Environment-friendly inflaming retarding smoke-inhibiting shaping phase-changing energy storage material and preparing method thereof

A phase-change energy storage material and shape-fixed phase-change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that the scheme of environmentally friendly flame-retardant shape-set phase change energy storage materials has not been disclosed in relevant literature, etc. Achieve the effects of improving low packaging efficiency, high impact strength, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

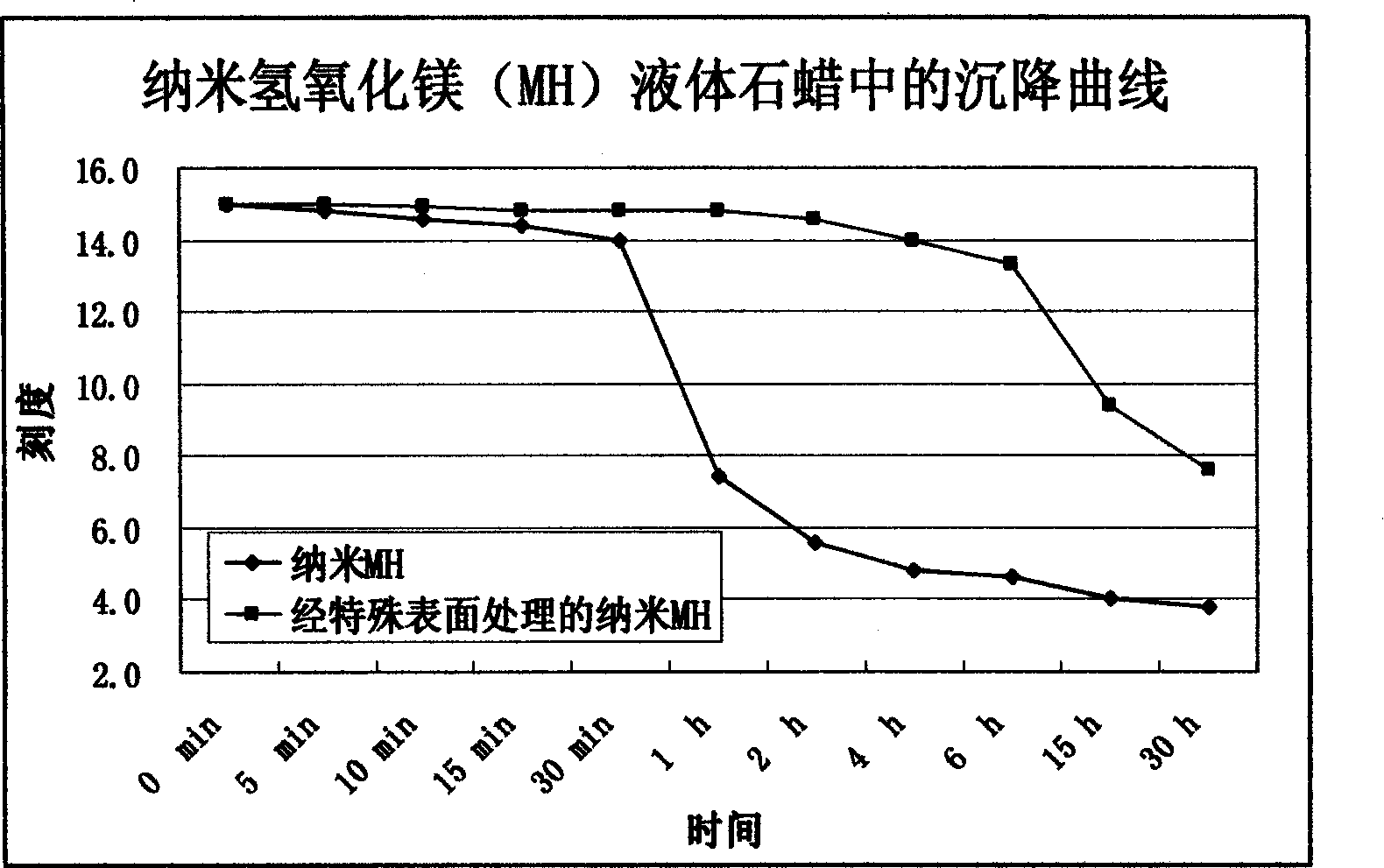

Method used

Image

Examples

Embodiment 1

[0030] Heat the double-roller closed rubber mixing machine (referred to as internal mixer) to 90°C, put 100 parts of EPDM elastomer, 100 parts of modified nano-magnesium hydroxide and 10 parts of red phosphorus (synergistic flame retardant) into the internal mixing Mixing in an internal mixer with a rotation speed of 40rpm and kneading for 15min to form a premixed material. Take 50 parts of 58# semi-refined paraffin wax with a latent heat of phase change of 164.5J / g, mix it into the premix in the internal mixer, adjust the mixing temperature to 120°C, adjust the speed to 60-80rpm, and mix for 15 minutes; The above parts are parts by mass.

[0031] Take out the above mixture, fill it into a mold of 150×150×10mm, heat the flat vulcanizer to 130°C, press it with a pressure of 6MPa, and take it out from the mold after natural cooling to obtain a plate-shaped flame-retardant qualitative phase change material , and then cross-linked by high-energy electron beam irradiation to compl...

Embodiment 2

[0036] Heat the double-roller closed rubber mixing machine (referred to as internal mixer) to 110°C, put 100 parts of EPDM elastomer, 100 parts of modified nano-magnesium hydroxide and 5 parts of red phosphorus (synergistic flame retardant) into the internal mixing Machine blending, the speed is 30rpm, and kneading for 10min to form a premix. Take 100 parts of 58# semi-refined paraffin wax with a latent heat of phase change of 164.5J / g, mix it into the premix in the internal mixer, adjust the mixing temperature to 100°C, adjust the speed to 80-100rpm, and mix for 30 minutes; The above parts are parts by mass.

[0037] Take out the above mixture, fill it into a mold of 150×150×10mm, heat the flat vulcanizer to 110°C, press it with a pressure of 5MPa, and take it out from the mold after natural cooling to obtain a plate-shaped flame-retardant qualitative phase change material , and then cross-linked by high-energy electron beam irradiation to complete the final setting and rein...

Embodiment 3

[0040] Heat the double-roller closed rubber mixing machine (referred to as internal mixer) to 120°C, put 60 parts of EPDM elastomer, 100 parts of modified nano-magnesium hydroxide and 10 parts of red phosphorus (synergistic flame retardant) into the internal mixing Machine blending, rotating speed is 20rpm, mixing 30min to form a premix. Take 100 parts of 58# semi-refined paraffin wax with a latent heat of phase change of 164.5J / g, mix it into the premix in the internal mixer, adjust the mixing temperature to 80°C, adjust the speed to 80-100rpm, and mix for 40 minutes; The above parts are parts by mass.

[0041] Take out the above mixture, put it into a mold of 150×150×10mm, heat the flat vulcanizer to 90°C, press it with a pressure of 3MPa, and take it out of the mold after natural cooling to obtain a plate-shaped flame-retardant qualitative phase change material , and then irradiated by high-energy electron beams to complete the final setting and reinforcement. The phase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com