Patents

Literature

386 results about "High energy electron beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

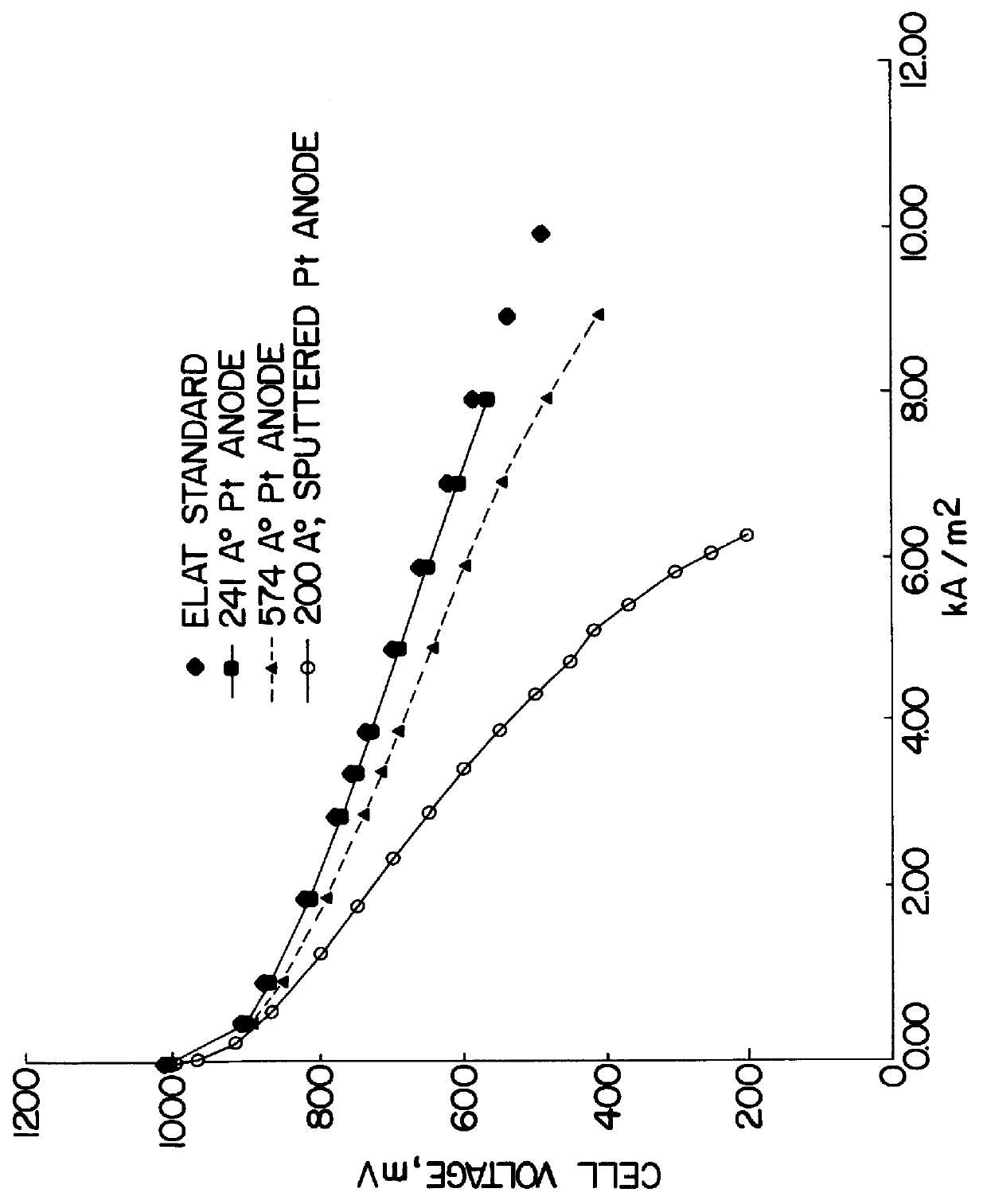

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

Dressing material containing medicine chitoholosida and its preparation method

InactiveCN1579559AHas therapeutic effectSustained releaseAbsorbent padsBandagesSolid componentPhosphate

The invention produces polyethylene alcohol hydrogel dressing containing medicine and chitosan with 60Co gamma-radial or high energy electron beam radial cross linking. Additional, adds in some humectant, plasticizer, medicine, the solvent is the secondary distilled water, physiological saline or phosphate neutral buffer liquid. The product can release medicine slowly and has natural amylose chitosan with biology sterilization activity, it has active sterilization function, at the same time, it has high water quantity, and good water reserving performance, the mechanical intensity is moderate, and the light penetration and air penetration are excellent. It can accord the demands for curing each kind of wound. It can used as the permanent dressing for light skin injuries, and it also can be applied to the temporally close of severe skin organization wound or burn wound.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

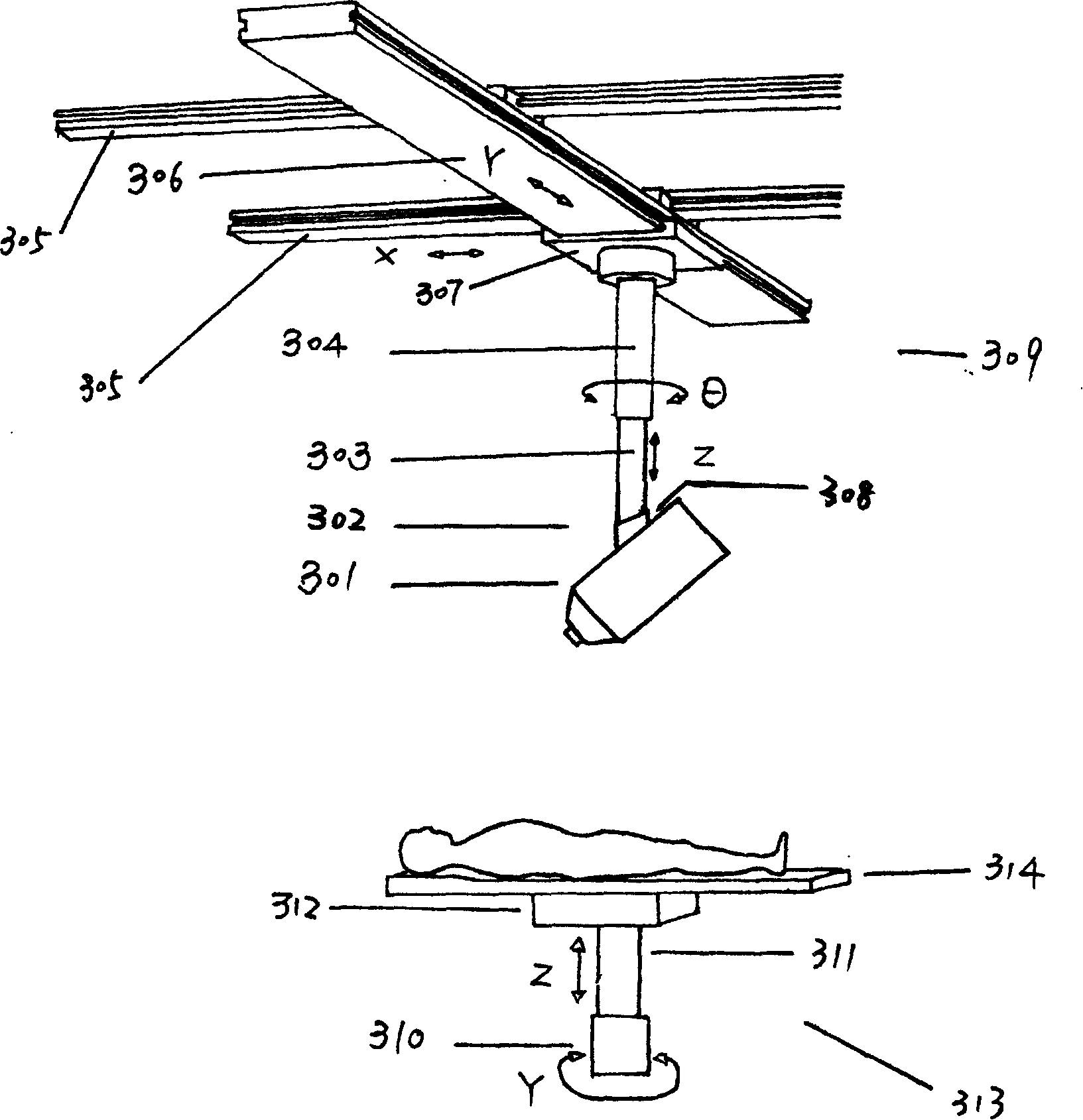

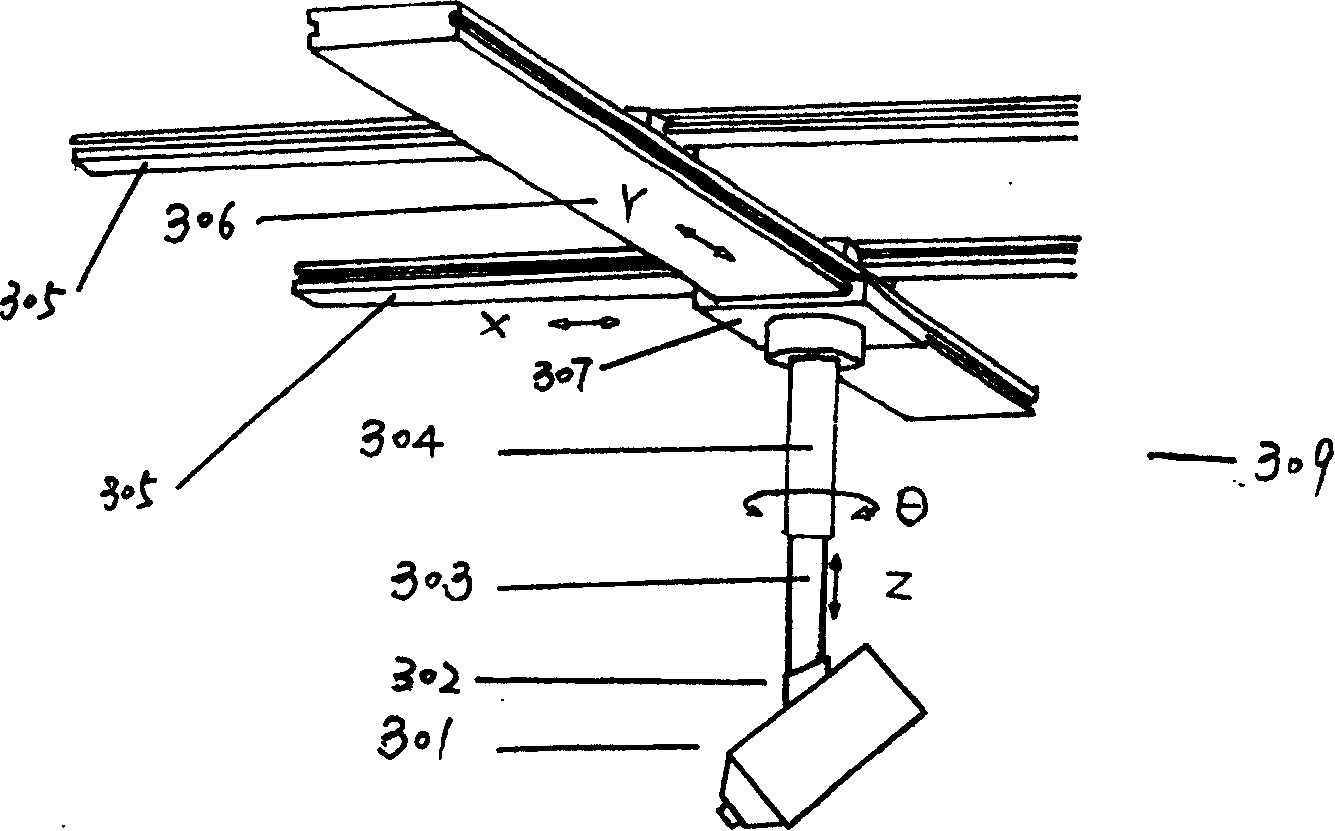

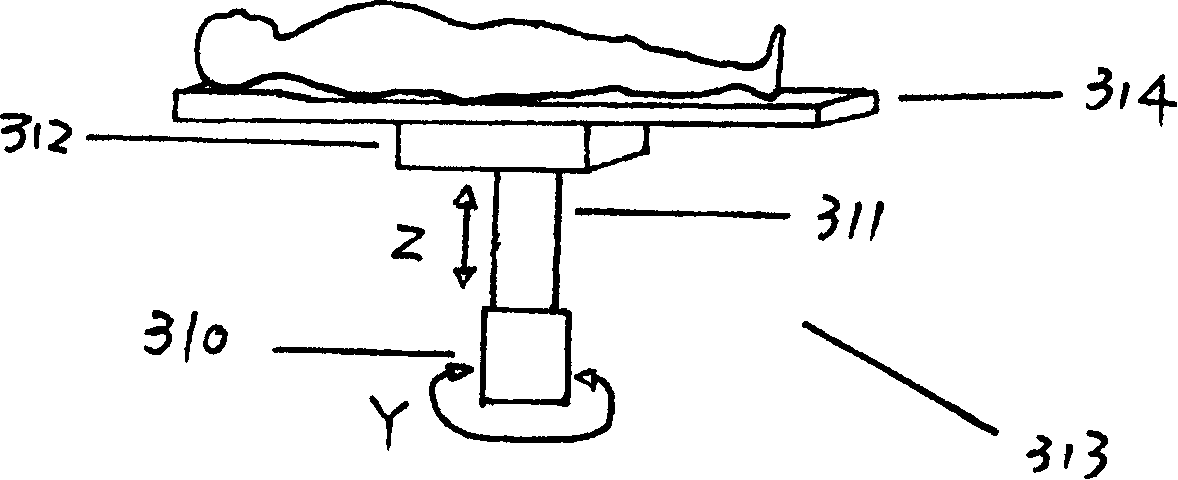

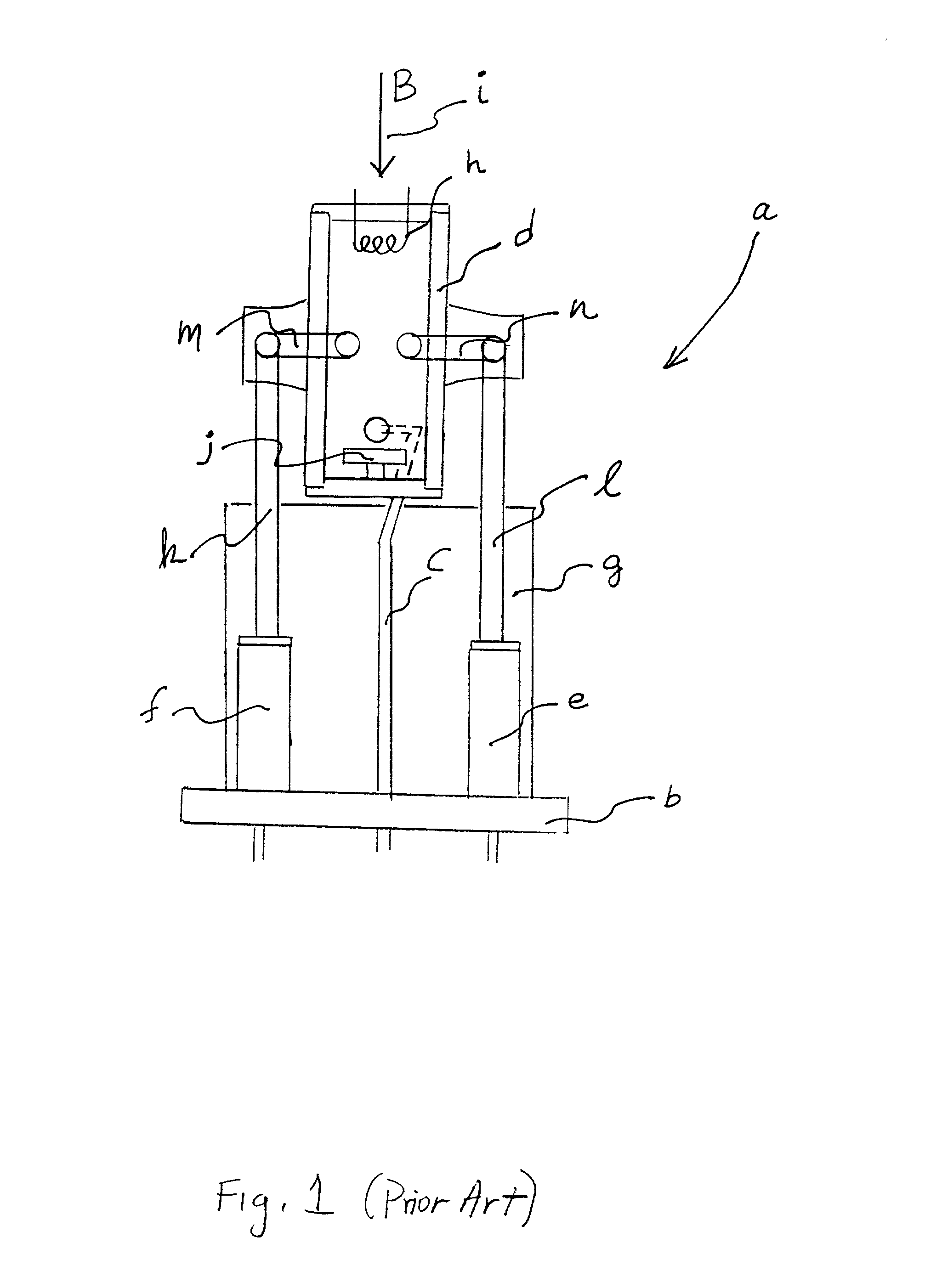

Radiotherapeutic apparatus in operation

InactiveCN1537657AReduce Multidimensional Motion DirectionReduce angle requirementsX-ray/gamma-ray/particle-irradiation therapyRadiation Dosages3d image

A radiotherapeutic apparatus using high-energy electron beams to radiate the bed of removed tumor and the residual tumor tissue in excision operation features that the CT or MRI 3D imaging software is used to determine the position of tumor focal, an analog technique is used to determine the incident direction, angle and position of electron beam, a radiotherapeutic plan system is used to calculate the radiation dosage, and a laser locator on the radiating head with straight-line electron accelerator is used to align the electron beam to the tumor focal.

Owner:高春平

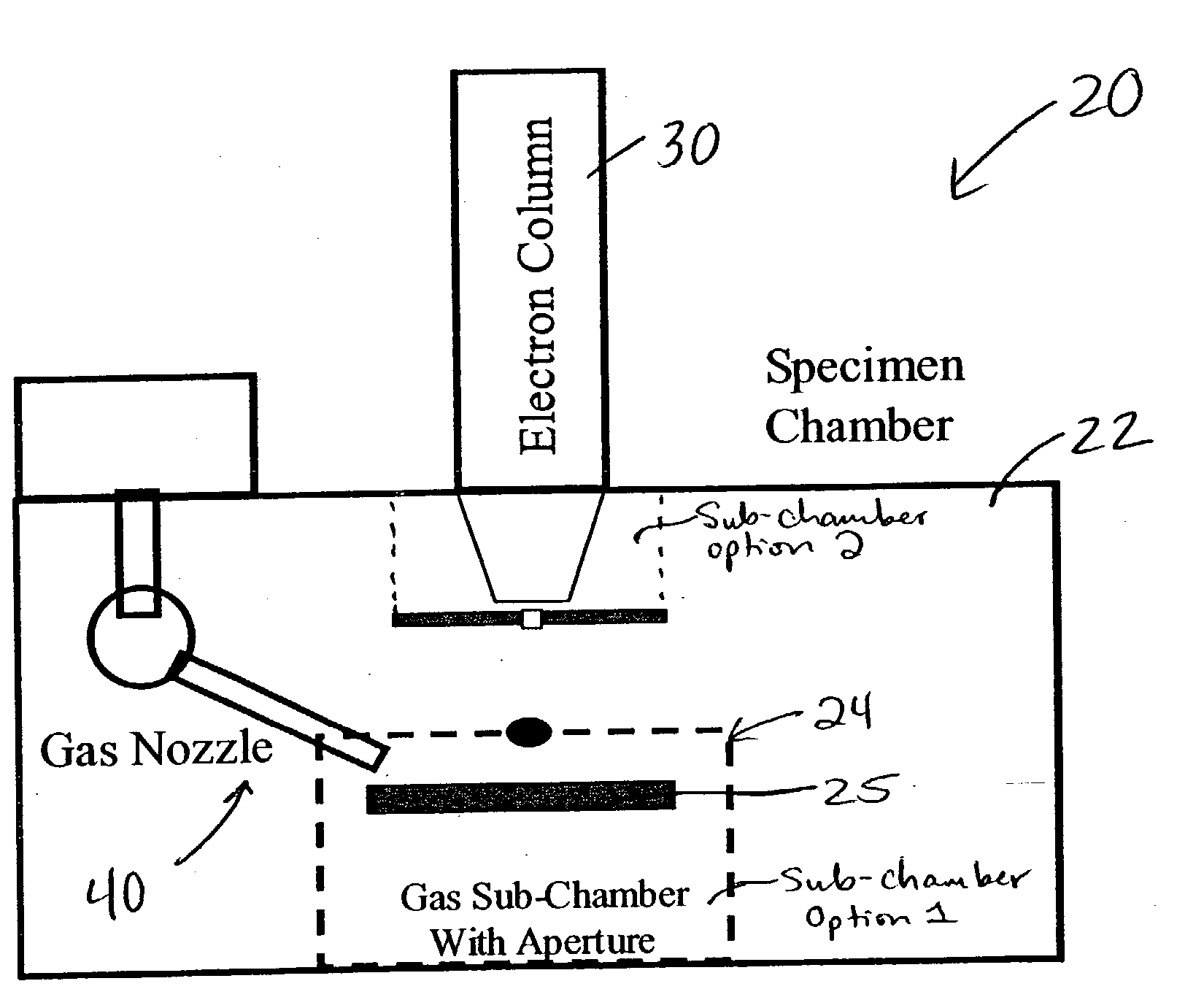

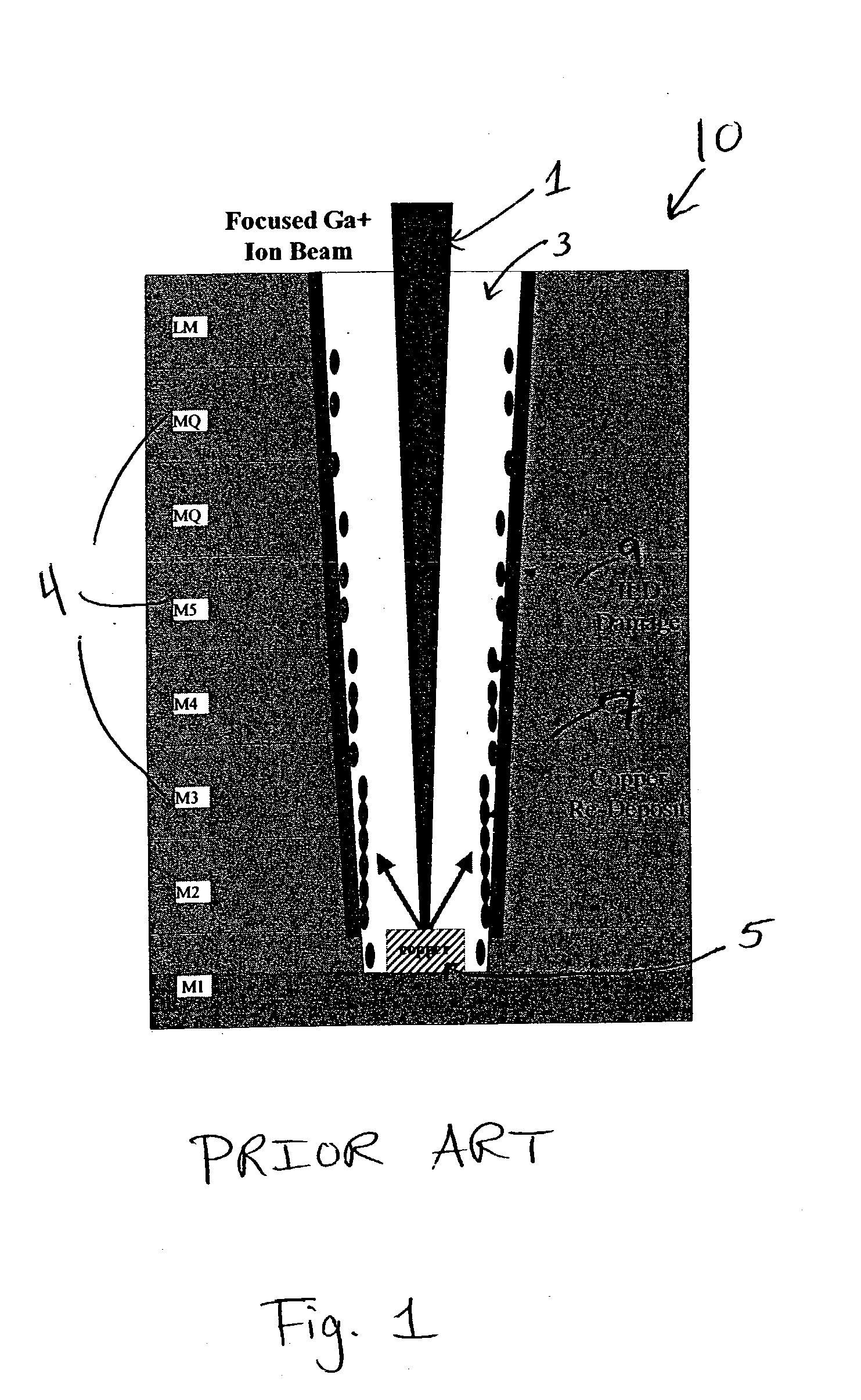

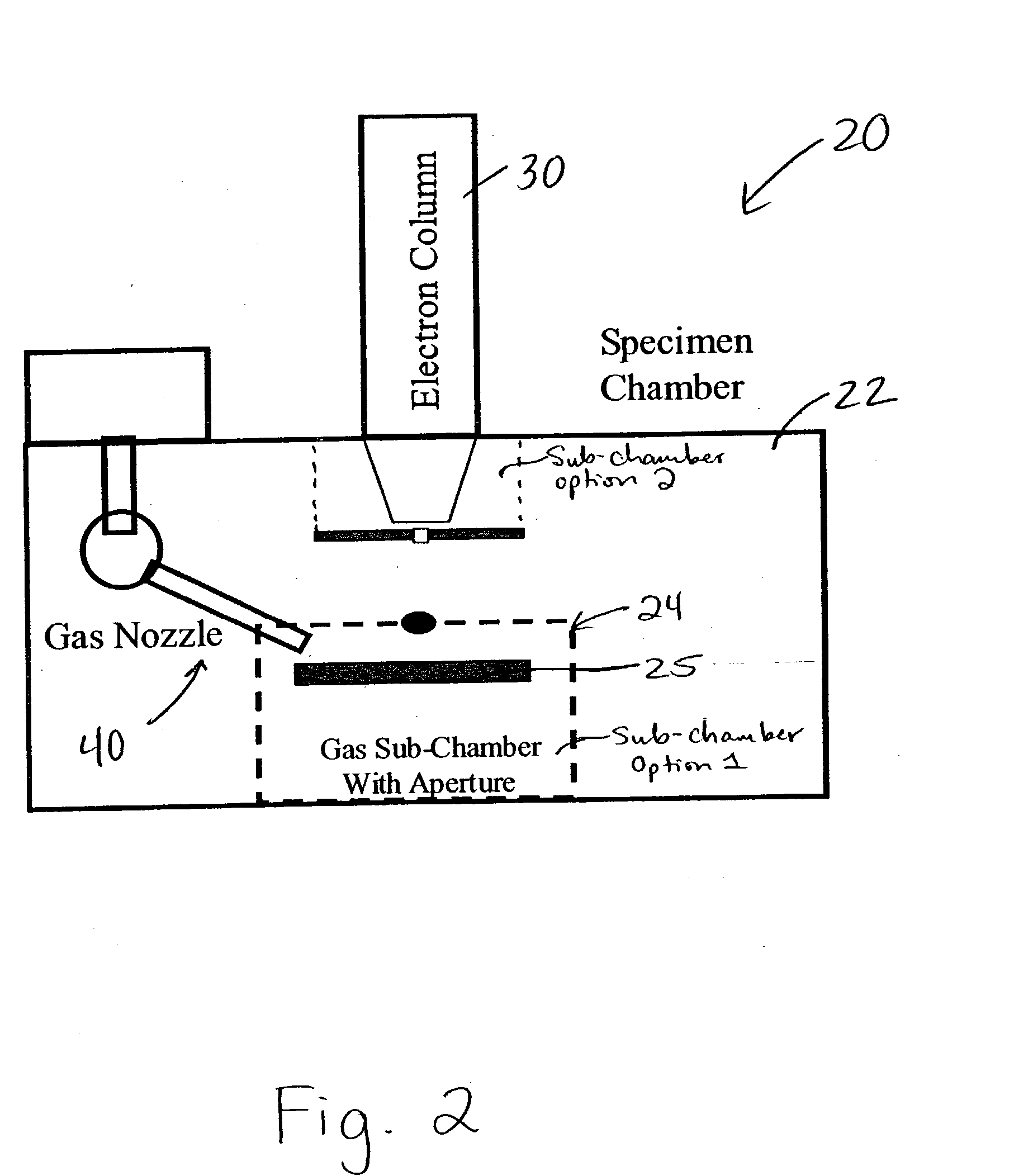

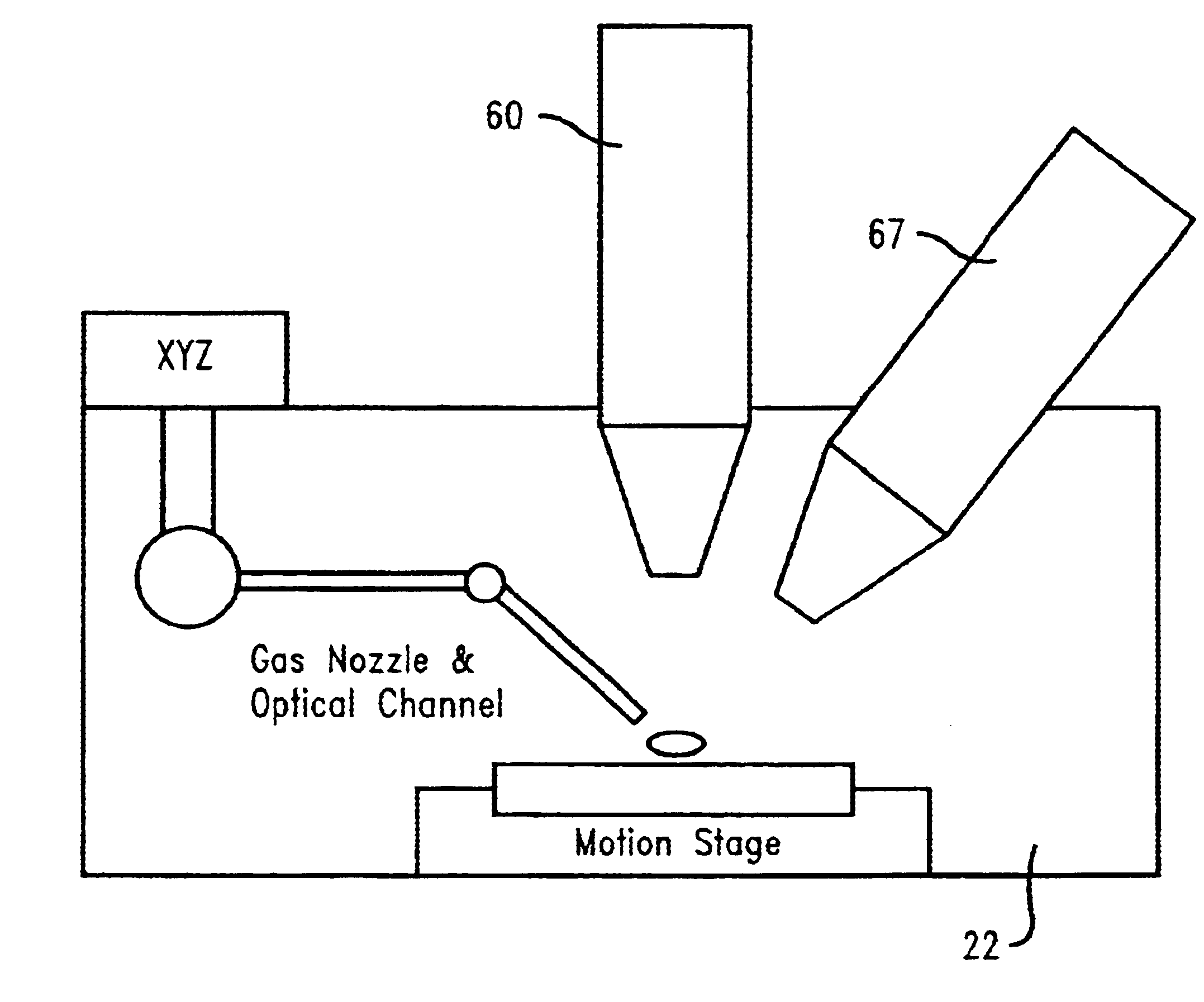

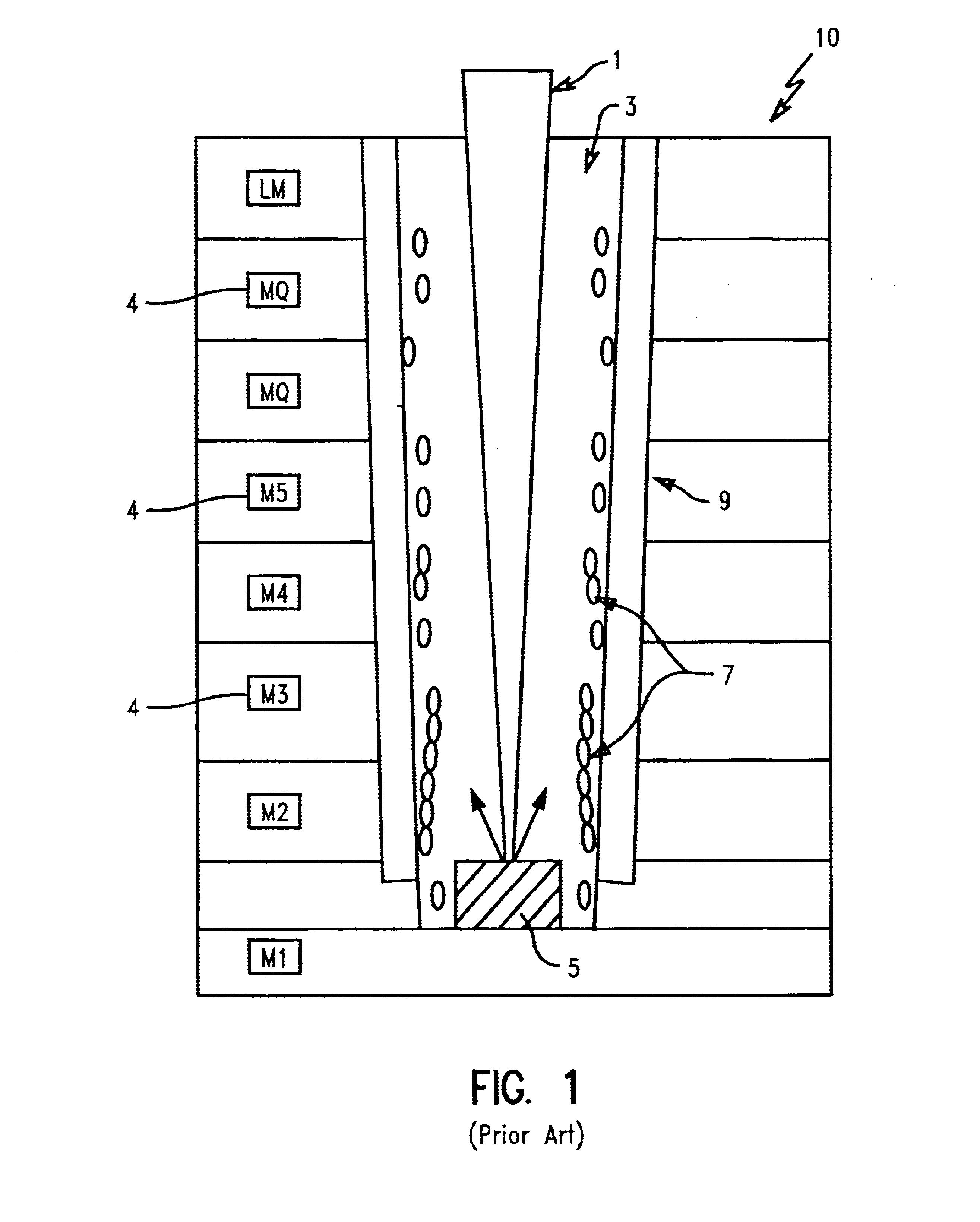

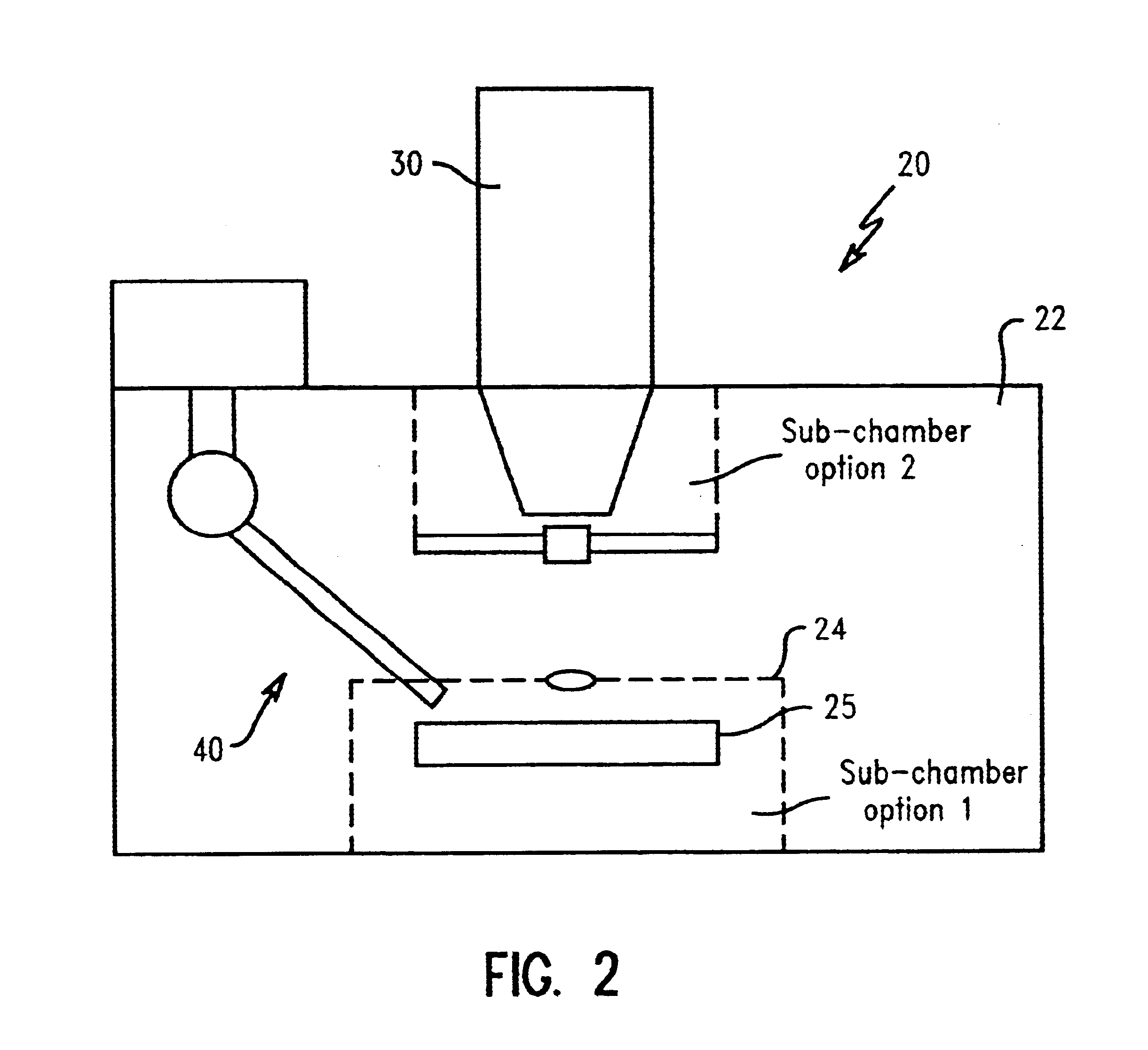

Apparatus and techniques for scanning electron beam based chip repair

A method and apparatus for editing an integrated circuit by bombarding a feature in need of editing with either a low-energy or high-energy electron beam in the presence of a gas whereby low energy electrons activate reactants adsorbed on the surface of the feature in need of editing to form active species on the feature surface. The reaction products from the process can be easily removed whereby IC damage, leakage between metal features, wafer contamination and physical sputtering of undesired material can be significantly minimized while still possessing nanometer-scale spatial resolution. The low energy electrons for activating the reactants adsorbed on the surface of the feature to be edited may be emitted from the electron beam itself or they may be secondary low energy electrons emitted from the surface of the feature being edited.

Owner:GLOBALFOUNDRIES US INC

Apparatus and techniques for scanning electron beam based chip repair

A method and apparatus for editing an integrated circuit by bombarding a feature in need of editing with either a low-energy or high-energy electron beam in the presence of a gas whereby low energy electrons activate reactants adsorbed on the surface of the feature in need of editing to form active species on the feature surface. The reaction products from the process can be easily removed whereby IC damage, leakage between metal features, wafer contamination and physical sputtering of undesired material can be significantly minimized while still possessing nanometer-scale spatial resolution. The low energy electrons for activating the reactants adsorbed on the surface of the feature to be edited may be emitted from the electron beam itself or they may be secondary low energy is electrons emitted from the surface of the feature being edited.

Owner:GLOBALFOUNDRIES US INC

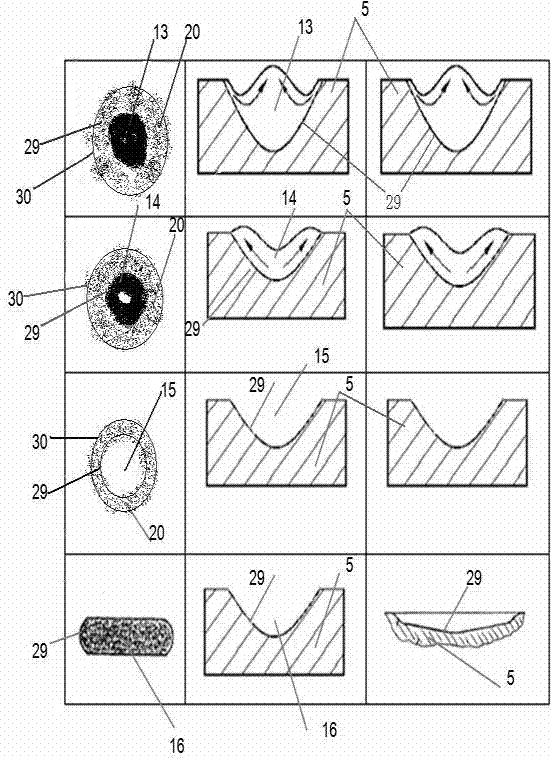

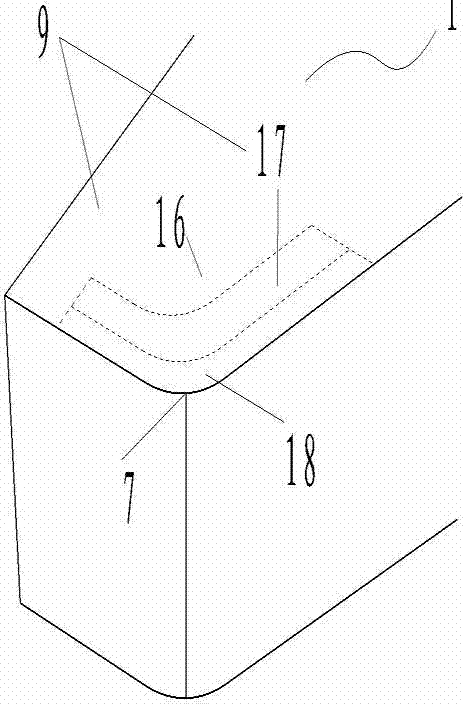

Compound model processing method and device for cutter

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

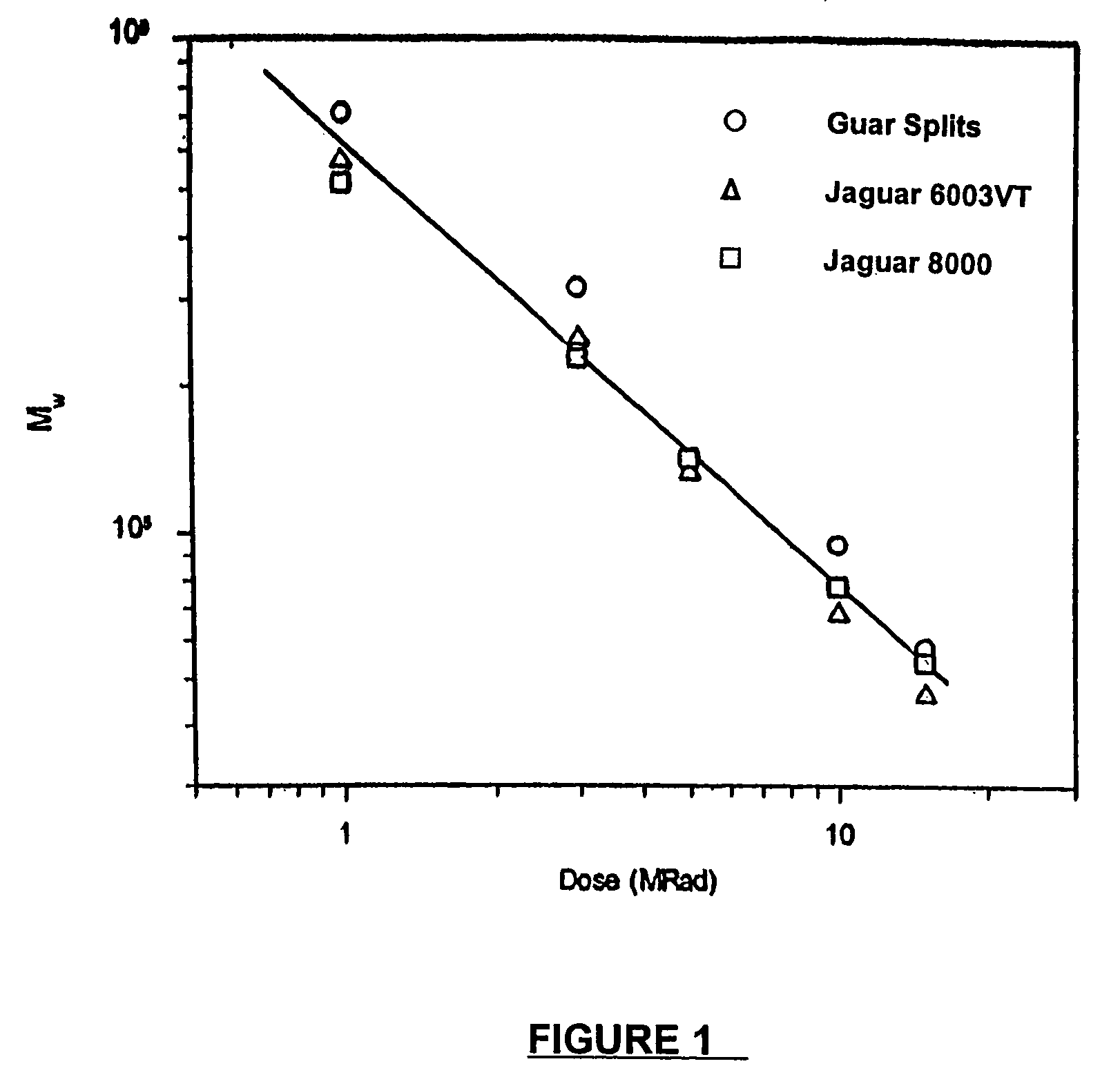

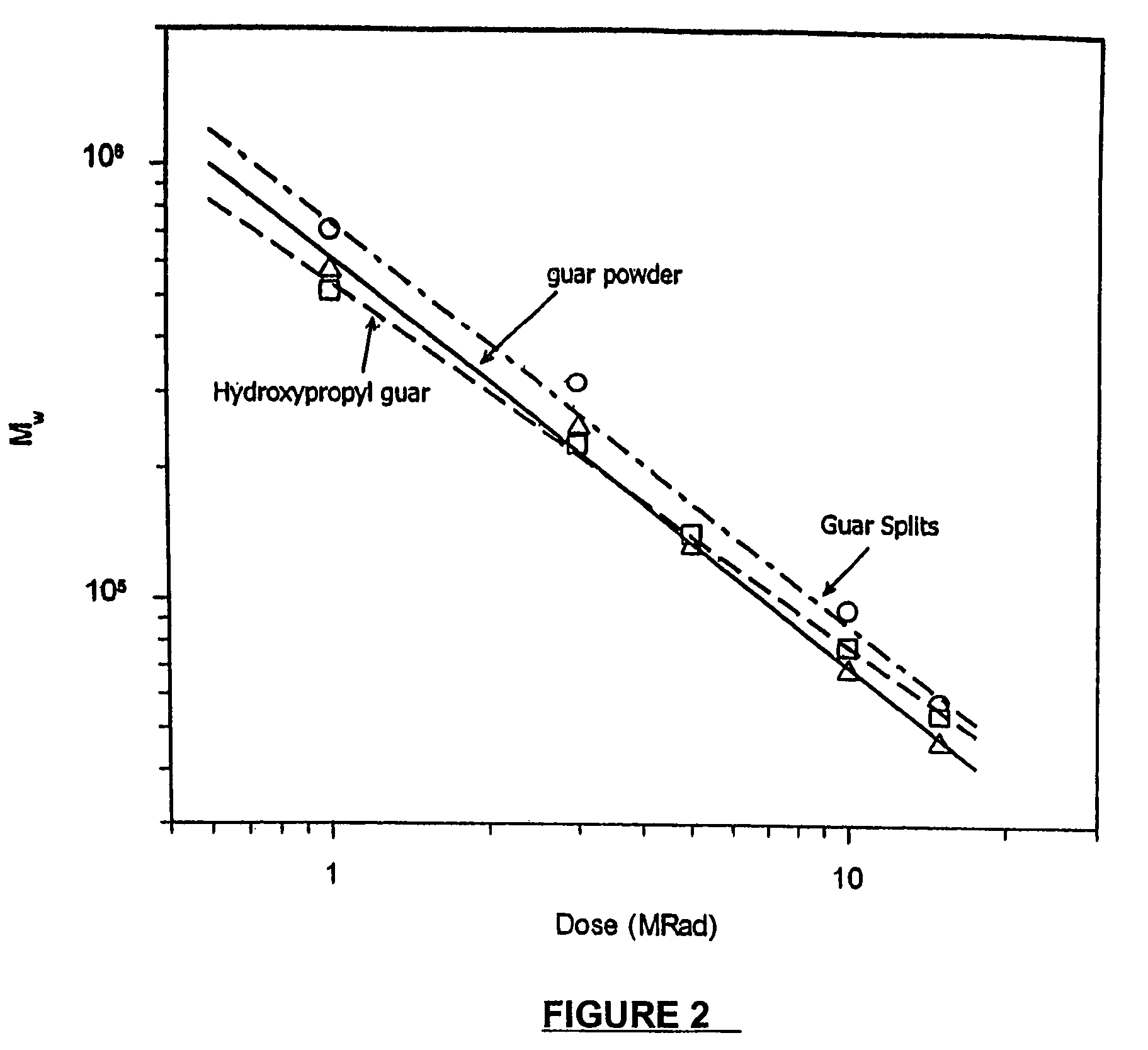

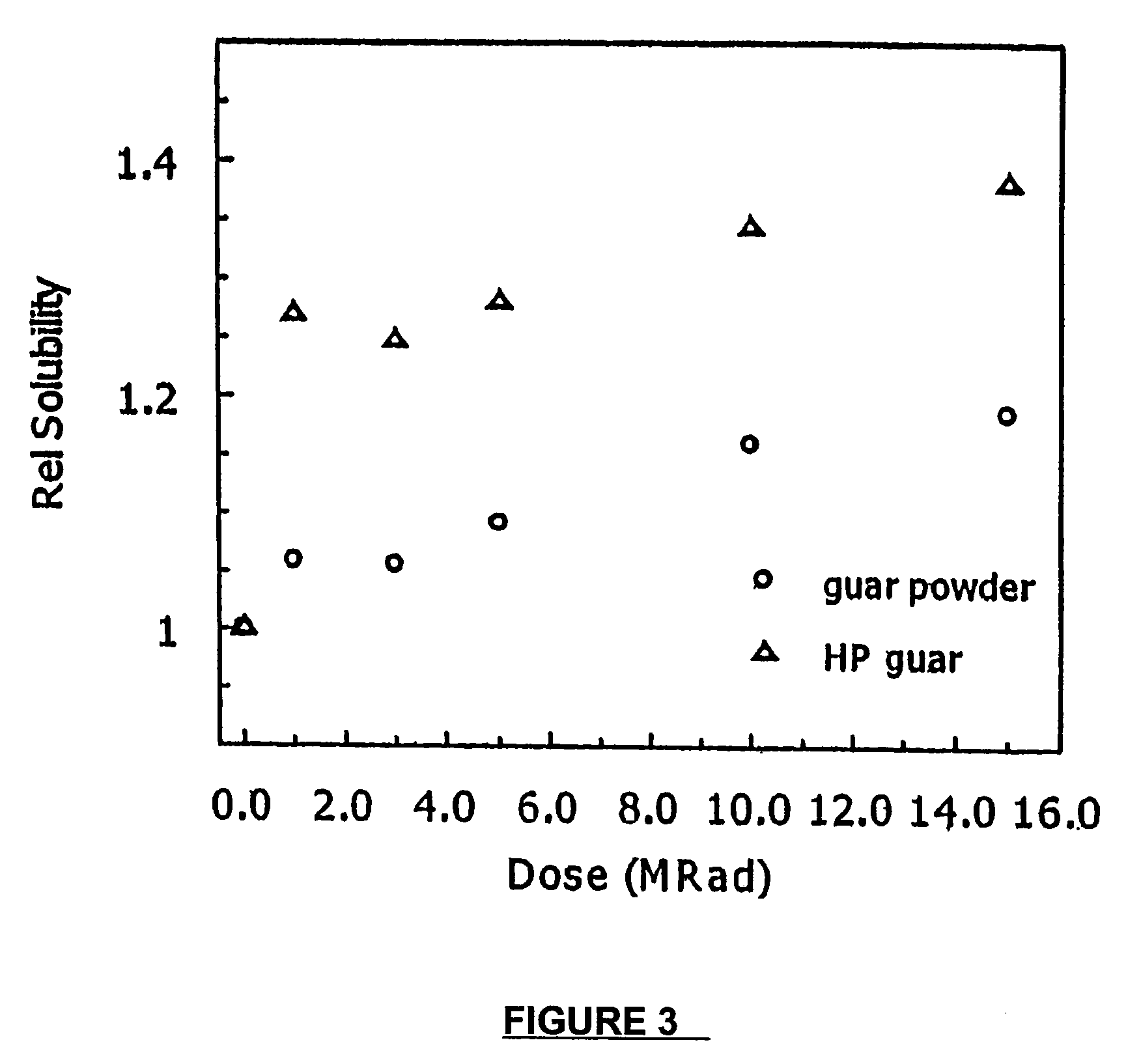

Molecular weight reduction of polysaccharides by electron beams

ActiveUS7259192B2Promote recoveryEasy to useOther chemical processesFibre treatmentHigh energyOil production

A method of depolymerizing galactomannan-type polysaccharide polymers and xanthan, preferably galactomannans, to a pre-selected lower molecular weight by irradiation with high energy electron beams. The preferred galactomannans for treatment according to this method are guar gum, guar splits and hydroxypropyl guar. In a preferred embodiment the guar gum is depolymerized preferably to a molecular weight of about 150,000 Daltons to about 200,000 Daltons. The depolymerized guar has a polydispersity of less than about 3.0 and is useful in oil well fracturing to enhance oil production.

Owner:RHODIA OPERATIONS SAS

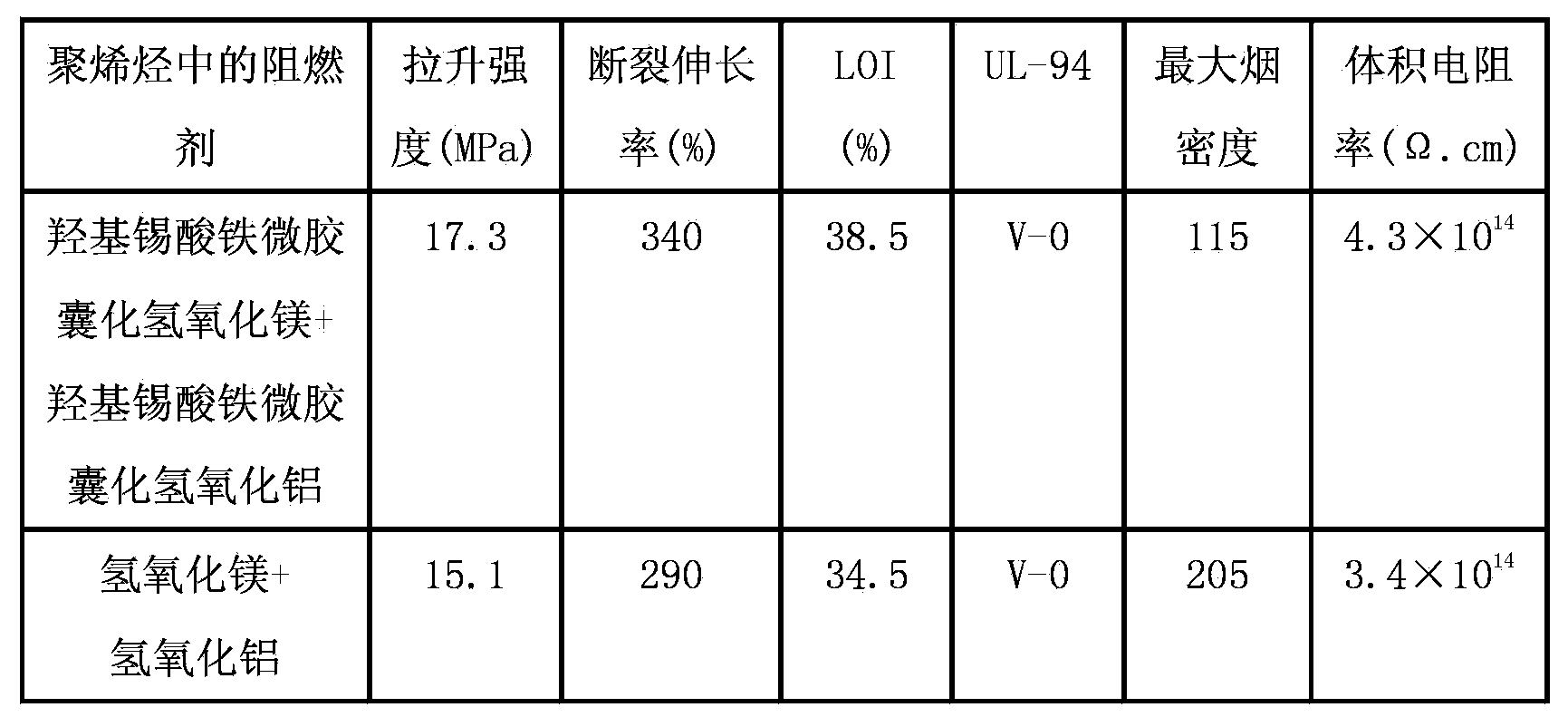

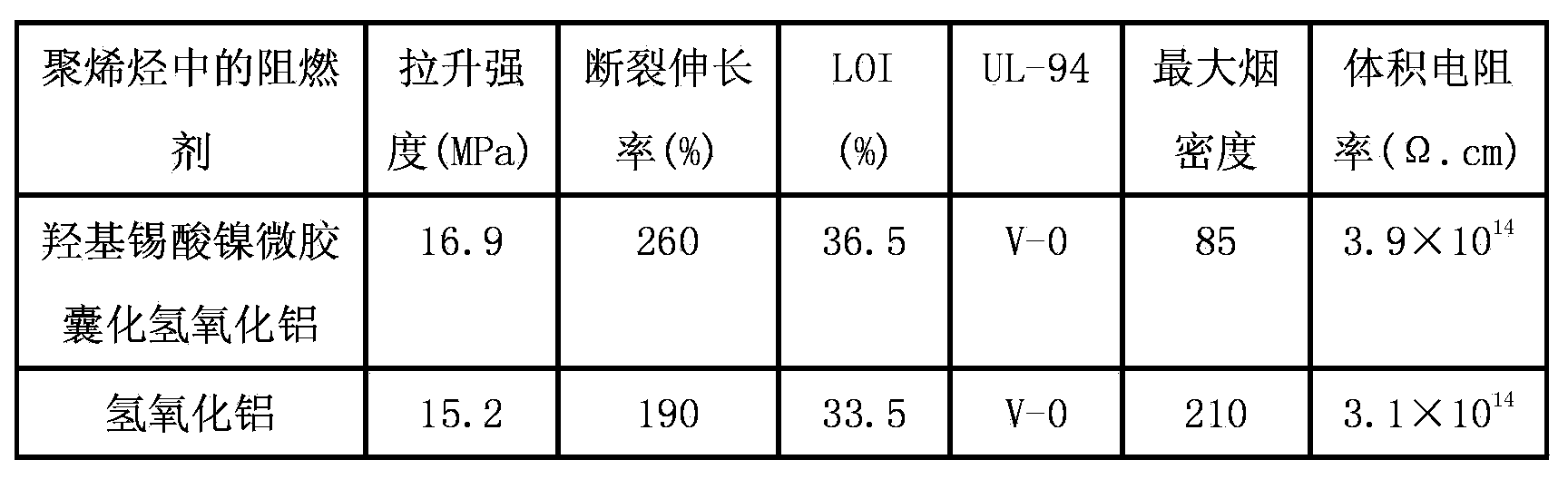

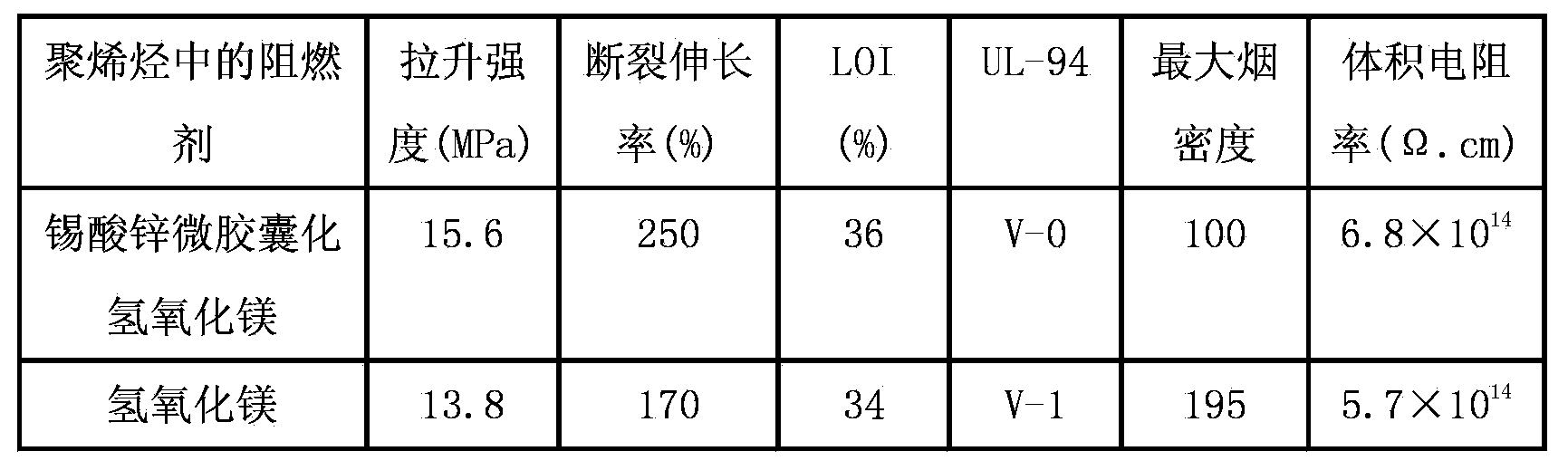

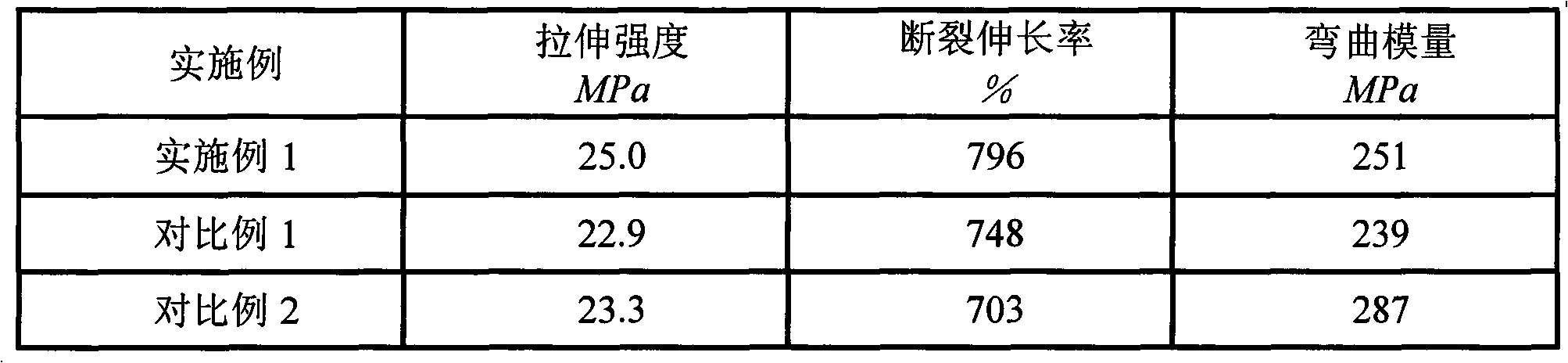

Low-smoke, halogen-free and flame-retardant irradiation crosslinking polyolefin composite material and preparation method thereof

InactiveCN103450544AImprove flame retardant performanceImprove mechanical propertiesPolyolefinPolymer science

The invention discloses a low-smoke, halogen-free and flame-retardant irradiation crosslinking polyolefin composite material and a preparation method thereof. The preparation method comprises the following steps of adding 0.5-5 parts of flame retardant synergist to 50-60 parts of polyolefin according to the mass ratio; uniformly mixing at 140-200 DEG C, and then adding 40-50 parts of microencapsulated metal hydroxide of a flame-retardant smoke suppressant synergist, 0.5-5 parts of multifunctional crosslinking agent and 0.1-1 part of antioxidant; extruding and cladding the materials on a conductive core of an electric wire or pressing into a board in a forming machine after evenly mixing; and finally carrying out irradiation crosslinking by a high-power electron beam or a cobalt source in a dosage of 80-240 KGy. The low-smoke, halogen-free and flame-retardant polyolefin composite material obtained by the microencapsulated metal hydroxide of the flame-retardant smoke suppressant synergist by irradiation crosslinking has good flame retardant property, excellent smoke suppressing property, and better mechanical property, and can be widely applied to the electric wires in the industries such as power, energy sources, petrochemical industries, electrons, communication, information, locomotives and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE

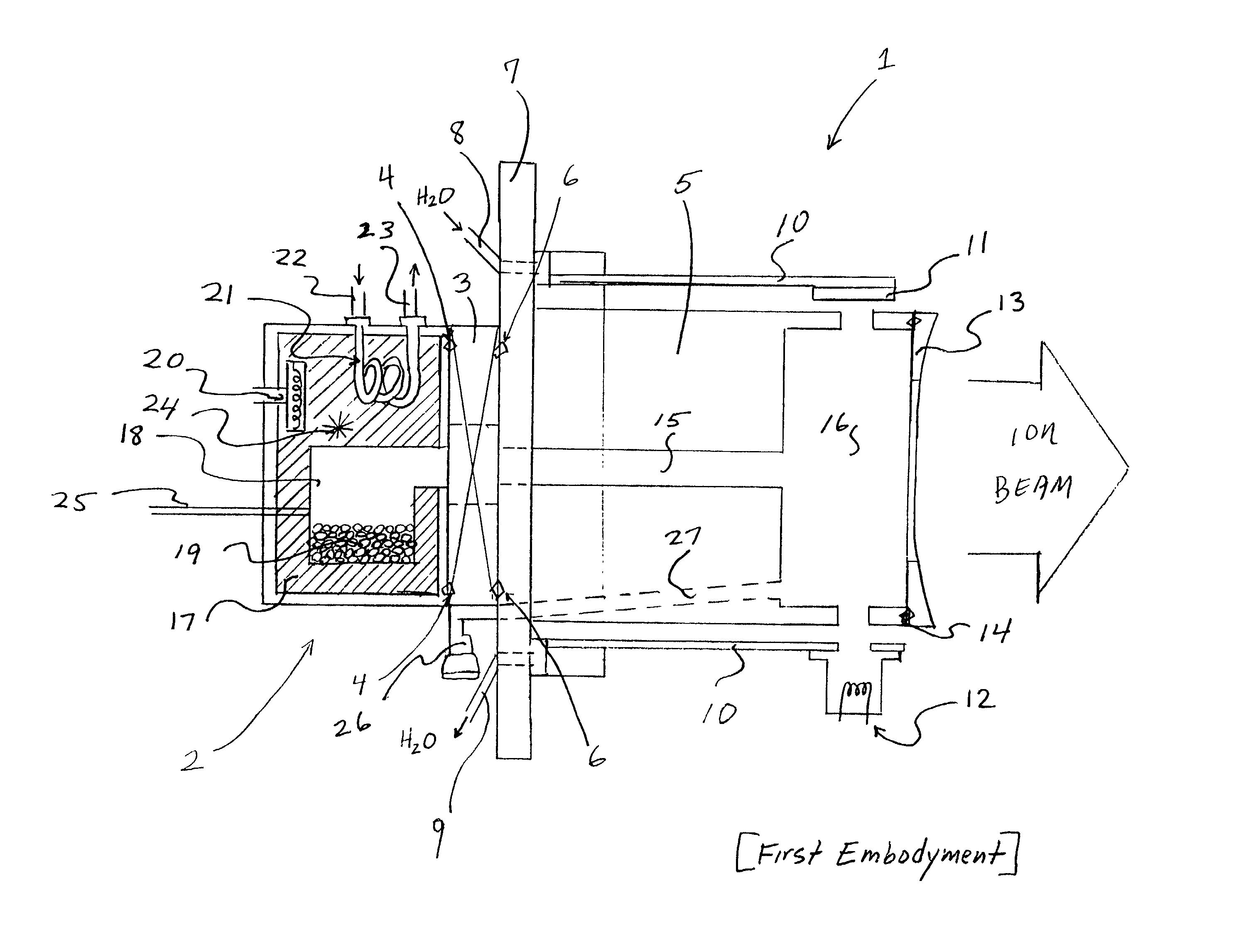

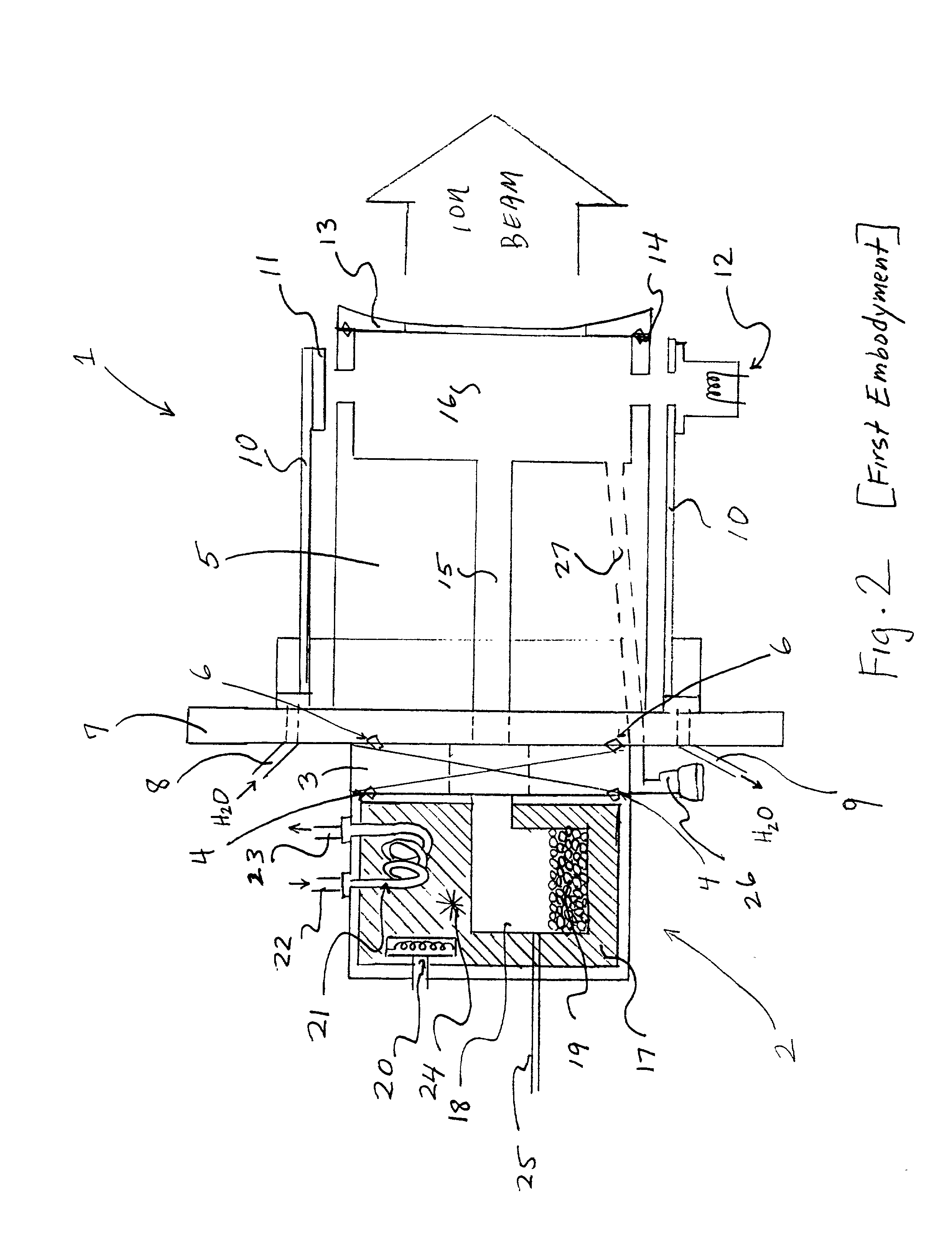

Electron beam ion source with integral low-temperature vaporizer

InactiveUS20020070672A1Maximizes conductanceMinimizes conductanceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energy beamIon implantation

An ion source for ion implantation system and a method of ion implantation employs a controlled broad, directional electron beam to ionize process gas or vapor, such as decaborane, within an ionization volume by primary electron impact, in CMOS manufacturing and the like. Isolation of the electron gun for producing the energetic electron beam and of the beam dump to which the energetic beam is directed, as well as use of the thermally conductive members for cooling the ionization chamber and the vaporizer, enable use with large molecular species such as decaborane, and other materials which are unstable with temperature. Electron optics systems, facilitate focusing of electrons from an emitting surface to effectively ionize a desired volume of the gas or vapor that is located adjacent the extraction aperture. The components enable retrofit into ion implanters that have used other types of ion sources. Demountable vaporizers, and numerous other important features, realize economies in construction and operation. Achievement of production-worthy operation in respect of very shallow implants is realized.

Owner:SEMEQUIP

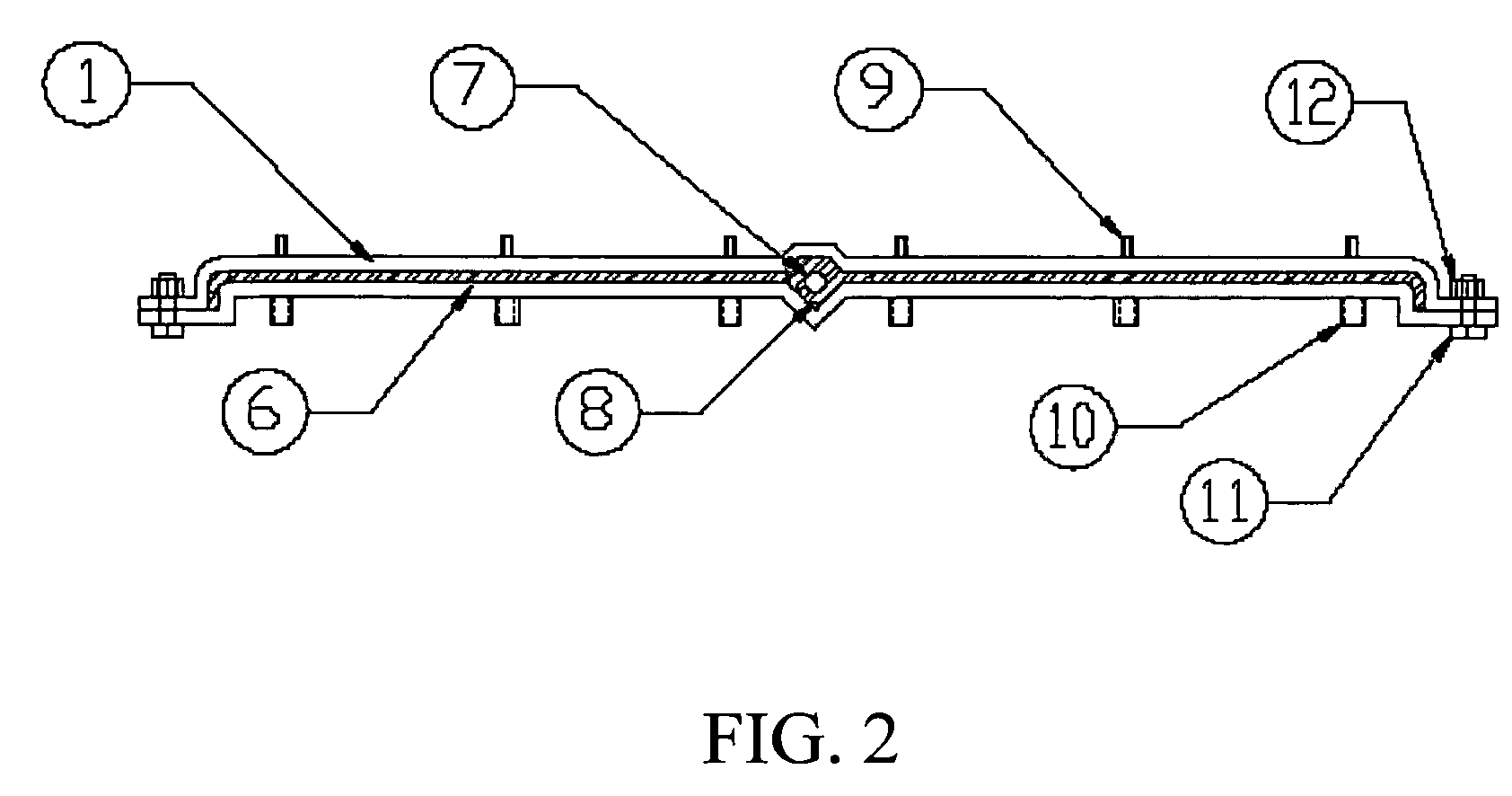

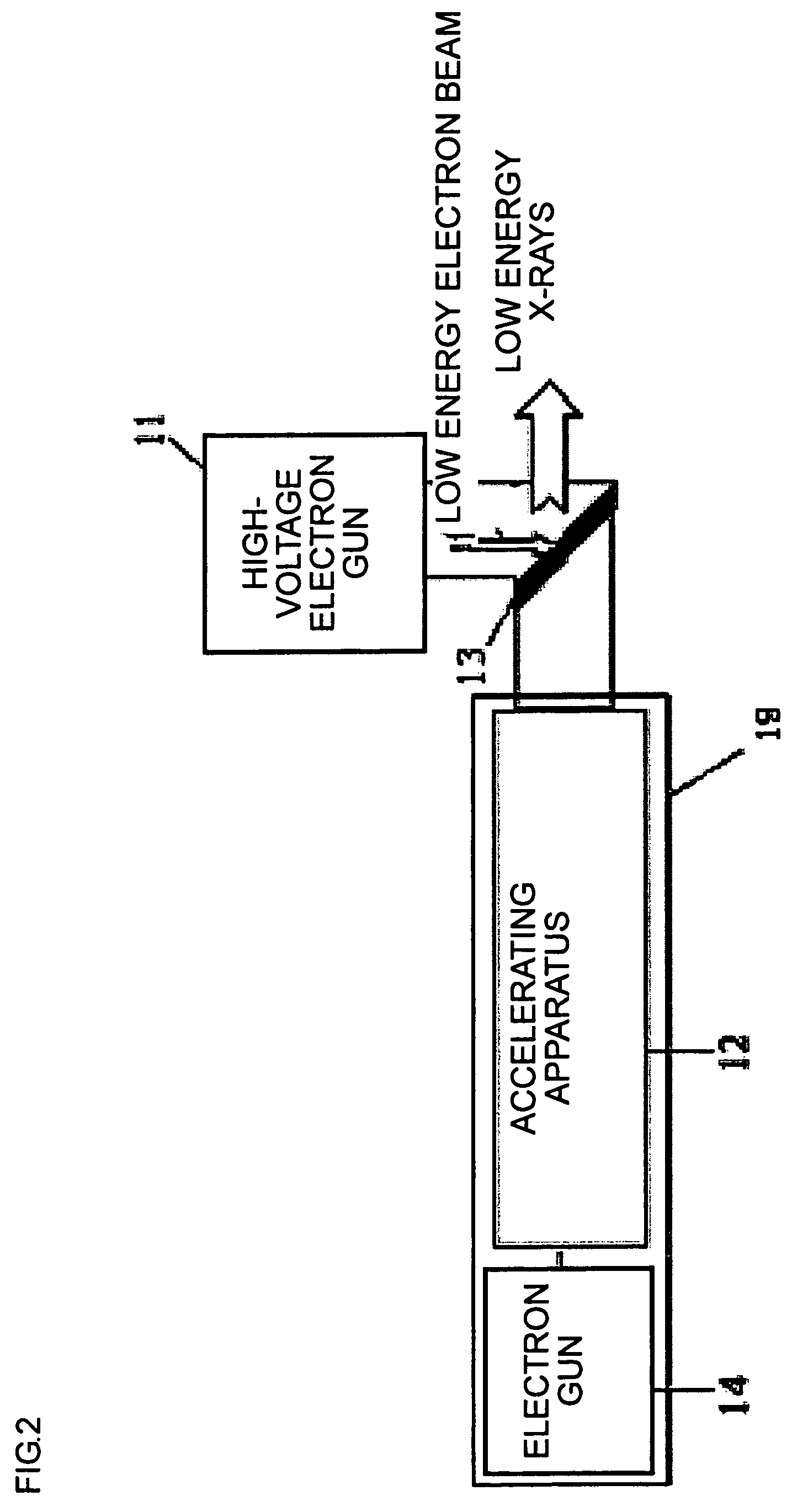

Method and apparatus for producing radioactive materials for medical treatment using x-rays produced by an electron accelerator

InactiveUS6907106B1Effective interceptionImprove cooling effectConversion outside reactor/acceleratorsRadioactive sourcesHigh energyX-ray

An apparatus and method for irradiating target objects, especially medical stents for in vivo implantation. A linear accelerator provides a high energy electron beam that impinges upon and is received by an x-ray conversion target. The x-ray conversion target is activated by either a static or dynamically moveable electron beam to generate and emit an x-ray flux so as to efficiently intercept the target object. The x-ray flux is directed to the target object for a desired time period and is of sufficiently high energy to efficiently impart radioactive properties to the target object. Alternatively, the target object is positioned within the path of the x-ray flux or is translated within the path during irradiation. Mechanical transport assemblies such as a carousel, rotational and / or linear translator and / or movement tube system also may be provided.

Owner:VARIAN MEDICAL SYSTEMS

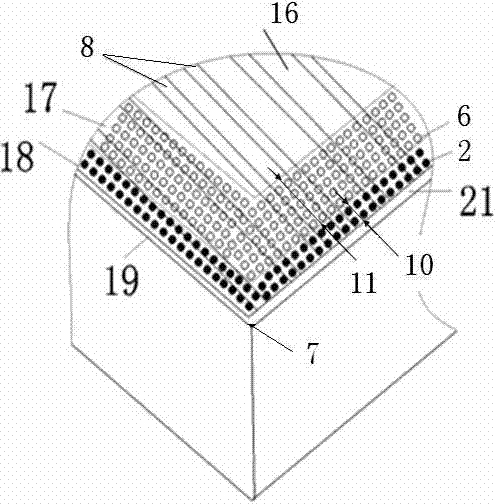

Gradient tungsten-copper composite and preparation method thereof

The invention provides a gradient tungsten-copper composite. The gradient tungsten-copper composite comprises tungsten frameworks manufactured through an electron beam selective melting forming method and copper filling phases manufactured through an infiltration method. The tungsten frameworks are arranged in many layers in the height direction of the tungsten frameworks, and each layer of tungsten framework is of a net-shaped porous structure. Pores of the tungsten frameworks on all the layers are filled with the copper filling phases, and the volume percentage compositions of the copper filling phases are increased or decreased layer by layer. The invention further provides a method for preparing the gradient tungsten-copper composite. The tungsten frameworks in the tungsten-copper composite are prepared through the high-energy electron beam selective melting technology, and the structural strength of the tungsten frameworks is obviously higher than that of a structure prepared through a traditional sintering method; and the copper filling phases can be prepared by means of free model adjustment and combination with the copper infiltration technology, and finally flexibility and controllability of the structure and performance of the tungsten-copper composite can be achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

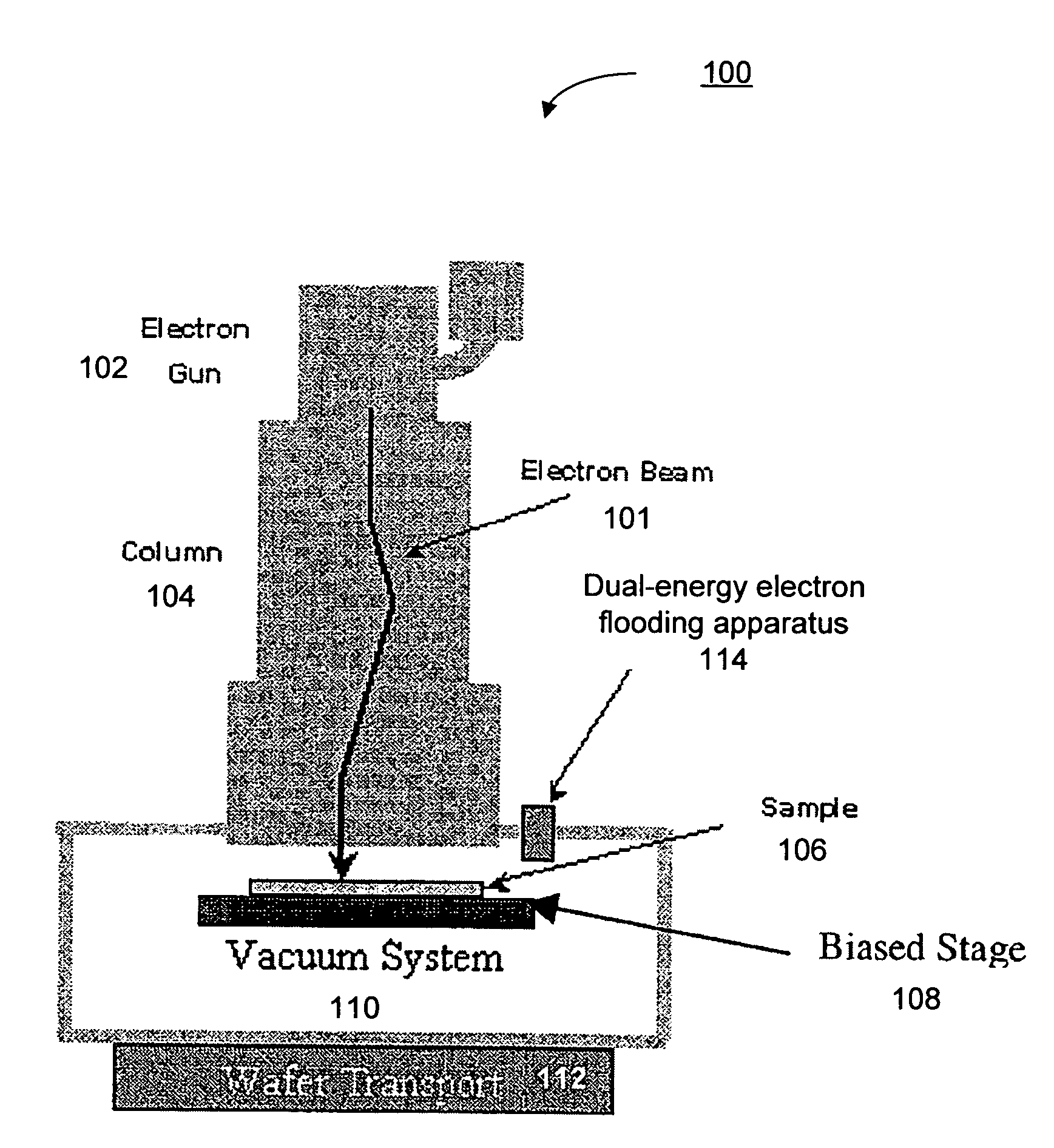

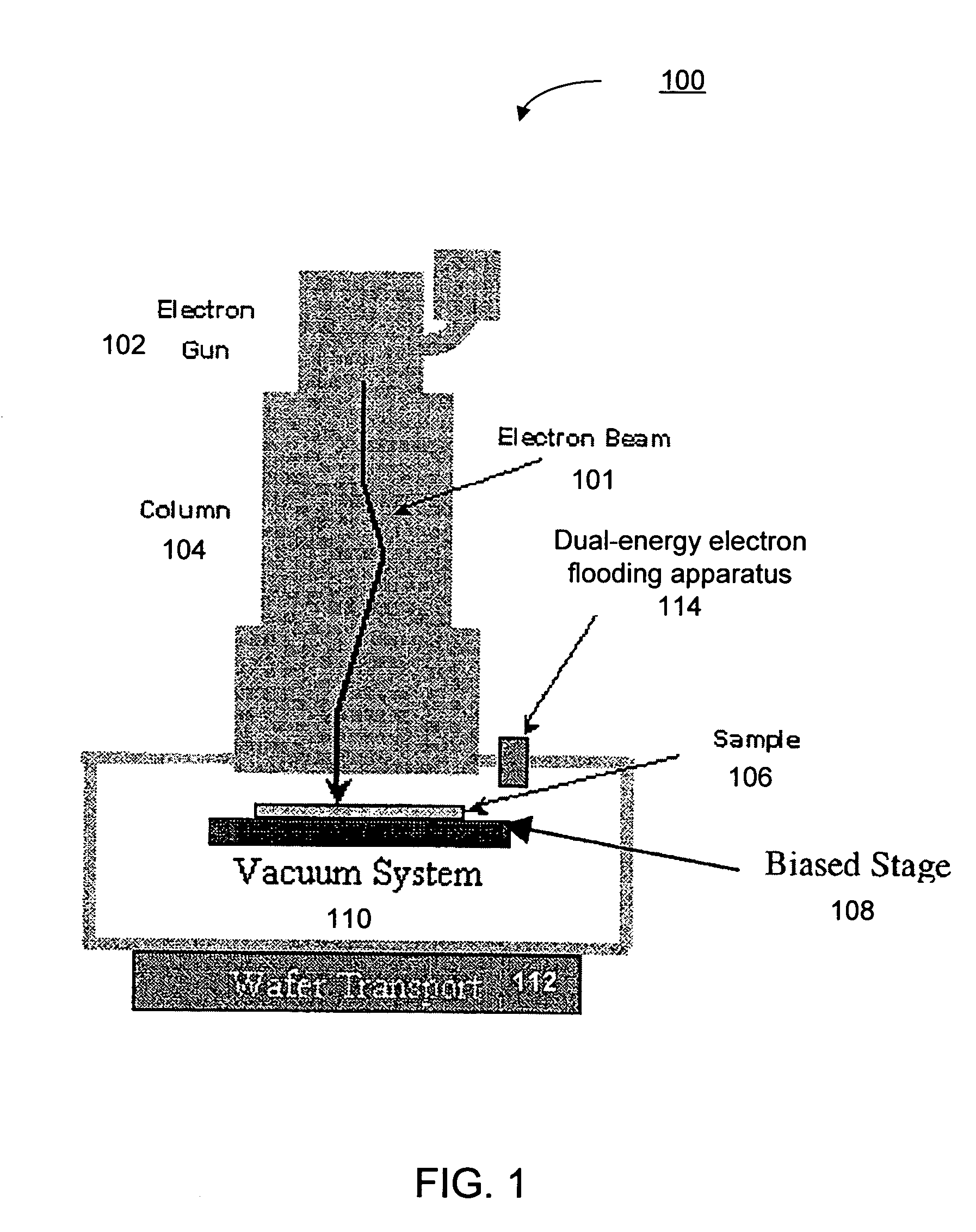

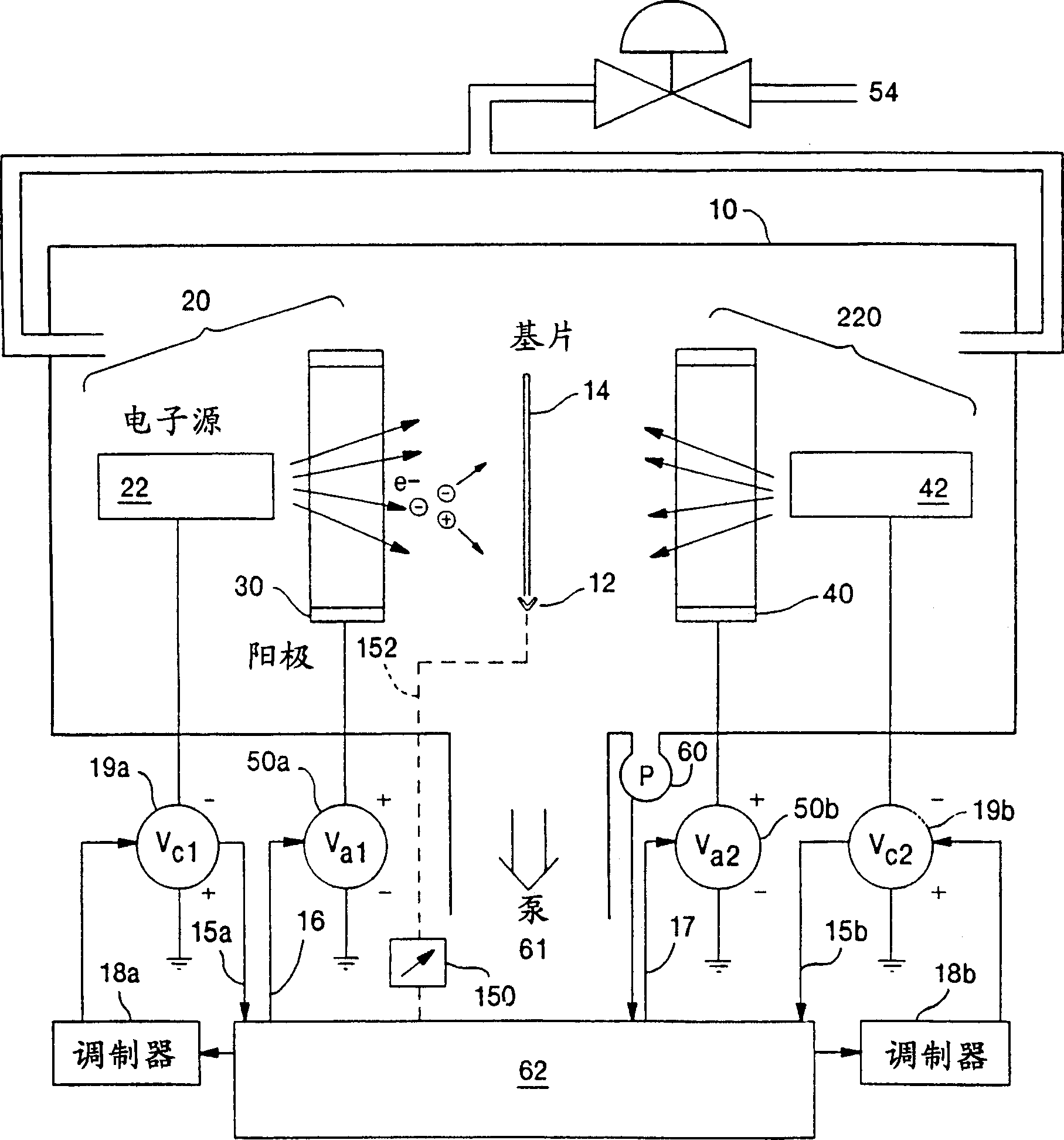

Dual-energy electron flooding for neutralization of charged substrate

One embodiment disclosed relates to a method of electron beam inspection or review of a substrate having insulating materials therein. An area of the substrate is simultaneously exposed to a lower-energy electron beam and an overlapping higher-energy electron beam. The area is subsequently inspected with another electron beam. Another embodiment disclosed relates to an electron beam tool for examination of a substrate having insulating materials therein. A first cathode is configured as an electron source for a lower-energy electron beam, and a second cathode is configured as an electron source for a higher-energy electron beam. At least one electron lens is configured to focus the lower-energy electron beam and the higher-energy electron beam onto an overlapping area of a substrate. An electron beam column is subsequently used to examine the substrate.

Owner:KLA TENCOR CORP

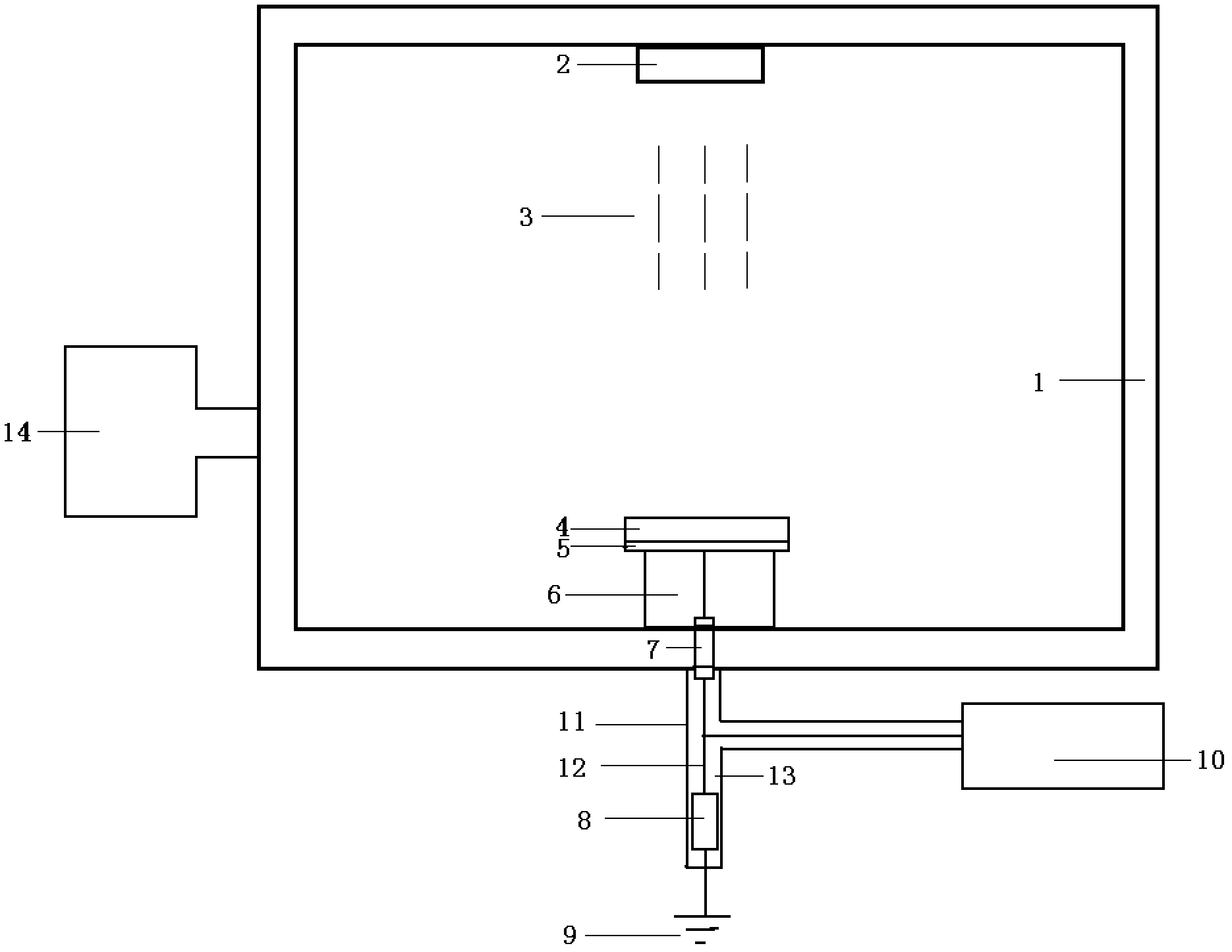

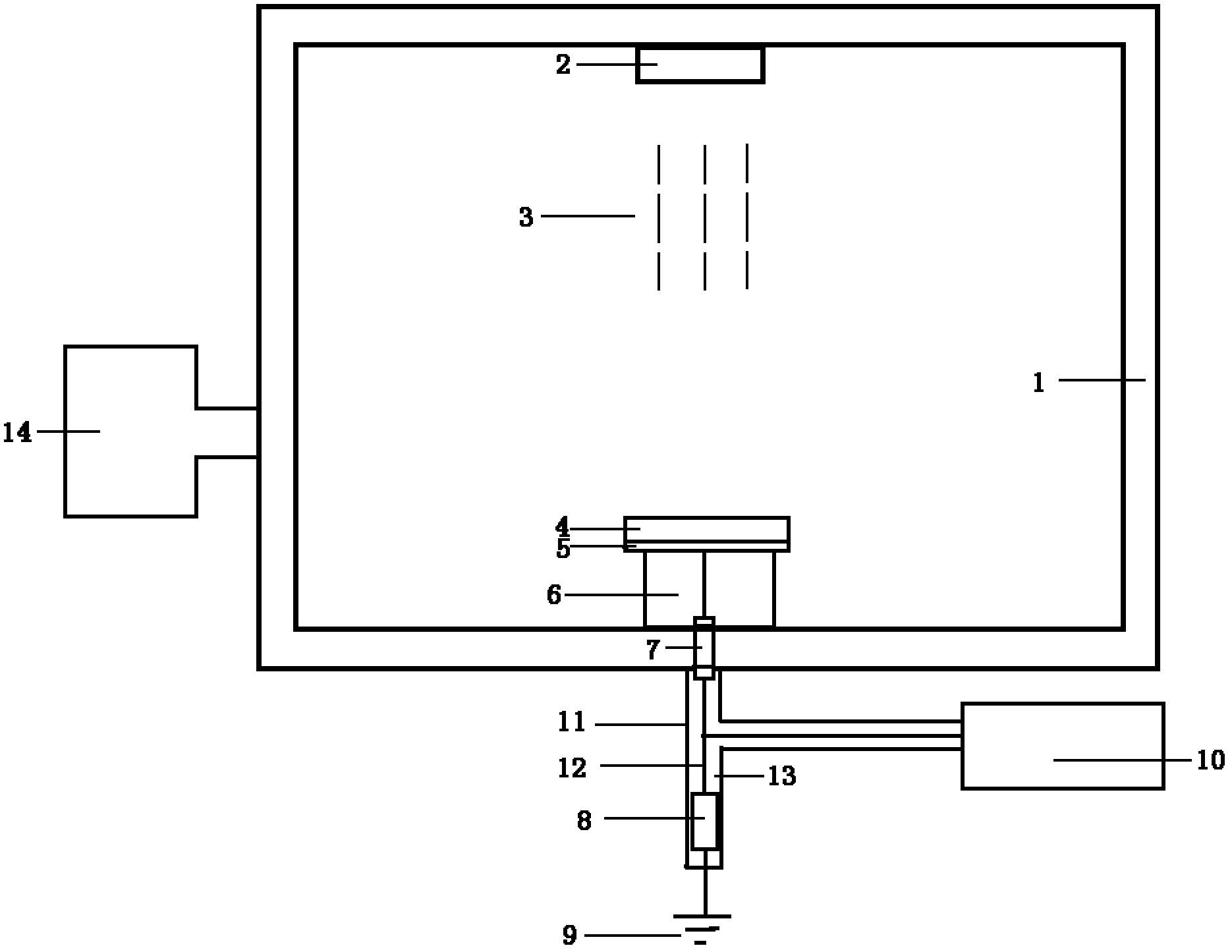

Device and method for monitoring internal discharge of materials for ground simulation satellite

InactiveCN102508127AEvaluate internal discharge performanceTesting dielectric strengthVacuum pumpingElectrical resistance and conductance

The invention relates to a device and a method for monitoring internal discharge of materials for a ground simulation satellite, which belongs to the technical field of space. The device comprises a vacuum chamber, an electronic gun, a sample base, a vacuum wall, a resistor, a conducting wire, an outer shielding layer, an insulation layer, a vacuum pumping system and an oscillograph. The method comprises the following steps that: a sample is fixedly arranged inside the vacuum chamber to be connected with a discharging signal circuit; the electronic gun is started after the vacuum chamber is vacuum pumped, the electronic gun transmits high-energy electron beams onto the surface of the sample, and the oscillograph is simultaneously started; and when the high-energy electrons are accumulated inside the sample to be saturated, the internal discharge phenomenon occurs, and the discharge waveform is displayed on the oscillograph. Due to the adoption of the device and the method, the electrification environment inside a satellite can be simulated on the ground, the internal discharge pulse can be monitored, so the internal discharge performance of the materials for the satellite can be evaluated.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

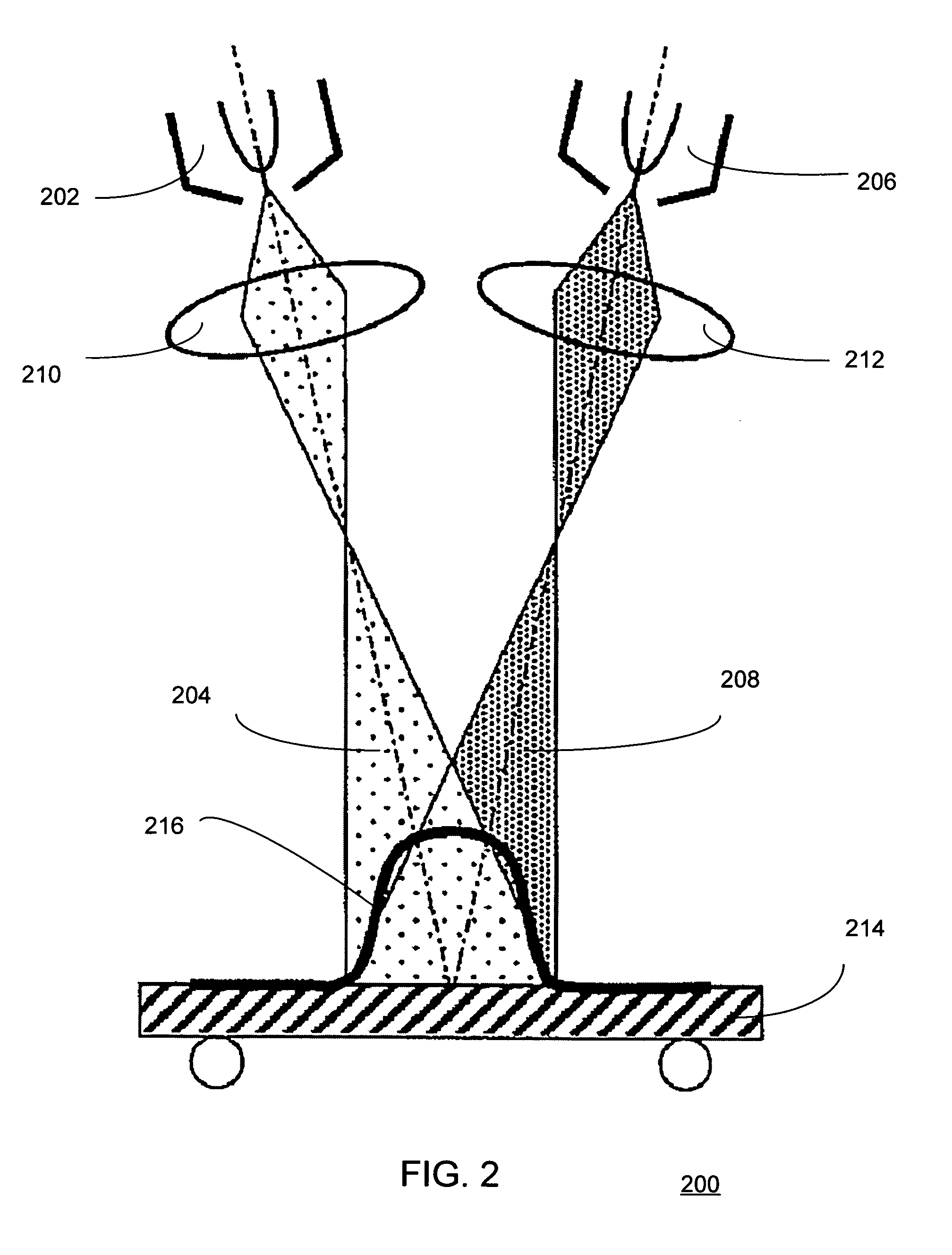

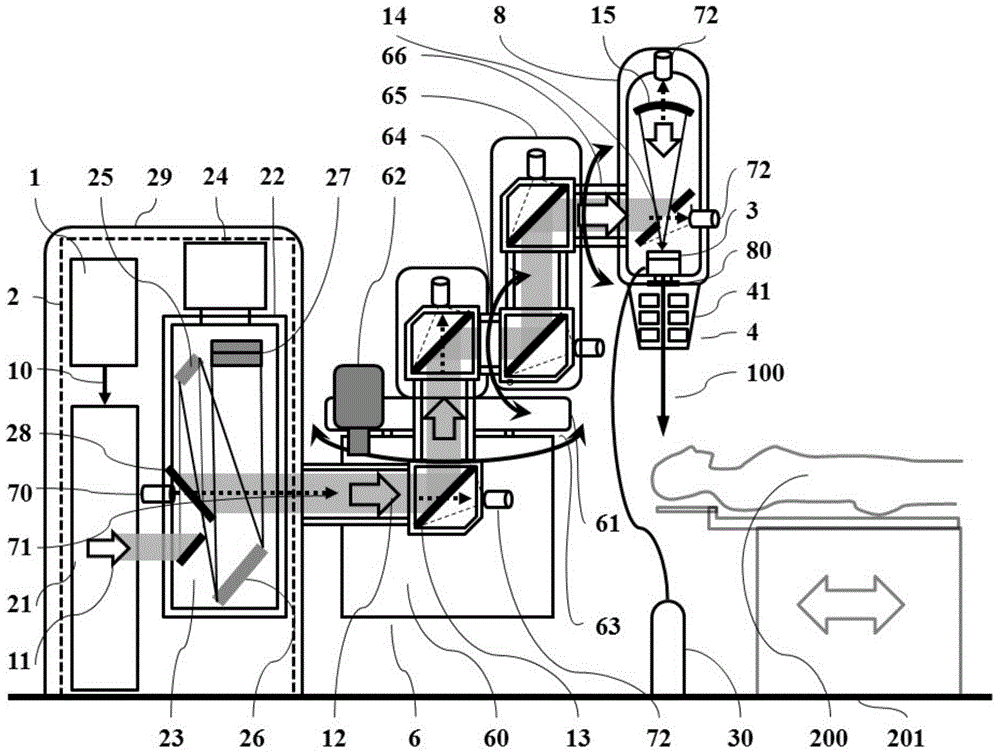

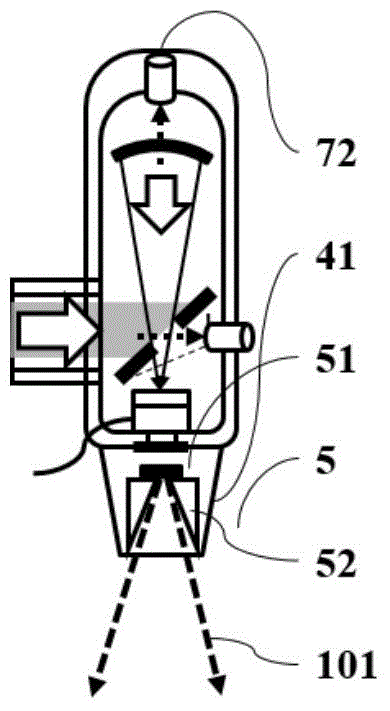

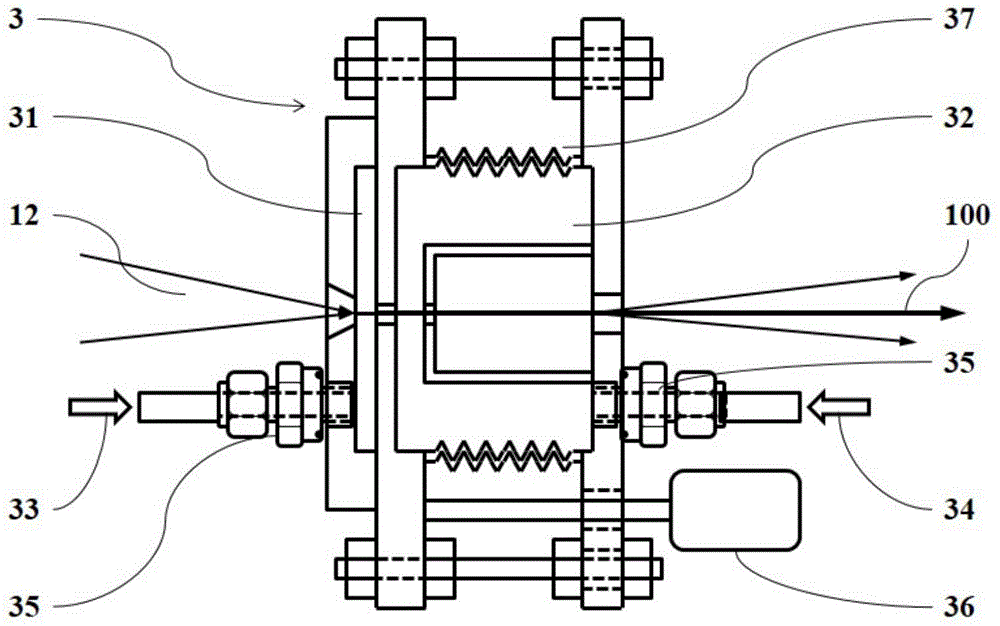

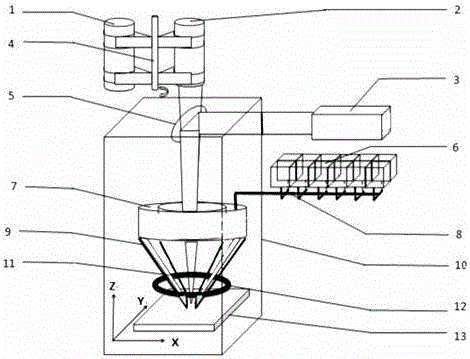

Extrahigh energy electron beam or photon beam radiotherapy robot system

ActiveCN104001270AObvious priceObvious installation site layout advantagesLight therapyPhoton Beam Radiation TherapyExternal irradiation

The invention provides an extrahigh energy electron beam or photon beam radiotherapy robot system which comprises a laser driving system, a laser plasma accelerator, an electron beam focusing system, a photon beam aiming system, a robot body and a laser beam stabilization system. The laser driving system generates and spreads intense laser pulses to the laser plasma accelerator installed at the tail end of the robot body, and therefore electron beams are generated; the electron beam focusing system guides the electron beams to diseased parts of a patient; the photon beam aiming system enables the electron beams to generate high energy photon beams so that extrahigh energy electron beam radiotherapy or photon beam radiotherapy can be performed; the robot body spreads the electron beams or the photon beams to the diseased parts of the patient in multiple directions; the laser beam stabilization system monitors the positions of laser beams and corrects errors. The extrahigh energy electron beam or photon beam radiotherapy robot system is more compact, more efficient, cheaper and easier to operate and has higher performance than an external irradiation radiation therapy system in the prior art.

Owner:SHANGHAI JIAO TONG UNIV

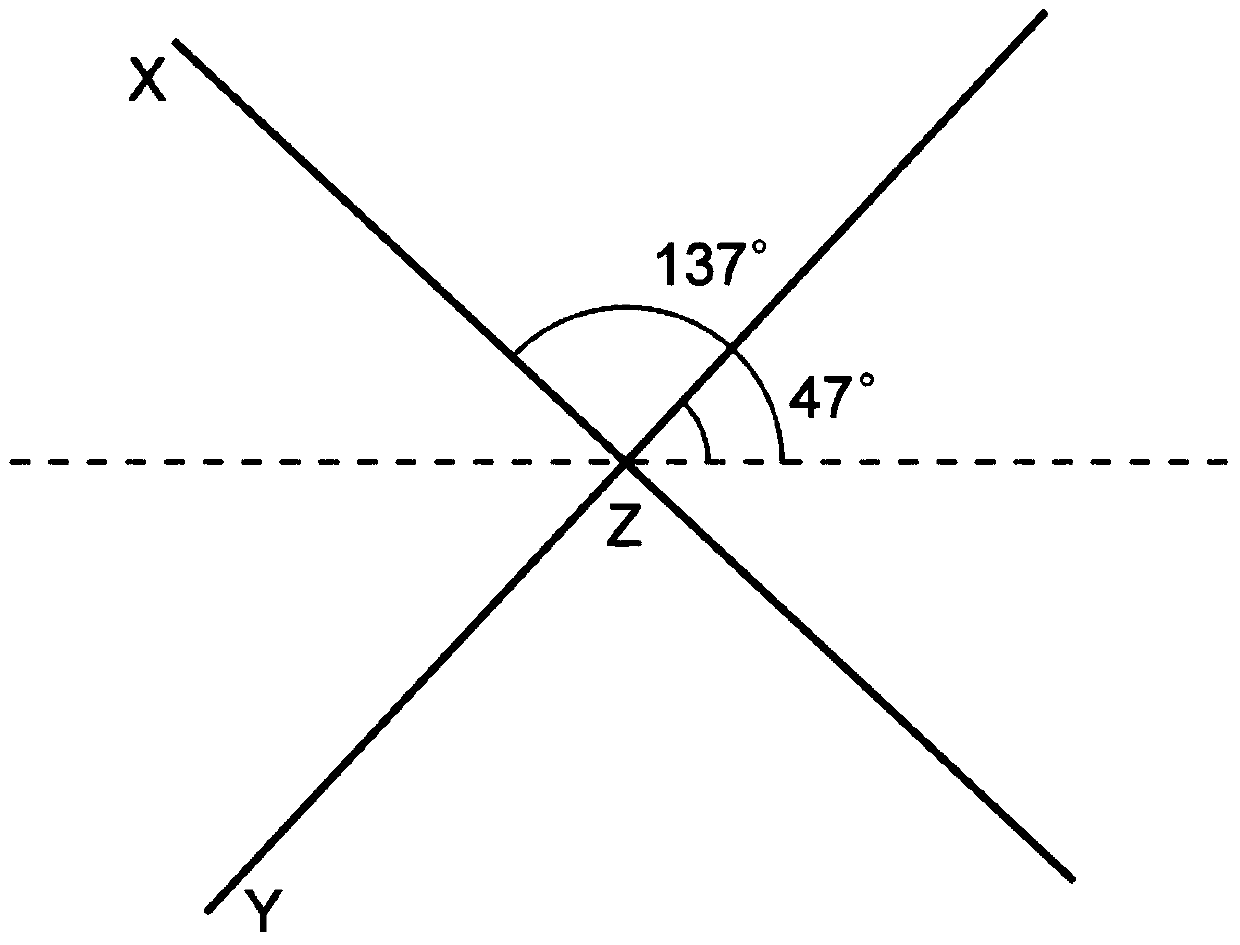

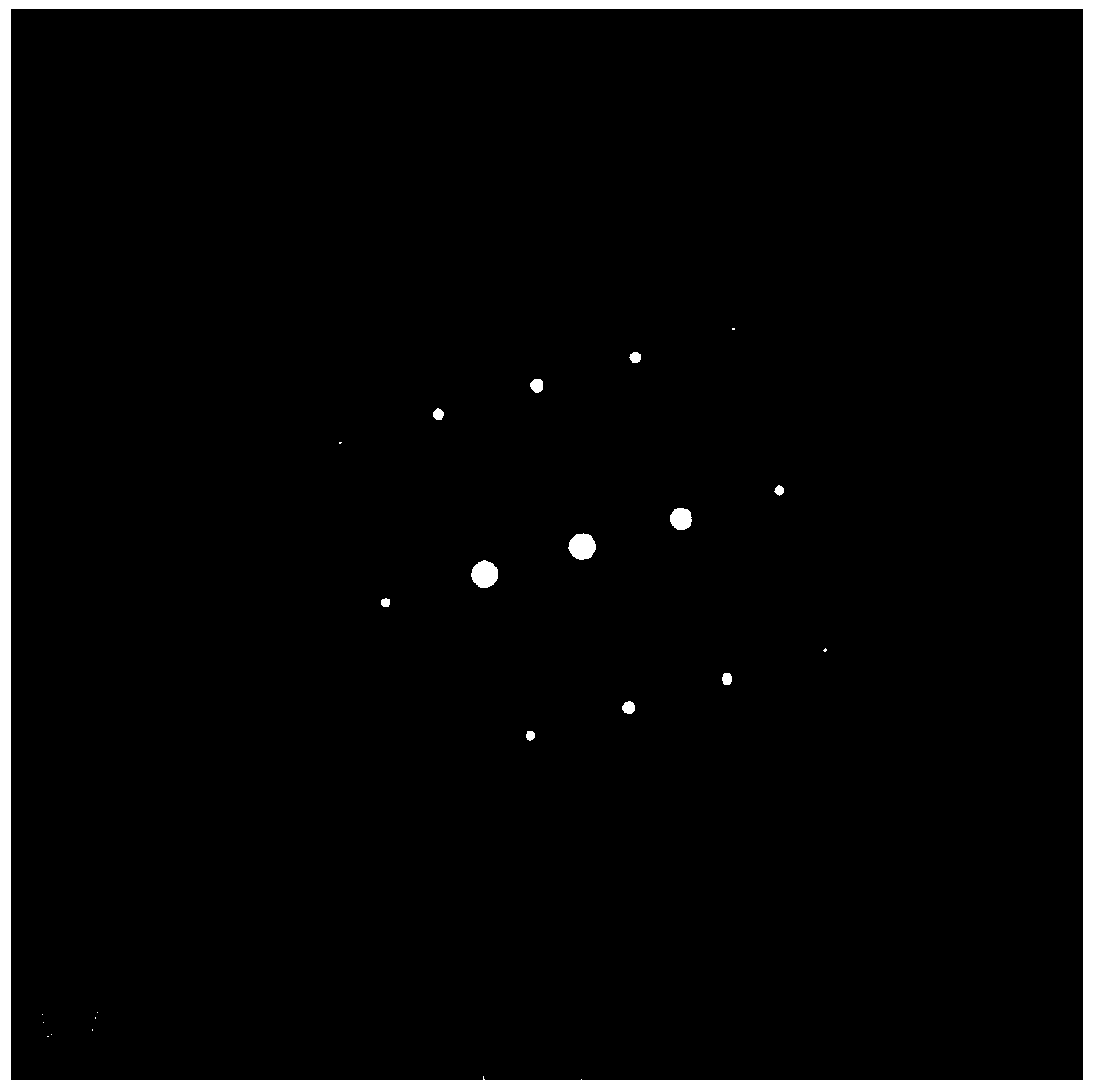

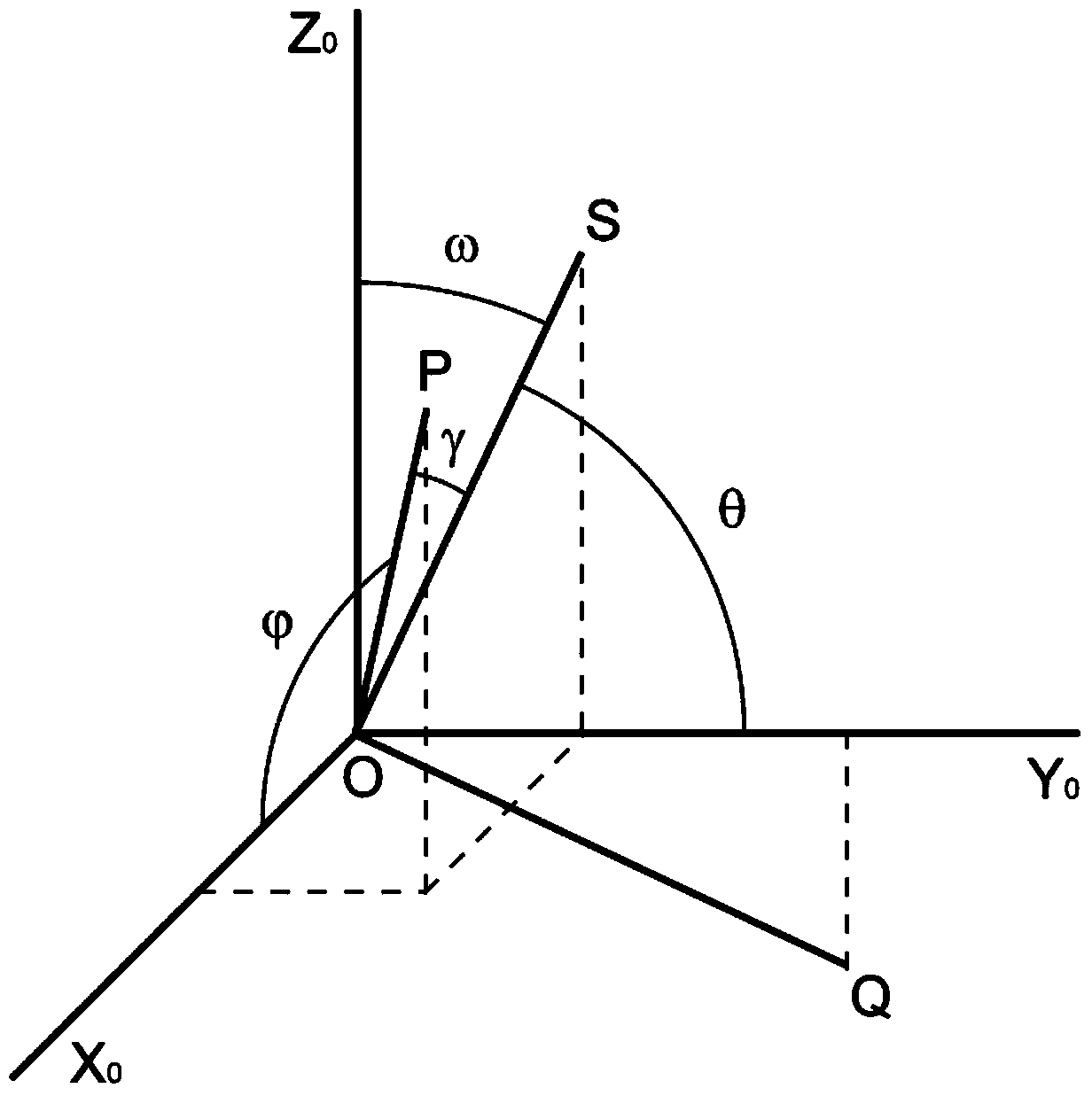

Method for automatically adjusting the crystal orientation through double-inclination sample stage of transmission electron microscopy

InactiveCN103995014ARealize automatic positioningReduce hands-on timeMaterial analysis by measuring secondary emissionTest efficiencyHigh energy

The invention provides a method for automatically adjusting the crystal orientation through a double-inclination sample stage of a transmission electron microscopy. The method comprises the following steps: calibrating the double-inclination sample stage; recording a single-crystal electronic diffraction pattern of a positive zone axis, and a camera constant, and recording five readings X1, Y1, Z1, A1 and B1 of the double-inclination sample stage; calibrating the diffraction pattern by utilizing the known lattice type and parameters of a to-be-detected sample; determining a reference coordinate system through the projection positions of two rotating shafts of the double-inclination sample stage to obtain double-inclination stage readings X2, Y2, Z2, A2 and B2 needed by assigned orientation; and inputting the calculated X2, Y2, Z2, A2 and B2 values by a user through a control panel of the transmission electron microscopy, thus being capable of realizing the automatic tilting and translation process. The calculation process is easily programmed and realized, the dependence degree of an operator is reduced, the testing efficiency can be greatly improved, and the sample damage caused by long-time high-energy electronic beam radiation can also be avoided.

Owner:FUJIAN UNIV OF TECH

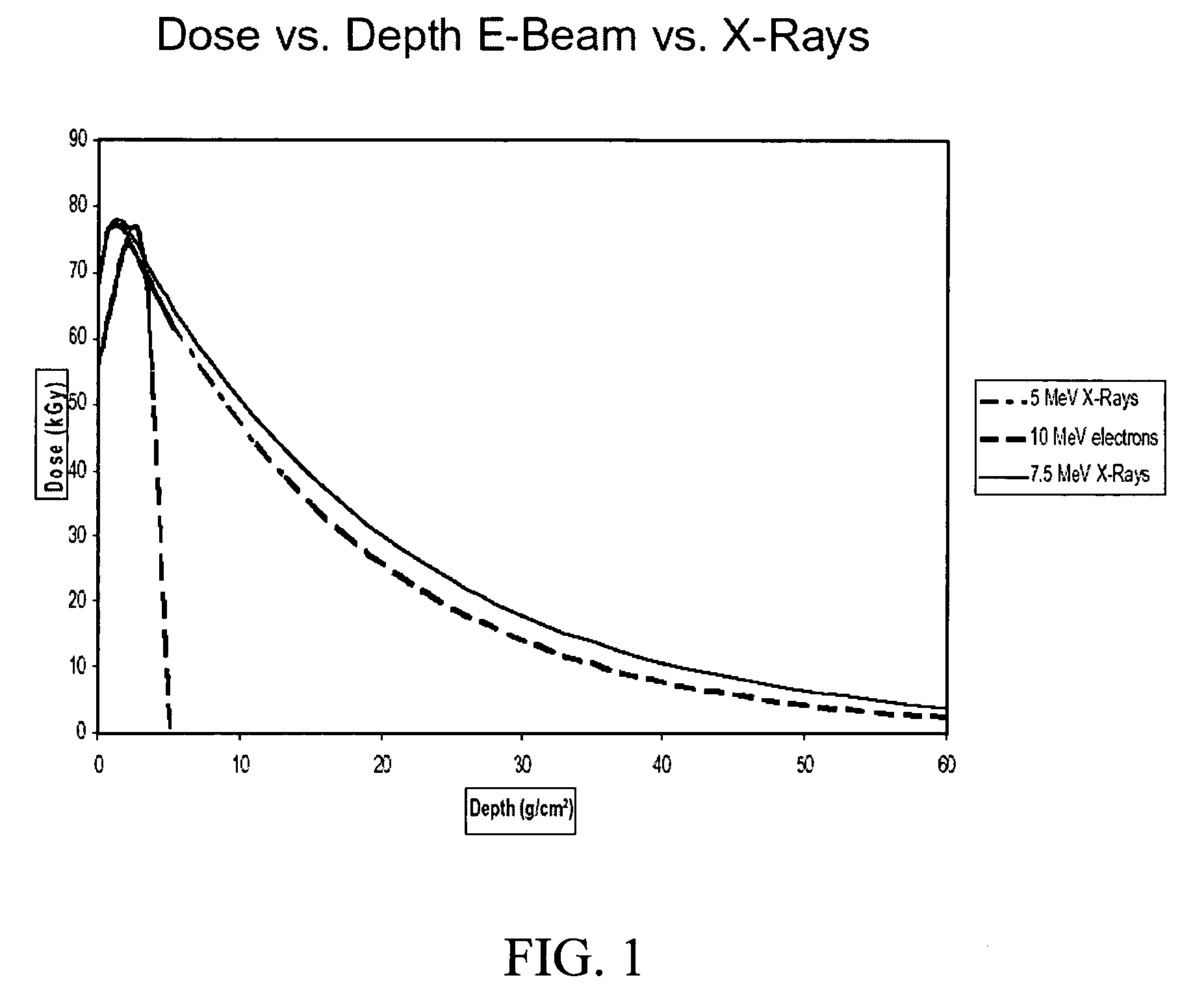

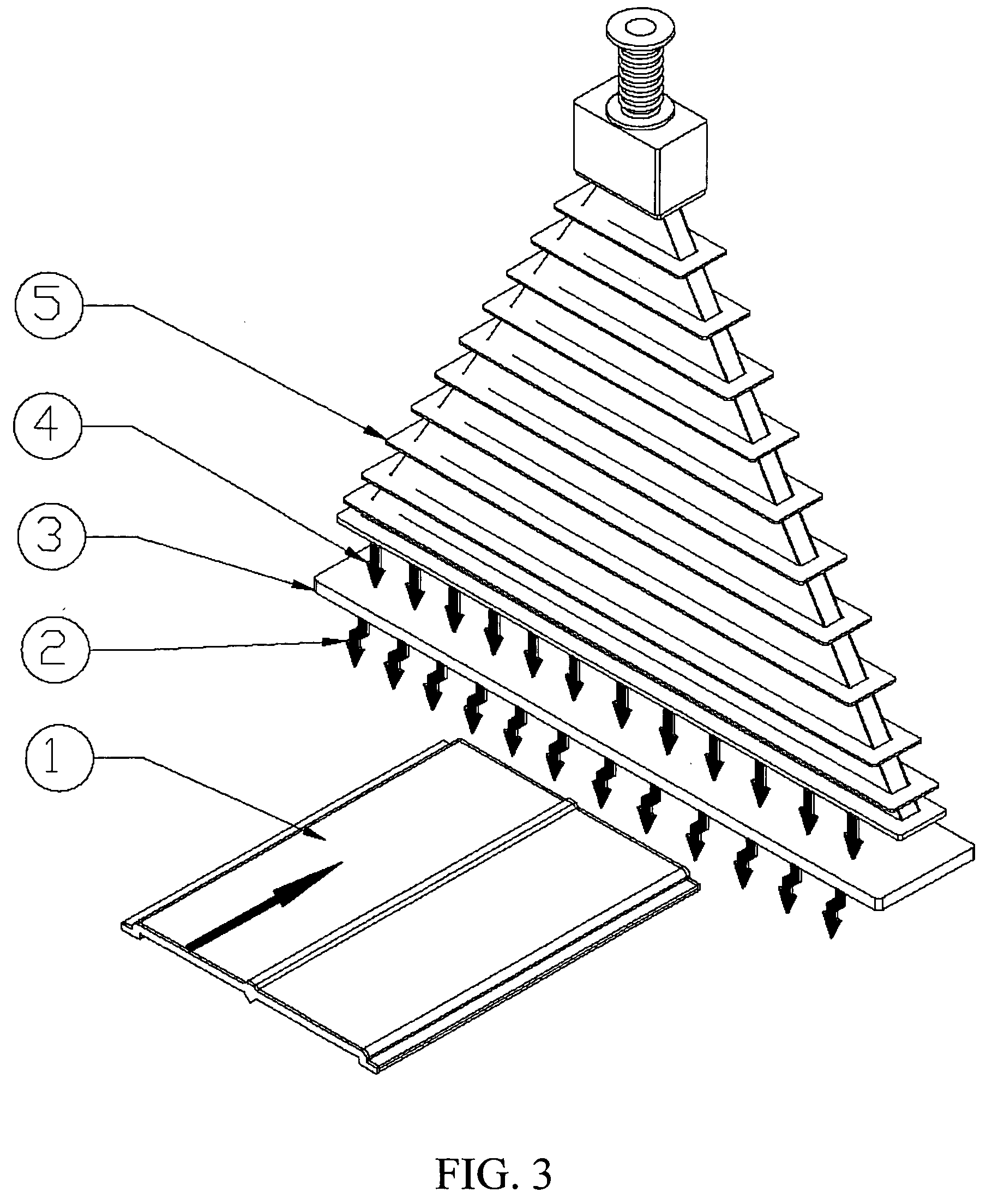

Processes for chemically affecting reactive materials with X-rays

InactiveUS20080196829A1Fast and energy efficientLess complicatedLamination ancillary operationsElectric discharge tubesPolymer scienceHigh energy

The present invention describes a method for curing polymers and polymer composites with X-rays generated by the bremsstrahlung effect, using a high power, high energy electron beam. The process generates X-rays with sufficient throughput and penetration for commercial use. The present invention employs high power, high energy electron beams to create the X-rays. The beams are typically run at energies ranging from 1 MeV to 10 MeV, preferably from 3 MeV to 10 MeV, and more preferably from 5 MeV to 7 MeV. The beams typically have powers ranging from 30 kW or higher, preferably 80 kW or higher, more preferably 100 kW of higher, and ideally at least 200 kW. Suitable polymers and polymer composites include, but are not limited to, polymeric molding materials, fiber reinforced molding materials, reactive monomer impregnated wood, similar and dissimilar materials bonded through adhesives.

Owner:ION BEAM APPL

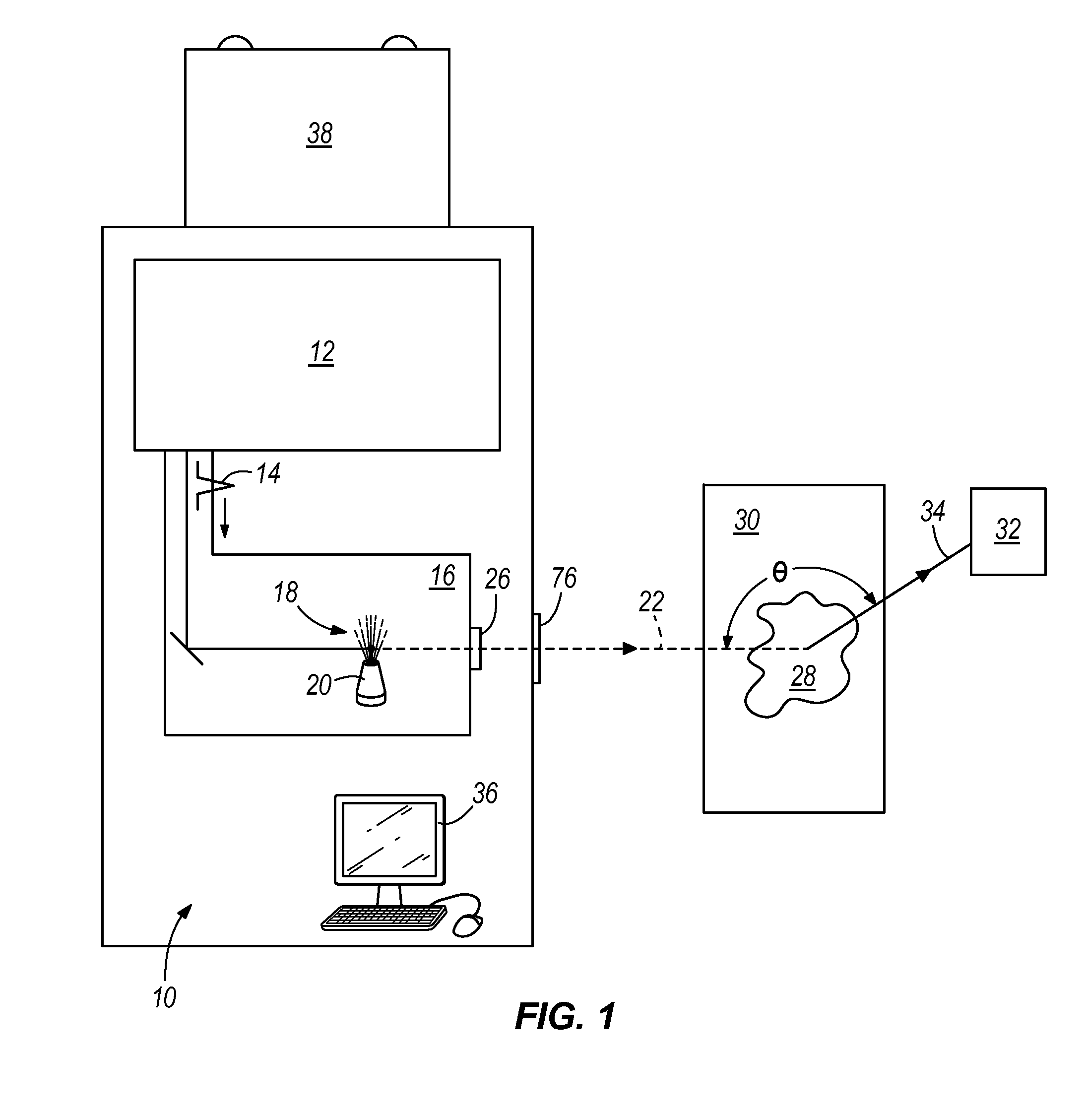

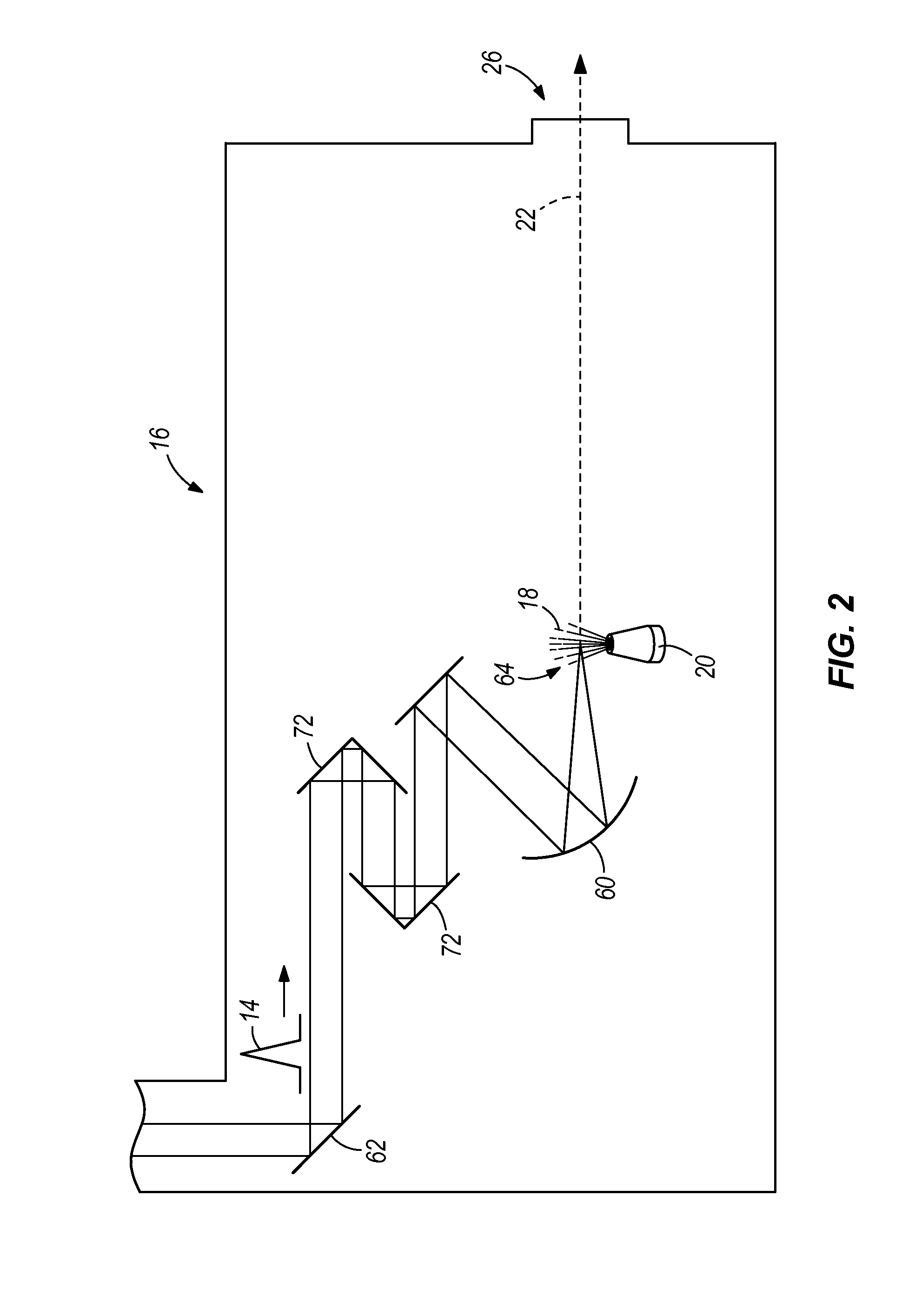

Laser-based accelerator for interrogation of remote containers

ActiveUS20100290587A1Narrow energy spreadImprove functionalityMaterial analysis by optical meansIon beam tubesHigh energyX-ray

A method and apparatus for generating high-energy beams of electrons or x-rays through laser wakefield acceleration to remotely examine containers is disclosed. By scanning the beam of electrons or x-rays across a container, an inspector can remotely determine whether the containers contain items of interest, such as special nuclear materials, without having to manually inspect the contents of the container. The invention can be compact enough to be portable, which provides for the flexibility to examine a variety of different containers under a variety of different conditions.

Owner:NUTECH VENTURES

Environment-friendly inflaming retarding smoke-inhibiting shaping phase-changing energy storage material and preparing method thereof

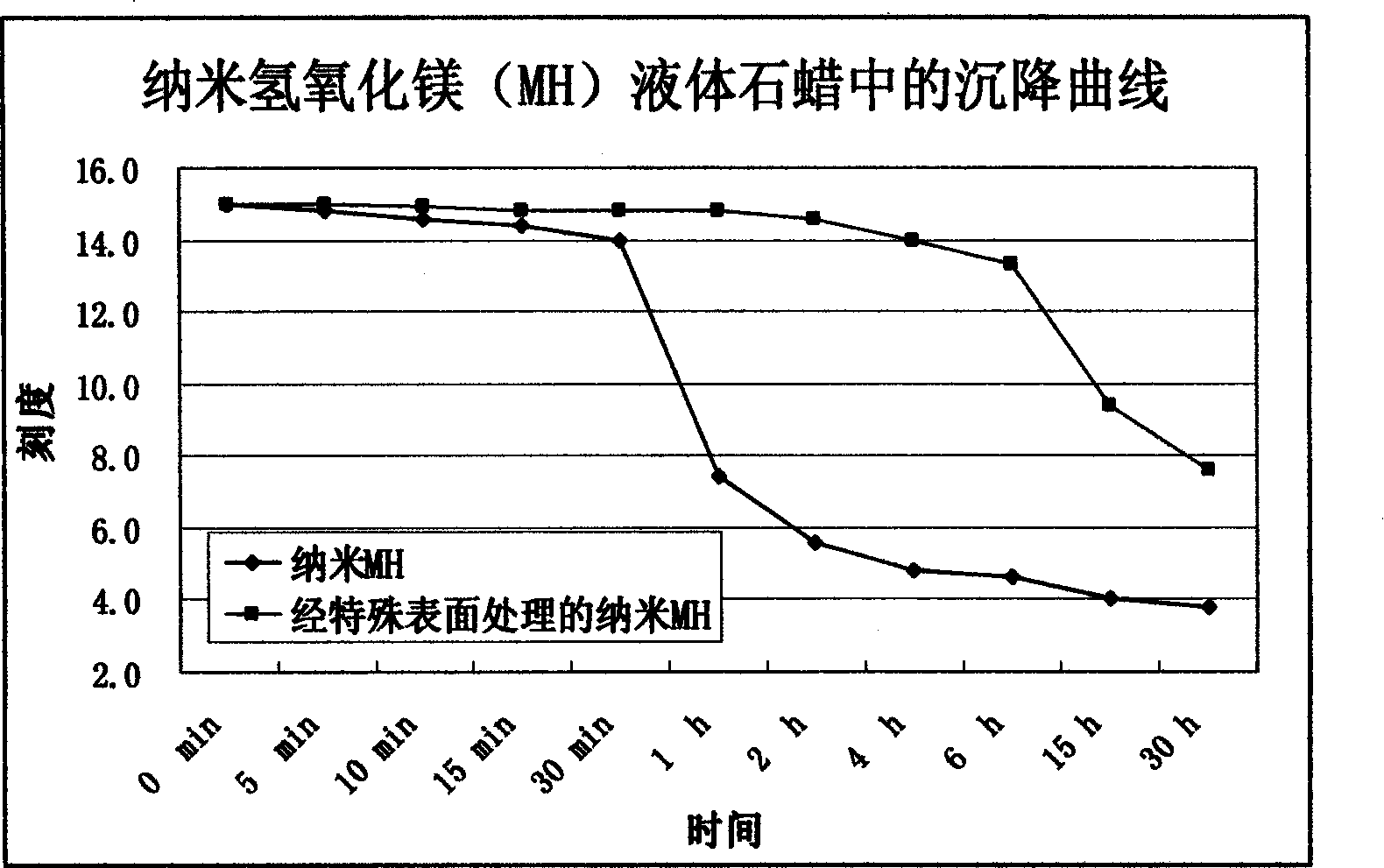

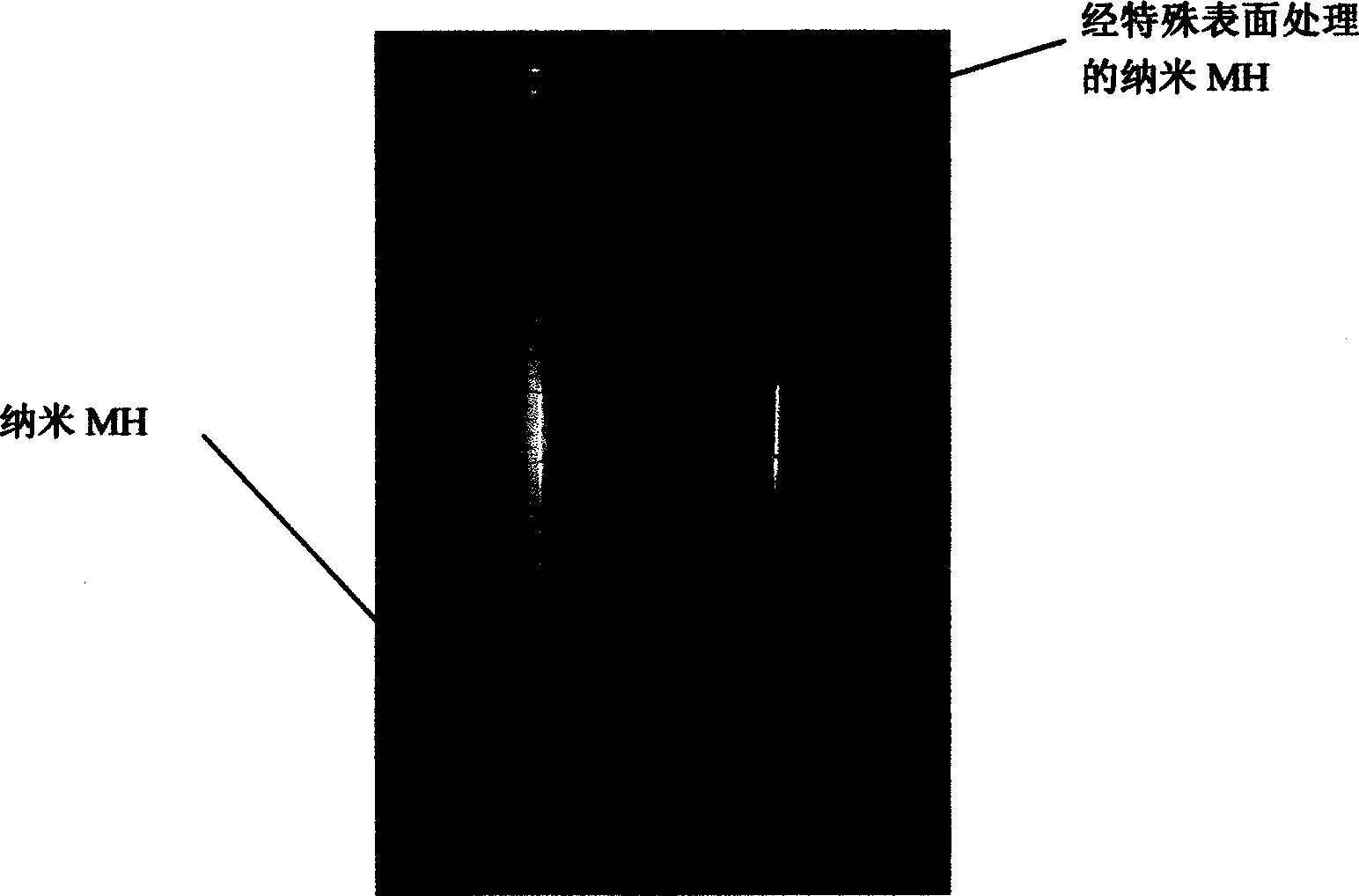

InactiveCN101531885AImprove flame retardant performanceSelf-extinguishingHeat-exchange elementsCross-linkElastomer

A preparing method of an environment-friendly inflaming retarding, smoke-inhibiting shaping phase-changing material is provided, comprising the following steps: adding the modified nanometer magnesium hydrate 100 parts, macromolecule elastomer 60-100 parts and flame retardant 1-10 parts to the refining machine to prepare the pre-mixing material under the conditions that the temperature is 50-15- centigrade and the rotating speed is 20-100 rpm; adding the phase-changing energy-saving material 50-100 parts under 20-70 phase-changing temperature to the pre-mixing material; continuing to refine the phase-changing material for 15-60 min to obtain the mixture; the parts above are all quality parts; filling the mixture to the mold and thermally-pressing the mixture by the vulcanizing press to form the plate material; after cooling to cross link by the high energy electronic beams. The phase-changing material and the modified nanometer magnesium hydrate are enveloped in the cross-linking net structure formed by the macromolecule elastomer, forming the inflaming retarding, self-extinguishing and smoke-inhibiting shaping phase-changing material; the phase-changing material enveloping rate of the product reaches 95-99%; the oxygen index reaches 23-28; the inflaming retarding performance is great; no toxic substance occurs wile burning the material, which can not generate the secondary pollution to the environment.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for preparing hydrophilic PVDF hollow fiber membrane by high energy electron beam mutual irradiation grafting

InactiveCN102626592AStrong surface activationPerformance is not affectedSemi-permeable membranesHollow fibre membraneFiber

The invention provides a method for preparing a hydrophilic PVDF hollow fiber membrane by high energy electron beam mutual irradiation grafting. By the mutual irradiation method of a grafting monomer and a base membrane by high energy electron beam, graft modification of the PVDF hollow fiber membrane having average pore size of 0.15-0.45 micrometer is carried out to improve its hydrophilicity. The concrete process is as follows: firstly cleaning the base membrane to remove an additive adhered to the base membrane, then immersing the treated base membrane in a monomer solution, carrying out mutual irradiation under high energy electron beam, and grafting the monomer onto the surface of the base membrane through free radical graft copolymerization so as to improve its hydrophilicity. After improvement of hydrophilicity, the pure water contact angle of the PVDF hollow fiber membrane, flux is increased and retention rate is raised. The monomer used is convenient and easy to obtain and requires low cost. The high energy electron beam only modifies the surface of the base membrane without influencing material performance. In addition, the method provided by the invention is simple and convenient to operate and can be completed at room temperature.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation device and method for multi-masterbatch, polyergic source and high throughput metal materials

The invention discloses a preparation device and preparation method of a high-flux metal material with multiple master batches and multiple energy sources. The device includes a high-energy electron beam generator, an arc generator, a laser, an arc generator and a high-energy electron beam generator. Converter, reflective laser prism, matrix master batch tank, high-efficiency ball mill-mechanical mixing-turbulent air mass synergistic mixing box, integrated structure of conduit and quality control valve, powder feeding pipe, atmospheric pressure and temperature controllable processing chamber, carrier protective gas , induction heating coil, self-heating three-dimensional motion sample processing platform, high-throughput preparation of new metal materials, using quality control valve to quantitatively distribute pure metal powder to the mixing box according to the calculated design requirements, high-efficiency ball milling-mechanical mixing-turbulent air mass synergy The mixing system thoroughly mixes multiple powders. The invention has wide application range, simple operation and wide range of materials that can be prepared.

Owner:SHANGHAI UNIV

Brake pad and preparation method thereof

ActiveCN106378453AGuaranteed mechanical propertiesHigh bonding strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantUltimate tensile strength

The invention provides a preparation method of a brake pad. The preparation method comprises the step of carrying out 3D printing on the surface attached with a metal layer, of a steel backing, by virtue of a raw material powder of the brake pad to obtain the brake pad, wherein the components of the metal layer are the same as metal components in the raw material components of the brake pad. According to the preparation method provided by the invention, a high-power electron beam enables the components in the material of the brake pad to be adequately reacted during a 3D printing process, so that the obtained brake pad has high mechanical performance and functional performance; and moreover, the steel backing with the surface attached with the metal layer having the components the same as the metal components in the raw materials of the brake pad is adopted, the metal layer is molten to form a thin molten bath under the scanning of the high-power electron beam during the 3D printing process, and adequate metallurgical bonding is carried out between the molten bath and the raw material powder of the brake pad, so that a wear-resistant layer in the brake pad and the steel backing have a high bonding strength. In addition, the power of the electron beam scans on the raw material powder of the surface of the steel backing during the 3D printing process, without influence on the organizational structure of the interior of the steel backing, thus the own mechanical performance of the steel backing is ensured.

Owner:SEED TECH CORP LTD

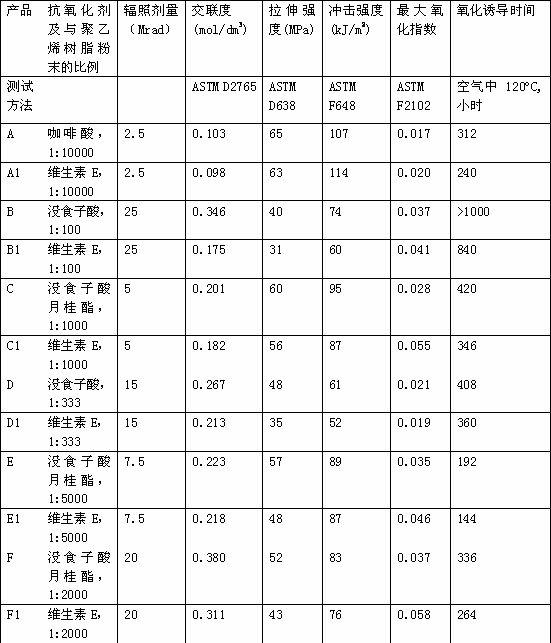

Antioxidant cross-linked polymer and preparation method thereof

ActiveCN102604188AImprove wear resistanceImprove oxidation stabilityProsthesisCross-linkPolymer science

The invention relates to an antioxidant cross-linked polymer and a preparation method thereof. The existing cross-linked ultra-high molecular weight polyethylene has relatively low strength and toughness. The polymer provided by the invention is a mixture of cross-linked ultra-high molecular weight polyethylene and an antioxidant at a weight ratio of (100-10000):1. The preparation method comprises the following steps of: dissolving the antioxidant into an organic solvent, adding the ultra-high molecular weight polyethylene resin powder, sufficiently mixing and drying; placing the mixture powder into a mould; heating and pressurizing so as to melt the mixture powder into block; cooling the block below the melting point and annealing while maintaining the pressure; reducing the temperature to normal temperature and demoulding to obtain block blank; and irradiating with high-power electron beam to obtain the product. The polyethylene material provided by the invention has excellent wear resistance, oxidation stability, tensile strength and impact strength, is suitable for manufacturing the friction lining of an artificial joint, and can reduce the wear of the artificial joint.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

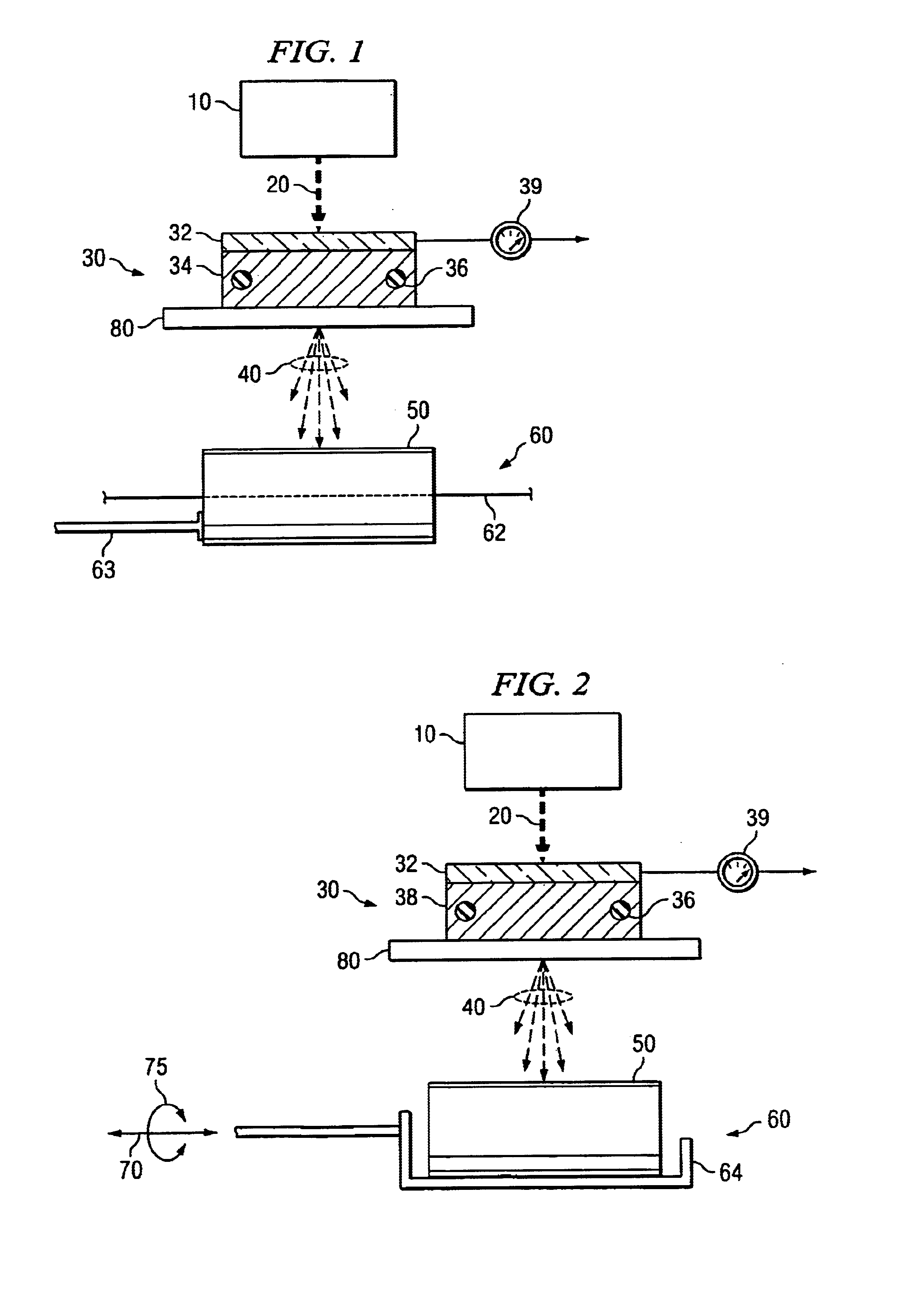

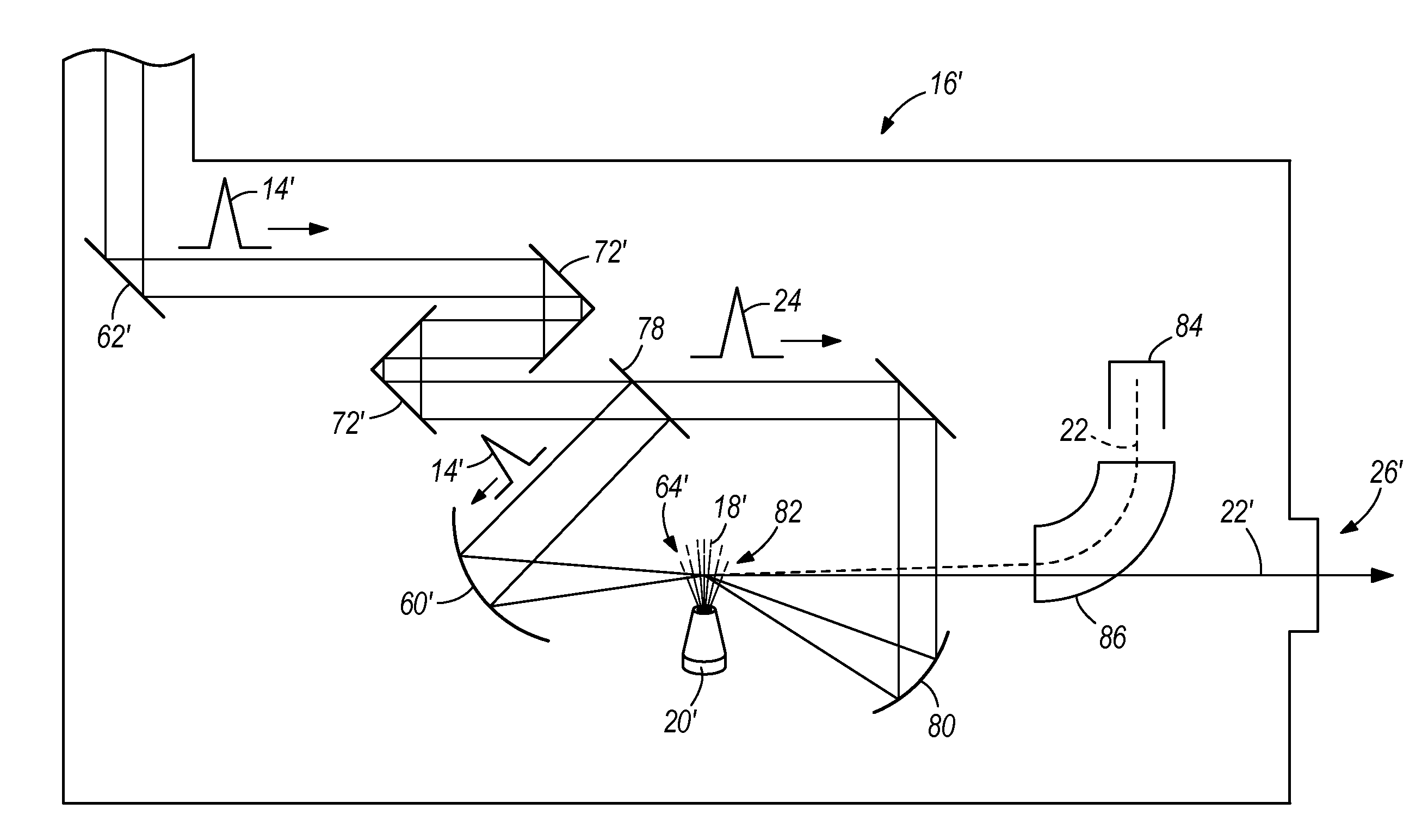

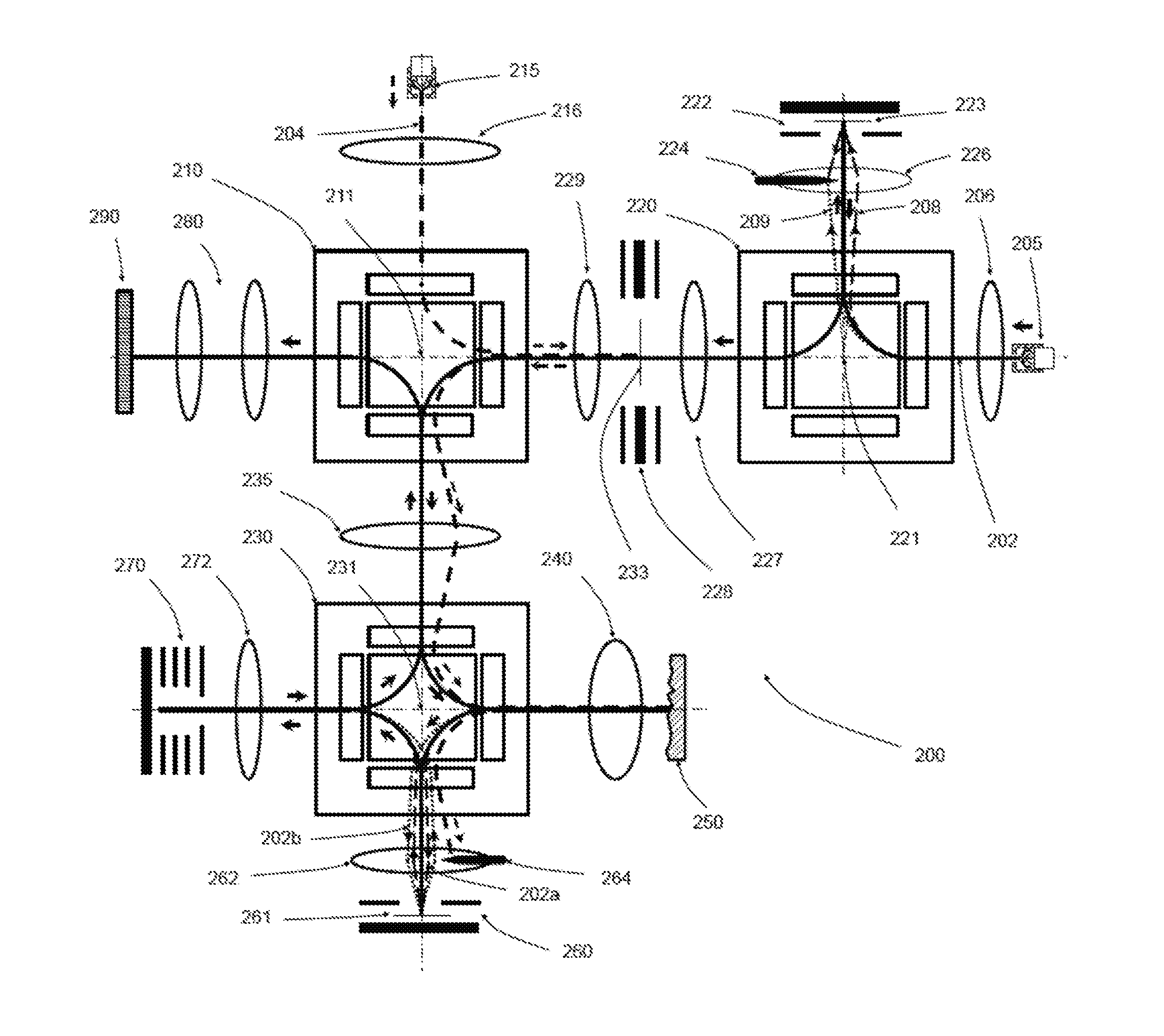

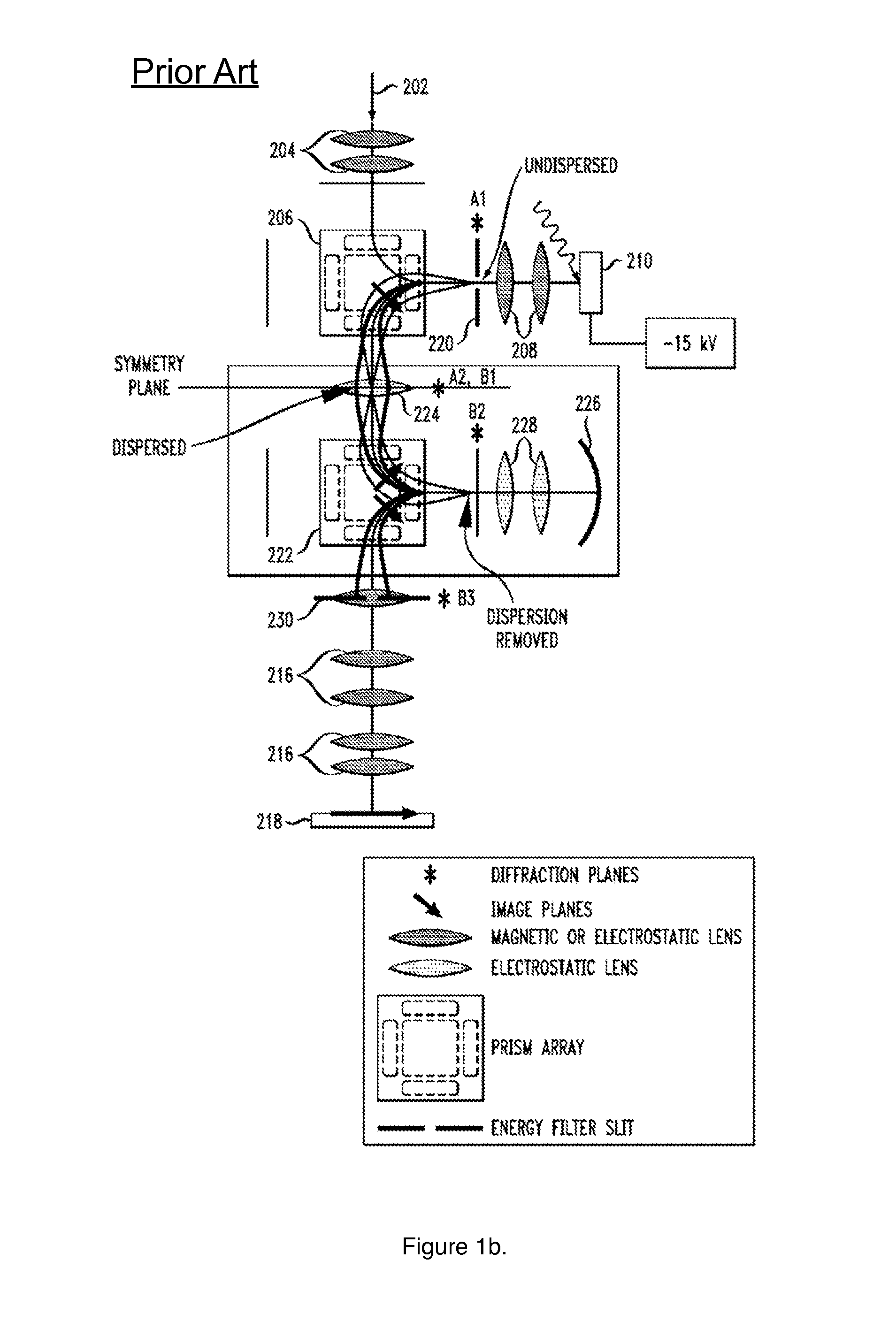

Aberration-corrected and energy-filtered low energy electron microscope with monochromatic dual beam illumination

ActiveUS8729466B1Excessive aberrationStability-of-path spectrometersMaterial analysis using wave/particle radiationBeam sourceHigh energy beam

One embodiment relates to an apparatus for correcting aberrations introduced when an electron lens forms an image of a specimen and simultaneously forming an electron image using electrons with a narrow range of electron energies from an electron beam with a wide range of energies. A first electron beam source is configured to generate a lower energy electron beam, and a second electron beam source is configured to generate a higher energy electron beam. The higher energy beam is passed through a monochromator comprising an energy-dispersive beam separator, an electron mirror and a knife-edge plate that removes both the high and low energy tail from the propagating beam. Both the lower and higher energy electron beams are deflected by an energy-dispersive beam separator towards the specimen and form overlapping illuminating electron beams. An objective lens accelerates the electrons emitted or scattered by the sample. The electron beam leaving the specimen is deflected towards a first electron mirror by an energy-dispersive beam separator, which introduces an angular dispersion that disperses the electron beam according to its energy. A knife-edge plate, located between the beam separator and first electron mirror, is inserted that removes all of the beam with energy larger and smaller than a selected energy and filters the beam according to energy. One or more electron lenses focus the electron beam at the reflection surface of the first electron mirror so that after the reflection and another deflection by the same energy-dispersive beam separator the electron beam dispersion is removed. The dispersion-free and energy-filtered electron beam is then reflected in a second electron mirror which corrects one or more aberrations of the objective lens. After the second reflection, electrons are deflected by the magnetic beam separator towards the projection optics which forms a magnified, aberration-corrected, energy-filtered image on a viewing screen.

Owner:ELECTRON OPTICA

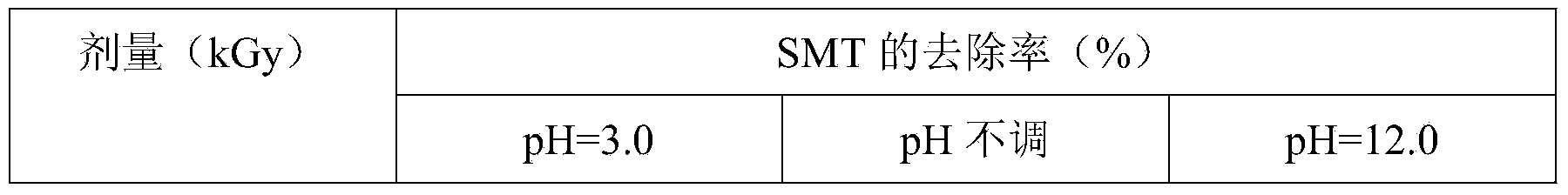

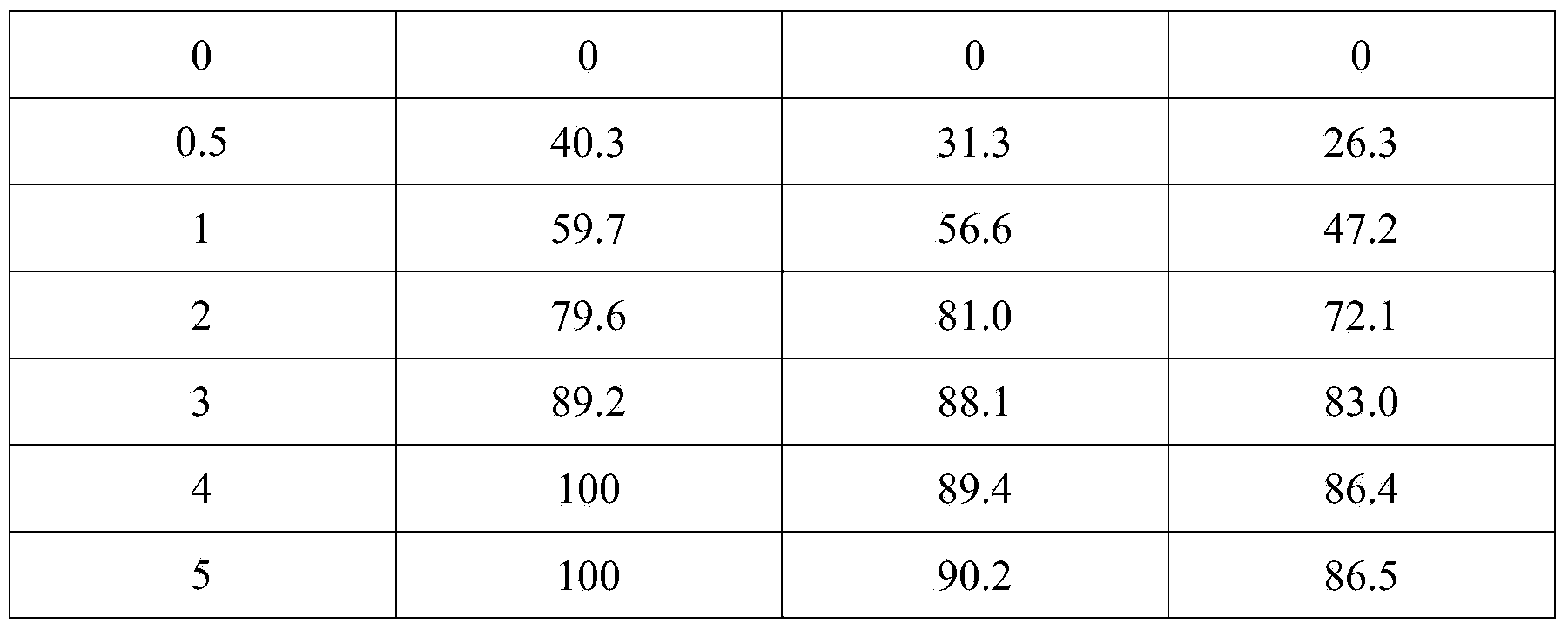

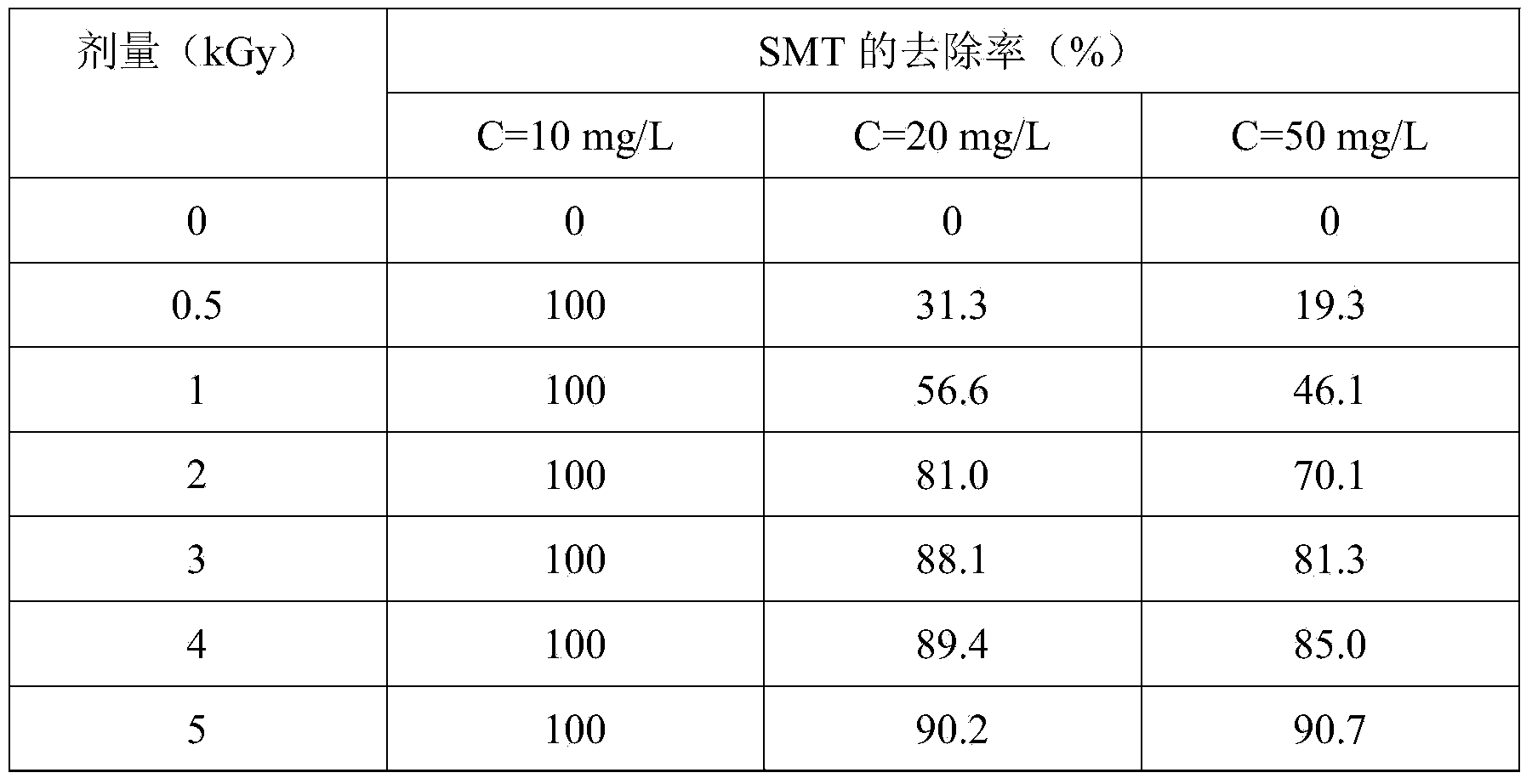

Method of removing sulfonamide antibiotics in water by utilizing ionization radiation technology

InactiveCN103482733AImprove degradation efficiencyCompletely degradedWater contaminantsWater/sewage treatment by magnetic/electric fieldsGamma rayAntibiotic Y

The invention discloses a method of removing sulfonamide antibiotics in water by utilizing an ionization radiation technology, belonging to the technical field of nuclear technology application and environmental protection. The method can be used for effectively removing sulfonamide antibiotic drugs (for example sulfamethazine) in water without adjusting pH of wastewater and adding any chemical agent by applying the ionization radiation (high-power electron beams generated by electron accelerator or gamma rays generated by a radioactive source) technology. The method disclosed by the invention is simple, effective, easy to operate and can be used for treating antibiotic wastewater.

Owner:TSINGHUA UNIV

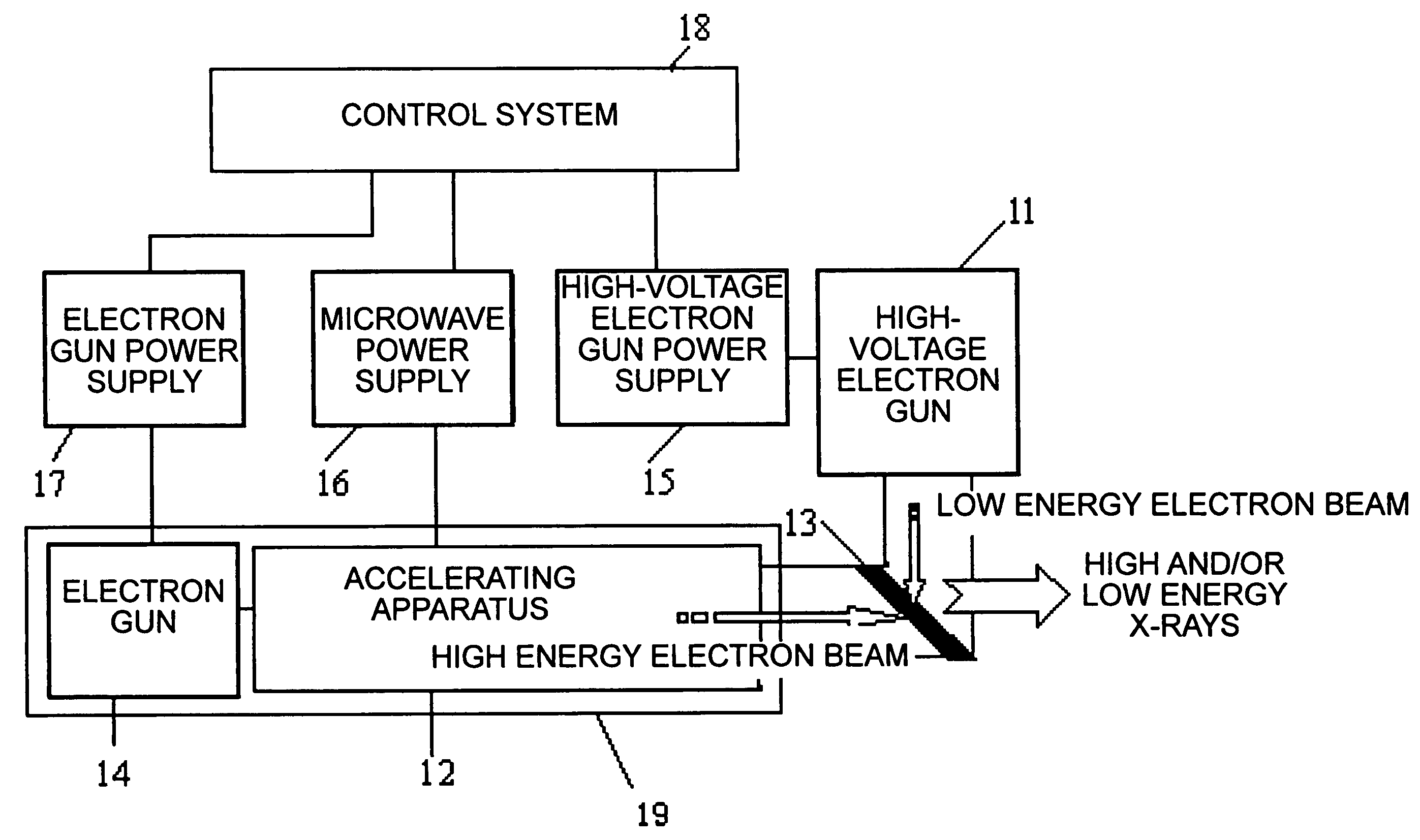

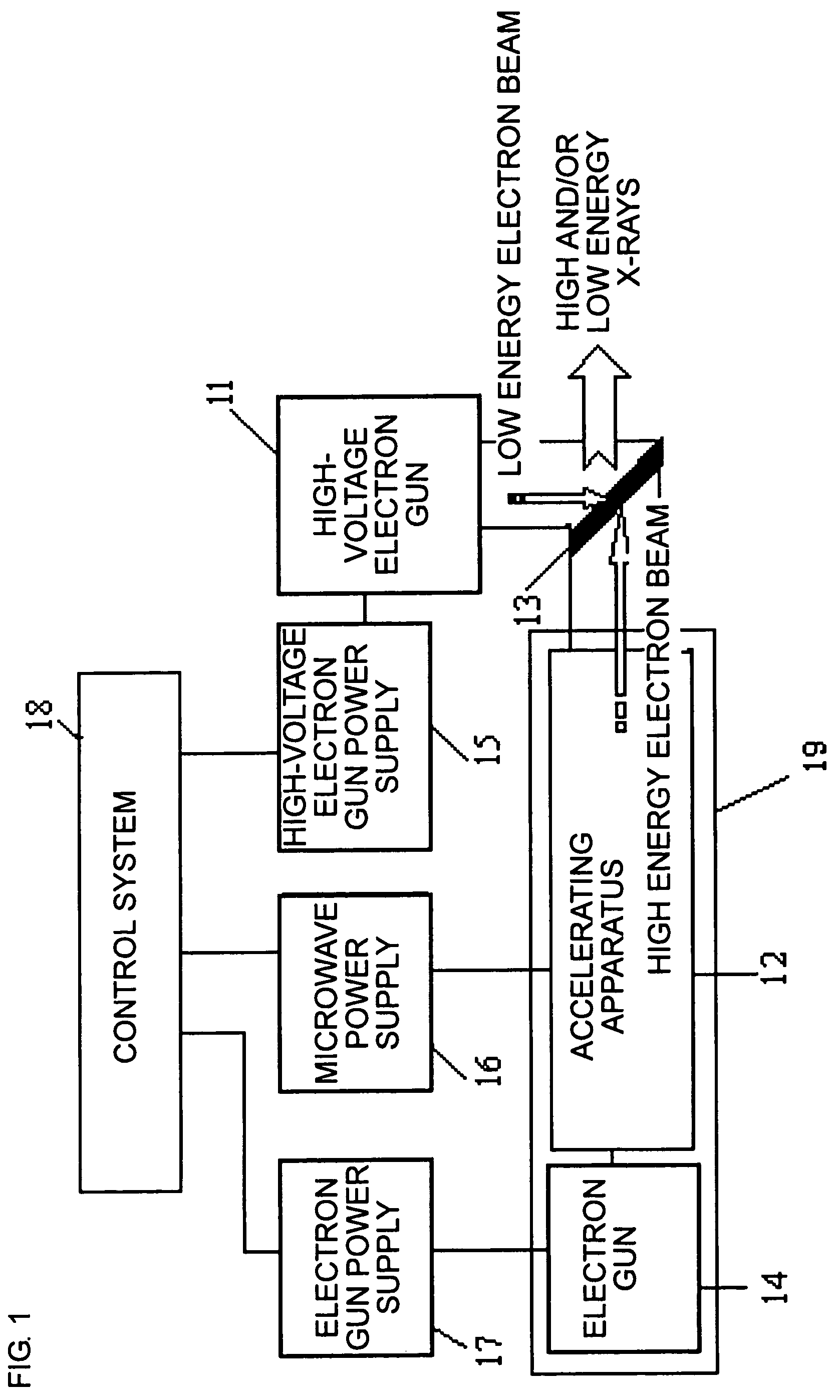

Device for outputting high and/or low energy X-rays

ActiveUS7645994B2Improve image qualityLarge adjustment rangeX-ray tube laminated targetsSolid-state devicesHigh energyX-ray

Owner:TSINGHUA UNIV +1

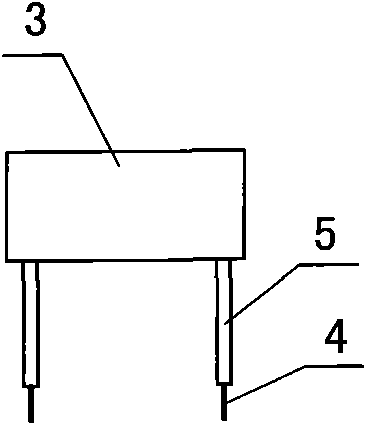

Method for manufacturing precise metal strip resistor

InactiveCN101587766AOverall goodImprove processing efficiencyResistor trimmingResistors adapted for applying terminalsElectrical resistance and conductanceMetal strips

A method for manufacturing precise metal strip resistor comprises: selecting an alloy strip and two metal strips; cleaning them; welding the two metal strips respectively on two sides of the alloy strip by high energy electron beam welding technique to form an integral resistor strip; punching the resistor strip transversely into a plurality of resistor bodies, or punching the alloy thin plate into a plurality of resistor bodies; then adjusting the numerical resistance values of the resistor bodies; and performing subsequent improvement processing to the resistor bodies to form precise metal strip resistor. Compared with the current technologies, The method provided in the invention reduces more than half of the production processes, increases the efficiency by tem times; reduces the product volume greatly, and realizes the production of surface applied precise splitter with low resistance, small volume and heavy bearable current. The resistor manufactured by the method provided in the invention has the characteristics of good performance, small volume and low material consumption.

Owner:BDS ELECTRONICS +1

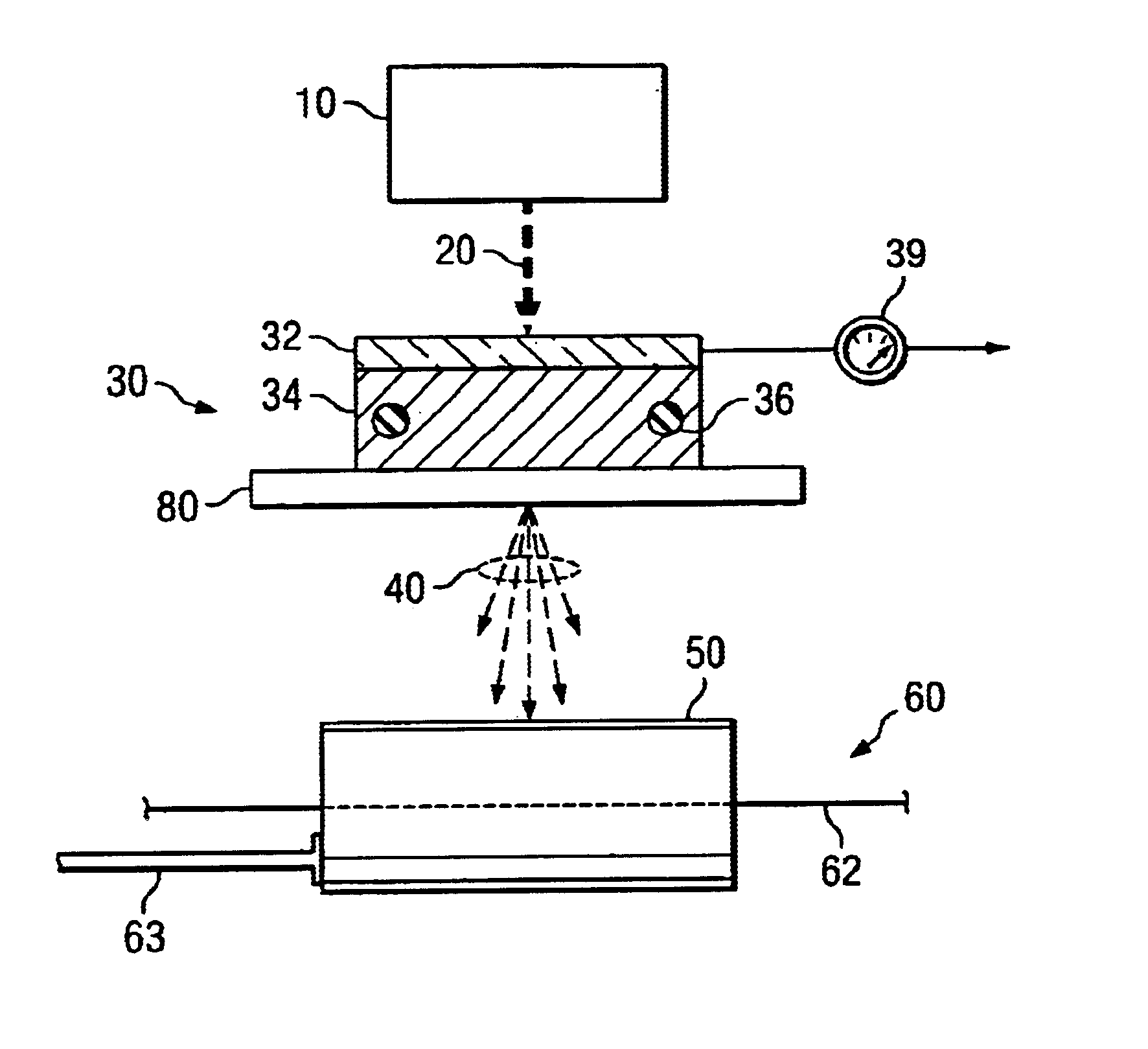

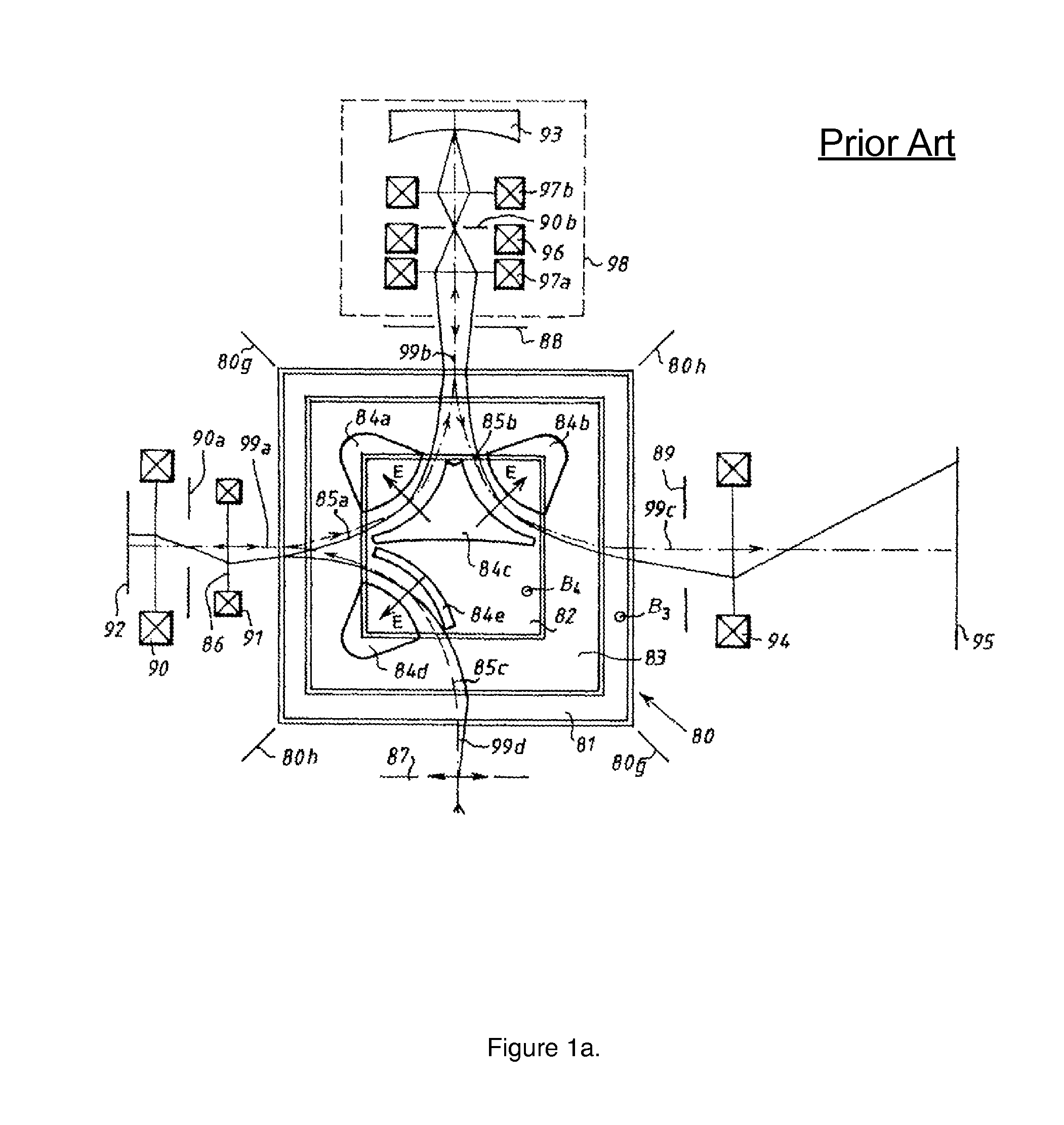

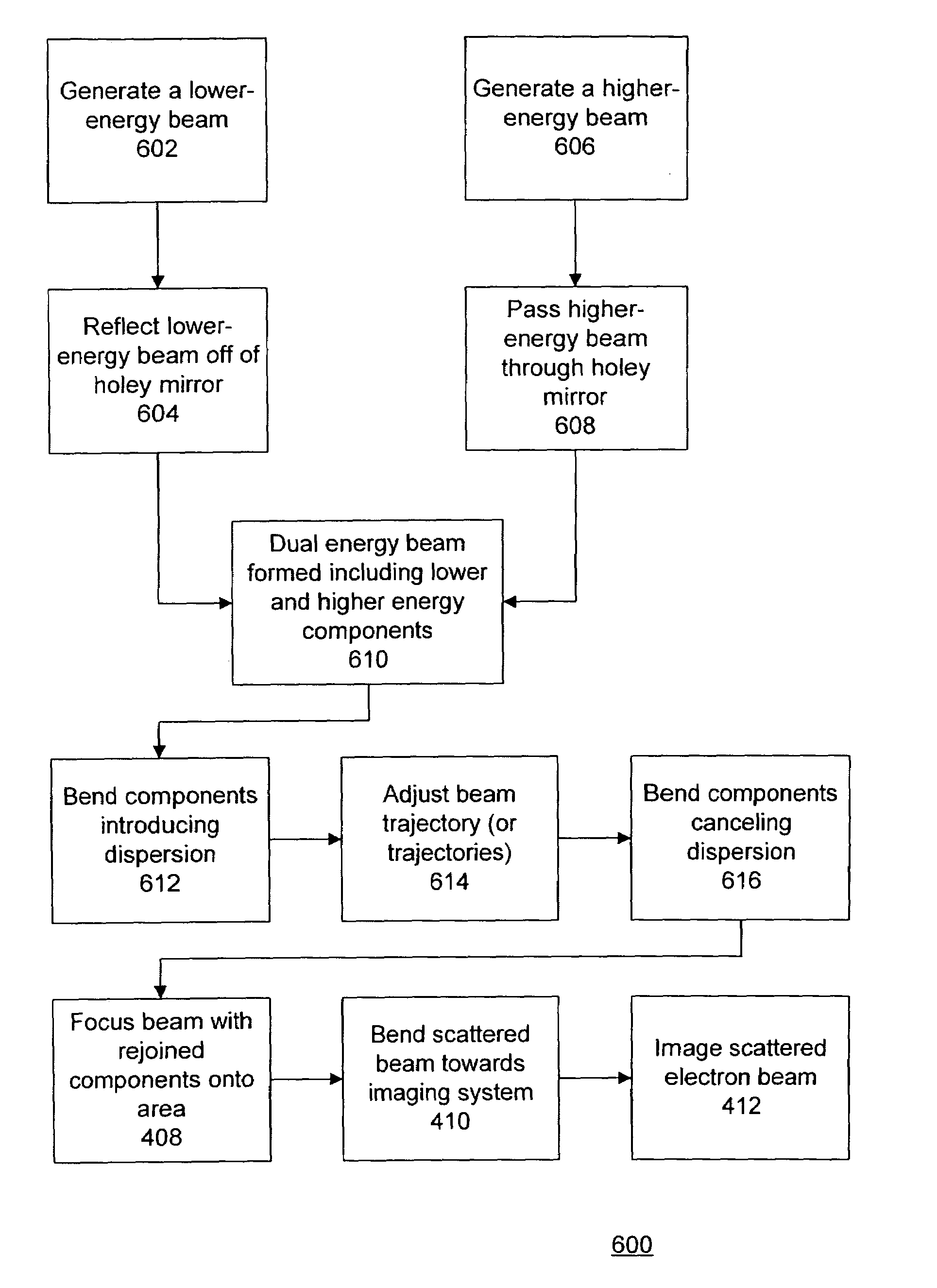

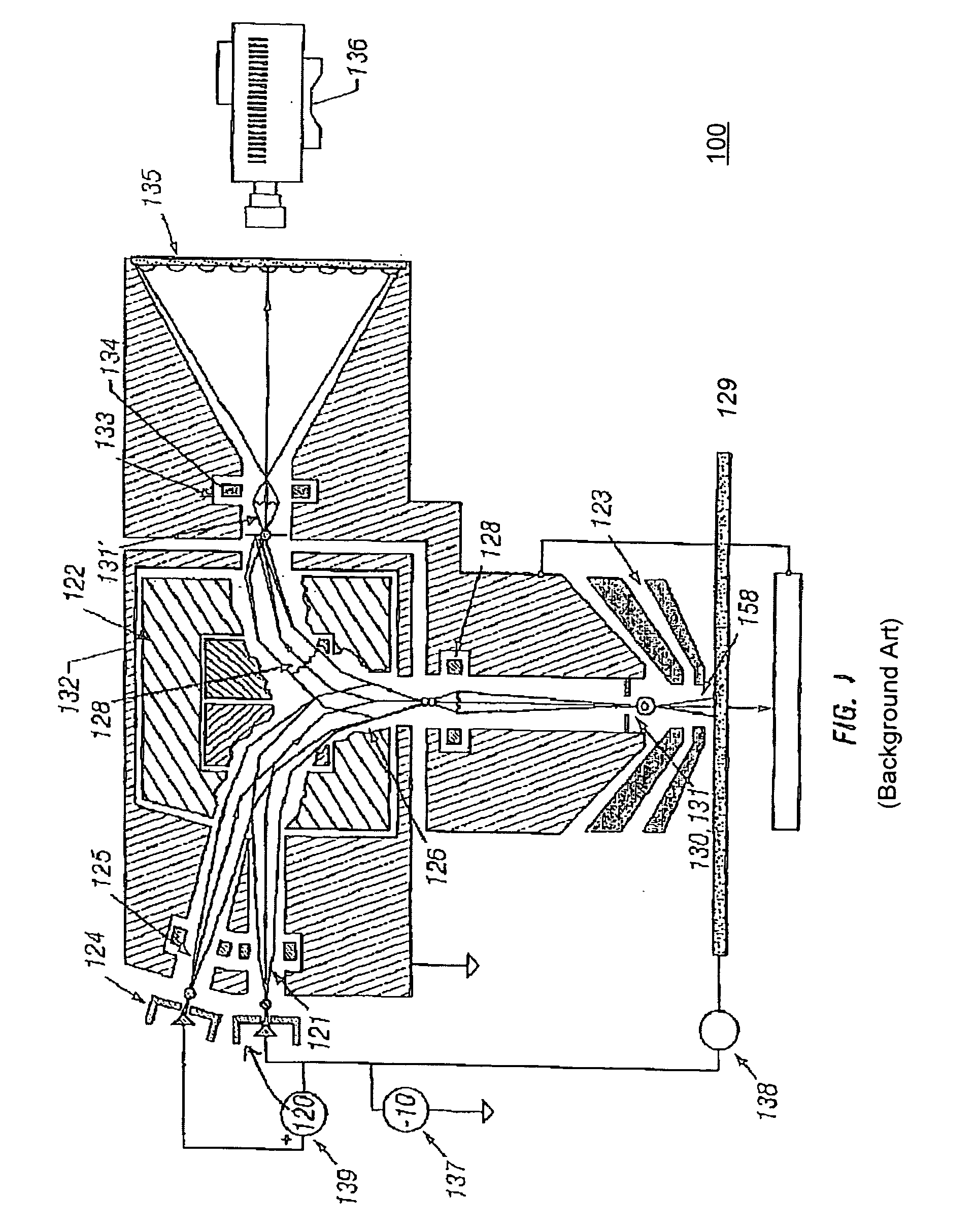

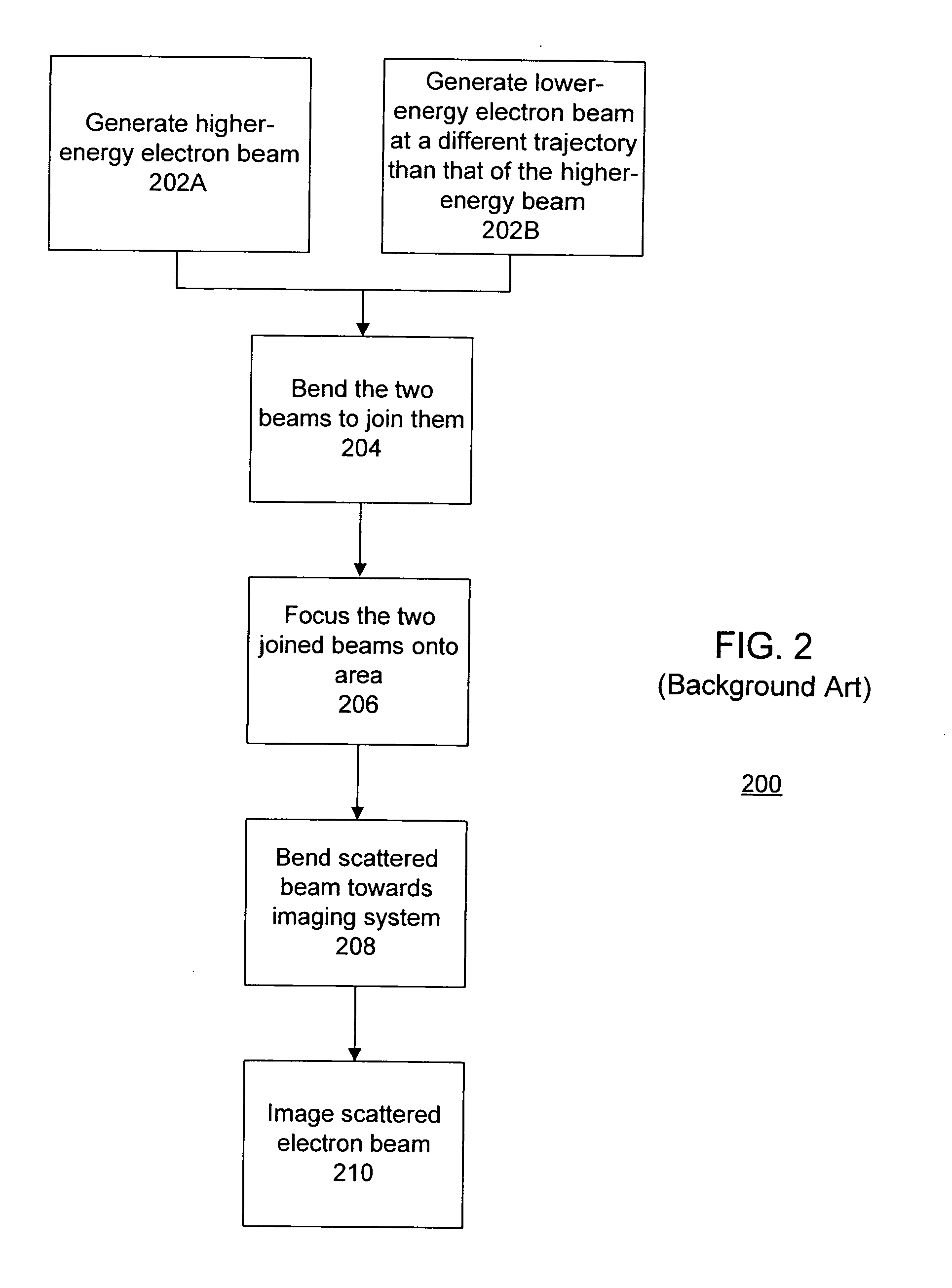

Holey mirror arrangement for dual-energy e-beam inspector

InactiveUS7217924B1Stability-of-path spectrometersMaterial analysis using wave/particle radiationBeam sourceDual energy

One embodiment relates to an apparatus for generating a dual-energy electron beam. A first electron beam source is configured to generate a lower-energy electron beam, and a second electron beam source is configured to generate a higher-energy electron beam. A holey mirror is biased to reflect the lower-energy electron beam. The holey mirror also includes an opening therein through which passes the higher-energy electron beam, thereby forming the dual-energy electron beam. A prism array combiner introduces a first dispersion between the lower-energy electron beam and the higher-energy electron beam within the dual-energy electron beam. A prism array separator is configured to separate the dual-energy electron beam traveling to a substrate from a scattered electron beam traveling away from the substrate. The prism array separator introduces a second dispersion which compensates for the dispersion of the prism array combiner. Other embodiments are also disclosed.

Owner:KLA TENCOR TECH CORP

Method for preparing drop resisting polyester and polypropylene fiber

InactiveCN1858335ALong-lasting anti-dripping performanceNo pollution in the processFibre treatmentPolyesterUltraviolet

The present invention provides a method of preparing molten drop preventing fiber with polyester and polypropylene fiber as base material and through grafting carboxyl group compound. The method includes irradiation grafting reaction to graft compound containing carboxyl group onto acrylic acid monomer under the irradiation of high energy electron beam, gamma ray or ultraviolet ray; and the subsequent soaking treatment in magnesium hydroxide or aluminum hydroxide solution. The method results in lasting molten drop preventing performance and has no toxicity and contamination. The polyester and polypropylene fiber through the molten drop preventing treatment produces no molten drop during burning, and can avoid secondary fire and damage to skin caused by molten drop.

Owner:天津市思腾纤维科技开发有限公司

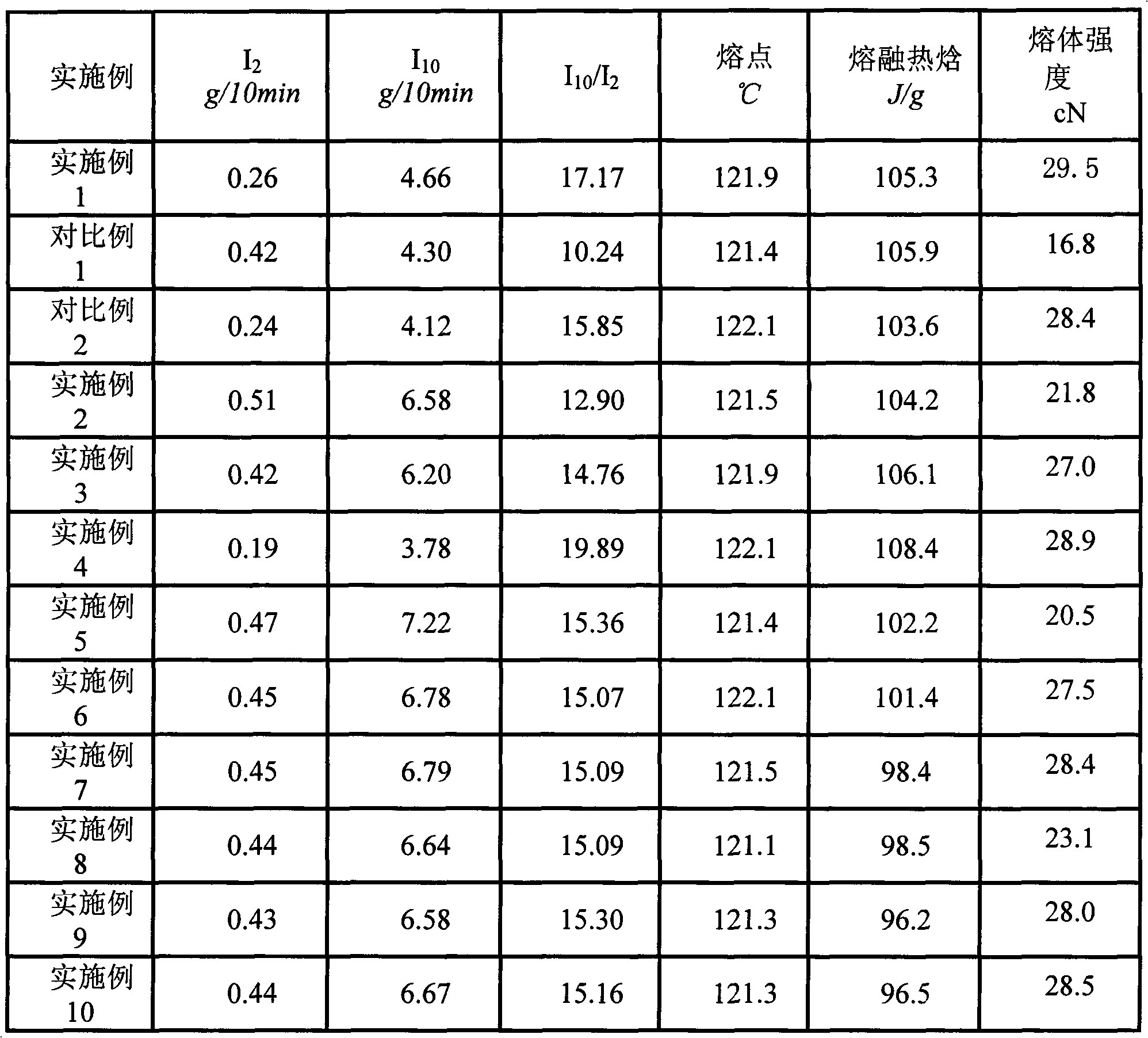

Method for preparing long chain branched polyethylene

InactiveCN102030910AReduce cross-linking reactionSensitive shear thinning propertiesHigh energyGamma ray

The invention provides a method for preparing long chain branched polyethylene. The method comprises the following steps of: (1) irradiating a substrate polyethylene with high-energy electron beams or gamma-rays to obtain pre-irradiated polyethylene, wherein the irradiation dose is 1 to 20OkGy; (2) blending the pre-irradiated polyethylene obtained in the step (1) and the substrate polyethylene and uniformly stirring to obtain a premixture, wherein in the premixture, the pre-irradiated polyethylene accounts for 1 to 99 weight percent and the substrate polyethylene accounts for 99 to 1 weight percent; and (3) performing reaction extrusion on the premixture obtained in the step (2) to prepare the long chain branched polyethylene. The method is simple, feasible and low in cost; and the obtained long chain branched polyethylene has more sensitive shear thinning property and higher melt strength, is applied to multiple kinds of processing technology, has high processability and particularly has good application prospect in the fields of thin films and foaming.

Owner:CHINA PETROLEUM & CHEM CORP +1

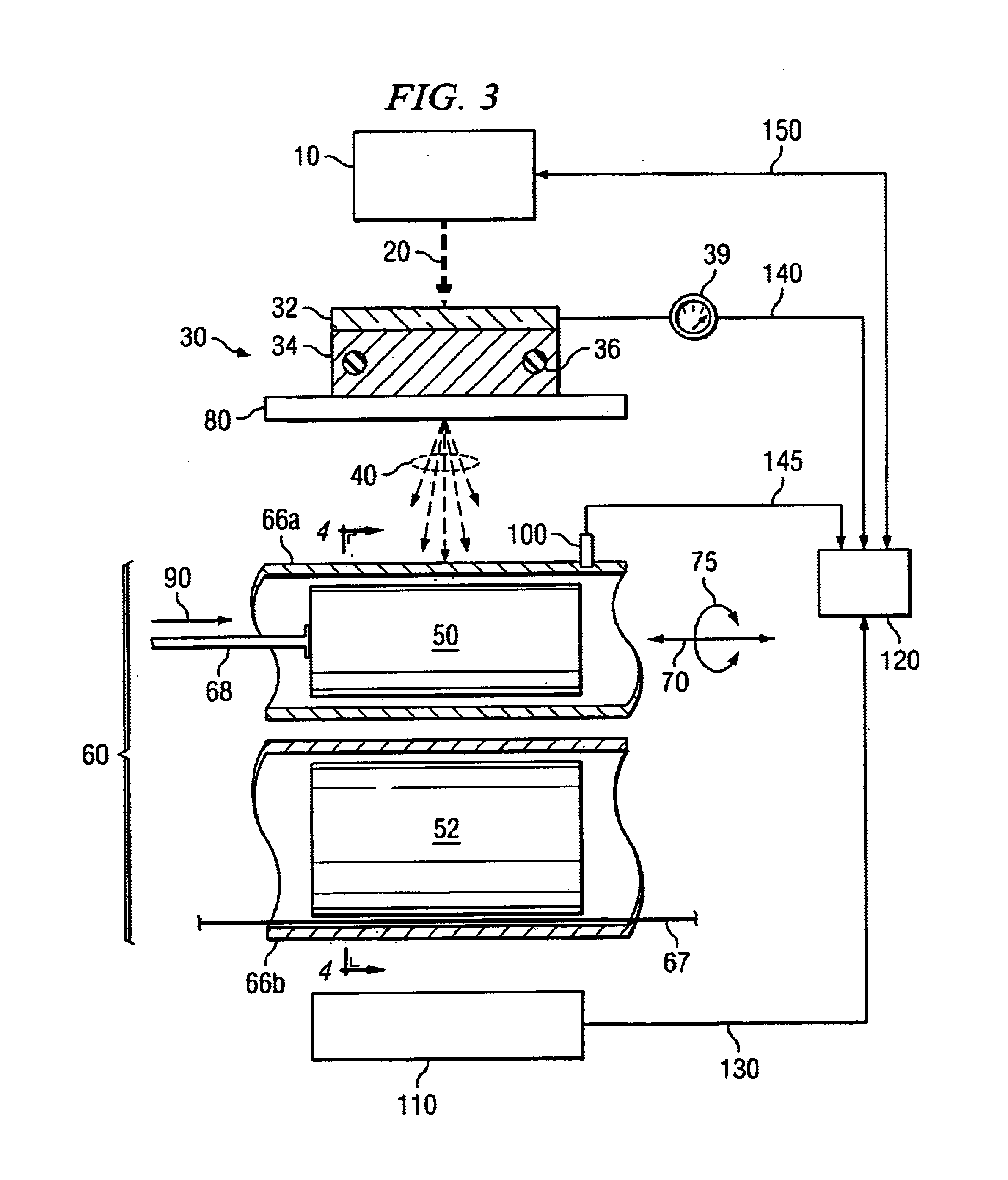

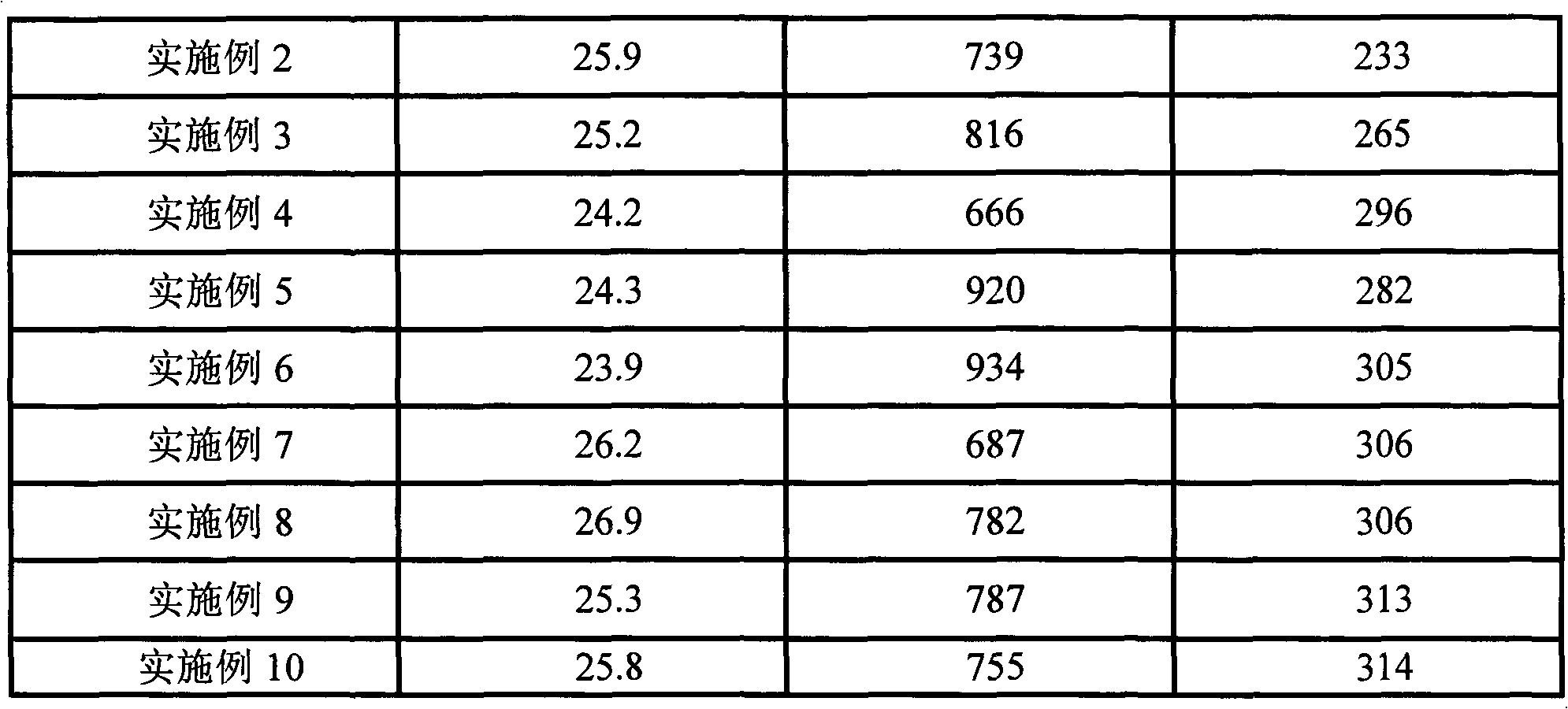

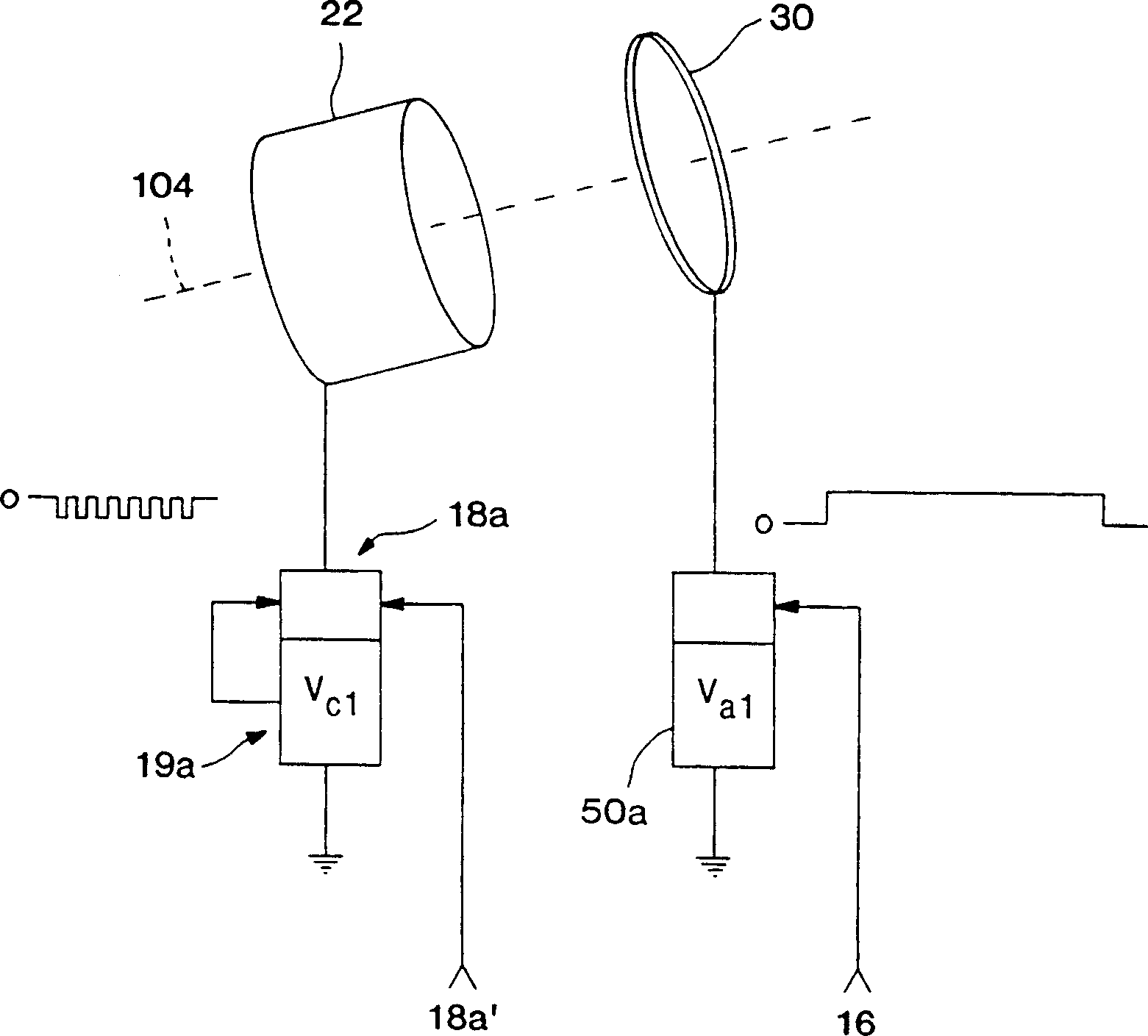

Plasma processing system and method

InactiveCN1397151AGood effectElectric discharge tubesSemiconductor/solid-state device manufacturingChemical physicsElectron flux

A substrate processing system includes a processing chamber (10), an electrically floating substrate holder (12) positioned in the chamber, a gas source (54) for supplying a process gas to the chamber, at least one ion source (20) located in the chamber, and a power source (19b) for energizing the ion source by positively biasing the anode (40) and negatively biasing the cathode (22) in a train of pulses of selectably variable duty cycle and magnitude to maintain a selected time averaged current, the bias in each instance being relative to the chamber. The ion source (20) ionizes the process gas producing ions for processing a substrate disposed on the floating substrate holder (12) in the chamber. The floating substrate is biased in accord with the net charge thereon as controlled by the energetic electron flux. One embodiment includes two such ion sources (22, 42). In this case, the power source energizes the first and second anodes (30, 40) and the cathodes (22, 42) in a time multiplexed manner, such that only one of the first or second ion sources is energized at any time and interactions between ion sources are eliminated.

Owner:INTEVAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com