Method for manufacturing large-scale flange forged piece by utilizing combined tyre die

A large-scale flange, combined technology, used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Problems such as difficulty in handling tire molds, to achieve the effect of reducing the production cycle, speeding up production, and reducing the difficulty of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

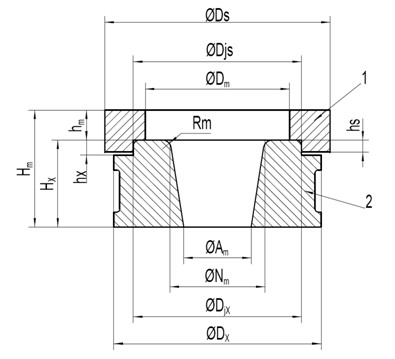

[0031] A method for manufacturing large-scale flange forgings using combined tire molds. According to the size of the mold cavity, the flange tire molds are classified in series, and the bore sizes are 401mm~500mm, 501mm~600mm, 601mm~700mm and 701mm~ The 800mm flange tire mold is divided into four series, the specific steps are as follows:

[0032] Step 1 Set up a combined tire mold stack,

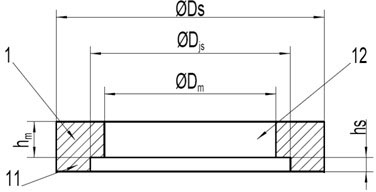

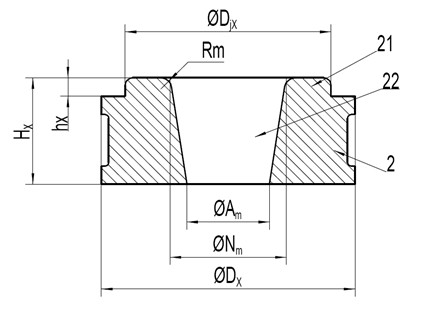

[0033]It is used to store the combined tire mold. The combined tire mold is composed of an upper mold 1 and a lower mold 2. The upper mold 1 is provided with a large end portion 12 of the tire mold cavity, and a circular ring is connected to the lower end of the upper mold 1. Cover 11, the small end portion 22 of the tire mold cavity is provided in the lower mold 2, the upper end of the lower mold 2 is a flange 21, and the flange 21 on the lower mold 2 of the same series and the circular sleeve on the upper mold 1 11 matching;

[0034] The combined tire mold stack is also used to store a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com