Heightened construction method for active service stone building bank protecting wall

A construction method and quay wall technology, applied in the directions of piers, quay walls, embankments, etc., can solve the problems of large disturbance of active revetment walls, large excavation depth, long construction period, etc., and achieve good application effects, improve bearing capacity, improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present application will be described in detail below in conjunction with embodiment and accompanying drawing:

[0030] In this embodiment, the welding process, bolt connection construction process, steel bar binding process and concrete pouring construction process, etc. will not be repeated in this implementation, and the embodiment of the structure related to the present invention will be focused on.

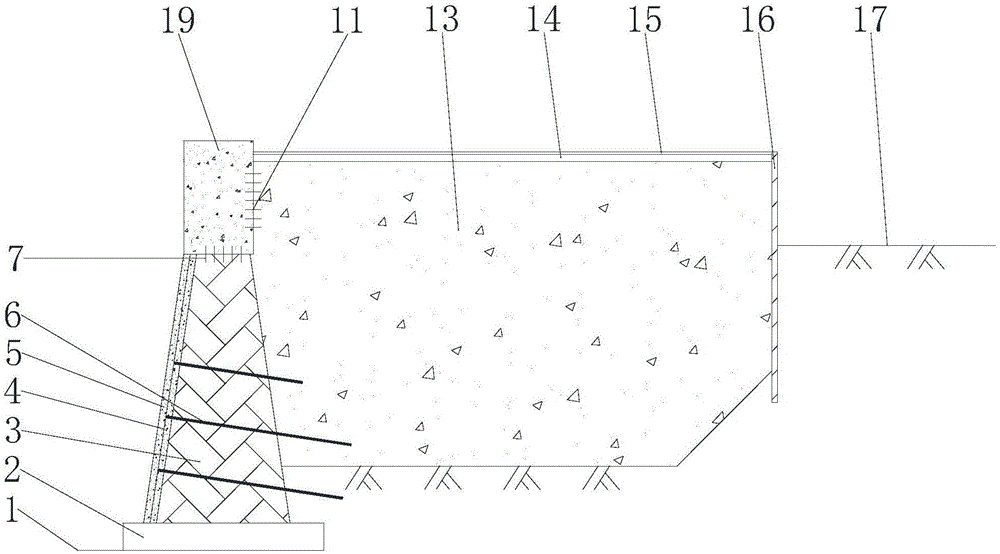

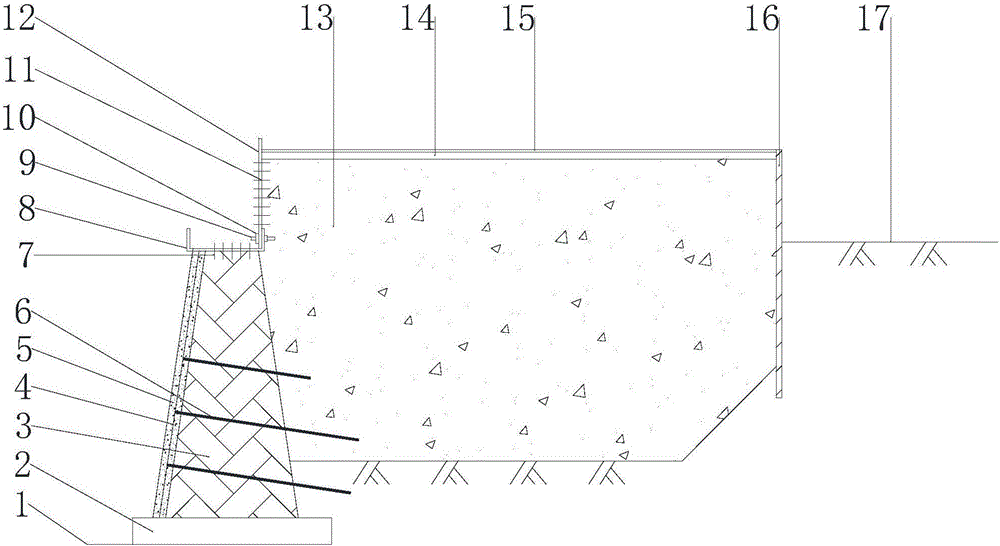

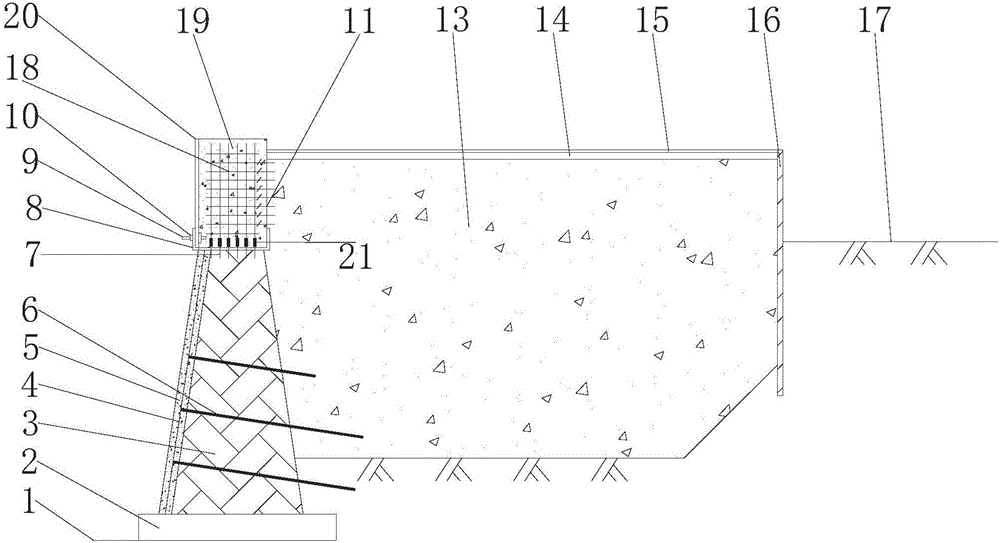

[0031] figure 1 It is a structural schematic diagram of the construction method for heightening the bank revetment wall in active service of the patent. refer to figure 1 As shown, the overall lifting formwork reinforcement system of this patent mainly includes: foundation elevation 1, original revetment retaining wall foundation 2, original revetment wall 3, lattice beam reinforcement 4, lattice beam 5, anchor rod 6, planting reinforcement 7, angle steel 8. Screw 9, nut 10, connecting bar 11, foam concrete sea-side formwork 12, foam concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com