Preparation method of hydrophobic TiO2 visible-light catalyst

A hydrophobicizing reagent, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, adsorption water/sewage treatment, etc. Degradation, narrow spectral response range of titanium-based semiconductors, etc., to improve adsorption capacity and spectral response performance, facilitate large-scale production applications, and broaden the response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

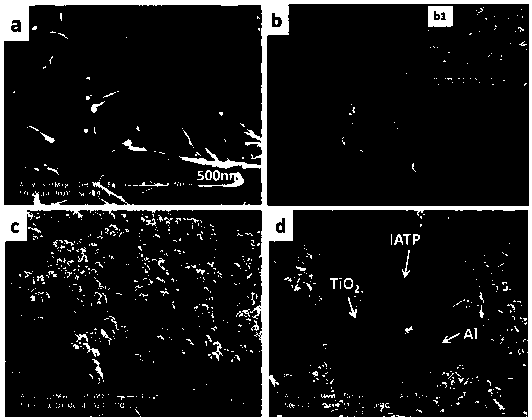

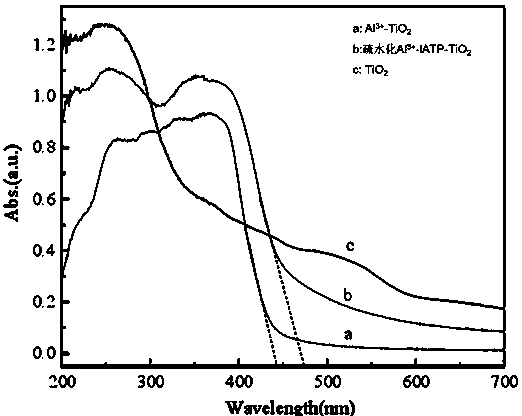

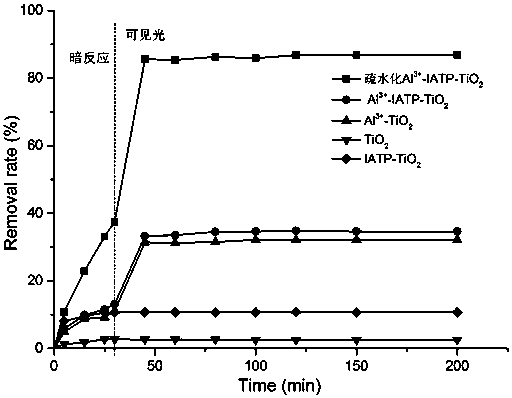

Image

Examples

Embodiment 1

[0029] (1) Weigh 20 g of irradiated modified attapulgite and dissolve it in 250 mL of ultrapure water, stir magnetically for 5 min, ultrasonically for 10 min, stir in a water bath at 60°C, add 4 g of octadecyltrimethylammonium chloride , and reacted for 4 hours under reflux to obtain hydrophobized photomodified attapulgite. Centrifuge at 10,000rpm to remove the precipitate, first wash with deionized water, and finally wash with ethanol (to remove unreacted substances), and dry in an oven at 80°C , and ground to obtain hydrophobized radiation-modified attapulgite powder.

[0030] (2) Weigh 0.6g Al 2 (SO 4 ) 3 Dissolved in 60 mL of ultrapure water, added 6 g of hydrophobized irradiation-modified attapulgite powder, and adjusted the movable ions to obtain Al 3+ Substituted hydrophobized irradiation modified attapulgite;

[0031] (3) Clean the crucible with deionized water, dry it in an oven for 60 minutes, weigh 16g of butyl titanate and dissolve it in 50mL of ultrapure water...

Embodiment 2

[0033](1) Weigh 20 g of irradiated modified attapulgite and dissolve it in 250 mL of ultrapure water, stir magnetically for 5 min, and ultrasonically for 10 min, stir in a water bath at 60°C, add 4 g of sodium linear alkylbenzene sulfonate, and reflux Hydrophobic irradiated modified attapulgite was obtained by reacting for 4 h in the state, centrifuged at 10,000 rpm to remove the precipitate, washed with deionized water and ethanol for 4 times, dried in an oven at 80°C, and ground to obtain the hydrophobized irradiated modified attapulgite. Sexual attapulgite powder.

[0034] (2) Weigh 0.6g Al 2 (SO 4 ) 3 Dissolved in 60 mL of ultrapure water, added 6 g of hydrophobized irradiation-modified attapulgite powder, and adjusted the movable ions to obtain Al 3+ Substituted hydrophobized irradiation modified attapulgite;

[0035] (3) Clean the crucible with deionized water, dry it in an oven for 60 minutes, weigh 16g of butyl titanate and dissolve it in 50mL of ultrapure water, a...

Embodiment 3

[0037] (1) Dissolve 20 g of irradiated modified attapulgite in 250 mL of ultrapure water, stir magnetically for 5 min, sonicate for 10 min, stir in a water bath at 60°C, add 4 g of polyacrylamide, and react for 4 h under reflux Obtain the attapulgite modified by hydrophobic irradiation, centrifuge at 10,000rpm to remove the precipitate, wash with deionized water and ethanol four times successively, dry in an oven at 80°C, and grind to obtain the hydrophobic irradiation modified attapulgite powder .

[0038] (2) Weigh 0.6g Al 2 (SO 4 ) 3 Dissolved in 60 mL of ultrapure water, added 6 g of hydrophobized irradiation-modified attapulgite powder, and adjusted the movable ions to obtain Al 3+ Substituted hydrophobized irradiation modified attapulgite;

[0039] (3) Clean the crucible with deionized water, dry it in an oven for 60 minutes, weigh 16g of butyl titanate and dissolve it in 50mL of ultrapure water, add 8g of Al prepared in step (2) 3+ For the replaced hydrophobized ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com