Method for measuring hemispherical total emissivity and heat conductivity of large temperature difference sample

A technology of full emissivity and thermal conductivity, which is used in the field of hemispherical full emissivity measurement of conductor materials, and can solve the problem of inability to measure the full emissivity of samples of conductor materials with large temperature differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

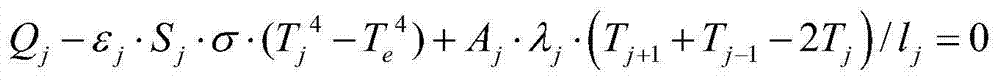

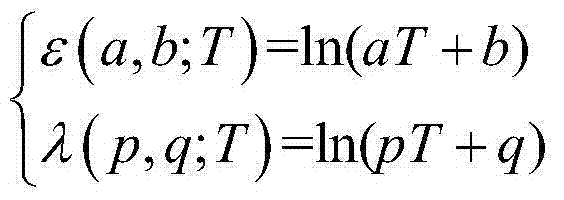

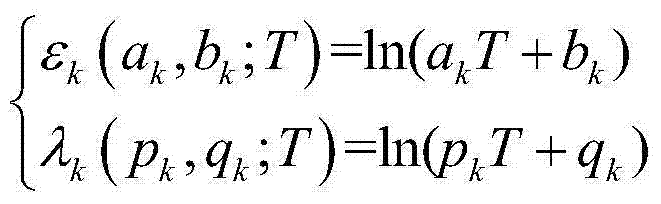

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described in detail below in conjunction with examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0039] The method for measuring the hemispherical total emissivity and thermal conductivity of a sample with a large temperature difference in this embodiment is applicable to the simultaneous measurement of the hemispherical total emissivity and thermal conductivity of the sample when the thermal conductivity of the sample is unknown. The specific steps include:

[0040]S1. Usually when preparing strip-shaped conductor material samples, the length of the sample is much larger than its width and thickness. However, in order to make the processing more operable and applicable, the length of the selected sample can be shortened to 80mm to 100mm at least. In this embodiment, the sample size specification of the selected strip con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com