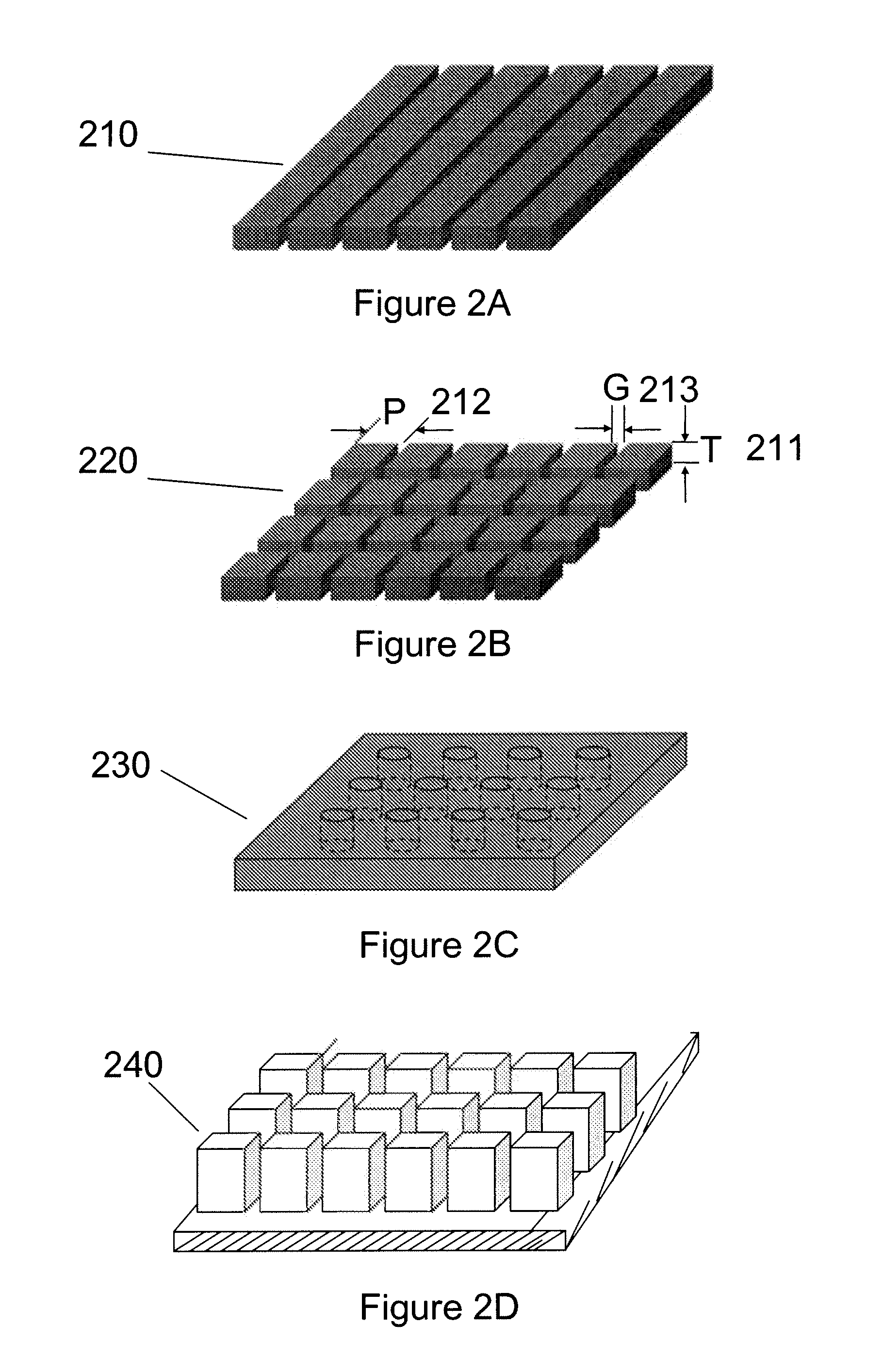

Multi-purpose plasmonic ambient light sensor and visual range proximity sensor

InactiveUS8330945B2Spectral response of the ambient light sensor is improvedPowerfulOptical filtersScattering properties measurementsLight sensingWavelength range

A visible wavelength range proximity sensor includes a visible light emitter with a peak wavelength in a visible wavelength range, and a plasmonic ambient light sensor, where a proximity sensing mode and an ambient light sensing mode are time multiplexed.

Owner:NANOLAMBDA

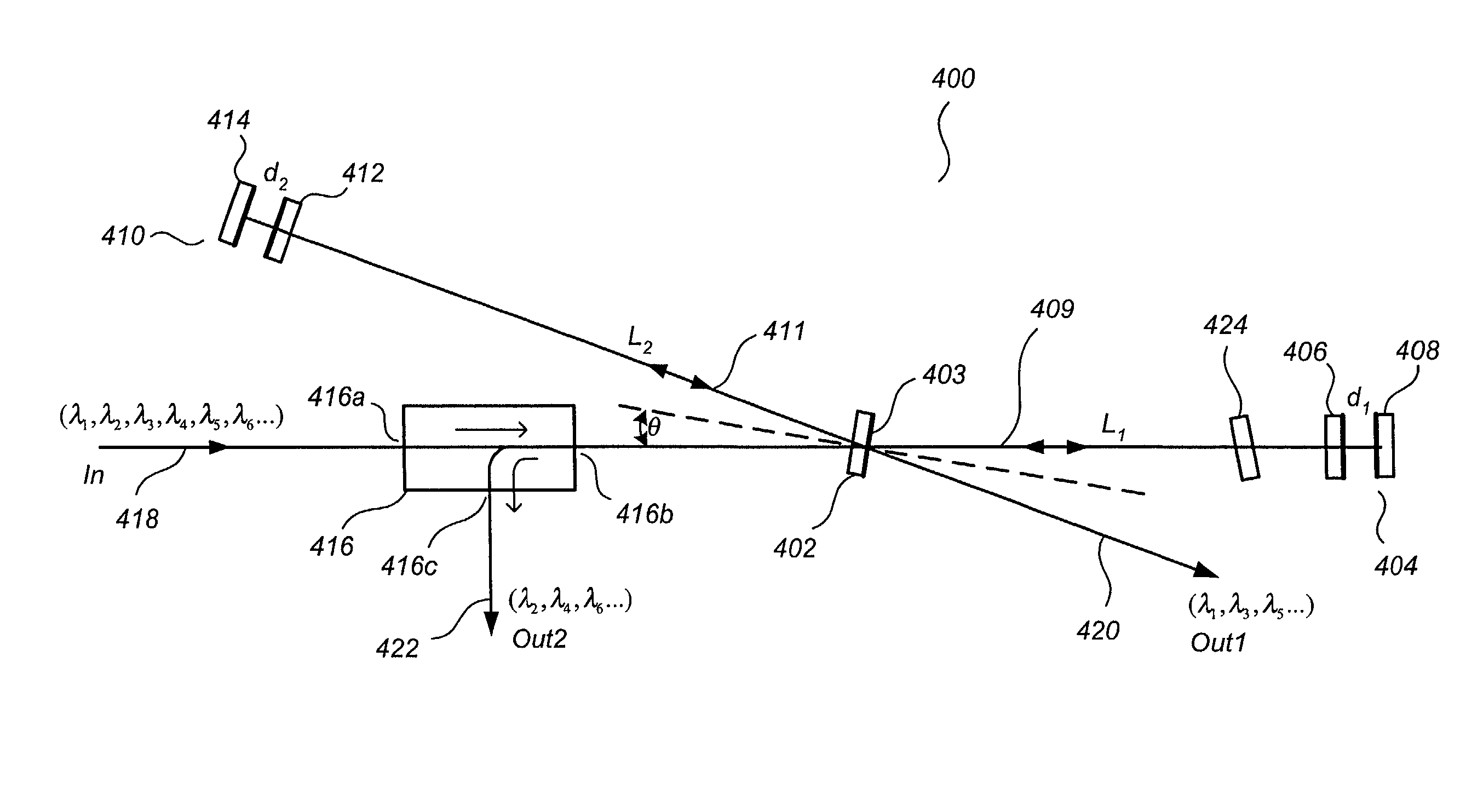

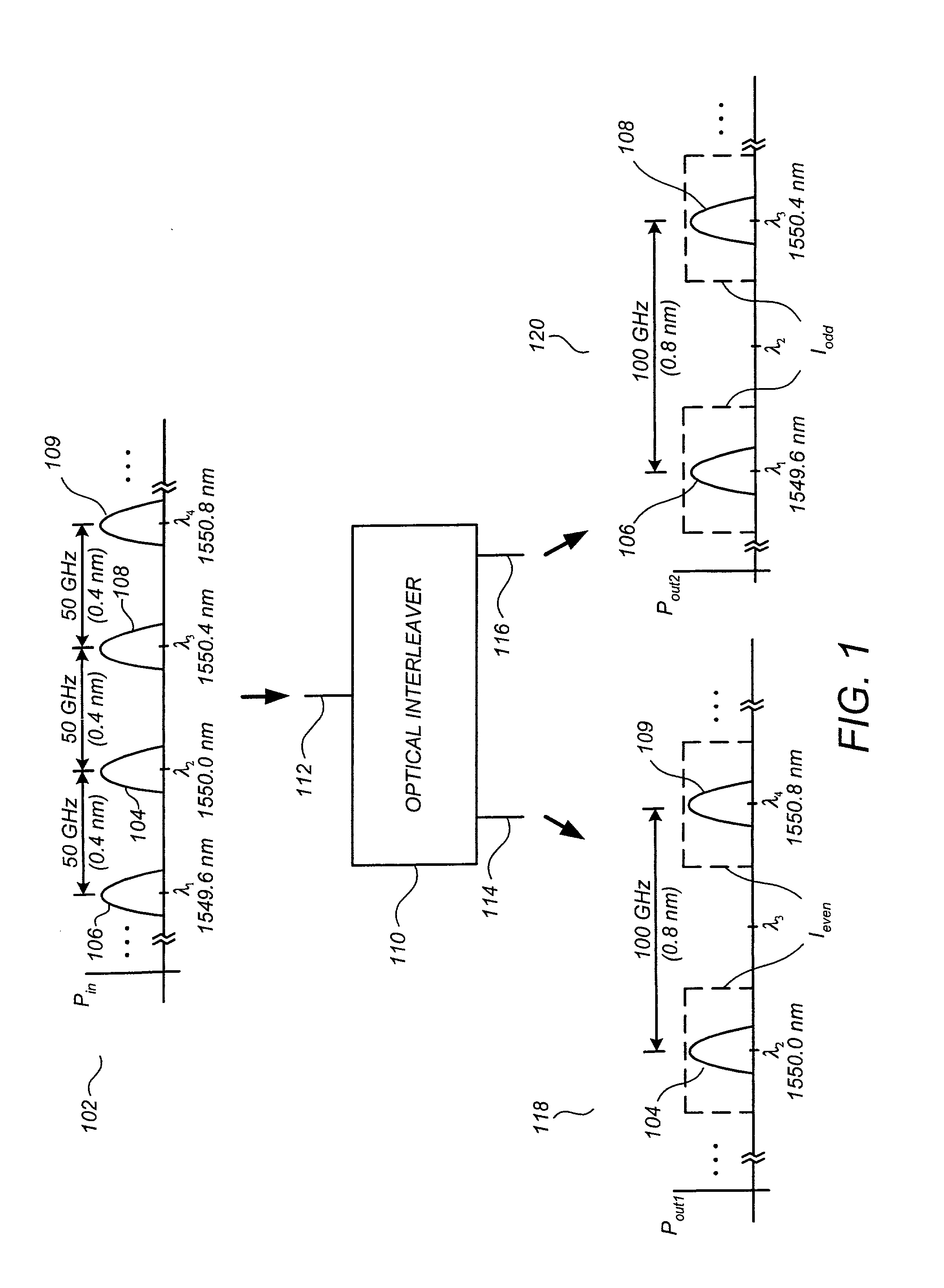

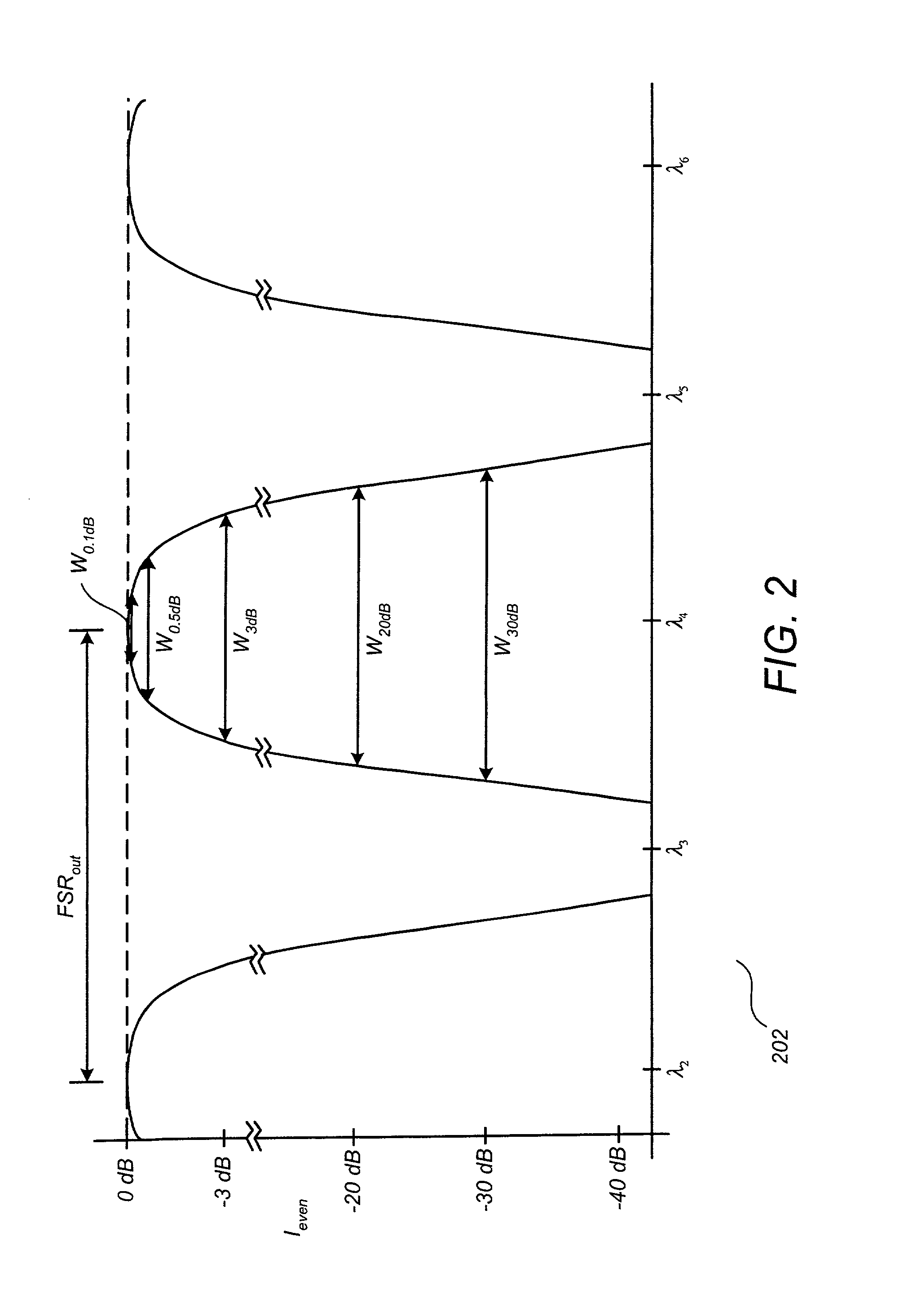

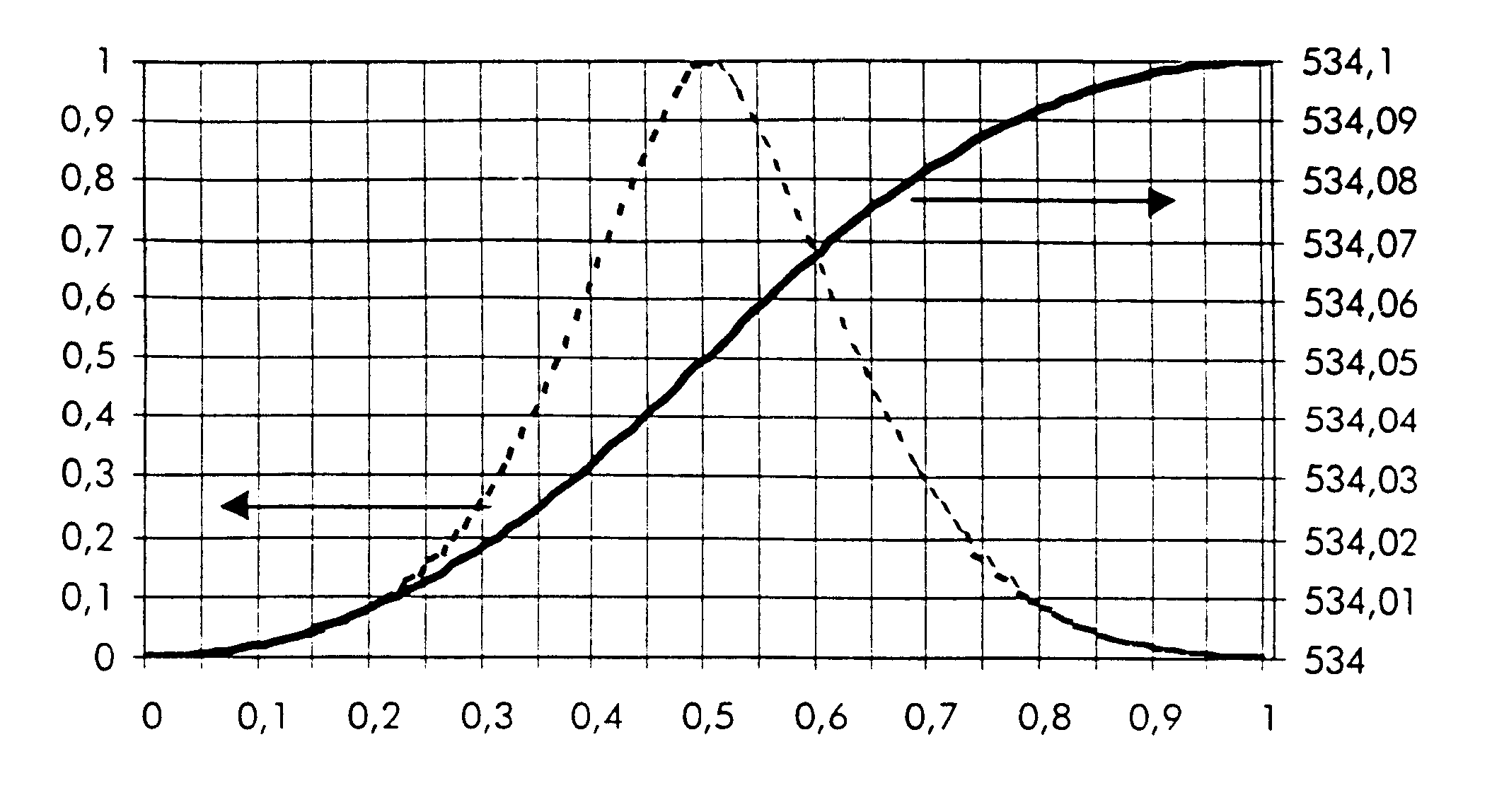

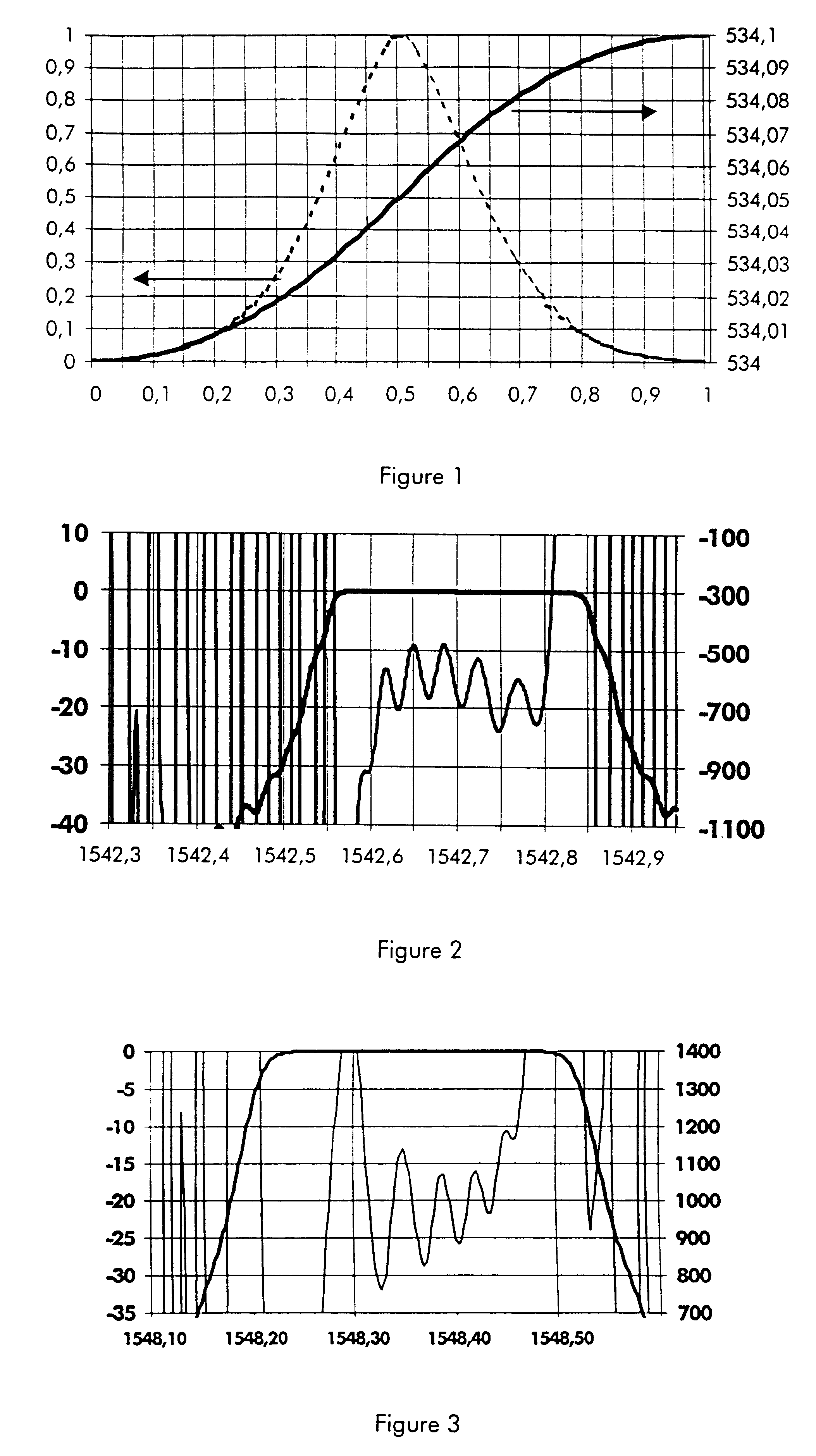

Optical interleaving with enhanced spectral response and reduced polarization sensitivity

InactiveUS20020126354A1Enhance thermal stabilityImprove spectral responseWavelength-division multiplex systemsPolarising elementsResonatorPartially reflective surface

An optical interleaver for receiving an incident beam carrying a wavelength-division-multiplexed (WDM) signal comprising a plurality of channels at center wavelengths .lambda..sub.1, .lambda..sub.2, .lambda..sub.3, .lambda..sub.4, .lambda..sub.5, .lambda..sub.6, . . . and generating therefrom at least one de-interleaved output signal comprising the odd channels .lambda..sub.1, .lambda..sub.3, .lambda..sub.5, . . . or the even channels .lambda..sub.2, .lambda..sub.4, .lambda..sub.6, . . . is described. The optical interleaver comprises a splitting element for splitting an incident beam into a first optical signal directed along a first path and a second optical signal directed along a second path, a first resonant element positioned along the first path, a second resonant element positioned along the second path, and a combining element positioned to receive and to interferometrically combine the outputs of the first and second resonant to produce the output signal. The optical interleaver may be implemented using a free-space configuration using a beamsplitter and a plurality of resonant cavities such as asymmetric Fabry-Perot resonators or Michelson-Gires-Tournois resonators. In an alternative preferred embodiment, the optical interleaver may be implemented in a Mach-Zender-style configuration using couplers and fiber ring resonators. According to a preferred embodiment in which the optical interleaver is in a free-space configuration, the splitting element that receives the incident beam comprises a partially reflective surface positioned such that a normal to the reflective surface is at a less-than-30 degree angle with respect to the incoming beam for increased stability against polarizations in the incoming beam. According to another preferred embodiment, thermal stability of the optical interleaver is enhanced by configuring and dimensioning the optical interleaver such that the amount of glass or other optical material in the first and second split-beam paths is equalized. In accordance with reciprocity principles, the optical interleaver is readily adapted to operate as an interleaver, de-interleaver, or add / drop multiplexer.

Owner:GAZILLION BITS

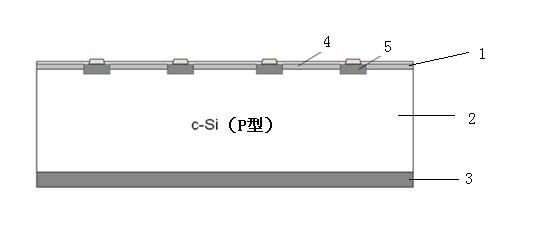

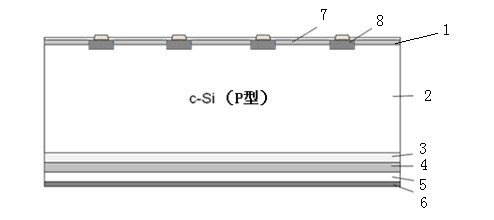

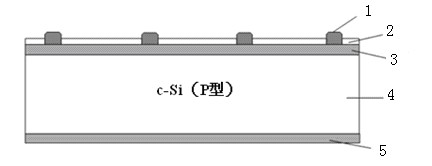

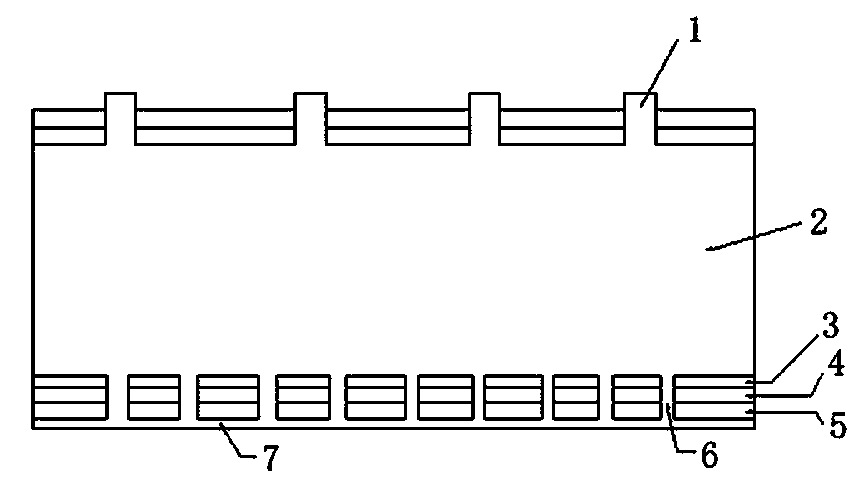

Novel crystalline silicon solar cell and manufacturing method thereof

InactiveCN102064216AImprove surface passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationHeterojunctionMaterials science

The invention discloses a novel crystalline silicon solar cell. The novel crystalline silicon solar cell comprises a crystalline silicon matrix, wherein the front surface of the crystalline silicon matrix has an emitter structure, and the back surface of the crystalline silicon matrix has a heterojunction structure; the heterojunction structure comprises an intrinsically hydrogenated amorphous silicon film, a hydrogenated amorphous silicon film, a transparent conductive oxide film and a metal conductive electrode in turn; the intrinsically hydrogenated amorphous silicon film covers the entire back surface of the crystalline silicon matrix; the hydrogenated amorphous silicon film is heavily doped by using a dopant which has the same conduction type as that of the matrix; and the metal conductive electrode passes through the transparent conductive oxide film and is in ohmic contact with a heavily doped layer. The invention also discloses a manufacturing method of the crystalline silicon solar cell. The crystalline silicon solar cell with the structure can reduce composite loss on the surface; meanwhile, the back surface of the solar cell forms a better light trap structure to improve open-circuit voltage of the solar cell, so that conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

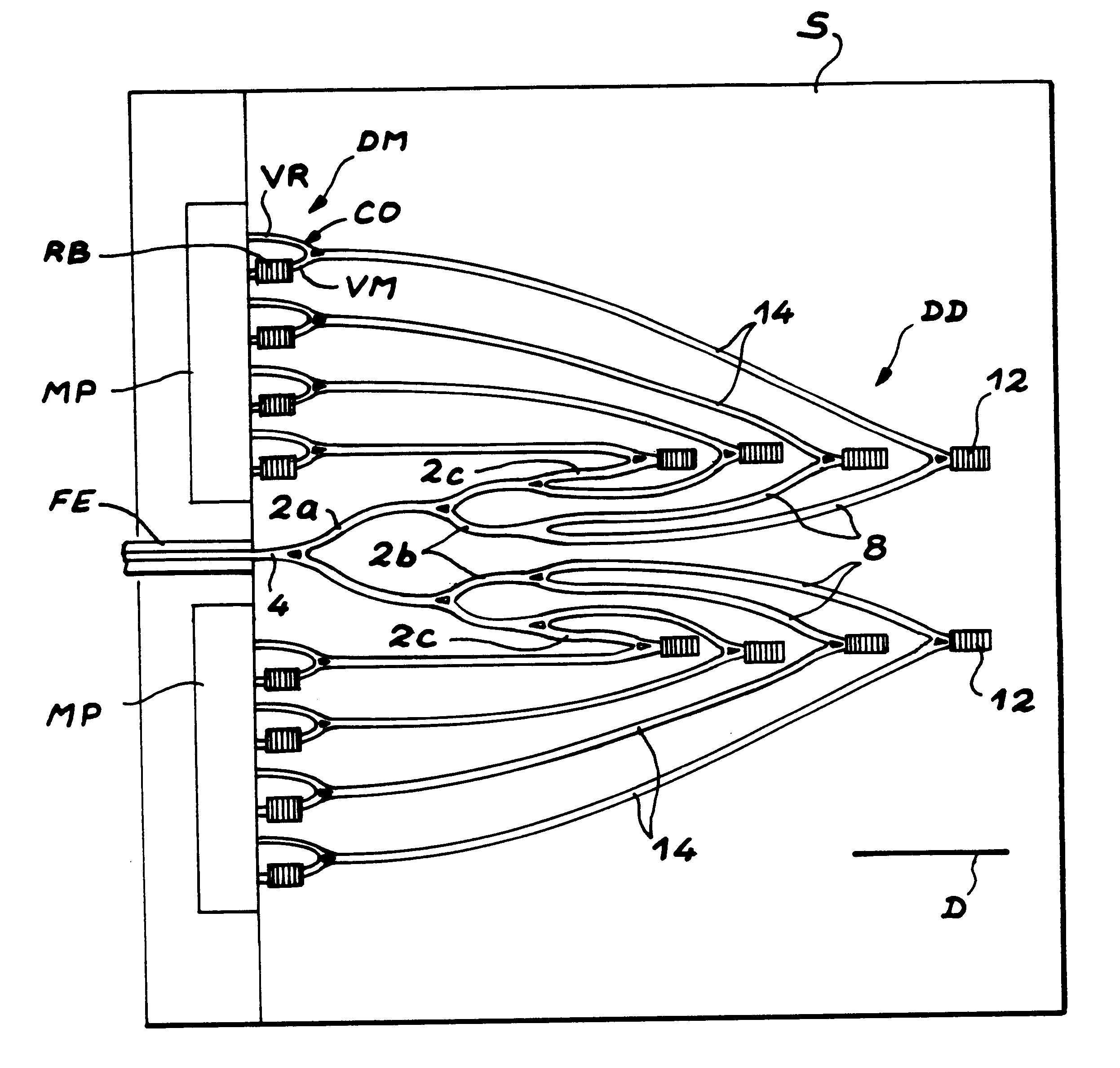

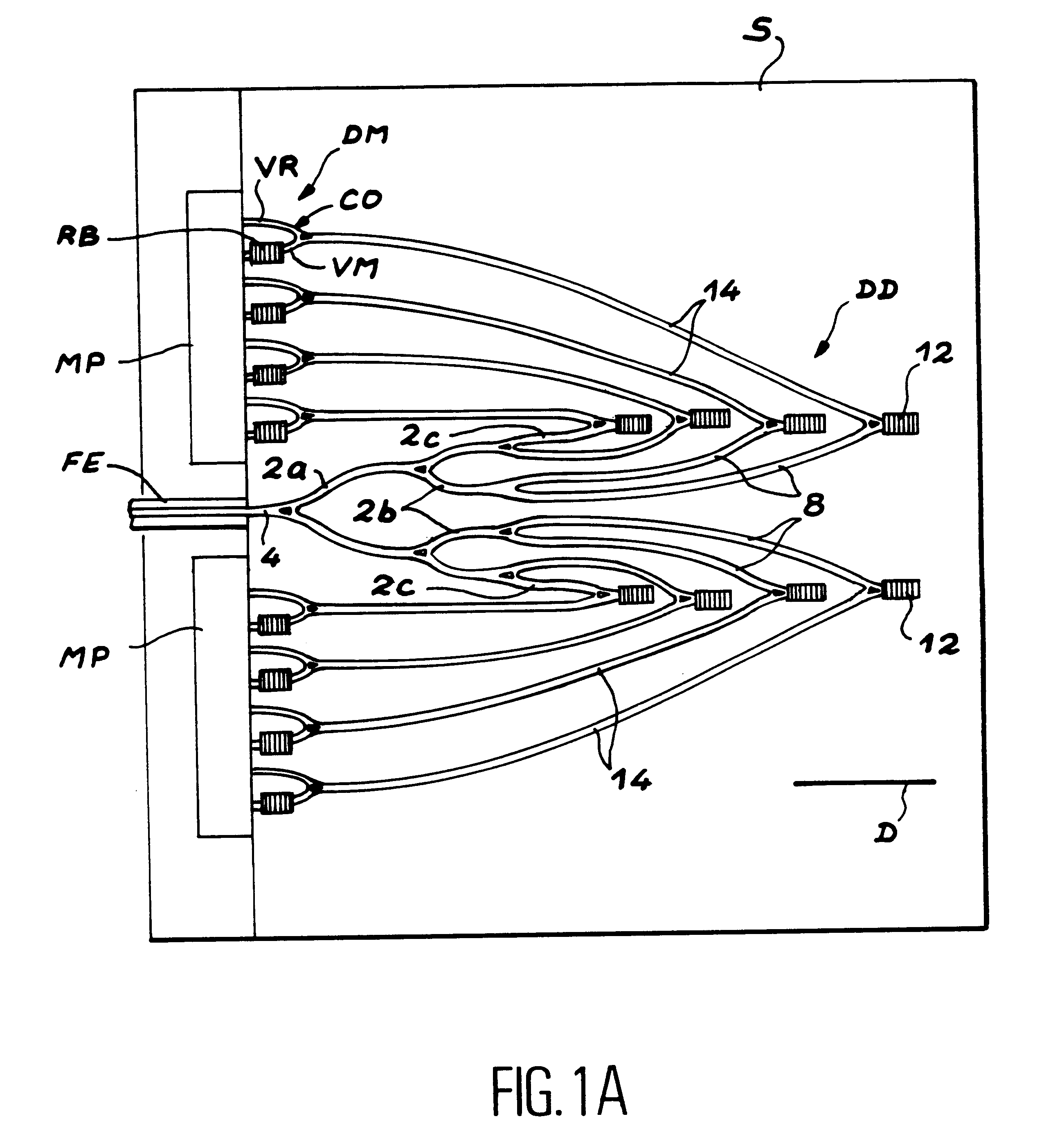

Device for reading spectral lines contained in an optical spectrum

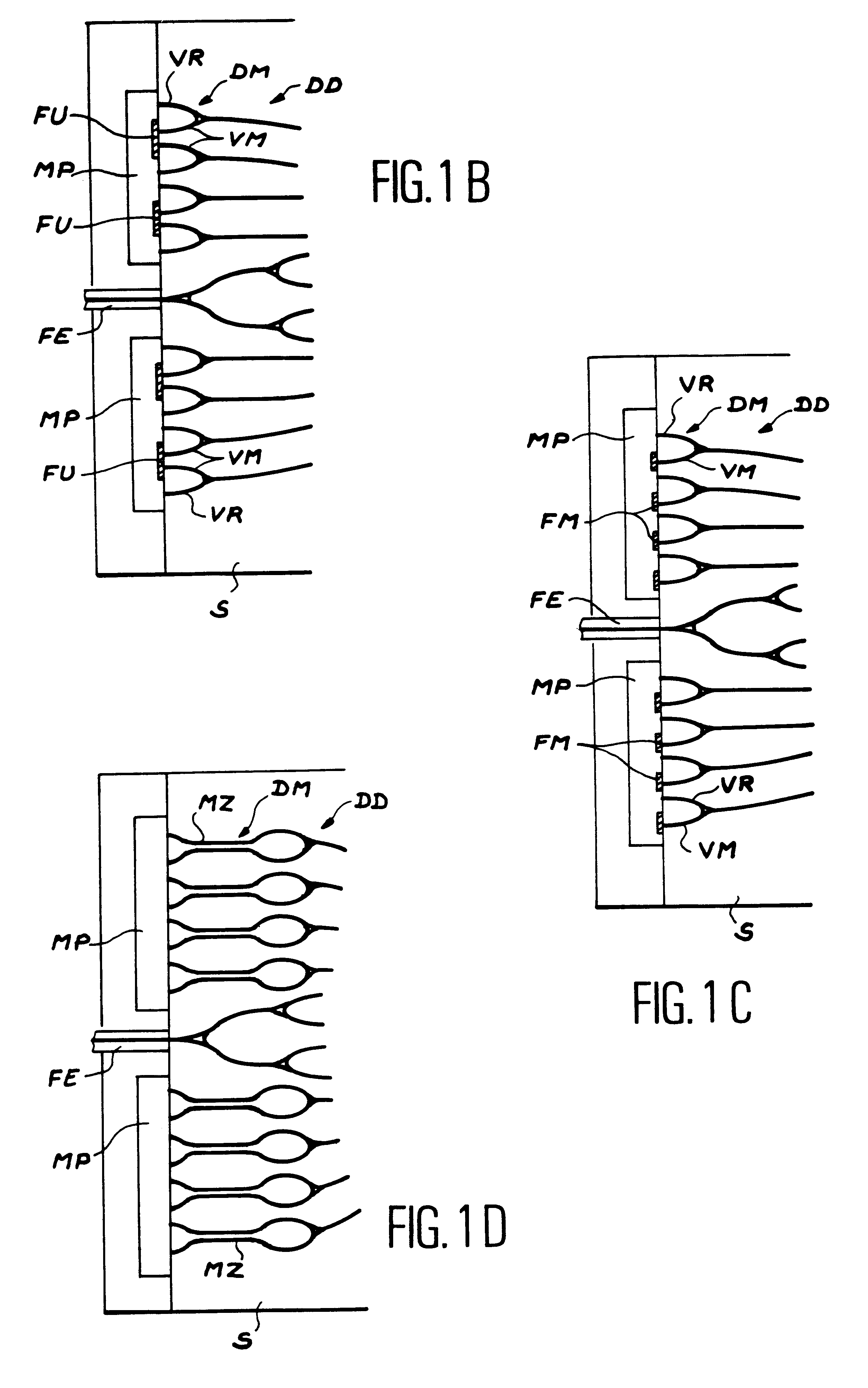

InactiveUS6639681B1Improve spectral responseThermometers using physical/chemical changesUsing optical meansPhotodetectionSpectral line

This device comprises a device (DD) for demultiplexing these lines in terms of wavelength, a device (DM) for measuring, by filtering, the wavelengths of the demultiplexed lines, comprising, for each of these lines, a measuring channel (VM) provided with a filter and a reference channel (VR), and means (MP) for the photodetection, for each line, of the light intensity transmitted by the corresponding measuring and reference channels. The wavelength of each of these lines is determined by calculating the ratio of the intensities thus detected. Application to the monitoring of structures.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

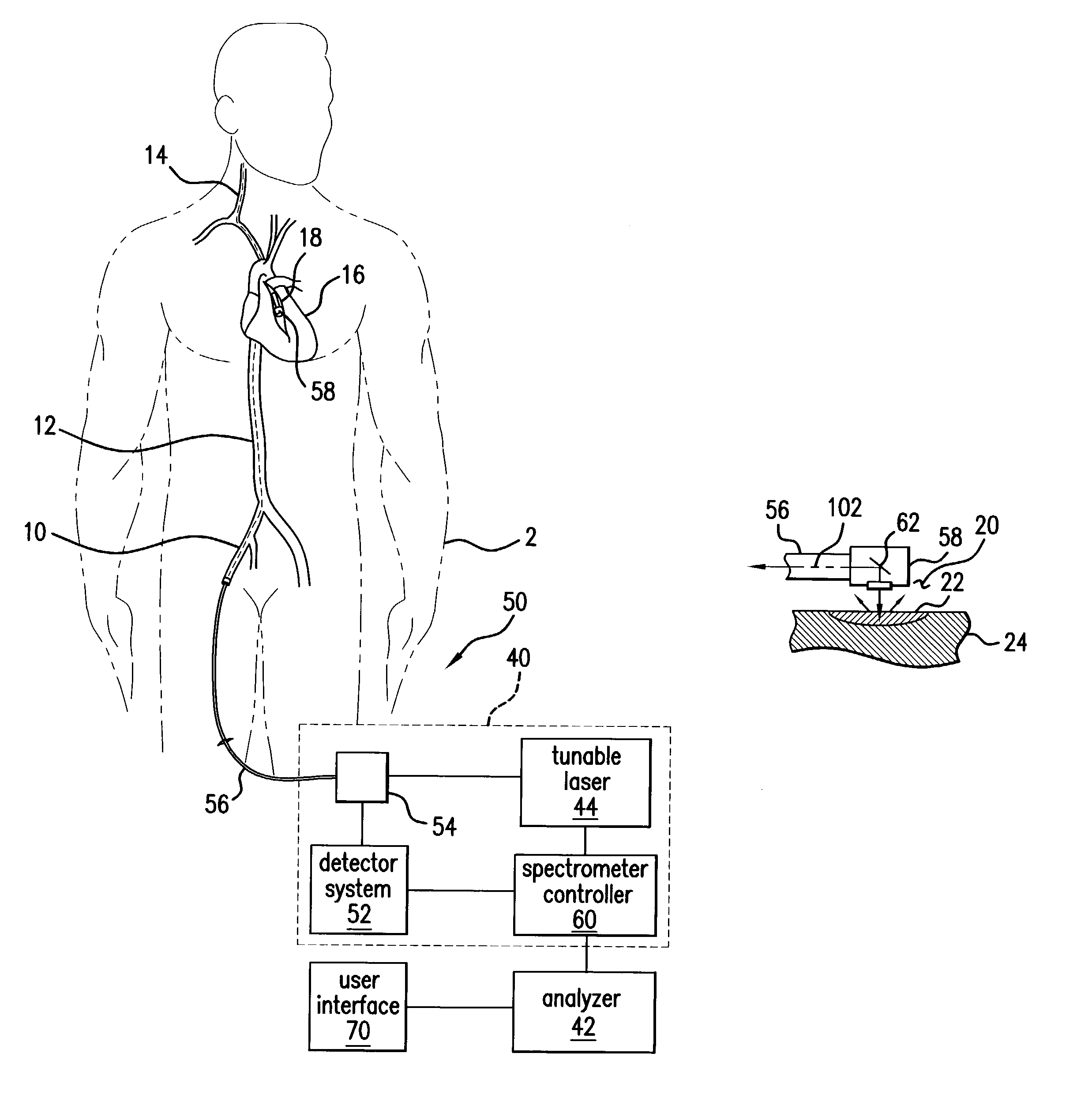

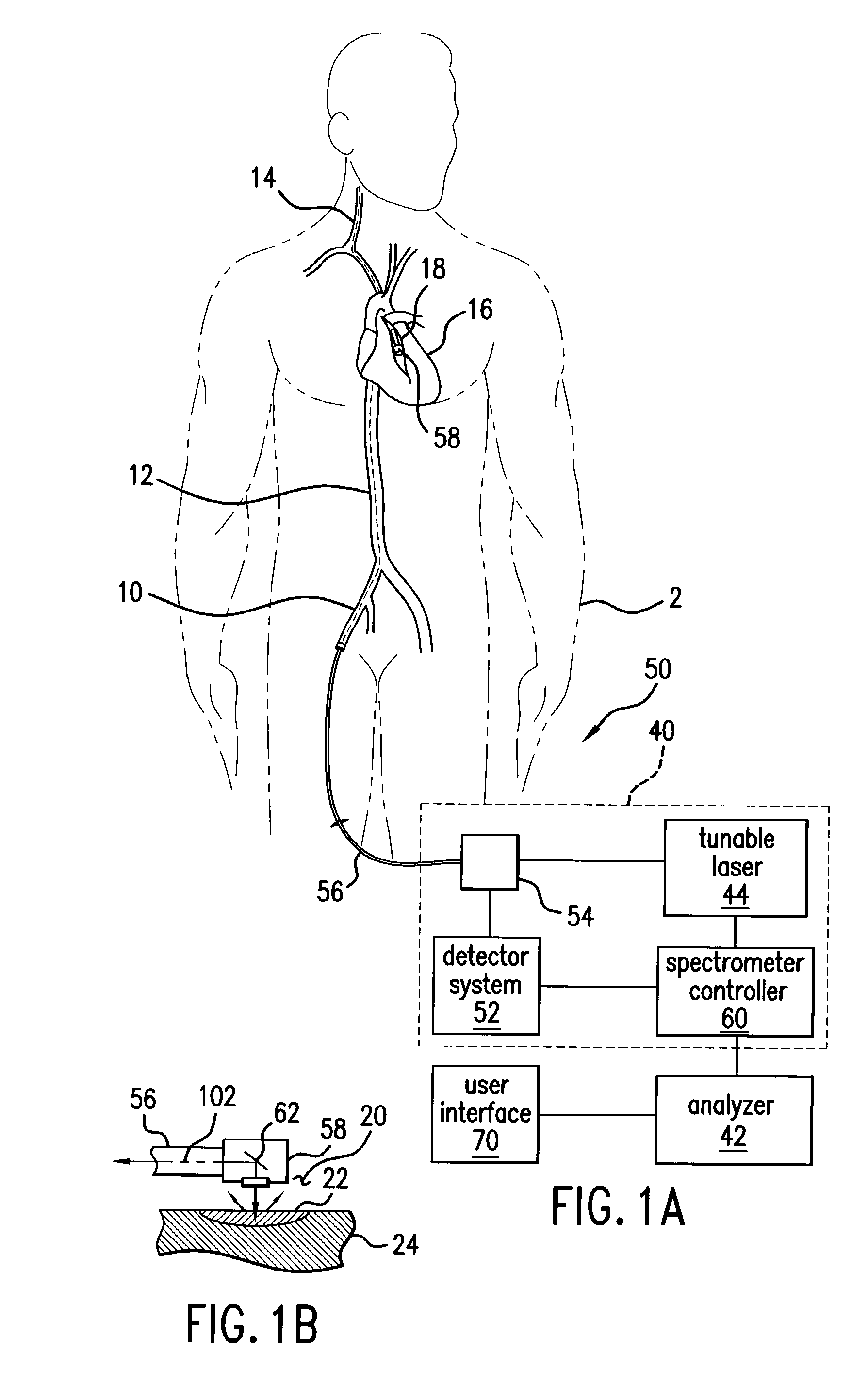

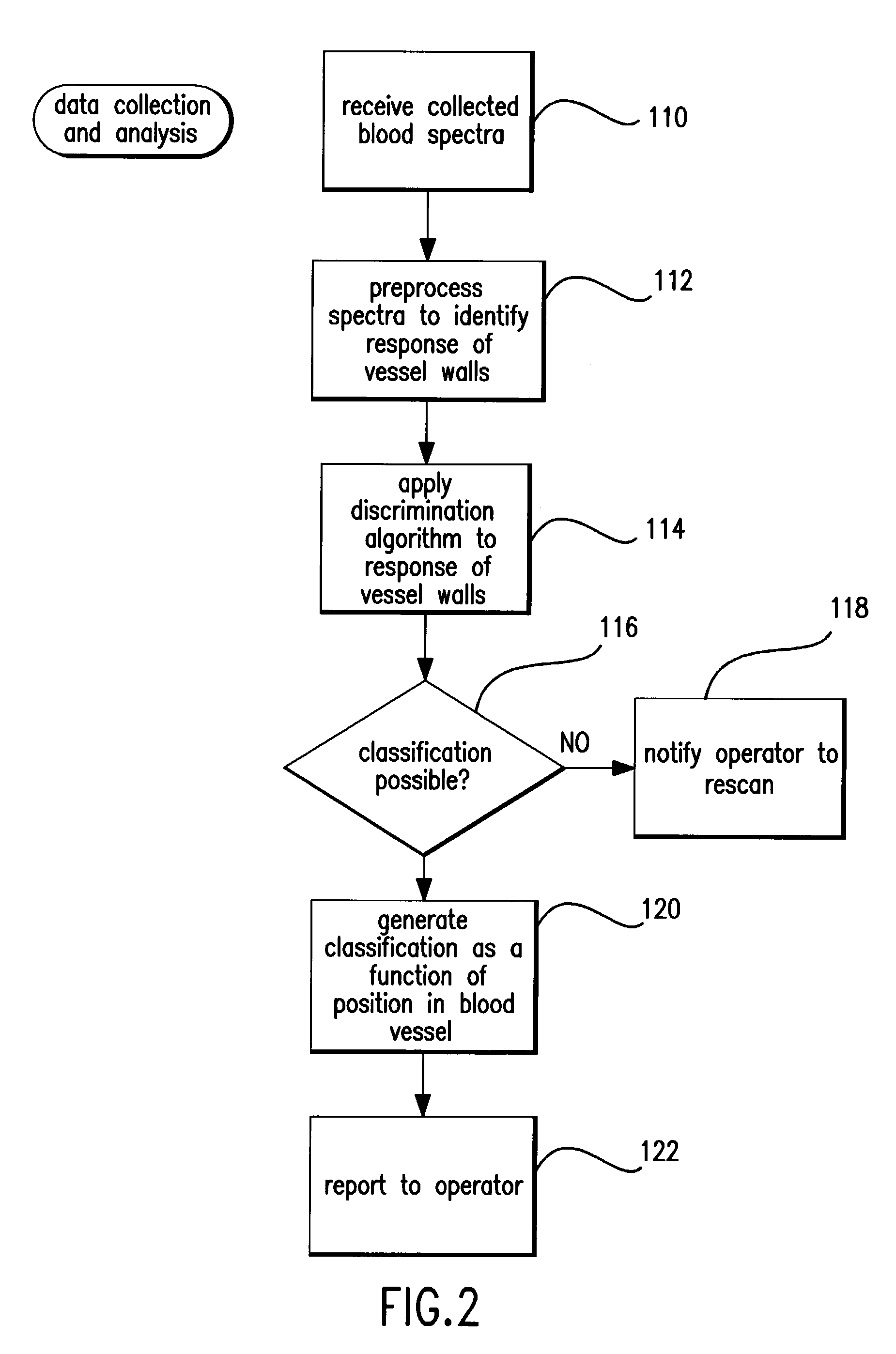

Spectroscopic unwanted signal filters for discrimination of vulnerable plaque and method therefor

ActiveUS7689268B2Improve spectral responseRobust modelDiagnostics using spectroscopySurgeryPretreatment methodIn vivo

Spectral variation contributed from the absorbance of unwanted correlated signals, such as blood at variable pathlengths between an in vivo catheter optic probe and a coronary vessel wall is an obstacle in the detection of vulnerable plaque. Preprocessing methods are described to reduce the impact of blood upon the spectral signal, based on the principles of Orthogonal Subspace Projection (OSP) and Generalized Least Square (GLS). The multivariate discrimination models used on the processed spectral information reduce the number of independent factors that include contributions from blood. The disclosed chemometric processing including preprocessing methods provide for in vivo spectral detection of medical analytes within the human body and in particular within the coronary vessel wall. A demonstration of how the preprocessing methods impact a discrimination modeling technique is provided, how the blood filters were developed and optimized, and finally how the OSP and GLS blood filters correct the spectral signal and improve the discrimination results of the models.

Owner:INFRAREDX INC

Low energy portable low-light camera with wavelength cutoff

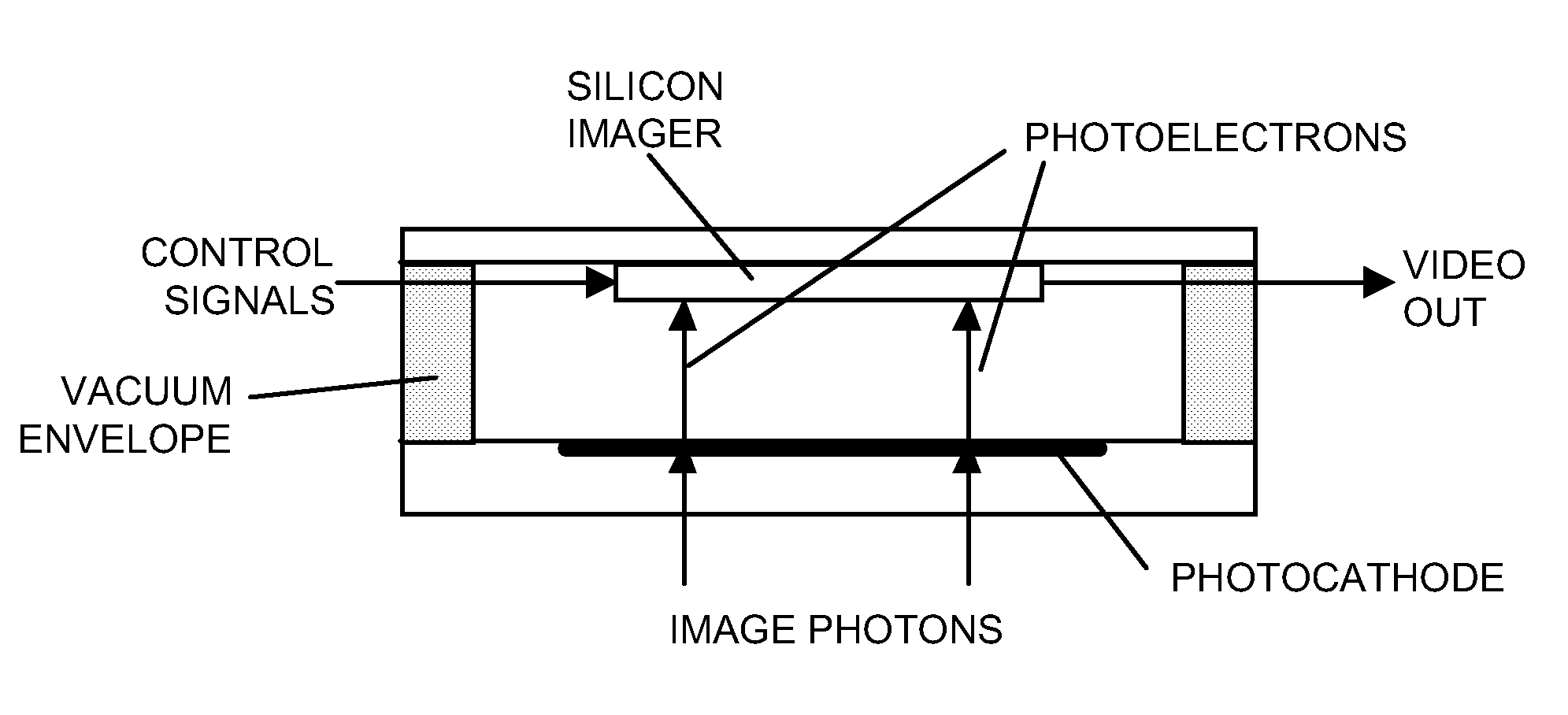

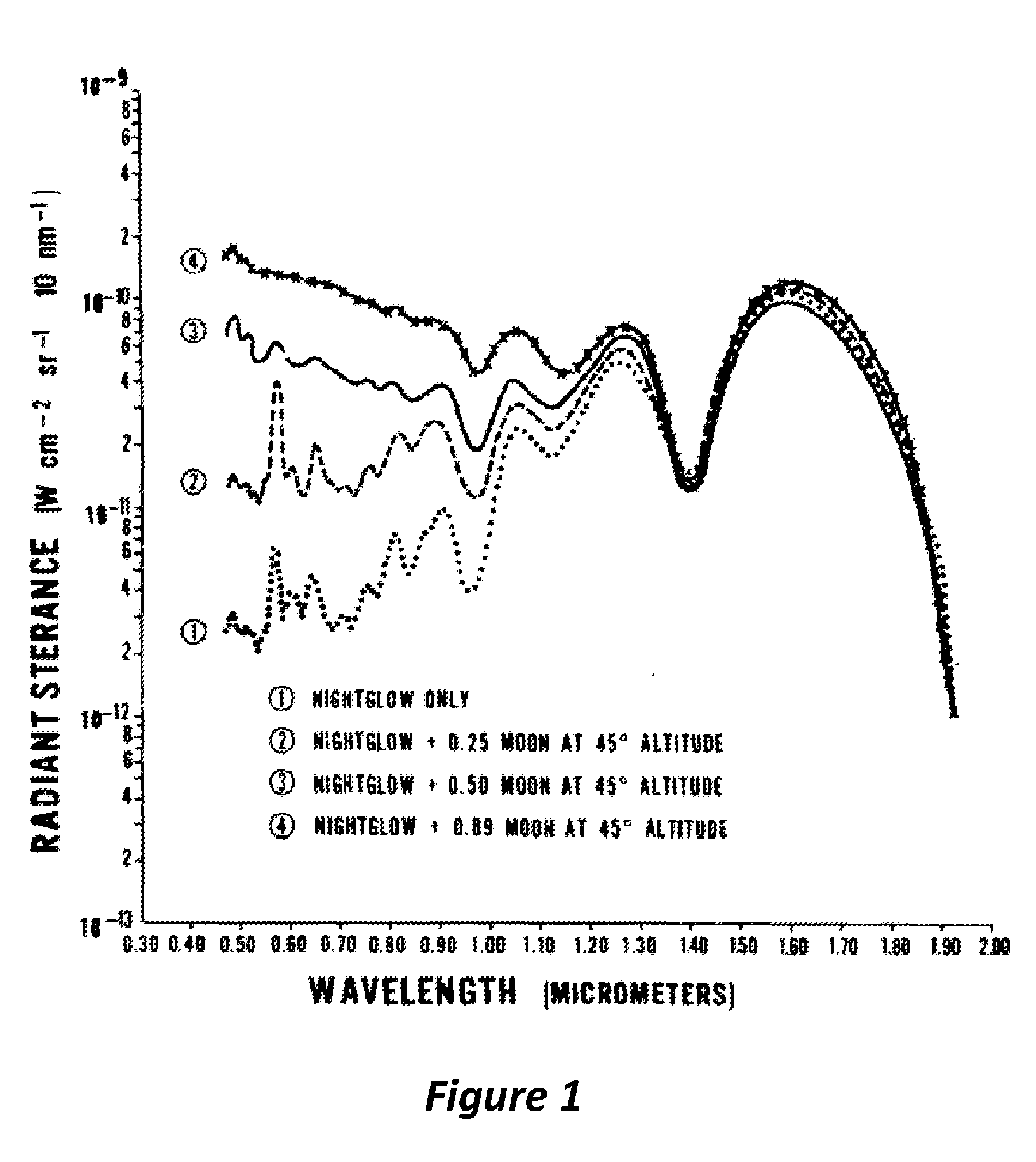

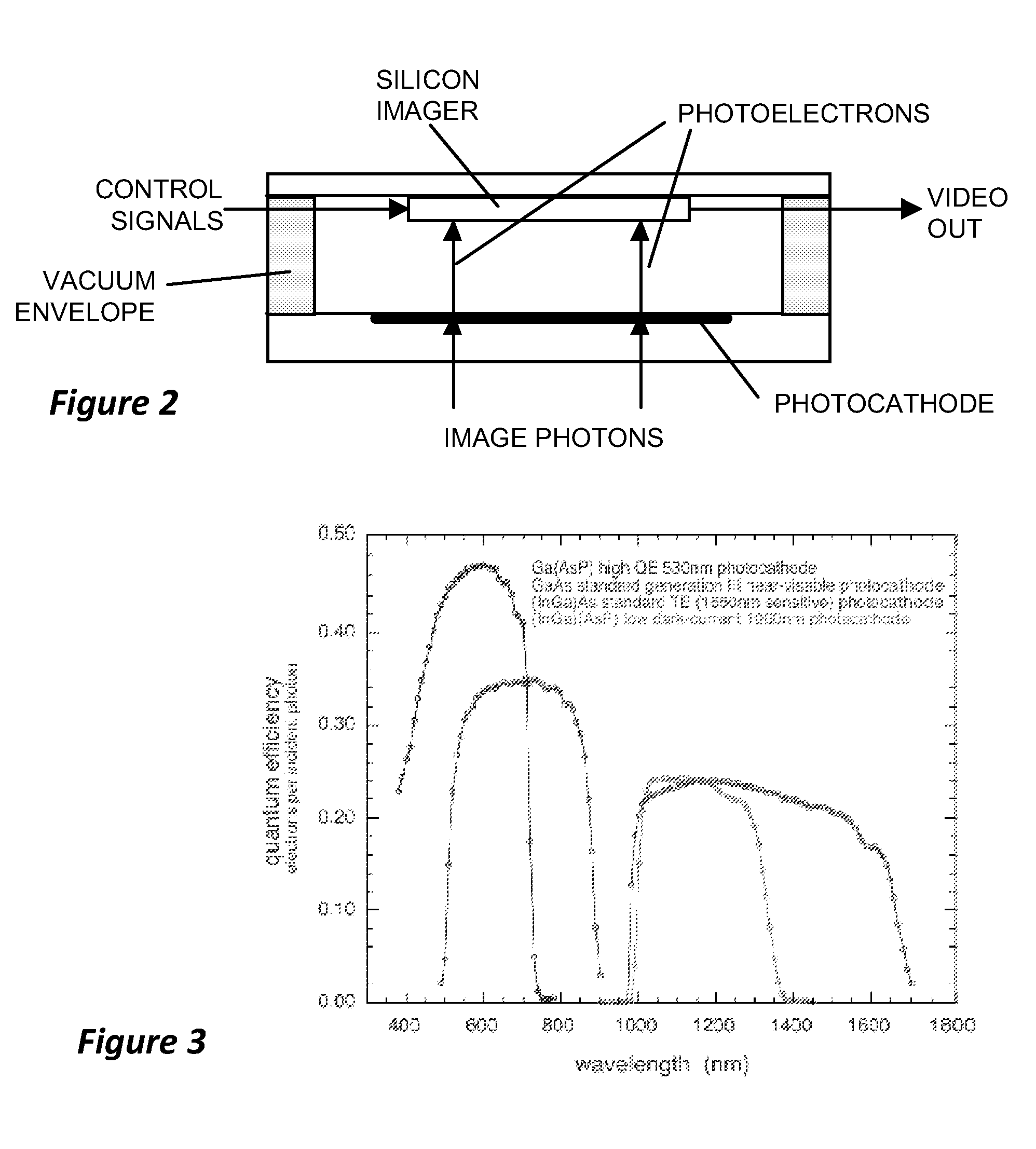

ActiveUS20110049365A1Improve spectral responseMaximization of detectionSolid-state devicesMaterial analysis by optical meansNight visionPower flow

A sensor for night vision applications is provided, wherein the sensor comprises a semiconductor absorption layer of composition that limits long wavelength response cutoff to between 1.25 to 1.4 μm wavelength. The selection of this cutoff frequency provides improved dark current performance, thereby requiring less cooling of the sensor. Consequently, energy consumption is reduced, as the sensor does not require active cooling, so that the sensor is particularly beneficial for mobile night vision applications where battery weight is of high importance.

Owner:EOTECH LLC

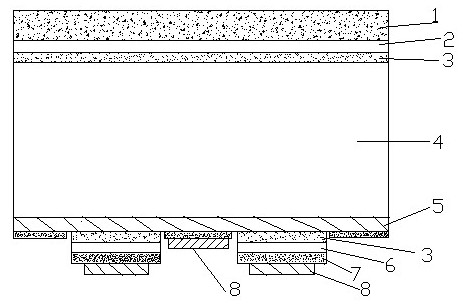

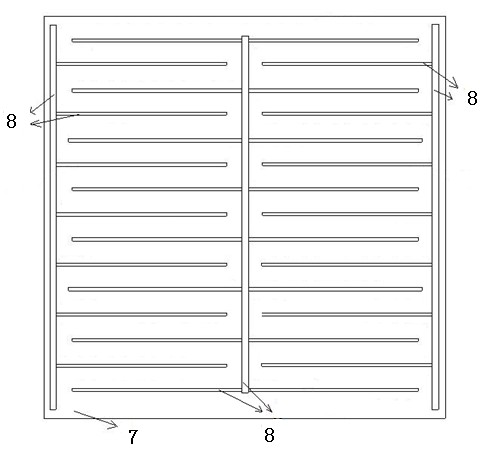

AlSb/CIS thin film solar cell of mechanical laminated layer

InactiveCN101217167AImprove photoelectric conversion efficiencyHigh theoretical conversion efficiencyPhotovoltaic energy generationSemiconductor devicesTransformation efficiencyCarbon nanotube

The invention relates to a mechanical laminated AlSb / CIS thin film solar cell, which pertains to a structural design of a semiconductor thin film solar cell. The invention is a double-junction four-terminal thin film solar cell which is formed by mechanically superimposing an AlSb top cell on a CIS bottom cell, wherein, the AlSb top cell is the solar cell which is produced by that an n-type aluminum-doped zinc oxide conductive layer is firstly deposited on a Corning 7459 glass, then a zinc oxide high resistance layer is deposited, a cadmium sulfide buffer layer is deposited, after that, an aluminum antimonide absorption layer and a carbon nano-tube coating are deposited to be taken as a transparent conductive layer, and finally a nickel / aluminum grid line is deposited; the CIS bottom cell is the solar cell which is produced by that molybdenum is deposited on a Soda lime glass, then the absorption layer of copper indium diselenide is deposited, the buffer layer of cadmium sulfide is deposited, after that, the high resistance zinc oxide and the aluminum-doped zinc oxide are deposited, and finally the nickel / aluminum grid line with the same shape and size of the top cell is deposited. The usage of the laminated cell with the structure can selectively absorb and transform the energy of the different regions of solar spectrum, expand the scope of the response of the spectrum and effectively improve the transformation efficiency of the thin film solar cell.

Owner:SICHUAN UNIV

Crystalline silicon PERC cell alkali polishing method not influencing front surface

InactiveCN105845778AReduced compound centerImprove spectral responseFinal product manufacturePhotovoltaic energy generationCell preparationCrystalline silicon

The invention belongs to the manufacturing technology of a photovoltaic solar cell and relates to a crystalline silicon PERC cell alkali polishing method not influencing the front surface. The method comprises the following steps: a) enabling an original silicon wafer to react for 160-180 s in a polishing solution, of which the KOH mass ratio is 10-20%, and the temperature is 78-83 DEG C, for polishing; b) plating a 100-120 nm SiNx film, serving as a mask, on the polished silicon wafer through PECVD; c) enabling the plated silicon wafer to be soaked in HF for 80-100s to remove the SiNx film plated on the front surface thoroughly; d) texturing the plate-removed silicon wafer in a texturing tank, of which the KOH mass ratio is 1.5-3%, and the temperature is 80-82 DEG C, the texturing time being 1100-1300 s; and e) finishing the follow-up steps by the textured silicon wafer according to a conventional PERC cell preparation method. The method can obtain a relatively-uniform polished surface, and meanwhile, can prevent causing influence on the front surface, thereby improving cell performance.

Owner:JINENG CLEAN ENERGY TECH LTD

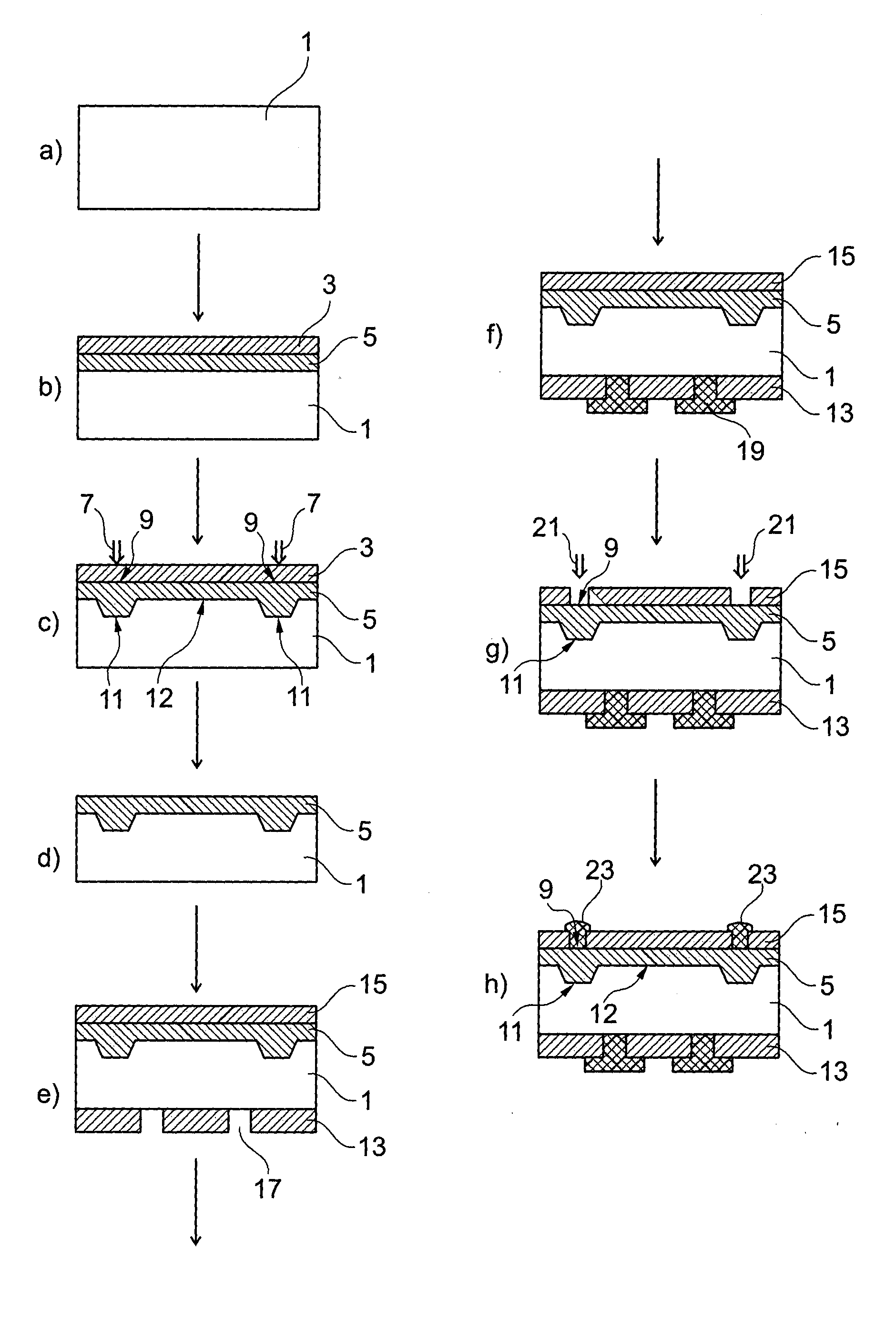

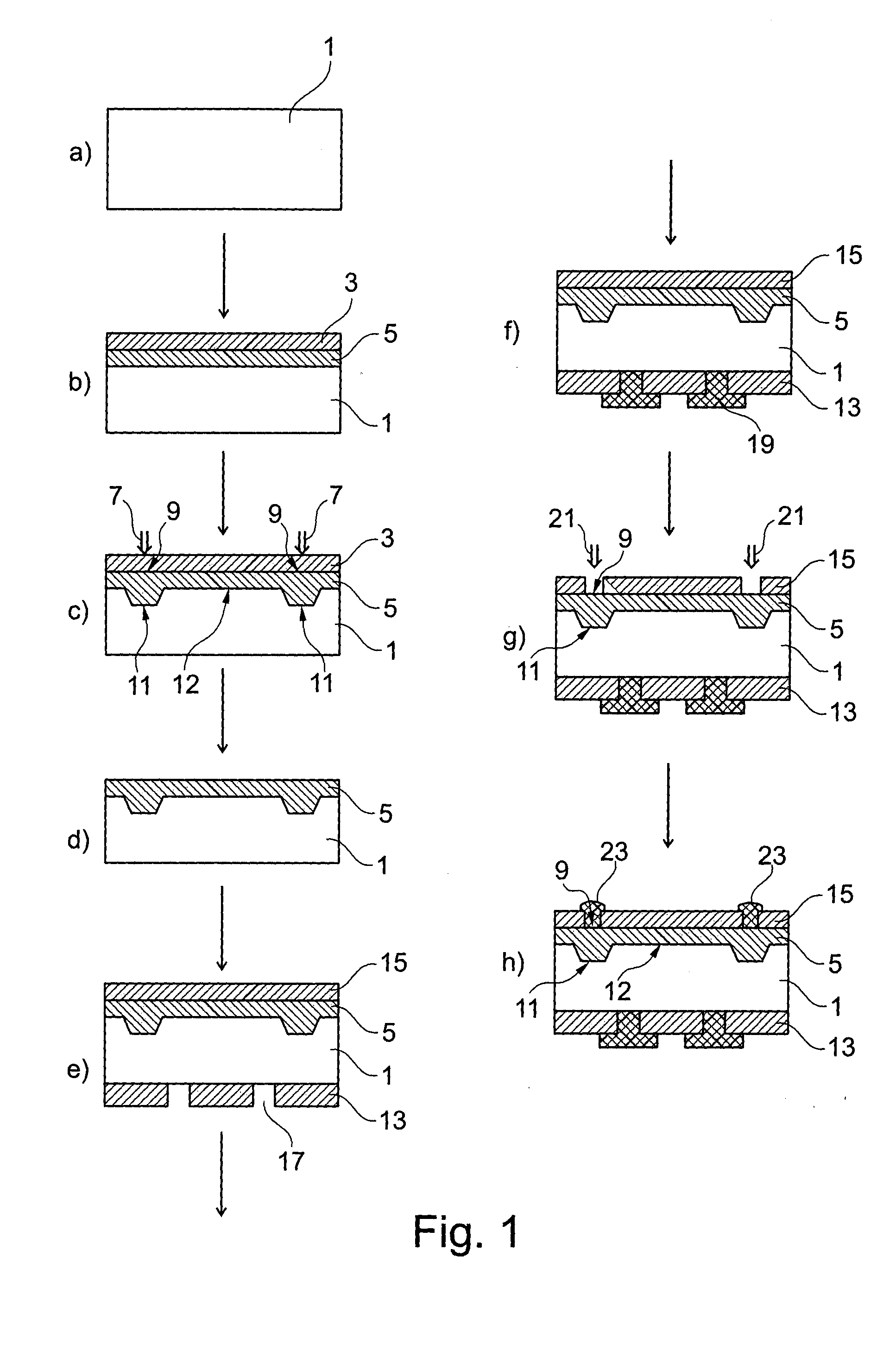

Method for forming a solar cell with a selective emitter

InactiveUS20150017747A1High long-term reliabilityImprove long-term reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLaser lightSource material

A method for producing a solar cell with a selective emitter is disclosed. A semiconductor substrate (1) is provided. A layer (3) of dopant source material with a dopant type opposite to the dopant type of the substrate (1) is formed at a surface of the substrate (1). By applying heat to the layer (3), a homogeneous lightly doped emitter region (5) is formed. In a first lasering step, selective heavily doped emitter regions (11) are formed by applying laser light (7) to contact surface areas (9). Optionally, the layer (3) is subsequently removed and an additional dielectric layer (15) is applied to the front side of the substrate (1). In a second lasering step, the layer (3) or the layer (15) are locally removed by applying laser light (21) to the contact surface areas (9), thereby locally exposing the surface of the substrate (1). In the locally exposed contact surface areas (9), metal contacts (23) are finally formed, using for example metal-plating techniques. Using two different lasering steps for laser doping, on the one hand, and laser removal for forming the metallization mask, on the other hand, allows optimizing each of the lasering steps independently from each other, thereby enabling improvements for the processing and resulting solar cell.

Owner:REC SOLAR

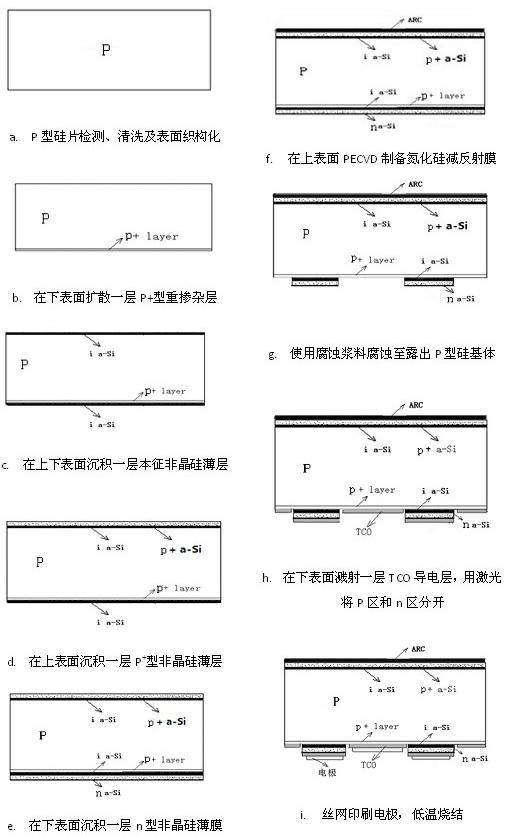

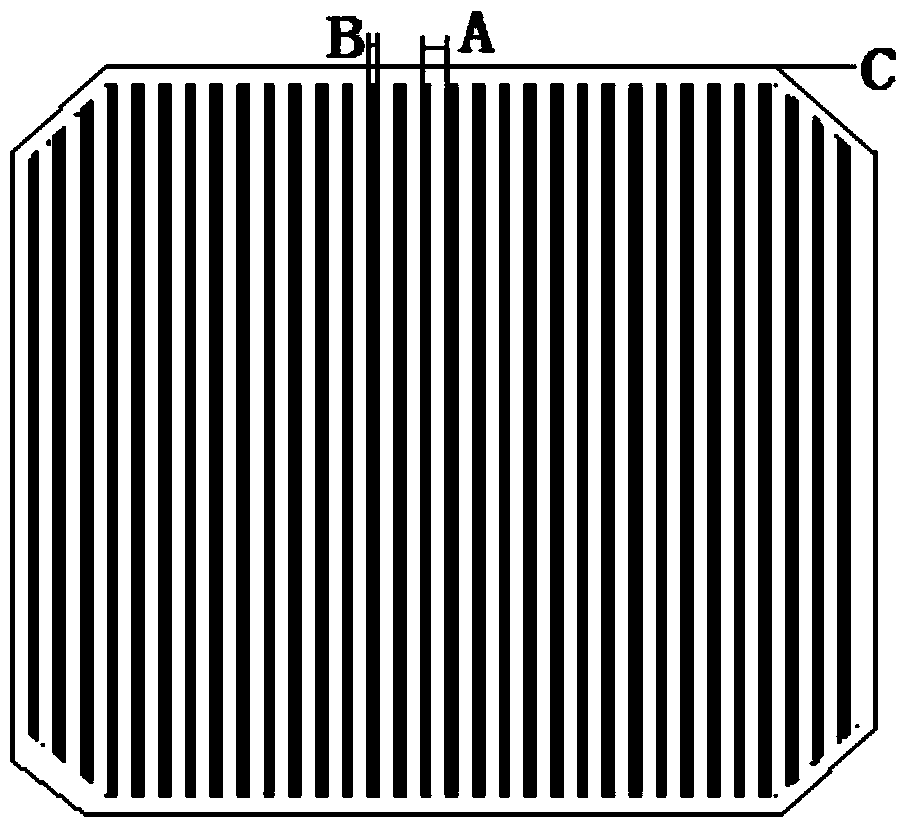

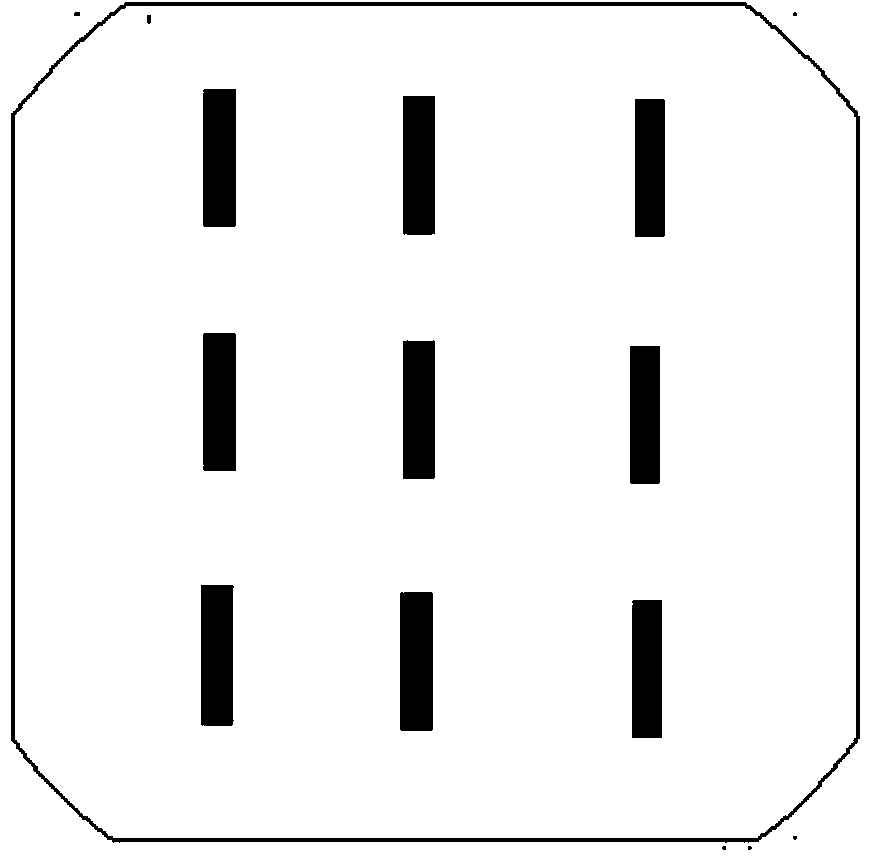

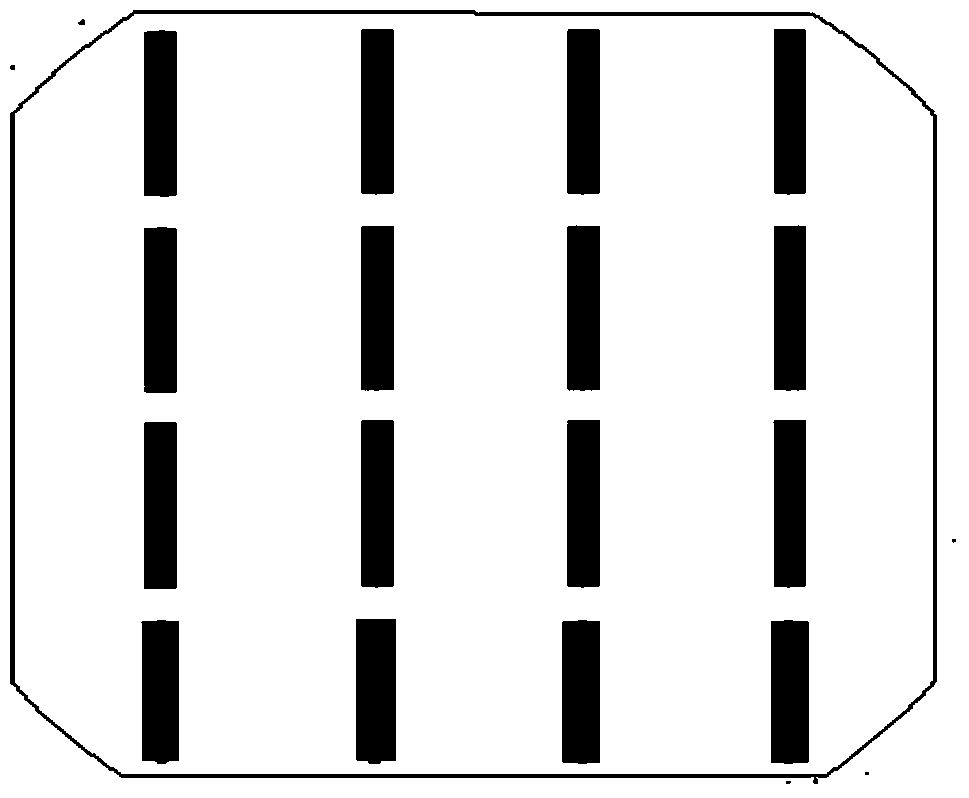

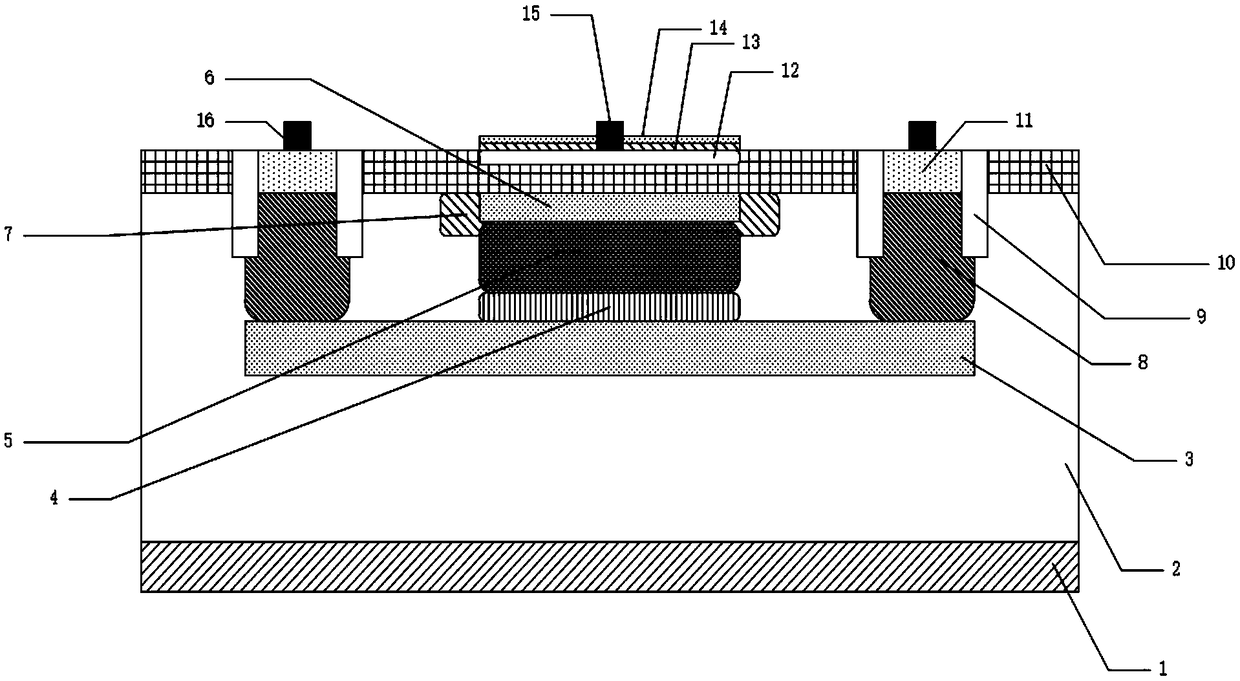

Back contact heterojunction solar battery based on P-type silicon slice

ActiveCN102214720AGood spectral responsePropagation path lengthPhotovoltaic energy generationSemiconductor devicesP type siliconEngineering

The invention relates to a solar battery, in particular to a back contact heterojunction solar battery based on a P-type silicon slice. According to a back face feature, the back contact heterojunction solar battery is divided into an N-type region and a P-type region, wherein the N-type region forms a P+a-si / i-a-si / P-c-si / P+c-si / i-a-si / N-a-si heterojunction structure; and the P-type region formsa P+a-si / i-a-si / P-c-si / P+c-si heterojunction structure. The solar battery has higher spectral response; sunshine has a longer light transmission route in the battery; the thickness of the solar battery is greatly reduced compared with that of the conventional crystal silicon solar battery; electrodes are all printed on the back face of the battery, so the problem that the front electrode of the conventional solar battery blocks light is solved; therefore, short-circuit current of the solar battery is increased and the conversion efficiency of the solar battery is improved greatly; and by a low-temperature sintering process, a production process is simplified greatly and production cost is reduced; and the solar battery is applicable to industrialized production.

Owner:山东力诺太阳能电力股份有限公司

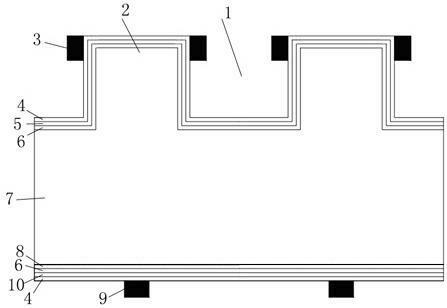

Front electrode diffraction type local back surface field passivation type crystalline silicon cell preparation method

ActiveCN103746026AReduce shading areaImprove efficiencyFinal product manufactureSemiconductor devicesBack surface fieldElectrode Contact

The invention discloses a front electrode diffraction type local back surface field passivation type crystalline silicon cell preparation method. A row of cavities which are arranged uniformly are formed in a silicon wafer substrate at the front electrode main gate position through a laser device to replace the main gate electrode and the gate electrode is led to the back surface of the cell to reduce the shading area of the main gate electrode and place the front electrode on the back surface; a layer of Al2O3 is deposited on the back surface of the silicon wafer through atomic layer deposition or the PECVD method to passivate the back surface f the cell, a layer of thick SiNx is deposited on the surface of the film to protect the passivation effect of the Al2O3, and then a back open-membrance pattern is designed, and a back electrode conductive window is prepared through laser or chemical corrosion method; and the back electrode, a back matched aluminum back surface field, a back front electrode and a front gate electrode are printed successively, and the printing and sintering processes are optimized to make the electrode contact region has the advantage of good filling effect.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

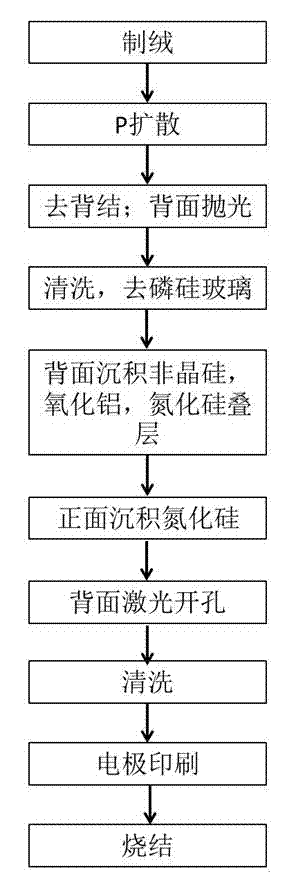

Preparation method of back passivated battery

ActiveCN103050573AImprove spectral responseImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesWave bandSilicon nitride

The invention relates to a preparation method of a back passivated battery, and belongs to the technical field of a production method of a solar battery. The process comprises the steps of: first, cleaning a P type monocrystalline silicon wafer and making a texture surface, and then carrying out P diffusion; then, corroding and polishing the back of the silicon wafer by an etchant solution; then, respectively cleaning the front face of the silicon wafer by HF solution, and cleaning the back of the silicon wafer by an RCA method; then, sequentially depositing amorphous silicon, aluminum oxide and silicon nitride on the back of the battery, and depositing silicon nitride on the front face of the silicon wafer; removing deposited thin film layer locally on the back of the silicon wafer by laser or corrosive slurry; and finally printing an electrode and sintering the electrode. The preparation method has the beneficial effects that the battery piece is laminated and passivated on the back, in particular by amorphous silicon, aluminum oxide and silicon nitride, so that the back of the battery not only has a good electric passivating effect, but also has a good internal reflective effect to a long-wave band. The long-wave band of the battery has a good spectral response, so that the utilization rate of sunlight and the photoelectric conversion efficiency of the battery are improved.

Owner:山东一开电气设备有限公司

Novel double-layer-film back-passivated solar cell structure

InactiveCN103400868AImprove spectral responseReduce reflectivitySemiconductor devicesDielectricSilver electrode

The invention discloses a novel double-layer-film back-passivated solar cell structure. The structure comprises silver electrodes, silicon-nitride dielectric films, an aluminum back field and a silicon substrate, wherein a layer of alumina passivation film and a layer of silicon oxynitride passivation film are further arranged on each silicon-nitride dielectric film, and a plurality of grooves are formed in back fields of the silicon-nitride dielectric films, the alumina passivation films and the silicon oxynitride passivation films and are distributed uniformly. The novel double-layer-film back-passivated solar cell structure has the advantage that the photoelectric conversion efficiency of a solar cell is further increased.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

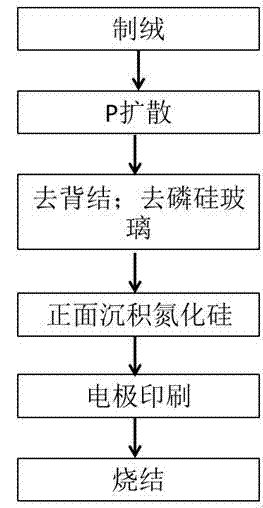

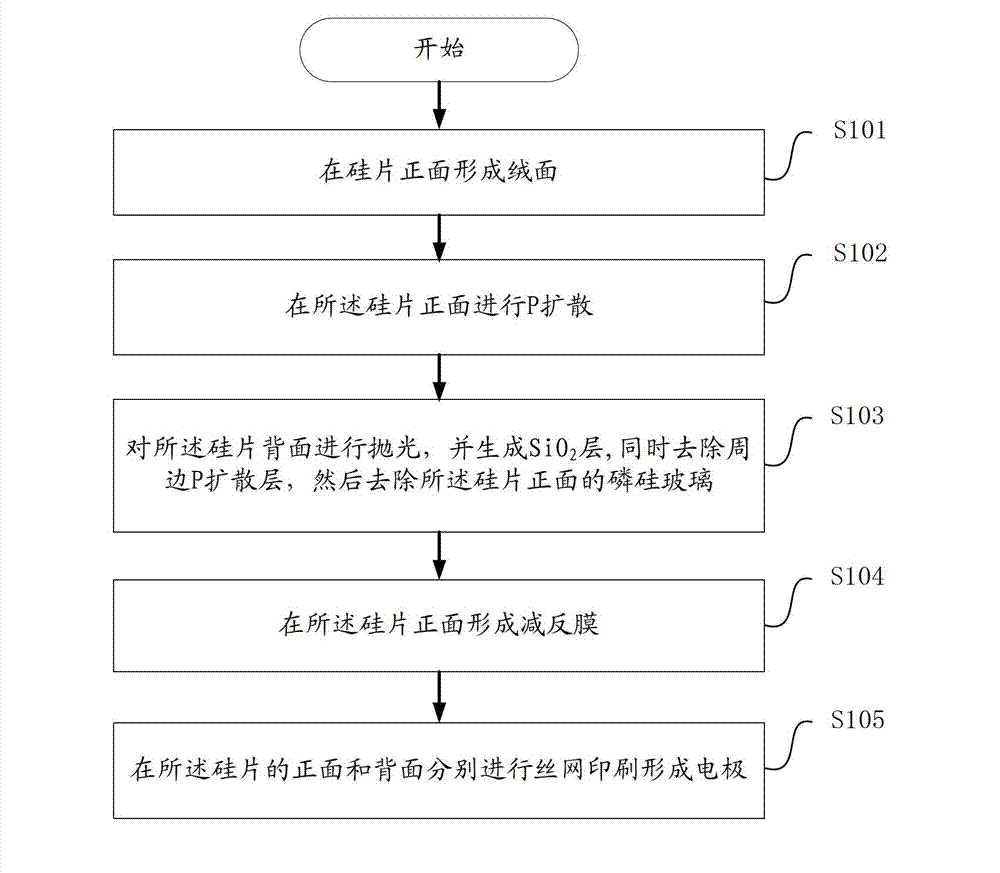

Production method of solar cell

ActiveCN103117330AHas a passivation effectImprove reflectivityRenewable energy productsSemiconductor devicesScreen printingPhotoelectric conversion

The invention discloses a production method of a crystalline silicon solar cell. The production method includes the steps of texturing the front surface of a silicon wafer; performing P diffusion to the front surface of the silicon wafer, polishing the back of the silicon wafer to generate a SiO2 layer, removing the peripheral P diffusion layer, and removing phosphorosilicate glass on the front surface of the silicon wafer; forming a reflection-degreasing film on the front surface of the silicon wafer; and respectively subjecting the front surface and the back of the silicon wafer to silk screen printing to form electrodes. By the use of the production method, the back surface of the silicon wafer can be bright as a mirror, and reflectivity of the back of the silicon wafer is improved effectively. In addition, the smooth back surface allows for formation of evener aluminum back field. The formed SiO2 layer functions in surface passivation, so that minority carrier lifetime can be prolonged. Photoelectric conversion rate of the solar cell produced by the production method can be improved greatly.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

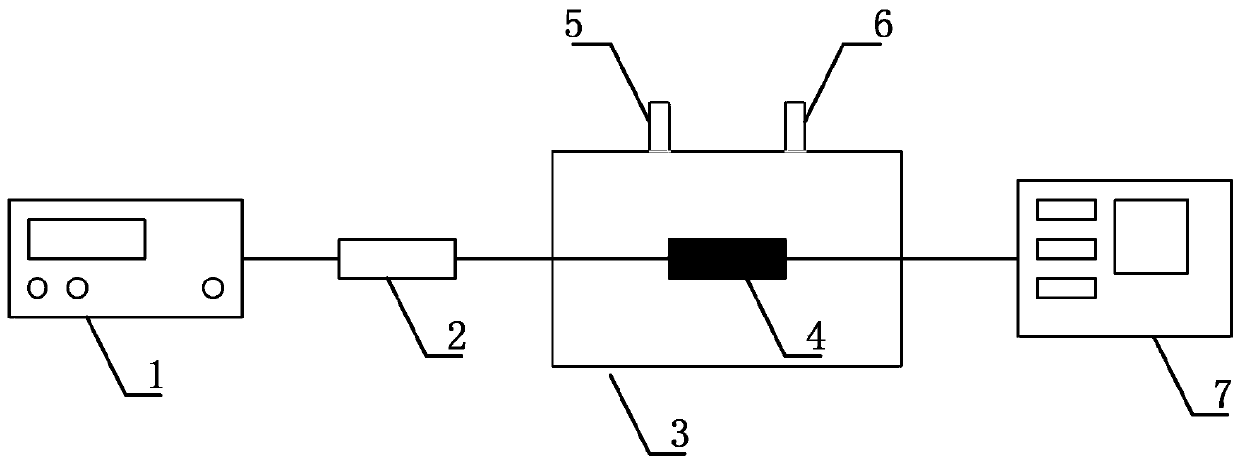

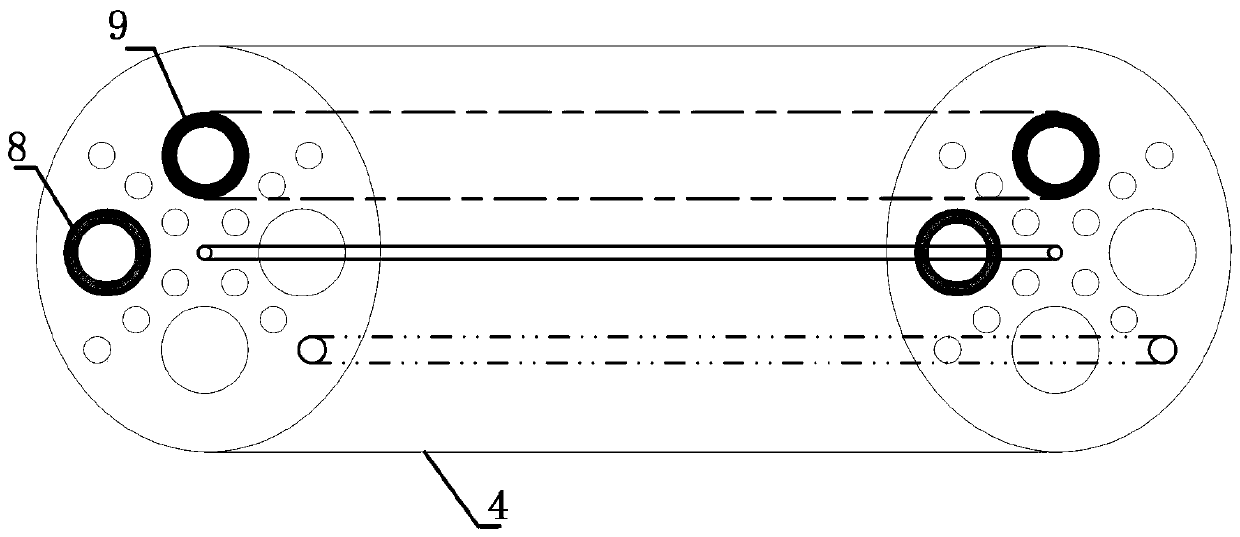

PCF (Pohotonic Crystal Fiber)-SPR (Surface Plasma Resonance) structure sensor capable of simultaneously measuring hydrogen and methane

PendingCN110220868AImprove gas sensitivitySimple manufacturing techniquePhase-affecting property measurementsPalladiumMethane

The invention discloses a PCF (Pohotonic Crystal Fiber)-SPR (Surface Plasma Resonance) structure sensor capable of simultaneously measuring hydrogen and methane. The PCF-SPR structure sensor is composed of a broadband light source, an optical attenuator, an air chamber, a PCF-SPR sensor and a spectrograph. Small air holes with a diameter of 1.5 microns are arranged at an angle of 45 degrees and 135 degrees on the cross section of the PCF-SPR sensor, and four ultra-large air holes with a diameter of 5 microns are vertically and horizontally distributed on the cross section of the PCF-SPR sensor, wherein the inner surfaces of the two ultra-large side holes are respectively coated with a hydrogen-sensitive film made of gold and a palladium-WO3 composite film, and a methane sensitive film madeof gold and an ultraviolet light curing fluorosilicone nano film. A gas sensing channel causes different peak shifts at different wavelengths; through structural parameter optimization, a gas mixtureof methane and hydrogen can be accurately measured by combining a side hole structure and polarization filtering without interfering with each other; and the PCF-SPR structure sensor has good multi-channel gas sensing repeatability, and a selective detection method can be applied to gases and other sensing applications, and has a good application prospect.

Owner:CHINA JILIANG UNIV

Single photon avalanche diode with high detection efficiency and manufacturing method thereof

ActiveCN109300992AImprove photon detection efficiencyPromote absorptionSolid-state devicesSemiconductor/solid-state device manufacturingSpectral responsePhoton detection

The invention discloses a single photon avalanche diode with high detection efficiency and a manufacturing method thereof. The multiplication region of the traditional single photon avalanche photodiode is relatively thin, which leads to commonly low detection sensitivity and photon detection efficiency. The single photon avalanche diode with high detection efficiency comprises a p- substrate layer, a p epitaxy layer, an n+ buried layer, an n-type charge layer, an inverted deep n well, a p-type charge layer, a p- semiconductor layer, an n well layer, shallow groove isolation layers, a p-type semiconductor layer, an n+ semiconductor layer, a p+ light absorption layer, a silicon dioxide anti-reflection film, a silicon nitride anti-reflection film, an anode electrode and cathode electrodes which are arranged coaxially. The p+ light absorption layer, the p-type semiconductor layer and the p-type charge layer are adopted to form a p+ / p / p-type charge layer structure, current can expand horizontally first and then flow to the avalanche multiplication region, the spectral response is increased, and the absorption of the light wavelength by the single photon avalanche diode can be effectively improved.

Owner:南通三彩集成光电科技有限公司

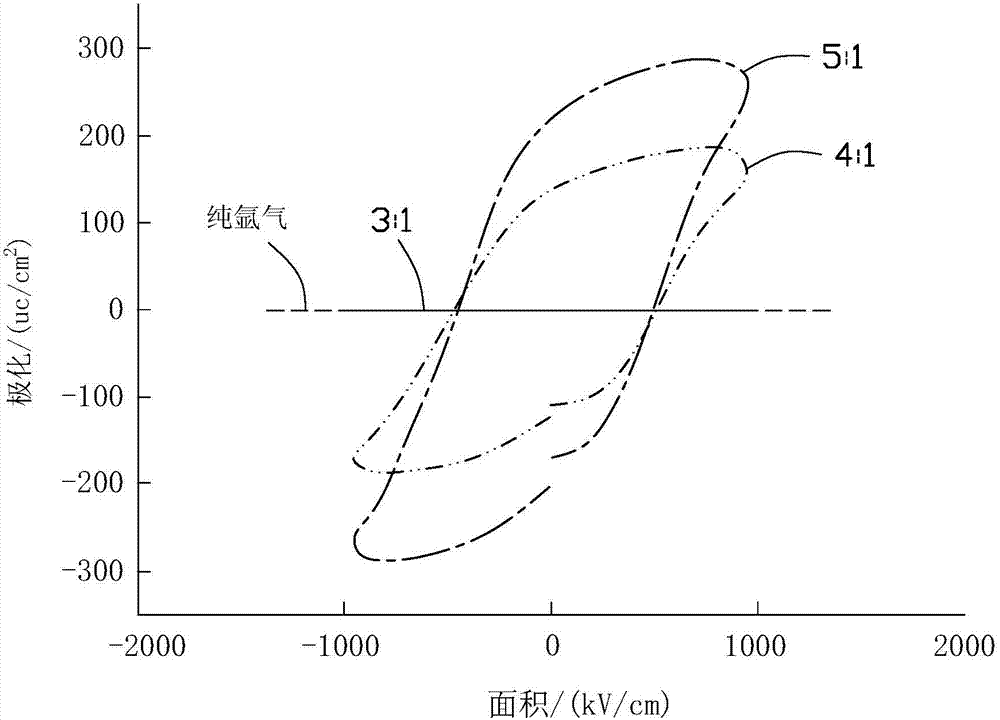

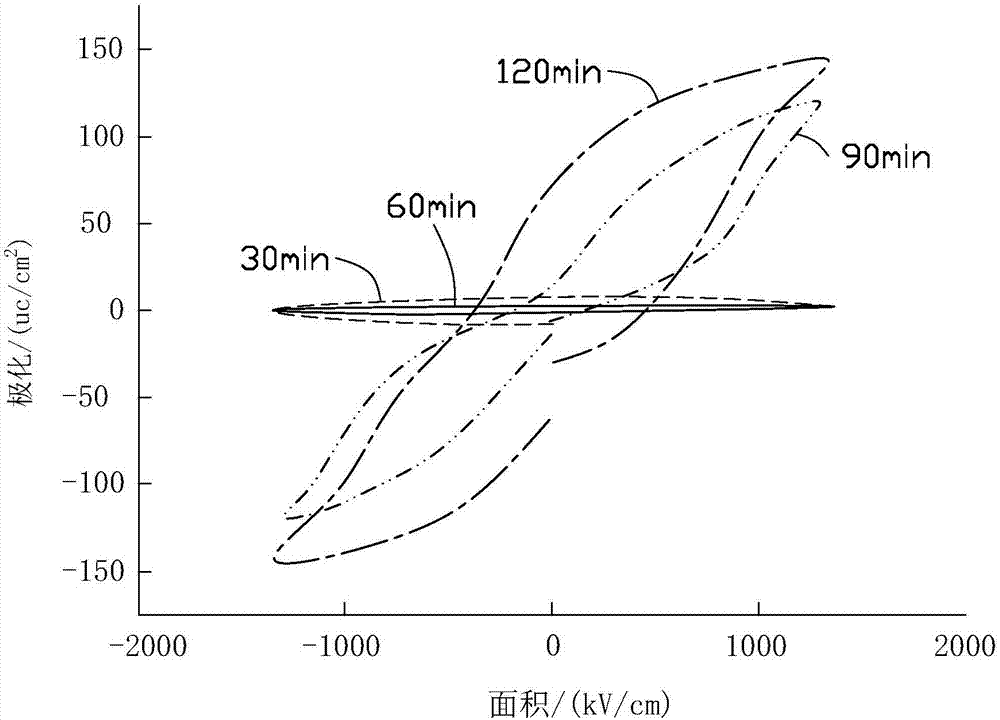

Black silicon solar cell and preparation method therefor

InactiveCN107275442AEnhanced light absorptionImprove performanceFinal product manufacturePhotovoltaic energy generationComposite filmSolar cell

The invention provides a preparation method for a black silicon solar cell, and the method comprises the following steps: preparing a black silicon substrate; sequentially depositing a BiFeO3 film and an ITO film on the black silicon substrate. According to the invention, the black silicon substrate is higher in light absorption performances after the BiFeO3 / ITO composite film is deposited. The deposition of the BiFeO3 / ITO composite film improves the effective separation of photon-generated carriers of the cell, thereby improving the spectrum response in a short-wave region of the black silicon cell, and improving the comprehensive performances of the cell.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

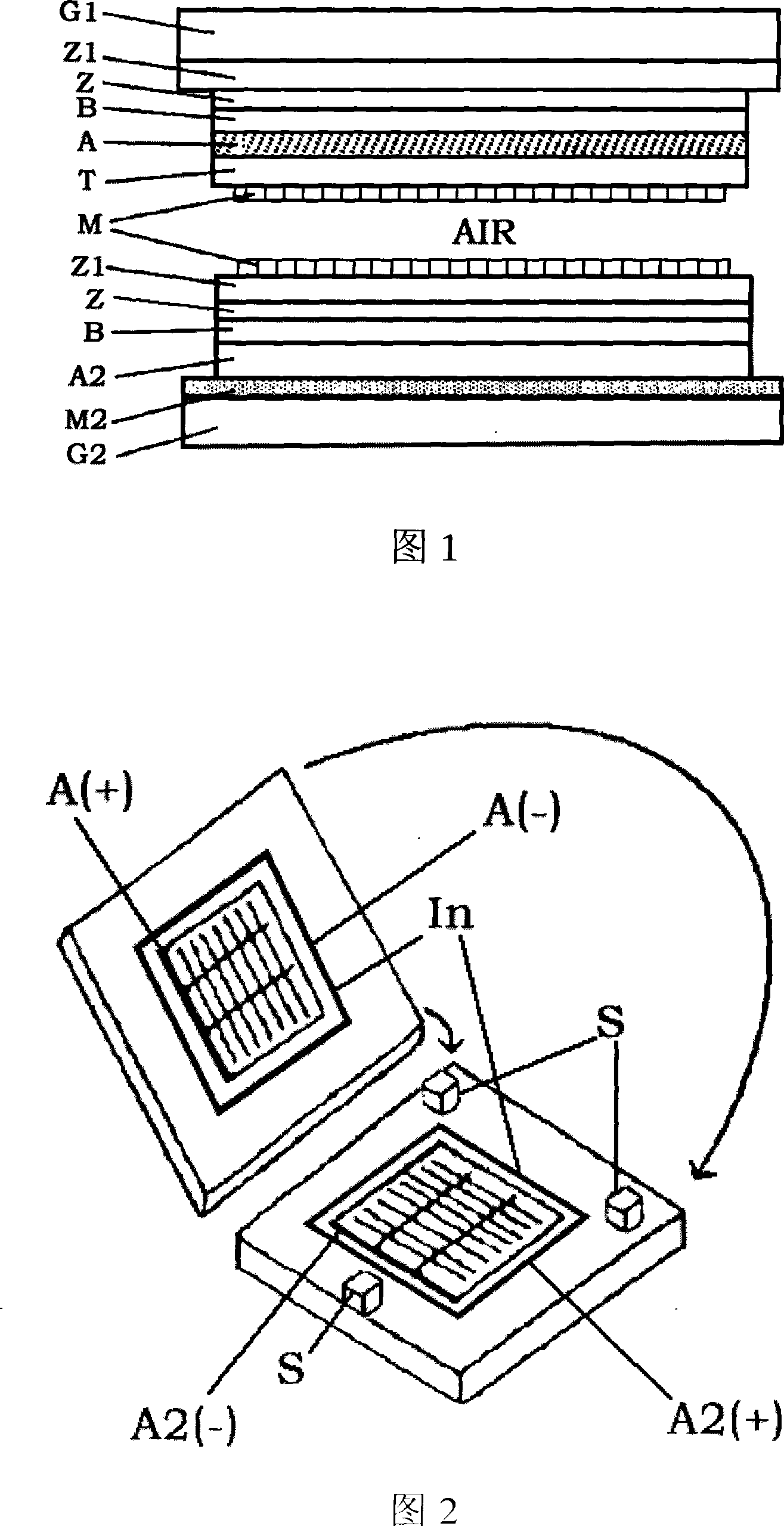

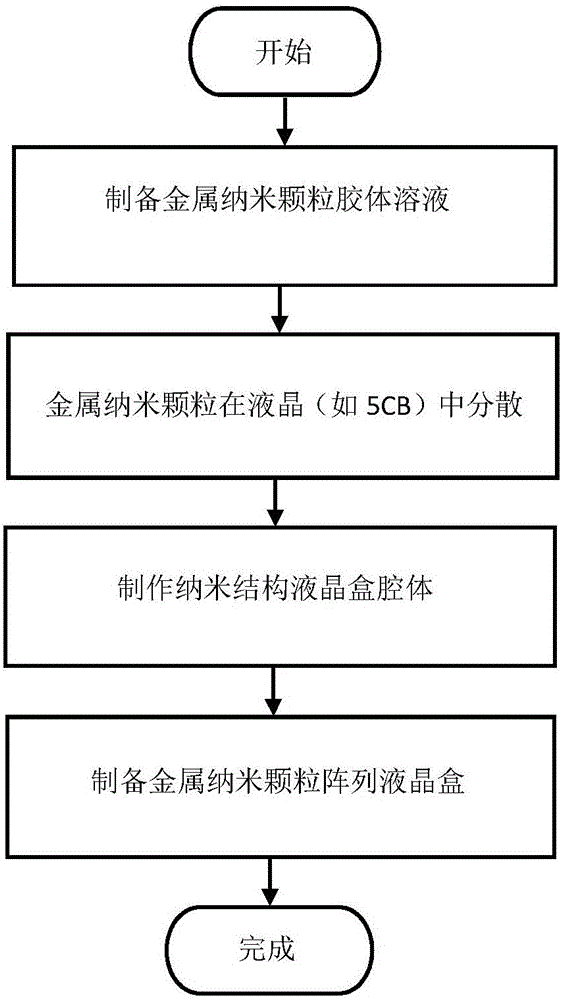

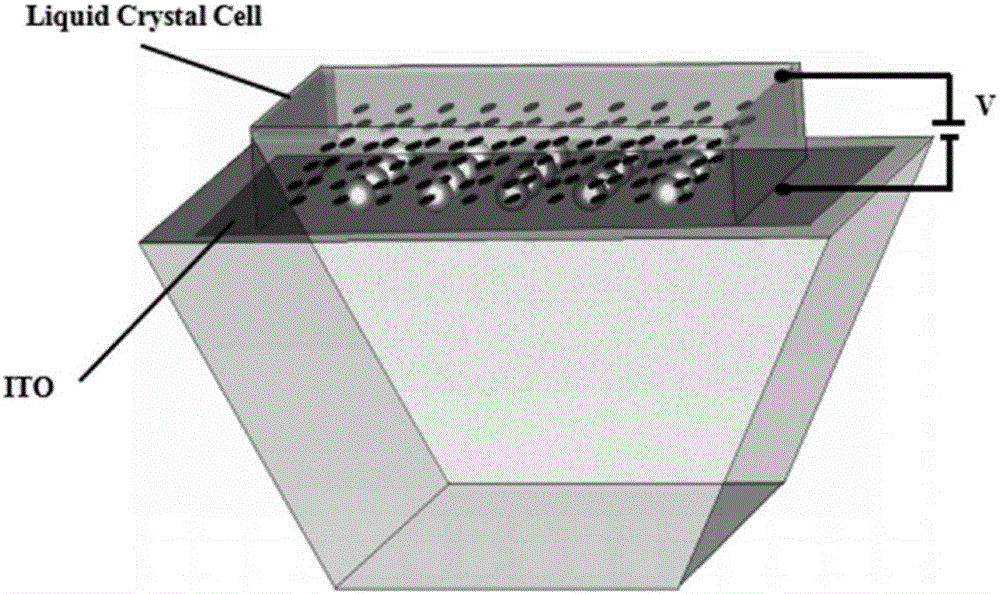

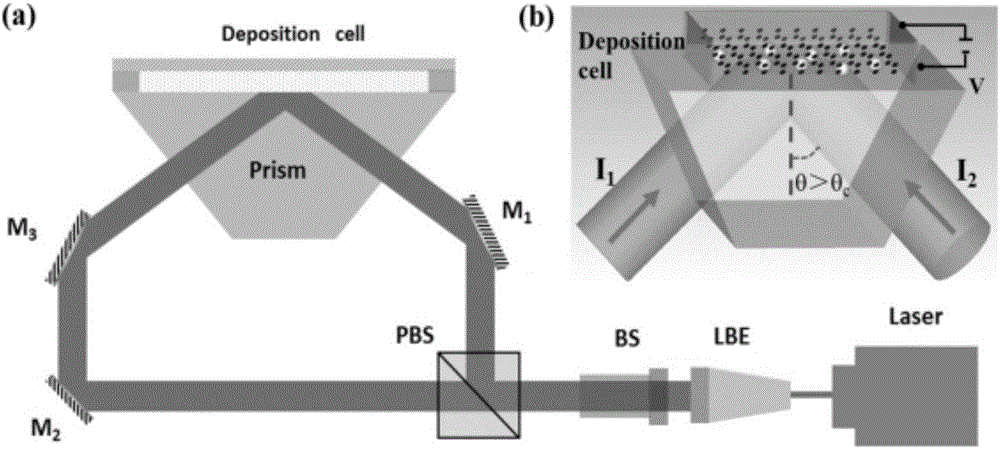

Production of photoelectric regulation metal nanoparticle and liquid crystal array structural box

InactiveCN105807466AImprove spectral responseImprove photoelectric control performanceNon-linear opticsSpectral responseNanostructure

The invention provides a production method of a photoelectric regulation metal nanoparticle and liquid crystal array structural box, and belongs to the technical field of photoelectricity. The production method provided by the invention is based on nano-structure polarization configuration, molecular configuration matching and an LSPR (Localized Surface Plasmon Resonance) principle of precious metal nanoparticles, utilizes a laser evanescent standing wave focused capturing deposition technology, and changes light intensity of laser evanescent standing waves so as to regulate the spatial form of a metal nano array and liquid crystal composite structure; when an optical field is utilized to regulate focused deposition, different voltages are loaded between upper and lower electrodes, and an electric field between the electrodes is changed to regulate the spatial structure of the metal nanoparticle and liquid crystal composite array structure so as to achieve different spectral responses and photoelectric regulation in a liquid crystal box. The metal nanoparticle and liquid crystal composite array structural box produced by the production method provided by the invention is helpful for providing a novel principle and a novel method for a novel surface plasmon photoelectric display technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method and device of diamond like carbon multi-layer doping growth

ActiveUS20100024873A1Improve spectral responseHigh electron mobilityFinal product manufactureSemiconductor/solid-state device manufacturingDiamond-like carbonSpectral response

A method of a:DLC multi-layer doping growth comprising the steps of: forming a plurality of a:DLC layers in one process, thereby creating a plurality of successively connected PIN junctions, starting from a first junction and ending in a last junction, respective PIN junctions having p-type, n-type, and intrinsic layers; varying the sp3 / sp2 ratio of at least the respective p-type and n-type layers and doping with at least silver to enhance electron mobility in respective PIN junctions; and connecting the plurality of a:DLC layers between electrodes at the first side and the second side to create a device having optimized spectral response to being oriented to a light source.

Owner:MAHRIZE MOSHE

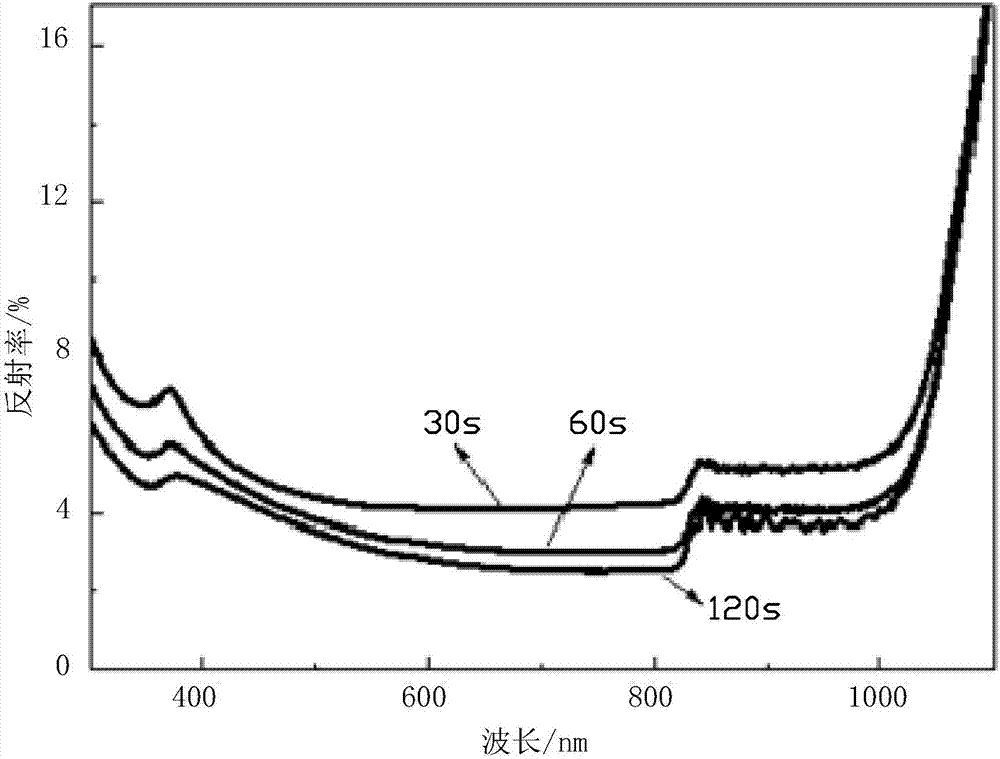

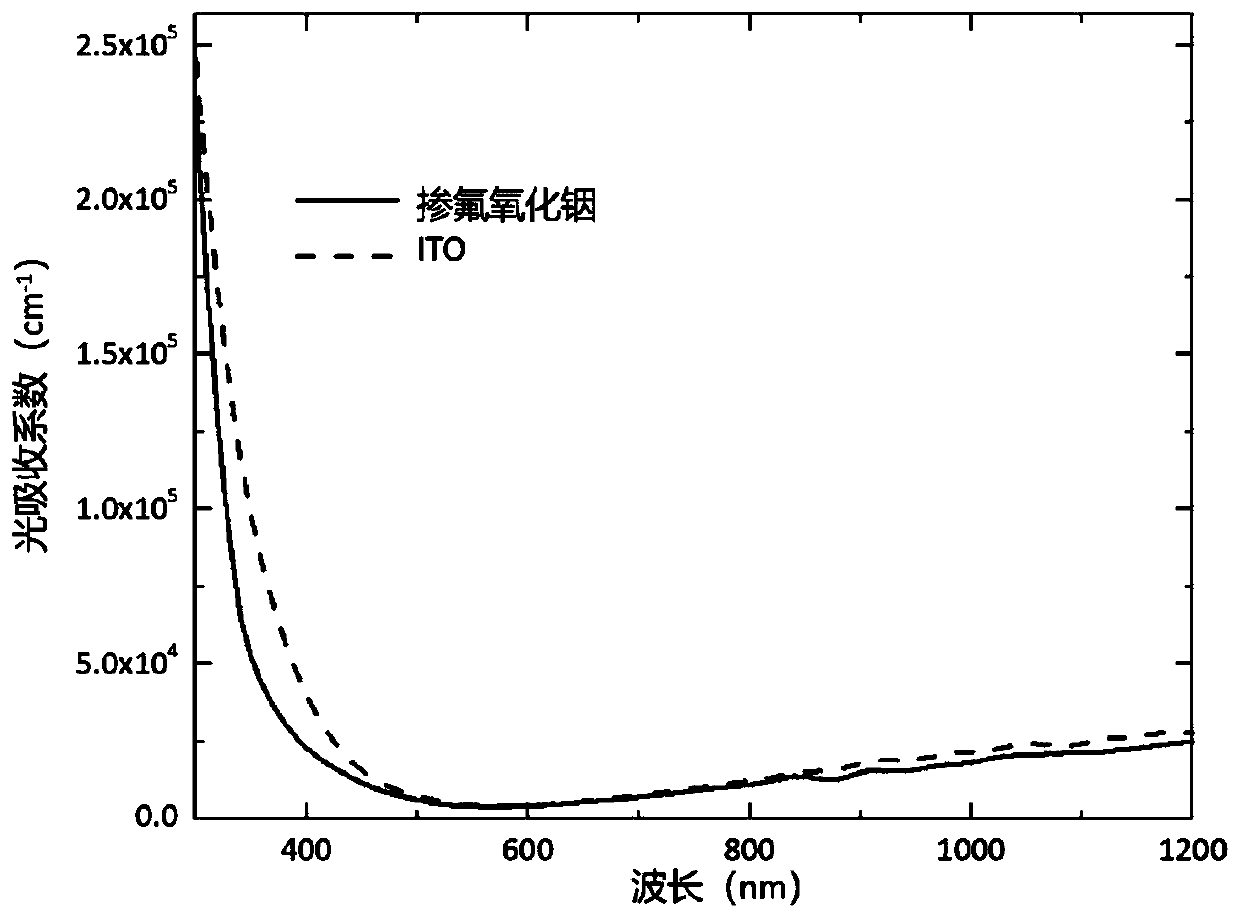

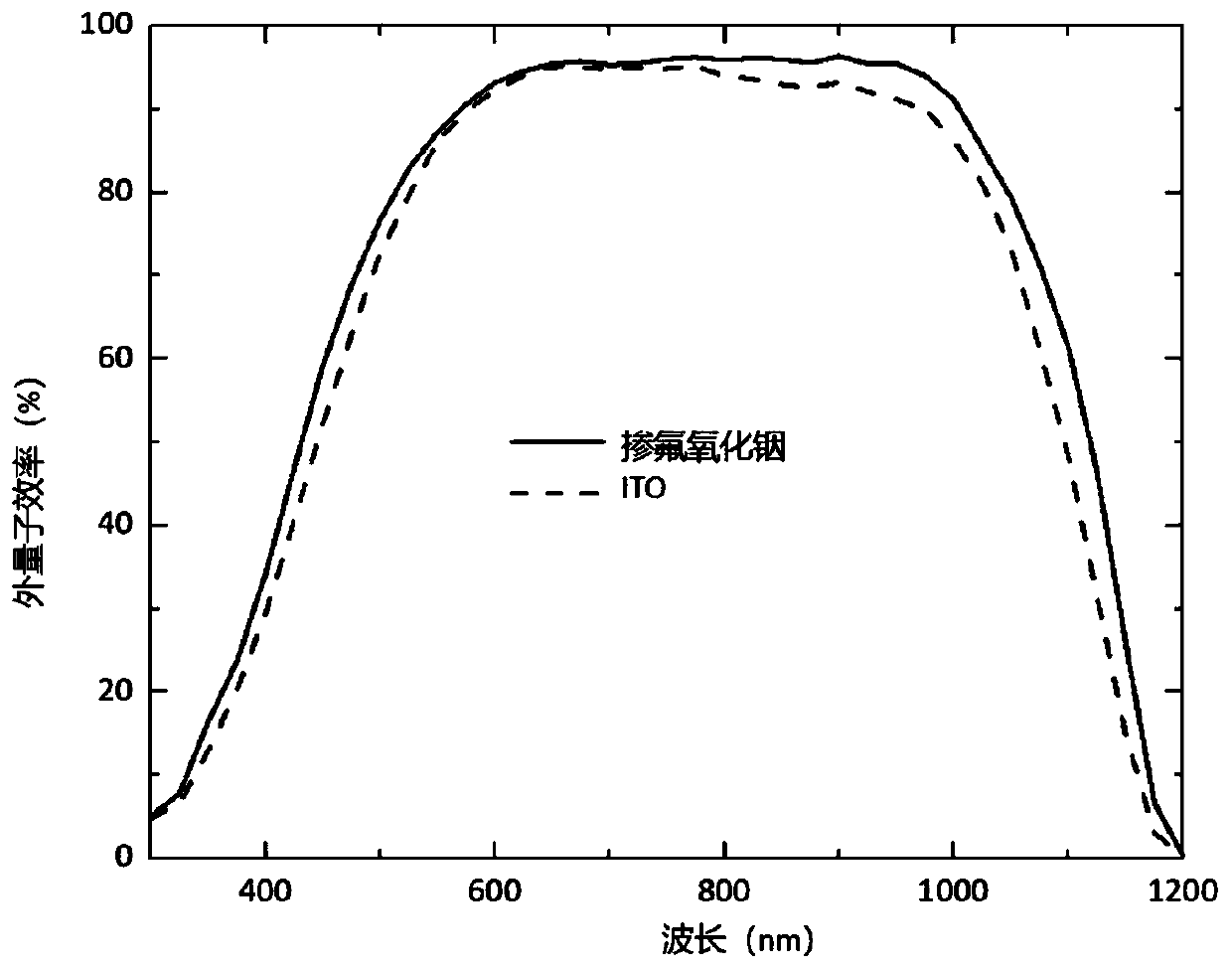

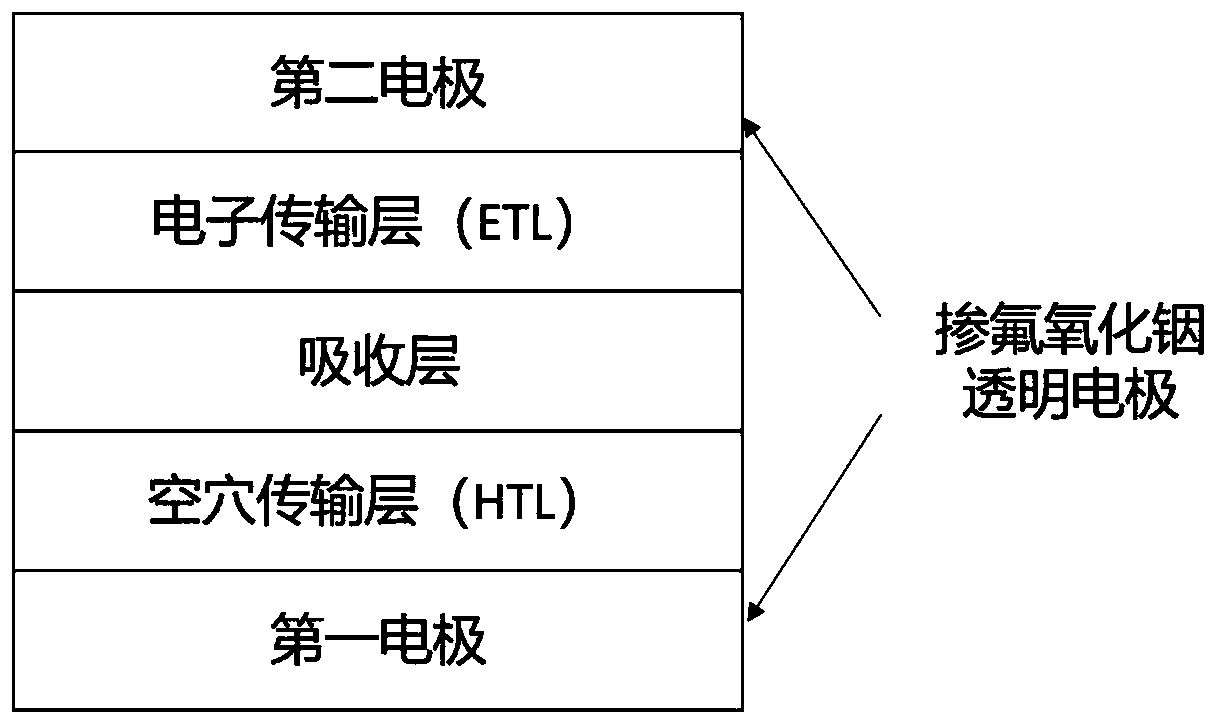

Preparation method and application of transparent conductive oxide film

InactiveCN111081812AImprove stabilityControllable natureFinal product manufactureSemiconductor devicesIndiumCharge carrier mobility

The invention provides a preparation method and application of a transparent conductive oxide film. According to the preparation method and application of the transparent conductive oxide film, magnetron sputtering technology is adopted; through process regulation and control, the high-efficiency deposition of a high-quality thin film can be realized; the preparation of a transparent conductive oxide film with carrier mobility higher than 60cm<2>V<-1 >s<-1> can be realized under a low-temperature condition; the electrical property of the oxide film is equivalent to that of ITO; and the opticalabsorptivity of the oxide film in a UV-Vis-IR full-wave band range is obviously reduced compared with that of the ITO. The fluorine-doped indium oxide transparent conductive oxide film prepared by the invention has good thermal stability; heat treatment at 250 DEG C or below basically does not cause the deterioration of material properties; the performance of the fluorine-doped indium oxide filmsubjected to proper post-treatment can be further improved; in addition, transition metal elements are not used, and therefore, the performance of the oxide film is stable, and meanwhile, the opticalproperties of the oxide film can be effectively regulated and controlled; and since the transition metal elements are not used, preparation cost is low.

Owner:SHENZHEN INST OF WIDE BANDGAP SEMICON

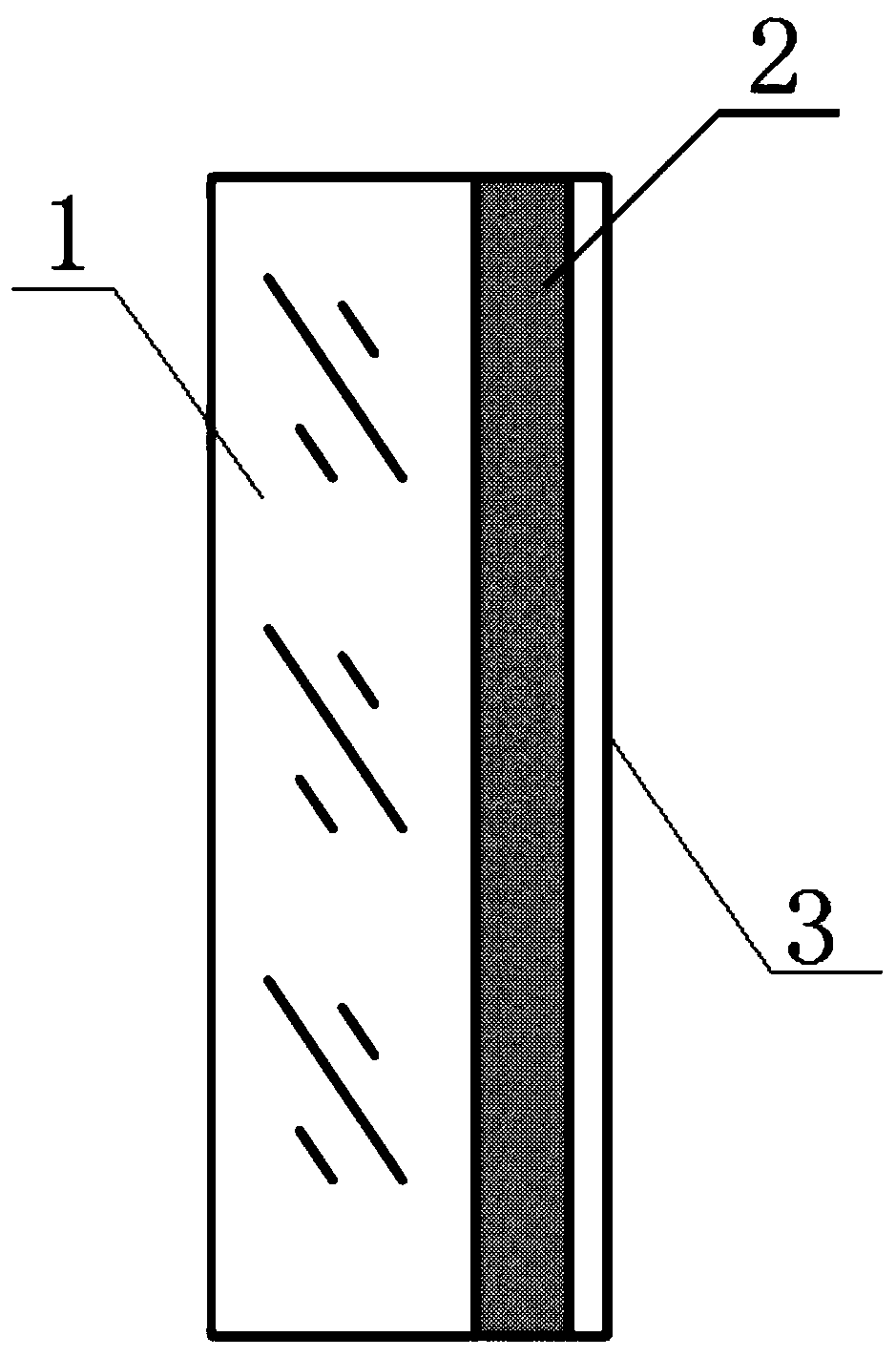

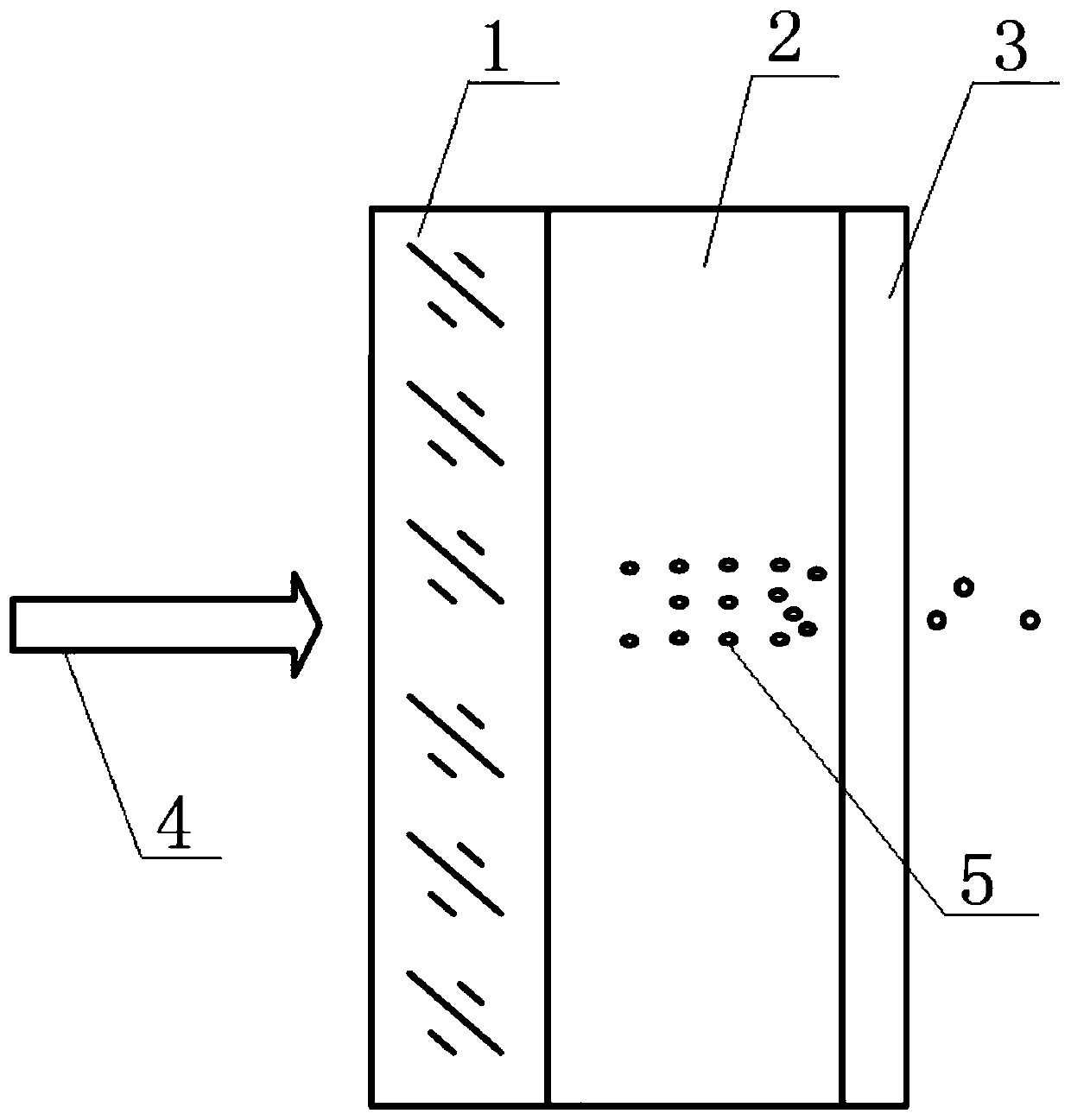

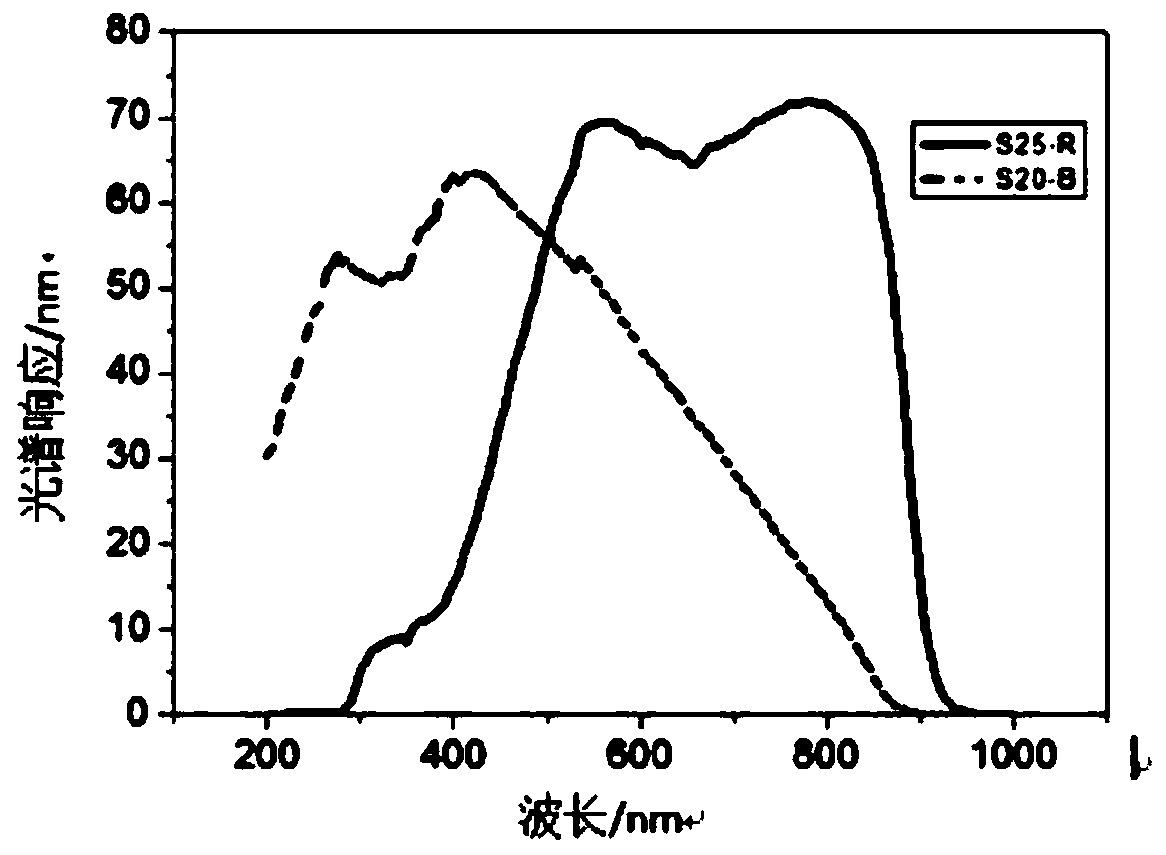

Transmission type multi-alkali photoelectric cathode with wide spectrum response and manufacturing method of cathode

ActiveCN109841466ASolve different short-wave ultravioletSolve visible lightPhoto-emissive cathodesPhoto-emissive cathodes manufactureState of artSurface layer

The invention relates to a transmission type multi-alkali photoelectric cathode with wide spectrum response and a manufacturing method of the cathode, and belongs to the field of photoelectric cathodes. The transmission type multi-alkali photoelectric cathode is prepared in a traditional method, in the manufacturing process of a Na2KSb substrate layer, when the thickness reaches that of the Na2KSbsubstrate layer in a S20-B multi-alkali photoelectric cathode, a reseau is disposed in front of the multi-alkali photoelectric cathode, the Na2KSb substrate layer is further manufactured so that thethickness of the substrate layer reaches the thickness of the Na2KSb substrate layer in a S25-R multi-alkali photoelectric cathode; and then the reseau is removed, the Cs3Sb surface layer is manufactured. Disadvantages in the prior art are overcome, and the problem that a present multi-alkali photoelectric cathode does not include simultaneous response to short-wave UV, visible light and long wavenear infrared spectroscopy is solved.

Owner:NORTH NIGHT VISION TECH

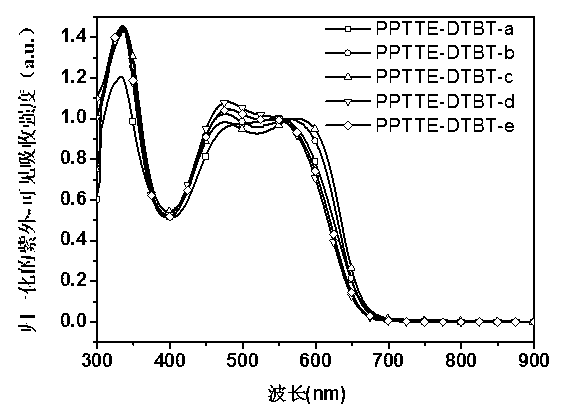

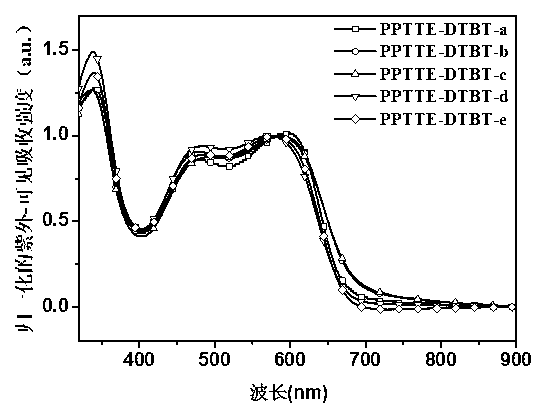

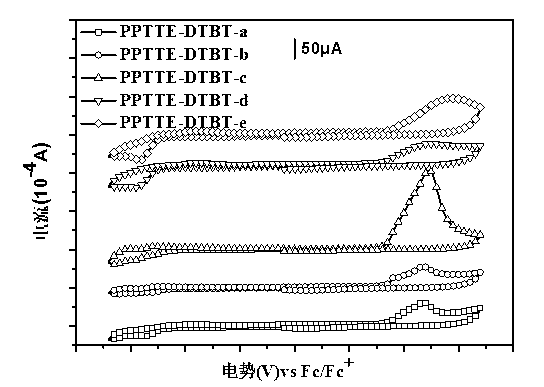

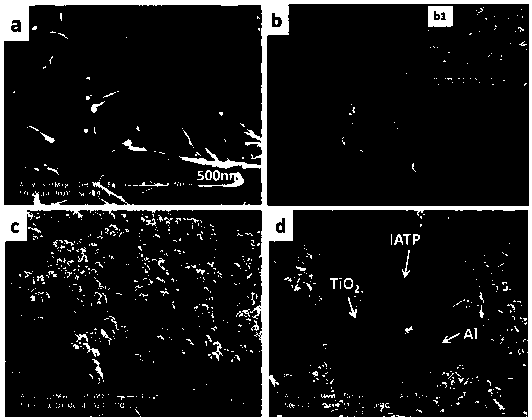

Perylene tetracarboxylic carboxylic ester group polymer acceptor materials and application thereof to solar battery

InactiveCN102924694AImprove spectral responseChange lengthSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batterySolar battery

The invention discloses perylene tetracarboxylic carboxylic ester group polymer acceptor materials and application thereof to a solar battery. The materials include a structure as refined in formula 1, in the formula 1, M is diazosulfide, dithienyl diazosulfide, selenole, dithienyl selenole, diselenium thiophene selenole, thiophene, dithiophene, terthienyl, benzene, selenophen, diselenide thiophene, terselenide thiophene, thiophene thiophthene, benzo dithiophene, benzo ditellurium thiophene, benzo ditellurium thiophene, or one of derivatives made on the basis of the compounds. R is a linear chain with more than four carbon atoms, a branched chain or an alkyl chain containing different heteroatoms. N is a natural number of 1-1000. By introducing comonomer M on the perylene ring skeletons 1, 7 positions, the level structure of polymer materials can be adjusted, and at the same time, optical property is improved, and use ratio of the materials to light is enhanced. By introducing R, dissolubility of the polymer materials can be adjusted, and utilization of a solution processing technology with low cost is facilitated. The materials can be applied to the field of organic optoelectronics.

Owner:WUHAN UNIV OF TECH

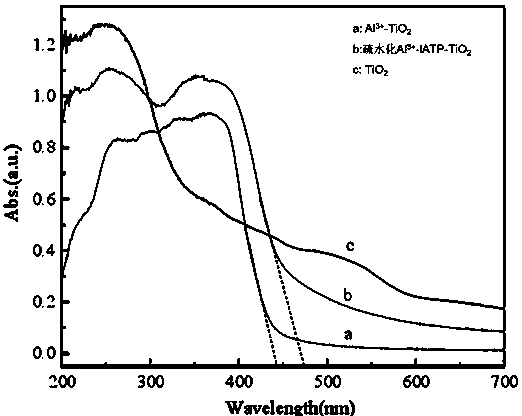

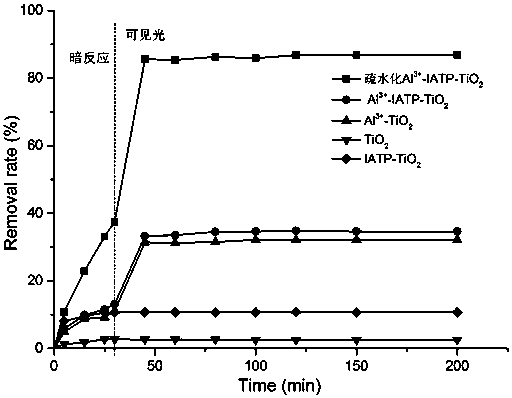

Preparation method of hydrophobic TiO2 visible-light catalyst

ActiveCN107552029AImprove adsorption capacityWide response spectrumPhysical/chemical process catalystsWater/sewage treatment by irradiationSpectral responseOrganic matter

The invention discloses a preparation method of a hydrophobic TiO2 visible-light catalyst. The hydrophobic TiO2 composite visible-light catalyst with high adsorption and wide spectral response is prepared by utilizing the strong adsorption property of hydrophobic attapulgite after being irradiated by high-power electron beams and the doping vario-property of migrating metal cations on the surfaceof the attapulgite, and the problems that a TiO2 photocatalyst has no adsorption or concentration capacity for strongly hydrophobic organic pollutants and is narrow in the spectral response range aresolved. The novel hydrophobic TiO2 visible-light catalyst material has the capacity of efficient concentration of the strongly hydrophobic organic pollutants and visible light degradation, and can beused for light degradation of indoor and industrial low-concentration VOCs (volatile organic chemicals) and water bodies and strongly hydrophobic organic matters in soil.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Heterojunction solar cell of inclined metal contact structure based on N type silicon wafer

InactiveCN102709340AAvoid the problem of large shading areaIncrease opening pressurePhotovoltaic energy generationSemiconductor devicesHeterojunctionScreen printing

The invention relates to a heterojunction solar cell of an inclined metal contact structure based on an N type silicon wafer. The heterojunction solar cell of the inclined metal contact structure based on the N type silicon wafer comprises an N type mono-crystalline silicon base body, a positive electrode, a negative electrode, transparent conductive films and a plurality of film layers manufactured and formed on the front face and the back face of the N type mono-crystalline silicon base body, wherein each film layer manufactured and formed on the back face of the N type mono-crystalline silicon base body comprises an N<+> heavily-doped layer, forming N<+> / N high-low junctions; one layer of transparent conductive film is manufactured and formed on the outermost layer of each of the front face and the back face of the N type mono-crystalline silicon base body; a recess is arranged on the front face of the N type mono-crystalline silicon base body; the positive electrode of the cell is put in the recess; and the negative electrode of the cell is put on the back face of the N type mono-crystalline silicon base body. Generating no drastic light failure phenomenon of the heterojunction solar cell constituted by the routine P type crystalline silicon and the crystalline silicon of a non-crystalline silicon film, the heterojunction solar cell of the inclined metal contact structure based on the N type silicon wafer is better in spectral response, and further is greatly thinned; the shading area of grid lines is decreased from 6% to 1% of the routine silk-screen printing mode, so that the conversion efficiency of the solar cell is improved; and additionally, with the adoption of a low temperature production process, the production cost is reduced.

Owner:ZHEJIANG JINKO SOLAR CO LTD

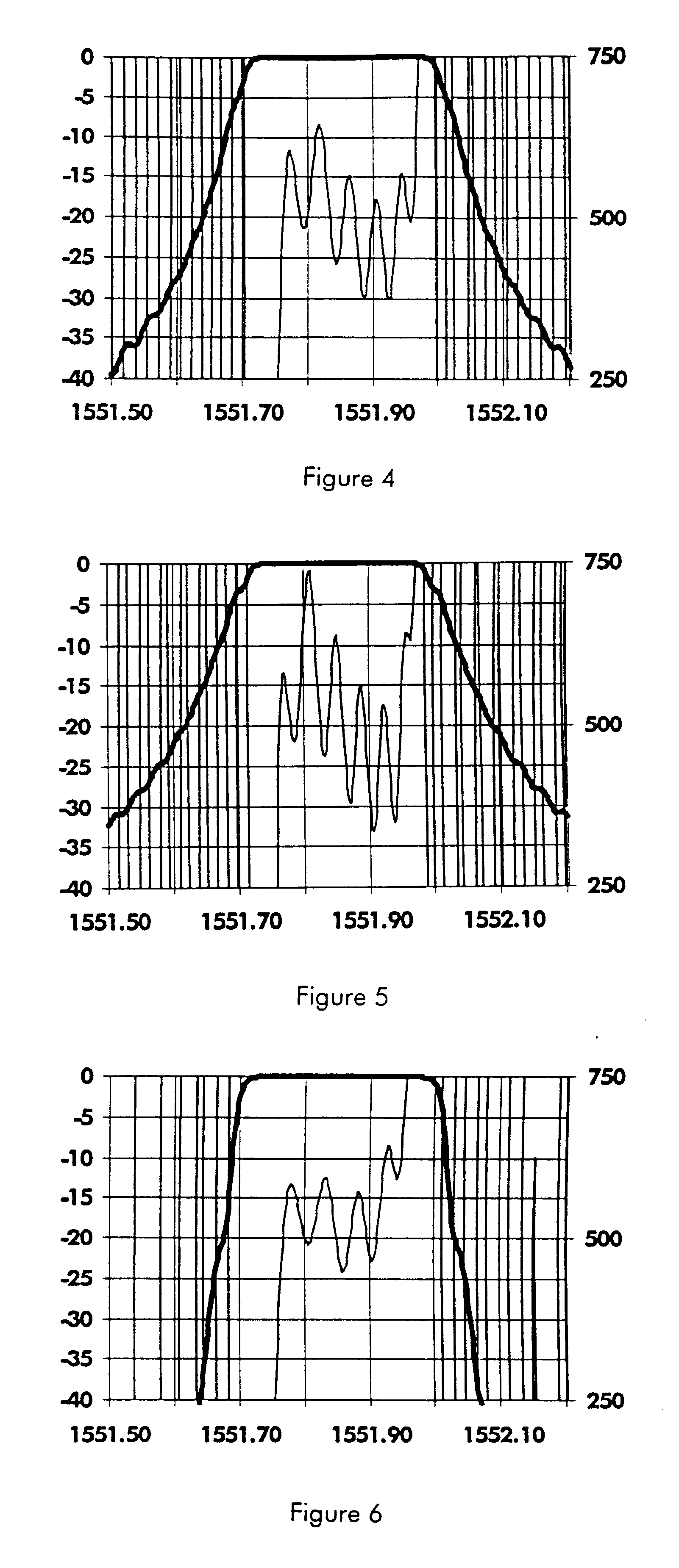

Optical filter with little variation in chromatic dispersion

InactiveUS6441962B1Improve spectral responseCladded optical fibreWavelength-division multiplex systemsWdm transmission systemsGrating

An optical filter has little variation in chromatic dispersion over its passband, the filter being constituted by a Bragg grating whose pitch varies as a function of distance along the filter with a change in the sense of its concavity. The filter also presents apodization, e.g. apodization by a super-Gaussian function or Blackman apodization. The filter of the invention is adapted to high data rate dense WDM transmission systems.

Owner:II VI DELAWARE INC

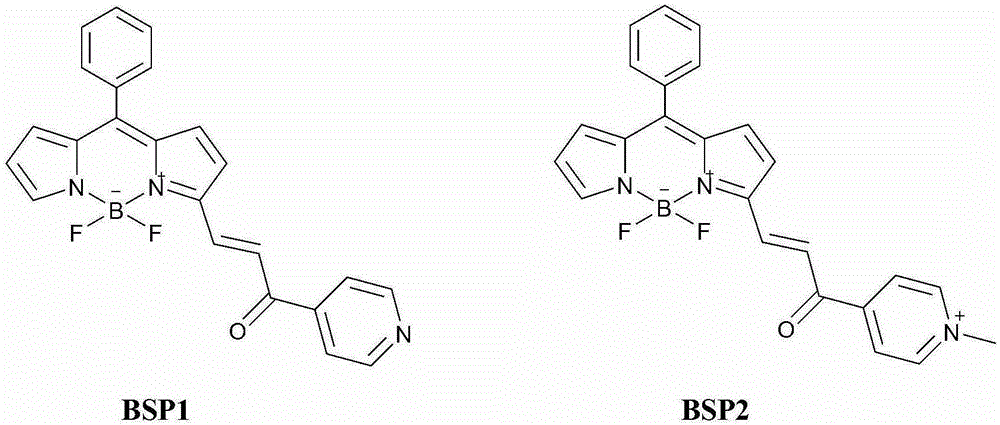

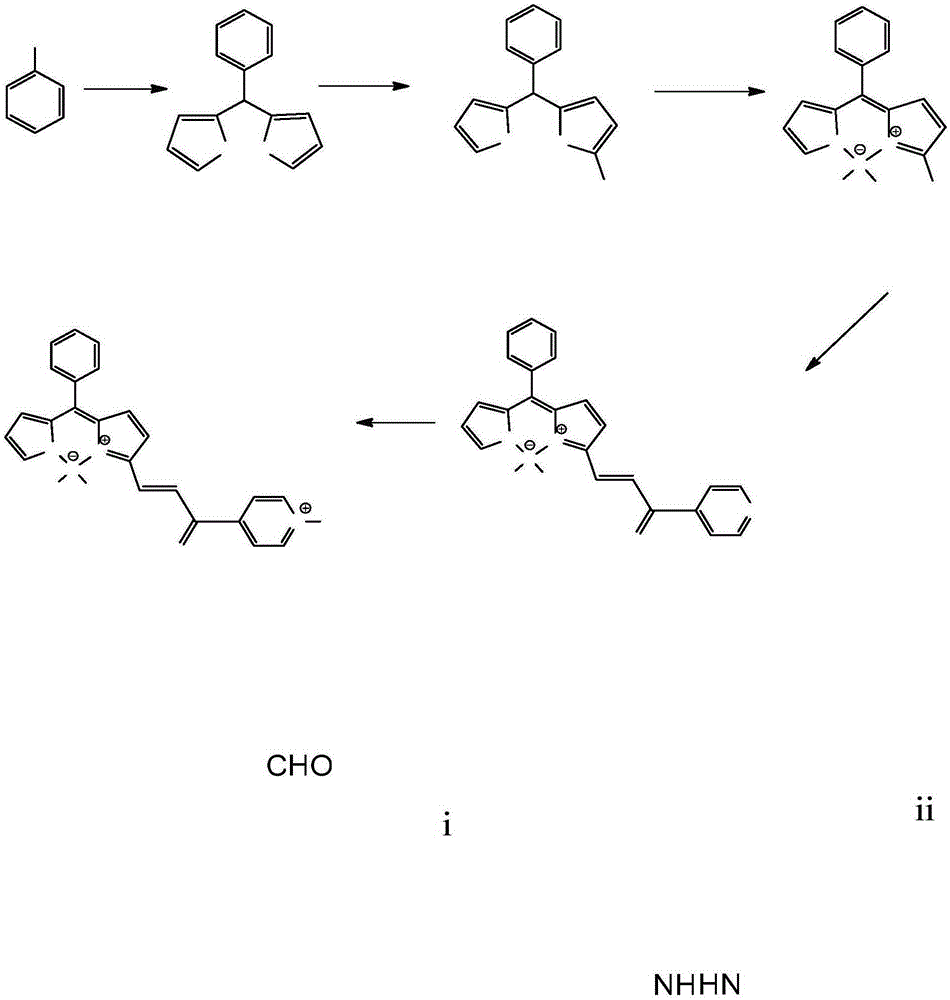

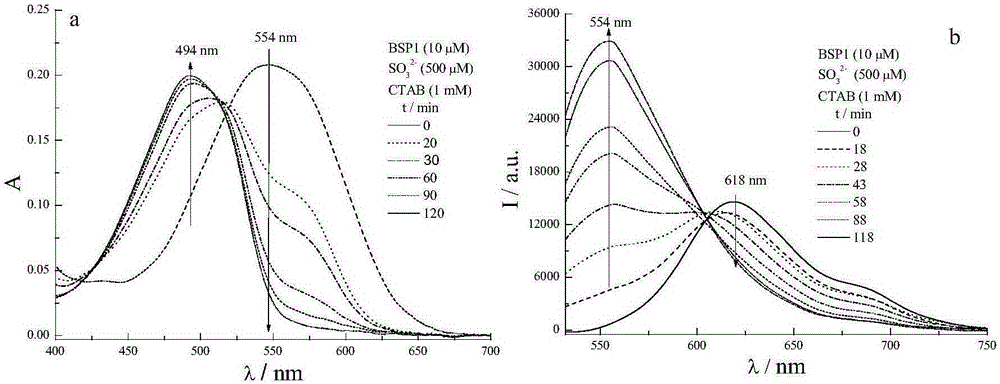

Boron dipyrromethene compound containing alpha,beta-unsaturated ketone, and application of same in detection of sulfite

InactiveCN105820183AGood choiceIncreased sensitivityGroup 3/13 element organic compoundsColor/spectral properties measurementsFluorescenceSulfate

The invention relates to a boron dipyrromethene compound containing alpha,beta-unsaturated ketone, and application of same in detection of sulfite. A novel fluorescent probe utilizes the characteristic that C-C double bonds on the alpha,beta-unsaturated ketone and sulfite undergo nucleophilic addition; after reaction with sulfite, the absorption and emission spectra of the compound both show substantial blue shift; and the probe has high detection sensitivity and selectivity to sulfite, has emission wavelength of 620 nm, is located in a red light zone and is applicable to detection of sulfite in a practical sample.

Owner:EAST CHINA UNIV OF SCI & TECH

Perovskite/N-type TOPCon/perovskite laminated solar cell and preparation method thereof

ActiveCN111525037AIncrease profitEnhanced light absorptionFinal product manufactureSolid-state devicesSolar cellHole transport layer

The invention relates to a preparation method of a perovskite / N-type TOPCon / perovskite laminated solar cell and the perovskite / N-type TOPCon / perovskite laminated solar cell. The method comprises the following steps: (1) preparing p+ doped regions on two sides of a silicon substrate after double-side texturing; (2) etching one surface of the silicon substrate in an acidic solution to remove a p+ doped region on the back surface; (3) preparing a tunneling oxide layer and an intrinsic amorphous silicon layer on the back surface of the silicon substrate; and (4) carrying out doping treatment on the intrinsic crystal silicon layer of the silicon substrate, and cleaning. (5) annealing the silicon substrate to form a doped polycrystalline silicon film; removing the polycrystalline silicon windingdegree on the front surface; (6) preparing composite layers on the two sides of the silicon substrate; (7) sequentially preparing a front electron transport layer, a front perovskite absorption layerand a front hole transport layer on the front composite layer of the silicon substrate; sequentially preparing a back hole transport layer, a back perovskite absorption layer and a back electron transport layer on the back composite layer of the silicon substrate; and (8) preparing metal electrodes on the two sides of the silicon substrate.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

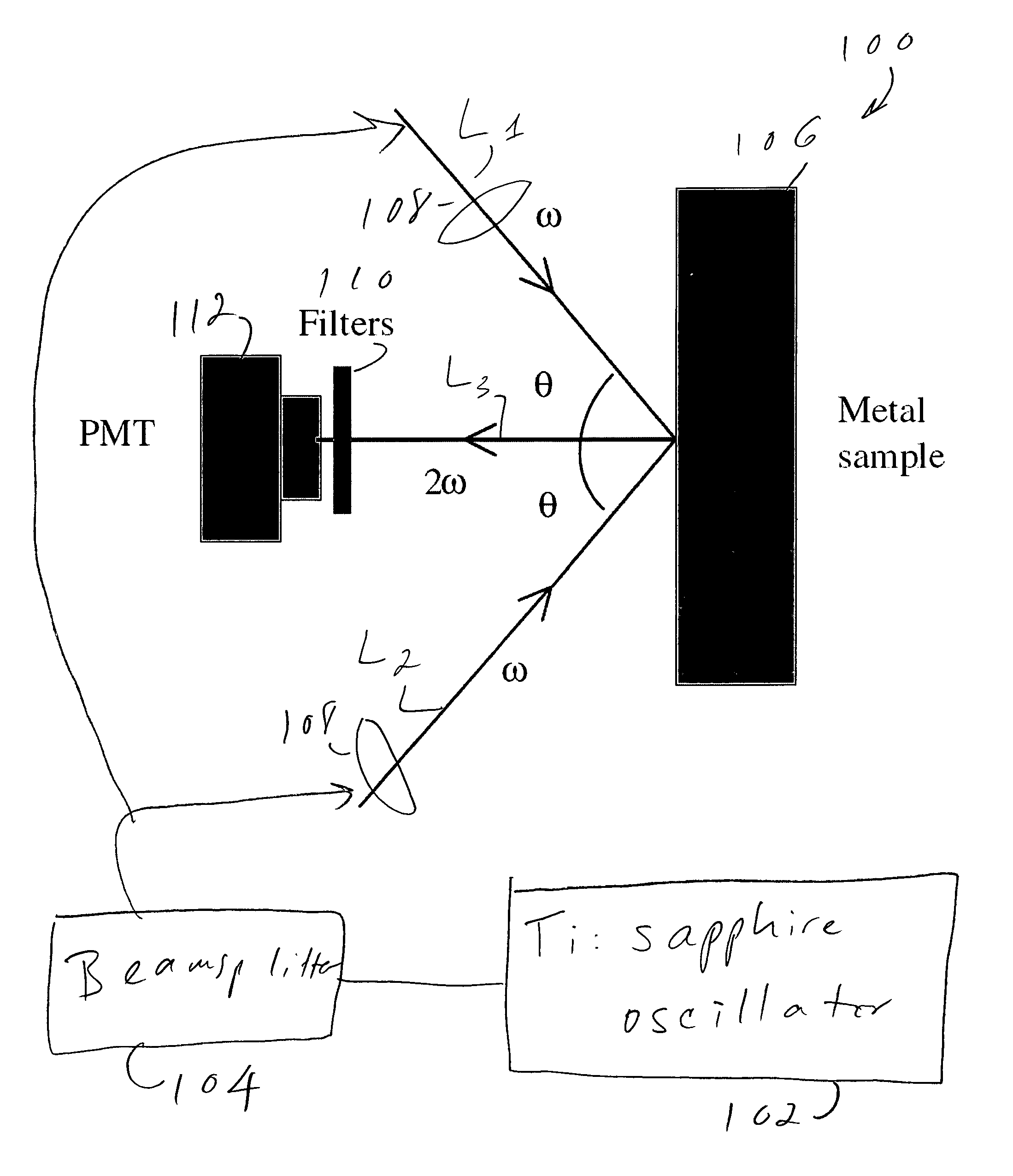

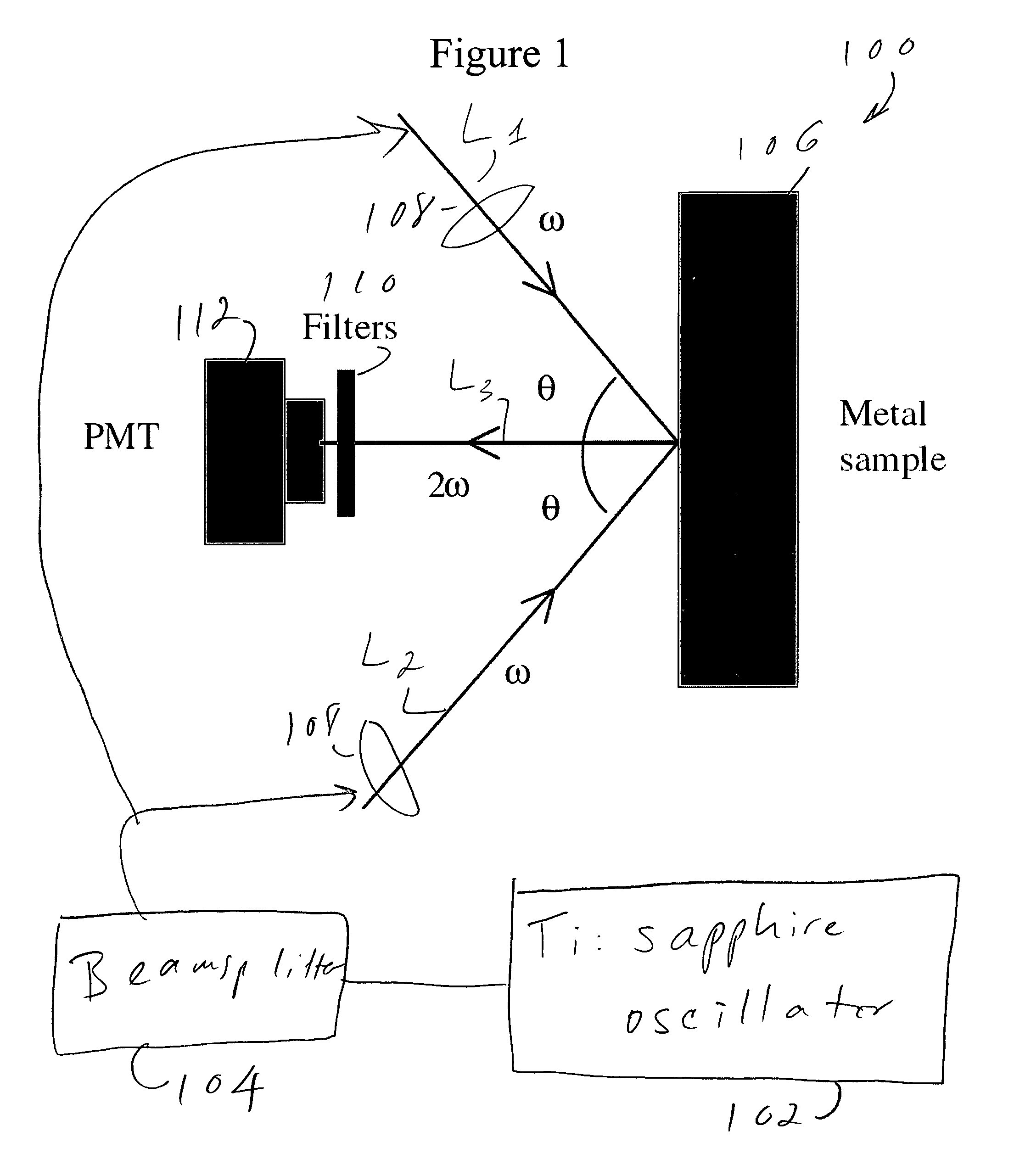

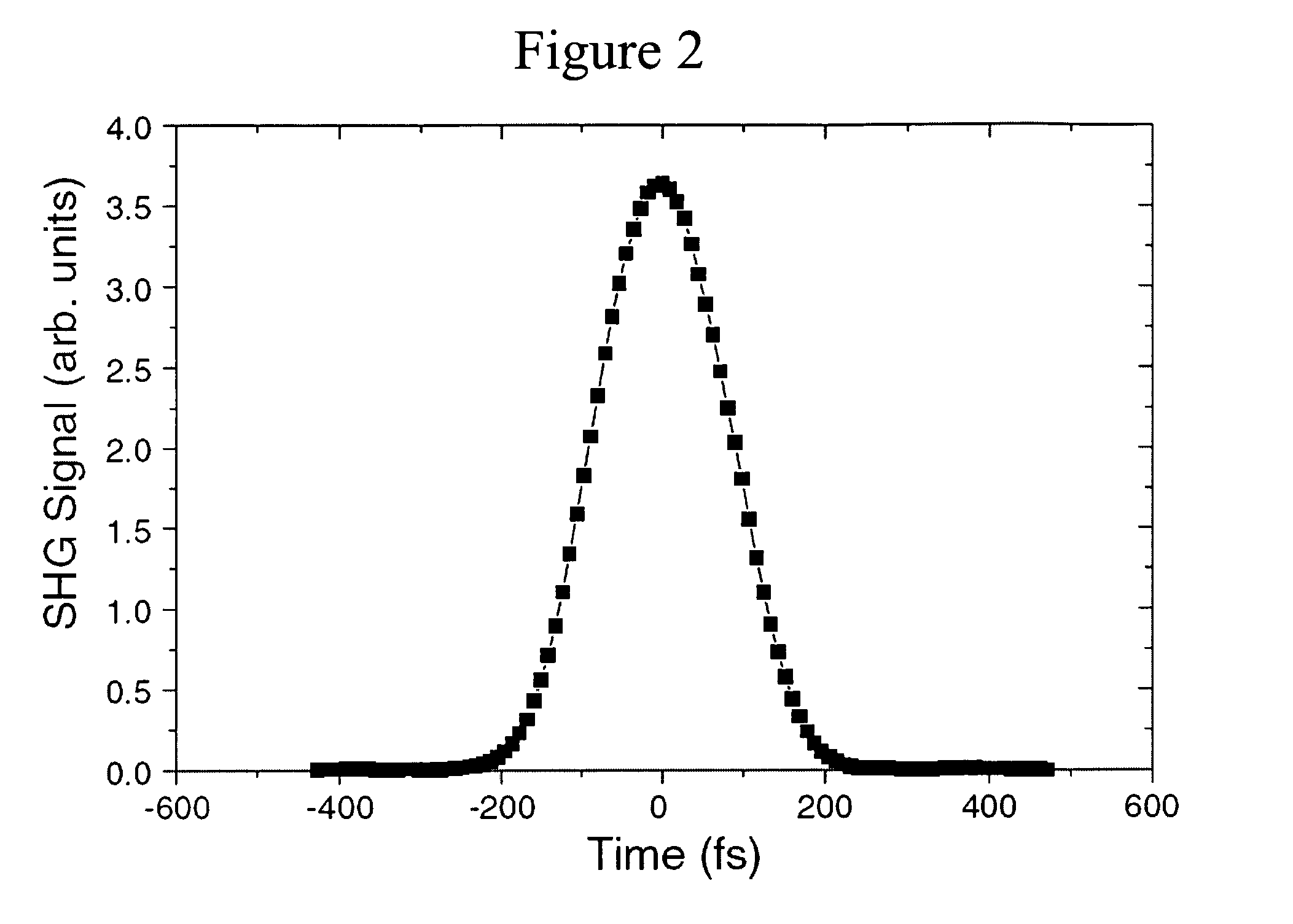

Dispersion-free, automatically phase-matched, and broad spectral-band femtosecond autocorrelation technique

InactiveUS7420685B1Avoid distractionImprove efficiencyScattering properties measurementsColor/spectral properties measurementsSpectral bandsFrequency spectrum

Two optical signals are autocorrelated by causing them to be incident on a metal surface, where they generate a second (or higher) harmonic signal. The resulting harmonic signal is detected by a photomultiplier tube or the like. The harmonic signal generation on the metal surface is phase-matched and dispersion free and can be performed over a wide range of wavelengths.

Owner:UNIVERSITY OF ROCHESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com