Preparation device and method for multi-masterbatch, polyergic source and high throughput metal materials

A technology for metal materials and preparation devices, which is applied in the field of preparation devices for high-throughput metal materials with multiple master batches and multiple energy sources, can solve problems such as lack of cooperation and mutual data sharing, and achieve the effects of preventing agglomeration and widening the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

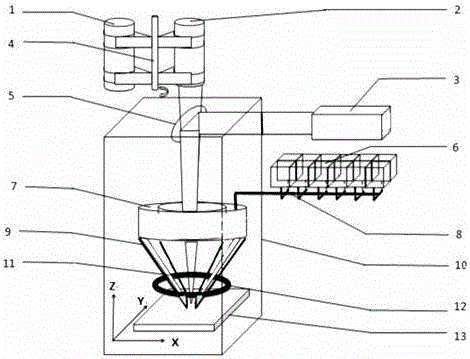

[0036] Such as figure 1 As shown, the preparation device of the multi-masterbatch multi-energy source high-throughput metal material of the present invention includes a high-energy electron beam generator 1, an arc generator 2, a laser 3, a converter 4 between the arc generator and the high-energy electron beam generator, and a reflector Laser prism 5, matrix masterbatch 6, mixing box 7, integrated structure of conduit and quality control valve 8, powder feeding pipe 9, atmosphere pressure temperature controllable processing chamber 10, induction heating coil 12, self-heating three-dimensional motion sample processing The platform 13, the high-energy electron beam generator 1, the arc generator 2, the laser 3, the converter 4 between the arc generator and the high-energy electron beam ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com