PBO fiber epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, which is applied in the field of PBO fiber composite materials, can solve the problems of the interface force between the reinforced fiber and the resin matrix, and the effect is not ideal, so as to improve the shear strength, improve the interface performance, and smoothly transfer the stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] First, immerse the PBO fiber in a solution containing 2% methanesulfonic acid, and treat it for 305 minutes under the action of 50W ultrasonic waves, take out the fiber, wash it with distilled water, dry it, and set it aside.

[0044] With 40 parts by mass of commercial epoxy resin E51, 5 parts by mass of epoxy resin A, 0.5 parts by mass of epoxy resin curing accelerator, 5 parts by mass of bisphenol A type benzoxazine resin Ba, 2.5 parts by mass of benzoxazine resin B Mix evenly, and pre-polymerize at 120°C for 2 hours, then add 100 parts of acetone to make a rubber compound.

[0045] Immerse 100 parts by mass of PBO fiber into the rubber compound obtained in the above steps, wind and dry to obtain a prepreg, spread the prepreg in a mold, first preheat at 100°C for 1h, and then press 130°C / 1h +140°C / 2h+150°C / 2h+170°C / 1h+180°C / 0.5h stepwise temperature increase and pressure curing, the pressure is maintained at 12-15MPa, then naturally cooled to room temperature, demoul...

Embodiment 2

[0051] In this example, only the composition of epoxy resin A and benzoxazine resin B in the rubber material is different from Example 1, and the rest are the same as Example 1.

[0052] In the present embodiment, epoxy resin A still is 5 mass parts, but its composition is the epoxy mixture of following three kinds of structures, wherein:

[0053]

[0054] 1 part by mass;

[0055]

[0056] 3 parts by mass;

[0057]

[0058] 1 part by mass;

[0059] In this embodiment, the content of benzoxazine resin B is still 2.5 parts by mass, but its composition is a mixture of benzoxazines with the following three structures:

[0060]

[0061] 1 part by mass;

[0062]

[0063] 1 part by mass;

[0064]

[0065] 0.5 parts by mass;

Embodiment 3

[0067]In this example, only the composition and content of epoxy resin A and benzoxazine resin B in the rubber compound are different from Example 1, and the rest are the same as Example 1.

[0068] In the present embodiment, epoxy resin A is 10 mass parts, and its composition is the epoxy mixture of following three structures, wherein:

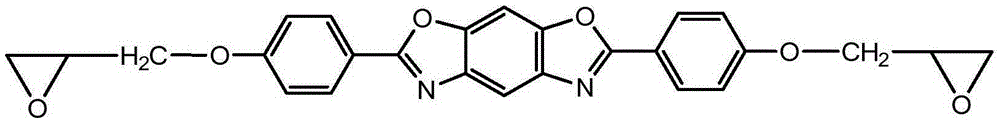

[0069]

[0070] 1 part by mass;

[0071]

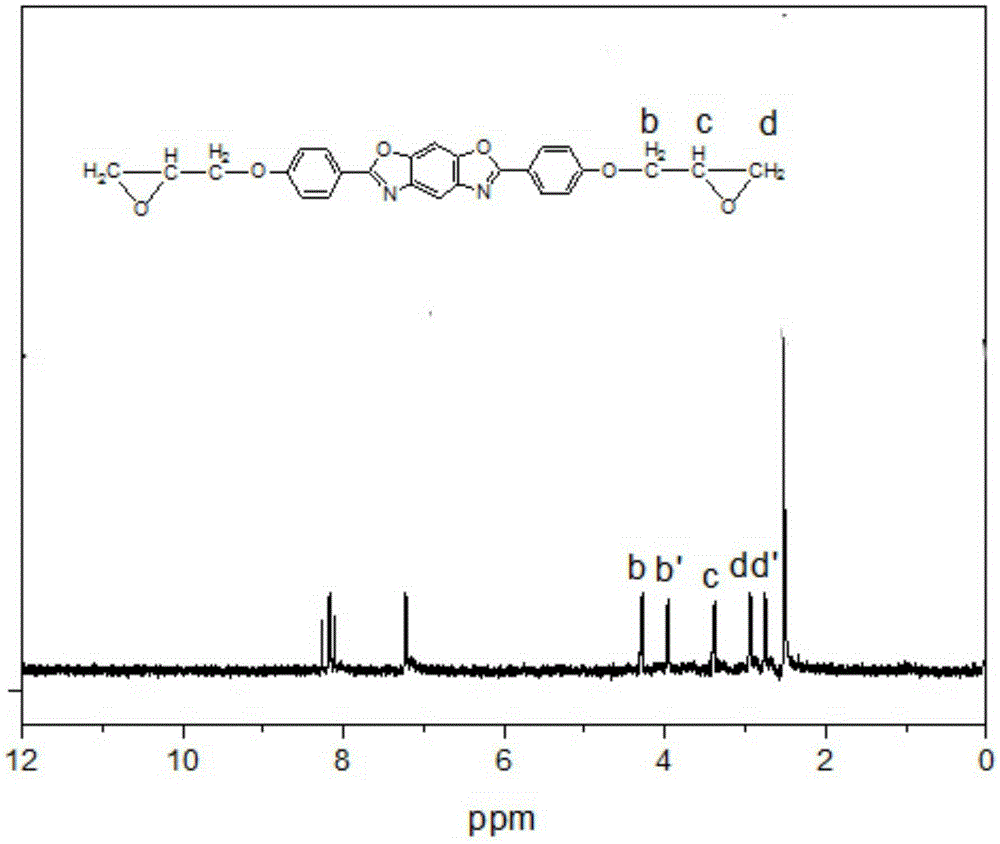

[0072] 7 parts by mass;

[0073]

[0074] 2 parts by mass;

[0075] In this embodiment, the content of benzoxazine resin B is 5 parts by mass, and its composition is a mixture of benzoxazines with the following three structures:

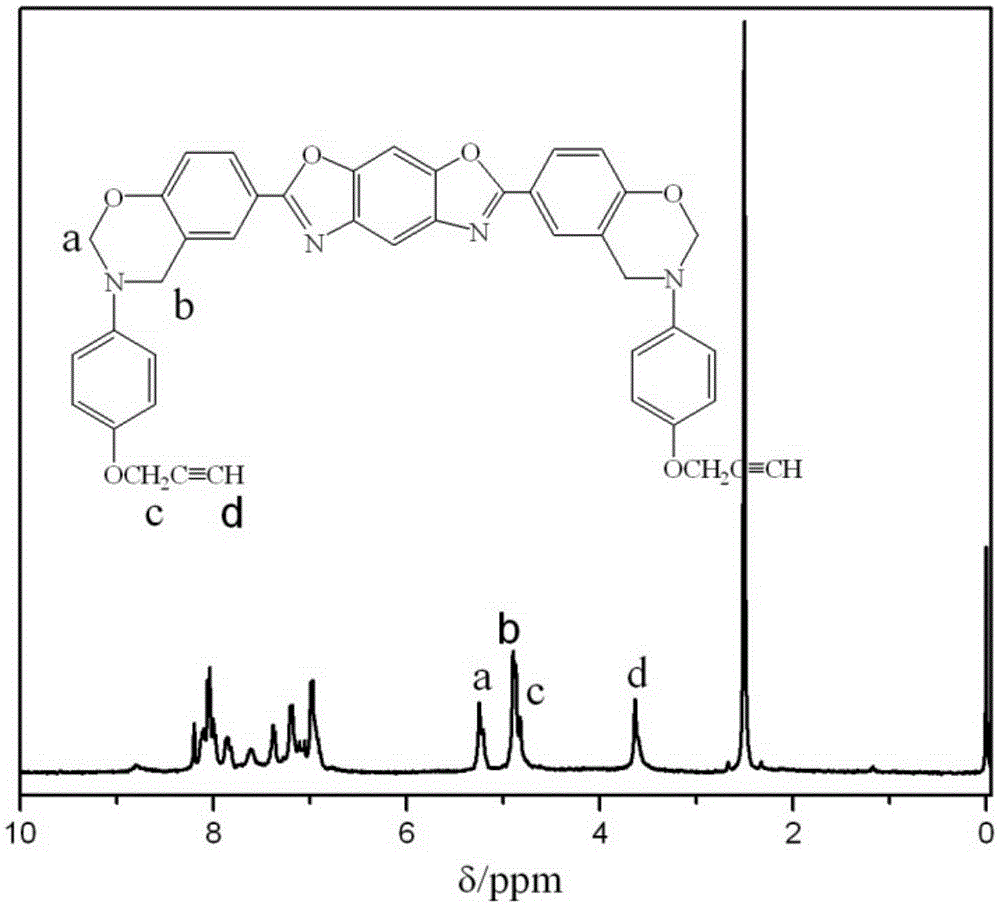

[0076]

[0077] 1 part by mass;

[0078]

[0079] 3 parts by mass;

[0080]

[0081] 1 part by mass;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com