Bound floating pipeline towing pipe method process

A pipe dragging method and floating pipe technology, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of large impact of sea conditions, reduce construction costs, and solve the effect of non-recyclable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

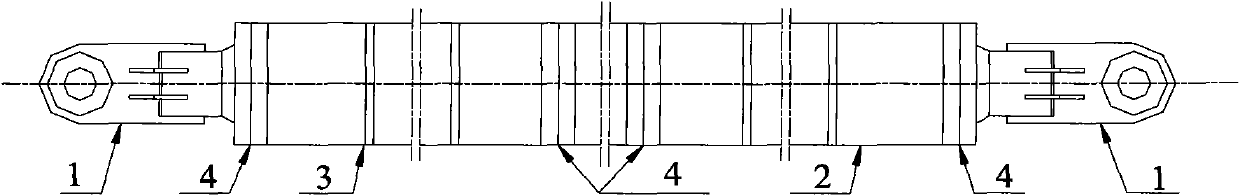

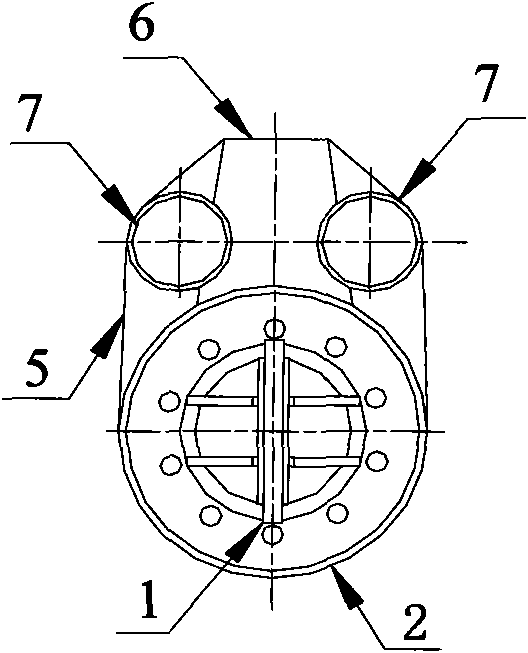

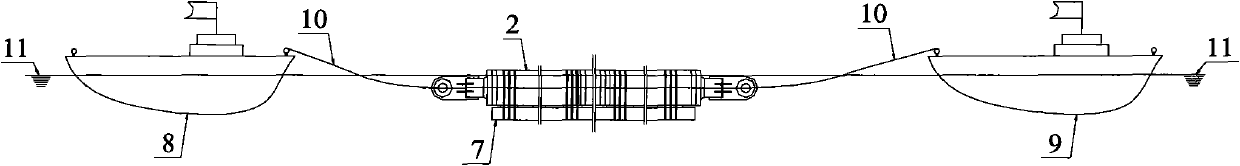

[0015] First, prefabricate cylinders 2 of 50m each section on the beach site, install a balance buoy on both sides of the first cylinder 2, and then install positioning cables on the corresponding cylinders 2 every 300m, and fix the floating pipes as process pipes 7 Prepare for connection; bind the process tube 7 to the floating tube through the lifting lug with the palm rope 5, and place a rubber or wood block 6 between the floating tube and the process tube 7 to fix the process tube 7, and the floating tube can be tied at most 3 process pipes; after the process pipe 7 is connected and tied, the balance buoy and the positioning cable are removed, the drag head at one end of the float pipe is connected to the tugboat, and the float pipe leaves the beach site by using the high tide, and the flip of the float pipe is completed in the water; the front tugboat 9 As the main tugboat, it provides traction for the floating tube, and the rear tugboat 8 follows the tail end of the float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com