Thin-film transistor structure and method of manufacture thereof

A technology of thin film transistor and manufacturing method, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problems of complicated process steps and increase of process cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The concept of the present invention is to redefine and design the disposition position of the gate, so as to have greater freedom in the design of the element size.

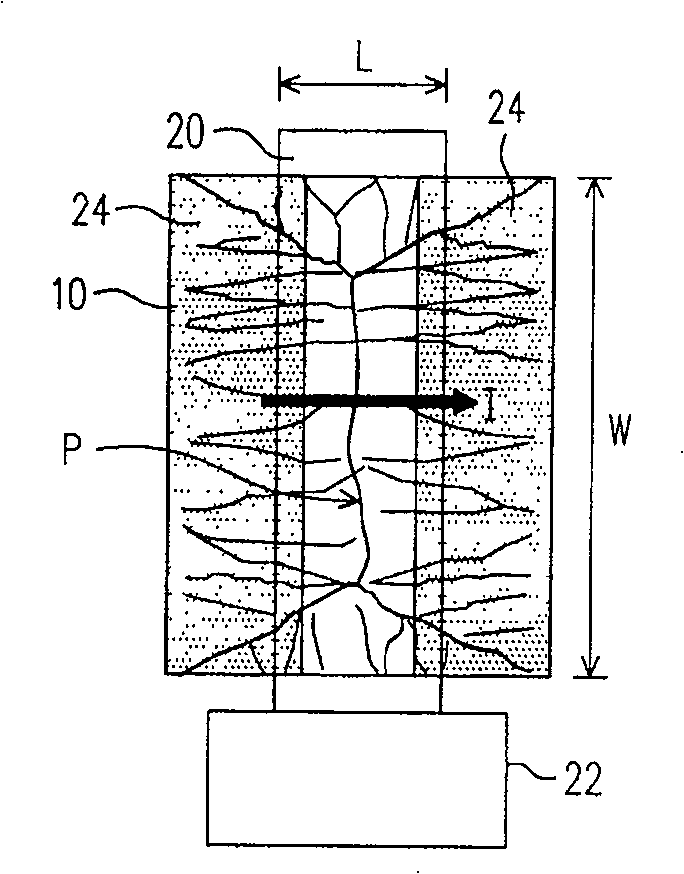

[0039] image 3 is a top view of a transistor according to an embodiment of the present invention. First, a strip-shaped silicon island 10 is still formed in the aforementioned manner. from image 3 It can be seen that the strip-shaped silicon islands formed by laser annealing are film regions with predetermined long sides and short sides. The strip-shaped silicon island 10 may be a polysilicon island, and the polysilicon island 10 is taken as an example for description below. The polysilicon island 10 has a longitudinal main grain boundary P in the middle, and there is also a transverse grain boundary roughly perpendicular to the longitudinal main grain boundary P, or called a secondary grain boundary. The steps are the same as known so far.

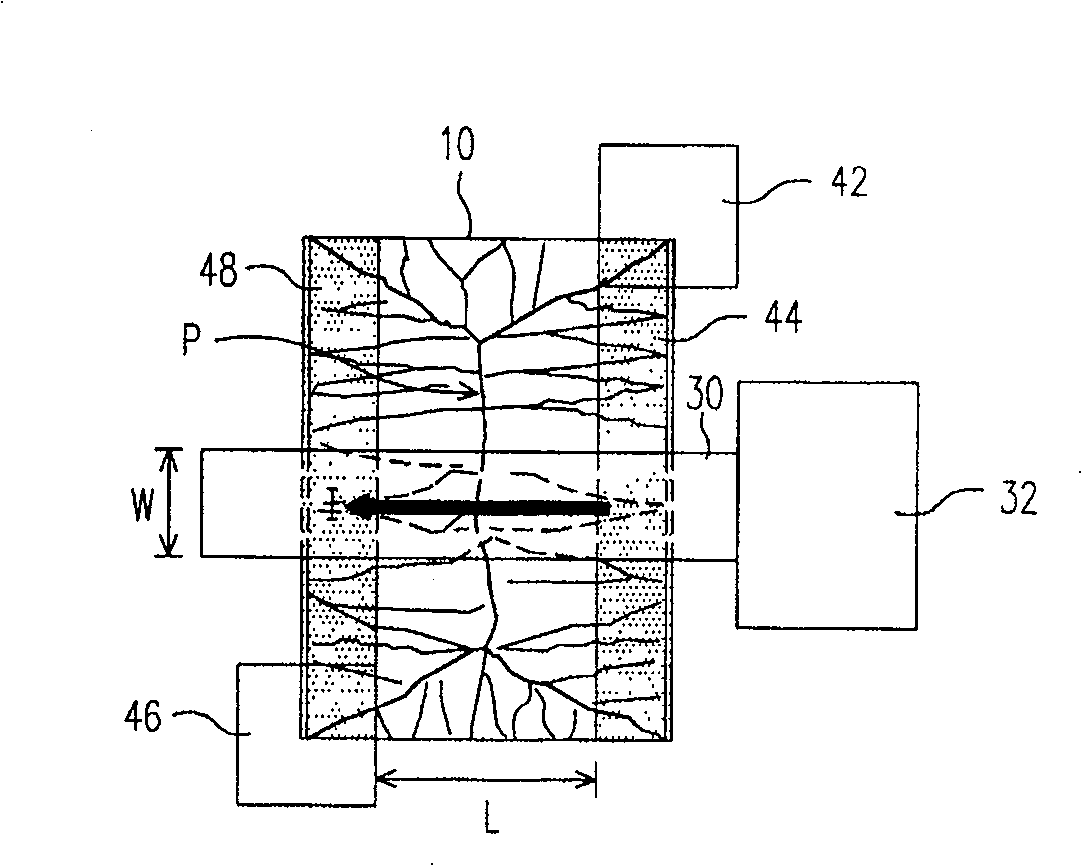

[0040]Next, the gate 30 is formed above the main grain b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com