Patents

Literature

211results about How to "Full reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for refining and separating polyoxymethylene dimethyl ether containing formaldehyde

PendingCN107118083AReduce consumptionSolving Formaldehyde Polymerization ProblemsOrganic chemistryOrganic compound preparationPipingChemistry

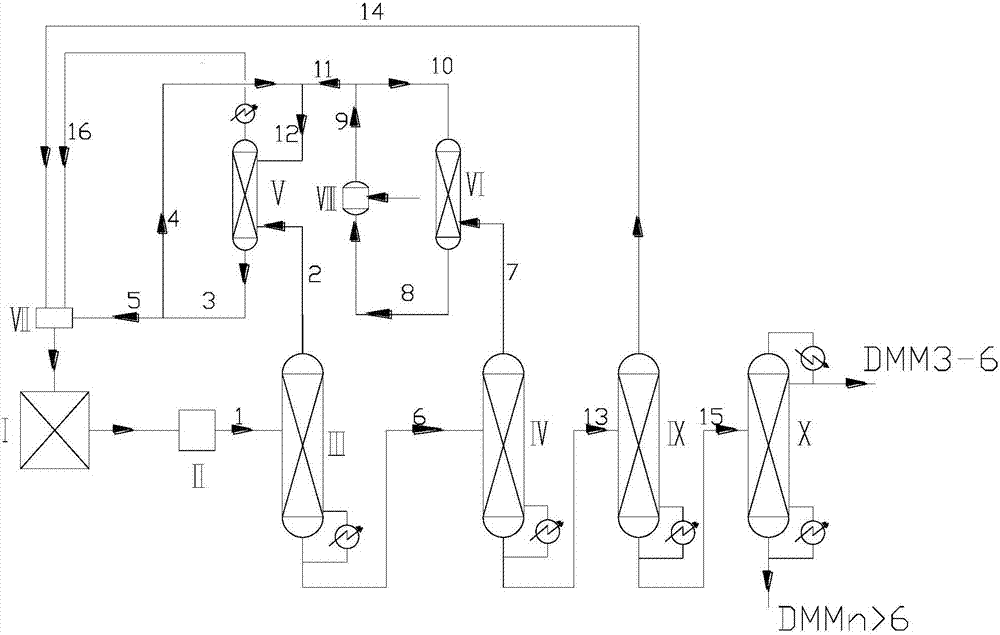

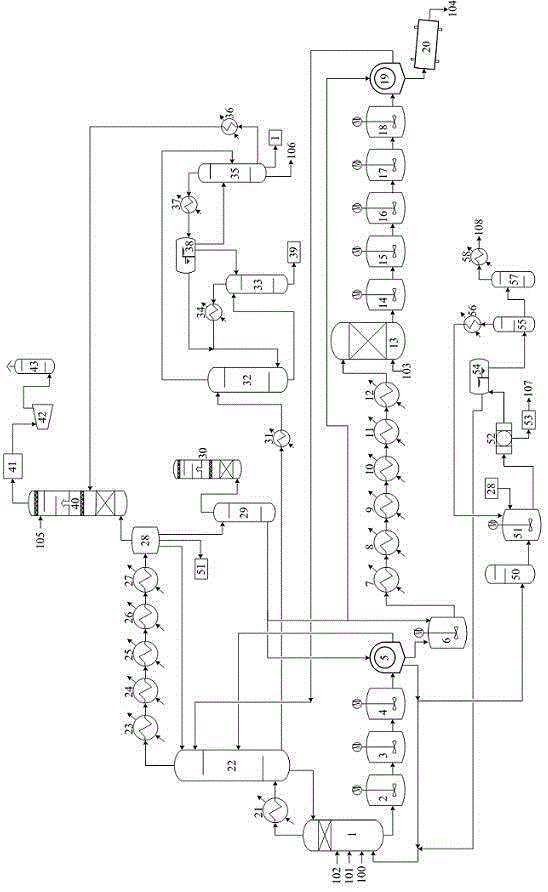

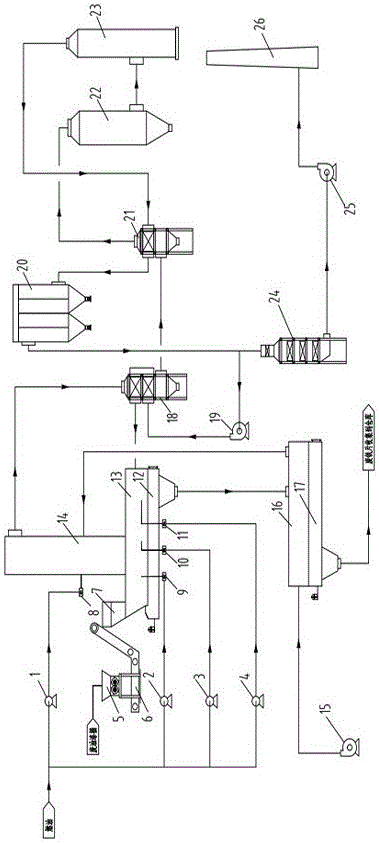

The invention relates to a device and a method for refining and separating polyoxymethylene dimethyl ether containing formaldehyde. The device mainly comprises a separation system and an elution and condensation circulating system. The separation system is mainly composed of a reaction unit (I), a deacidification device (II), a first normal-pressure fractionating column (III), a second normal-pressure fractionating column (IV), a vacuum distillation column (IX), a vacuum distillation column (X) and a dehydration device (VII); the elution and condensation circulating system comprises a first elution and absorption column (V), a second elution and absorption column (VI), an elution solution storage tank (III) and a related pipeline. According to the device and the method, provided by the invention, a separation-elution system is organically combined so that the problem that a condenser and a pipeline are blocked by formaldehyde polymerization in a process of separating a polyoxymethylene dimethyl ether product containing aldehyde is solved and the formaldehyde in the separated product can be 100 percent recycled; a continuous separation process, which takes DMM3-6 as a product, of the polyoxymethylene dimethyl ether product containing the formaldehyde is realized and energy saving and environment protection are saved.

Owner:TIANJIN UNIV

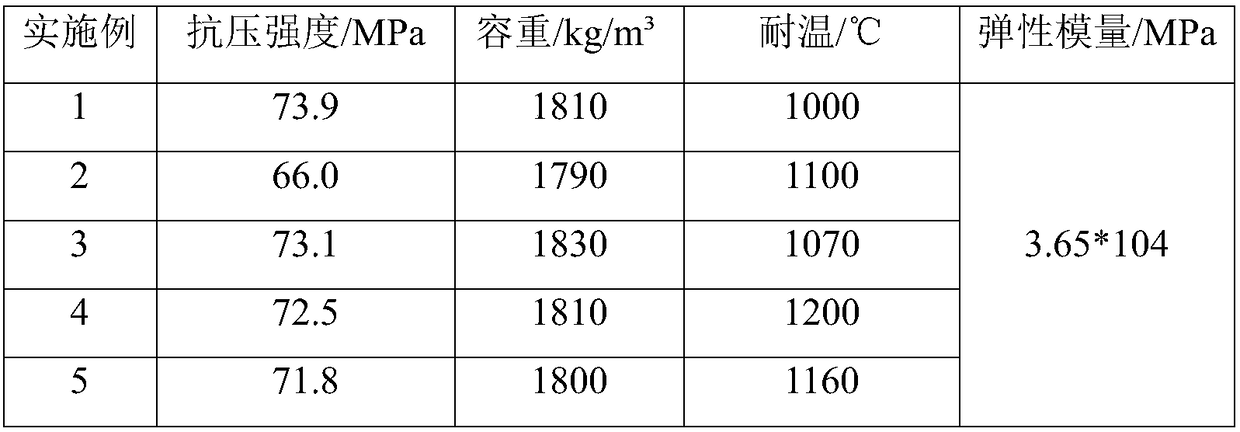

Aerated concrete block and preparation method thereof

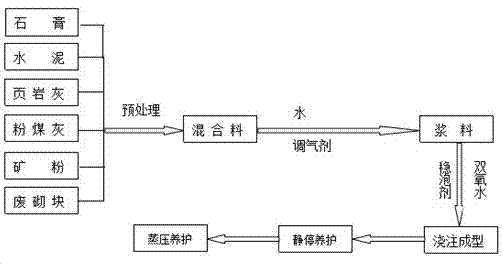

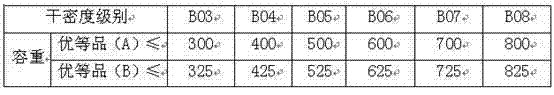

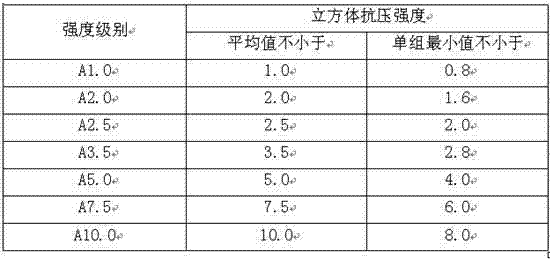

The invention belongs to the technical field of building materials and particularly relates to an aerated concrete block and a preparation method thereof. The technical scheme is as follows: the aerated concrete block comprises the following components in parts by weight: 20-50 parts of cement, 20-55 parts of shale ash, 10-40 parts of mineral powder, 0.08-0.12 part of foam stabilizer, 0.5-3 parts of natural gypsum and 3-7 parts of hydrogen peroxide, wherein the ratio of water to material is 0.58-0.65. The heat self-preservation aerated concrete block prepared by the invention has the low volume weight of 200-500kg / m<3>, the heat conductivity coefficient of 0.06-0.12W / m.k and the compensative strength of 0.8-3MPa, and various indexes such as fire resistance, freezing resistance and the like of the aerated concrete block can be up to the national traditional autoclaved aerated concrete standard.

Owner:UNIV OF JINAN

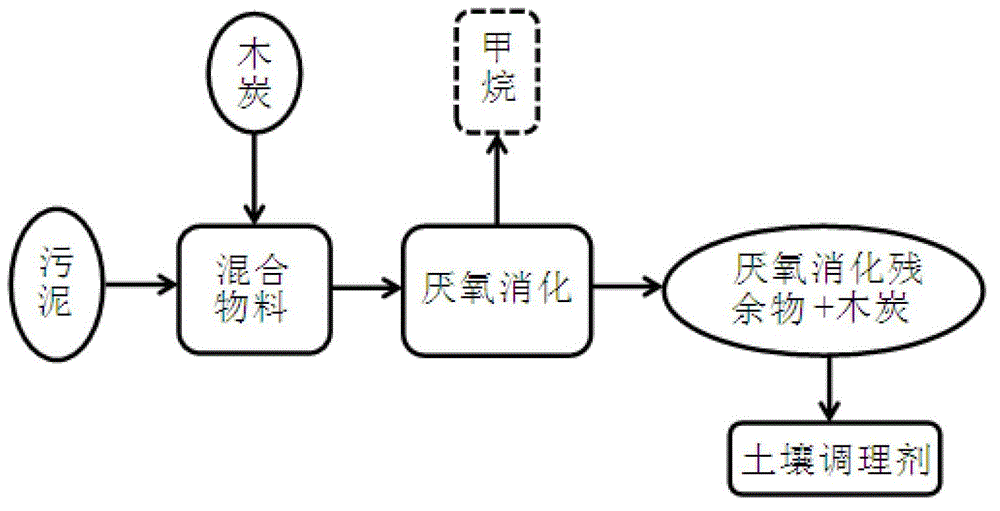

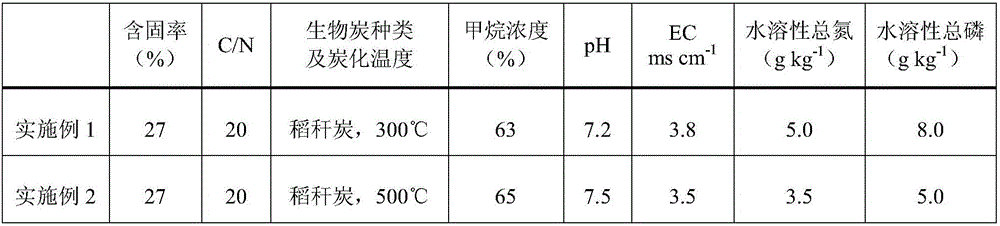

Method using charcoal for promoting anaerobic digestion of sludge to produce methane

InactiveCN104150730AIncreased anaerobic digestionImprove soil physical and chemical propertiesWaste based fuelBiological sludge treatmentAerobic digestionChemistry

The invention relates to a method using charcoal for promoting anaerobic digestion of sludge to produce methane, and the method comprises the following steps: (1) adding 0.5 to 5% by volume of the dry charcoal powder into the sludge to obtain a mixed material, adjusting the mixed material pH value to 7.5-8; and (2) putting the mixed material into a sealed anaerobic digestion device for anaerobic digestion of the sludge in the condition of an intermediate temperate of 30-40 DEG C or a high temperature of 50 to 60 DEG C by means of stirring. Compared with the prior art, the charcoal powder is used as an adding material, organic matters in the sludge are fully recycled and reused, the environment pollution is reduced, the sludge anaerobic digestion time is brought forward by 15-25%, the methane production yield is increased by 40-60%; the method is simple in operation, low in investment and treatment cost, and conductive to reducing environment pollution of the sludge, separation of organic remains produced by the anaerobic digestion of the sludge and the charcoal is not needed, and the organic remains can be directly applied to soil as a soil conditioner.

Owner:TONGJI UNIV

Method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste

InactiveCN108525843AValue cost enhancementGreat benefitWet separationMechanical material recoveryNiobiumSlag

The invention discloses a method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste. The method is characterized in that the difficult-to-treat mine solid waste is taken as a raw material, wherein the difficult-to-treat mine solid waste is a valuable component material containing a trace of (Ta, Nb)2O5, lepidolite and feldspar, and themethod comprises the step of recovering the tantalum-niobium concentrate, the feldspar powder and the lepidolite, recovering of the tantalum-niobium concentrate is achieved though the following steps,the series-connection technology of weak magnetism, medium magnetism and strong magnetism is carried out on the difficult-to-treat mine solid waste raw material for separation of iron slag, magneticminerals and non-magnetic mineral so that the influence of iron minerals on the reselection of the tantalum-niobium ore can be eliminated, a tantalum-niobium ore waste stone raw material is obtained,the tantalum-niobium ore waste stone raw material undergoes classification by adopting a stage grinding-stage separation process method, coarse grains enter a ball mill for ore grinding, a high-frequency vibration fine sieve is adopted for carrying out intensifying classification on the fine fraction, and then the tantalum-niobium concentrate and the feldspar-lepidolite mixture with tailings beingiron-tantalum-niobium contained weak-magnetic impurities are prepared. The method has the advantages that the technology is simple, the efficiency is high, the economic and technical benefits are obvious, and the recovery rate of the tantalum-niobium and other mineral resource products is high.

Owner:江西金辉再生资源股份有限公司

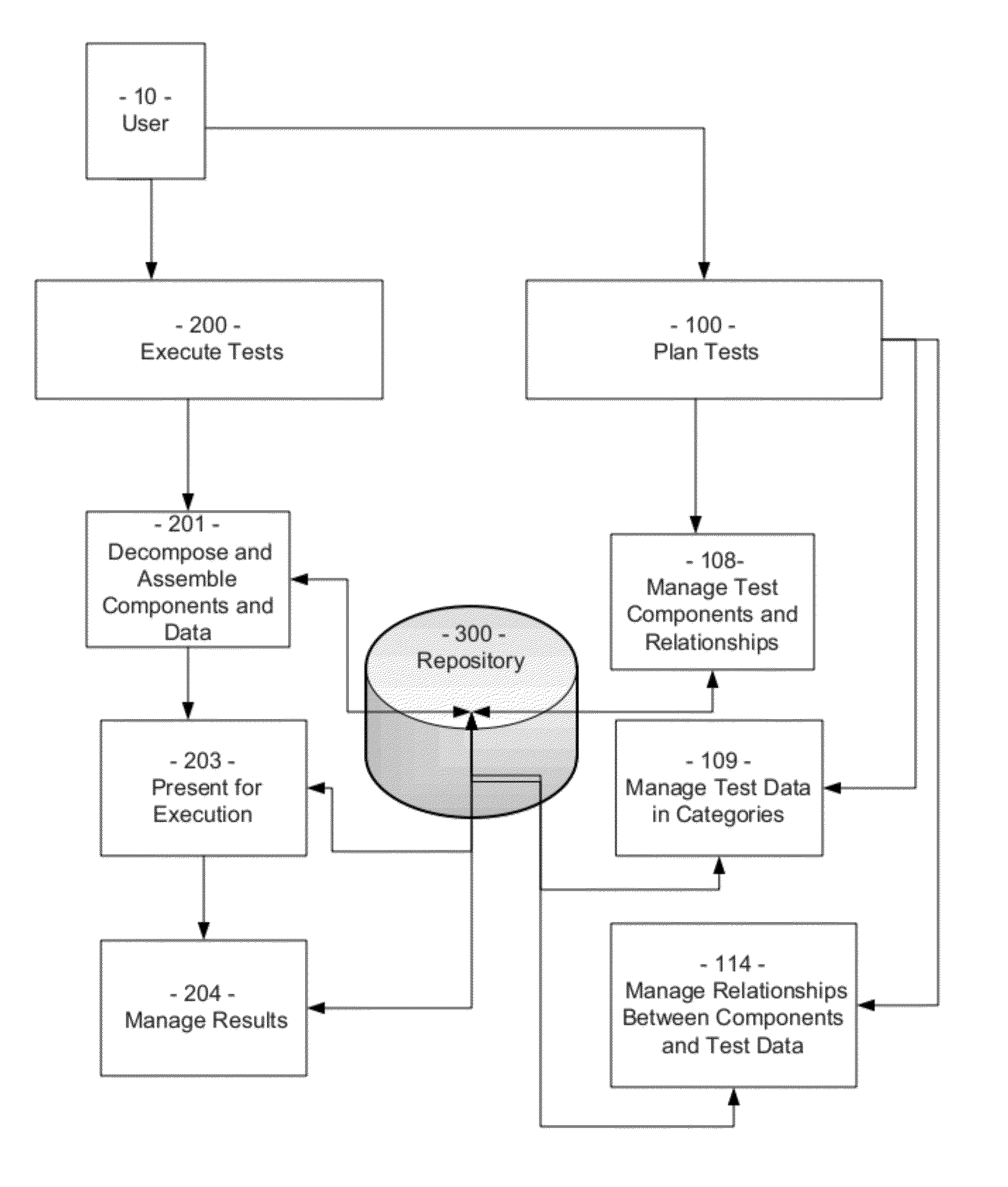

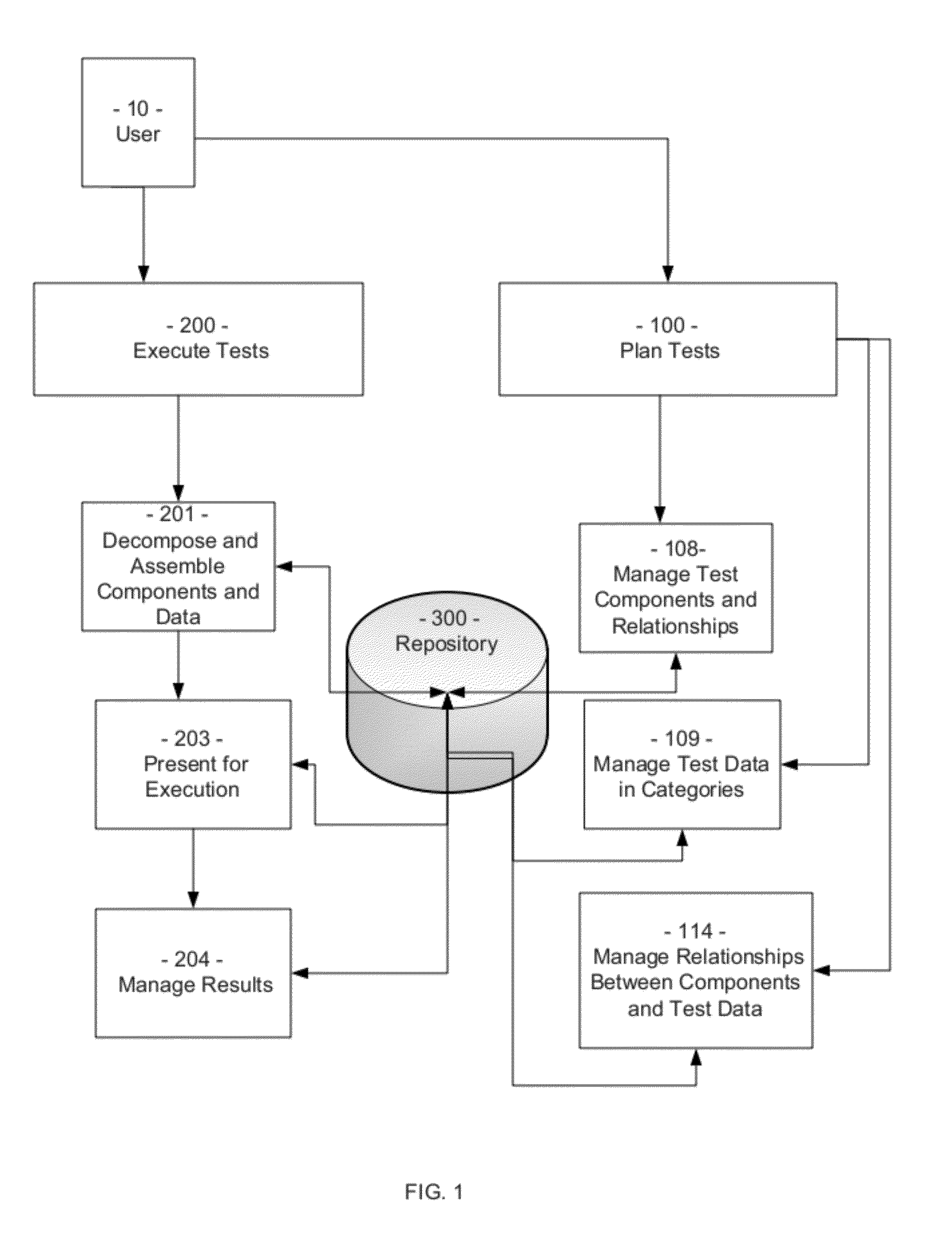

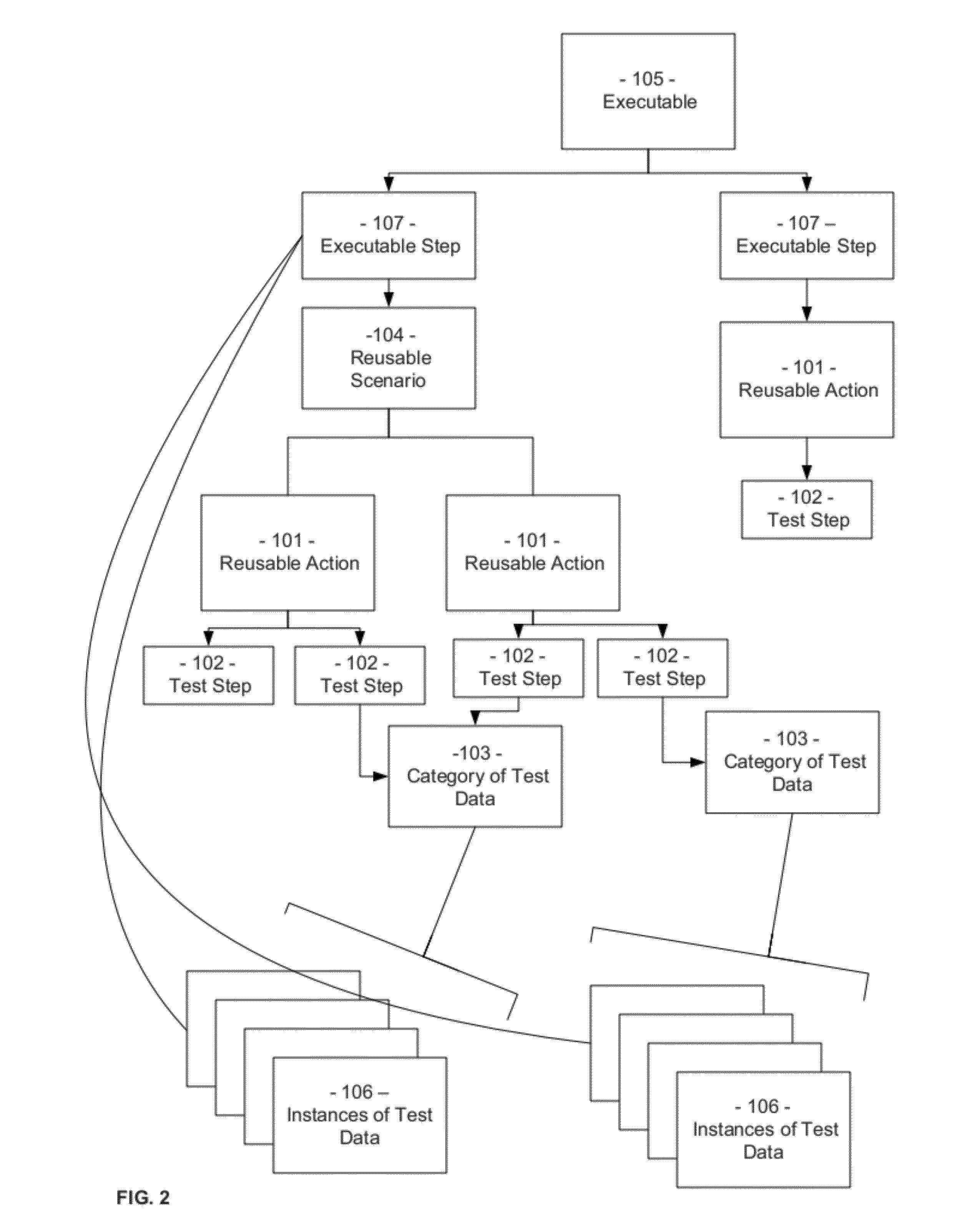

Software testing supporting high reuse of test data

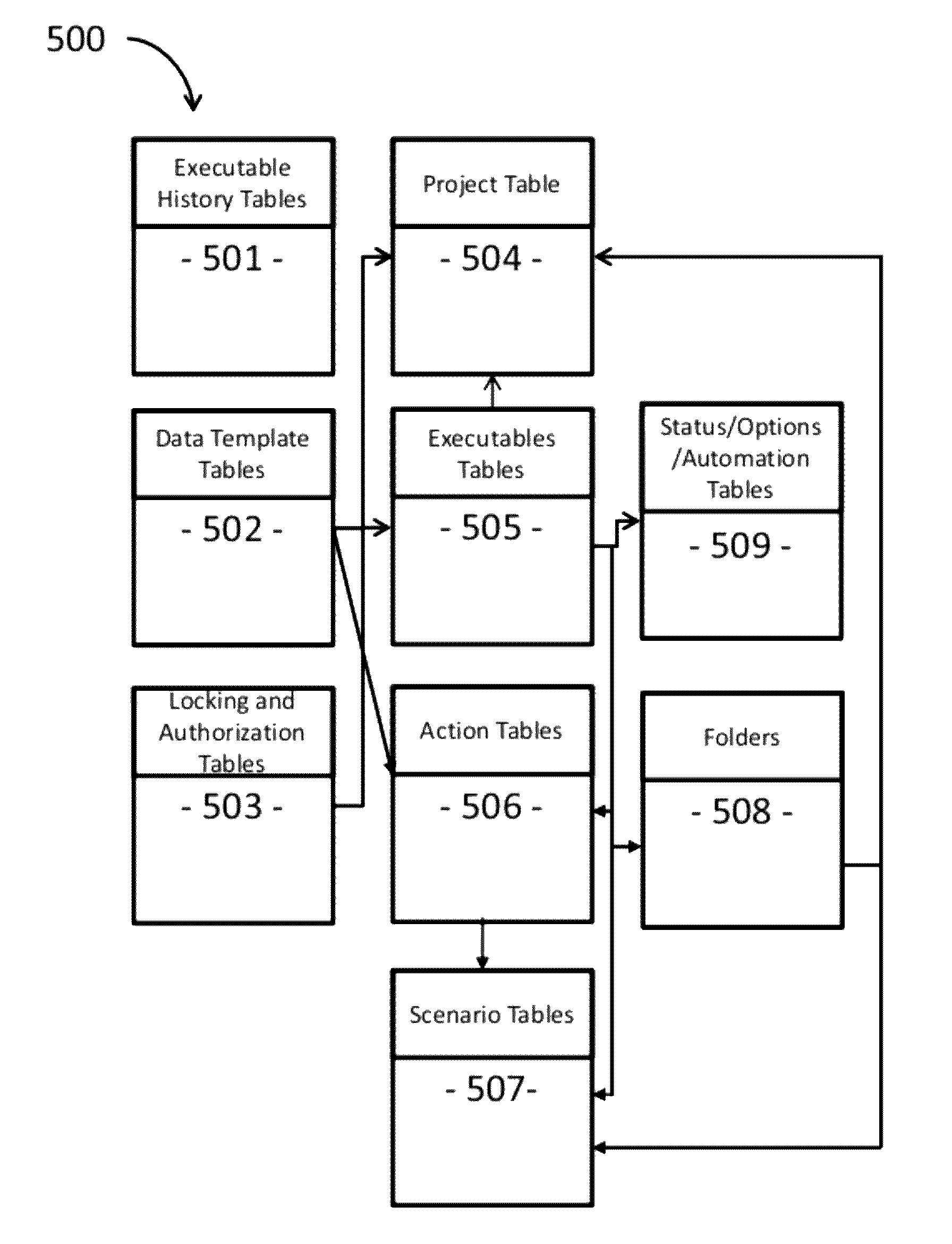

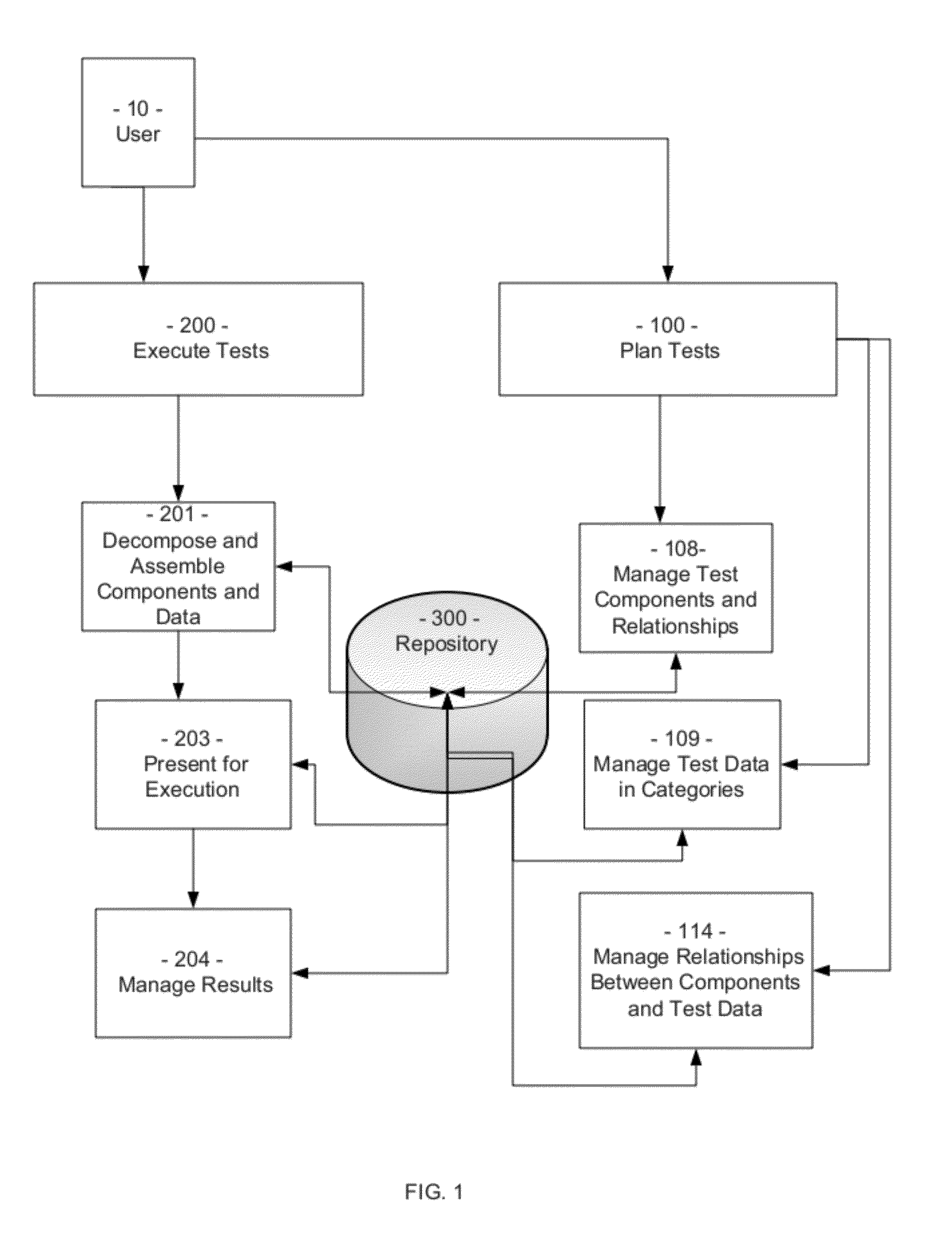

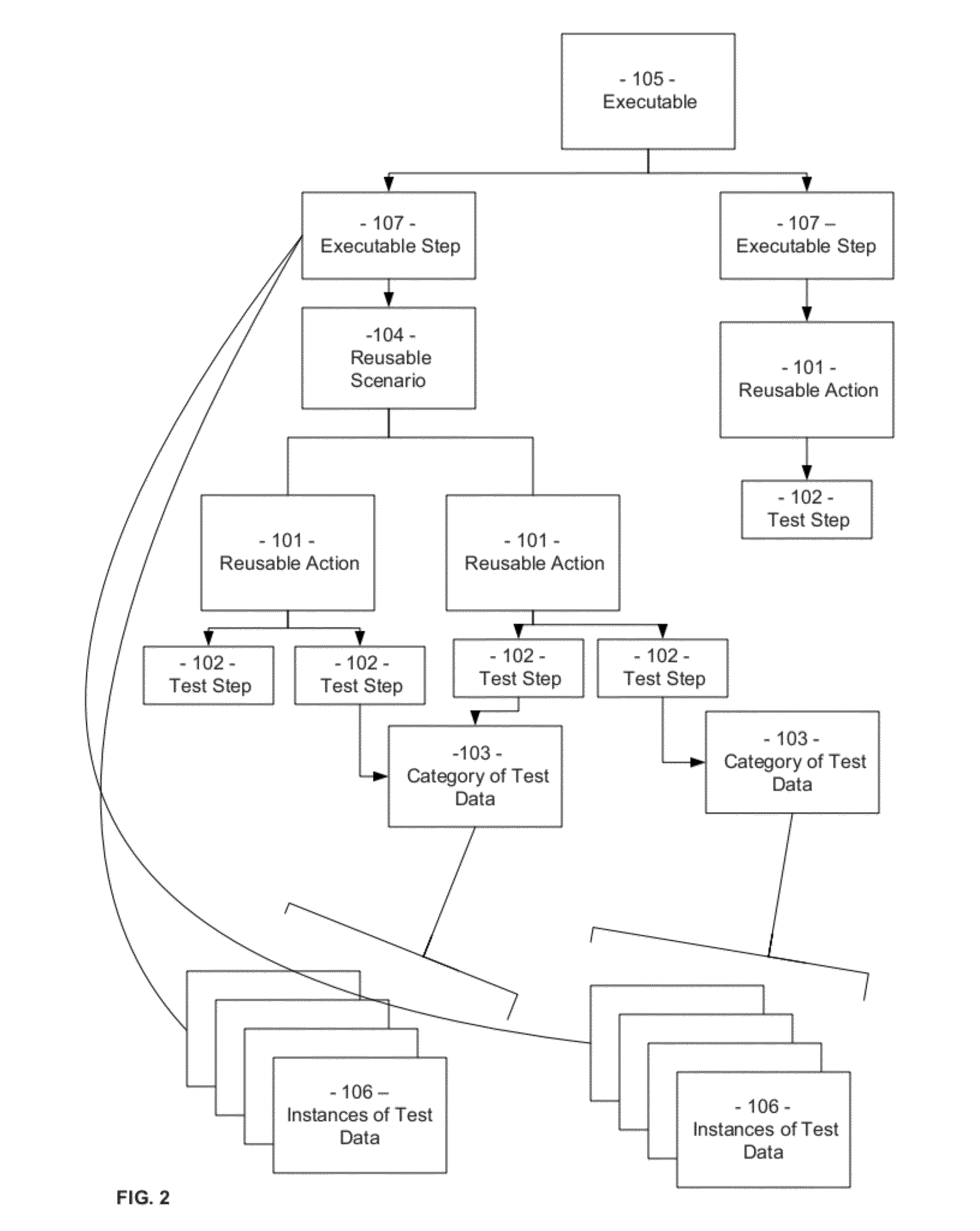

ActiveUS20120260129A1Limited reusabilityImprove distributionSoftware testing/debuggingComputer hardwareData needs

A software testing system and method provides full reuse of software tests and associated test data in a centralized shared repository, including enabling the full reuse of test assets including test actions, test scenarios, test data; and automation scripts. Reusable test components consisting of test steps and the type of test data needed by those test steps, are managed and maintained. These components are assembled into reusable components with no binding of test data until execution time, thereby treating the test data as a reusable asset. A reusable test is initially defined using only an indication of a type or category of data, and not bound to the actual data itself, until it is assembled into an executable immediately prior to automated or manual test execution.

Owner:WILSON SANDRA L +1

PTA production method with low energy consumption, low material consumption andlow refuse discharge

ActiveCN105001073AEfficient recyclingEmission reductionOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidSlurry

The invention relates to a Purified Terephthalic Acidproduction method with low energy consumption, low material consumption and low refuse discharge. The PTA production method comprises the following steps: tail gas of an oxidation reactor is outputted and passes through by-product steam of a first stage steam generator and is sent to an acetic acid regeneration tower for recycling acetic acid; a refined mother liquor is returned to the acetic acid regeneration tower, the original vacuum filtration filter is replaced by a pressure filter, and filter cakes are directly pulped and supplied to a refining section; through recovered acetic acid recovery extraction, an oxidized mother liquor is processed by extraction, and an acetic acid methyl ester removed tower top backflow liquid of the acetic acid regeneration tower is used for oxidizing, washing filter cakes of the refining section and blending slurries of the refining section. The method and system provided by the invention can effectively control acetic acid consumption in tail gas and waste water, recycle organic matters of the refined mother liquid, realize reuse of water, reduce consumption of steam and electric energy, reduce refuse discharge, and also can supply benzoic acid, mixed phthalic acids and other by-products. The invention has the advantages of short process flow, good operationality, low production cost and low apparatus investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

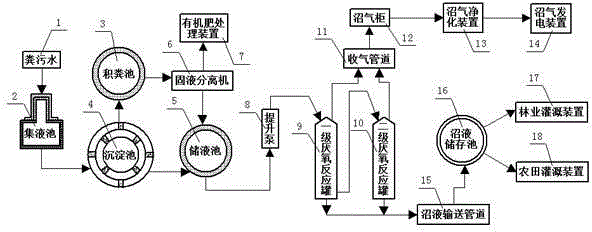

Large-scale piggery dung treatment ecological circulation system

ActiveCN104817170AAvoid emissionsIn line with the development conceptBio-organic fraction processingClimate change adaptationOxidation resistantSlurry

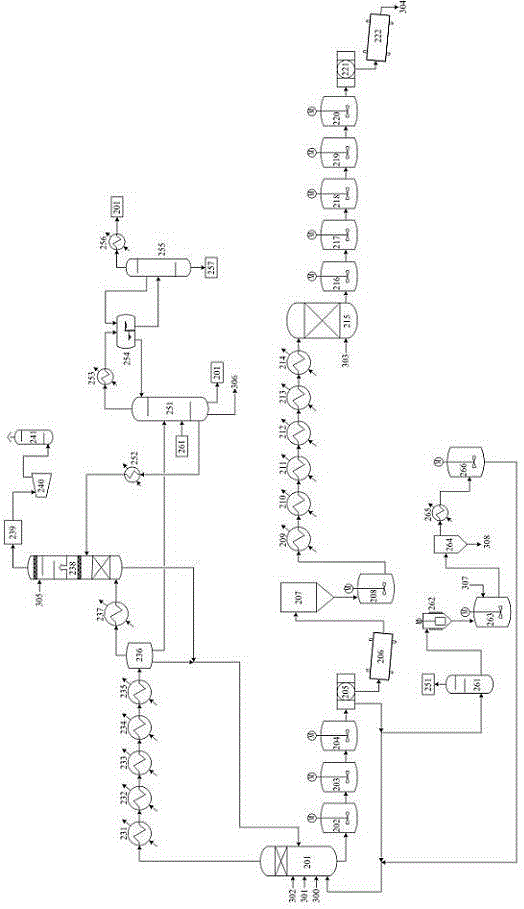

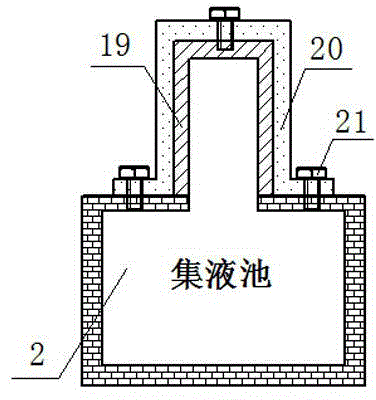

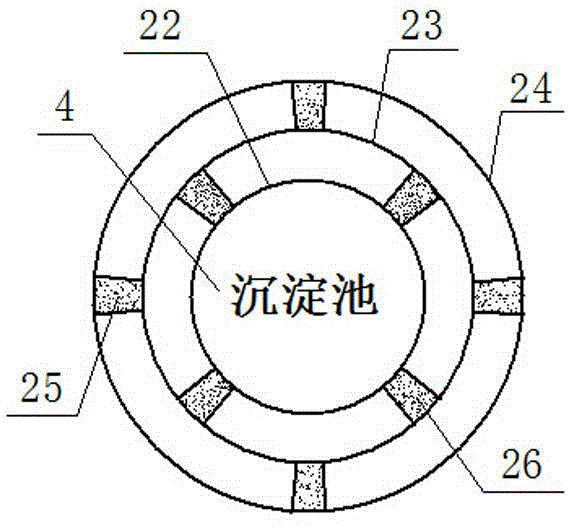

The invention discloses a large-scale piggery dung treatment ecological circulation system which comprises a dung collection unit, a solid-liquid separation unit, an anaerobic fermentation unit, a biogas utilization unit and a biogas slurry utilization unit. The dung collection unit comprises a slurry collection tank, a dung accumulation tank, a settling tank and a slurry storage tank, the solid-liquid separation unit comprises a solid-liquid separator and an organic fertilizer treatment device, the anaerobic fermentation unit is a multistage anaerobic reaction device and comprises a primary anaerobic reaction tank and a secondary anaerobic reaction tank, the biogas utilization unit comprises a biogas cabinet, a biogas purification device and a biogas power generation device, the biogas slurry utilization unit comprises a biogas slurry storage tank, a forestry irrigation device and a farmland irrigation device, and high-temperature oxidation resistant plastic soft protection layers are arranged above the dung accumulation tank and the slurry storage tank. Dung water is fermented to generate biogas and biogas slurry, organic fertilizers are generated after solid-liquid separation, the possibility of secondary pollution caused by waste gas is avoided, waste is effectively and sufficiently reused, and comprehensive utilization rate is increased.

Owner:MUYUAN FOODS CO LTD

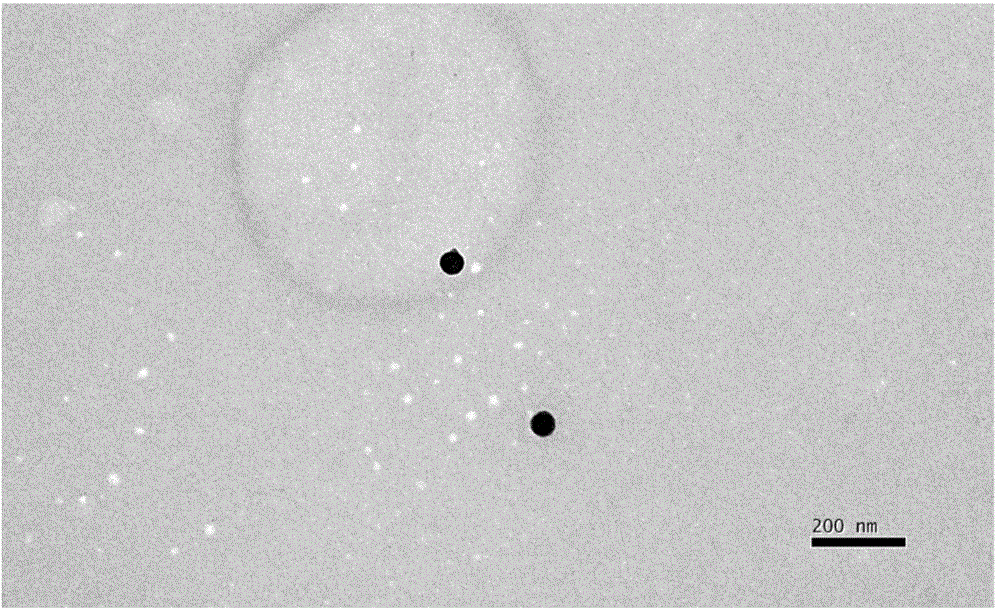

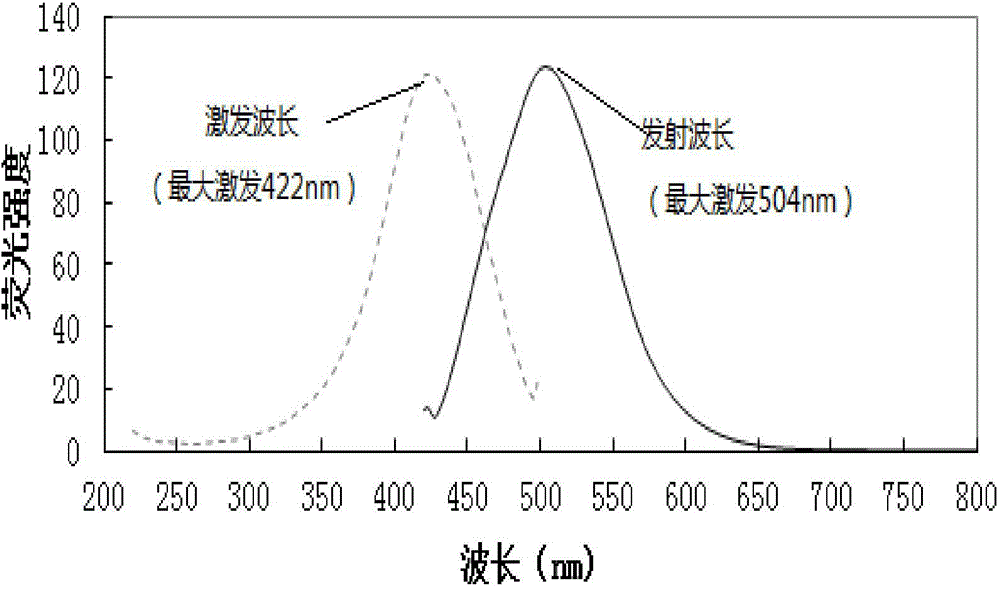

Carbon quantum dot fluorescence labeling material with orange peels used as carbon source as well as preparation method and application of carbon quantum dot fluorescence labeling material

ActiveCN104560035AFull reuseRaw materials are cheap and easy to getLuminescent compositionsHigh pressureComputational chemistry

The invention relates to a carbon quantum dot fluorescence labeling material with orange peels used as a carbon source as well as a preparation method and an application of the carbon quantum dot fluorescence labeling material. The orange peels are used as a raw material, and a simple method for one-step synthesis of a high-fluorescence-quantum-efficiency carbon quantum dot is established. The method comprises steps as follows: the orange peels are mixed with water; then a mixed liquid is mixed with concentrated sulfuric acid; the pH is adjusted by the aid of NaOH, and undissolved residues are removed in a centrifugal manner; then dichloromethane is added to a centrifuged supernate, and a non-fluorescence fat-soluble substance is removed in the centrifugal manner; finally, the centrifuged supernate passes through a film, and the fluorescence labeling material is prepared. According to the method, high-temperature and high-pressure reactions are not required to be performed by equipment such as plasma emitters, hydrothermal reaction kettles, muffle furnaces and the like during synthesis, reaction conditions are mild, operations are simple and convenient, the cost is very low, the method can be implemented in ordinary laboratories, the synthesized fluorescence labeling material lays a foundation for the further application to work such as bio-labeling, heavy metal analysis, antibody labeling, cell staining and the like.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

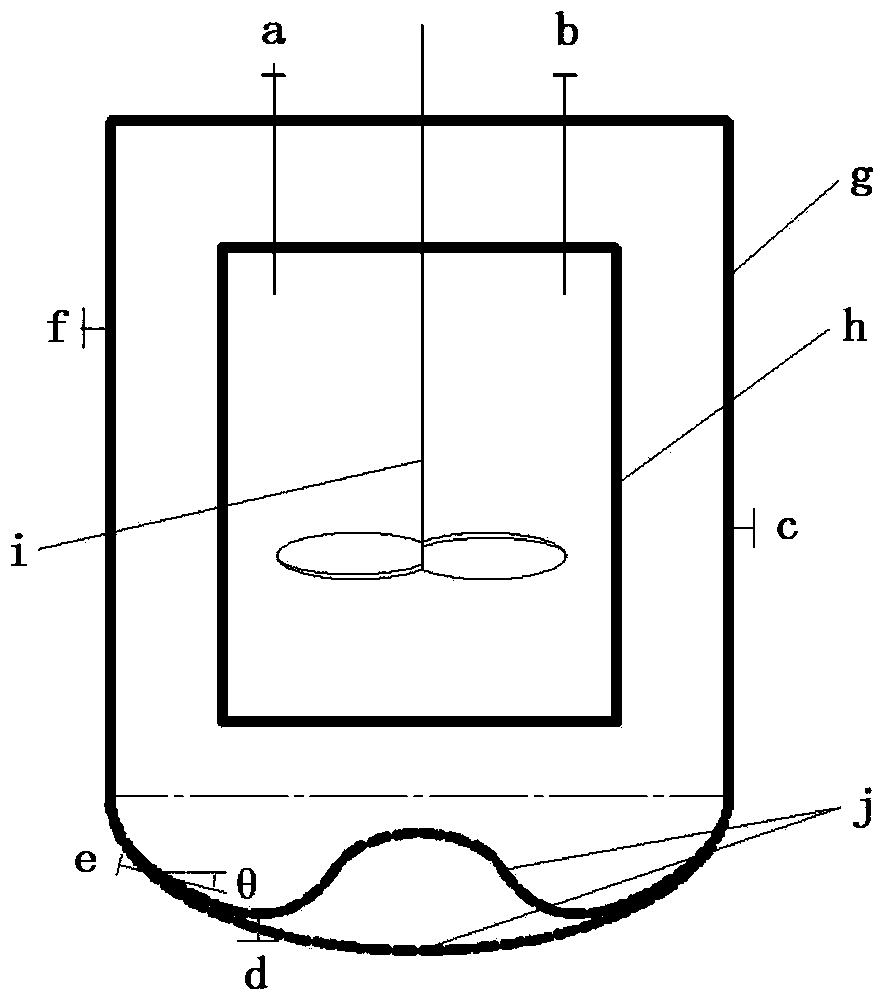

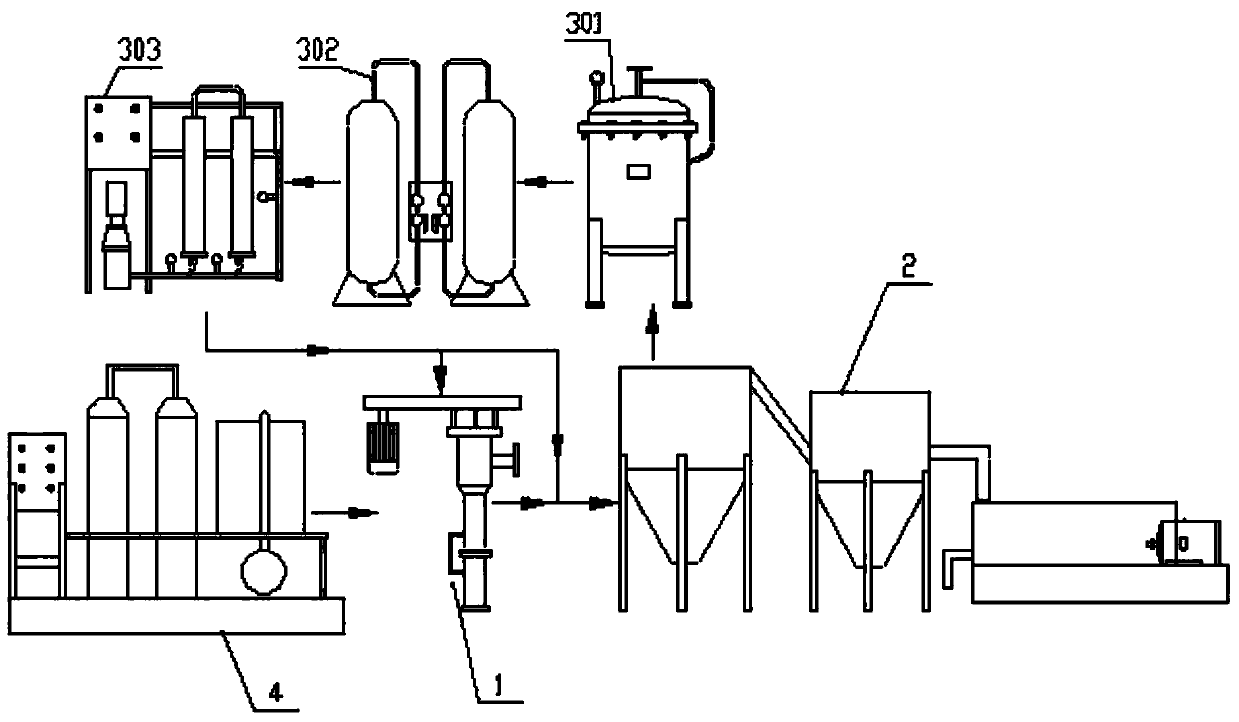

Separation and purification system of organic synthesis feed liquid and separation and purification method thereof

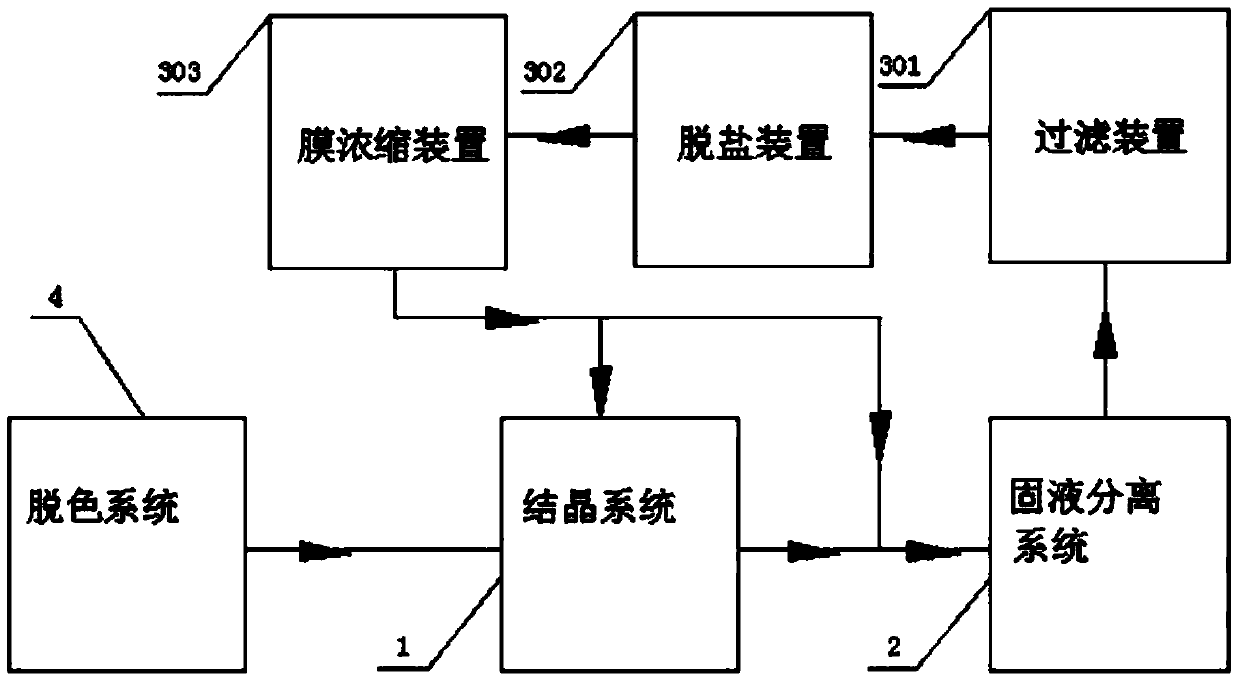

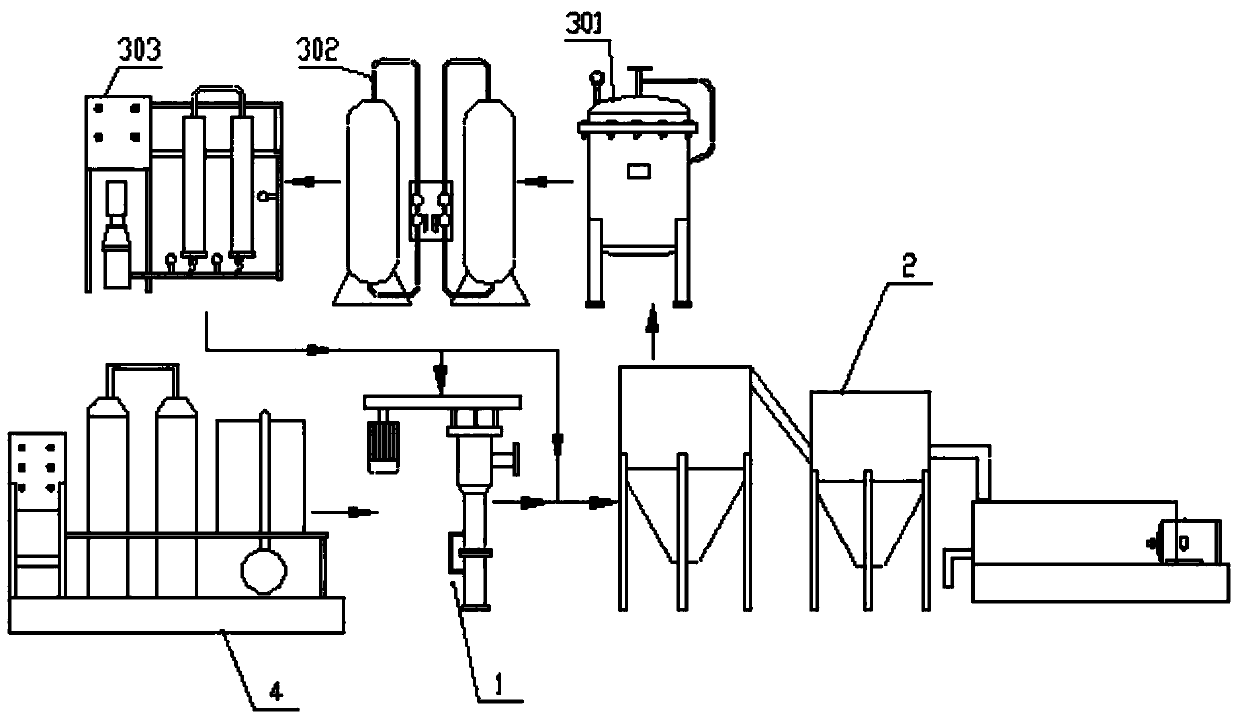

InactiveCN104174181AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentChemical industryPurification methods

The invention aims at the field of chemical industry and relates to a separation and purification system of organic synthesis feed liquid and a separation and purification method of the organic synthesis feed liquid. The separation and purification system comprises a crystallization system and a solid-liquid separation system which are sequentially arranged from front to back, wherein the crystallization system comprises a mixed suspension-mixed product-removal (MSMPR) crystallizer and a draft-tube-baffled (DTB) crystallizer which are connected with each other in series; the separation and purification system also comprises a liquid processing system used for processing waste liquid produced by the solid-liquid separation system; the liquid processing system comprises a desalting device and a membrane concentration device which are sequentially arranged from front to back. By virtue of the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof, the organic synthesis feed liquid is separated and purified by using a continuous crystallization technology, an electrodialysis technology and a membrane separation and concentration technology; the produced waste liquid is fully recycled and used, so that the separation and purification efficiency is improved, the purity and the yield of products are improved and the discharge of the waste liquid is reduced; the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof are strong in production industrialization and low in costs, and are especially suitable for producing iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

Software testing supporting high reuse of test data

ActiveUS8677320B2Limited reusabilityImprove distributionError detection/correctionSpecific program execution arrangementsData needsTest execution

A software testing system and method provides full reuse of software tests and associated test data in a centralized shared repository, including enabling the full reuse of test assets including test actions, test scenarios, test data; and automation scripts. Reusable test components consisting of test steps and the type of test data needed by those test steps, are managed and maintained. These components are assembled into reusable components with no binding of test data until execution time, thereby treating the test data as a reusable asset. A reusable test is initially defined using only an indication of a type or category of data, and not bound to the actual data itself, until it is assembled into an executable immediately prior to automated or manual test execution.

Owner:WILSON SANDRA L +1

Method for producing methane by sludge

ActiveCN101654322AIncrease productionFull recoveryWaste based fuelBiological sludge treatmentSludgeFermentation

The invention relates to an application of sludge as a source and discloses a method for producing methane by sludge, comprising the following steps: carrying out the anaerobic fermentation of the sludge under the alkali condition for 4-12 days so as to hydrolyze the sludge and acidate a hydrolyzed sludge solution; adjusting the pH value of the fermented mixture to be neutral, adding 8-15V% anaerobic granular sludge in the fermented mixture and continuously carrying out anaerobic fermentation at 30-40 DEG C for 6-14 days to generate methane. The method for producing methane by sludge not onlyobviously improves the yield of the methane produced by sludge, but also is beneficial to reducing the sludge pollution to the environment.

Owner:TONGJI UNIV

Pollution-free production process of plant fiber pulp

InactiveCN102108644AStrong wettingImprove permeabilityPulp de-wateringFibrous raw materialsFiberSlurry

The invention provides a pollution-free production process of plant fiber pulp. The method is characterized by obtaining the bleached fine pulp with concentration being 30-40% through coarse pulp preparation, defibrination treatment, desanding treatment, screening treatment, concentration and shoving treatment. The process has the following beneficial effects: the auxiliary has strong wetting and infiltrating functions, promotes the sodium hydroxide to rapidly wet the surface of the fibers and be infiltrated into the fibers with the reactive agent generated by hydrogen peroxide in the presence of the decomposing agent and ensures the chromophore in the lignin to be decomposed into low molecular colorless substances while the lignin is degraded and dissolved out; the stabilizing agent can complex and shield chromogenic metal ions and is characterized by reducing generation of the chromophoric groups, thus improving the whiteness of the pulp; under the action of the surfactant in the auxiliary, the dissolved lignin, colloid and the like can be uniformly dispersed in the water to be prevented from being adsorbed by the plant fibers again; and the pulp washing and bleaching procedures are omitted in the method, and at the same time, the waste water in the pulping process can be fully reused through simple treatment, thus not producing pulping back liquor causing serious pollution.

Owner:深圳市美中现代科技发展有限公司

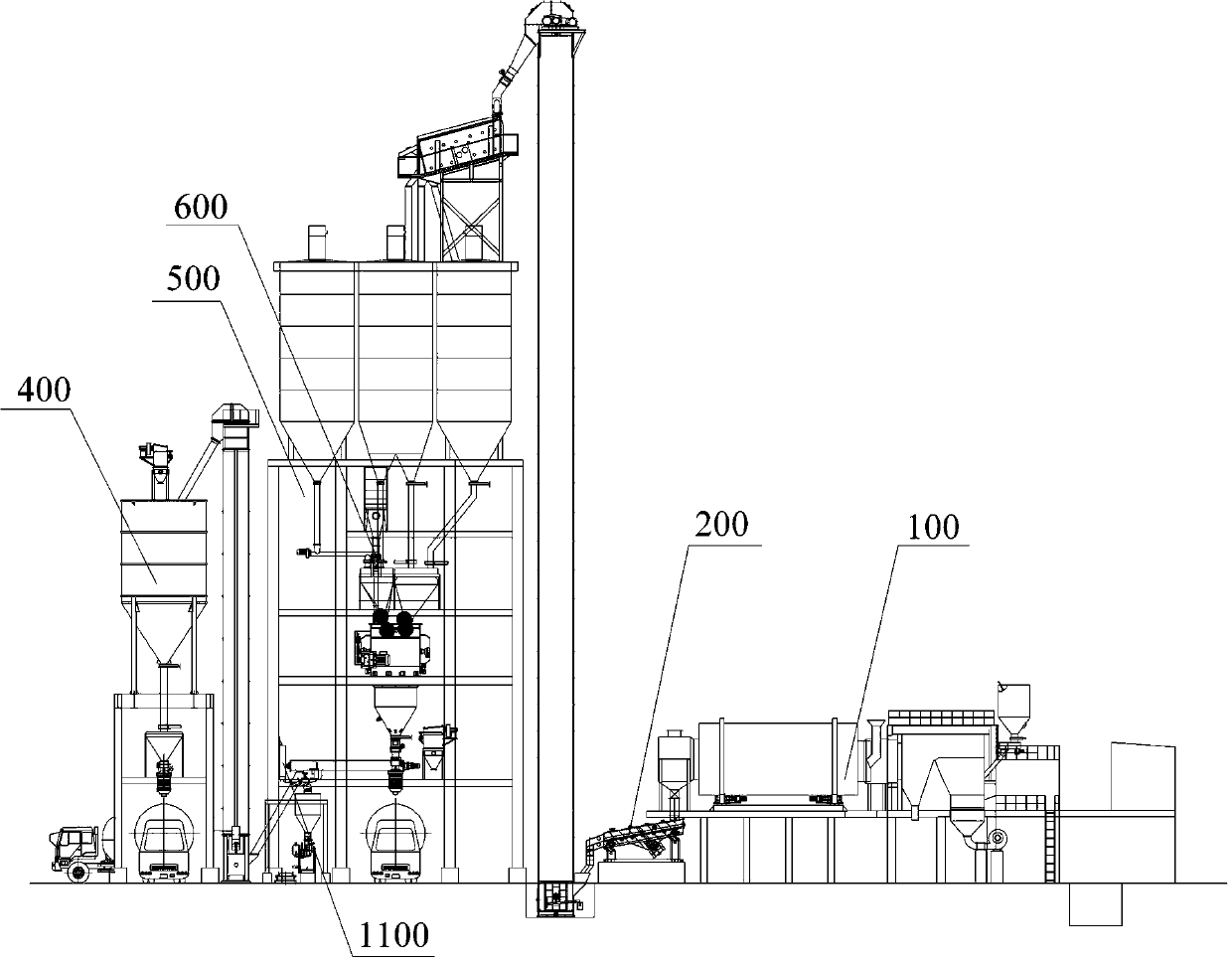

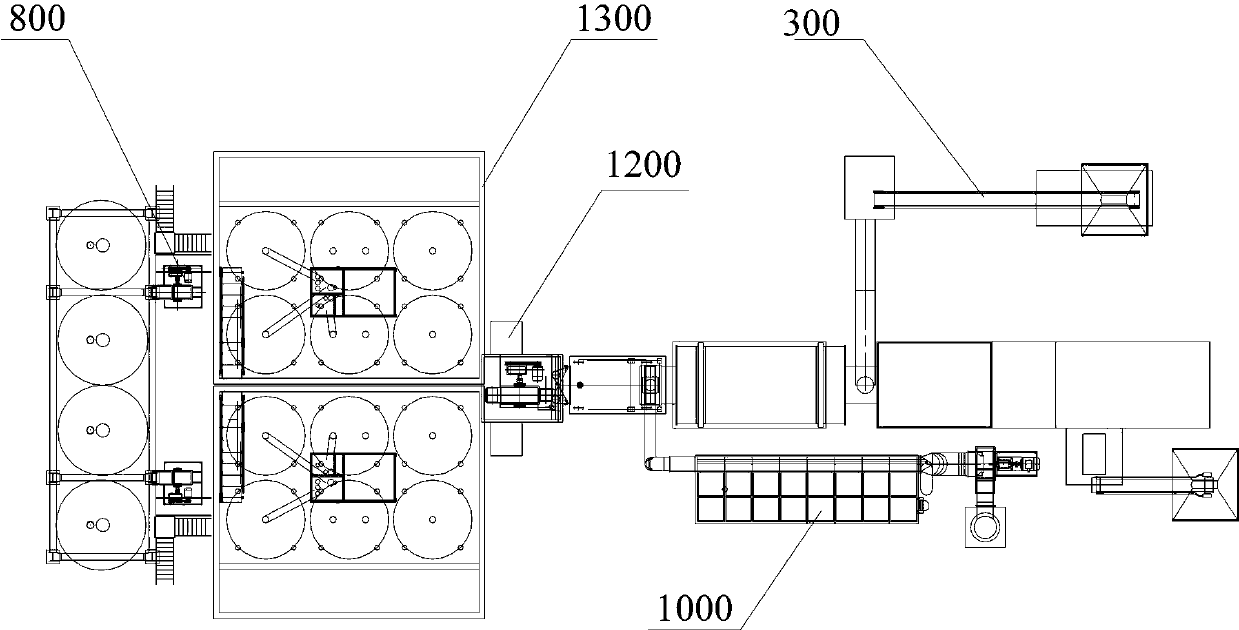

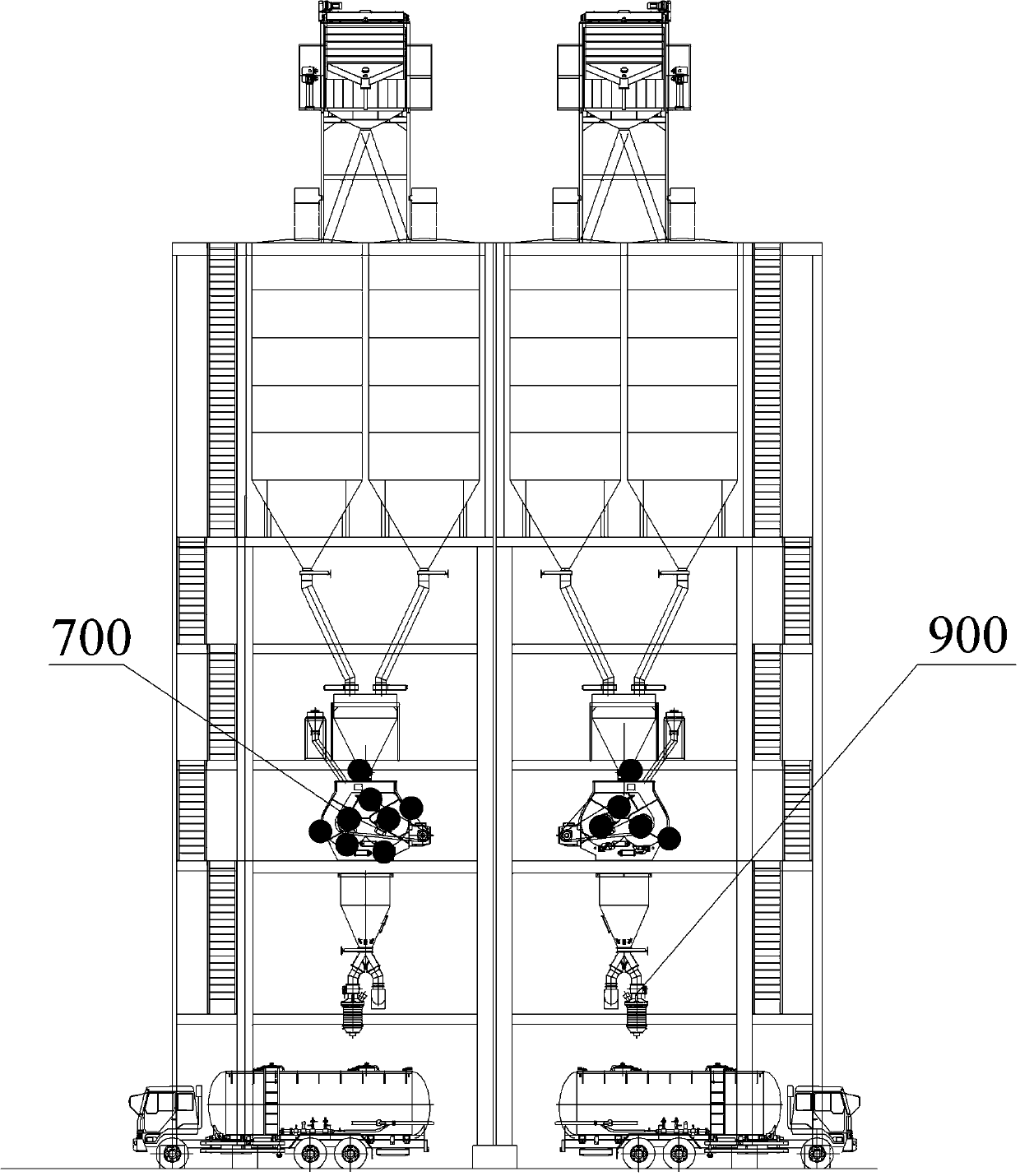

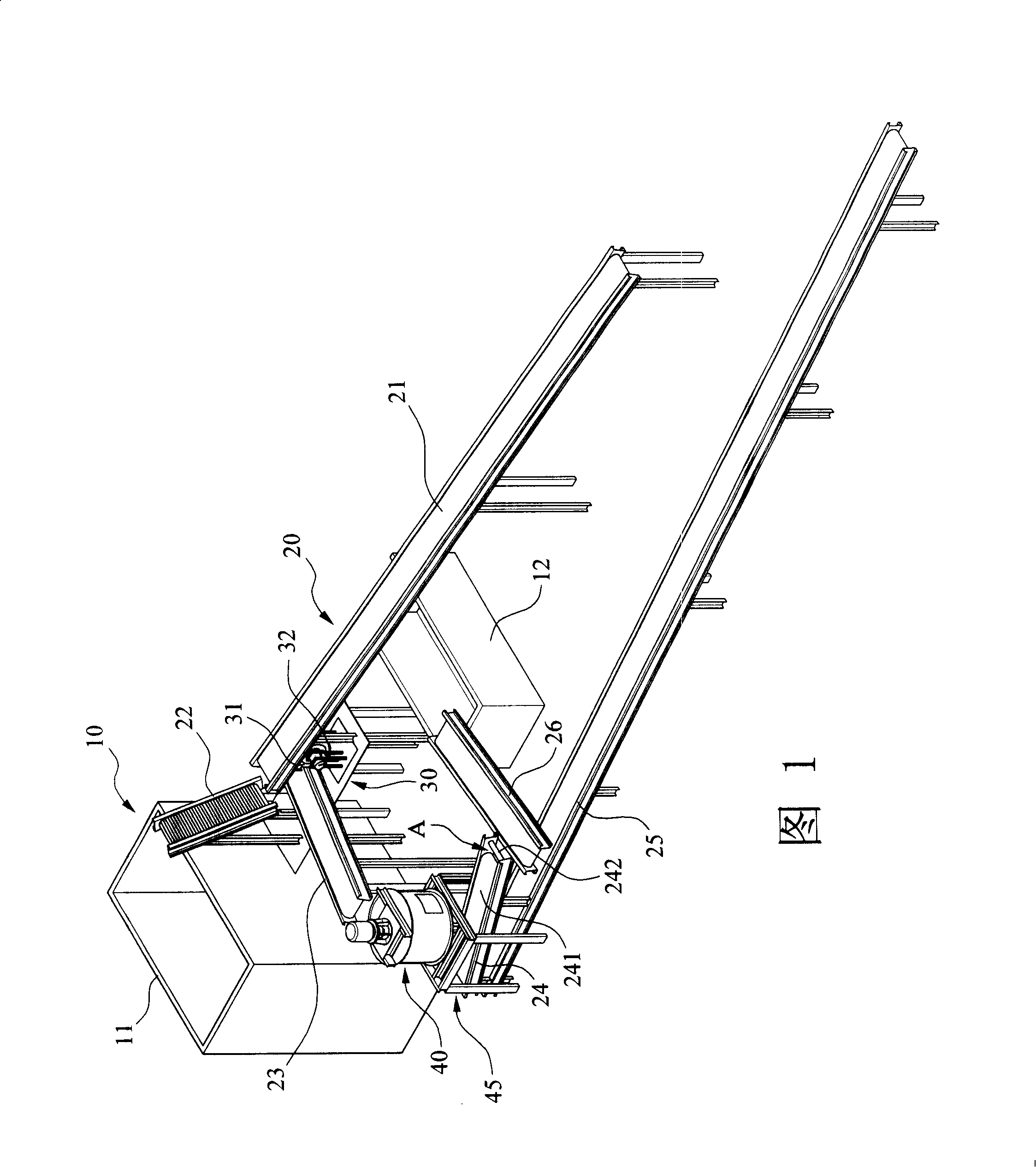

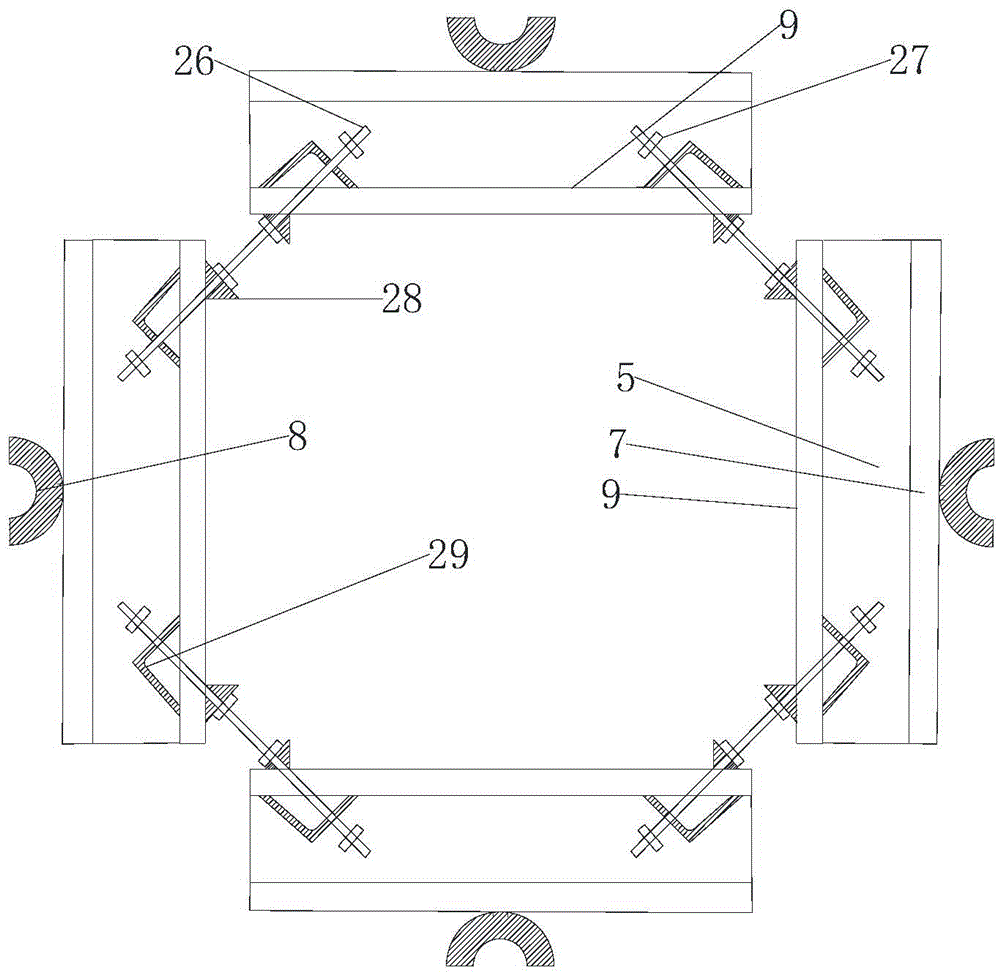

Double-floor type structure dry-mixed mortar station and construction method thereof

InactiveCN103273571AImprove combustion efficiencyRealize stepless speed regulation functionIndustrial buildingsMixing operation plantElastic vibrationSelf locking

The invention provides a double-floor type structure dry-mixed mortar station and a construction method thereof. The double-floor type structure dry-mixed mortar station comprises a drying system, a sieving system, a material supplying system, a storage system, a main body structure, a metering system, a stirring system, a packaging system, a bulking system, a dust-removing system, an electric system, a pneumatic system and an outer packaging system. The double-floor type structure dry-mixed mortar station is characterized in that a variable-frequency feeding device is additionally arranged on a coal cabin charging belt machine in the drying system; aggregates are sieved at a plurality of grades; a primary sieving segregation and sand feeding manner is adopted before bucket lifting; a secondary sieving segregation and sand feeding manner is adopted after the bucket lifting; a sieving machine is provided with an elastic vibration support; a gas tank pulse type automatic dust collector is adopted; a main body adopts a double-floor type structure; two sets of large cubic horizontal double-shaft spiral belt agitating main engines are arranged, one set is standby and the two sets can also be turned on at the same time to use; a multi-finished-product cabin with a manual gate valve and a double-bagging machine are adopted to rapidly bulk and bag to deliver products; and the pneumatic system has bidirectional self-control and self-locking functions so as to guarantee the safety and the reliability of the work of double gas paths and improve the intelligent degree of the whole system.

Owner:上海鸿得利重工有限公司

Preparation of aromatic nitrile compound by waste-free circulation method

InactiveCN101081821AReduce consumptionFull recoveryCarboxylic acid nitrile preparationOrganic compound preparationChemical industryCyclic process

The present invention is no-waste liquid cyclic process for preparing aromatic amino nitrile compound. The cyclic process synthesizes aromatic amino nitrile compound R1-NH-R2-CN by using aromatic amine compound R1-NH2 and hydroxyl alkyl nitrile compound HO-R2-CN as materials and in several combined cyclic systems, and has no waste liquid drainage. The cyclic process has full utilization of materials, saving in resource, high product yield, zero waste liquid drainage and other advantages, and is suitable for use in chemical industry.

Owner:成都圣洁环保有限责任公司

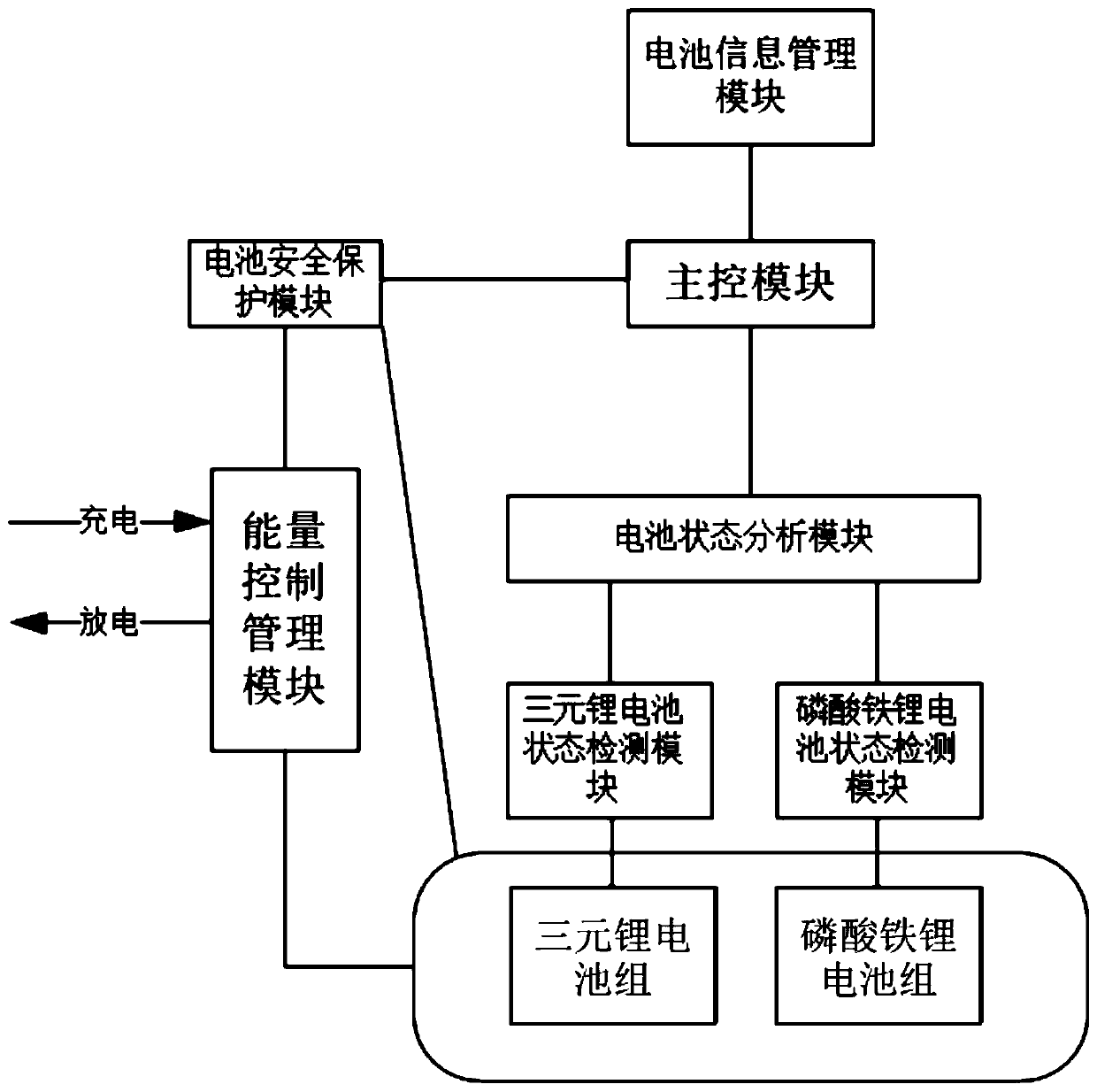

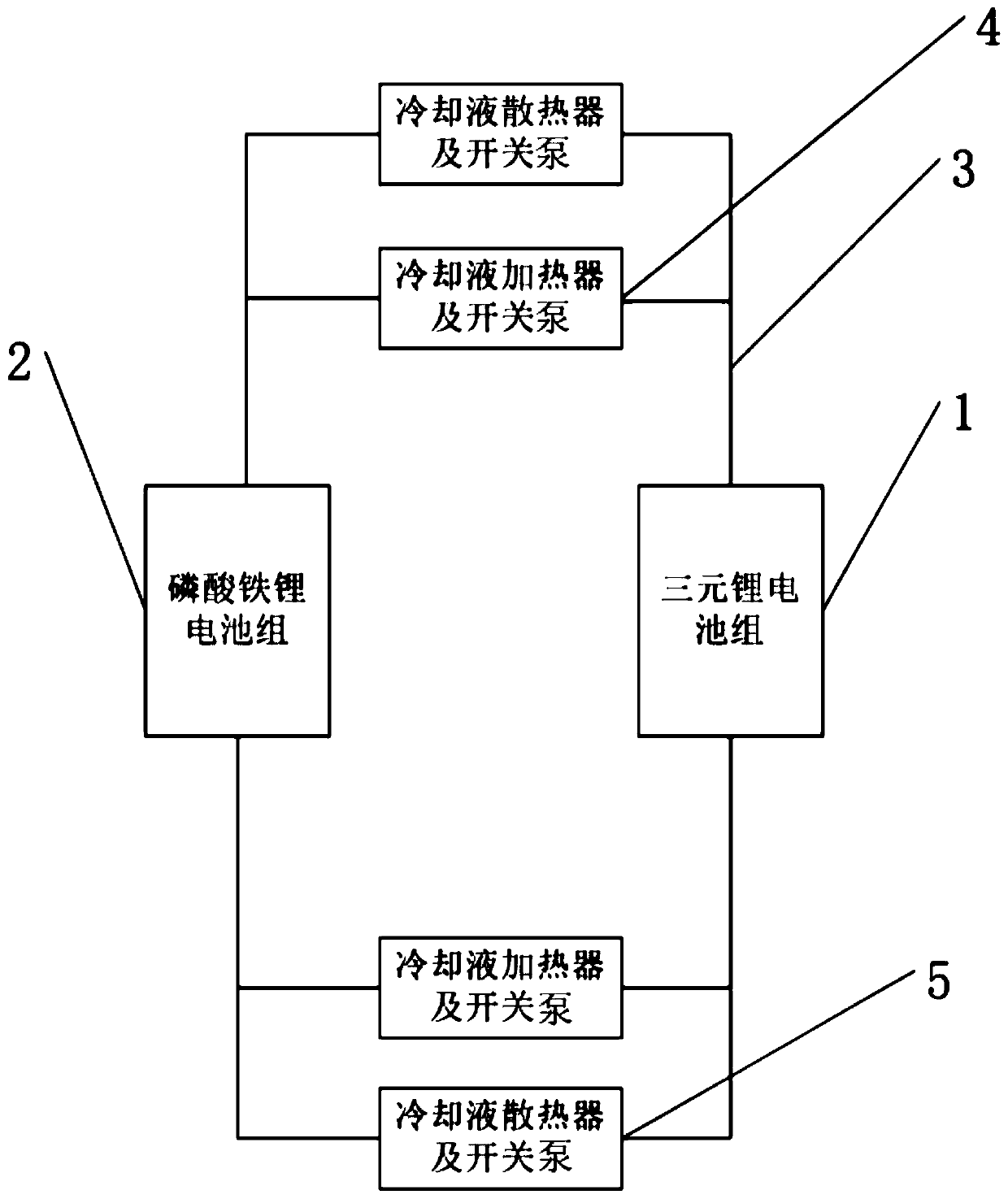

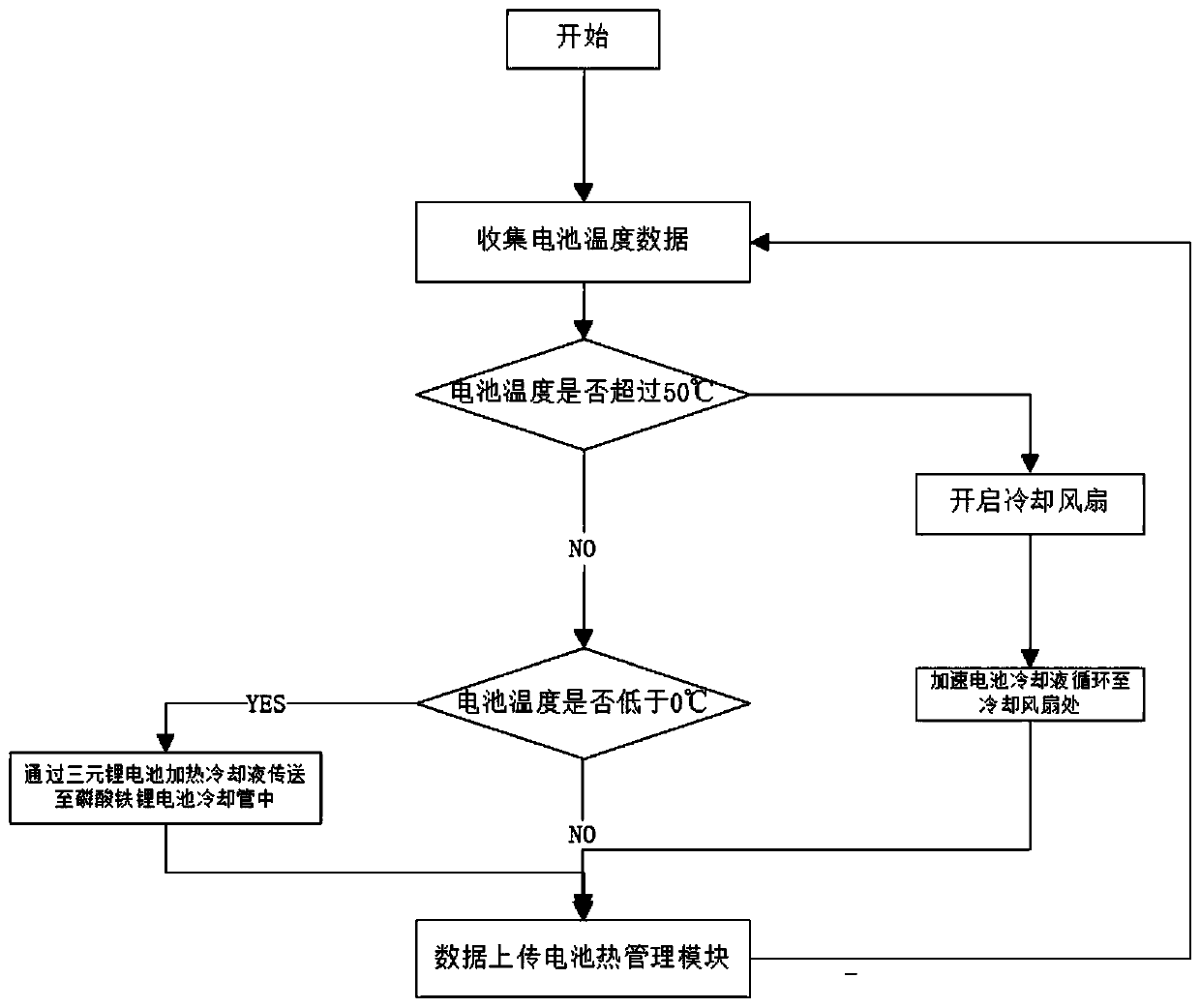

Retired lithium iron phosphate and ternary lithium battery hybrid coordination control method and system

ActiveCN110380144AFull reuseIncrease energy densitySecondary cells servicing/maintenanceLithium vanadium phosphate batteryPower battery

The invention discloses a retired lithium iron phosphate and ternary lithium battery hybrid coordination control method and system. The control method comprises the following steps: screening retiredbatteries, screening and grouping the retired batteries of the same type which meet the requirement that the residual life is close to the residual capacity; connecting different types of battery packs in series to form a battery module, wherein the different types of battery packs in the battery module meet the following conditions: the number of the different types of battery packs, the total capacity of the battery packs and the average service life of battery cells in the battery packs are equal; monitoring and arranging the performance of the battery in the battery module, monitoring andanalyzing the performance of the module, and then managing and controlling the battery module, wherein the retired battery comprises lithium iron phosphate and a ternary lithium battery. The lithium iron phosphate battery and the ternary lithium battery of a retired electric vehicle are used as objects, the advantages of the two lithium batteries are fully played, the raw material cost of the power battery is saved, the service life of the retired batteries is prolonged, and the performance of the power battery is fully utilized.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

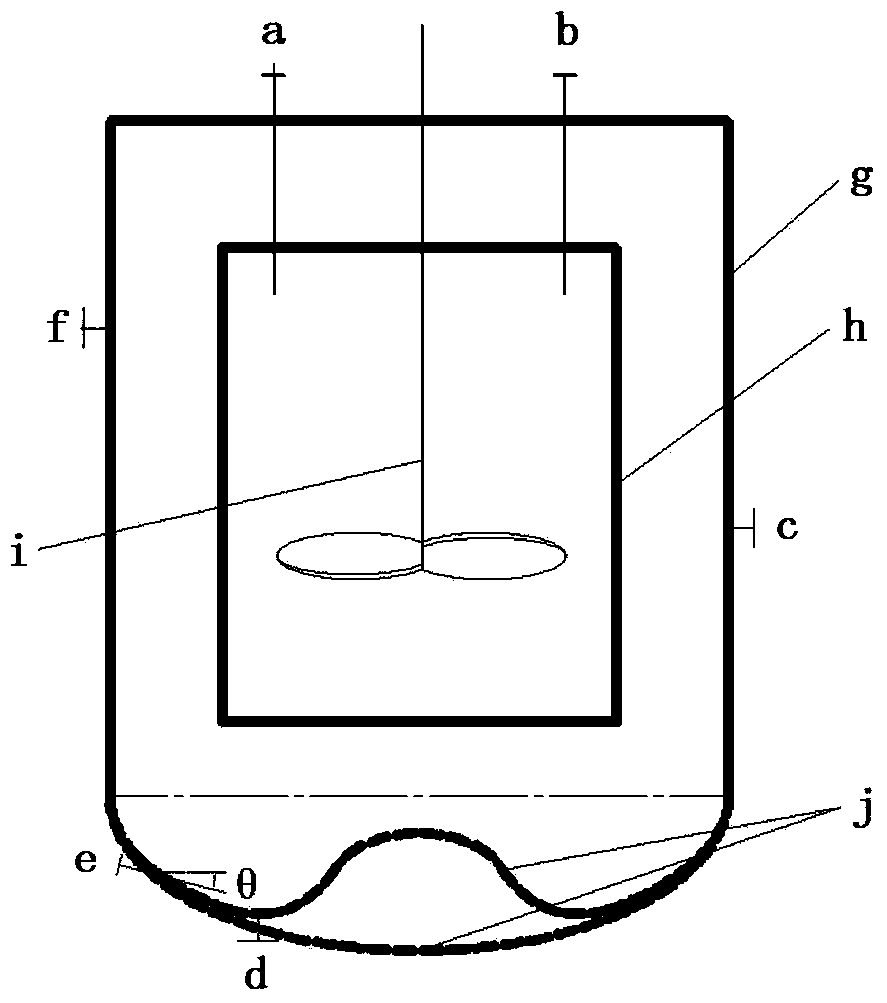

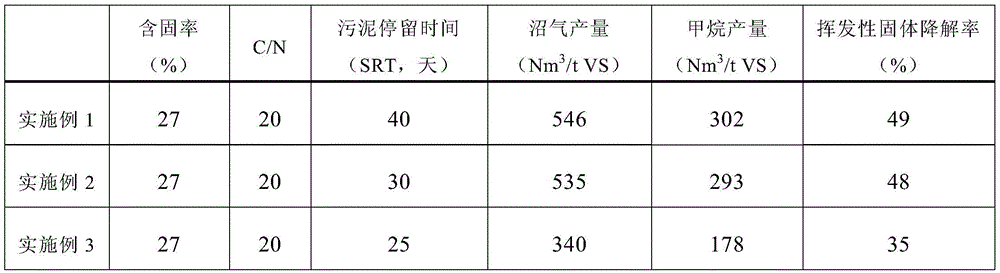

Method for producing methane through high-temperature dry type anaerobic co-fermentation

InactiveCN105586362ASlow down the accumulation of organic acidsPromote enrichmentWaste based fuelFermentationChemistryOrganic acid

The invention discloses a method for producing methane through high-temperature dry type anaerobic co-fermentation. The method comprises the following steps that 1, livestock feces and urine, crop straw and water are mixed according to the mass ratio of 4:(0.5-3.5):(0-4) to obtain a mixed material, the solid content of the mixed material ranges from 20% to 40%, VS ranges from 15% to 25%, and C / N ranges from 20 to 35; 2, a biogas inoculum and the mixed material are mixed according to the weight ratio of 1:1, then the mixture is placed in an anaerobic fermentation tank, nitrogen is introduced into the anaerobic fermentation tank for 10-20 min, and the fermentation temperature ranges from 55+ / -2 DEG C; 3, the sludge retention time ranges from 20 days to 40 days. According to the method, the problems of high-concentration ammonia fermentation inhibition and organic acid accumulation can be effectively relieved, the biogas content in the whole anaerobic fermentation process can be improved by 15% to 40%, the methane yield can be improved by 15% to 45%, and finally it can be guaranteed that methane is continuously and efficiently produced by a fermentation system.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Method for recycling waste offset printing ink of mix of various colors

InactiveCN103342916AFull reuseImprove suitabilityColor measuring devicesInksResource savingEngineering

The invention discloses a method for recycling waste offset printing ink of a mixture of various colors. At present, burning and covering treatment are adopted for the large amount of waste ink of a mixture of various colors, and thus pollution is caused to the environment. The method comprises the following steps: filtering and distilling the waste ink of a mix of various colors and then performing first grinding to mill the ink; measuring the color and the using amount of a complementary color ink; mixing the mixed ink with the complementary color ink, a carbon black pigment, varnish and a drier and performing second grinding to mill the ink so as to obtain prepared black ink; measuring the color difference and the density variation between the prepared black ink and solid black ink on a standard color card and comparing with the same-batch same-color color difference value and the same-color density deviation value in GB / T7705-2008 solid printing requirements; repeating the operation of the steps (4) to (7) if the requirements are not met, until the conditions are met. The method has the advantages of adoption of common equipment, simple process, capability of realizing recycling of the waste ink, contribution to environmental protection and resource saving.

Owner:HANGZHOU DIANZI UNIV

Draining control method for multi-drum washing machine

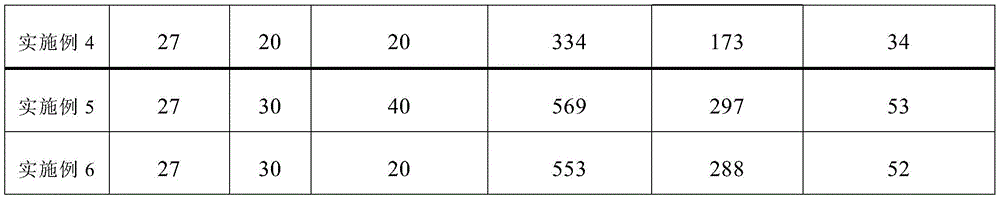

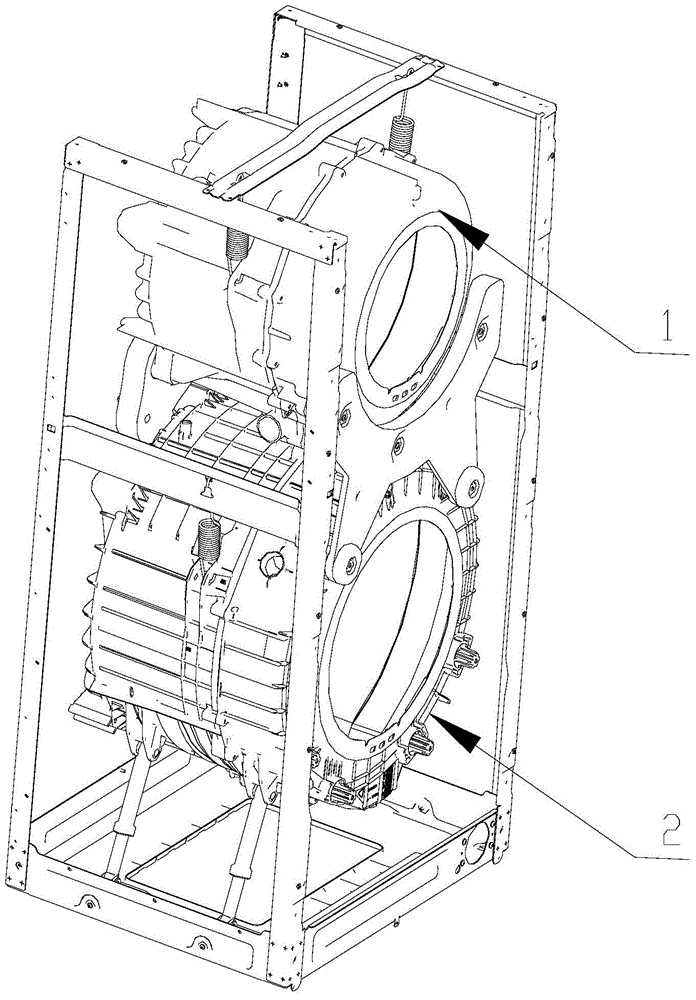

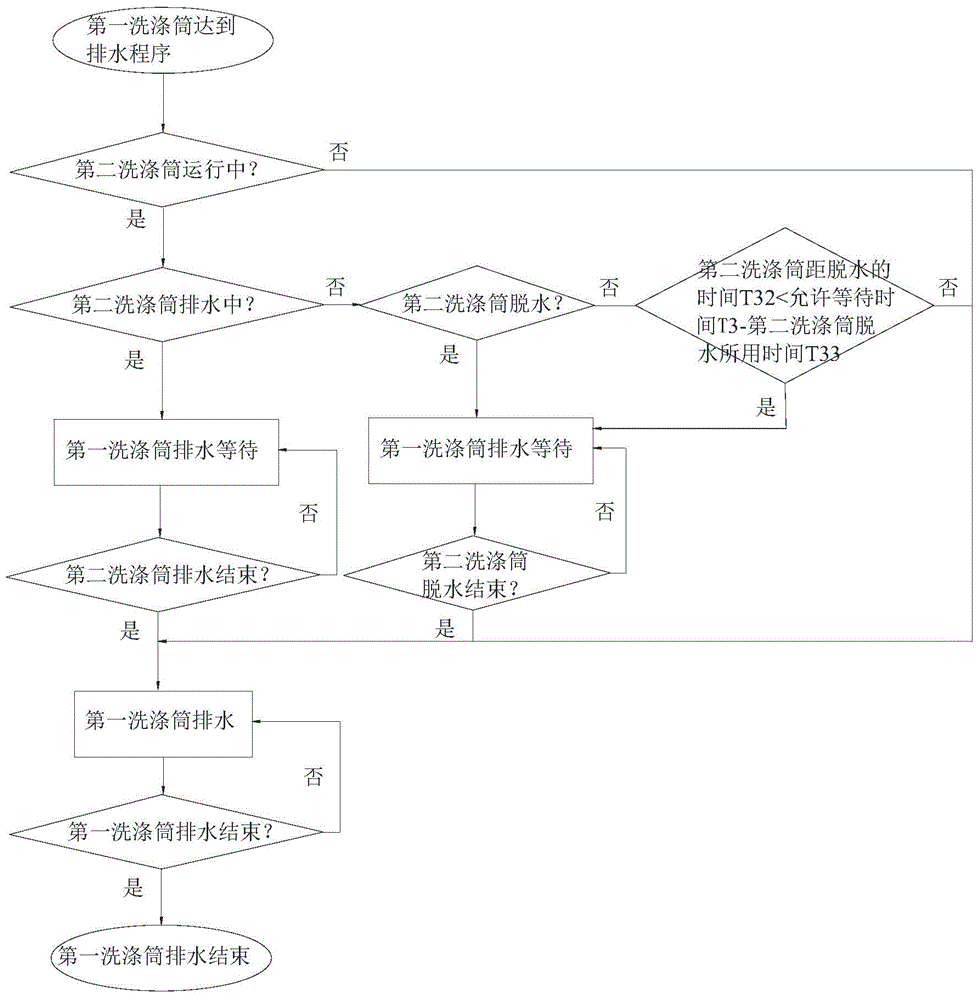

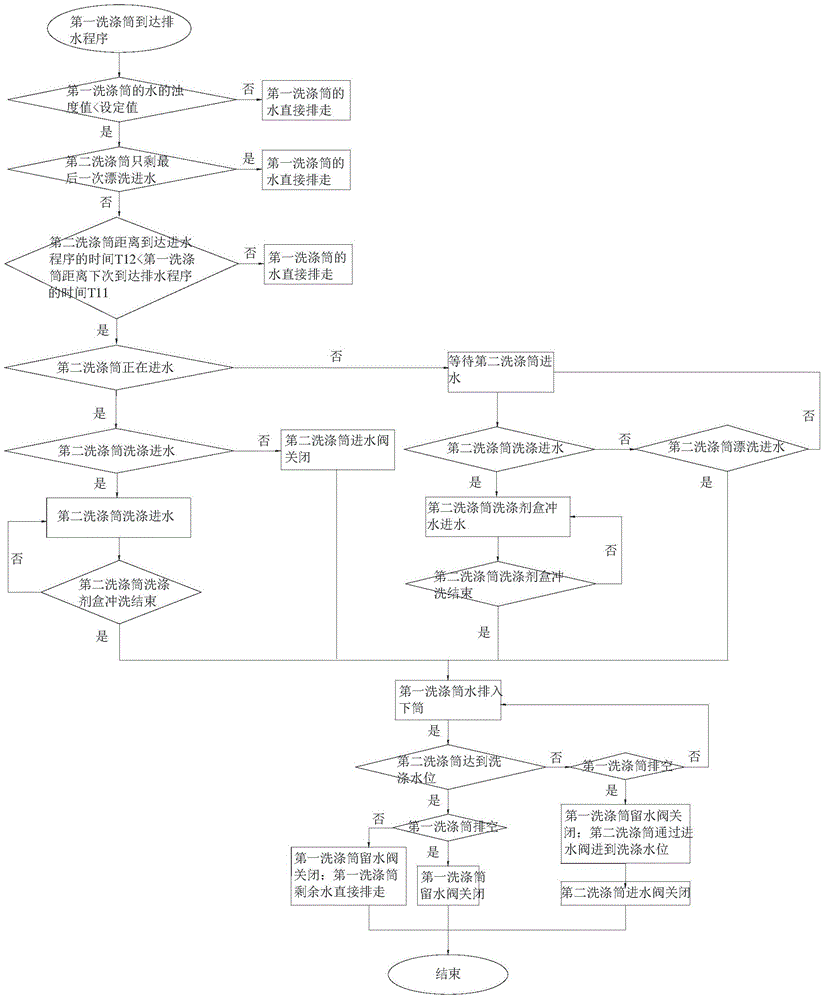

ActiveCN105734894AWeight increaseRealize the shock absorption effectControl devices for washing apparatusTextiles and paperEngineeringMechanical engineering

The invention relates to a draining control method for a multi-drum washing machine. The multi-drum washing machine at least comprises a first washing drum and a second washing drum. When the first washing drum reaches a draining program, whether the second washing drum is carrying out dewatering at the moment or not is judged; if yes, the first washing drum waits to carry out draining until the second washing drum completes dewatering; if not, whether the first washing drum needs to wait to carry out draining until the second washing drum completes dewatering or not is judged. The process of judging whether the first washing drum needs to wait to carry out draining until the second washing drum completes dewatering or not comprises the steps that it is determined that the time, from the current moment to the dewatering moment, of the second washing drum is T32 and the dewatering time of the second washing drum is T33, and an allowable waiting time T3 is set; if T32+T33<T3, the first washing drum waits to carry out draining until the second washing drum completes dewatering; otherwise, water in the first washing drum is directly drained.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

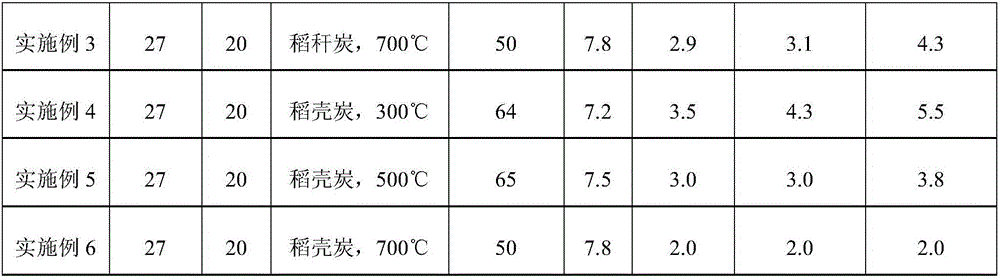

Method for producing methane and preparing fertilizer simultaneously

ActiveCN106399385AImprove qualityReduce inhibitionBio-organic fraction processingExcrement fertilisersMixed materialsFermentation

The invention discloses a method for producing methane and preparing a fertilizer simultaneously. The method comprises the following steps: (1) mixing excrement and urine of beasts and birds and crop straw at the weight ratio of (3.5-4.5):1, thus obtaining a mixed material; and (2) mixing rice straw charcoal or rice husk charcoal with the mixed material at the weight ratio of (0.5-2.5):10, placing the obtained mixture in an anaerobic fermentation tank, and carrying out fermentation. With the adoption of the method provided by the invention, the gas dredging and medium delivery generated in a reaction matrix can be effectively improved, the utilization efficiency of microbes for the matrix can be improved, and meanwhile, the high-quality fertilizer is produced.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Recycling system and recycling method for waste liquor produced in separation and purification of organically synthesized feed liquid

InactiveCN104176844AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentElectricityOrganic synthesis

The invention relates to a recycling system and a recycling method for waste liquor produced in separation and purification of an organically synthesized feed liquid, and belongs to the field of chemical engineering. The recycling system for the waste liquor comprises a filter device, a desalting device and a membrane concentrating device which are arranged from the front to the rear in sequence, or the filter device is replaced with a filtrate collecting slot, wherein the filter device is used for filtering and collecting the waste liquor; the filtrate collecting slot is used for stewing and collecting the waste liquor; the desalting device is used for desalting the collected waste liquor; the membrane concentrating device is used for concentrating a liquid which is desalted by virtue of the desalting device; and the desalting device is preferably an electrodialysis device. According to the recycling system and the recycling method, a membrane separating and concentrating technology, an electrodialysis technology and the like are comprehensively utilized to separate and purify the organically synthesized feed liquid, and the produced waste liquor is sufficiently recycled, the separating and purifying efficiency and the purity and the yield of products are improved, discharge of the waste liquor is reduced, the production industrialization is strong and the cost is low, and thus, the recycling system and the recycling method are especially suitable for being applied in production of iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

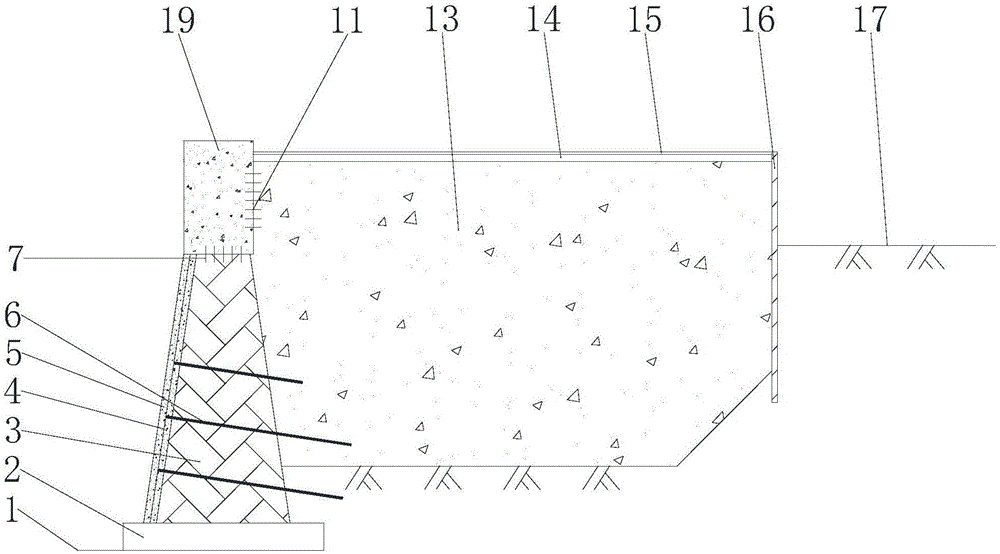

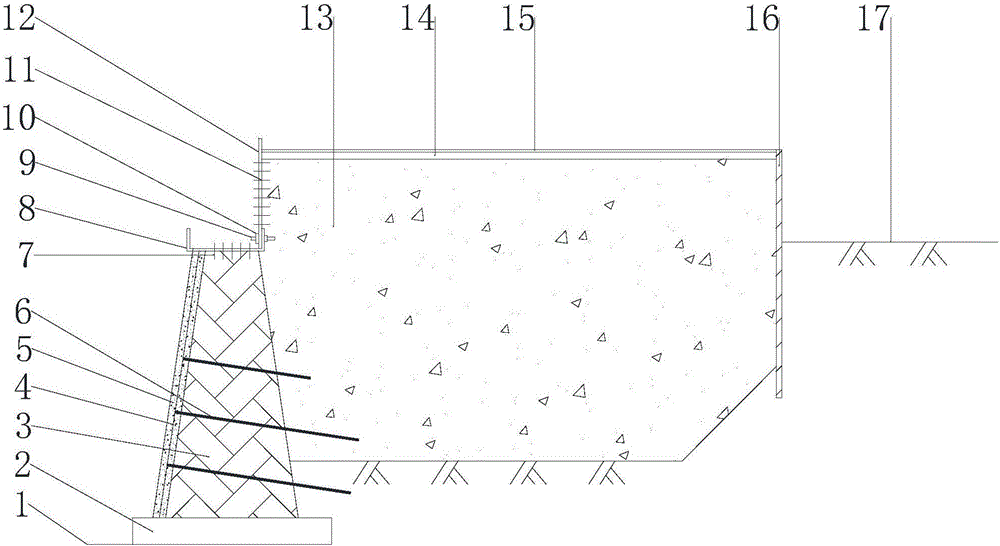

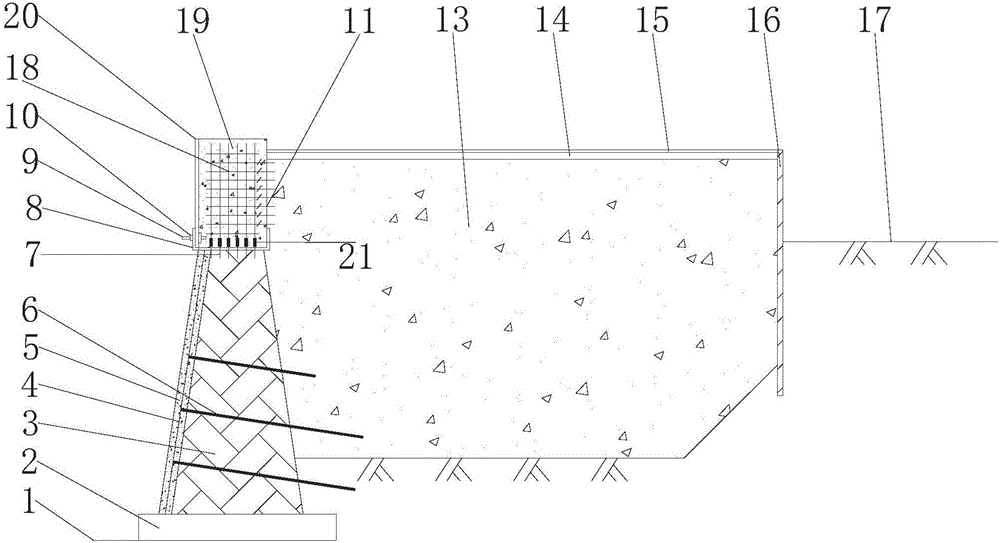

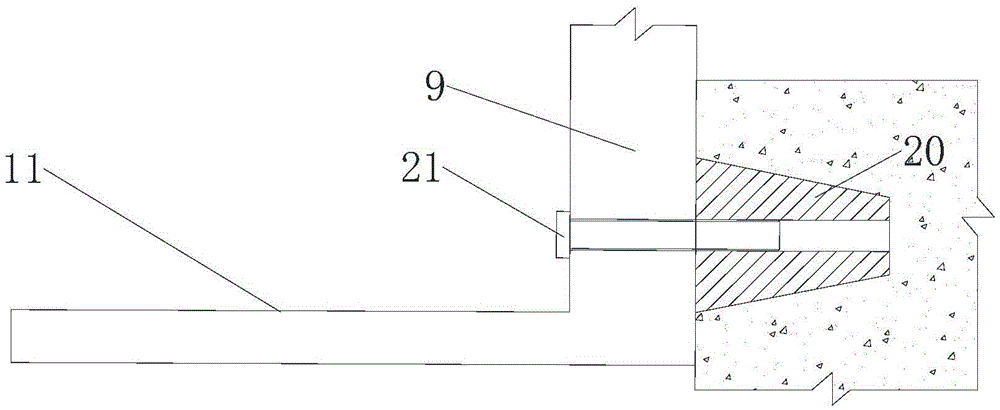

Heightened construction method for active service stone building bank protecting wall

The invention relates to a heightened construction method for an active service stone building bank protecting wall. The heightened construction method includes the following steps that (1) an original bank protecting slope is cleaned and repaired; (2) anchor rod construction is carried out; (3) lattice girder construction is carried out; (4) foam concrete construction is carried out; (5) pavement construction is carried out; (6) newly-increased protection bank construction is carried out; and (7) concrete curing is carried out. A structure related in the heightened construction method comprises angle iron arranged at the top of an original protection bank according to a certain distance, the angle iron and embedded steel bars at the top of the original protection bank are connected in a welded manner, and a foam concrete sea side formwork and a newly-increased protection bank side mold are connected with the angle iron in a fastened manner through screws; prefabricated slabs are evenly inserted and piled on the foam concrete bank side, a foam concrete bank side formwork is arranged to be in a separated manner and is connected with the prefabricated slabs in a fastened manner through box iron, the screws and nuts; and newly-increased protection bank framework reinforcing steel bars and original protection bank embedded steel bars are connected through a direct threaded sleeve. The heightened construction method for the active service stone building bank protecting wall has the beneficial effects of being reliable in structure, convenient to construct, short in time limit for a project, environment-friendly and good in concrete appearance quality.

Owner:ZHEJIANG UNIV CITY COLLEGE

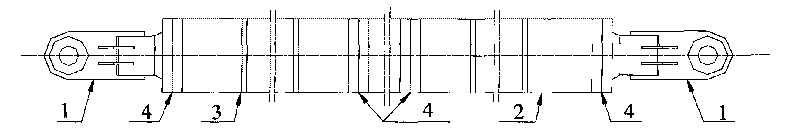

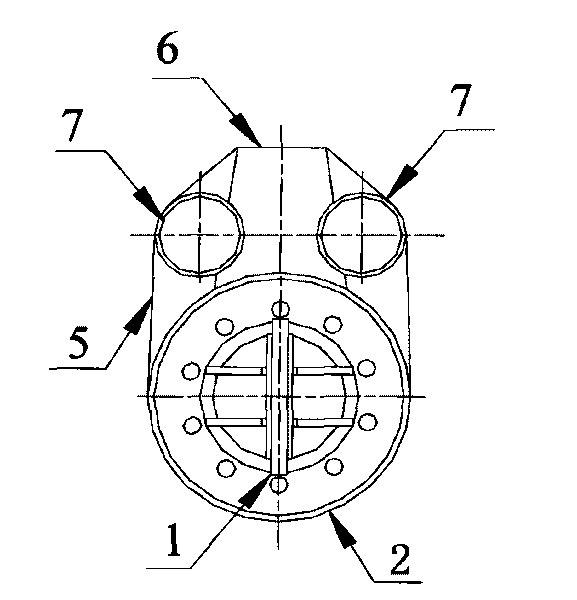

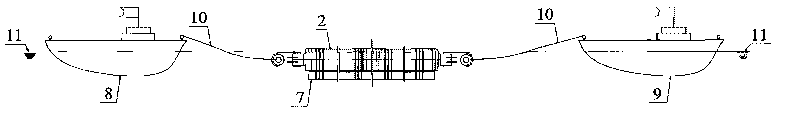

Bound floating pipeline towing pipe method process

InactiveCN101761691ASolution can not be recycledReduce construction costsPipe laying and repairEngineeringSubmarine pipeline

The invention relates to a bound floating pipeline towing pipe method. In the method, a floating pipe is used for replacing a buoy in the prior bound buoy towing pipe method, the specification of the floating pipe comprises a plurality of segments of cylinders, each segment is 50m in length and is an independent sealed bin, a plurality of supporting ribbed plates and longitudinal ribbed plates are welded inside, an air valve and a water valve are arranged for marine load adjustment, every two segments are connected through an inner flange, and a towing head is respectively arranged at both ends of the whole body. The invention has the advantages that the problem of size limitation for a process pipe in the bound buoy towing pipe method is solved, and the requirement for sea conditions is also greatly broadened; meanwhile, the problem that a frock pipe can not be reclaimed in a bunched pipeline towing pipe method is also solved, so that a floating pipe device can be repeatedly utilized, and the construction cost of submarine pipeline laying is further lowered.

Owner:NEPTUNE OFFSHORE ENG DEV

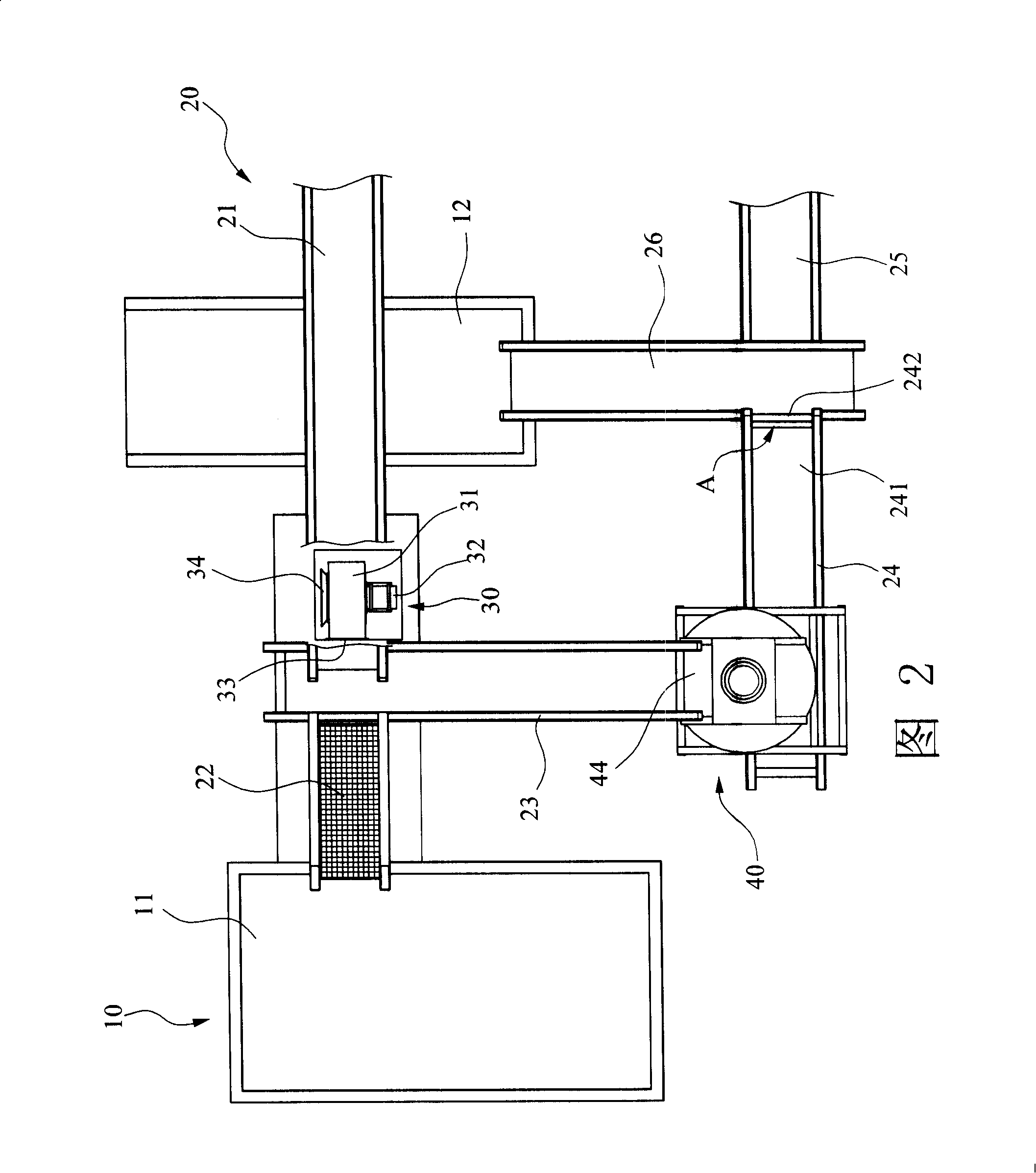

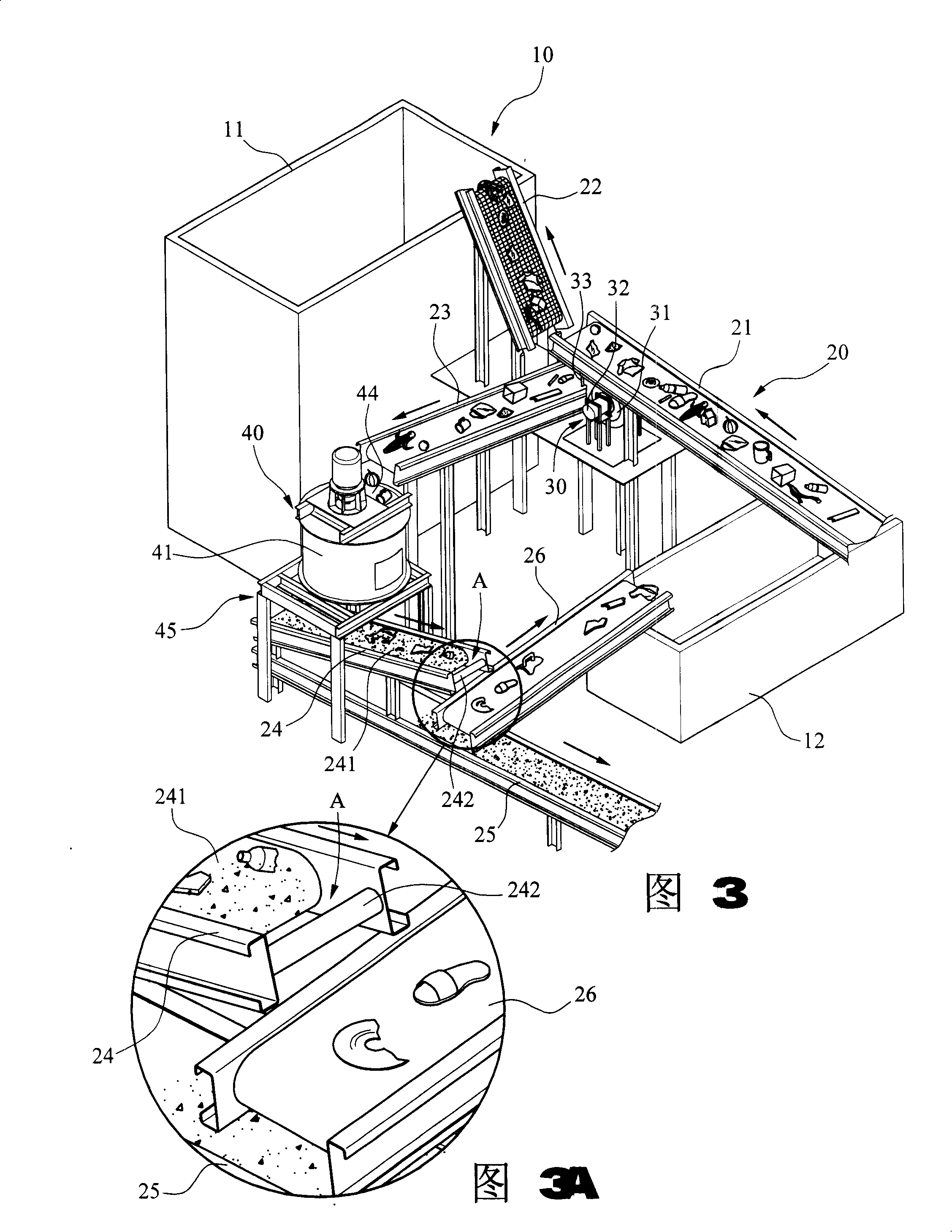

Large-scale organic matter refuse treatment classifying device

ActiveCN101234390AEffective classificationRecycling OperationsGas current separationSolid waste disposalTransmission beltOrganic matter

The invention provides a sorting device for processing the large scale organic compound waste, comprising an air supply apparatus which is arranged on the lower part of the transmission terminal of a mixed garbage transmission belt. The air supply apparatus consists of a blower provided with an air supply outlet which corresponds to a light waste transmission belt. A crushing device is arranged between the transmission operation channel of a heavy garbage transmission belt and a crushing garbage process transmission belt. The crushing device comprises a cylinder provided with a garbage inlet which corresponds to the heavy garbage transmission belt. The transmission in the cylinder is provided with at least a crushing component. With the crushing component, the organic material of impossible crushing is crushed and reprocessed to suit the completeness of the water sorting process of the whole waste process technology system, thus effectively and fully sorting, recycling and reusing the organic material.

Owner:无锡市长江机电有限公司

Environmental protection asphalt modifier and preparation method thereof

The invention relates to an environmental protection asphalt modifier. The environmental protection asphalt modifier comprises the following components in parts by weight: 40-50 parts of waste rubber powder, 16-20 parts of organic montmorillonite, 8-10 parts of an activating agent, 5-8 parts of stearic acid, 10-15 parts of a stabilizer, 1-6 parts of an antioxidant, 3-10 parts of a warm mix agent, 15-20 parts of nanosilver and 12-18 parts of silicon carbide. The environmental protection asphalt modifier is small in use amount, low in cost, and high in environment-friendly performance. The invention further provides a preparation method for the asphalt modifier.

Owner:江苏金阳新材料科技有限公司

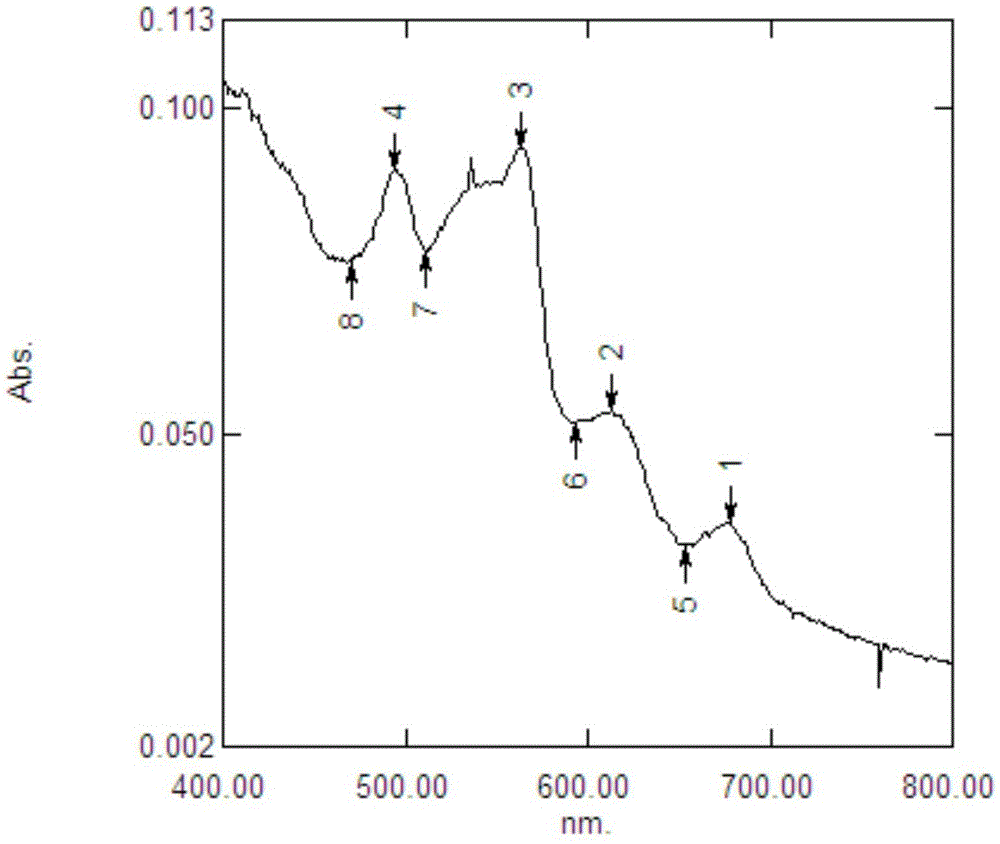

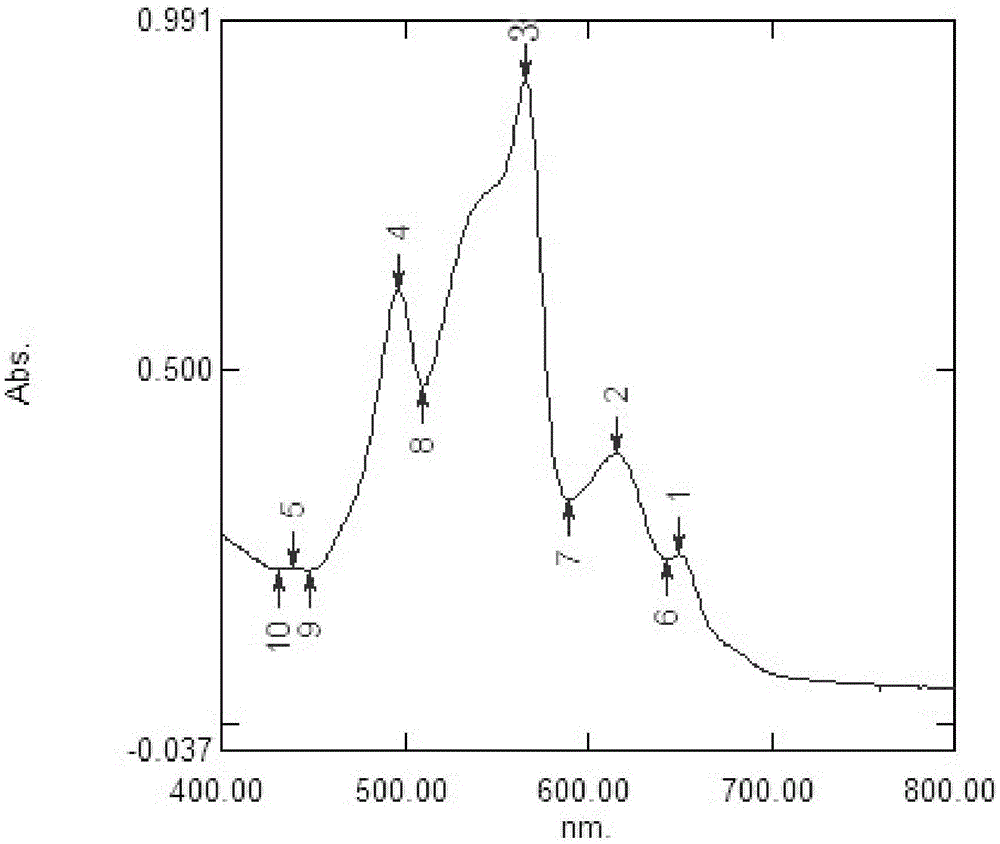

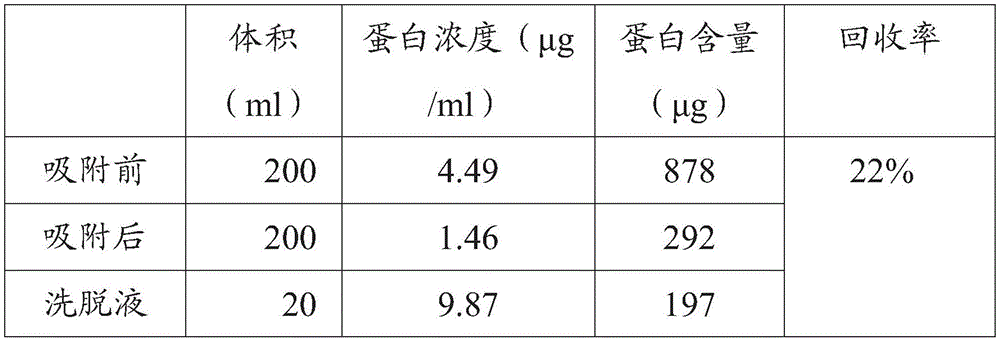

Method for separating phycobiliprotein from laver processing wastewater

ActiveCN105601732AAchieve the purpose of usingReduce pollutionDepsipeptidesPeptide preparation methodsWastewaterIon exchange

The invention discloses a method for separating phycobiliprotein from laver processing wastewater. The method comprises the following steps: (1) filtering laver processing wastewater to remove impurities to obtain laver processing wastewater without impurities; (2) adsorbing phycobiliprotein in the laver processing wastewater without impurities with ion exchange packing so as to obtain phycobiliprotein adsorbed ion exchange packing; and (3) eluting the phycobiliprotein adsorbed ion exchange packing with 0.1-0.5M of sodium chloride-PBS buffer solution to obtain purified phycobiliprotein. According to the method, purified high-active-value phycobiliprotein can be reclaimed from laver processing wastewater, so that the aim of waste utilization can be achieved; meanwhile, environmental pollution caused by direct drainage of laver processing wastewater can be reduced due to extraction of the phycobiliprotein.

Owner:南通中国科学院海洋研究所海洋科学与技术研究发展中心 +1

Energy-saving environment-friendly treatment system for recycling of waste metal paint buckets

ActiveCN107525081AFull reuseReduce processing costsCombustion technology mitigationIncinerator apparatusQuenchingIncineration

The invention belongs to the field of environment-friendly waste metal paint bucket treatment and purification and discloses an energy-saving environment-friendly treatment system for recycling of waste metal paint buckets. The system comprises an automatic feeding system, a pyrolysis system, an iron scrap recovery system, an incineration system, a waste heat utilization system, a quenching system, a deacidifying system, a dedusting system, a denitration system and a smoke discharging system. After pyrolysis treatment, sheet iron of the waste metal paint buckets enters a cooling furnace to be cooled and recovered, and other systems completely recycle waste heat. Due to adoption of recycled smoke for pyrolysis, generated NOx is greatly reduced, fuel saving is realized by complete utilization of energy, and tail gas treatment cost is reduced.

Owner:大连科林能源工程技术开发有限公司

Fly ash-based concrete

ActiveCN108546050AGuaranteed StrengthLight weightCement productionGeopolymer cementThermal stability

The invention discloses fly ash-based concrete. The fly ash-based concrete is prepared from the following raw materials in parts by mass: 200 to 300 parts of coarse aggregate of artificial fly ash, 50to 150 parts of fine aggregate of artificial fly ash, 5 to 20 parts of silica fume, 100 parts of geopolymer cement, 0.5 to 3 parts of water reducing agent, 20 to 40 parts of water and 5 to 15 parts of additive. By adopting the fly ash-based concrete disclosed by the invention, the strength of the concrete is ensured, and the bulk density of the concrete can be lowered. Meanwhile, and the fly ash-based concrete has excellent thermal stability and chemical stability. The fly ash is taken as a substrate material, so that the fly ash can be fully reused, and the problem of environmental pollutioncaused by the fly ash is solved.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for improving production of methane from surplus sludge of wastewater treatment plant

InactiveCN103193369AIncrease fatty acid content and methane productionFully Recycle and ReuseWaste based fuelBiological sludge treatmentChemistryAcid production

The invention belongs to the technical field of environmental protection and relates to a method for improving production of methane from surplus sludge of a wastewater treatment plant. The method comprises the following steps of: (1) thoroughly mixing sludge with ryegrass for fermentation, hydrolysis and acid production; and (2) performing anaerobic fermentation on the mixture obtained in the step (1) to generate methane. The method for prompting the production of methane from surplus sludge of the wastewater treatment plant with energy grass is capable of improving the yield of short chain fatty acids and the yield of methane from sludge at the same time, and also capable of recovering and reutilizing organic matters in the sludge more thoroughly; and pollution of sludge on the environment is reduced.

Owner:TONGJI UNIV

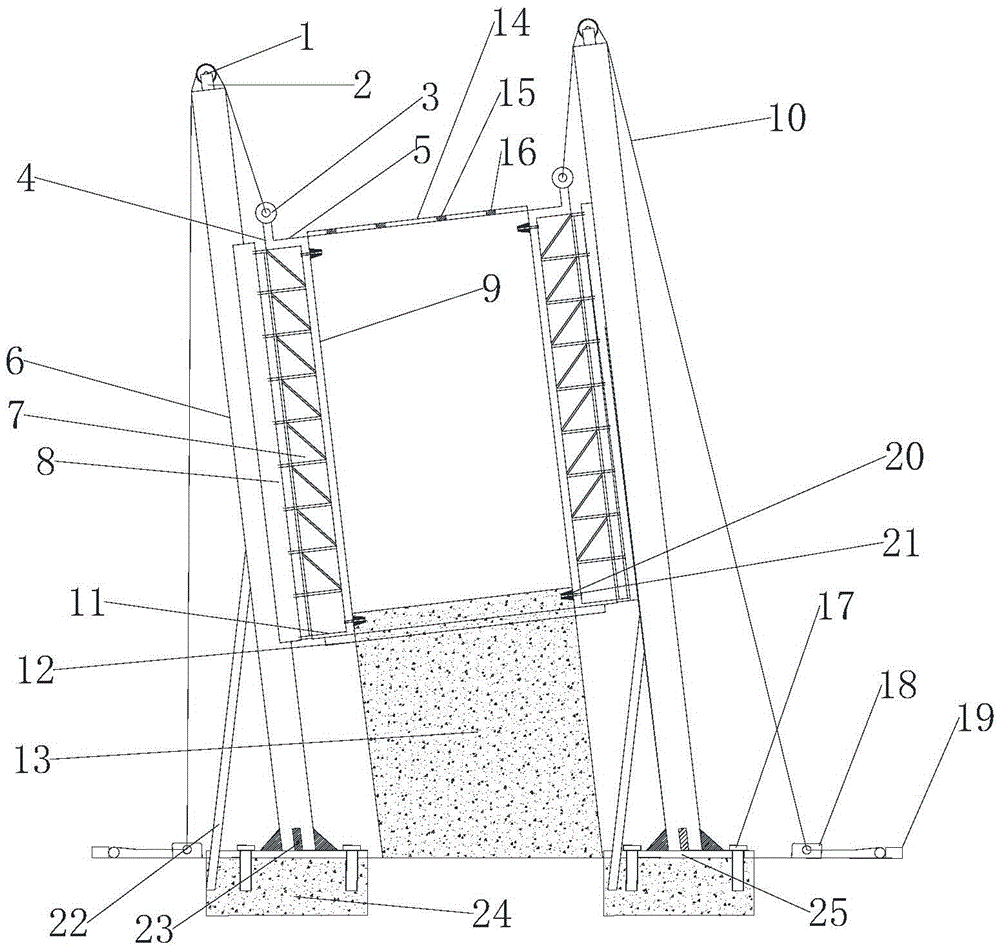

Construction method for ultrahigh oblique post with super-large cross section based on integral lifting formwork reinforcing system

InactiveCN105464216AStable structureAvoid damageForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural engineering

Provided is a construction method for an ultrahigh oblique post with a super-large cross section based on an integral lifting formwork reinforcing system. The method comprises the following steps: (1) installing slant section steel columns; (2) installing a formwork lifting system; (3) assembling side forms; (4) pouring concrete; (5) dismounting a formwork; (6) by using a guiding rail, integrally lifting the formwork reinforcing system along the slant section steel columns; (7) and pouring concrete again on the top of a concrete post which is formed in the first concreting, to heighten the post until the post reaches elevation. The construction method for an ultrahigh oblique post with a super-large cross section based on an integral lifting formwork reinforcing system is advantaged by reliable structure, convenient construction, short construction duration, friendly environment, and good concrete appearance quality.

Owner:JINAN CHANGXING CONSTR GRP

Method for preparing anhydrous sodium sulfate from chromium-containing mirabilite

ActiveCN107934993AAvoid the problem of excessive hexavalent chromiumReduce the content of hexavalent chromiumChromium compoundsAlkali metal sulfites/sulfatesChemical industryChromium trioxide

The invention relates to the field of a chemical industry and particularly relates to a method for preparing anhydrous sodium sulfate from chromium-containing mirabilite as a by-product in the production process of sodium dichromate. The method comprises dissolving a certain concentration of chrome-containing mirabilite in chromium-containing waste water, adding quantitative sodium thiosulfate into the waste water to promote reduction of hexavalent chromium into trivalent chromium under 0.1-1 Mpa at 80-190 DEG C, wherein the trivalent chromium in a form of chromium trioxide hydrate is precipitated, adding a small amount of sulfuric acid to neutralize, filtering to acquire the chromium trioxide hydrate, removing impurities, carrying out decoloration, evaporating to precipitate anhydrous sodium sulfate crystals, and carrying out continuous centrifugal separation and drying. The method is simple and easy, utilizes cheap raw materials, has low energy consumption and a high automation degree and is suitable for large-scale production. The quality of the industrial anhydrous sodium sulfate product obtained by the method meets the requirements of class I products in the GB / T 6009-2014 industrial anhydrous sodium sulfate standard.

Owner:陕西省商南县东正化工有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com