Patents

Literature

34results about How to "Solution can not be recycled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

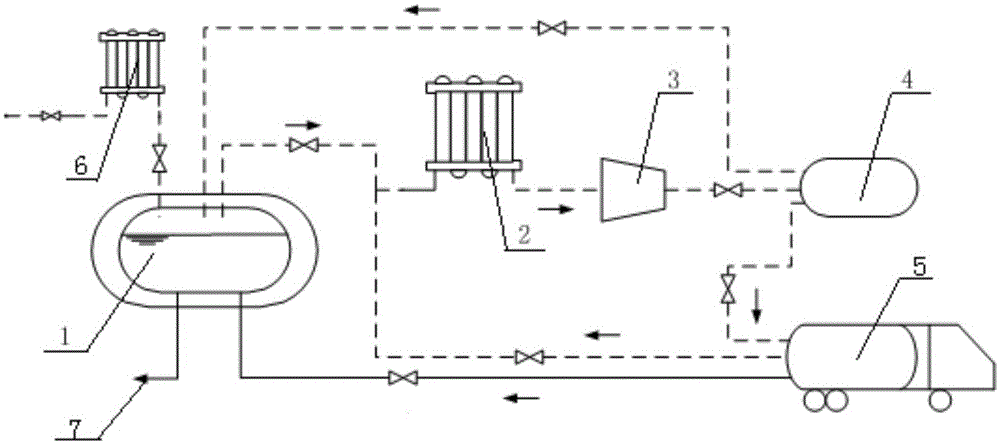

Compression recycling method for evaporation gas of liquefied natural gas

InactiveCN105135208ASimple processReduce complexityContainer filling under pressureGas phaseEvaporation

The invention relates to the technical field of liquefied natural gas, in particular to a compression recycling method for evaporation gas of liquefied natural gas. The method comprises the following steps that S1, after heat is absorbed by a liquefied natural gas storage tank, the liquefied natural gas in the liquefied natural gas storage tank partially evaporates into the evaporation gas; S2, after pressure in the liquefied natural gas storage tank rises, the evaporation gas flows out of a gas phase outlet of the liquefied natural gas storage tank; S3, after the evaporation gas flowing out in S2 is heated and pressurized, the evaporation gas is stored in an evaporation gas recycling tank; S4, after pressure of the evaporation gas in the evaporation gas recycling tank is lowered, the evaporation gas is fed into a liquefied natural gas tank car, and pressure in the liquefied natural gas tank car is increased; and S5, liquefied natural gas in the liquefied natural gas tank car is pressed out by high pressure to enter the liquefied natural gas storage tank. According to the compression recycling method for the evaporation gas of the liquefied natural gas, the problem of release of the evaporation gas in the liquefied natural gas storage tank is solved, and the amount of the evaporation gas generated by unloading and pressurization is lowered through evaporation gas unloading.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

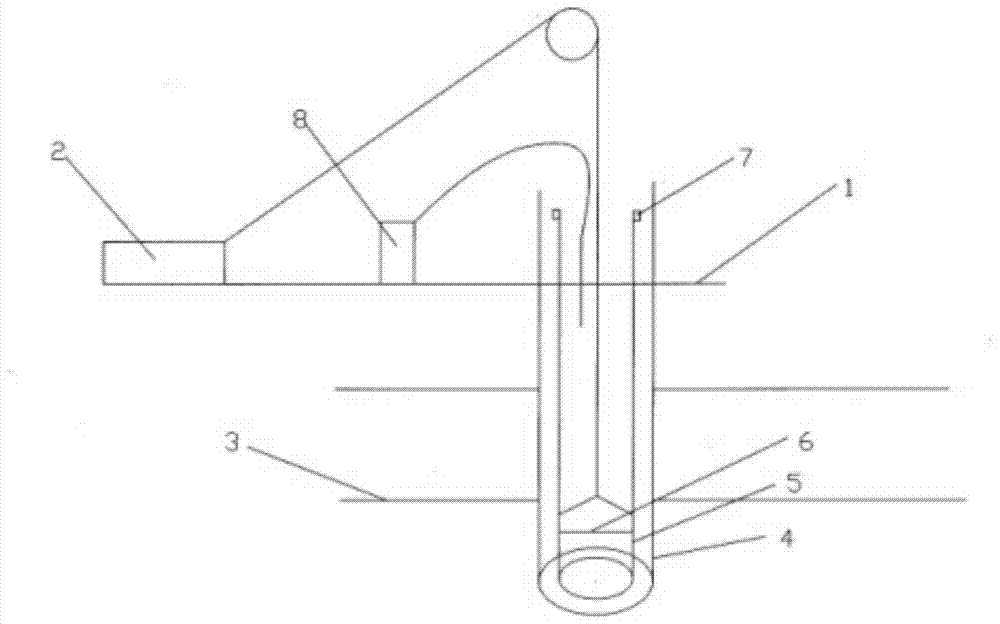

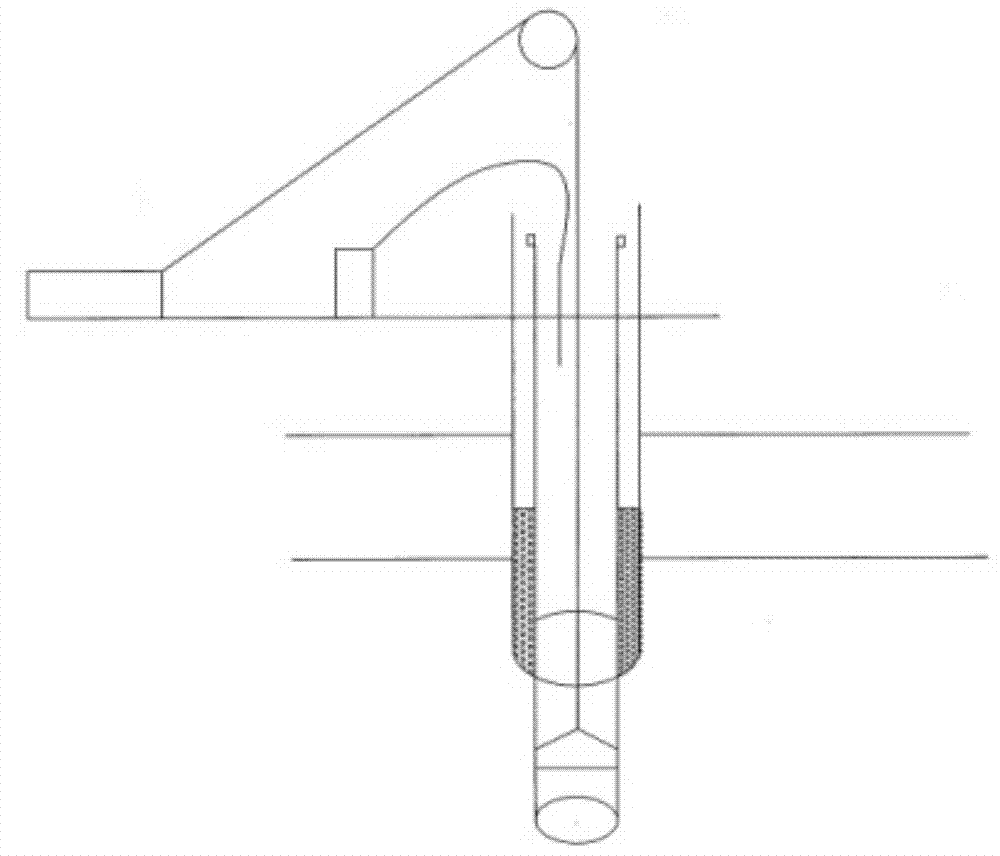

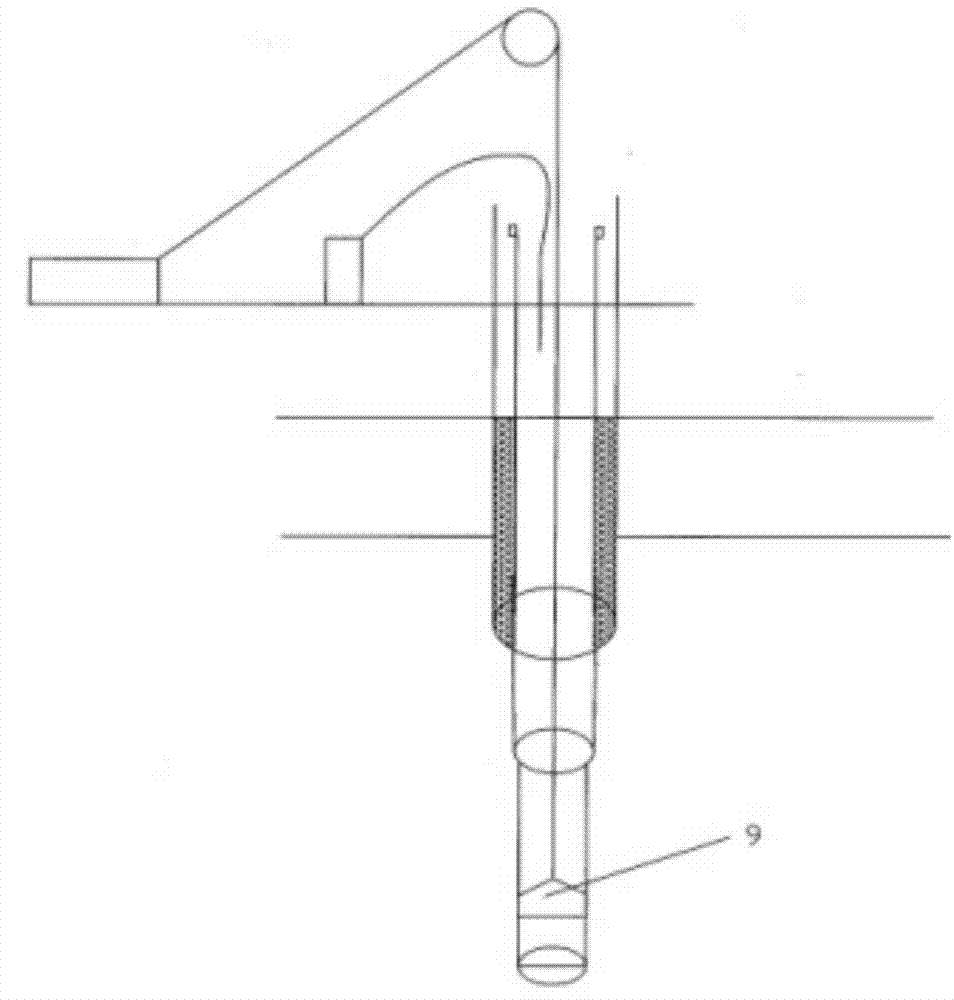

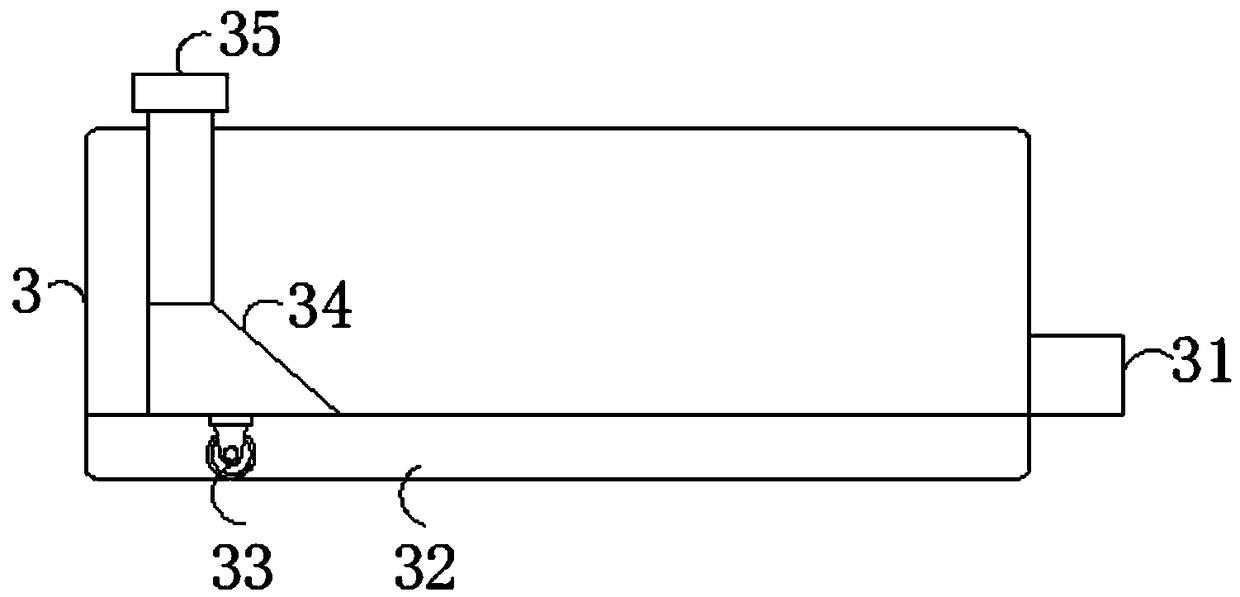

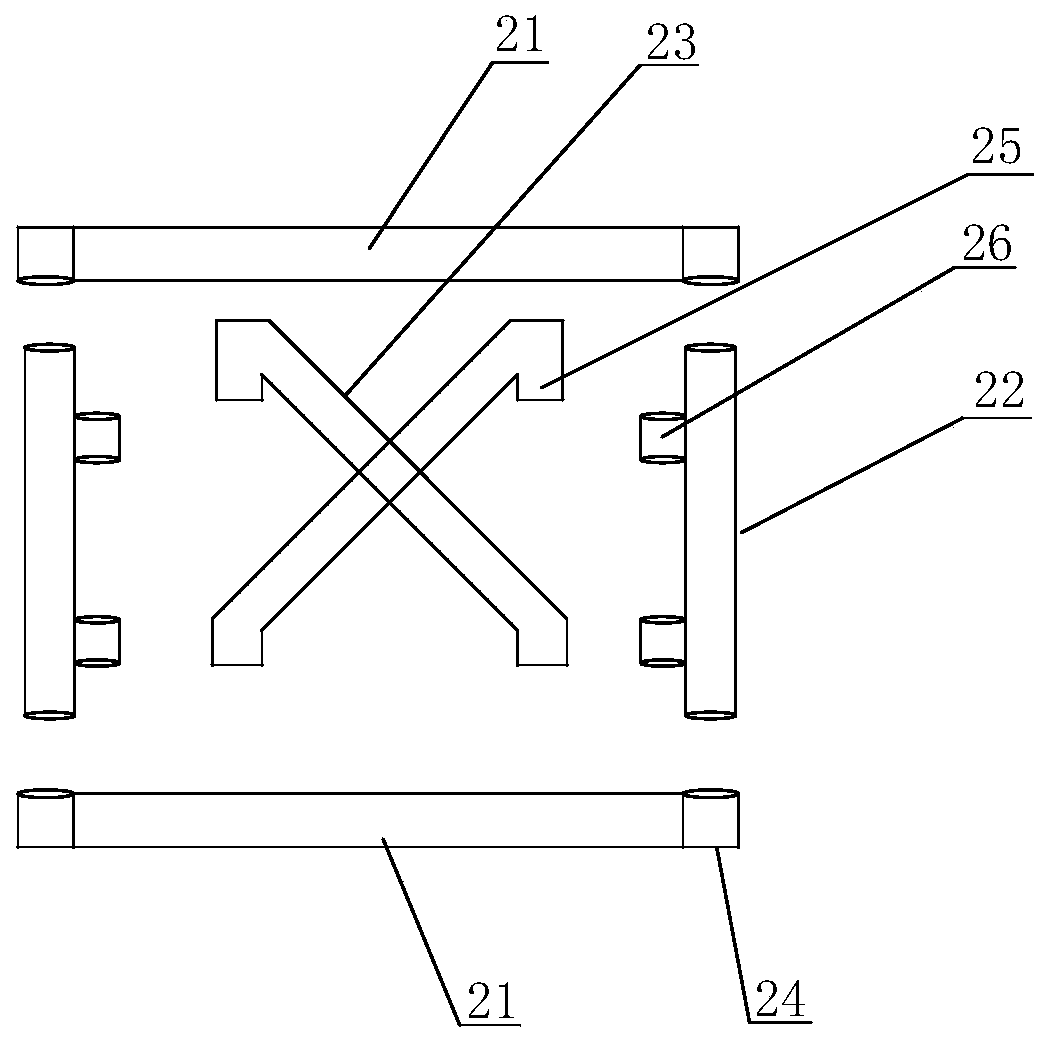

In-water drilled pile foundation construction system capable of recovering steel protective barrels and construction method thereof

InactiveCN104514219AEnable pull-out recoveryReduce construction costsBulkheads/pilesSeabedSlurry pump

The invention relates to the technical field of deep-water-area drilled piles and particularly discloses an in-water drilled pile foundation construction system capable of recovering steel protective barrels and a construction method thereof. The system comprises a seaborne drill platform located on the sea surface, a crawler crane, a vibratory hammer, an outer steel protective barrel arranged between a seabed stable geological layer and the seaborne drill platform, an inner steel protective barrel arranged in the outer steel protective barrel, a drill bit arranged in the inner steel protective barrel and a slurry pump arranged on the seaborne drill platform, wherein the crawler crane and the vibratory hammer are arranged on the seaborne drill platform, a counter-force frame and a jack are arranged between a top opening of the inner steel protective barrel and the seaborne drill platform, and the drill bit is connected with the vibratory hammer through the crawler crane. The problem that deep-water-area drilled pile steel protective barrels in the prior art cannot be recovered is solved.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

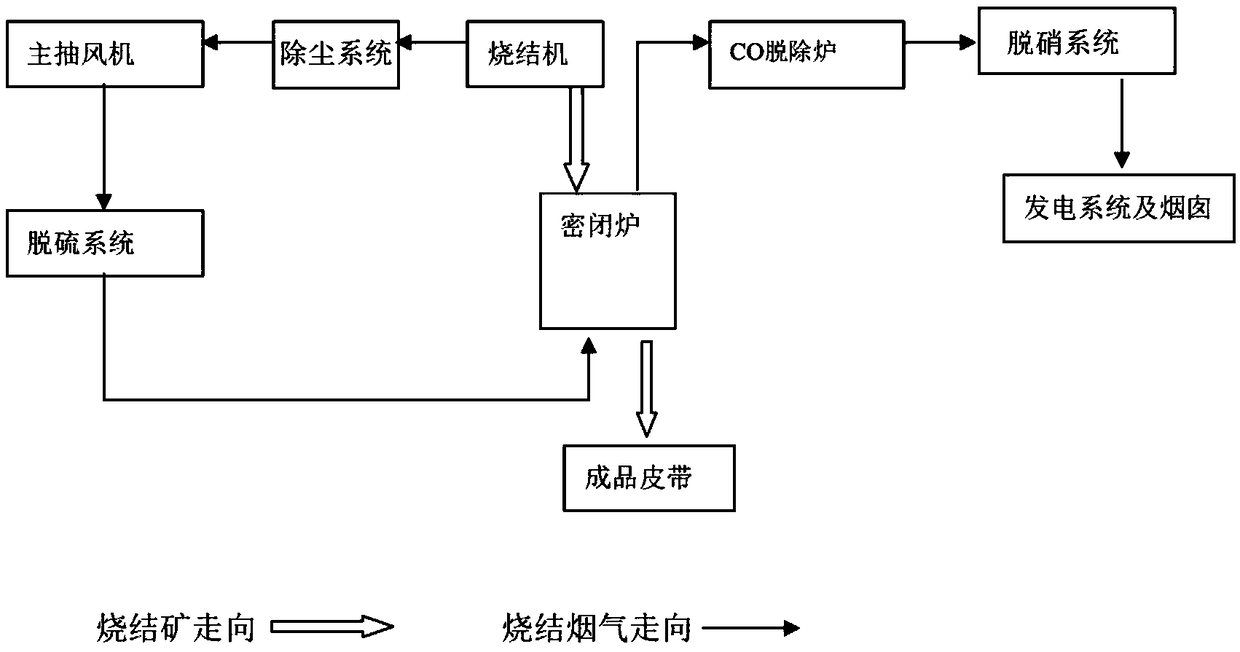

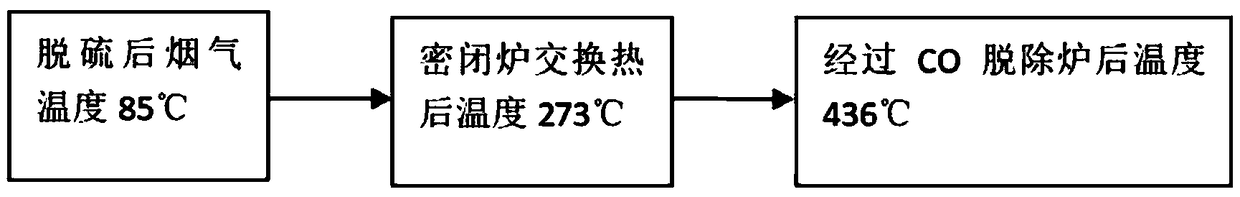

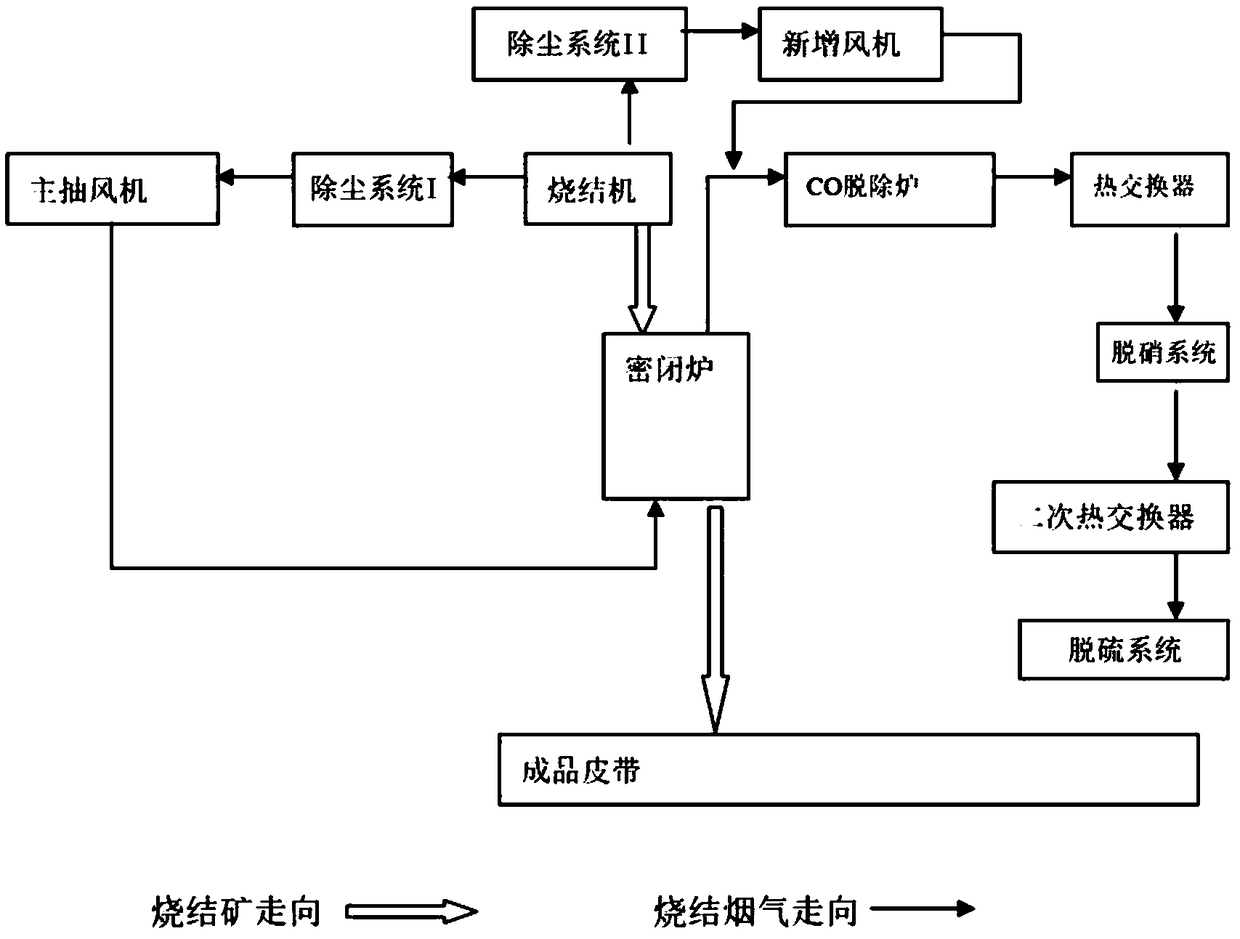

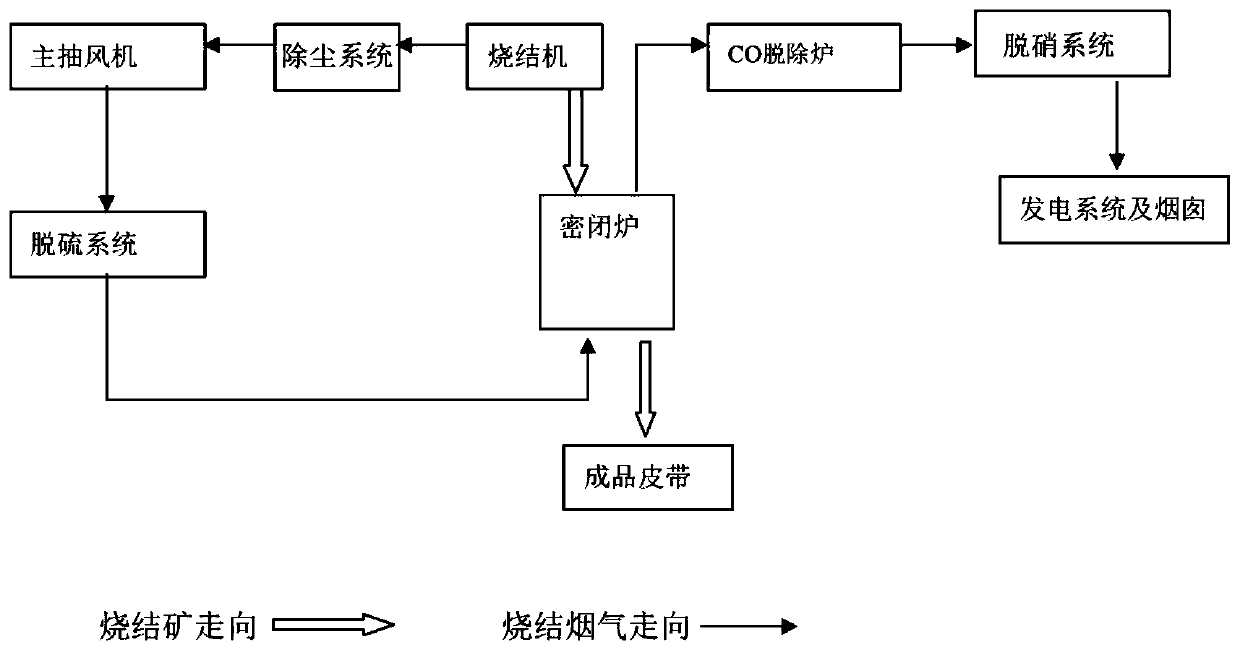

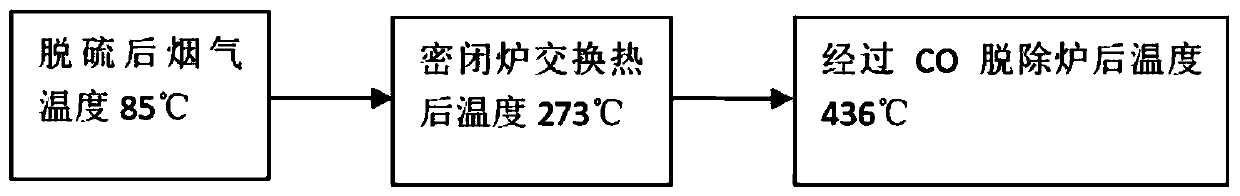

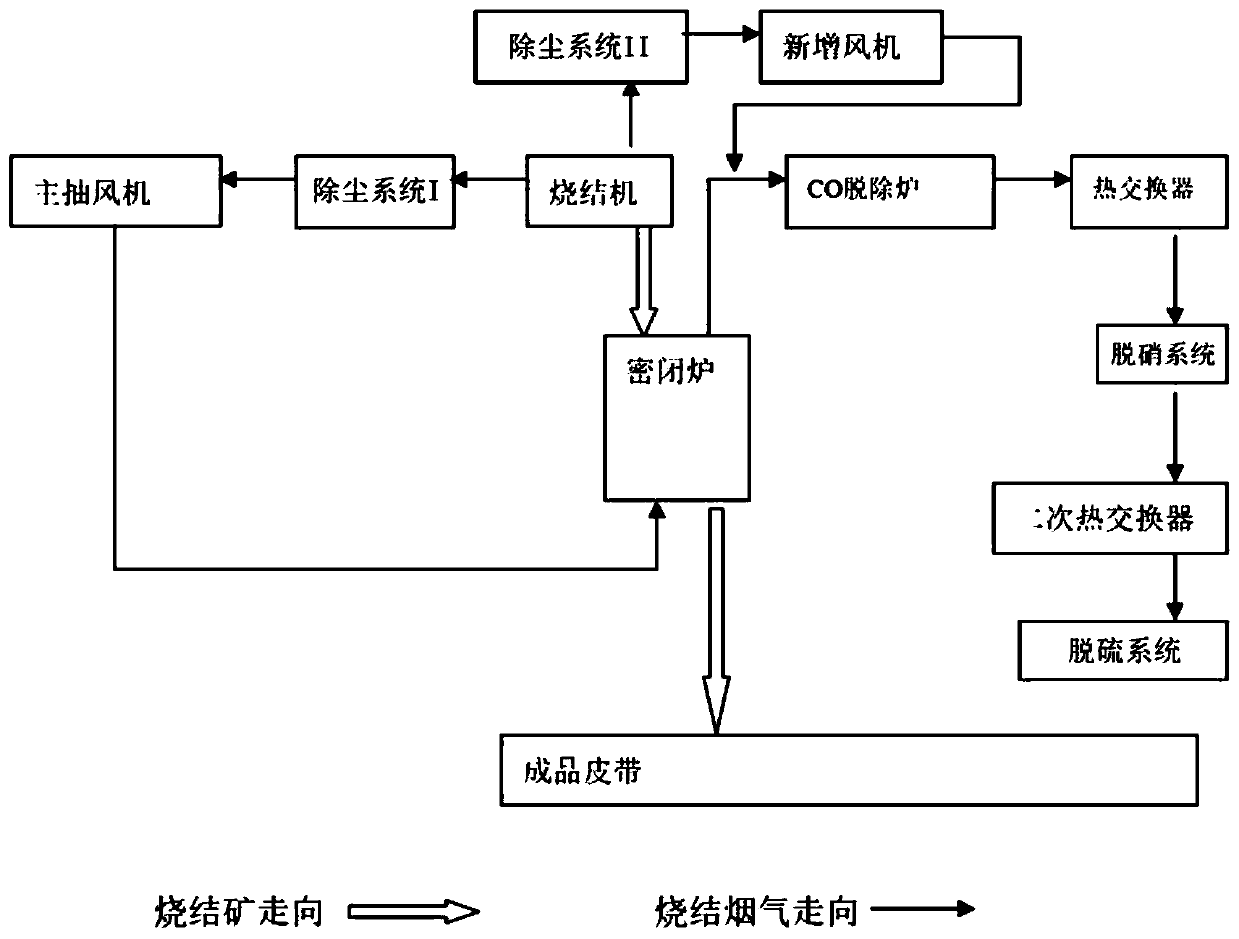

Sinter waste heat and sintering flue gas pollutant cooperative treatment process

InactiveCN108692579AHigh recovery rateSolve the problem that the temperature is low and cannot be recycledWaste heat treatmentParticulatesFlue gas

The invention relates to a sinter waste heat and sintering flue gas pollutant cooperative treatment process. The treatment process comprises the steps that sintering flue gas generated by metallurgy sintering is subjected to dedusting treatment to remove particulate matters to be then subjected to heat exchange treatment with sinter generated by metallurgy sintering, and at least part of CO in thesintering flue gas is oxidized and removed during heat exchange treatment; and the sintering flue gas is subjected to CO desorption treatment, and at least part of CO in the sintering flue gas is oxidized and removed during CO desorption treatment. According to the arrangement conditions of a sintering machine and a gas desulfurization system at present, the sintering flue gas can adopt the technology that SO2 is firstly or lastly desorbed. The cooperative treatment process solves the problems about CO desorption and utilization, and cooperative treatment of sinter waste heat and sintering flue gas pollutant is achieved.

Owner:杨清海

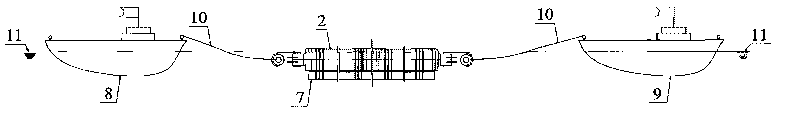

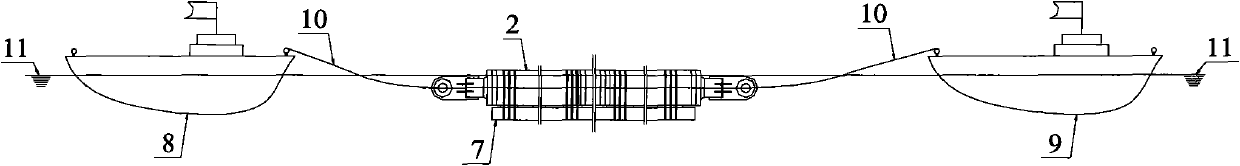

Bound floating pipeline towing pipe method process

InactiveCN101761691ASolution can not be recycledReduce construction costsPipe laying and repairEngineeringSubmarine pipeline

The invention relates to a bound floating pipeline towing pipe method. In the method, a floating pipe is used for replacing a buoy in the prior bound buoy towing pipe method, the specification of the floating pipe comprises a plurality of segments of cylinders, each segment is 50m in length and is an independent sealed bin, a plurality of supporting ribbed plates and longitudinal ribbed plates are welded inside, an air valve and a water valve are arranged for marine load adjustment, every two segments are connected through an inner flange, and a towing head is respectively arranged at both ends of the whole body. The invention has the advantages that the problem of size limitation for a process pipe in the bound buoy towing pipe method is solved, and the requirement for sea conditions is also greatly broadened; meanwhile, the problem that a frock pipe can not be reclaimed in a bunched pipeline towing pipe method is also solved, so that a floating pipe device can be repeatedly utilized, and the construction cost of submarine pipeline laying is further lowered.

Owner:NEPTUNE OFFSHORE ENG DEV

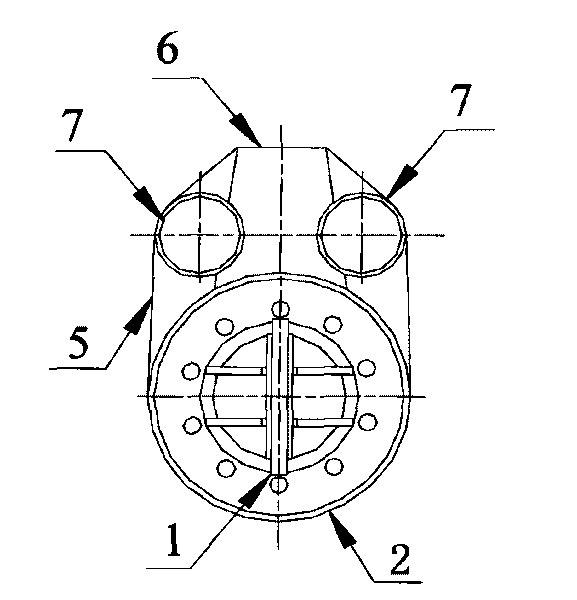

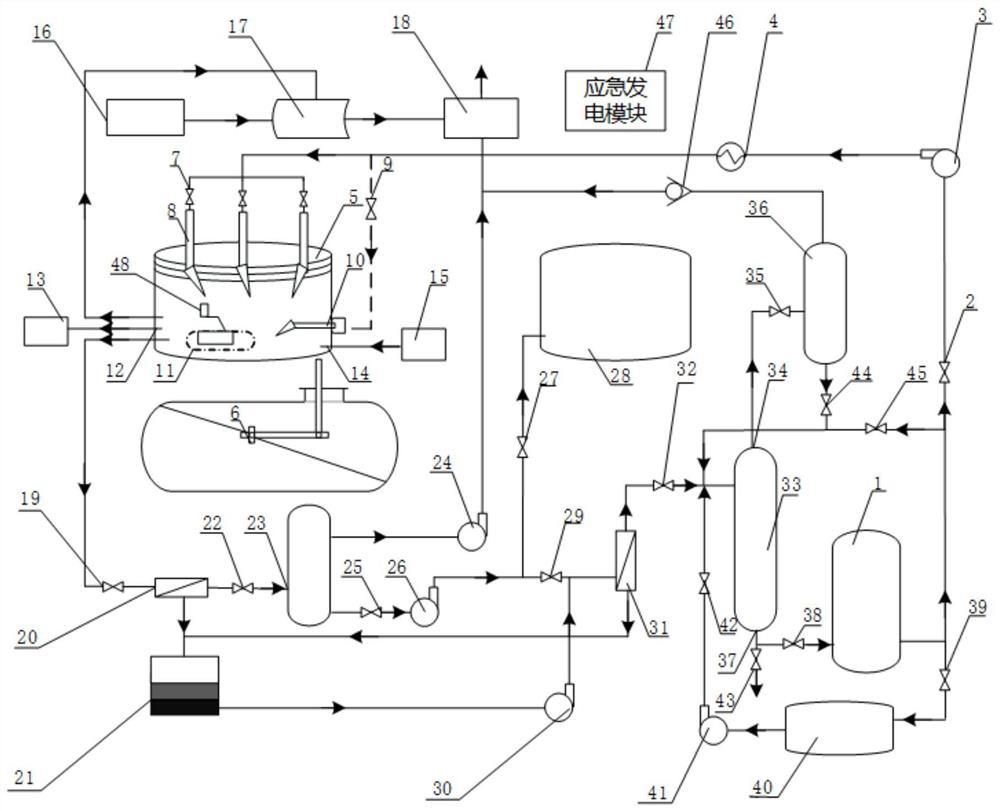

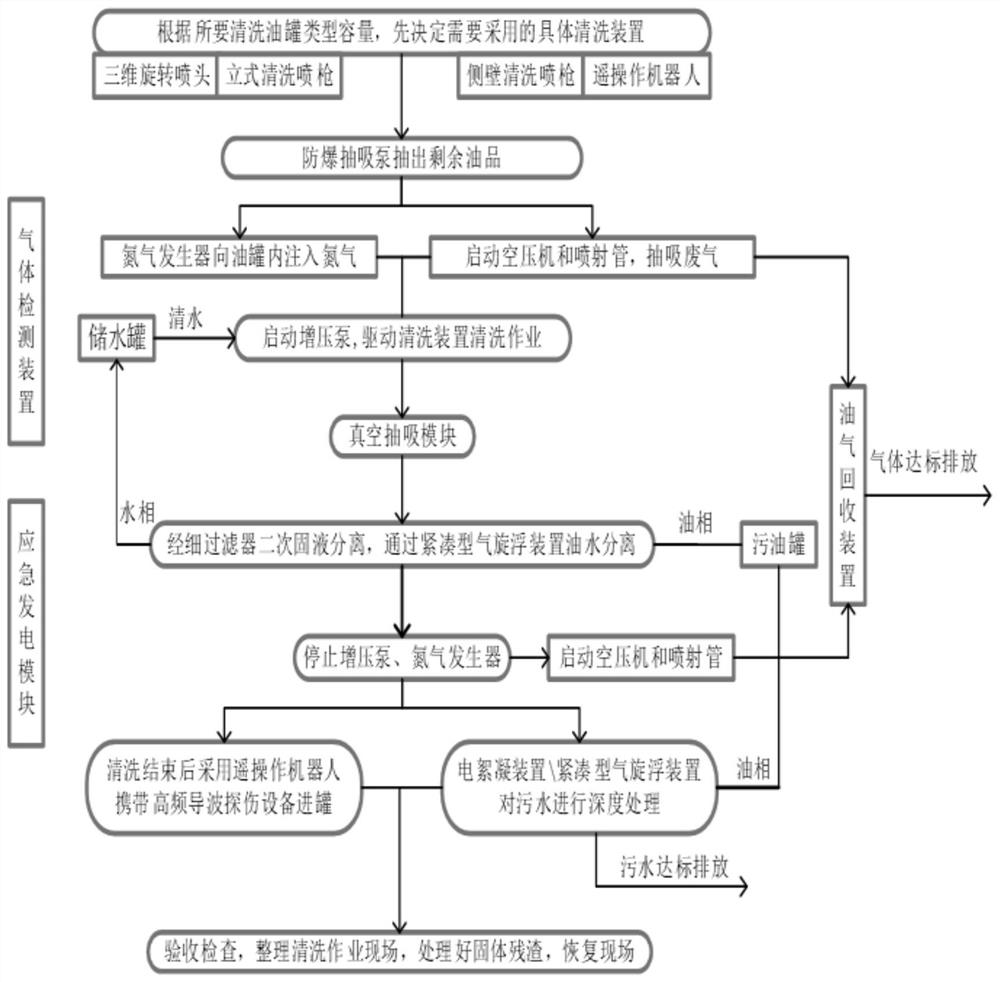

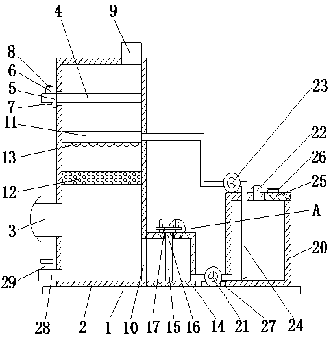

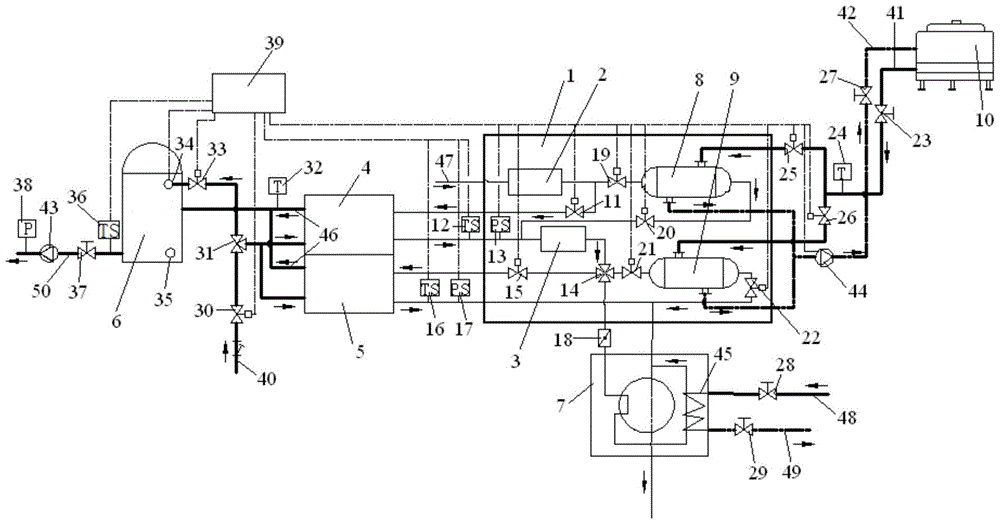

Unmanned rapid cleaning system for airport oil tank

InactiveCN111687155ASolution can not be recycledSolve the fugitive emission of oil and gasFatty/oily/floating substances removal devicesWithdrawing sample devicesWater storage tankAir compressor

The invention discloses an unmanned rapid cleaning system for an airport oil tank. The unmanned rapid cleaning system comprises a cleaning module, a gas detection module, a nitrogen generation module,a vacuum suction module, an oil-water separation and reuse module, a waste water up-to-standard discharge treatment module, an oil-gas recovery treatment module, a nondestructive detection module andan emergency power generation module, wherein the cleaning module comprises a rotary spray head, a cleaning spray gun, a teleoperation robot, a water storage tank, a booster pump, a heater and cleaning equipment, the vacuum suction module comprises a coarse filter, a vacuum pump, a vacuum tank, a solid phase collecting tank, an anti-explosion suction pump and a transfer tank, the oil-gas recoverytreatment module comprises an air compressor, an injection pipe and an oil gas recovery device, and the nondestructive detection module comprises high-frequency guided wave flaw detection equipment and the teleoperation robot. The unmanned rapid cleaning system is safe, efficient, closed in the whole process, labor-saving and time-saving, adopts module combination, well solves the problems that cleaning water cannot be recycled in the operation process, oil gas is discharged unorganized, and waste water does not reach the standard after operation, and guarantees safe operation of jet fuel tanks.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Preparation method of heterogeneous solid catalyst for preparing ammonia by hydrolyzing urea

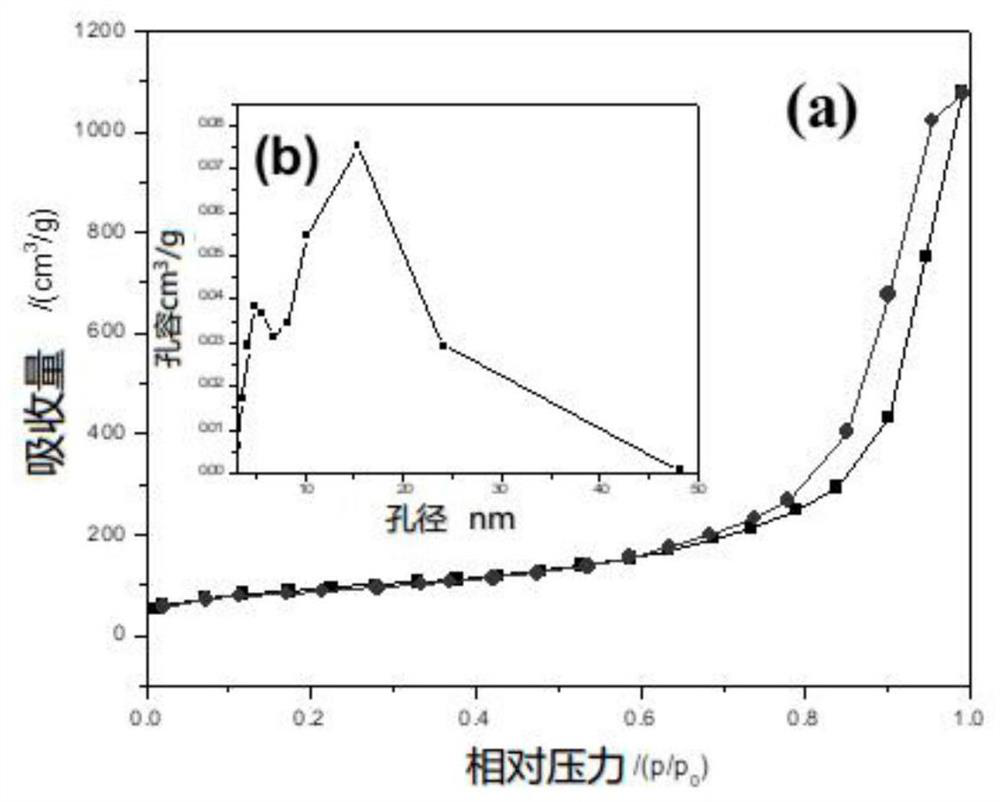

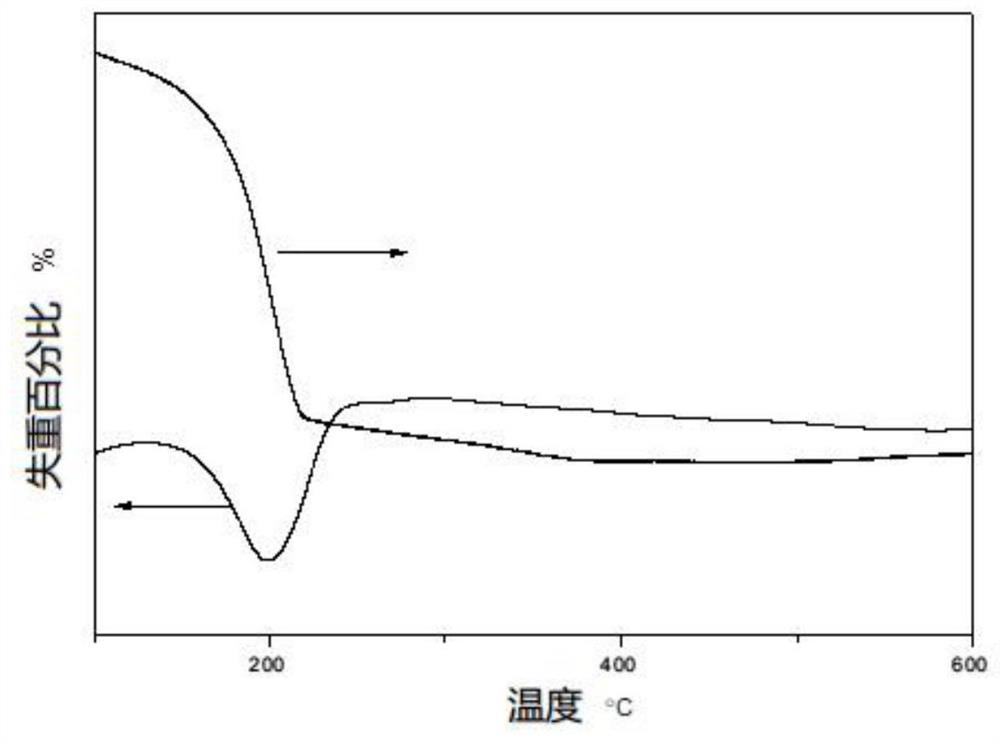

PendingCN112619637AFavorable for catalyzing the hydrolysis reactionLow costMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionPtru catalystAluminium oxides

The invention provides a preparation method of a heterogeneous solid catalyst for preparing ammonia by hydrolyzing urea. The preparation method comprises the following steps: S1, preparing an aluminum oxide precursor; S2, preparing a catalyst carrier; and S3, preparing the catalyst. According to the invention, Al2O3 is used as a carrier, alkaline metal oxide is used as an active component, the heterogeneous solid catalyst is prepared by an impregnation method, after the alkaline oxide active component is loaded on alumina, the catalyst can expose more catalytic active sites, and the catalytic hydrolysis reaction of urea is promoted. The heterogeneous solid catalyst prepared in the invention has the advantages of stable physical and chemical properties, good hydrothermal stability, difficult loss of active components after long-term use, re-usability and low preparation cost; meanwhile, the catalyst can reduce the operation temperature and pressure, reduce the steam consumption and reduce the operation cost of the system.

Owner:CHINA HUADIAN ENG +1

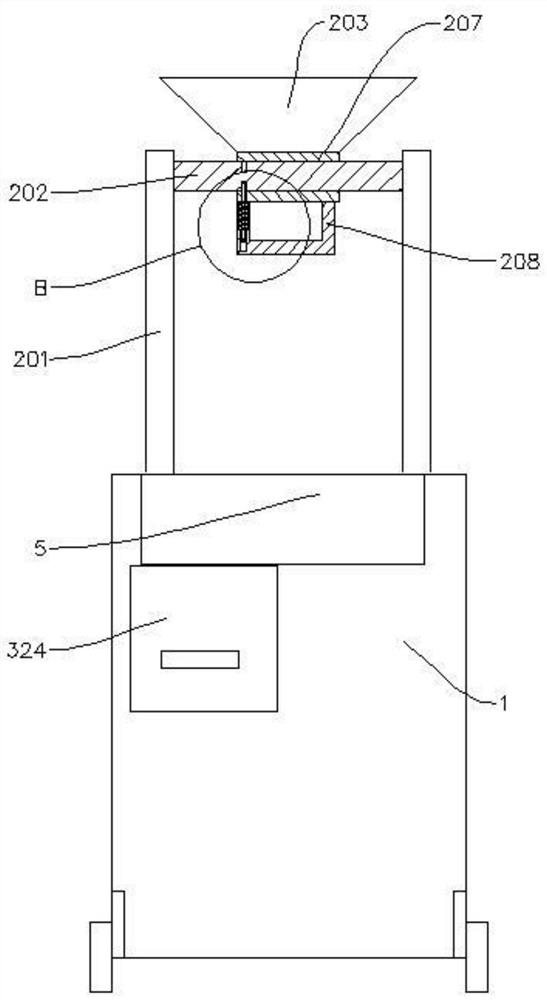

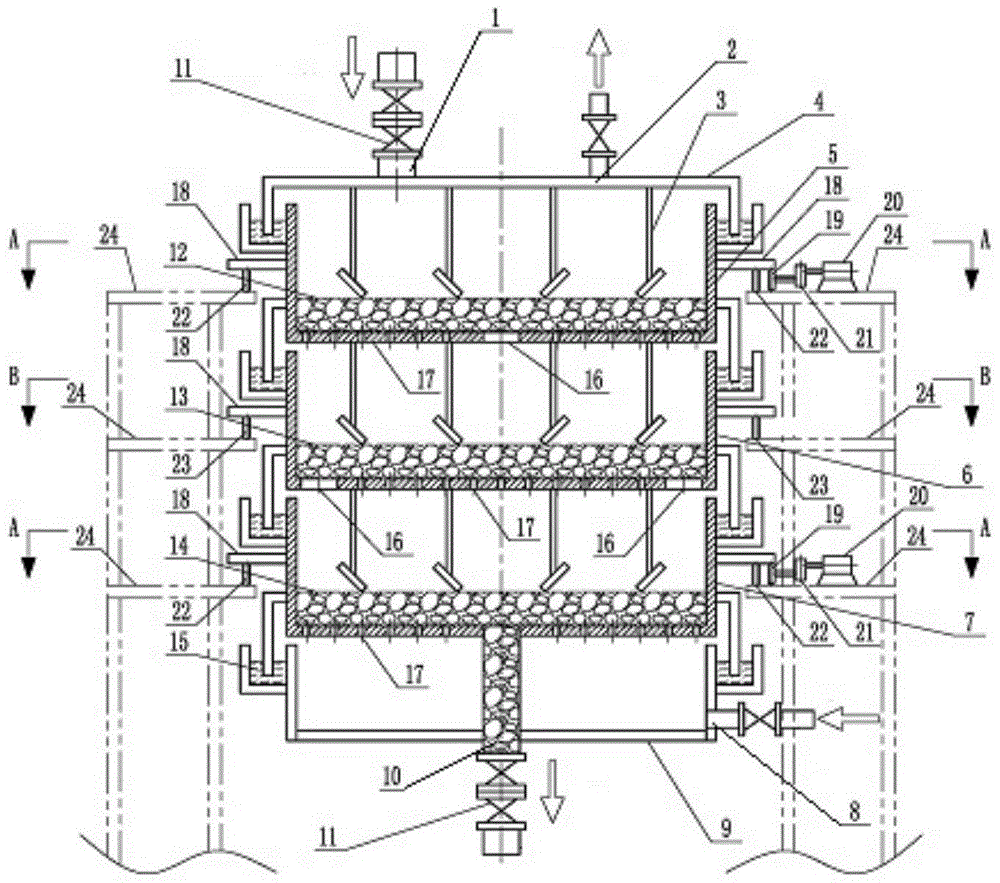

Waste gas treatment device capable of cyclically utilizing water resources for chemical engineering production

InactiveCN109012127AAvoid wastingSolution can not be recycledDispersed particle filtrationStationary filtering element filtersWater resourcesEngineering production

The invention discloses a waste gas treatment device capable of cyclically utilizing water resources for chemical engineering production. The waste gas treatment device comprises a bottom plate, wherein a box body is fixedly connected to the left side of the top of the bottom plate; the bottom of the left side of the box body is communicated with an air inlet pipe; a dustproof net is arranged on the top of the left side of the box body in a penetrated way; a sealing pad is sleeved on the surface of the dustproof net and is positioned outside the box body; the right side of the sealing pad is in contact with the left side of the box body. Through the matching of a medicine spraying plate, a net plate, an atomization spray head, a filtering box, a filtering plate, a rubber pad, a cover plate, a threaded rod, a second screw nut, a medicine liquid box, a first water pump, a water inlet pipe, a second water pump and a water suction pipe, the goal of cyclically using the water resources of the waste gas treatment device for chemical engineering production is achieved, so that the water resources can be cyclically used; the waste resource waste is effectively avoided; the compliance withthe trends of energy saving and environment protection is realized; the problem that the water resources of the waste gas treatment device for chemical engineering production cannot be cyclically utilized is solved.

Owner:陈根章

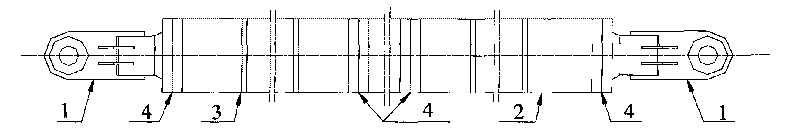

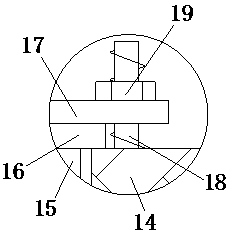

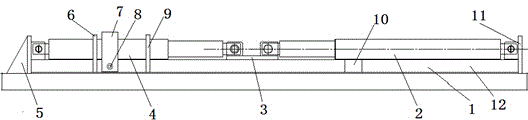

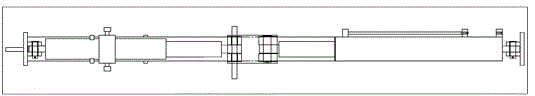

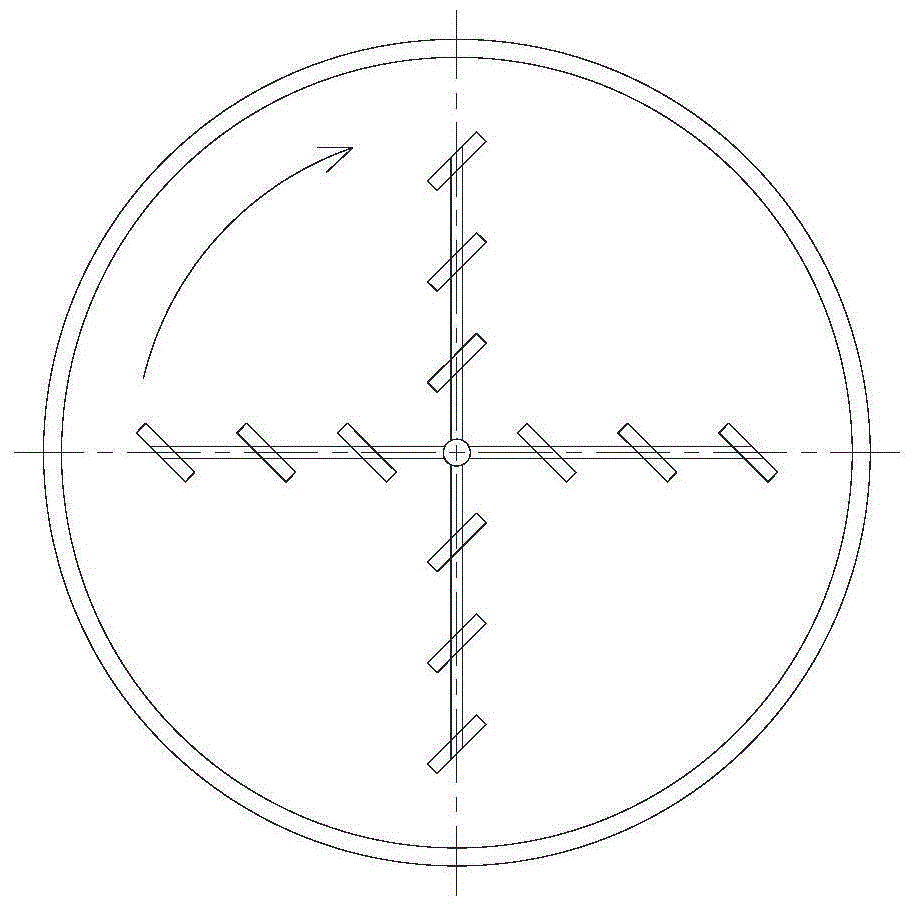

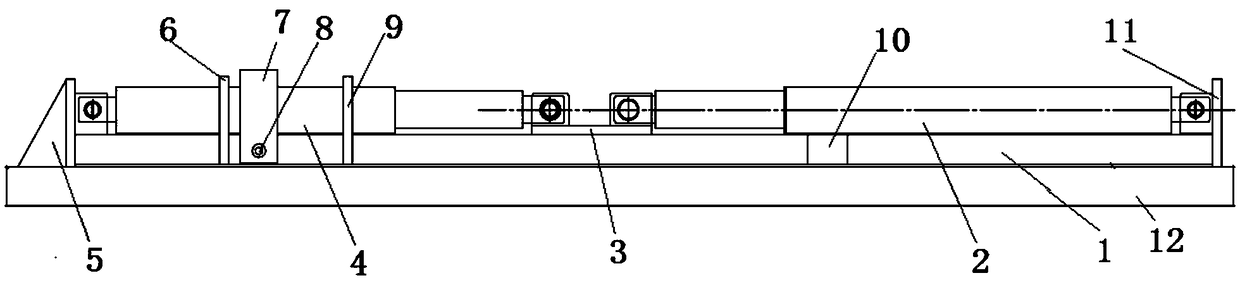

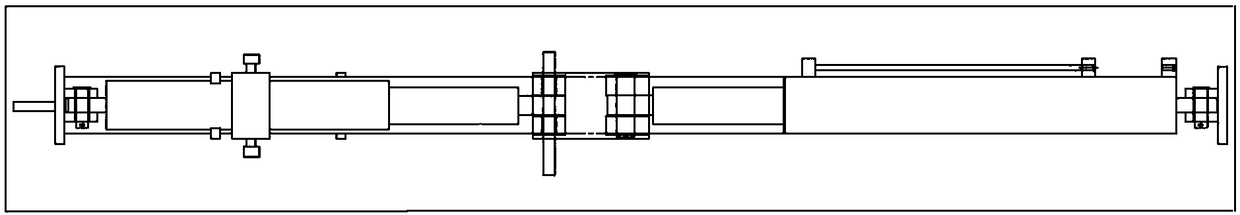

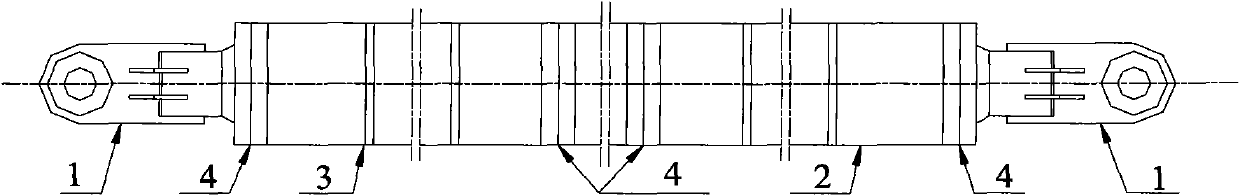

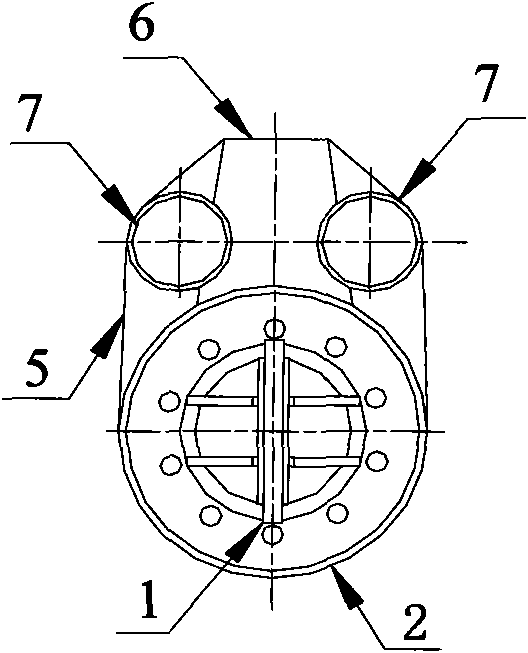

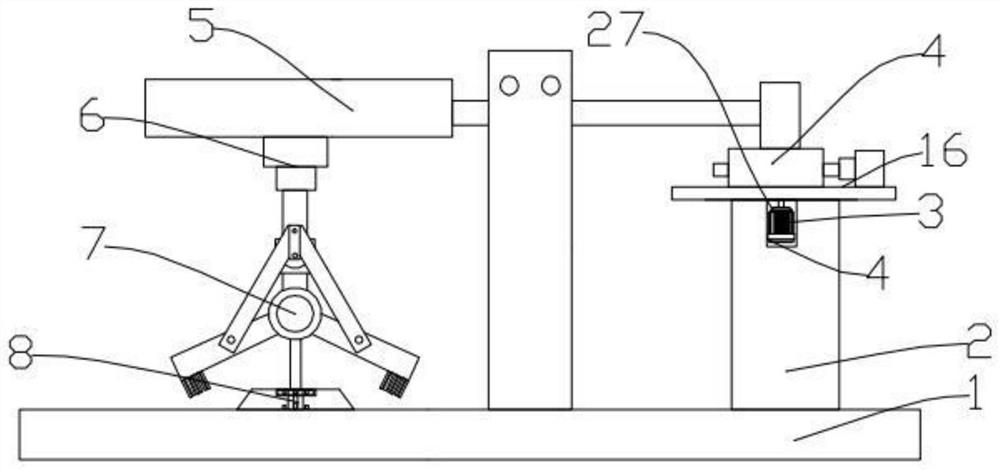

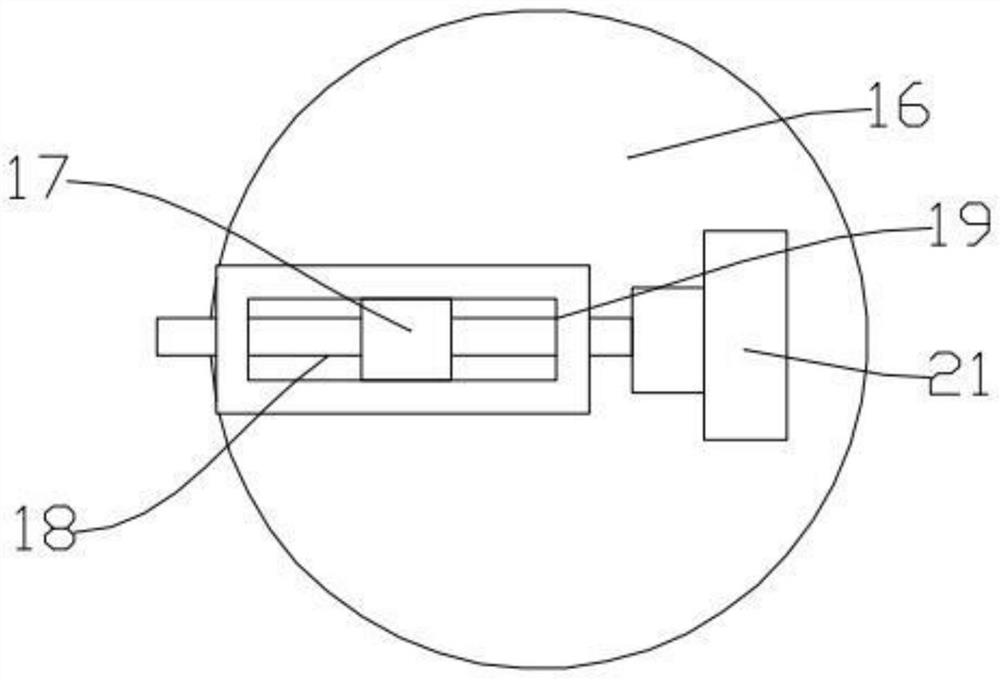

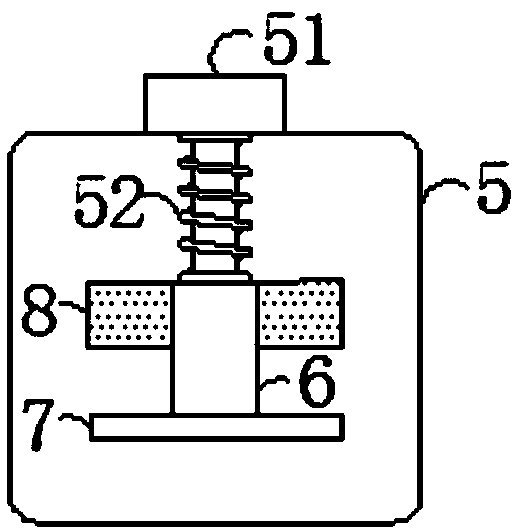

Device for disassembling oil cylinder

ActiveCN105750879AAchieve disassemblyAvoid easy disassemblyMetal working apparatusEconomic benefitsCylinder block

The invention discloses a device for disassembling an oil cylinder. The device for disassembling the oil cylinder comprises a telescopic oil cylinder, wherein the tail end of a cylinder body of telescopic oil cylinder is fixedly connected onto one end of a base through a fixing bracket I; the free end of a cylinder lever of the telescopic oil cylinder is provided with a sliding block; the sliding block is provided with a pin hole used for connecting a cylinder lever of a to-be-disassembled oil cylinder; the base is of a strip groove-shaped structure, and is fixedly connected onto a fixing platform; the other end of the base is provided with a fixing bracket II used for connecting the to-be-disassembled oil cylinder. According to the device for disassembling the oil cylinder, an existing telescopic oil cylinder is adopted to be connected with the to-be-disassembled oil cylinder through the sliding block, the other end of the to-be-disassembled oil cylinder is connected onto the fixing bracket II, and the telescopic oil cylinder is started, so that the disassembly of the to-be-disassembled oil cylinder can be realized; the problems existing in the prior art that waste and old oil cylinders are difficult to disassemble and cannot be recycled are effectively solved; the recycling of components and parts on the waste and old oil cylinders is greatly improved; the procurement cost of equipment is decreased; the economic benefit is improved; moreover, the device for disassembling the oil cylinder has the characteristics of being simple in structure, convenient for assembly and disassembly and low in cost.

Owner:GUIZHOU PANJIANG MINING MACHINERY

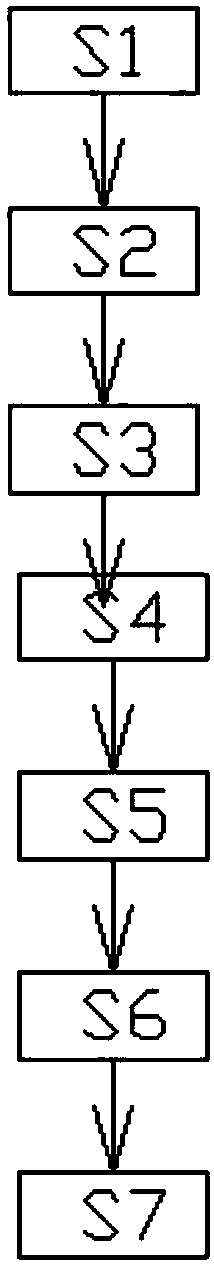

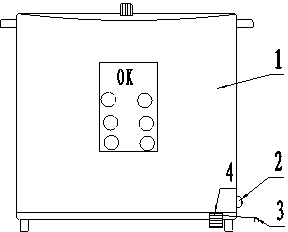

Self-help shopping system and method

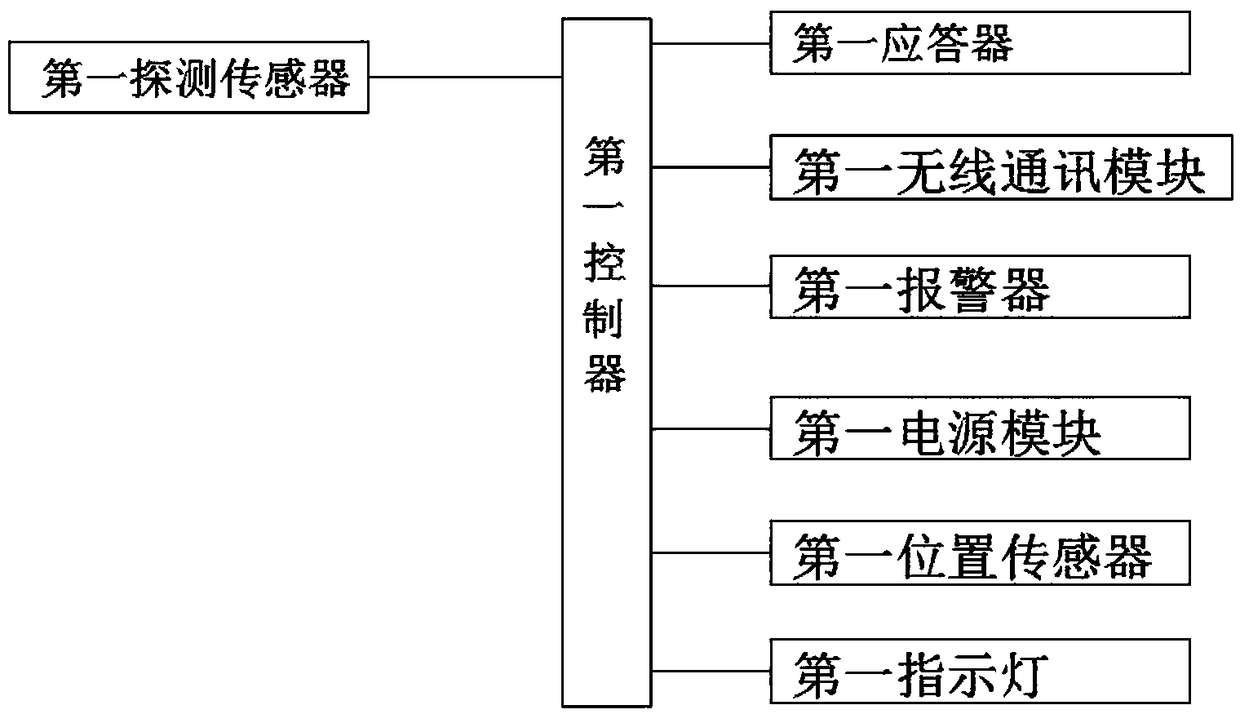

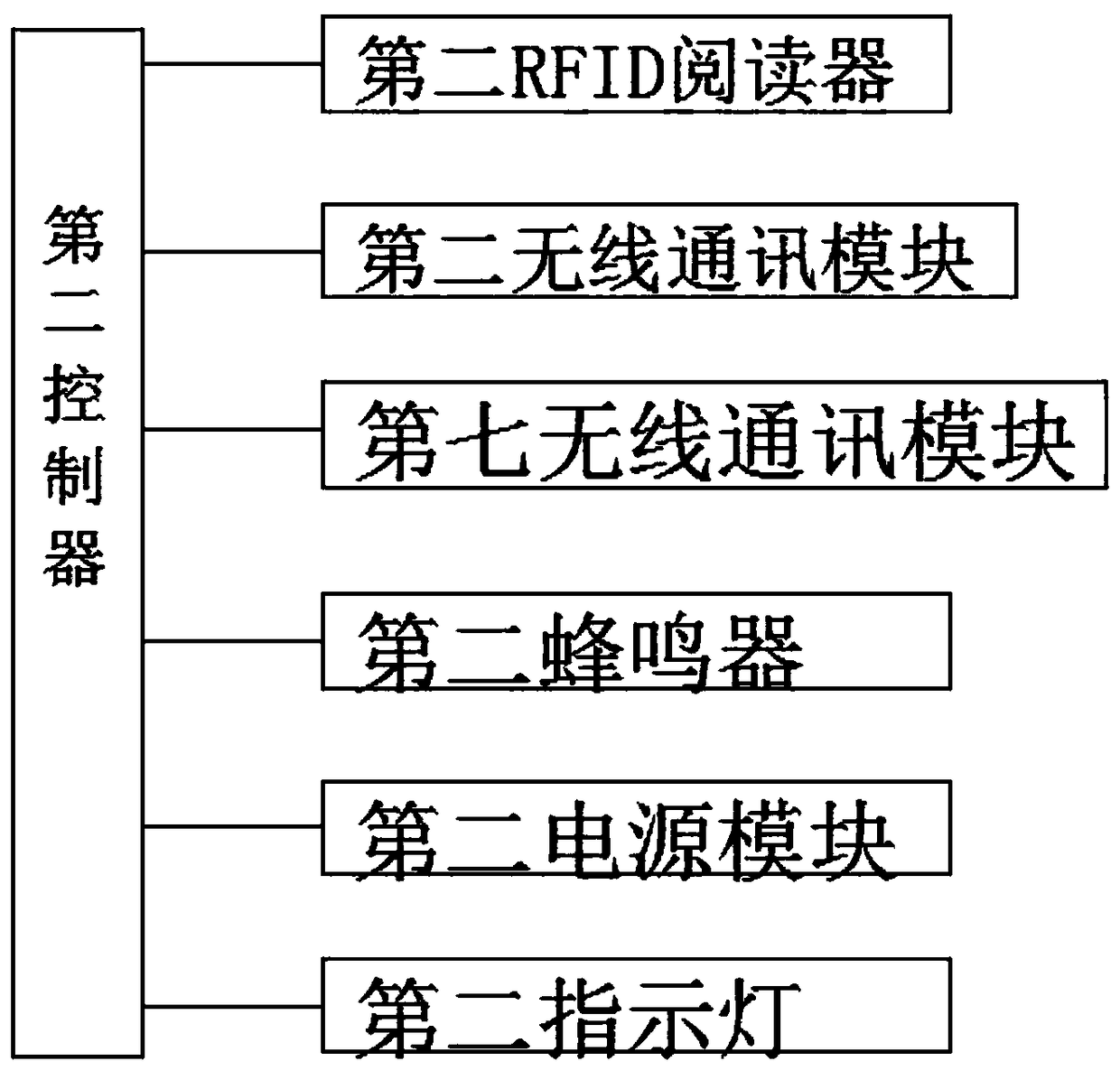

PendingCN108665260ASolution can not be recycledReduce labeling costsCoin-freed apparatus detailsCo-operative working arrangementsPaymentComputer science

The invention discloses a self-help shopping system and a method. The system comprises an intelligent label, a regional communicator, a host, an intelligent settlement system, an intelligent label unlocking device and an access control. The method comprises a main program, wherein the main program comprises the following steps of: S1, changing the static state of the intelligent label; S2, sendinginformation to the regional communicator or to the host by the intelligent label; S3, forming a shopping list by the intelligent settlement system when the intelligent label is at the intelligent settlement system; S4, judging whether payment is completed or not by the intelligent settlement system, and starting the intelligent label unlocking device if the payment is completed successfully; S5,unlocking the intelligent label by the intelligent label unlocking device; S6, separating the intelligent label from the corresponding commodity. According to the invention, the inconvenience factorsbrought by queuing are avoided, the cost is greatly reduced, the commodity security is improved, the intelligent degree is improved, the labor quantity is reduced, the shopping experience is improved,and the compatibility is strong.

Owner:魏志光

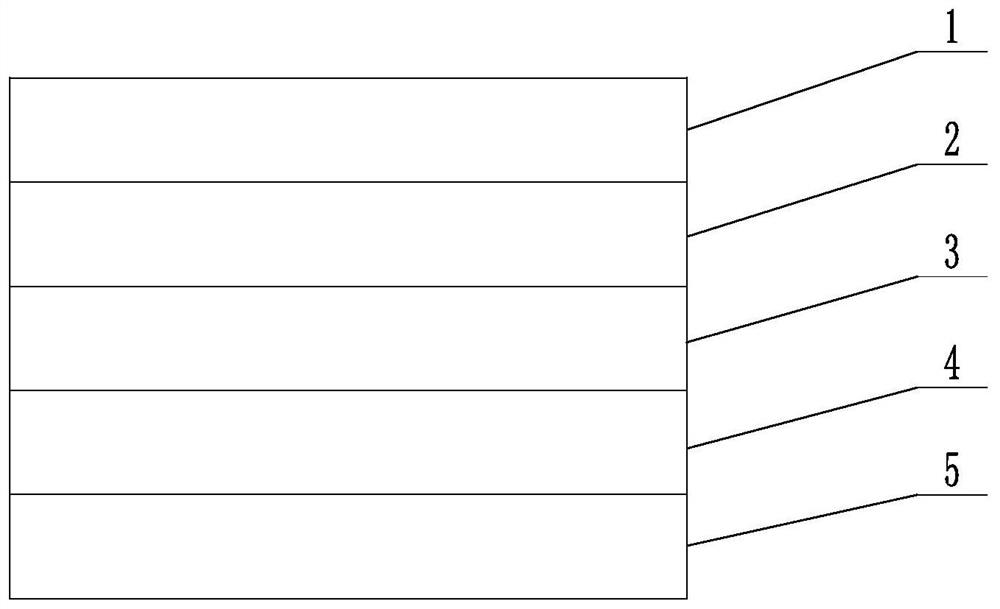

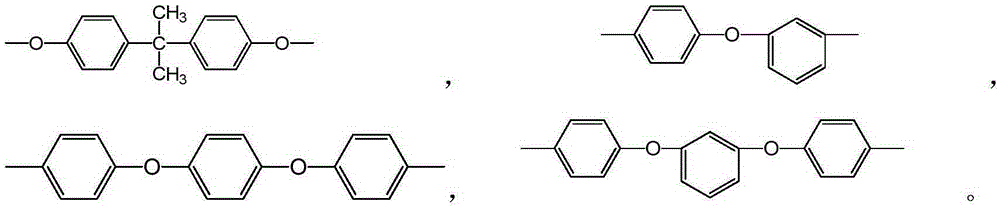

Image comparison physical foaming gasket and preparation method thereof

ActiveCN113306255AAvoid being used by copy transfersHigh anti-counterfeiting levelStampsPackage recyclingProcess engineeringPolypropylene

The invention relates to the technical field of anti-counterfeiting products, in particular to an image comparison physical foaming gasket and a preparation method thereof. The image comparison physical foaming gasket comprises a first lamination layer, a foaming layer, a second lamination layer, a printing layer and a BOPP (biaxially-oriented polypropylene) film layer which are sequentially arranged from top to bottom, wherein the printing layer information comprises a two-dimensional code and randomly distributed particle points, and a corresponding relation exists between the two-dimensional code and the randomly distributed particle points. According to the invention, the two-dimensional code is combined with the random particles, the anti-counterfeiting feature of each gasket is unique, the imitation difficulty is high, the identification is simple, and the anti-counterfeiting effect is good. According to the preparation method, a film spraying mode is adopted for production, glue is not adopted, the product is healthier and safer, waste materials in the production process can be recycled for secondary utilization, and energy conservation and environmental protection are achieved.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

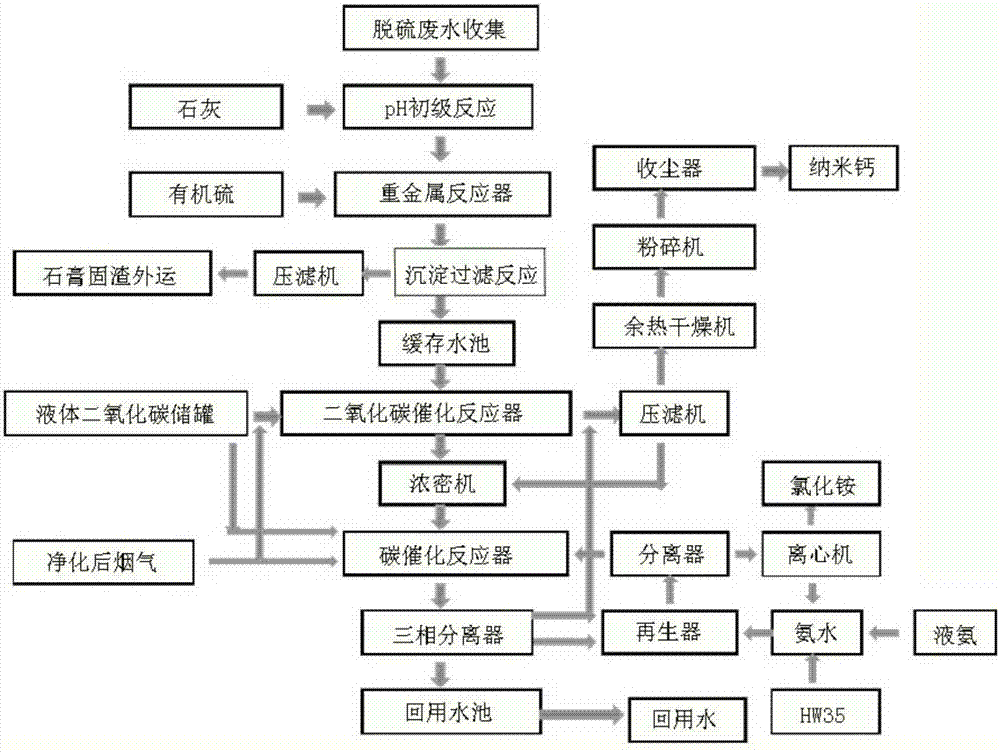

Desulfurization wastewater zero discharging process with carbon dioxide method

InactiveCN107459054ASolution can not be recycledSolve the high concentration of chloride ionsCalcium/strontium/barium carbonatesNanotechnologyWastewaterFluoride

The invention provides a desulfurization wastewater zero discharging process with a carbon dioxide method. The process comprises the following steps: collecting desulfurization wastewater; performing a pH primary reaction; adjusting the pH value to an alkaline condition by adding lime, so as to precipitate magnesium ions, fluoride ions, sulfate ions and heavy metal ions; finally, enabling chlorine ions and ammonia gas to react through an organic substance catalytic reaction, so as to obtain an ammonium chloride product. According to the process, the problem that the wastewater cannot be recycled as the desulfurization wastewater is high in the content of chlorine ions is solved.

Owner:WUHAN HAOPUNENG ENVIRONMENTAL PROTECTION EQUIP ENG

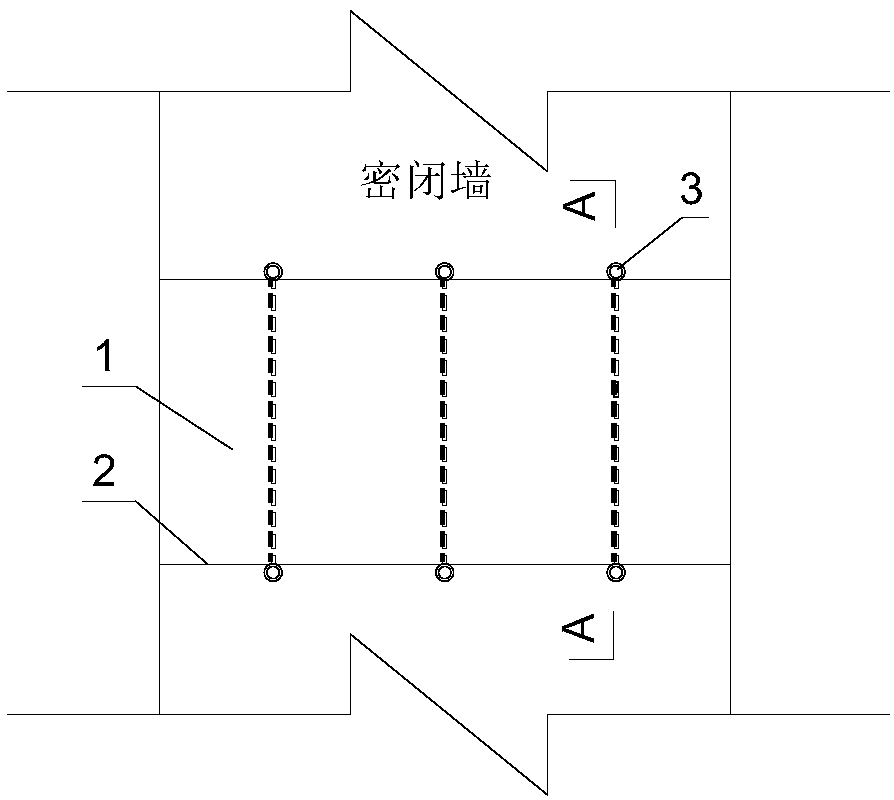

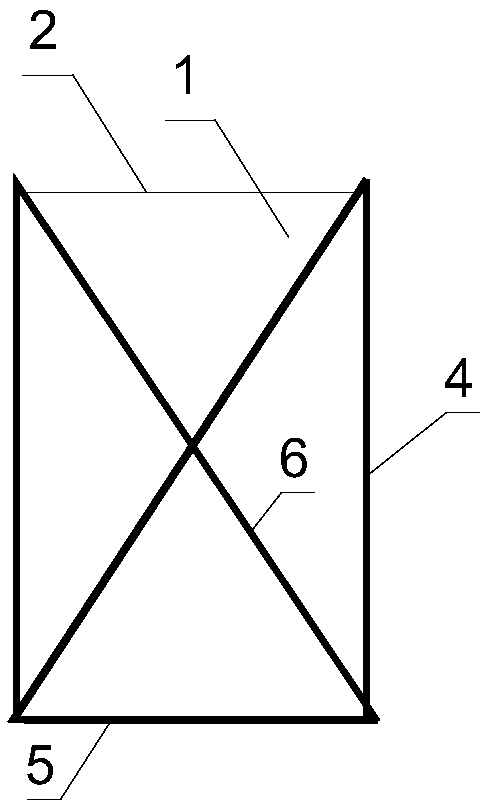

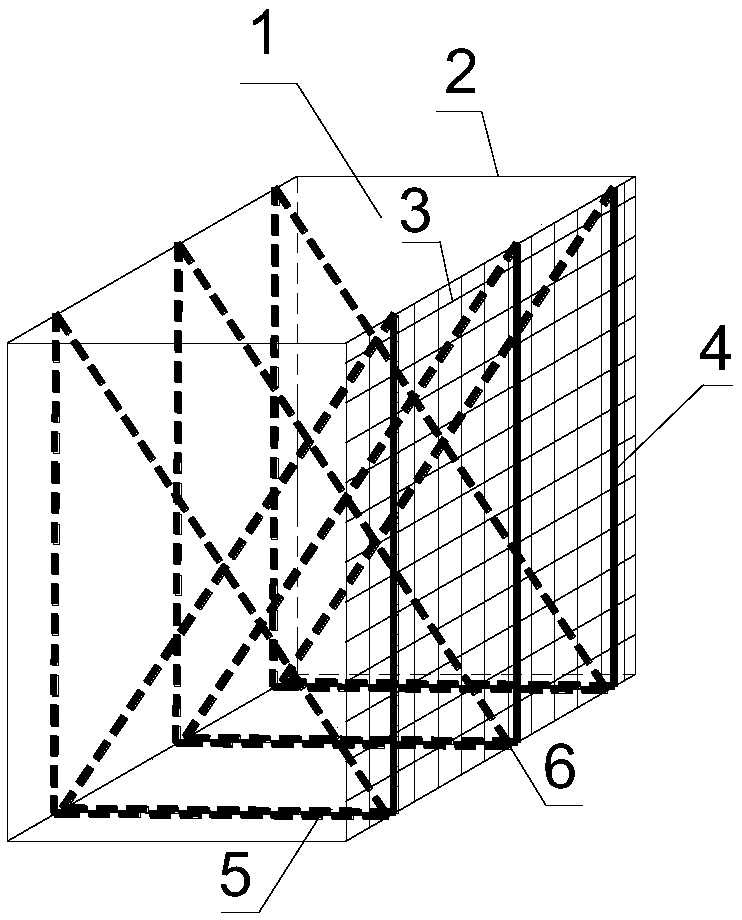

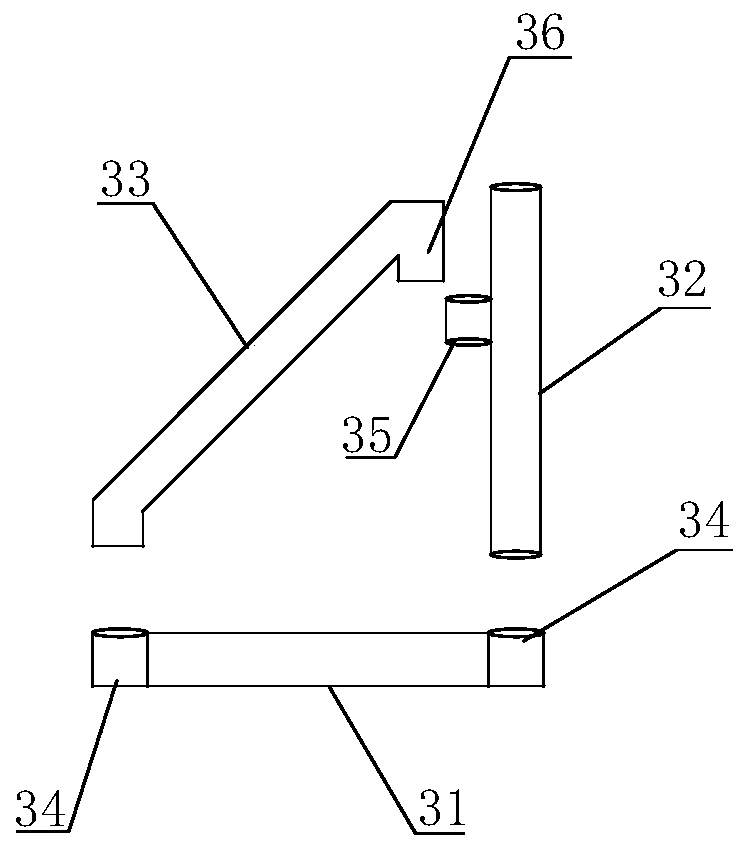

Fast die erecting device for closed wall and construction method

The invention discloses a fast die erecting device for a closed wall. A closed wall body is included. The fast die erecting device is composed of a vertical rod, a horizontal rod and an oblique rod, wherein the vertical rod, the horizontal rod and the oblique rod are connected with each other in a hinge manner, the vertical rod is vertically placed on a bottom plate of the closed wall body, the horizontal rod is fixed on the bottom plate of the closed wall body, the oblique rod penetrates through a flexible closed bag and is connected with the horizontal rod and the vertical rod to form a tripod structure, and a steel mesh is placed between the vertical rod and the flexible closed bag. The construction method comprises steps that S1, the vertical rod, the horizontal rod and the oblique rodfor steel pipe processing are respectively prepared, the vertical rod, the horizontal rod and the oblique rod are hinged through pins, and the air-cylinder coated cloth is processed into the flexibleclosed bag. The fast die erecting device is advantaged in that fast die erecting in a closed state is realized, a problem that a side vertical mold individual body can not be recycled in the closed wall is solved, enclosure cost is reduced, and roadway enclosure efficiency is improved.

Owner:徐州和盛矿业科技有限公司

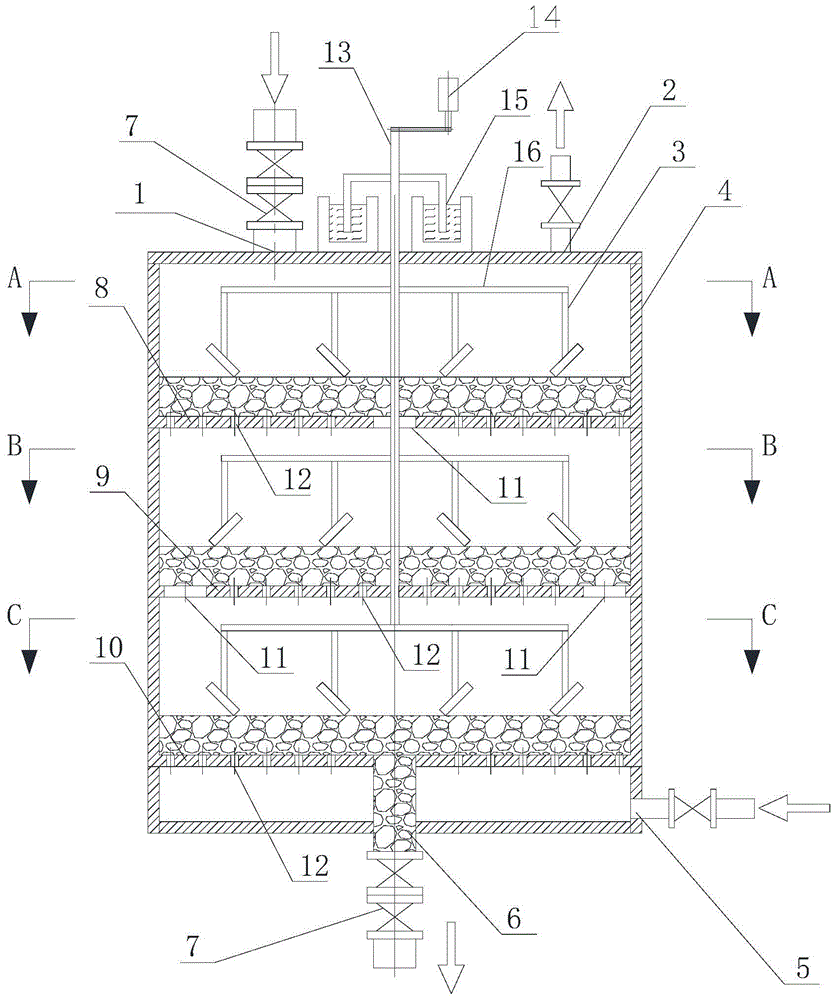

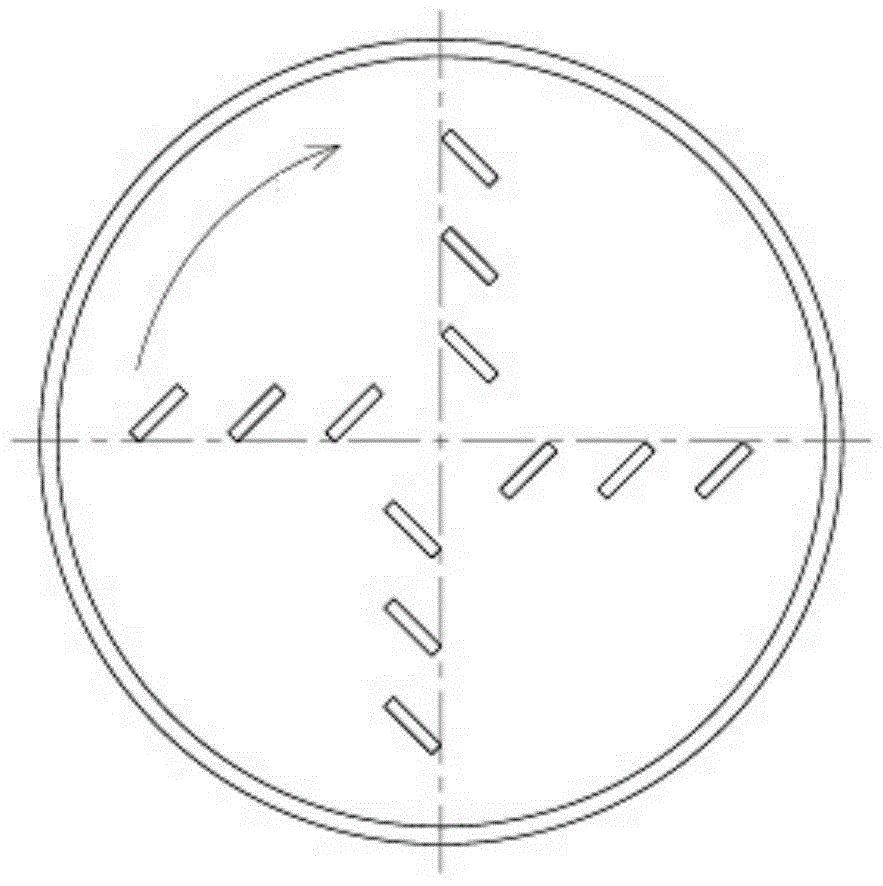

Air-cooling device and method for air-permeable materials

ActiveCN104894323BIncrease the itineraryFully contactedFluidised-bed furnacesEngineeringSmall footprint

The invention relates to the technical field of cooling of breathable materials, and provides an air cooling device and method of the breathable materials. The air cooling device of the breathable material is characterized in that a plurality of layers of material falling plates are arranged, and material falling holes in adjacent material falling plates are in staggered distribution along the projection in the vertical direction, so that the falling height of the materials every time is the height of each material falling chamber, and the problems that the height fall of the materials is large, and the pulverization rate is high are solved. On the basis of the device and method, rakes which move relative to the materials are arranged in the material falling chambers, and the materials are stirred by the rakes to do gathering or scattering motion, so that the strokes of the materials under the same height condition are longer; the materials are in full contact with cooling gas, the cooling time is longer, and therefore the heat exchange efficiency is improved. In addition, the device is vertically arranged, and therefore the occupied area is small.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

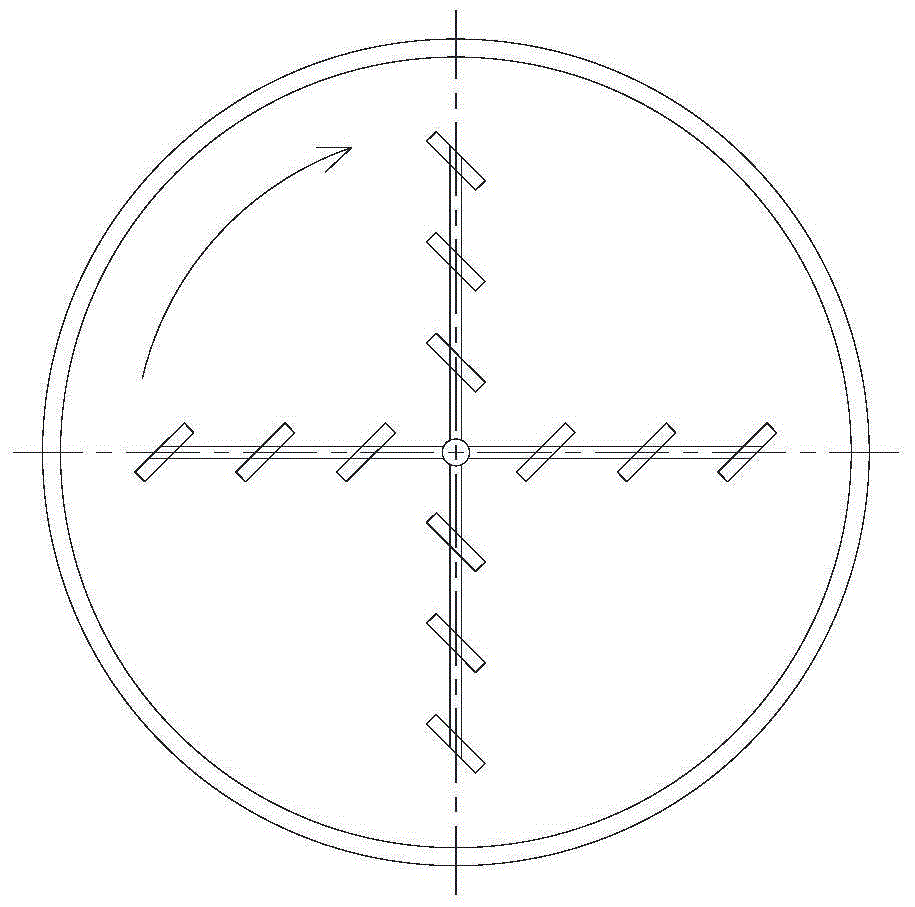

Oil cylinder removal device

ActiveCN105750879BAchieve disassemblyAvoid easy disassemblyMetal working apparatusEconomic benefitsPetroleum engineering

The invention discloses a device for disassembling an oil cylinder. The device for disassembling the oil cylinder comprises a telescopic oil cylinder, wherein the tail end of a cylinder body of telescopic oil cylinder is fixedly connected onto one end of a base through a fixing bracket I; the free end of a cylinder lever of the telescopic oil cylinder is provided with a sliding block; the sliding block is provided with a pin hole used for connecting a cylinder lever of a to-be-disassembled oil cylinder; the base is of a strip groove-shaped structure, and is fixedly connected onto a fixing platform; the other end of the base is provided with a fixing bracket II used for connecting the to-be-disassembled oil cylinder. According to the device for disassembling the oil cylinder, an existing telescopic oil cylinder is adopted to be connected with the to-be-disassembled oil cylinder through the sliding block, the other end of the to-be-disassembled oil cylinder is connected onto the fixing bracket II, and the telescopic oil cylinder is started, so that the disassembly of the to-be-disassembled oil cylinder can be realized; the problems existing in the prior art that waste and old oil cylinders are difficult to disassemble and cannot be recycled are effectively solved; the recycling of components and parts on the waste and old oil cylinders is greatly improved; the procurement cost of equipment is decreased; the economic benefit is improved; moreover, the device for disassembling the oil cylinder has the characteristics of being simple in structure, convenient for assembly and disassembly and low in cost.

Owner:GUIZHOU PANJIANG MINING MACHINERY

A kind of composite core and preparation method thereof

ActiveCN106611628BAvoid the risk of obsolescenceRealize recyclingInsulated cablesCable/conductor manufactureFiberYarn

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

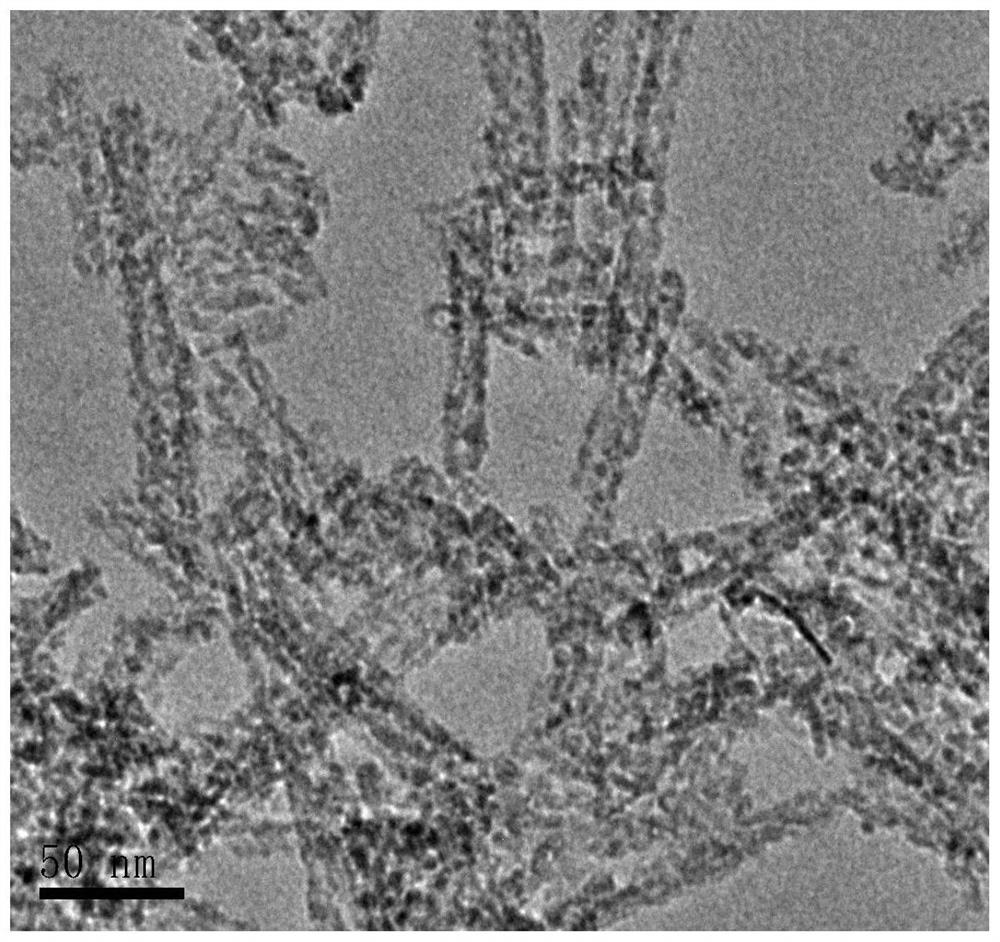

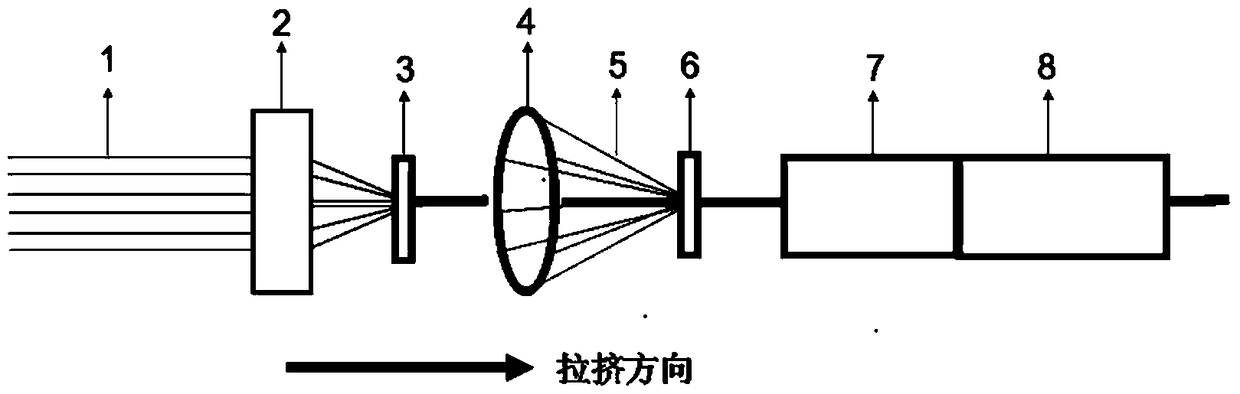

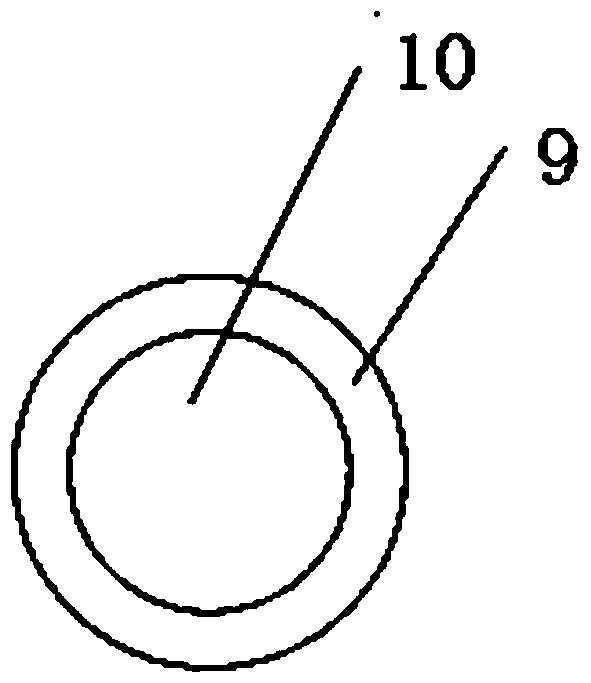

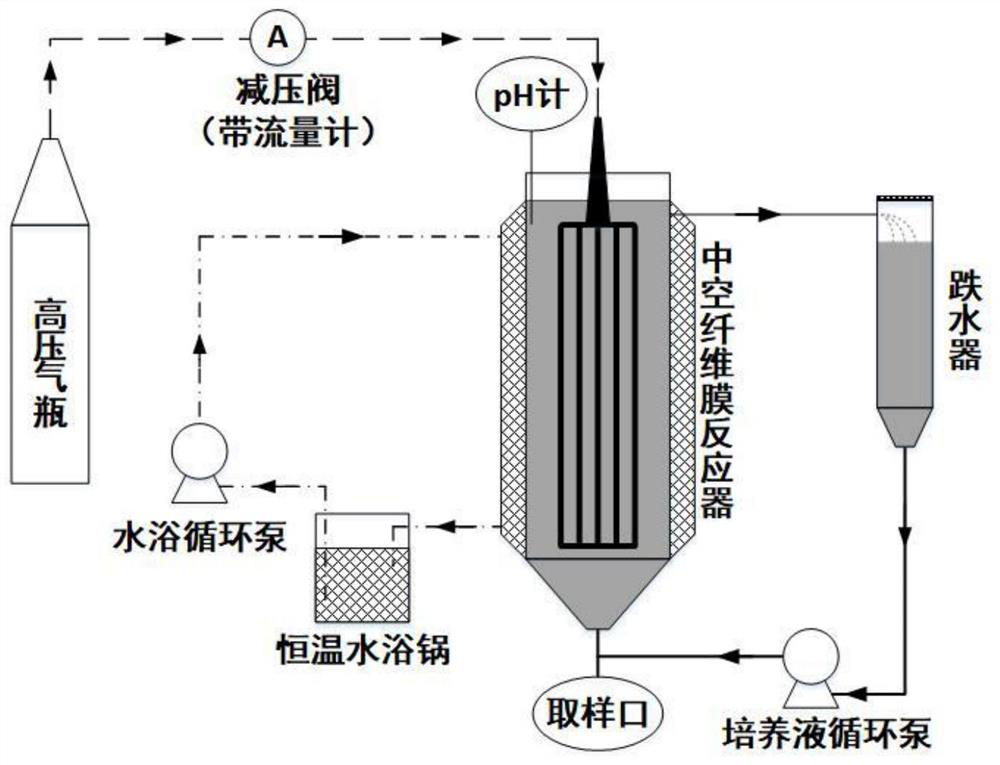

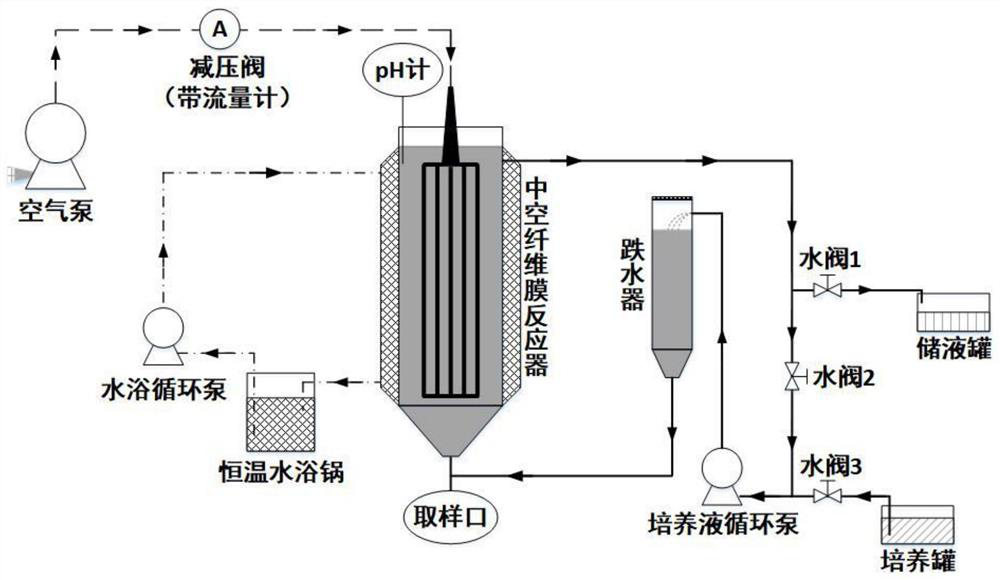

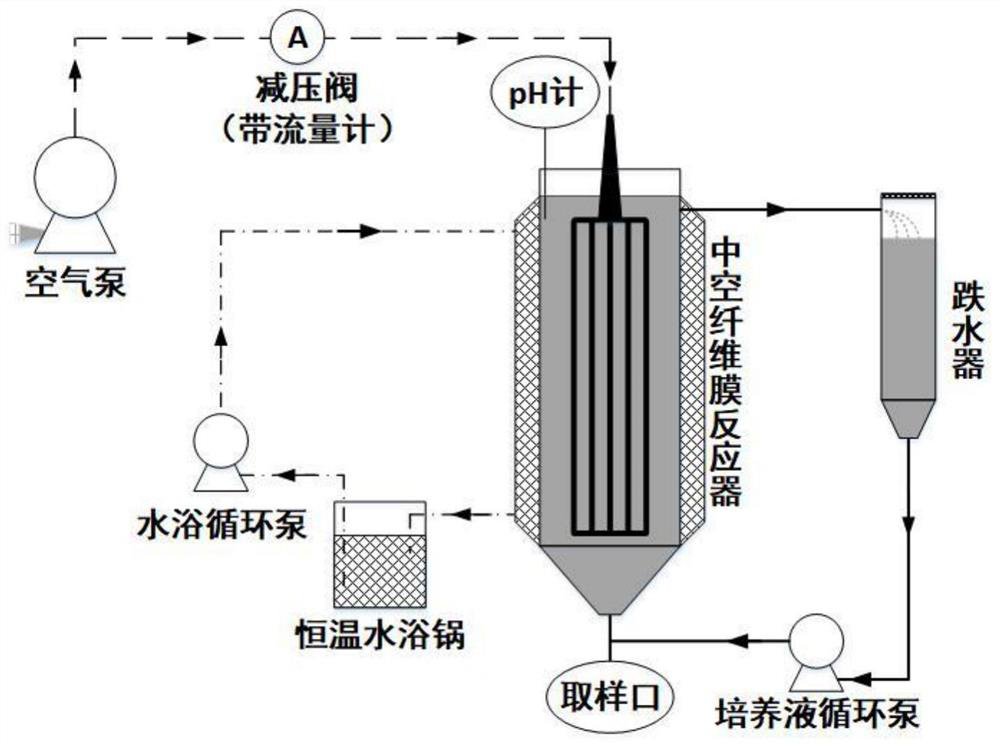

A method for enriching Thiobacillus ferrooxidans with a hollow fiber membrane to form a biofilm, a hollow fiber membrane reactor and its application

ActiveCN110117564BReduced operating requirementsReduce management costsBioreactor/fermenter combinationsBiological substance pretreatmentsThiobacillus ferrooxidansIron sulfate

The invention discloses a method for forming a biological membrane by enriching thiobacillus ferrooxidans by using a hollow fiber membrane, a hollow fiber membrane reactor and application. The methodincludes the steps that a reaction system with the hollow fiber membrane reactor as a core is built, a culture medium and an inoculation body are added, and thiobacillus ferrooxidans enrichment culture is carried out to form the biological membrane; mixed gas containing hydrogen is supplied to the surface of the membrane by the hollow fiber membrane reactor through bubble-free gas output; the temperature of the hollow fiber membrane reactor is stabilized at 25-35 DEG C through water bath heating; after several days of operation, a culture solution is discharged through a sampling port, and thehollow fiber membrane reactor with the membrane surface enriched with the thiobacillus ferrooxidans biological membrane is obtained; the hollow fiber membrane reactor enriched with the biological membrane can be used for generating an iron sulfate solution and schwertmannite. The method realizes separation of thiobacillus ferrooxidans culture and utilization, can achieve culture / utilization circulation, and solves the problem that the culture solution cannot be repeatedly used.

Owner:SOUTHWEAT UNIV OF SCI & TECH

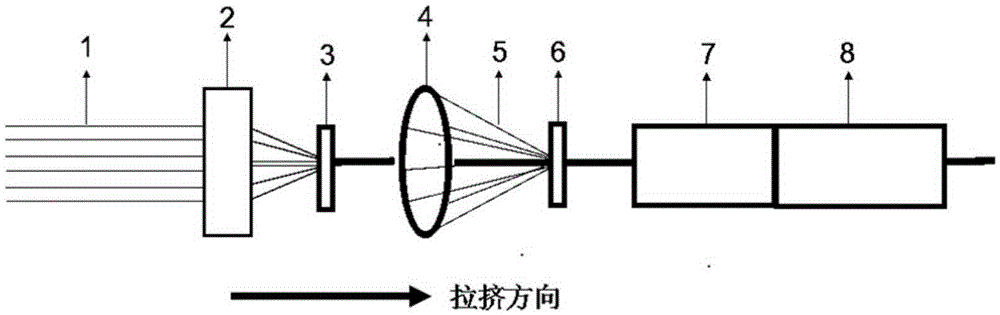

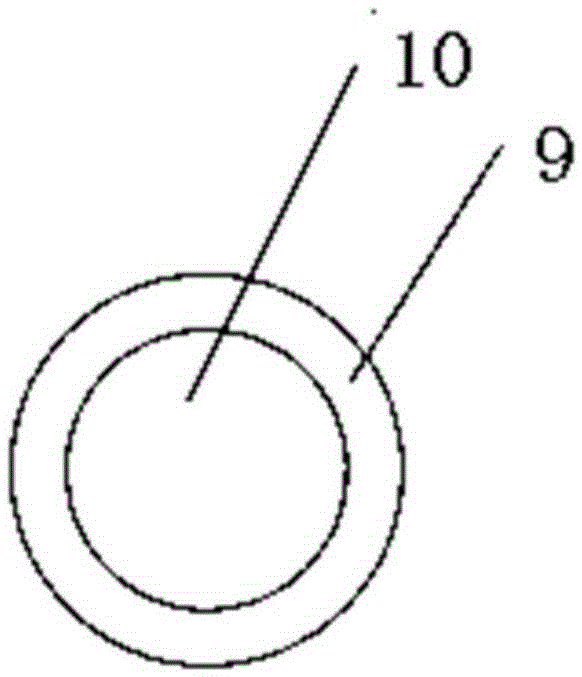

Composite core and preparation method thereof

ActiveCN106611628AGood effectAvoid the risk of obsolescenceInsulated cablesCable/conductor manufactureYarnFiber

The invention provides a composite core and a preparation method thereof. The mixed yarn of thermoplastic polymer nanofibers, carbon fibers and glass fibers is used as a raw material. The preparation process comprises the steps that 1) carbon fibers and thermoplastic polymer nanofiber mixed yarn are collected into a carbon fiber round bar body through a buncher; and 2) glass fibers and thermoplastic polymer nanofiber mixed yarn wrap the carbon fiber round bar body to form a profile, and the profile is cooled and shaped to form a finished product. According to the composite core and the preparation method thereof, the problems of common composite core raw material recovery, irreversible damage and the like are creatively solved; and the composite core has the advantages of high tensile and bending performance and stable high temperature operation.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Bound floating pipeline towing pipe method process

InactiveCN101761691BWork around size constraintsSolution can not be recycledPipe laying and repairOcean bottomLine tubing

The invention relates to a bound floating pipeline towing pipe method. In the method, a floating pipe is used for replacing a buoy in the prior bound buoy towing pipe method, the specification of the floating pipe is 820x8mm, each segment is 50m in length and is an independent sealed bin, a plurality of supporting ribbed plates and longitudinal ribbed plates are welded inside, an air valve and a water valve are arranged for marine load adjustment, every two segments are connected through an inner flange, and a towing head is respectively arranged at both ends of the whole body. The invention has the advantages that the problem of size limitation for a process pipe in the bound buoy towing pipe method is solved, and the requirement for sea conditions is also greatly broadened; meanwhile, the problem that a frock pipe can not be reclaimed in a bunched pipeline towing pipe method is also solved, so that a floating pipe device can be repeatedly utilized, and the construction cost of submarine pipeline laying is further lowered.

Owner:NEPTUNE OFFSHORE ENG DEV

Recycling method for recovering metal type powder coating

The invention provides a recovery and reuse method of metal powder paint. The method is to mix the metal powder paint recycled powder after sieving with the prepared base powder according to a certain proportion, and stir the mixture at a high speed evenly to obtain the metal powder paint. Powder coating fresh powder. The method has the advantages of simple process, easy operation and low cost, and the recovered metal type powder can be recycled, while the performance, color and workability are the same as those of the original powder, thereby achieving effective recycling, protecting the environment and saving resources.

Owner:ZHEJIANG WANFENG MOTORCYCLE WHEEL

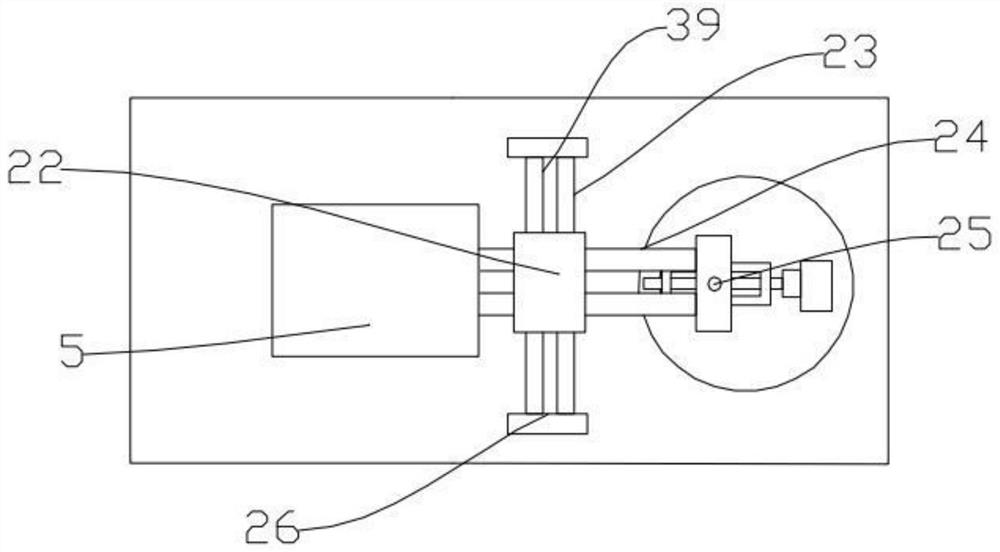

Oil-free screw air compressor compound heat recovery system

InactiveCN104005959BImprove gas production efficiencySolution can not be recycledRotary/oscillating piston pump componentsLiquid fuel engine componentsCooling towerTransducer

The invention discloses a composite heat recovery system of an oil-free screw air compressor, comprising an oil-free screw air compressor and a PLC controller, wherein the oil-free screw air compressor exchanges heat with a first air heat exchanger and a second air respectively The device is connected with the adsorption air dryer, the first air heat exchanger and the second air heat exchanger are both connected with the circulating water tank, and the oil-free screw air compressor is also connected with a cooling tower. The compound heat recovery system of the oil-free screw air compressor of the present invention, the first air transducer and the second air transducer are arranged outside the oil-free screw air compressor, and the circulation operation of the cooling water heat recovery system is controlled by the PLC controller Switching with the cooling tower system solves the problem that the heat generated during the working process of the existing oil-free screw air compressor cannot be recycled. The primary energy consumption required by water has the advantages of high efficiency, energy saving, and environmental protection, and is of great significance to sustainable development.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Numerical control milling machine with metal scrap recycling function

ActiveCN113909551AEasy to operateCompact structureMilling equipment detailsMaintainance and safety accessoriesElectric machineryScrap

The invention discloses a numerical control milling machine with a metal scrap recycling function. The numerical control milling machine comprises a numerical control machine tool body, a supporting frame, a transmission assembly, a first driving motor, a position adjusting assembly, a mounting block, a first hydraulic machine, a scrap cleaning mechanism and a scrap recycling assembly. The first driving motor is fixedly arranged in a motor containing groove, the output end of the first driving motor rotationally penetrates through the motor containing groove to be fixedly connected with the position adjusting assembly, the transmission assembly is hinged to the position adjusting assembly, the mounting block is fixedly connected with the transmission assembly, the fixed end of the first hydraulic machine is fixedly connected with the mounting block, the telescopic end of the first hydraulic machine is fixedly connected with the scrap cleaning mechanism, and the scrap recycling assembly is fixedly arranged at the bottom of the scrap cleaning mechanism. The invention belongs to the technical field of milling machines, and particularly relates to the numerical control milling machine with the metal scrap recycling function, wherein metal scraps can be cleaned, scrap accumulation is avoided, and the cleaned scraps can be recycled.

Owner:SHANDONG YISHUI MACHINE TOOL

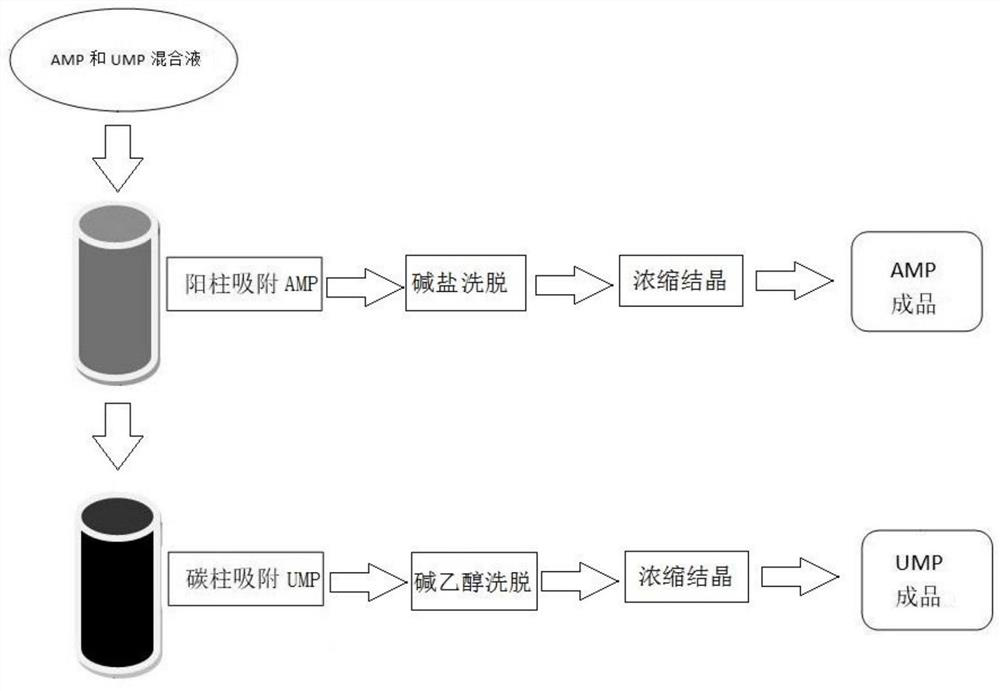

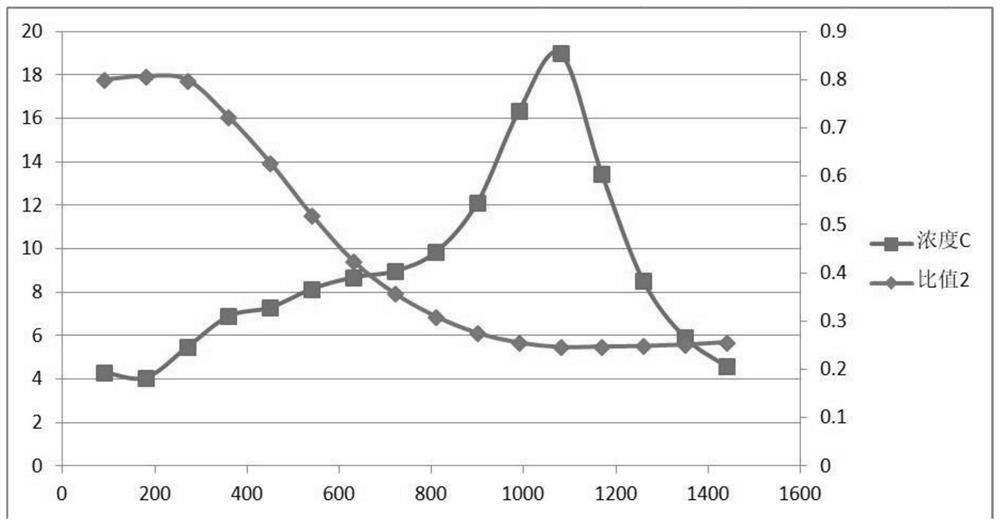

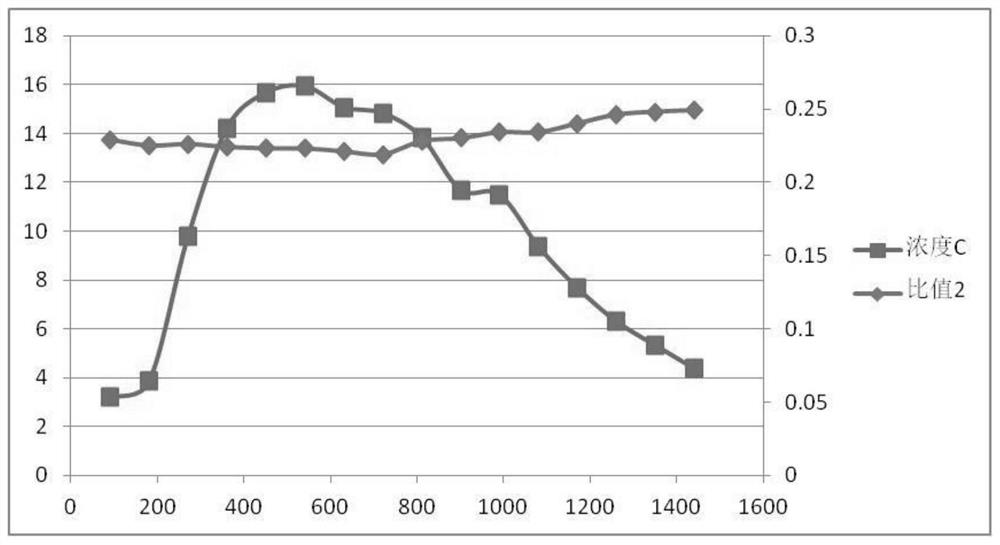

Recycling application of 5 '-AMP and 5'-UMP in nucleotide chromatographic separation

PendingCN113387987ASolution can not be recycledSolve quality problemsSugar derivativesSugar derivatives preparationChromatographic separationNucleotide

The invention discloses a recycling application of 5 '-AMP and 5'-UMP in nucleotide chromatographic separation. The recycling application comprises the following steps: regenerating cation resin; mixing AMP and UMP and loading a sample; washing with water; performing elution; concentrating and crystallizing; and finally, obtaining finished products 5 '-AMP and 5'-UMP. According to the application, the structure difference of 5 '-AMP and 5'-UMP is utilized, that is, 5 '-UMP has no amino group, cannot carry positive charges during ionization under acidic conditions and cannot be exchanged by cation exchange resin, and AMP has amino group, carries positive charges during ionization under acidic conditions and can be exchanged by cation exchange resin, so that two nucleotides can be separated through cation exchange resin, the problem that part of AMP and UMP cannot be recycled or the quality is reduced after recycling is solved, and the total yield is increased by 20%-30%. Through exploration of elution of salts and alkali salts with different concentrations, a method for saving an elution solution and obtaining high-purity 5 '-AMP and 5'-UMP is found.

Owner:NANTONG QIUZHIYOU BIOSCI & BIOTECH

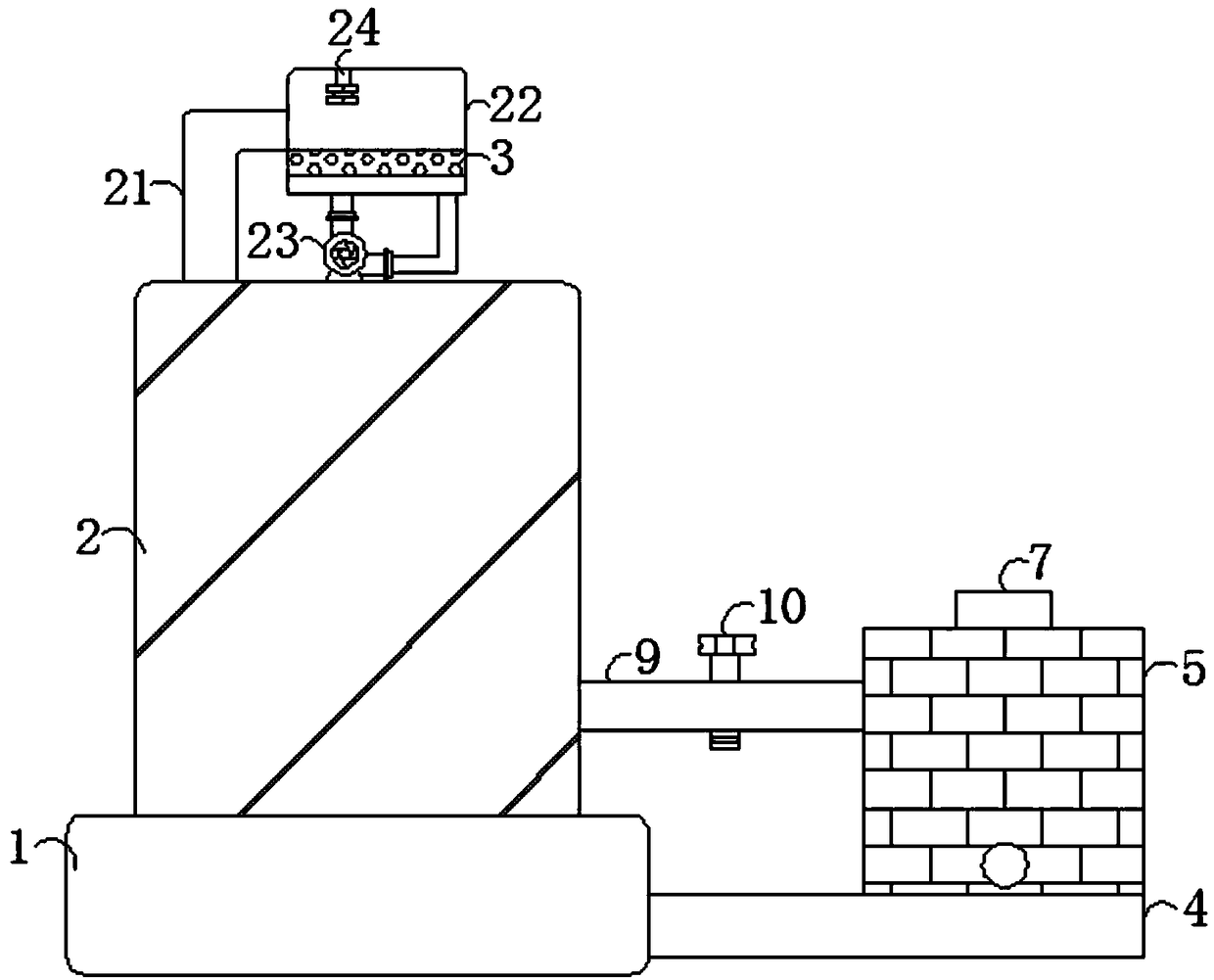

Environmental-friendly industrial furnace with purification function

InactiveCN108645228ASolution can not be recycledSolve pollutionHuman health protectionUsing liquid separation agentWater sourceSewage

The invention discloses an environmental-friendly industrial furnace with a purification function. The environmental-friendly industrial furnace comprises a base. An industrial furnace body is fixed above the base. An exhaust pipe is arranged above the industrial furnace body. A purifier is connected to one end of the exhaust pipe. A water pump is arranged at the bottom of the purifier. One end ofthe water pump is connected with a main atomizing nozzle through a water outlet pipe, and the other end of the water pump is connected with a water inlet pipe. According to the environmental-friendlyindustrial furnace, a scraper is arranged, the water pump introduces water into atomizing nozzles, the atomizing nozzles spray water mist on exhaust gas, solid particles fall into a filter due to thedead weight of the solid particles, the liquid enters the water pump from the water inlet pipe for circulating spraying, a handle is pushed to roll a rolling wheel in a wheel groove, the scraper is driven to move toward one side of the filter, and the solid particles can be pushed to a sewage outlet for discharge; and the problems that the solid particles cannot be treated after the exhaust gas is filtered in water, and a water source cannot be recycled are solved.

Owner:CHANGXING CAZENOVE FUNANCE IND CO LTD

Power line storage device for electric cooker

The invention relates to a power line storage device for an electric cooker. A control button and a rotary shaft are mounted on an electric cooker body, and the control button is connected with the rotary shaft and a power line. According to the storage device, the rotary shaft and the control button are mounted on the electric cooker body, so that when the electric cooker is used, only the power line is needed to be pulled out; when the electric cooker is not users, the control button is pressed, and the power line is retracted onto the rotary shaft; the problem that the power line cannot be retracted is well solved.

Owner:崔金兰

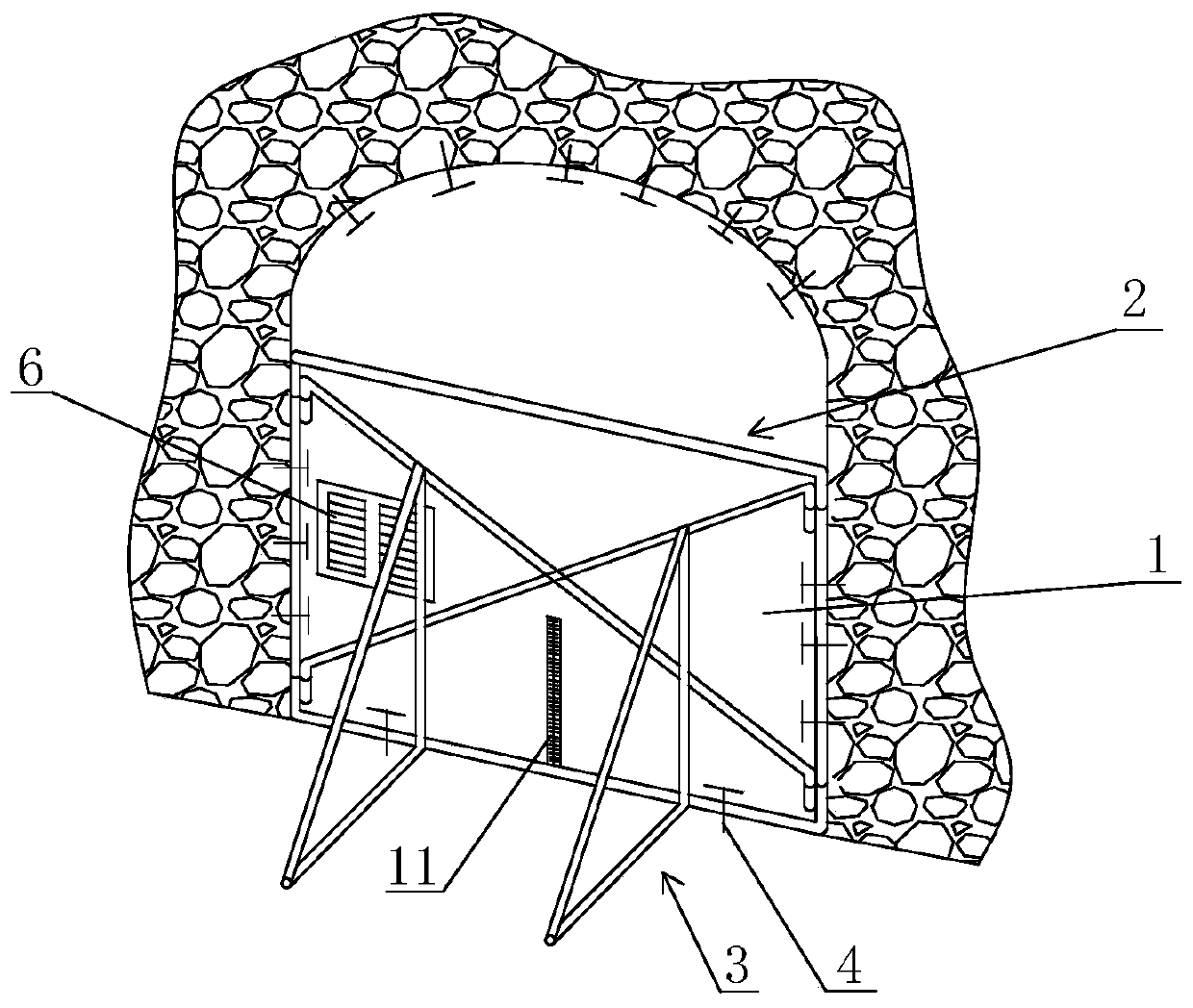

Metal ore rapid sealing wind blocking device

PendingCN110905578AQuickly achieve airtight air blockingRapid realization of temporary air distributionMining devicesTunnel/mines ventillationMetallurgyAssembly disassembly

The invention discloses a metal ore rapid sealing wind blocking device. The device comprises a rapid assembling steel structure and a windshield cloth, wherein the quick assembling steel structure comprises a rectangular frame used for supporting the windshield cloth and a triangular support used for supporting the rectangular frame; the rectangular frame and the triangular support are both formedby connecting a plurality of rod bodies, wherein the rectangular frame is located in the plane where the section of a roadway is located, the triangular support is arranged at the leeward side of therectangular frame, and the plane where the triangular support is located is perpendicular to the section of the roadway; and the windshield cloth is arranged on the windward side of the rectangular frame, the edge of the windshield cloth is fixed with the wall surface of the roadway, and a zipper type air door is arranged at the position, close to the lower position, of the middle of the windshield cloth. According to the device, the structure is reasonable, the assembly and disassembly are easy, metal ore sealing wind blocking and temporary air distributing can be rapidly achieved, the roadway sealing efficiency is improved, the problem that a sealing monomer cannot be recycled is solved, and the sealing cost is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Recovery and utilization method for acidic water of hydrocarbon steam conversion hydrogen production plant

InactiveCN100448502CSolution can not be recycledReduce pollutionWater/sewage treatmentDistillation separationTemperature controlAcid water

This invention relates to a recovery and utilization method for acid water of a hydrocarbon steam transformation hydrogen-manufacturing device, which drives the acid water from a hydrogen-manufacturing device to an acid vapour extractive tower to carry out vapour extraction, the temperature at the top of the tower is controlled at 95-101deg.C, the bottom temperature is at 97-102deg.C, the pH of the extracted acid water is 6.5-7.5, and the water processed by vapour is boosted by a pump and filtered by a filter to get filtered water then to be cooled to 60-80deg.C to enter into a storage tank, which can reduce pollution and waste of acid water and recover and utilize all of the acid water as the water for heat-conversion and cooling devices or other devices.

Owner:杨会喜

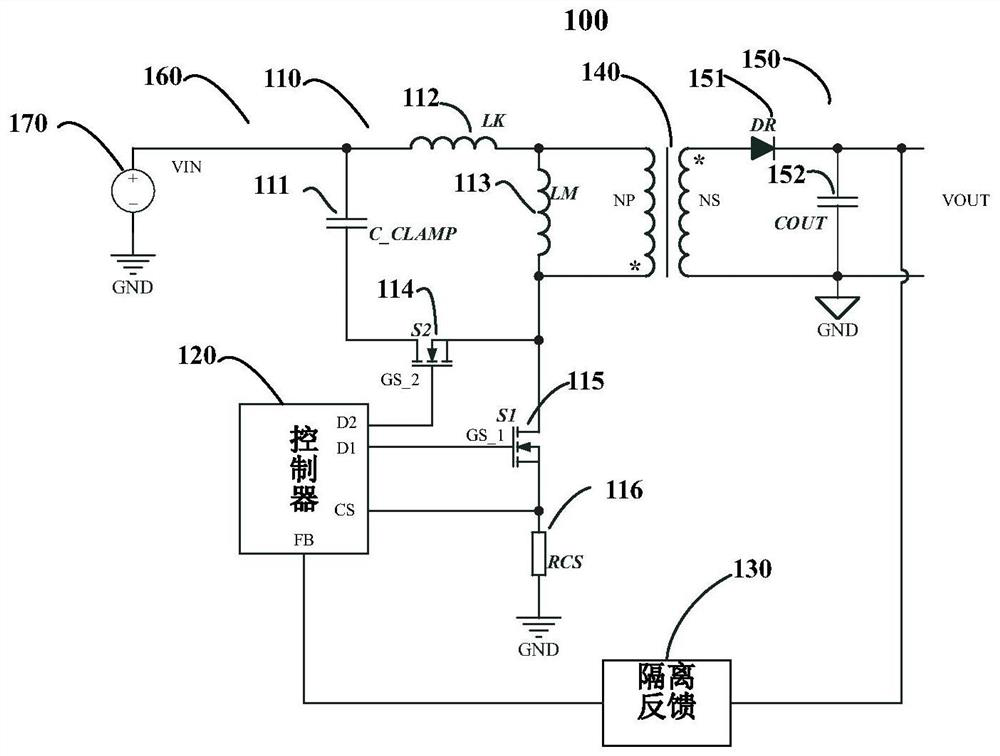

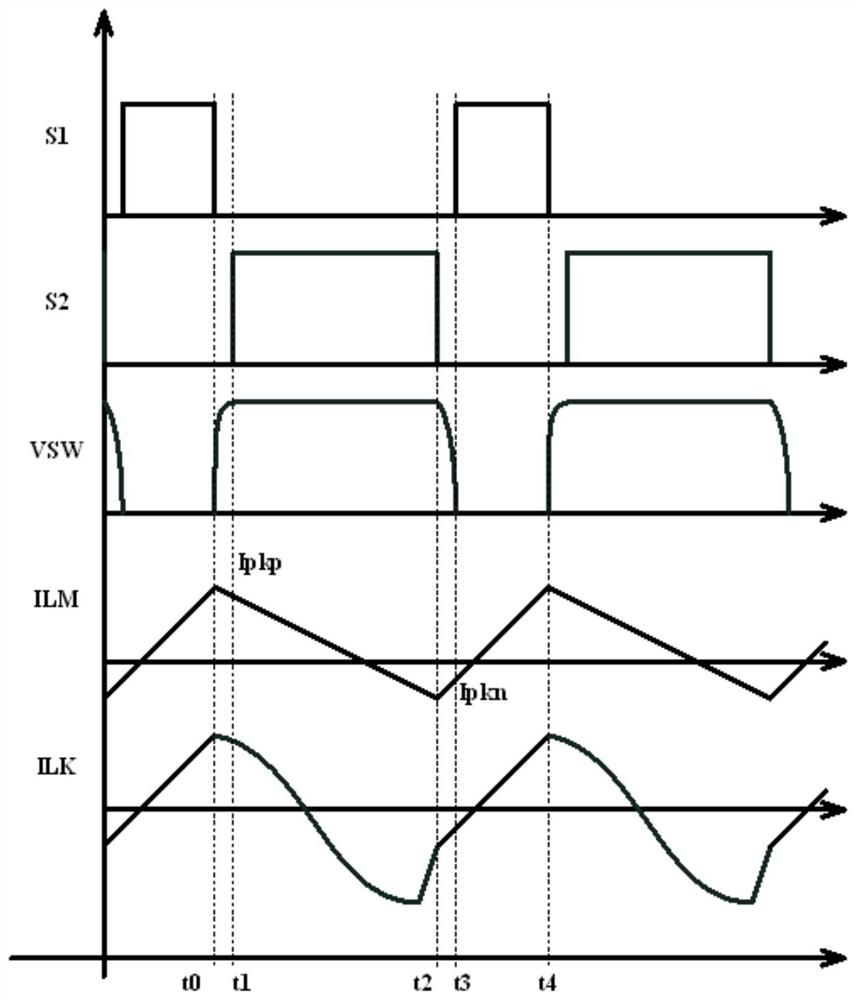

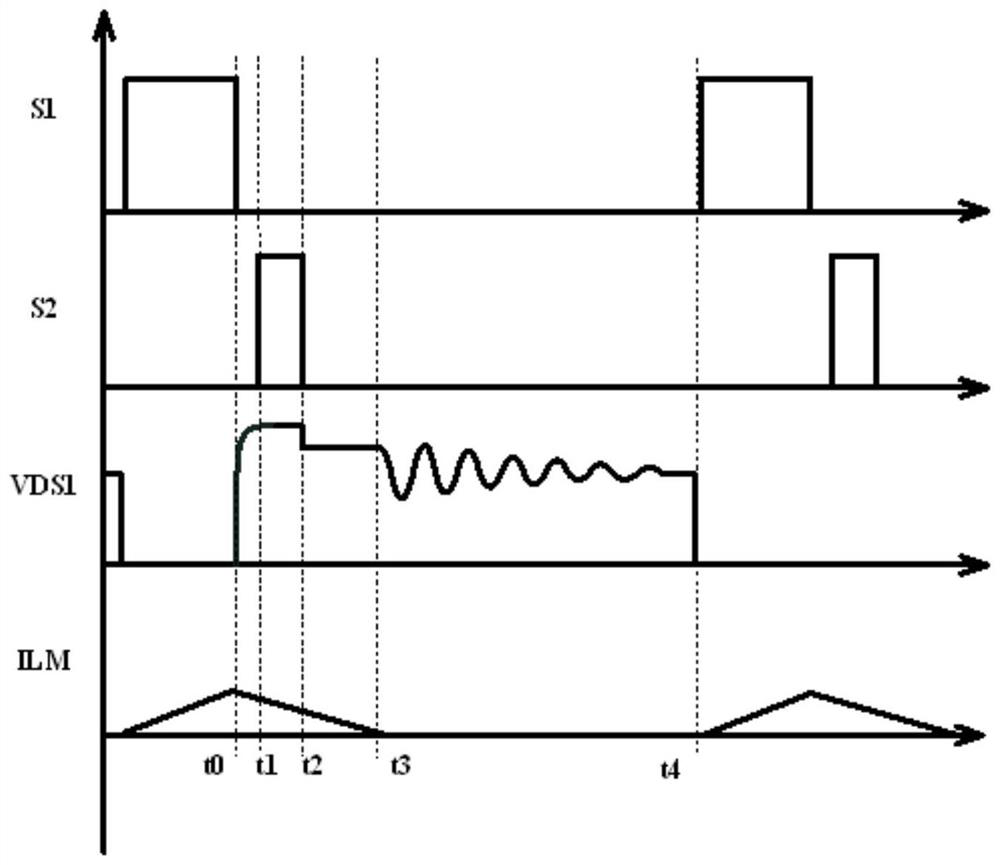

A Control Method of Active Clamp Flyback Converter

ActiveCN110677045BSolution can not be recycledImprove light load efficiencyDc-dc conversionElectric variable regulationClamp capacitorCapacitance

The invention discloses a control method of an active clamp flyback converter. In the flyback transformer, the main switch tube controls the current magnitude of the primary winding of the flyback transformer, and the clamp switch tube controls the primary side of the flyback transformer. The node voltage is clamped, and the controller generates a control signal for controlling the main switch tube and the clamp switch tube by detecting the feedback voltage; when the converter works at a light load, a fixed dead time passes after the main switch tube is turned off Immediately turn on the clamp switch tube, the converter charges the clamp capacitor through the clamp switch tube to recover leakage inductance energy, wherein the conduction time of the clamp switch tube is less than the leakage inductance and the output junction capacitance of the main switch tube and the clamp switch tube the resonance period. The present invention does not need to connect a large resistor in parallel to the clamp capacitor, thereby improving the light-load efficiency.

Owner:MORNSUN GUANGZHOU SCI & TECH

A co-processing process of sinter waste heat and sinter flue gas pollutants

InactiveCN108692579BHigh recovery rateSolve the problem that the temperature is low and cannot be recycledDispersed particle separationWaste heat treatmentParticulatesMetallurgy

Owner:杨清海

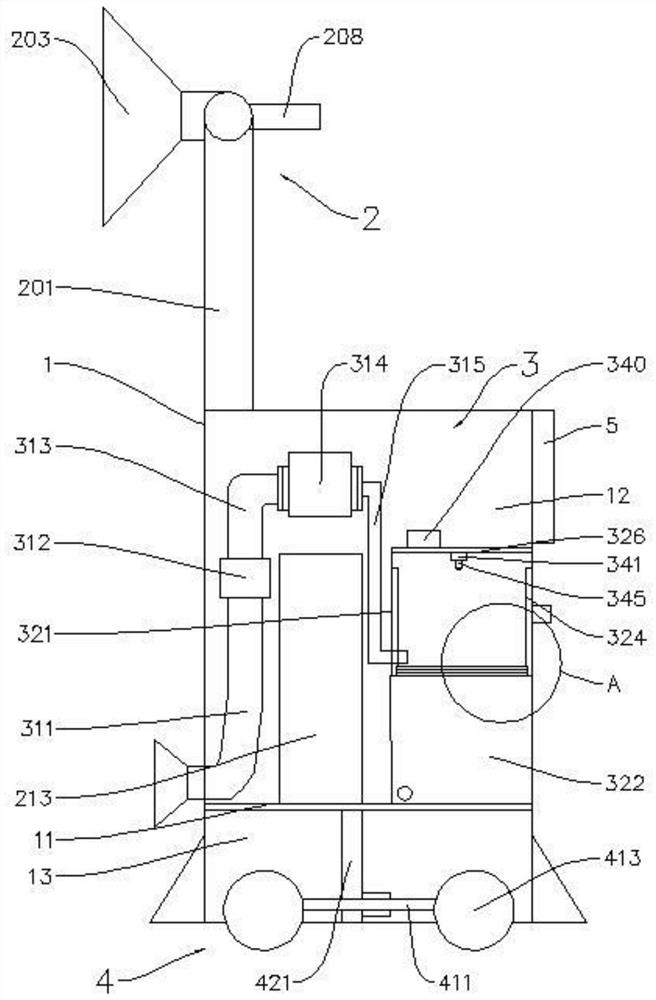

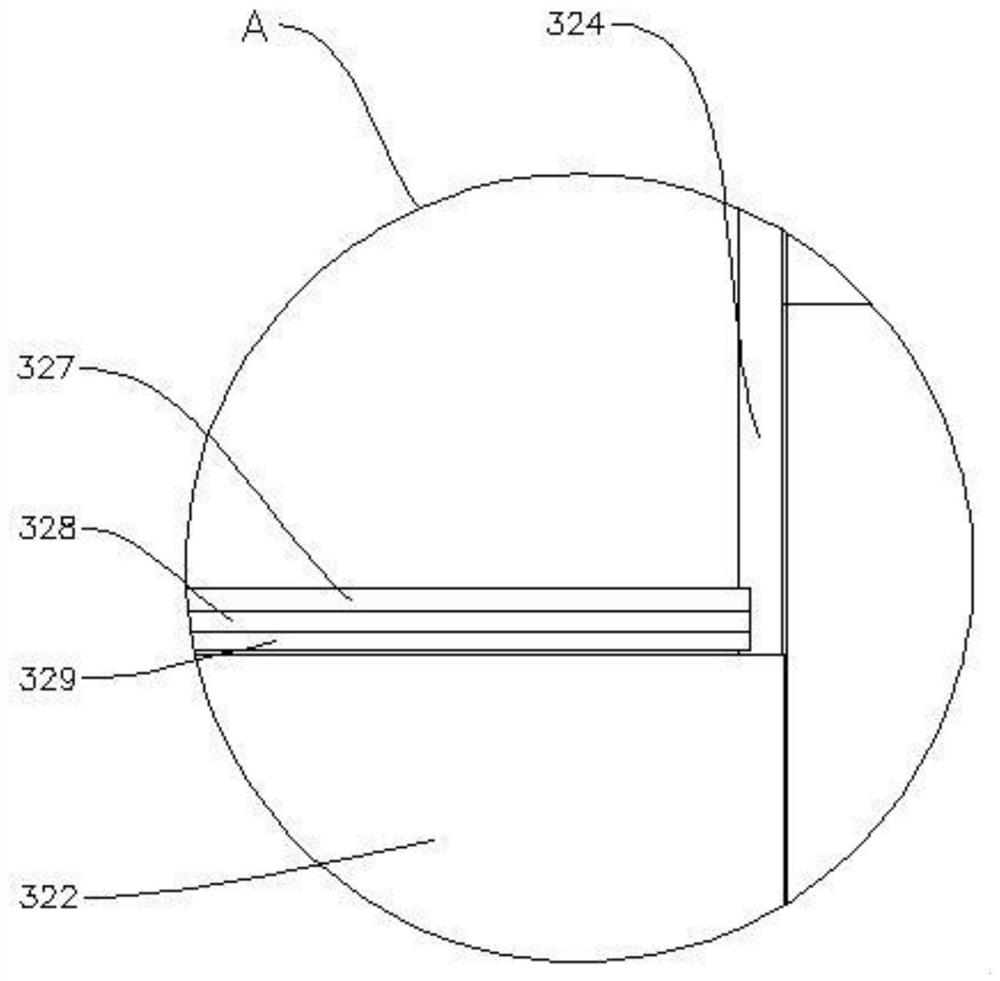

Dust fall type lighting device for rail transit engineering construction

ActiveCN113262595APrevent secondary liftingSolution can not be recycledLighting applicationsCombination devicesEnvironmental engineeringMechanical engineering

The invention discloses a dust fall type lighting device for rail transit engineering construction, which comprises a box body, a lighting mechanism, a dust fall mechanism and a moving mechanism, a partition plate is arranged in the box body to divide an inner cavity of the box body into a first placing cavity and a second placing cavity which are arranged up and down, the lighting mechanism is arranged in the box body, the dust fall mechanism is arranged in the first placing cavity, the dust falling mechanism comprises a dust suction assembly and a water spraying filtering assembly, the dust suction assembly is connected to the water spraying filtering assembly, one end of the dust suction assembly extends to the outer side of the box body, and the moving mechanism is arranged in the second containing cavity. By arranging the dust falling mechanism, the dust suction assembly sucks dust into the filter box, the water spraying assembly pumps out water in the water purification box and sprays the water into the filter box, so that the dust in the air is adsorbed, secondary raising of the dust is avoided, the water is filtered by the filter box and flows into the water purification box, and circulation is conducted, so that the problem that construction is affected by raising of the dust is solved. And the water is recovered and recycled.

Owner:江西安福华洋劳务合作有限公司

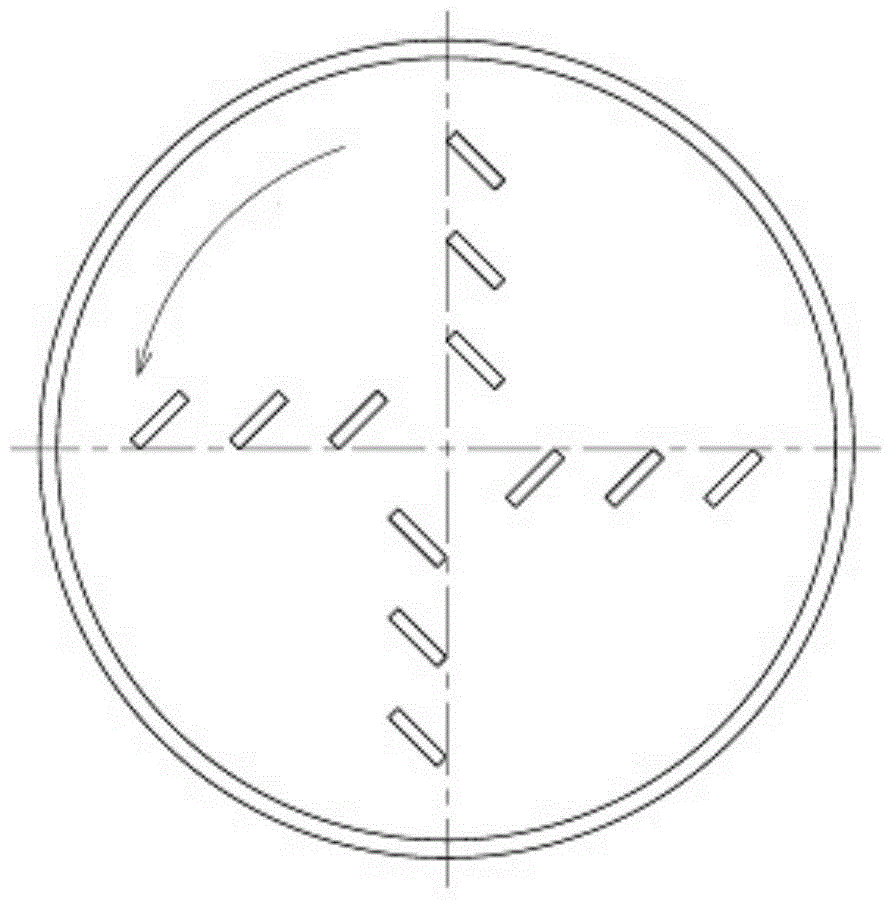

Air-cooling device and method for air-permeable materials

ActiveCN104862439BIncrease the itineraryFully contactedFluidised-bed furnacesHeight differenceEngineering

The invention relates to the technical field of cooling of an air-permeable material and provides an air-cooling device and method for an air-permeable material. According to the air-cooling device for the air-permeable material, multiple layers of material storage barrels are arranged, and discharging holes in bottom plates of the adjacent material storage barrels are distributed in a manner that the projections of the discharging holes in a vertical direction are staggered, so that the height that the material drops each time is the height of each material storage barrel, and the problems of large material height difference and high pulverizing rate are solved. On the basis, material rakes making relative motion with the material are arranged in the material storage barrels, and the material is gathered or dispersed under the agitating action of the material rakes, so that the stroke of the material is longer under the condition of the same height, the material is in full contact with cooling gas, the cooling time is longer, and accordingly, the heat exchange efficiency is improved. Moreover, the device is vertically arranged, so that the occupied area is small.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com