Patents

Literature

484 results about "Assembly disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

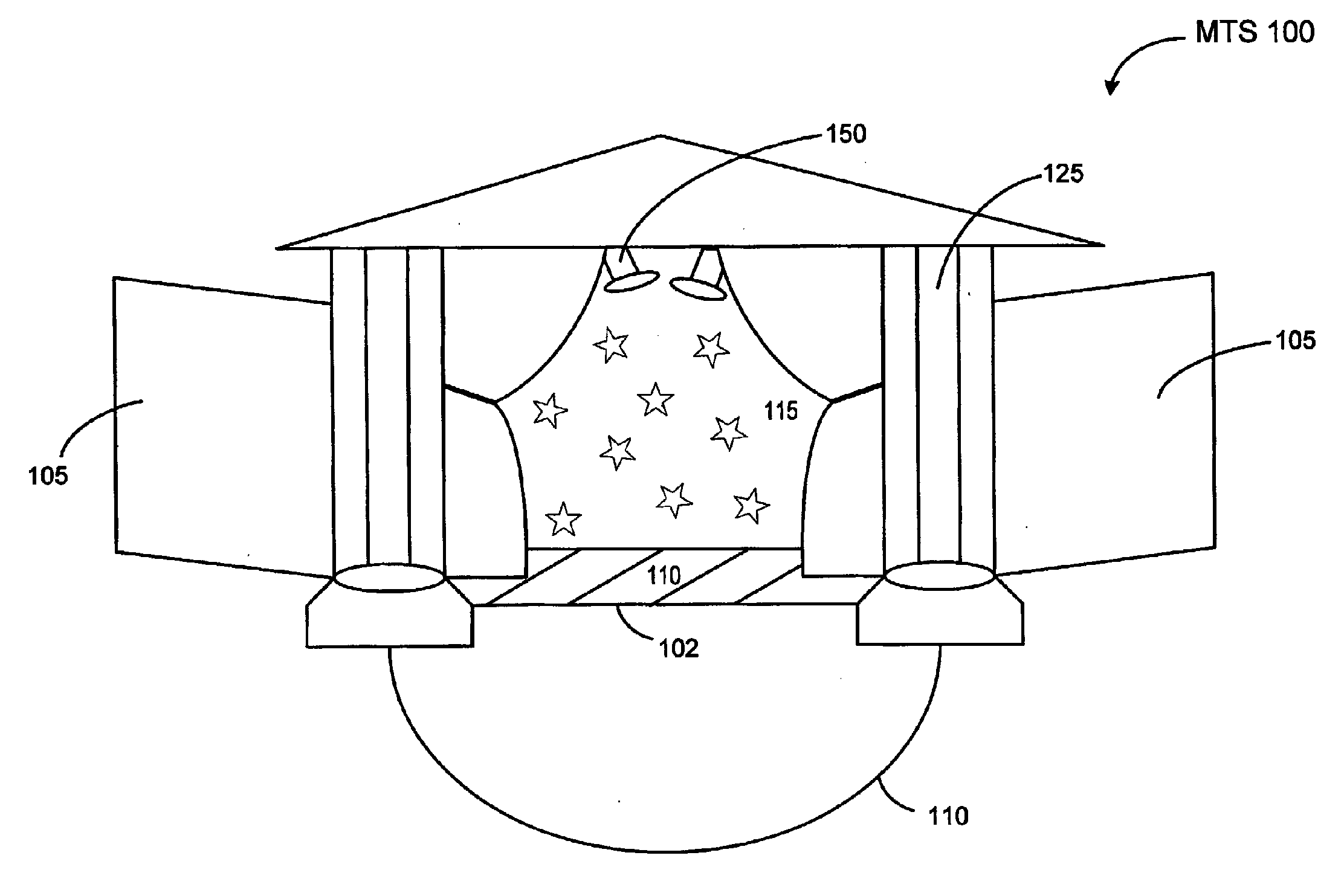

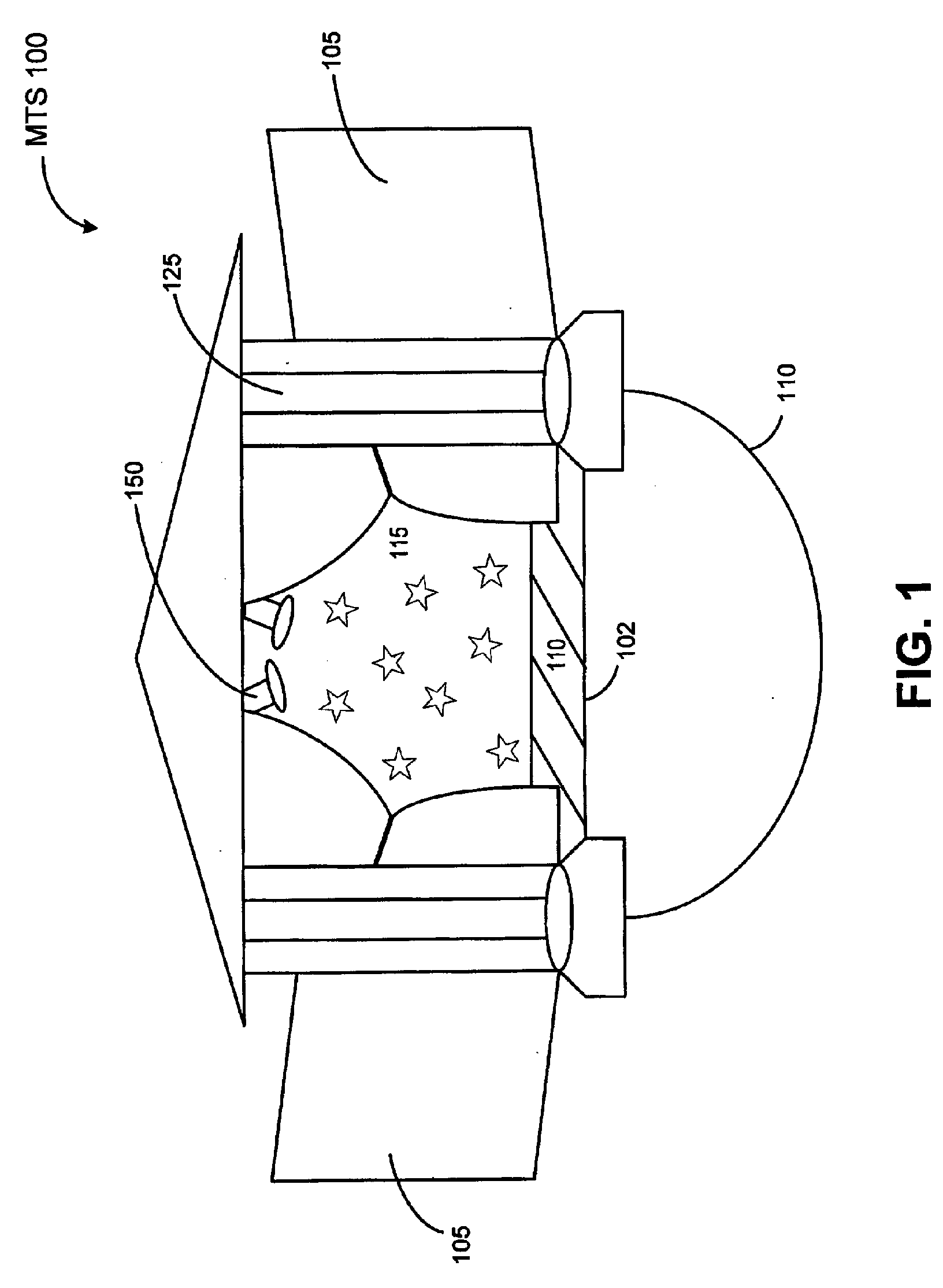

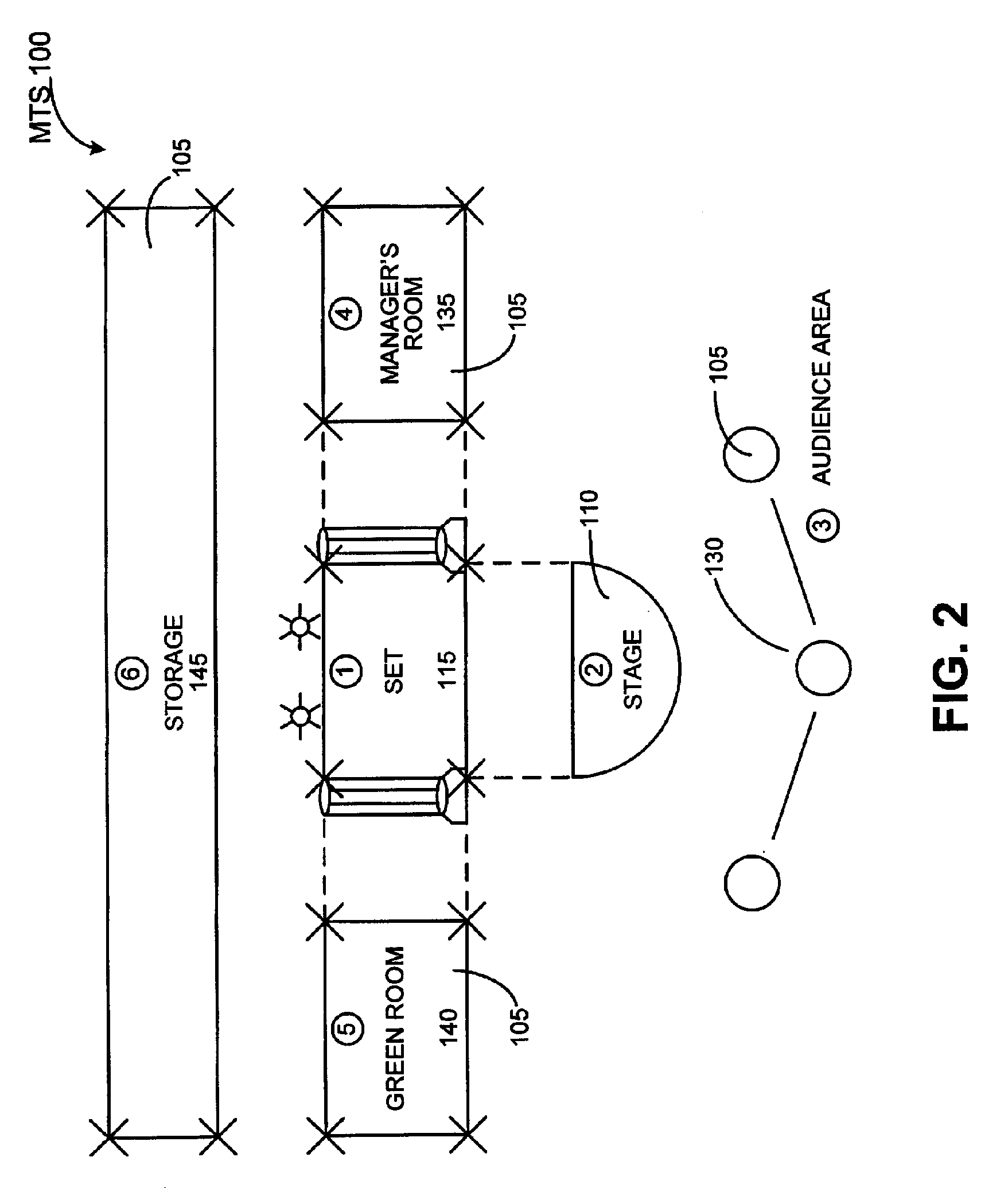

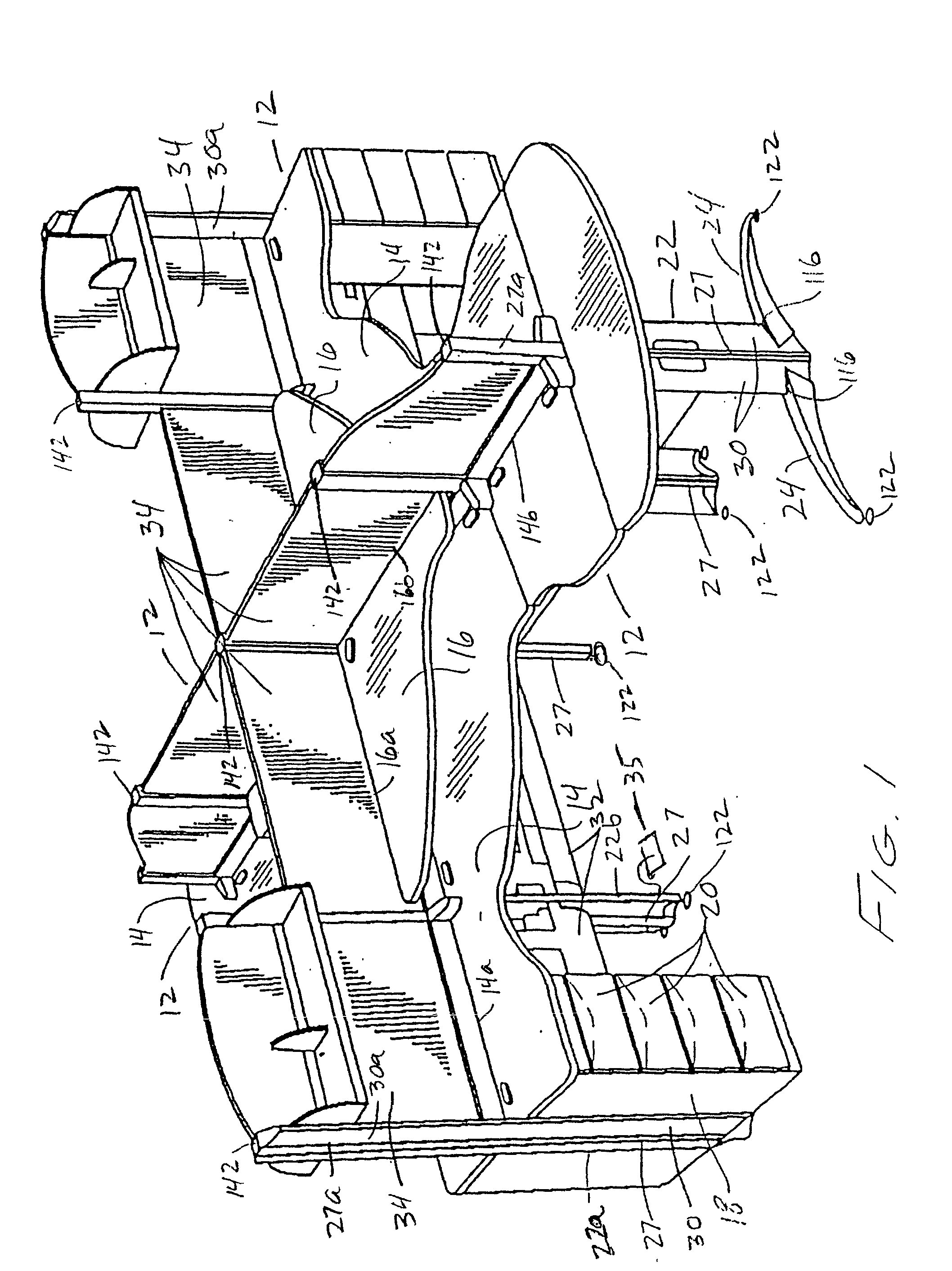

Modular theatre system

A versatile modular theatre system for providing large-scale entertainment or for use in the home. In accordance with various exemplary embodiments, the present invention provides families and consumers with an alternative to conventional home theatre entertainment systems and commercial and educational presentation systems. The present invention provides a multipurpose, multi-venue, modular set and stage that seeks a full-sensory approach to entertaining, educating, informing, and uplifting audiences. In accordance with another exemplary embodiment, the present invention comprises at least one of a modular set, a stage, a control room, a green room, a storage space, an audience area, and one or more accessories. Preferably, one or more of the rooms are configured to be customizable and / or removably attachable to the set and / or stage. In accordance with another exemplary embodiment, the present invention provides a commercial presentation theatre system comprising modular components. Theatre systems in accordance with present invention preferably feature linkable walls that allow the user to customize the size and shape of the modular components of the system and to facilitate assembly, disassembly, and transport.

Owner:DAVEY MARK

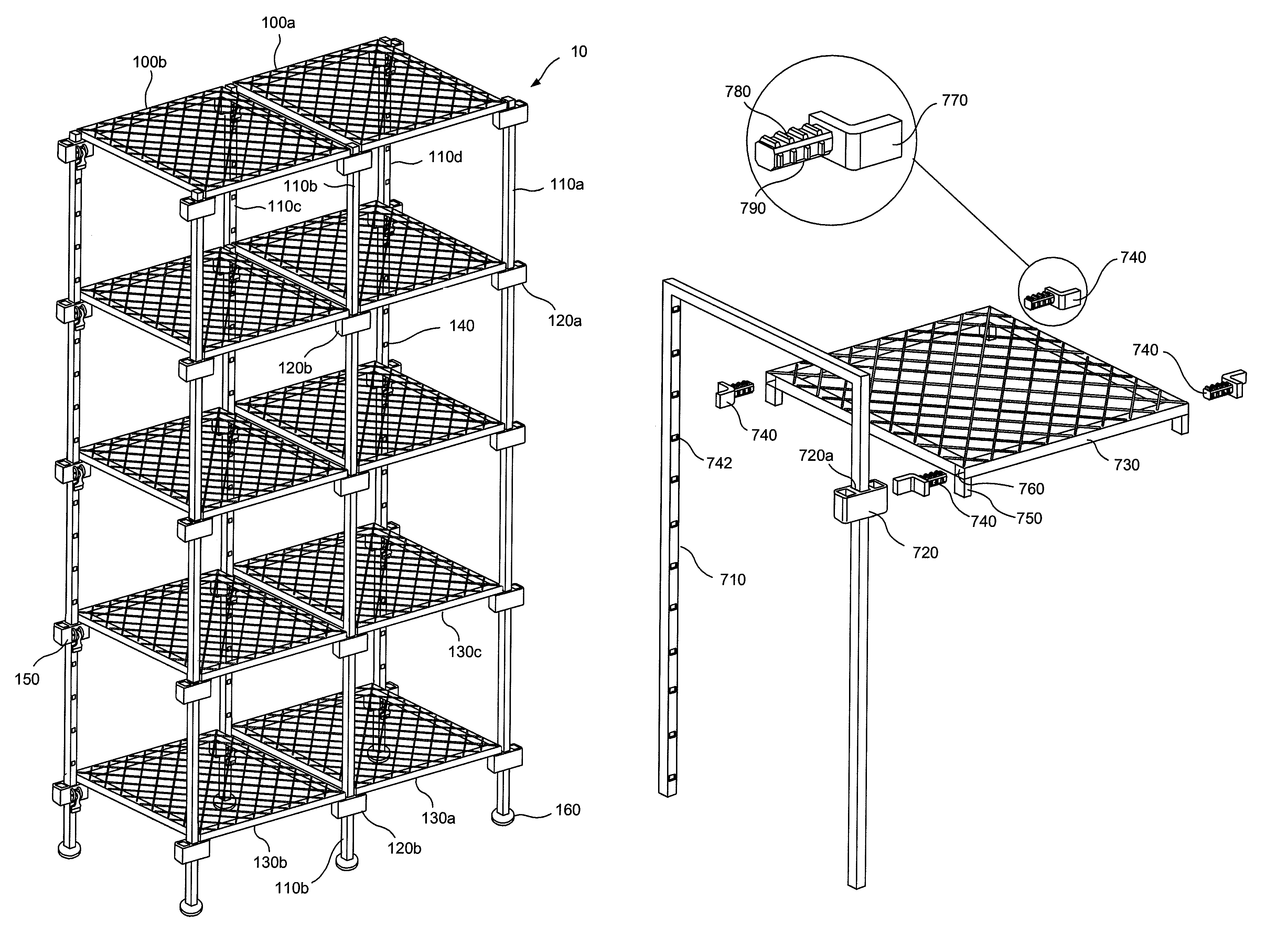

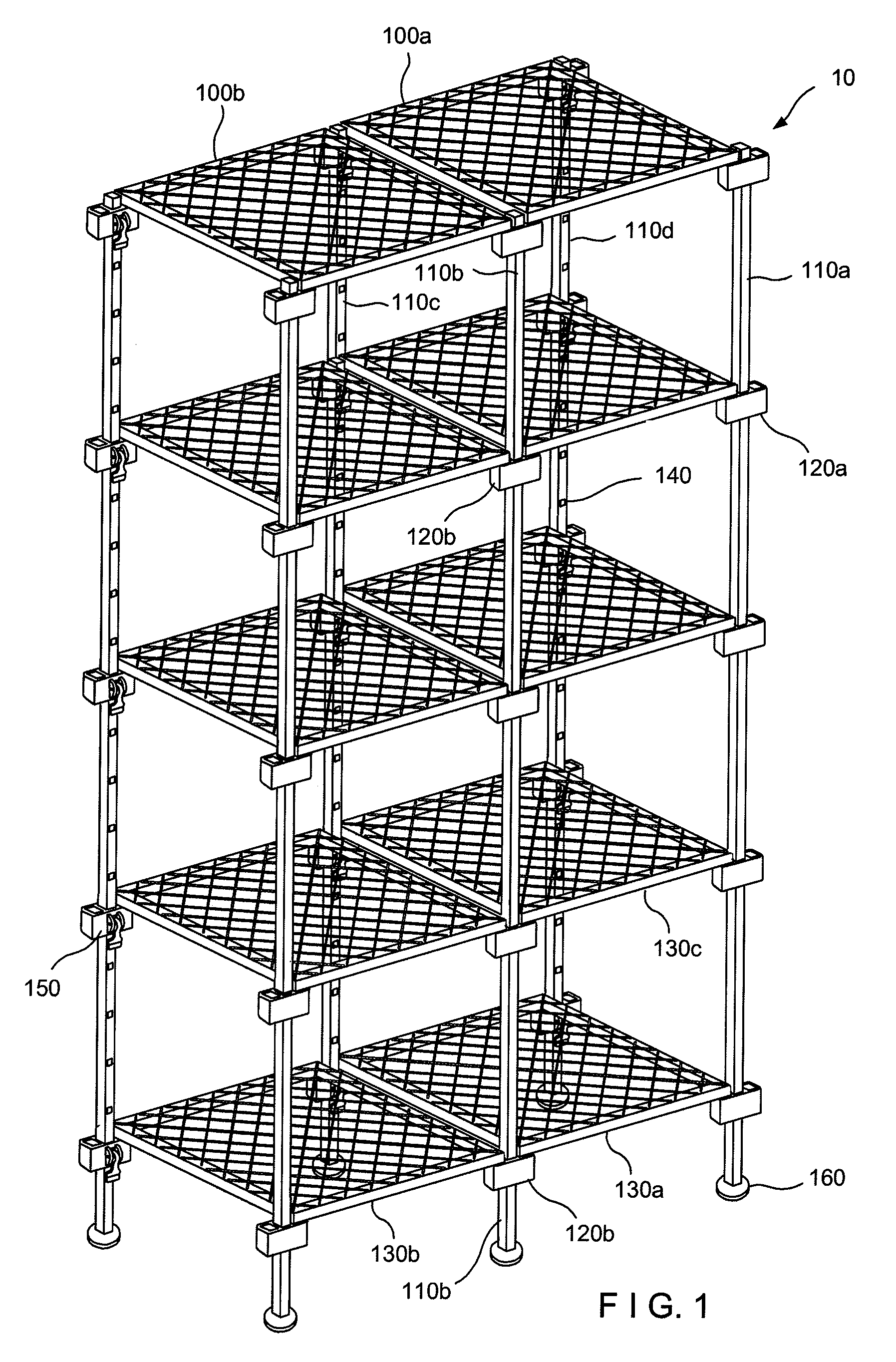

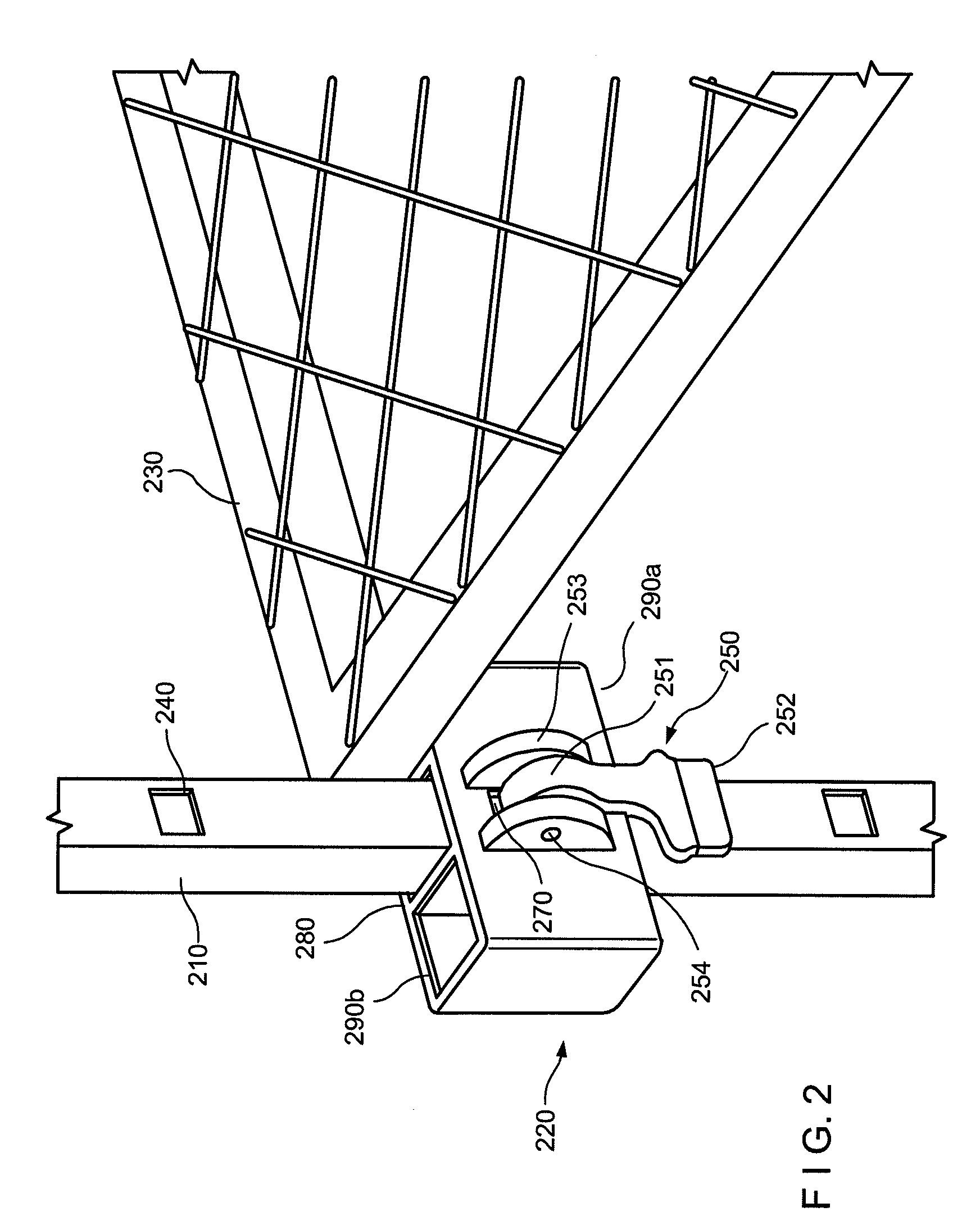

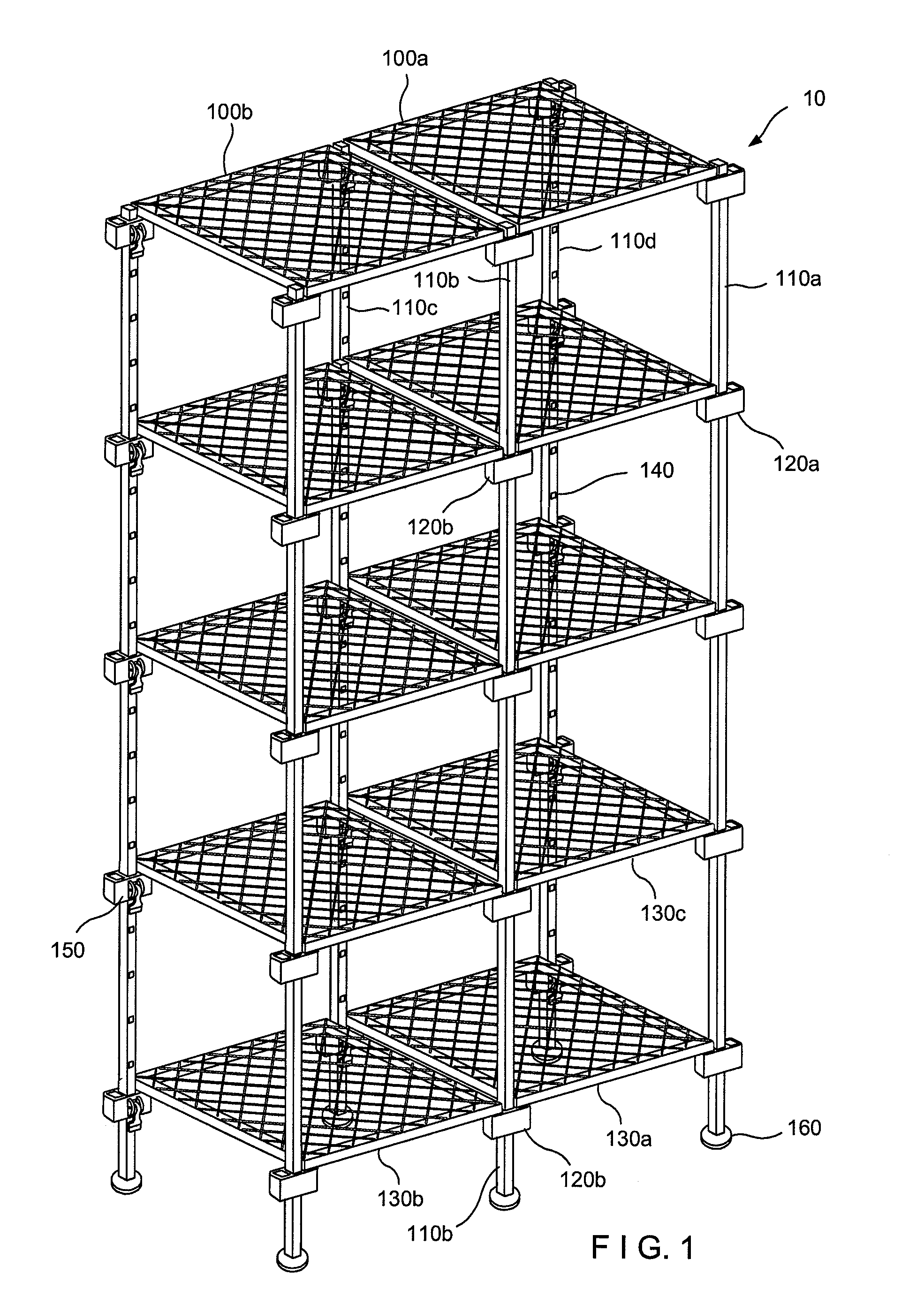

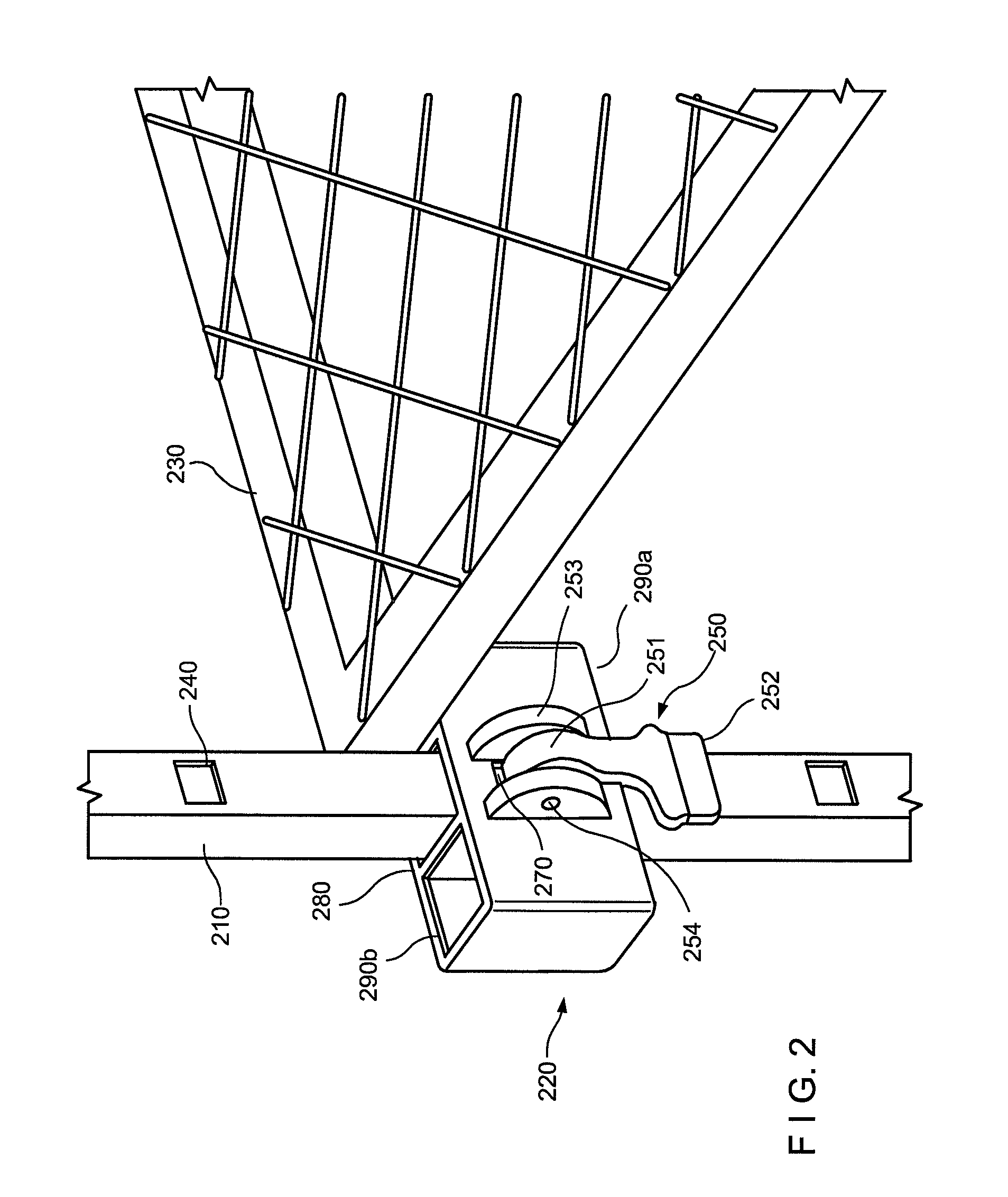

Shelving system with stabilizing brackets and method of assembly

A shelving system includes one or more shelving units. Each shelving unit has posts each post having one or more indents, connectors with slots for mounting the post and one or more shelves. Each shelf has protrusions on a periphery to insert into one of the connector slots. Each shelving unit and shelving system can be assembled, disassembled, and adjusted without the use of tools or other components. The shelving units can be assembled together to create a multiple shelving unit system without the use of tools or other components.

Owner:ORGANIZE IT ALL

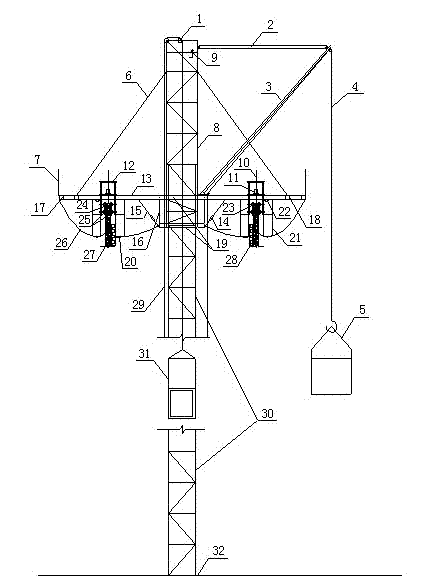

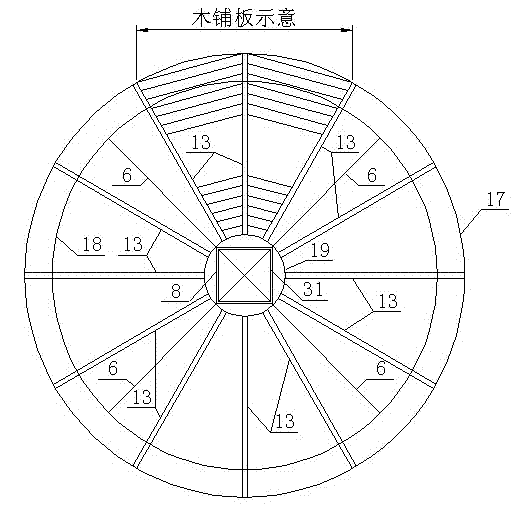

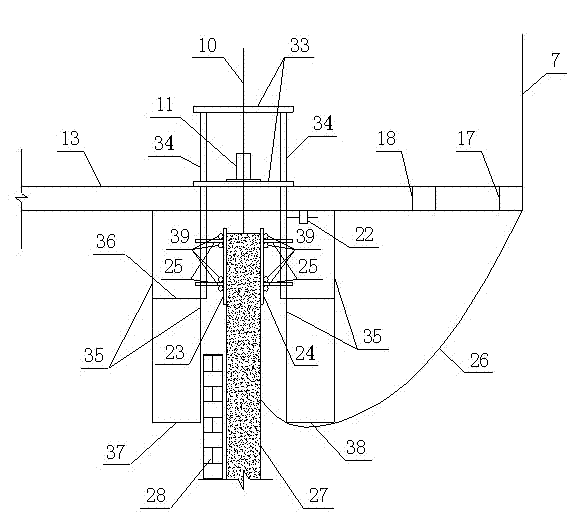

Construction method of circular reinforced concrete chimney cylinder wall and hydraulic sliding mould device

ActiveCN102535843ALess one-time investmentReduce construction costsForms/shuttering/falseworksBuilding material handlingReinforced concreteAssembly disassembly

The invention discloses a construction method of a circular reinforced concrete chimney cylinder wall, and a hydraulic sliding mould device, wherein a hydraulic sliding mould construction method is a rapid construction method of dynamically and continuously molding concrete; loads such as an operation platform and a template are completely supported on a support rod which is stabilized by low-age concrete and has small rigidity; the operation platform and the template are driven to climb along the cylinder wall by a hydraulic jack; and the hydraulic jack climbs on the support rod by an oil path system. The hydraulic sliding mould construction employing the sliding mould as an external cylinder wall and building a lining adopts an ''outside sliding and inside building'' construction process featured by synchronously constructing the external cylinder wall and the lining. The hydraulic sliding mould construction is featured by dynamic continuous construction, having fast construction speed in comparison with mould reverse, symmetrically distributing the hydraulic jack on the circumference of the chimney cylinder wall, forming the template by combining a fixed template with a moveable plate and a contracting and separating template, convenient to assemble and dismount as well as regulate the diameter and the circumference of the combined template structure, capable of gradually decreasing the diameter and the circumference of the combined template structure along with the diameter change of the chimney diameter. The hydraulic sliding mould construction is advantaged in few invested construction operators and convenient management.

Owner:马鞍山钢铁建设集团有限公司

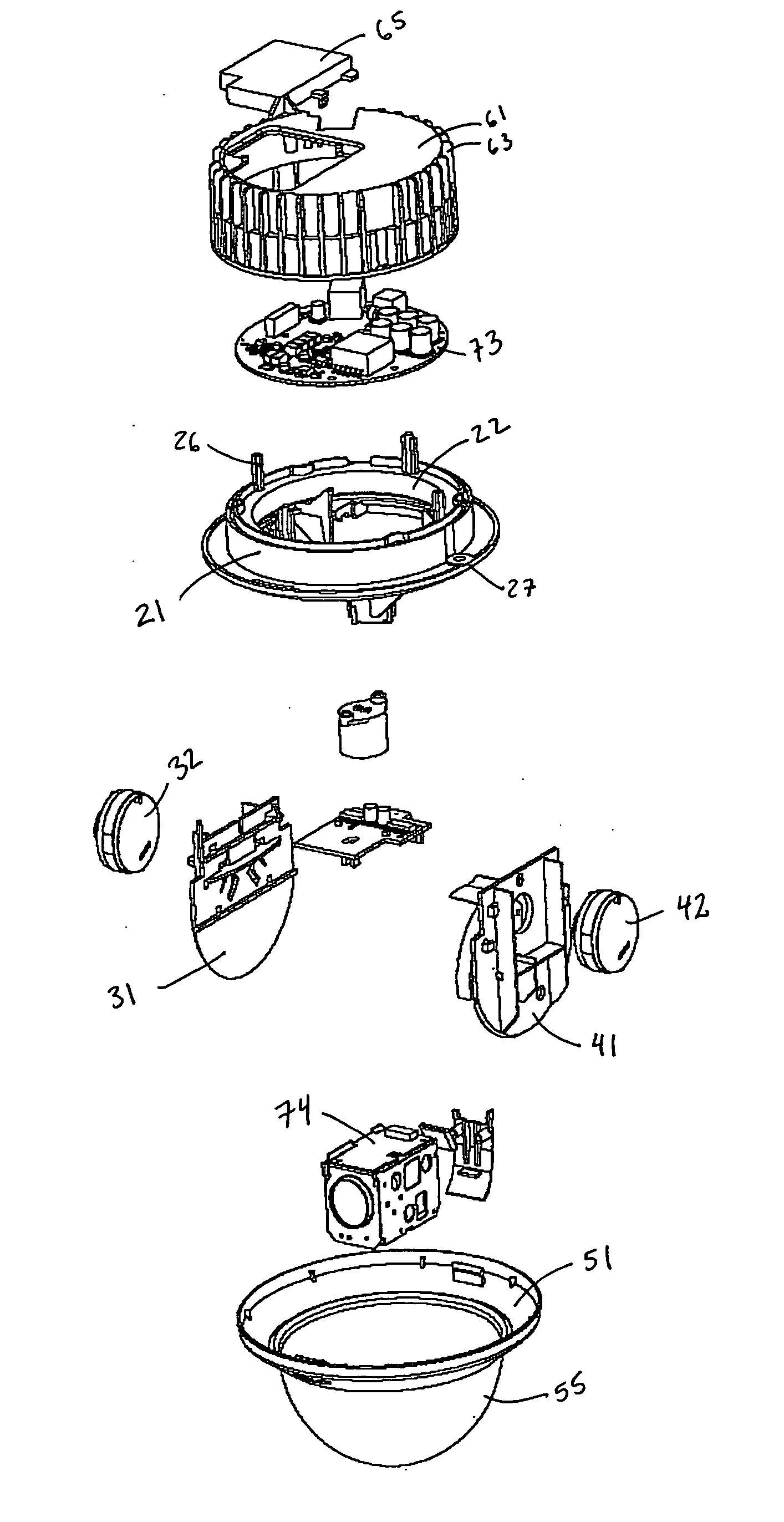

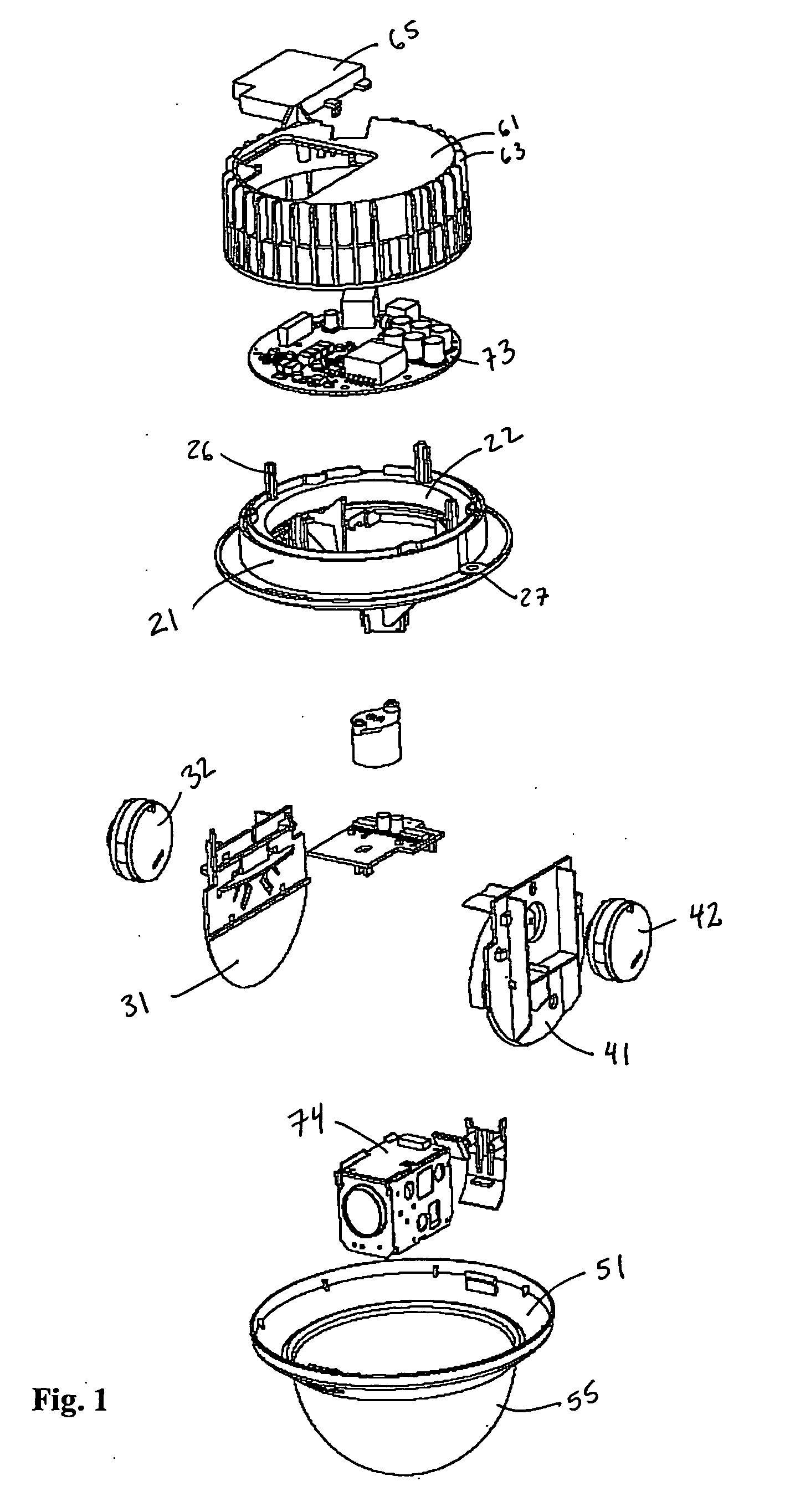

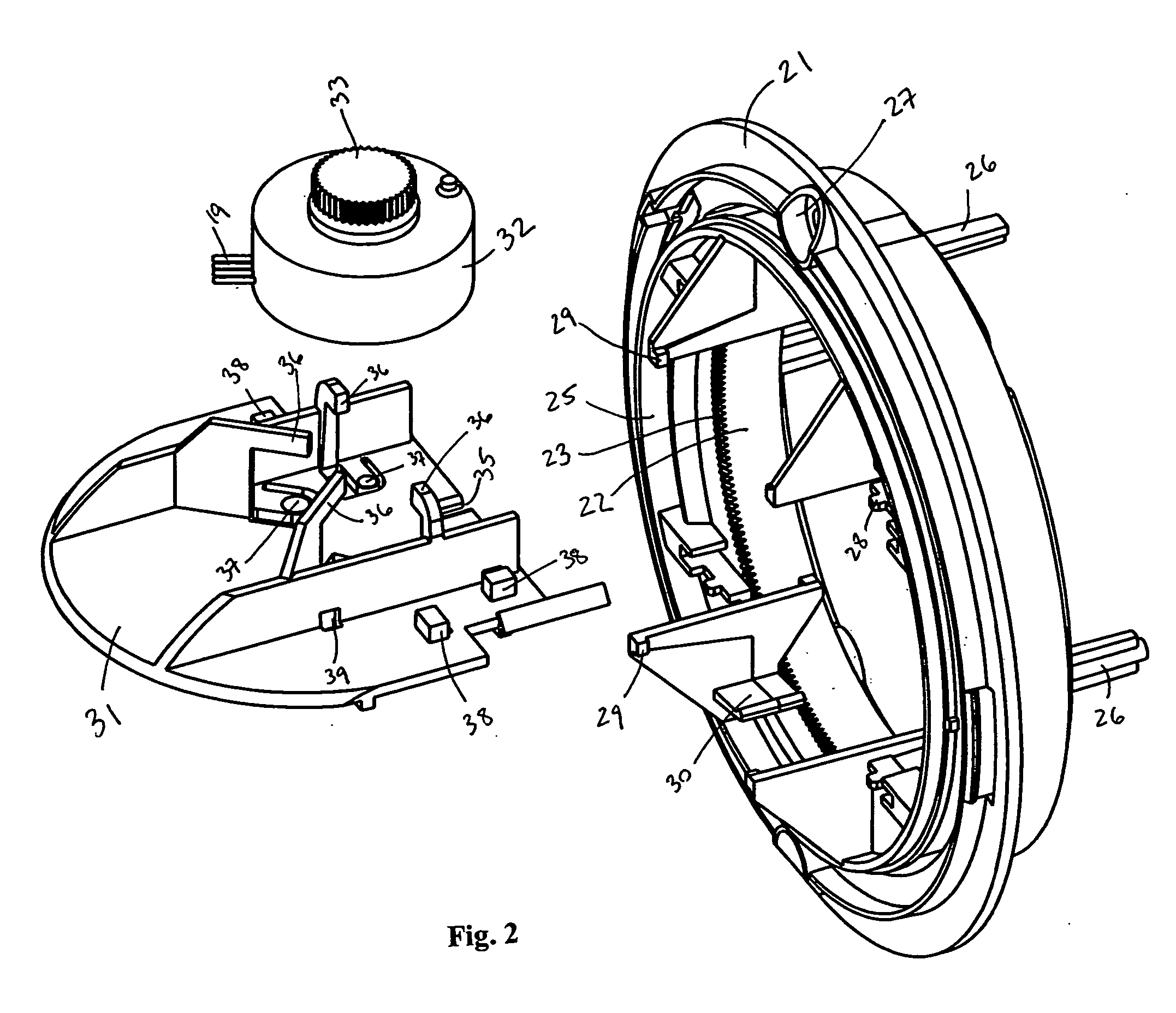

Camera support and mounting assembly

InactiveUS20070053681A1Precise positioningMinimal numberTelevision system detailsColor television detailsTension memberFastener

The present invention is a camera mounting structure that is made using a minimal number of parts that are attached together without the use of hardware or fasteners. One or more motors are each mounted to a support bracket using locking tabs, boss registers, clips and / or tension members. Pins or registers on each motor correspond to openings or slots on each support bracket for precise positioning of the motor when attached to the bracket. Each motor support bracket is, in turn, attached to a rotatable ring that moves in a base without the use of hardware or fasteners. Motors and brackets are provided for the pan and tilt movements of the camera. The rotatable ring is journaled directly to the based using an annular channel in the base to further minimize the number of parts making up the mounting assembly, allowing for easy assembly, disassembly, service and repair.

Owner:PELCO INC

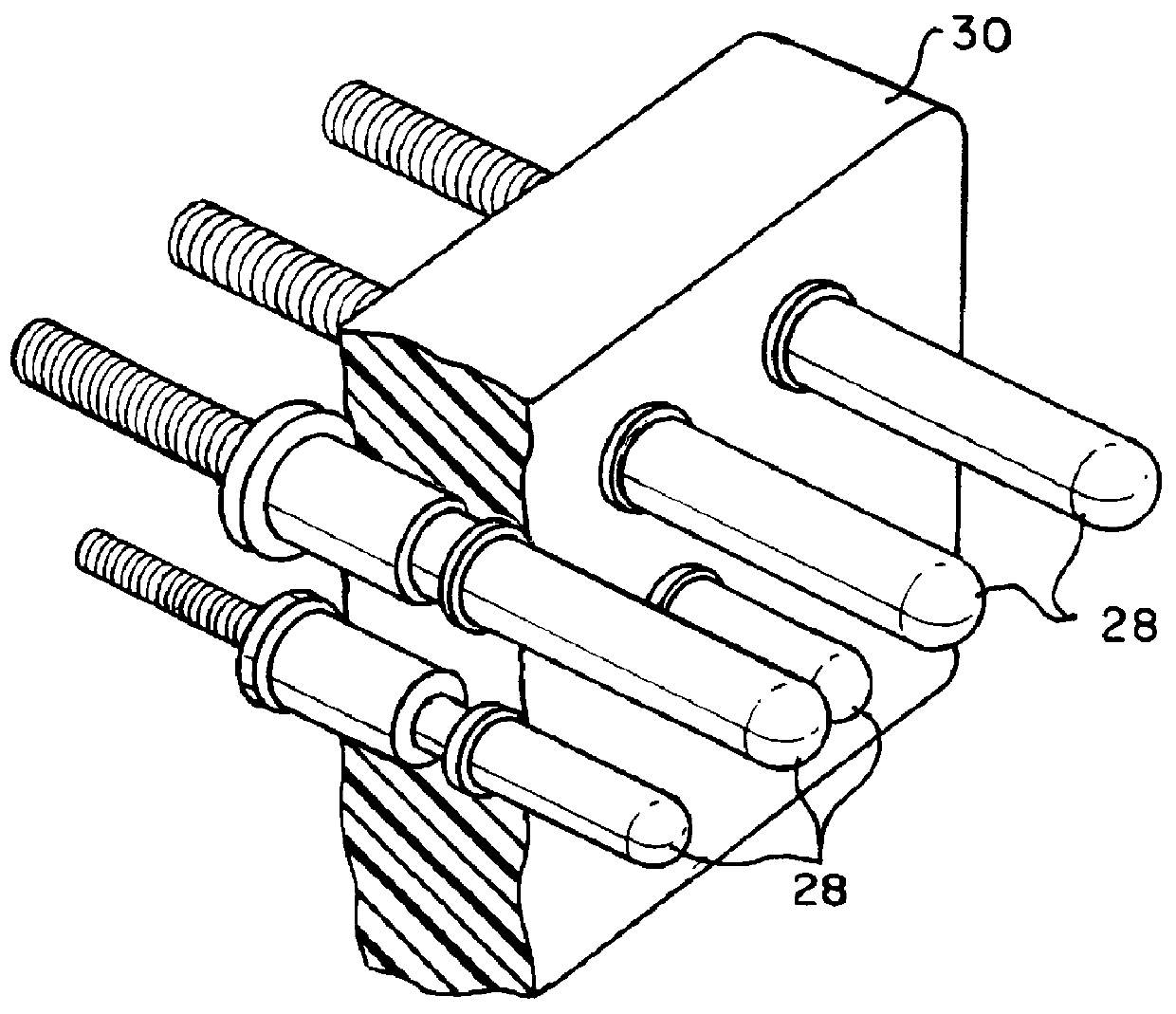

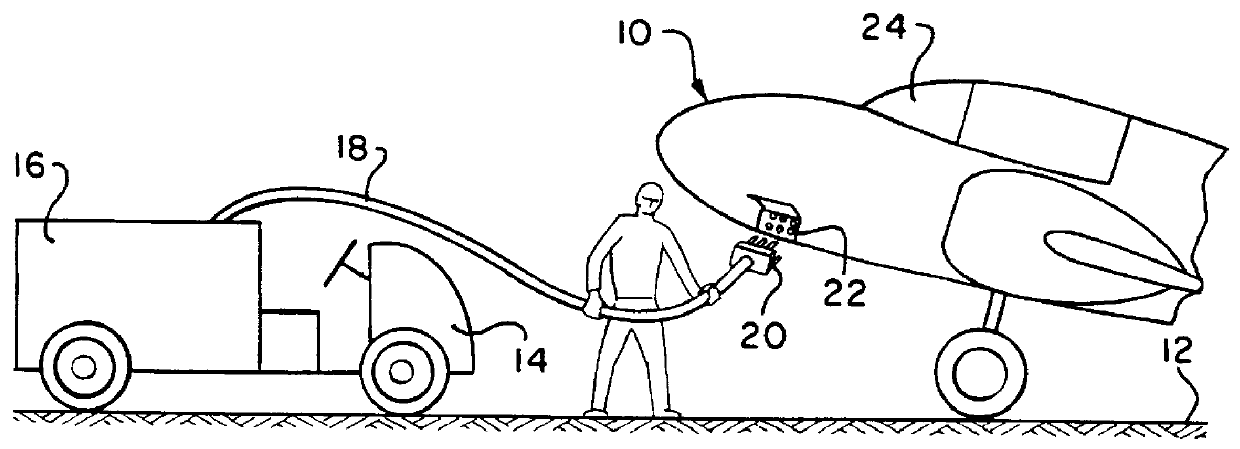

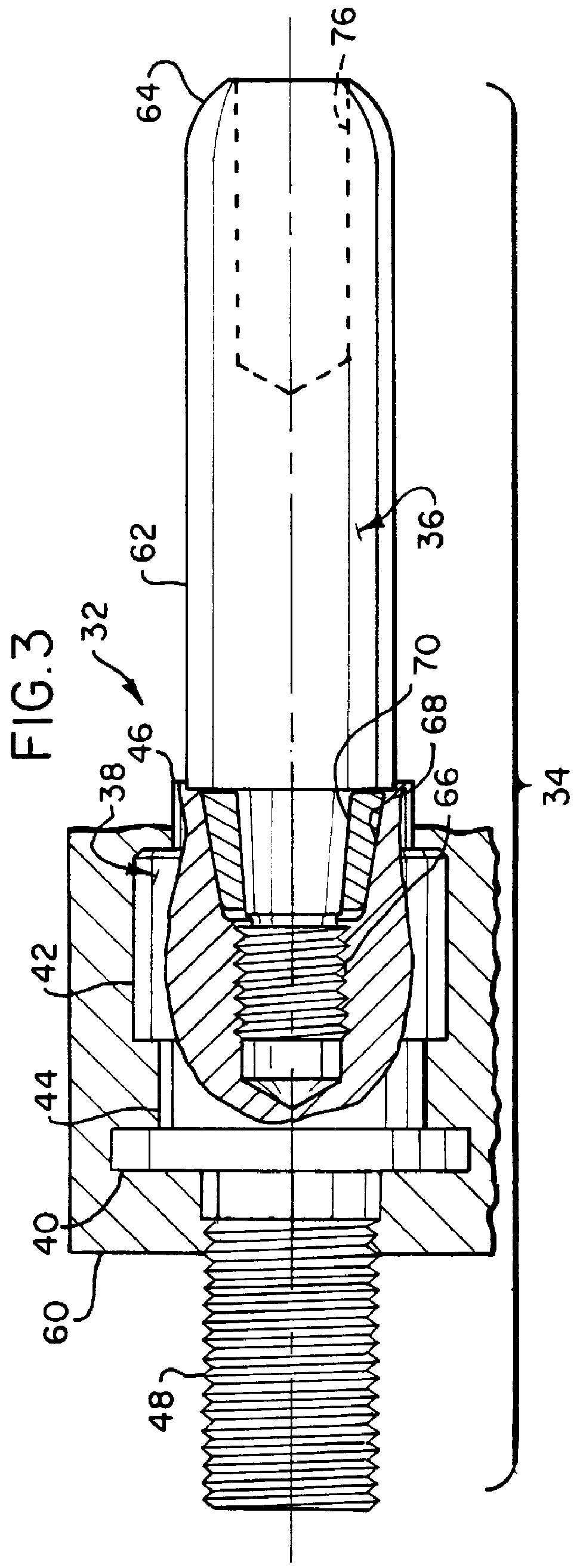

Electrical connector with replaceable pin contacts not requiring accompanying re-termination

An electrical receptacle (32) mounted to an aircraft (10) includes a pin contact assembly (34) having a pin body (62) releasably threaded within a threaded insert (38). A collet (70) enhances mechanical securement and electrical contact between the insert (38) and pin body (62). The outer end of the pin body (62) is configured (76) to receive a wrench for assembly disassembly of the parts.

Owner:WPIVIKING +1

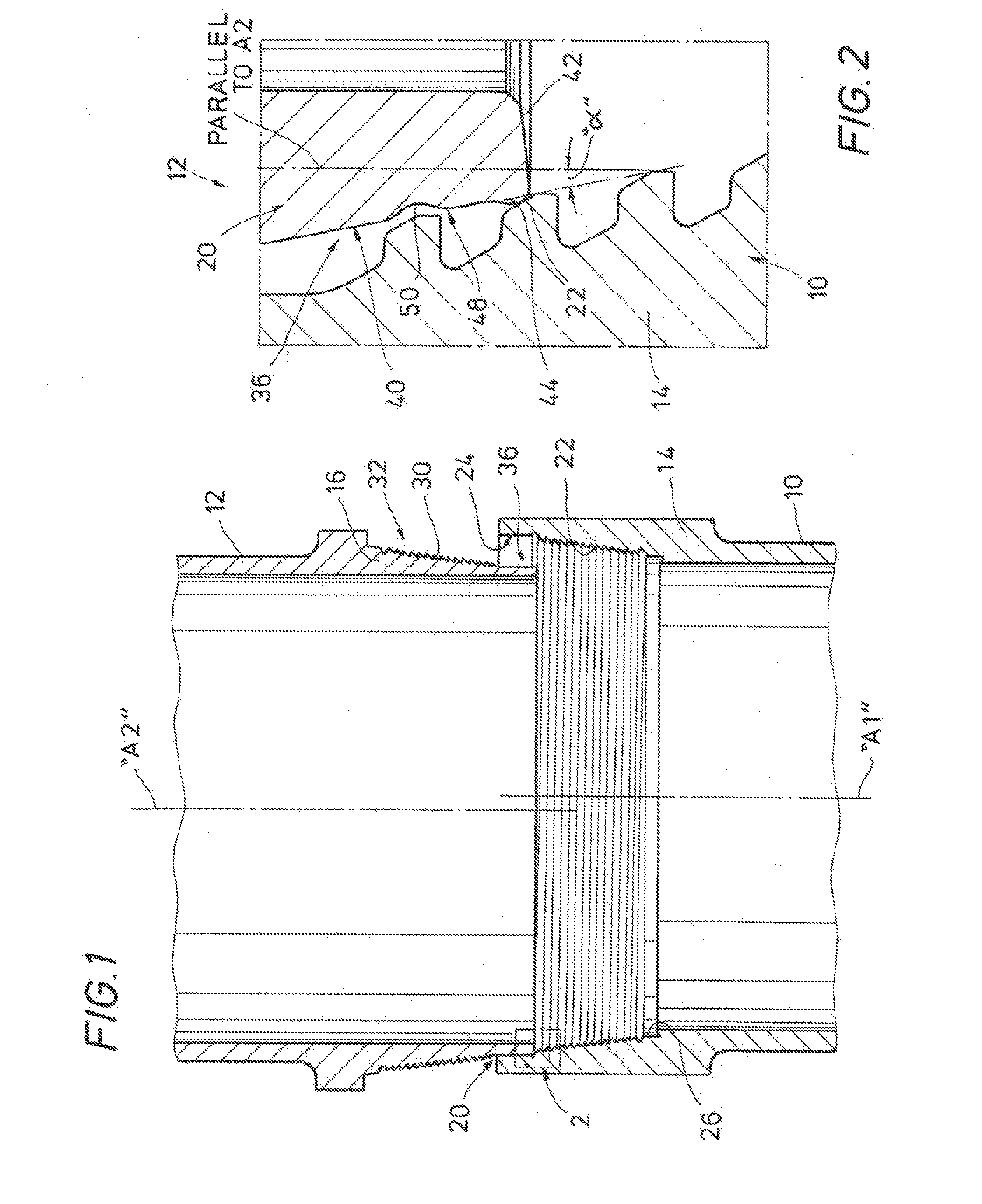

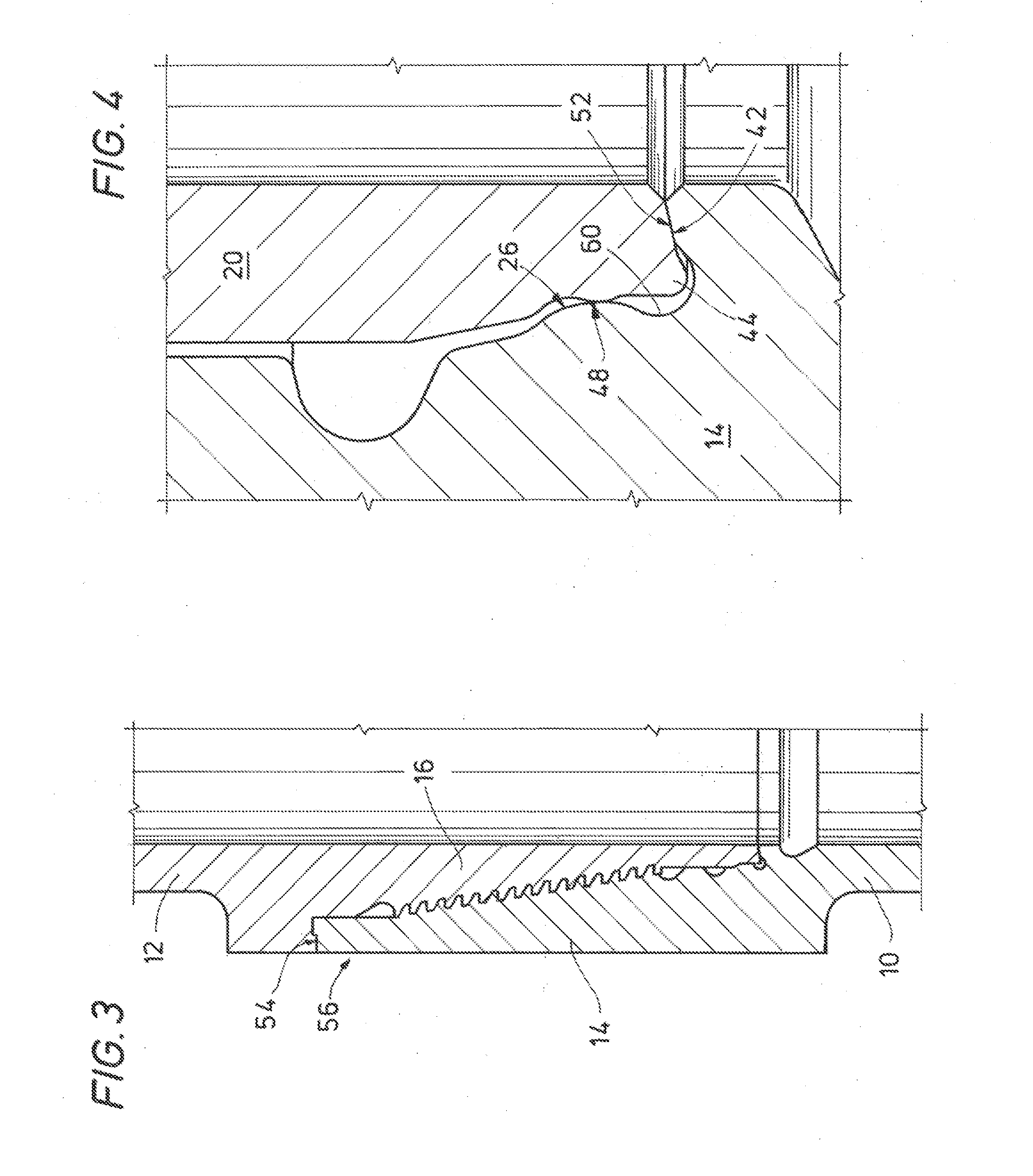

Alignment guide feature for metal to metal seal protection on mechanical connections and couplings

A connection is established between a pin connector and a box connector defined on a pair of tubular members such as casing segments in the field of oil and gas recovery. The pin connector and box connector include features for the protection of metallic-sealing surfaces during assembly, disassembly, transport and handling of the tubular members. The pin connector includes a stabbing flank with an inwardly tapered annular flank surface thereon, and an alignment protrusion extending outward with respect to the pin-side metallic sealing surface in a direction normal to a cone angle defined by the inwardly tapered annular flank surface. The alignment protrusion engages internal surfaces of the box connector to concentrically align the pin connector with the box connector, and thereby protects the metallic sealing surfaces from damage that might otherwise result from collisions between the pin connector and the box connector.

Owner:VETCO GRAY

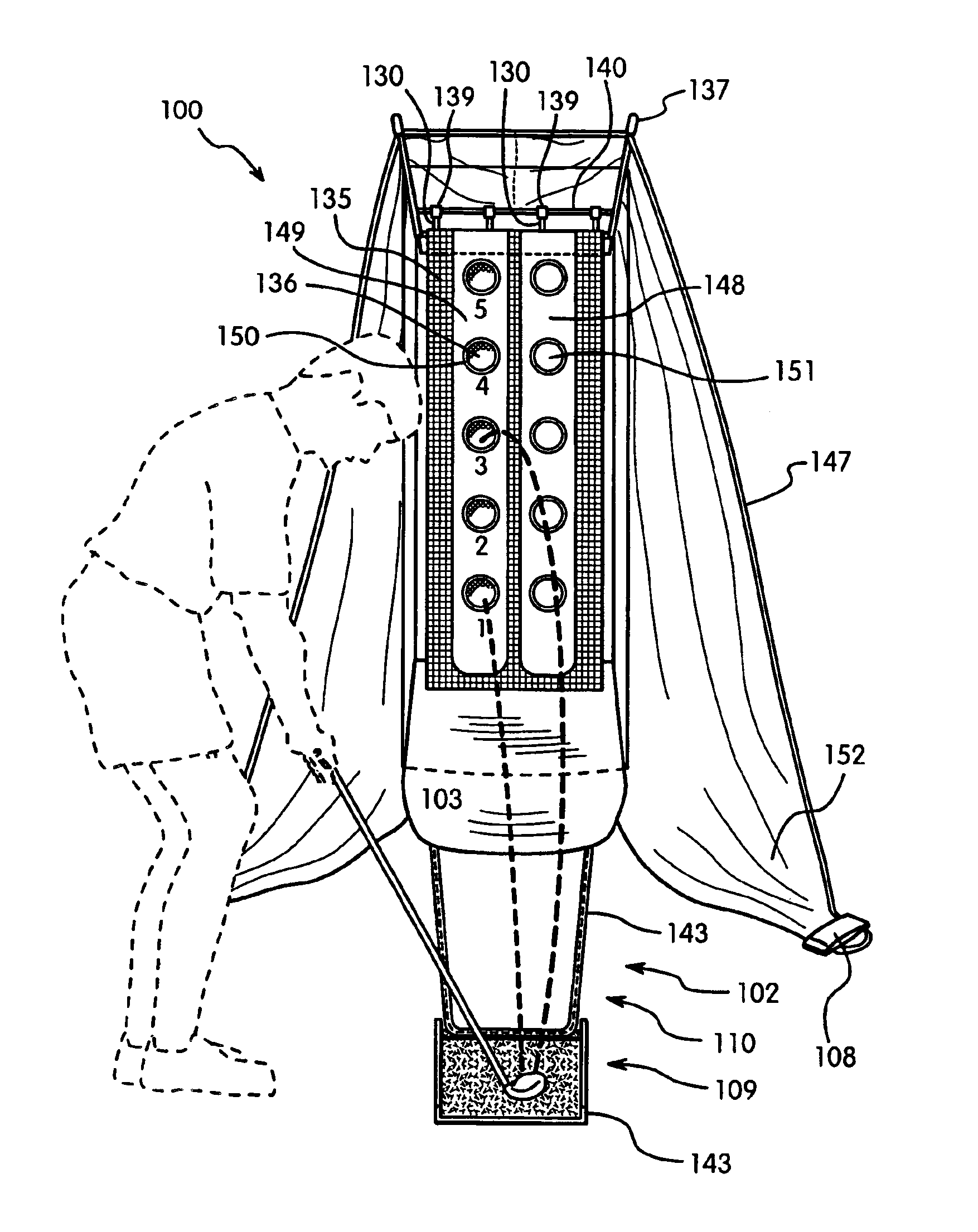

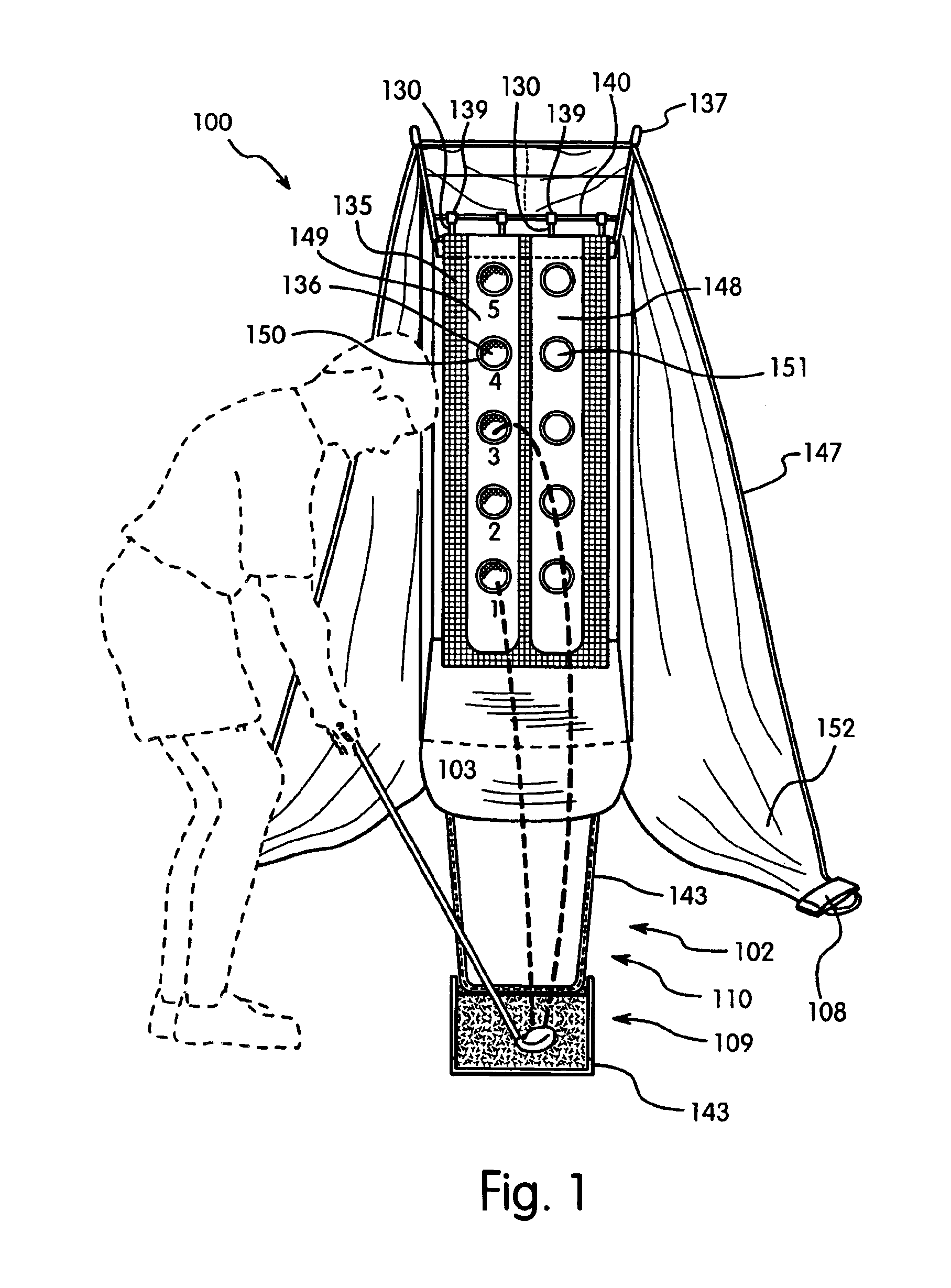

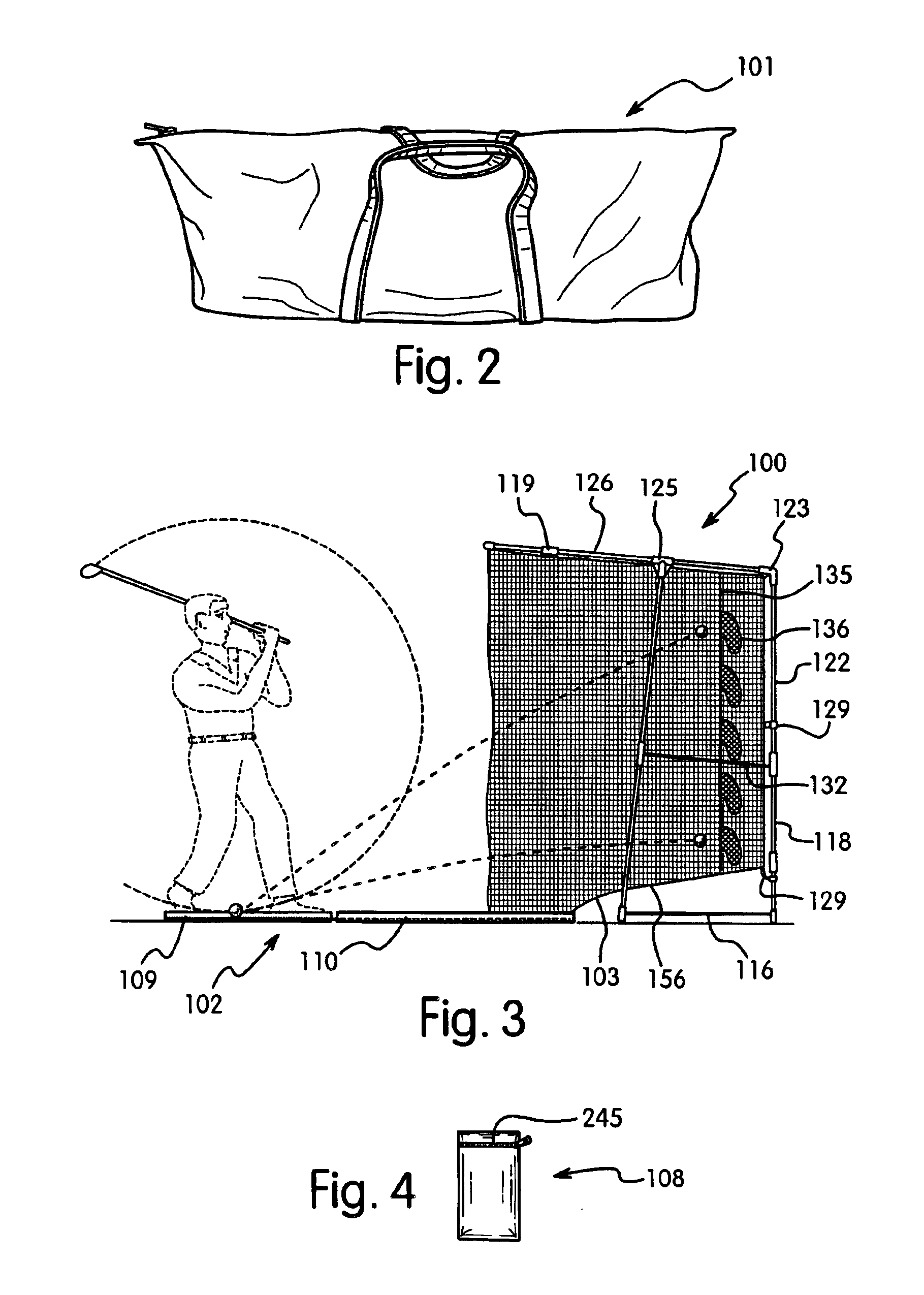

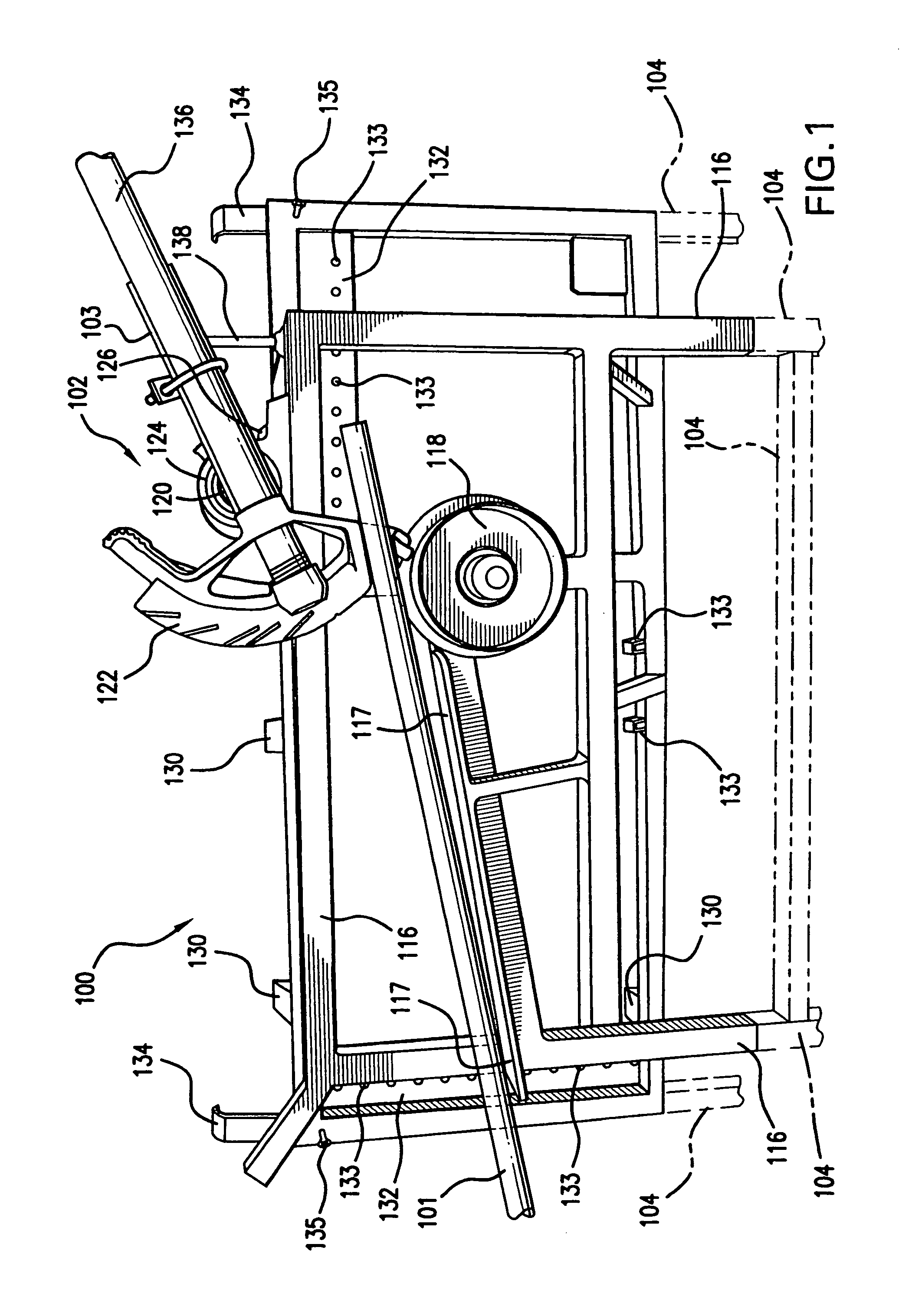

Golf short game training, practice and contest game kit

InactiveUS6905418B2Efficient and effective and economicalEasy to disassembleGymnastic exercisingBall sportsSteel tubeEngineering

A Golf Short Game Training, Practice and Contest Game assemblage, which is easy to assemble, disassemble and transport from location to location (in, for example, the provided carrying bag) and which includes a main frame which is assembled from various steel pipes and connecting parts, a netting which is supported by the frame and which includes an inclined chute-shaped floor net which is affixed to or integral with the bottom floor of the netting, the front side of which is lower than the back portion of the netting; and a target which is suspended from the top portion of the netting and has at least one hole in it which is larger than a golf ball.

Owner:RHEE YONG SU

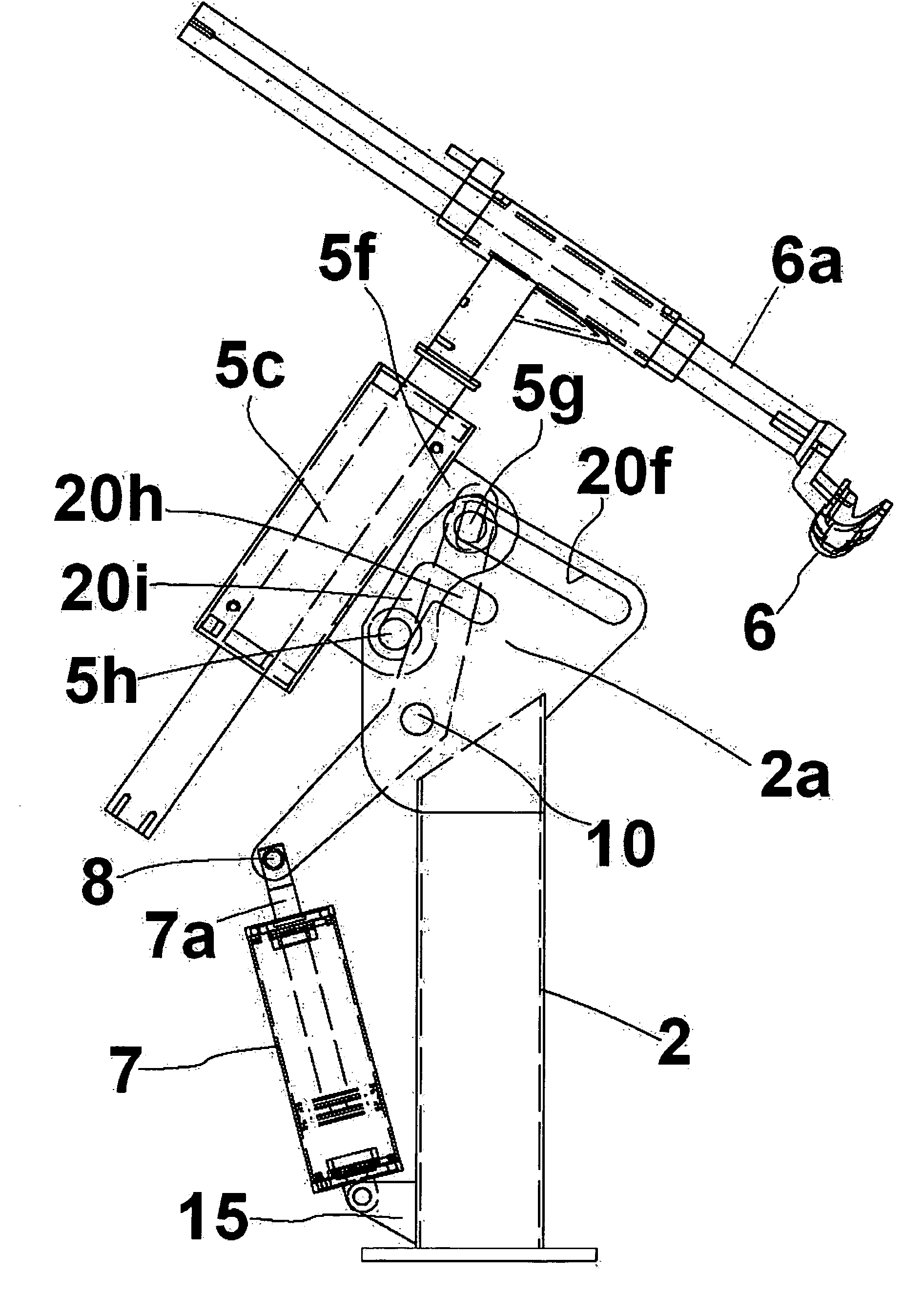

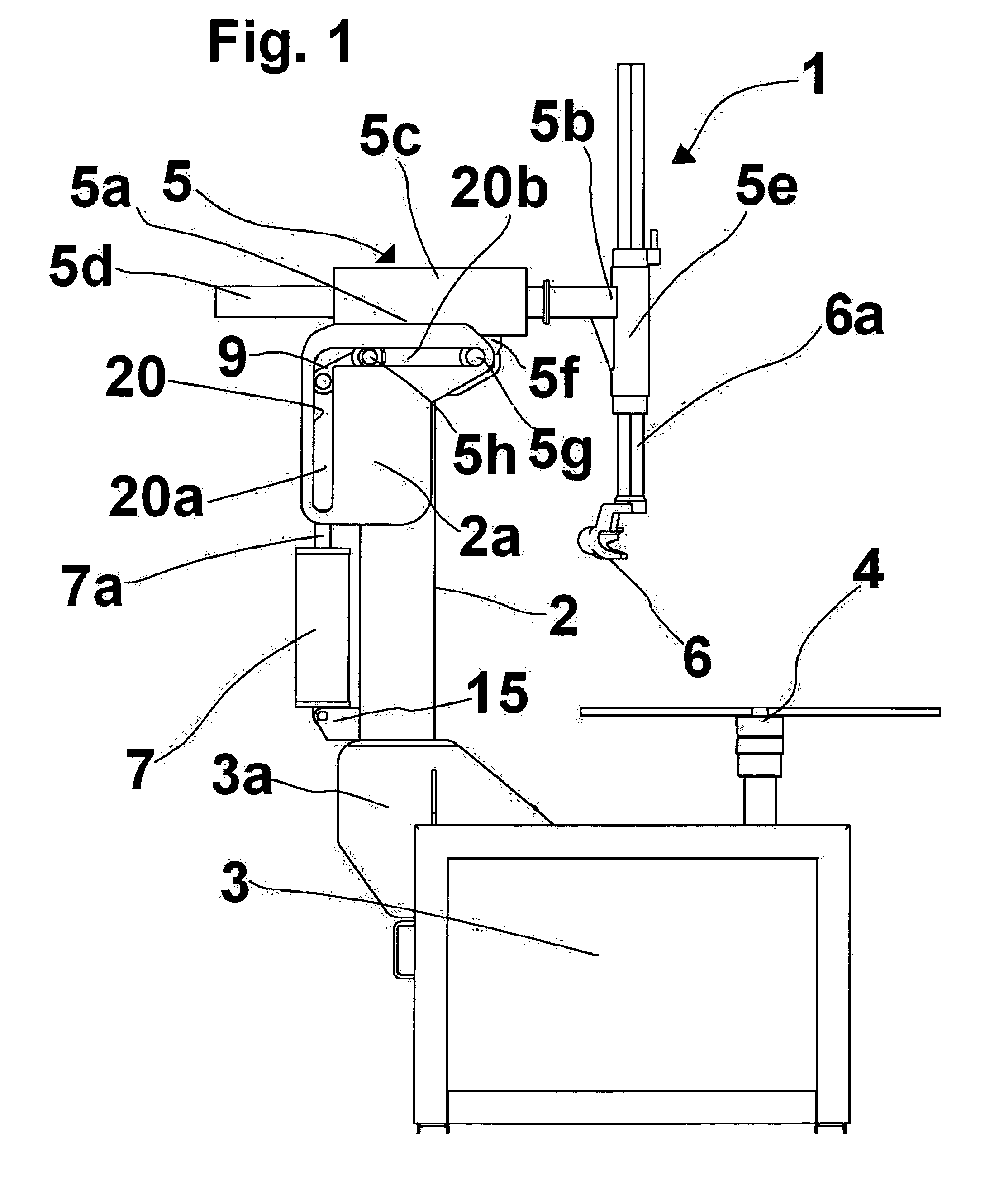

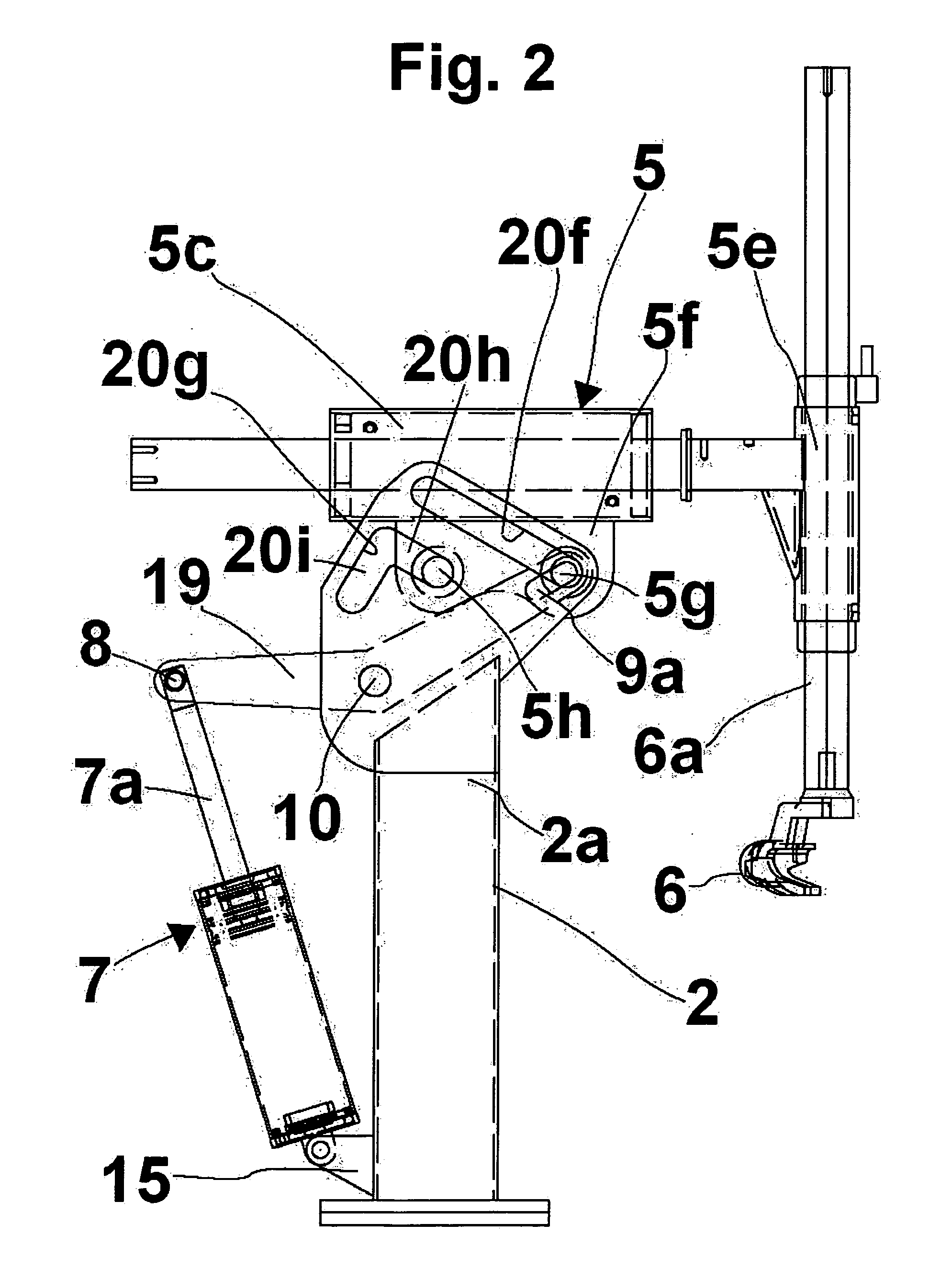

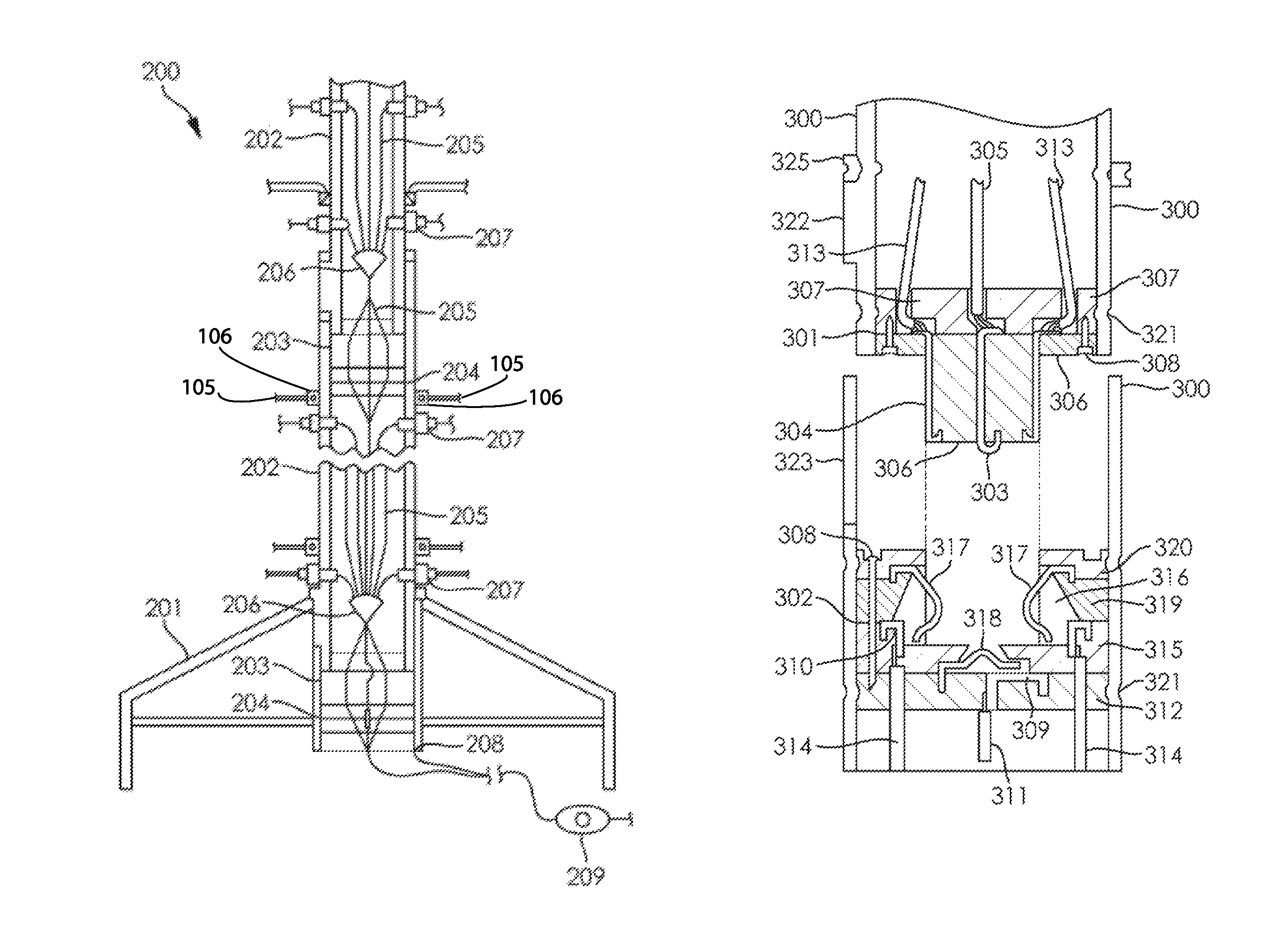

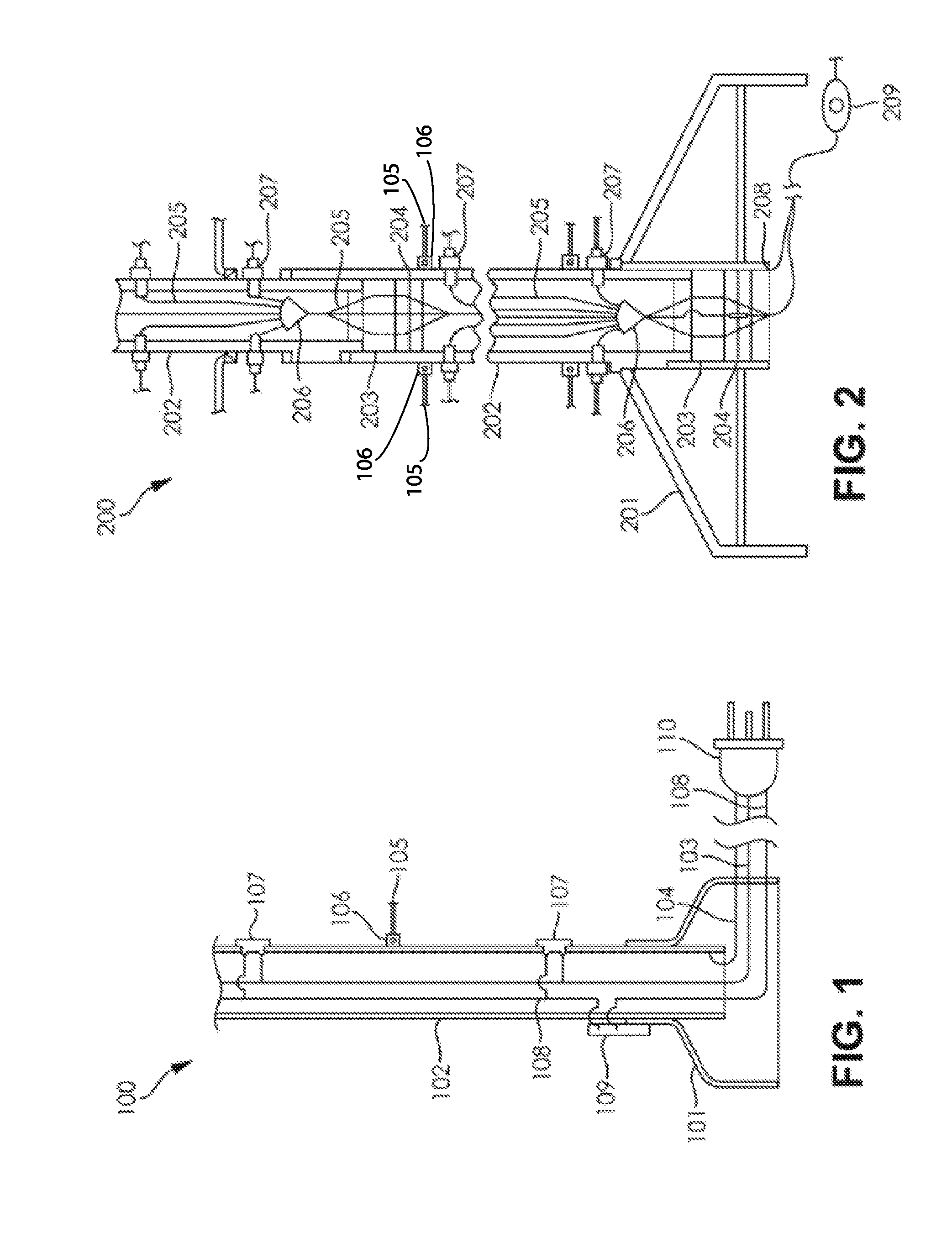

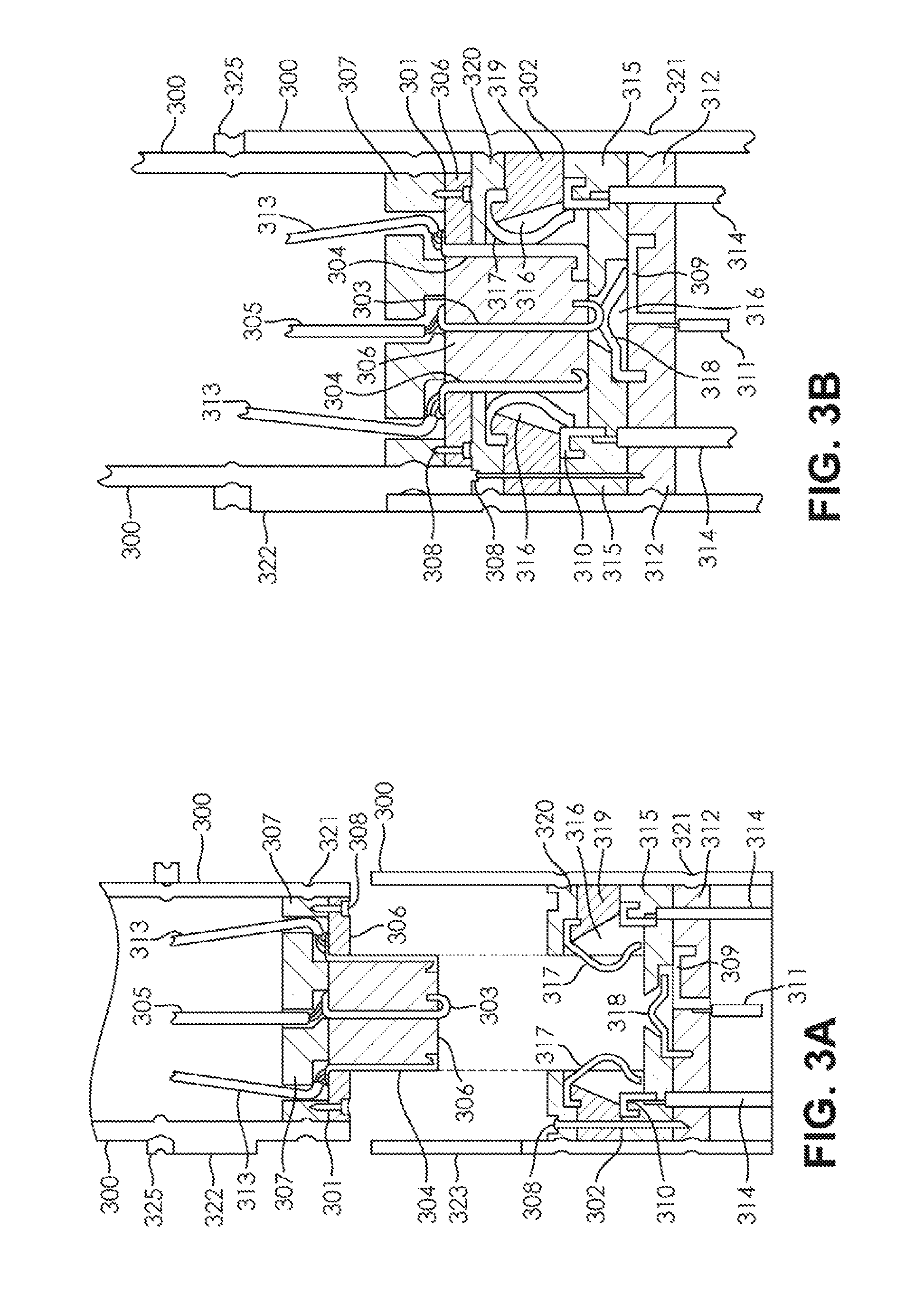

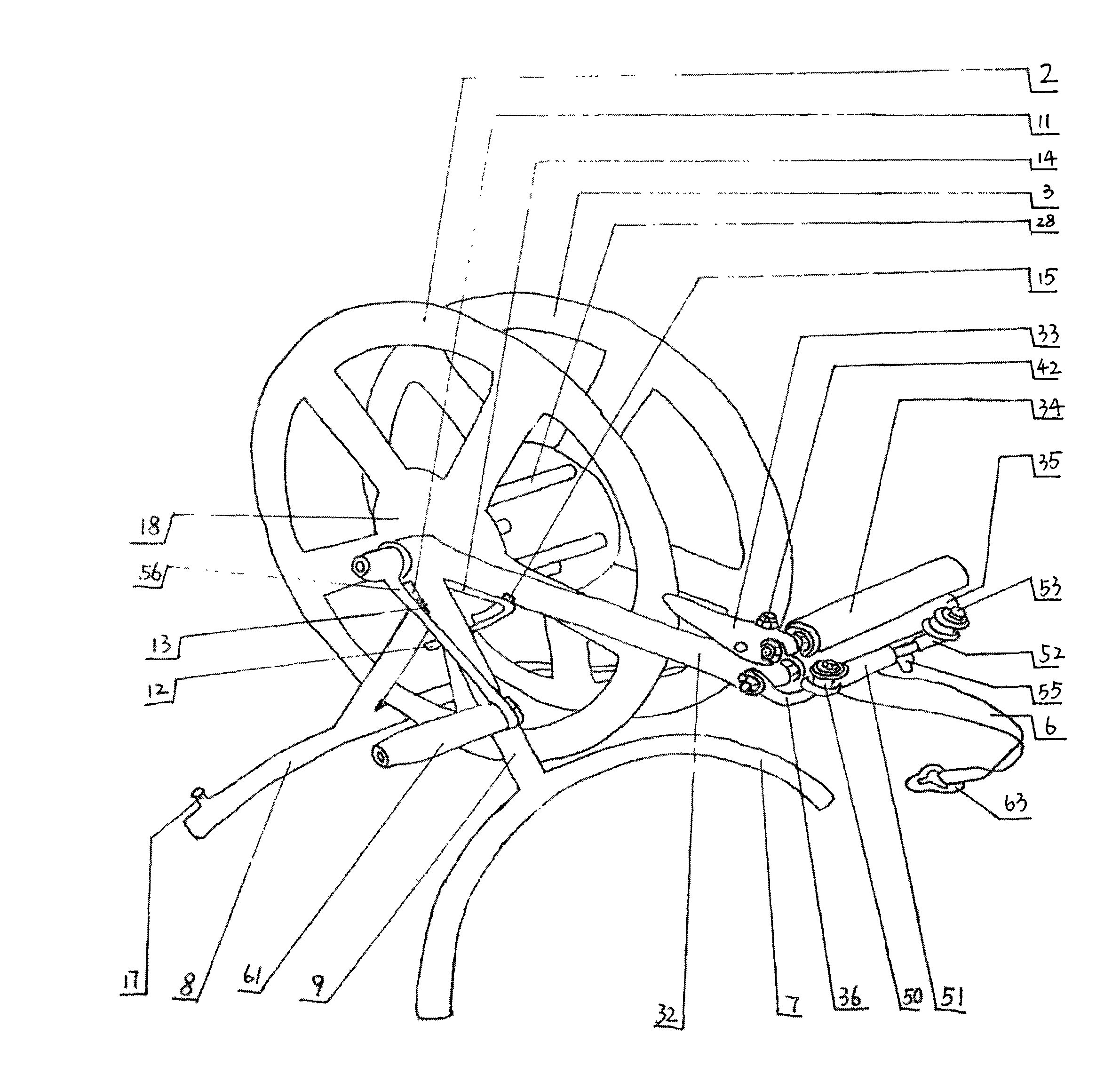

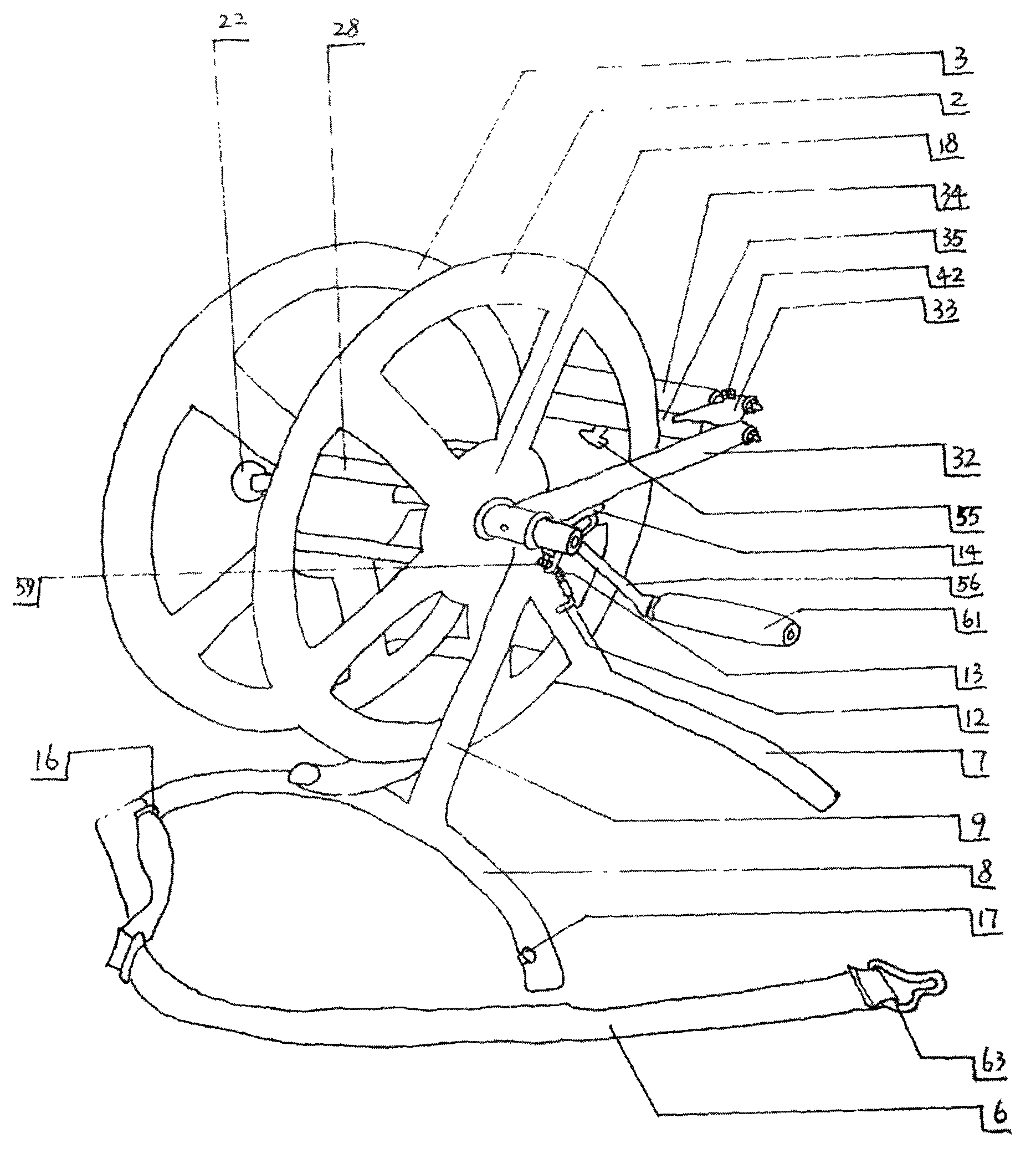

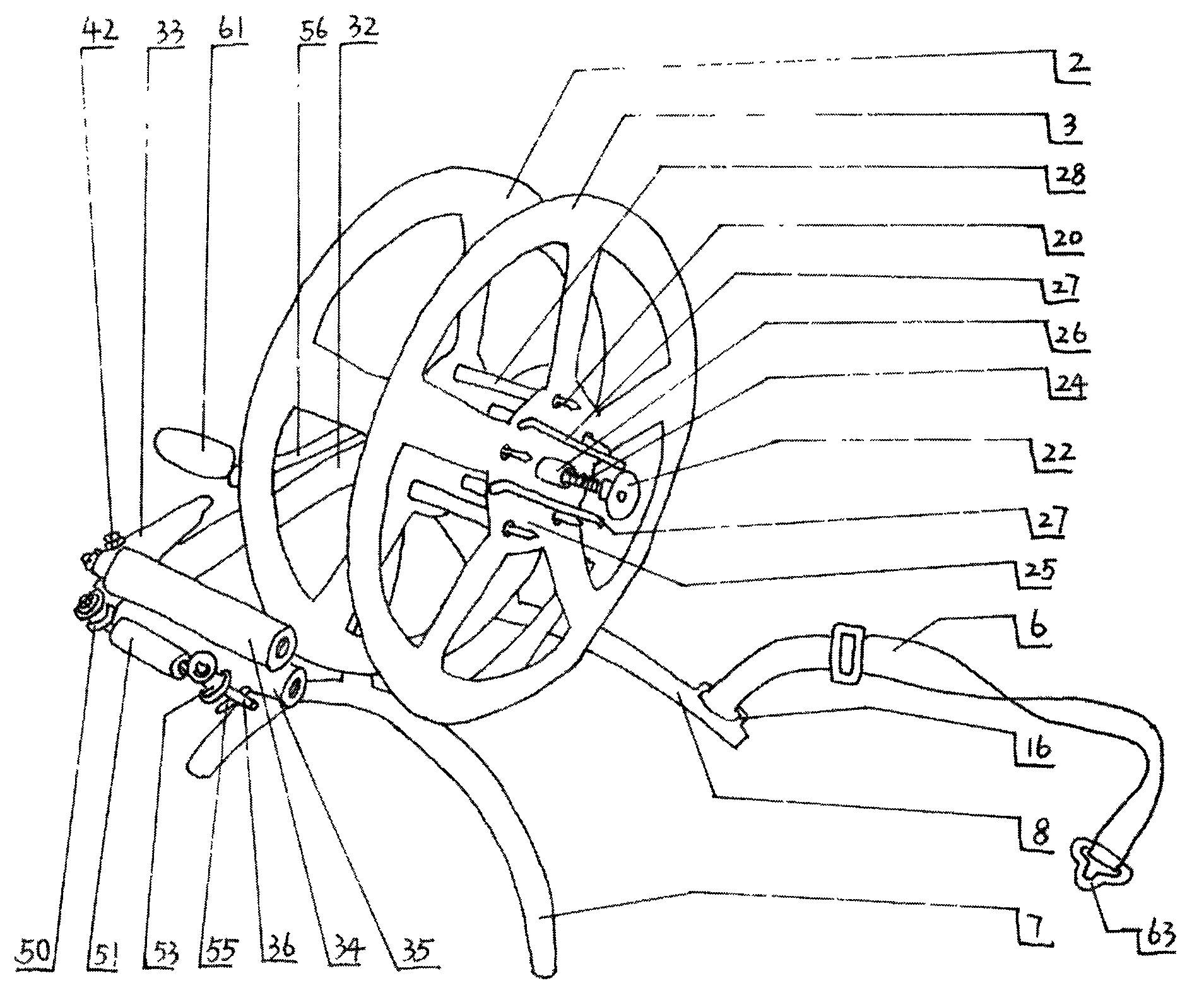

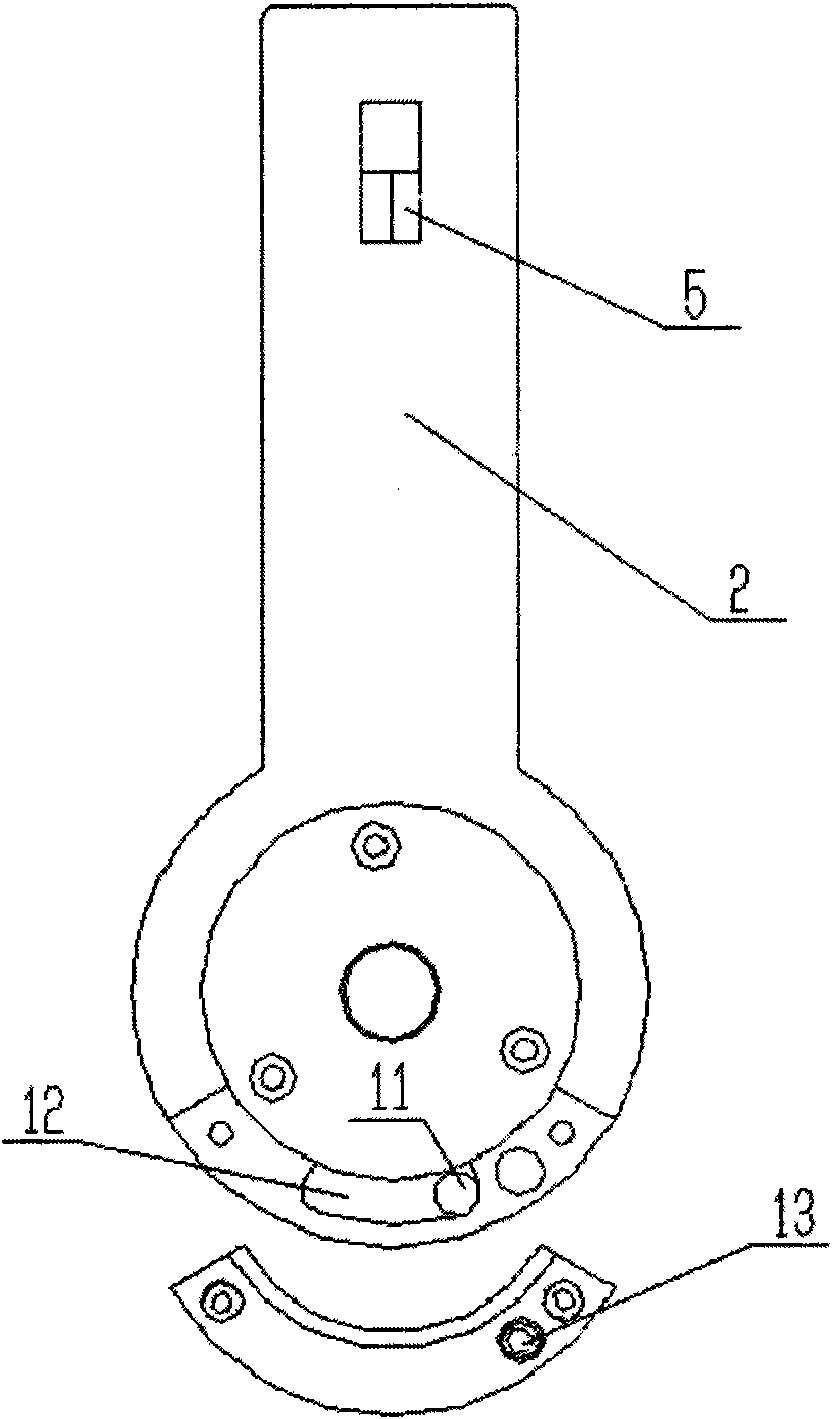

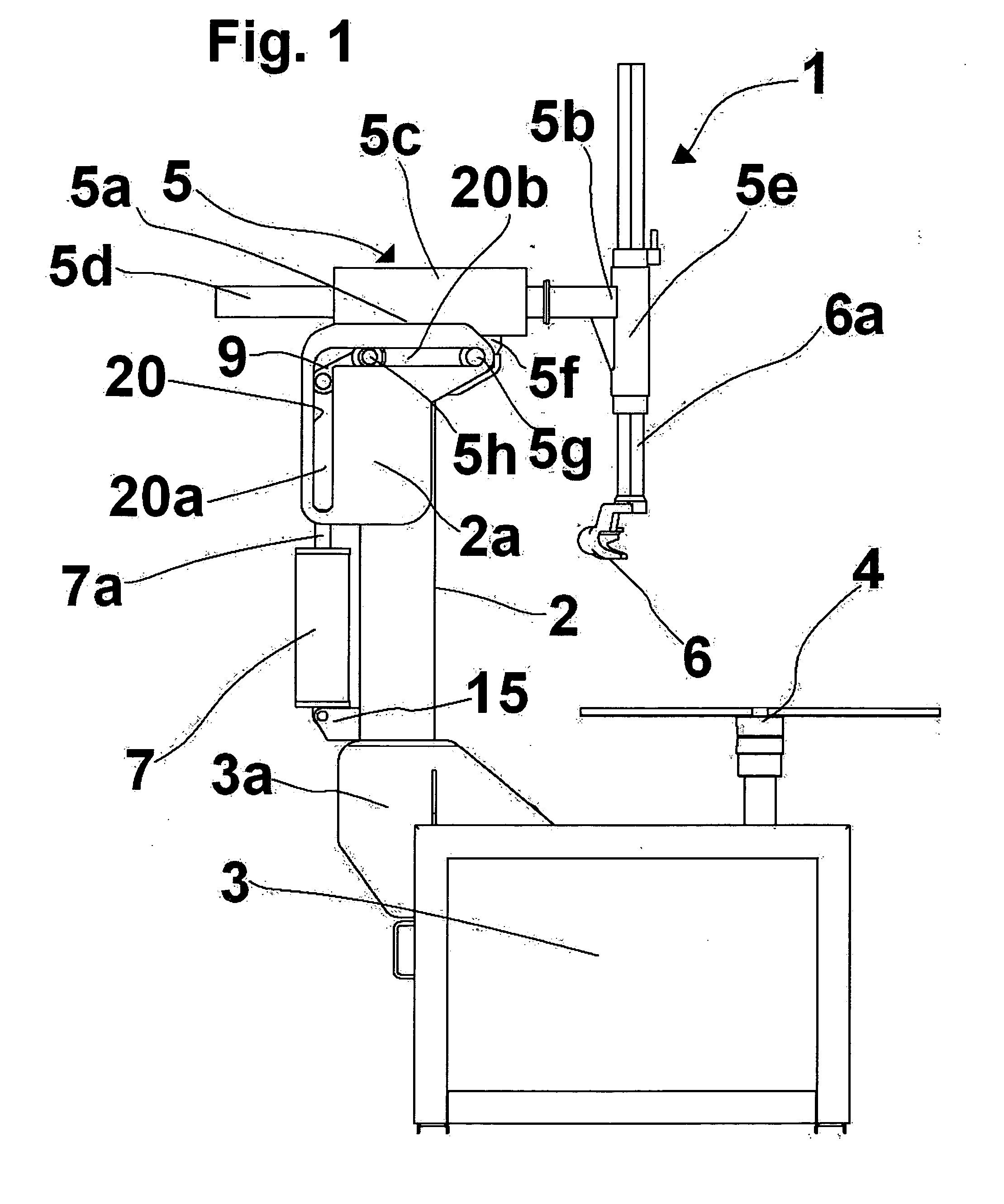

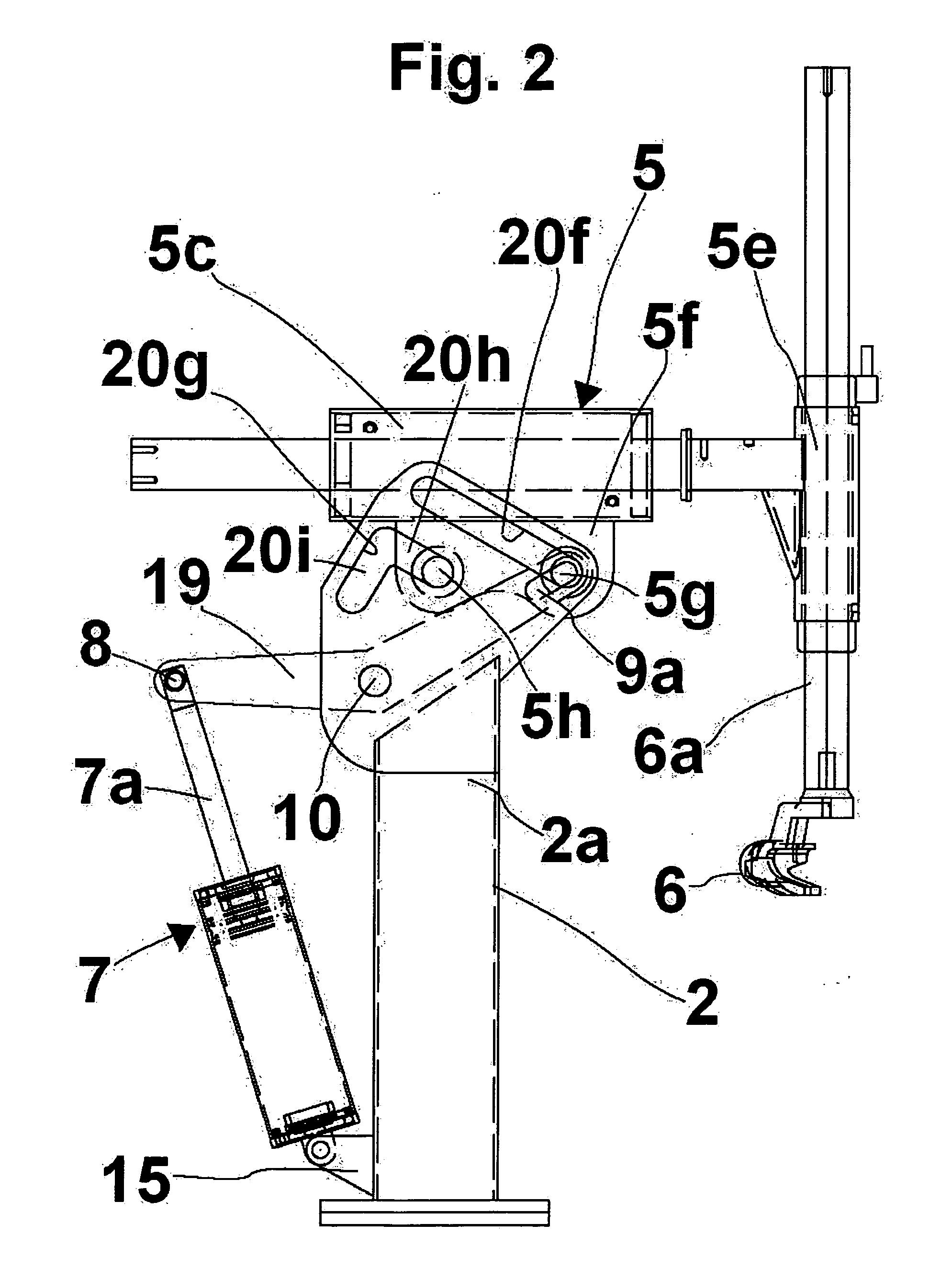

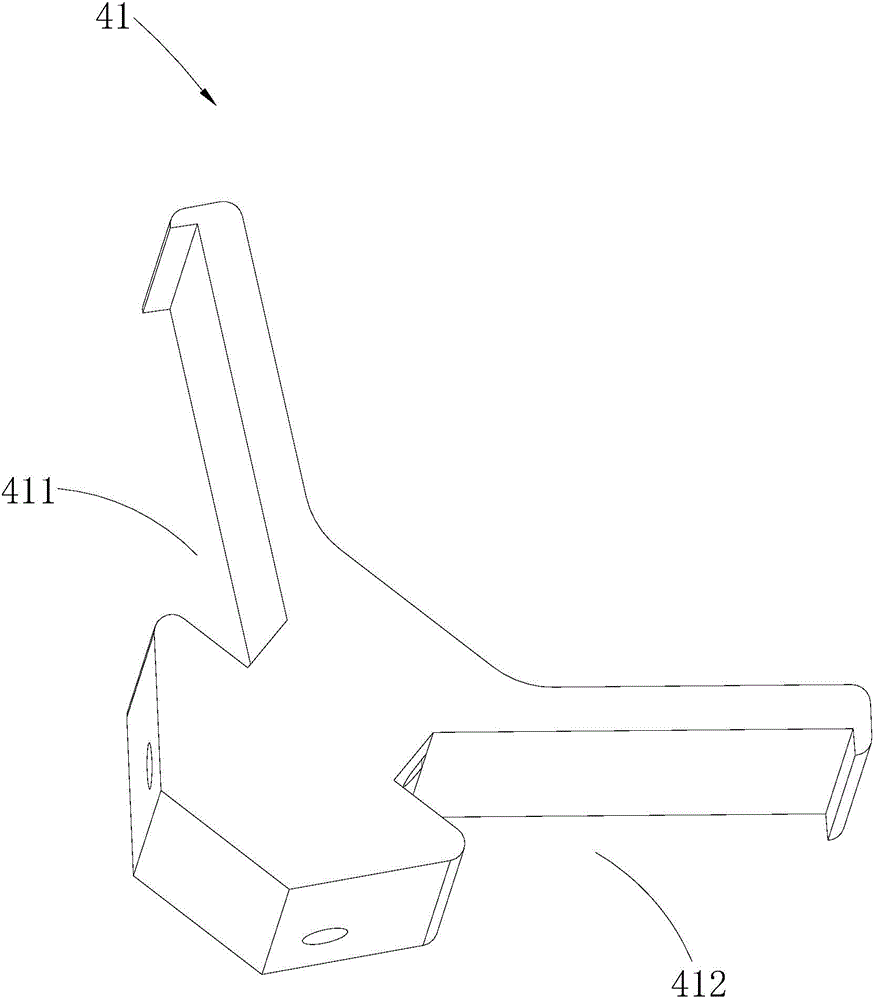

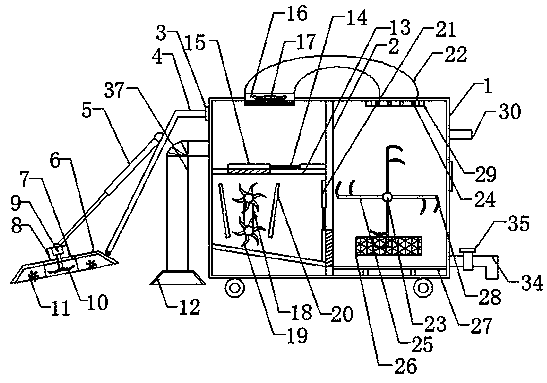

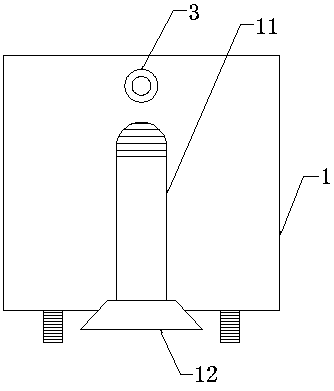

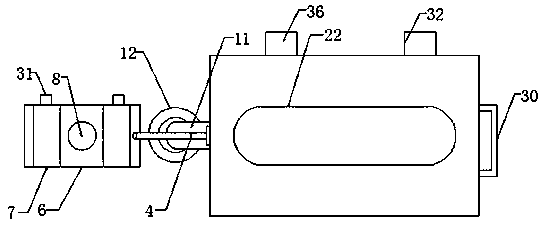

Assembling-disassembling machine provided with a overturnable mounting-dismounting tool

ActiveUS7341090B2Minimal effortWithout causing unbalanceTyre repairingRest positionAssembly disassembly

The present invention relates to an assembling-disassembling machine provided with a base, a rotating support device (4) for a wheel rim or tyred wheel, an upright or column element (2) extending upwards from the base, and at least one mounting / dismounting tool (6) supported by the upright or column element (2) and mounted on one end of a tool carrying arm (5) in order to transversely extend from the upright element (2). The assembling-disassembling machine also comprises rotating and shifting support means located between the upright or column element (2) and the tool-carrying arm (5) at an upper level with respect to the rotating support device (4), whereby said tool-carrying arm (5) can be rotated and shifted with respect to the upright or column element (2) between a working position, in which the tool (6) is close to the rotating support device (4) and at least one rest position far from the rotating support device (4).

Owner:BUTLER ENG & MARKETING

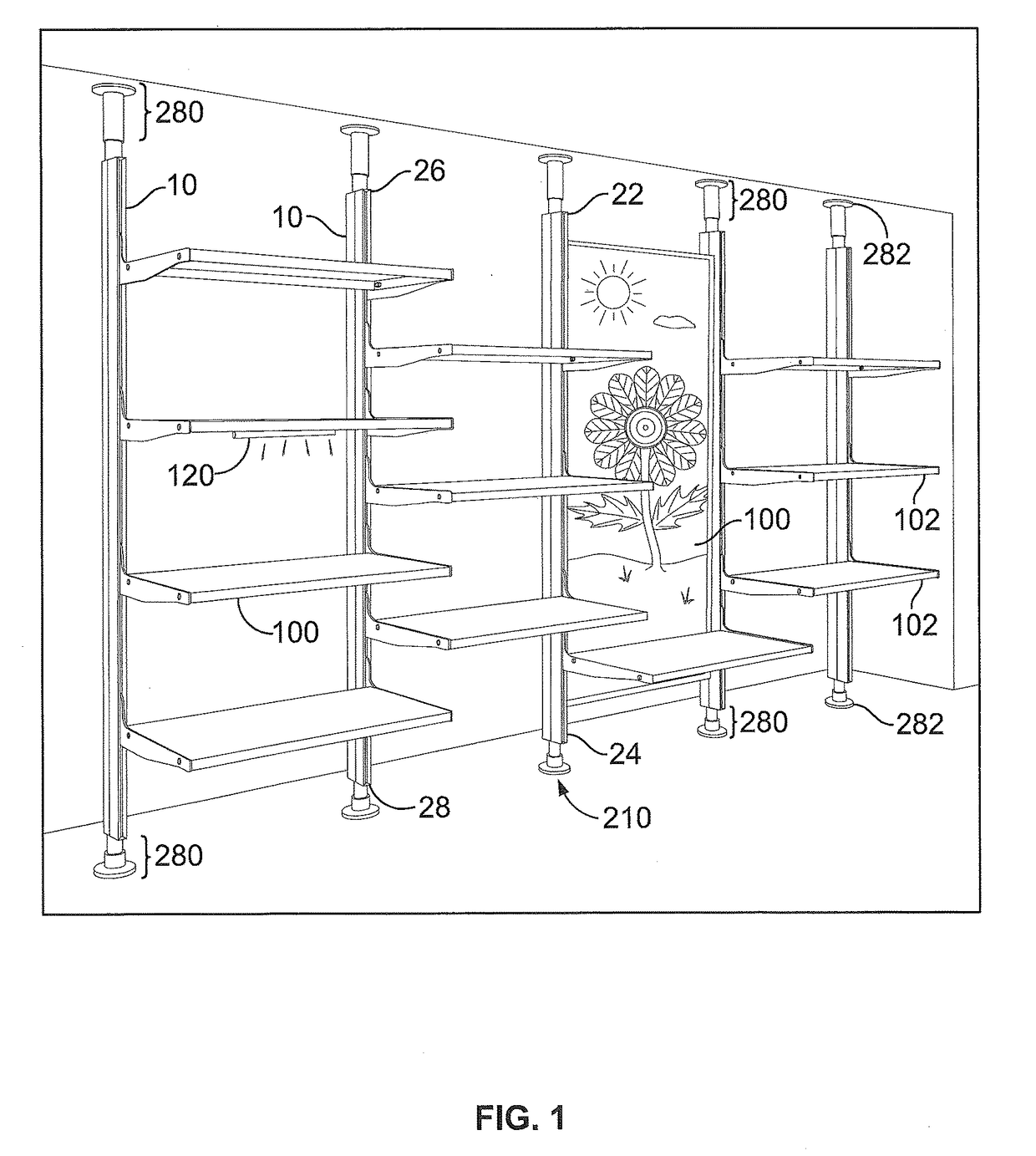

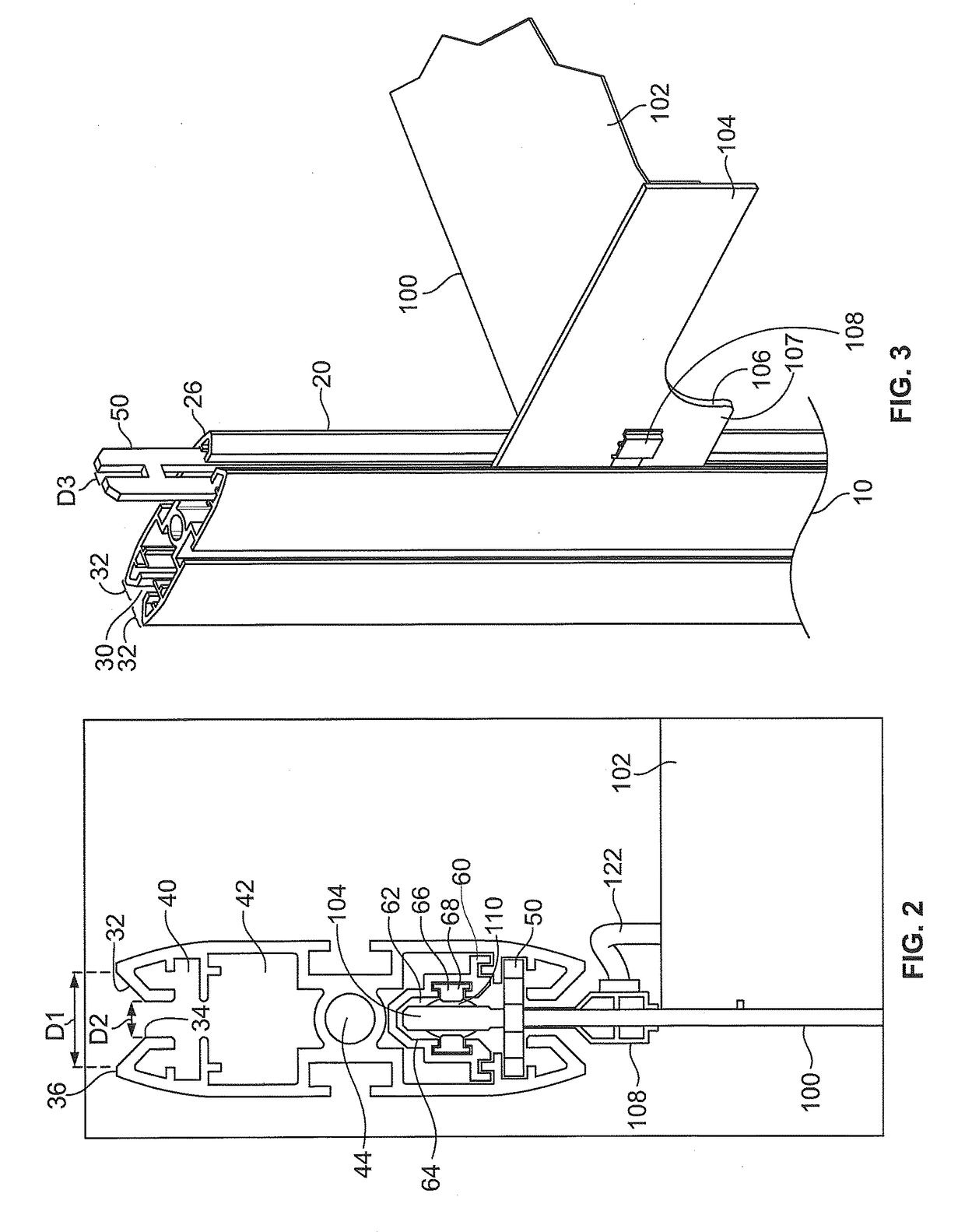

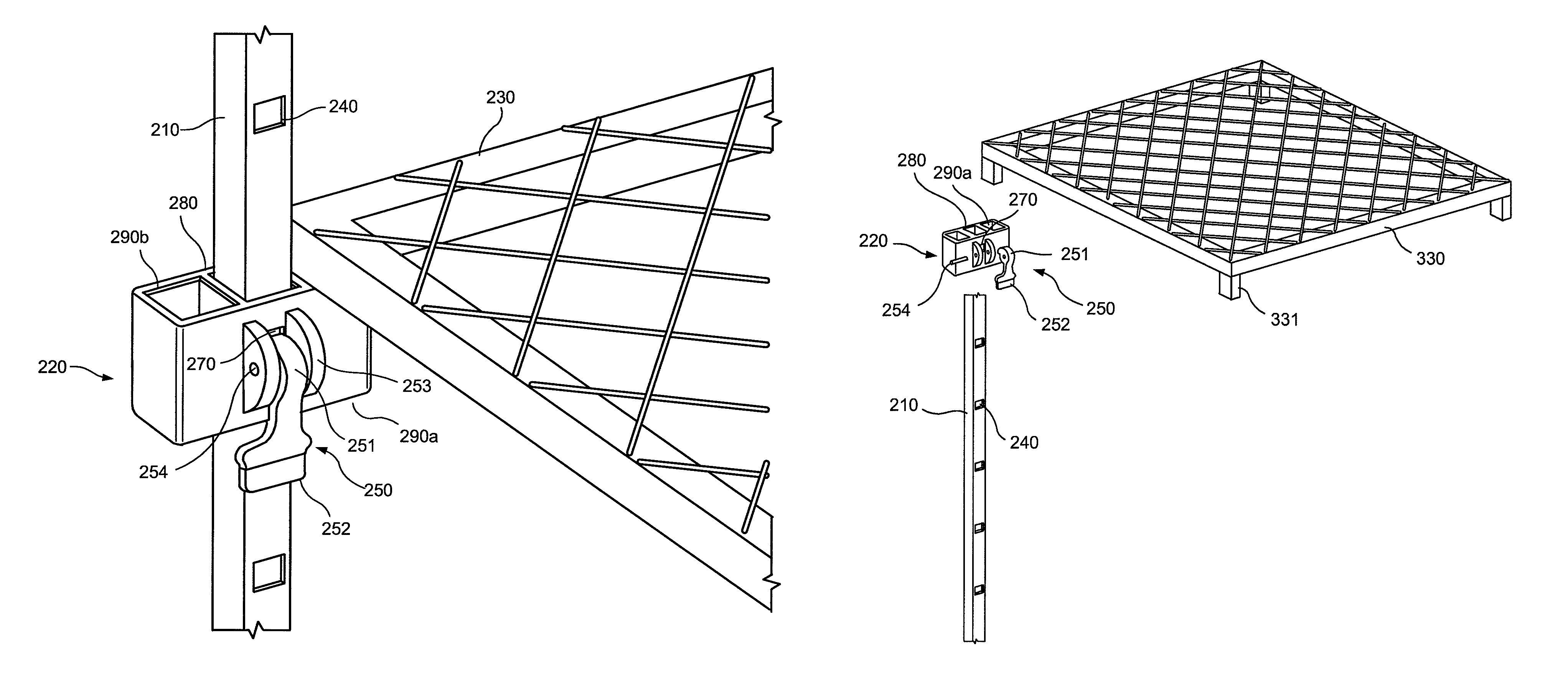

Vertical support for shelving system and shelving system

A vertical support provides for the rapid assembly, disassembly, and modification of a shelving system in a variety of configurations, as determined by the practical and aesthetic requirements of the user. The vertical support facilitates the mounting of a variety of attachment members, such as shelves, hangers, or media boards, that contain powered appliances, allowing the user to further customize the shelving system to his practical and aesthetic requirements. The vertical support makes it easy for a user to mount these attachment members and hides the connections of the various components, to maximize the aesthetic appeal of the shelving display. Additionally, vertical support can be configured with other subcomponents to form shelving systems.

Owner:OPTO INT

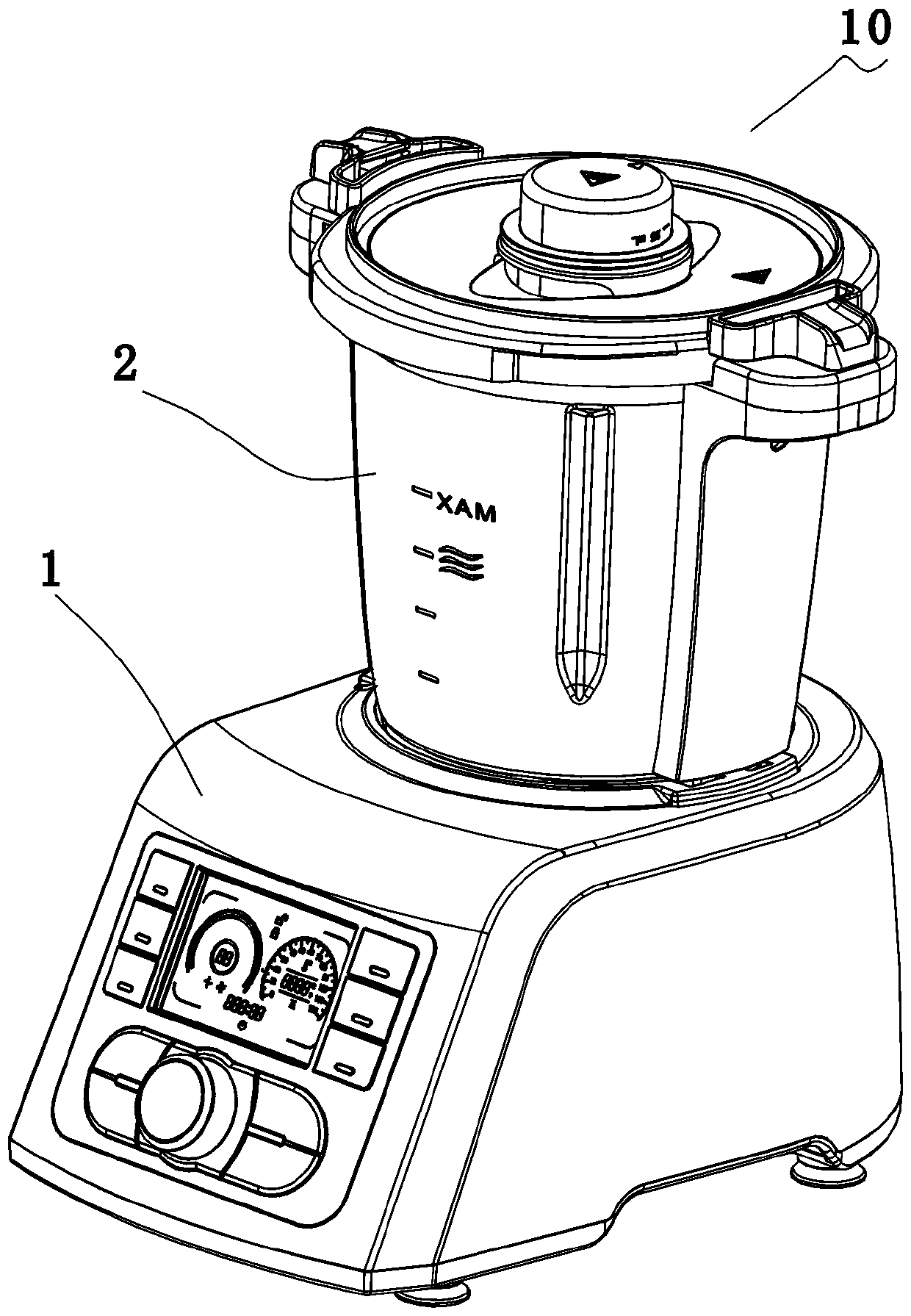

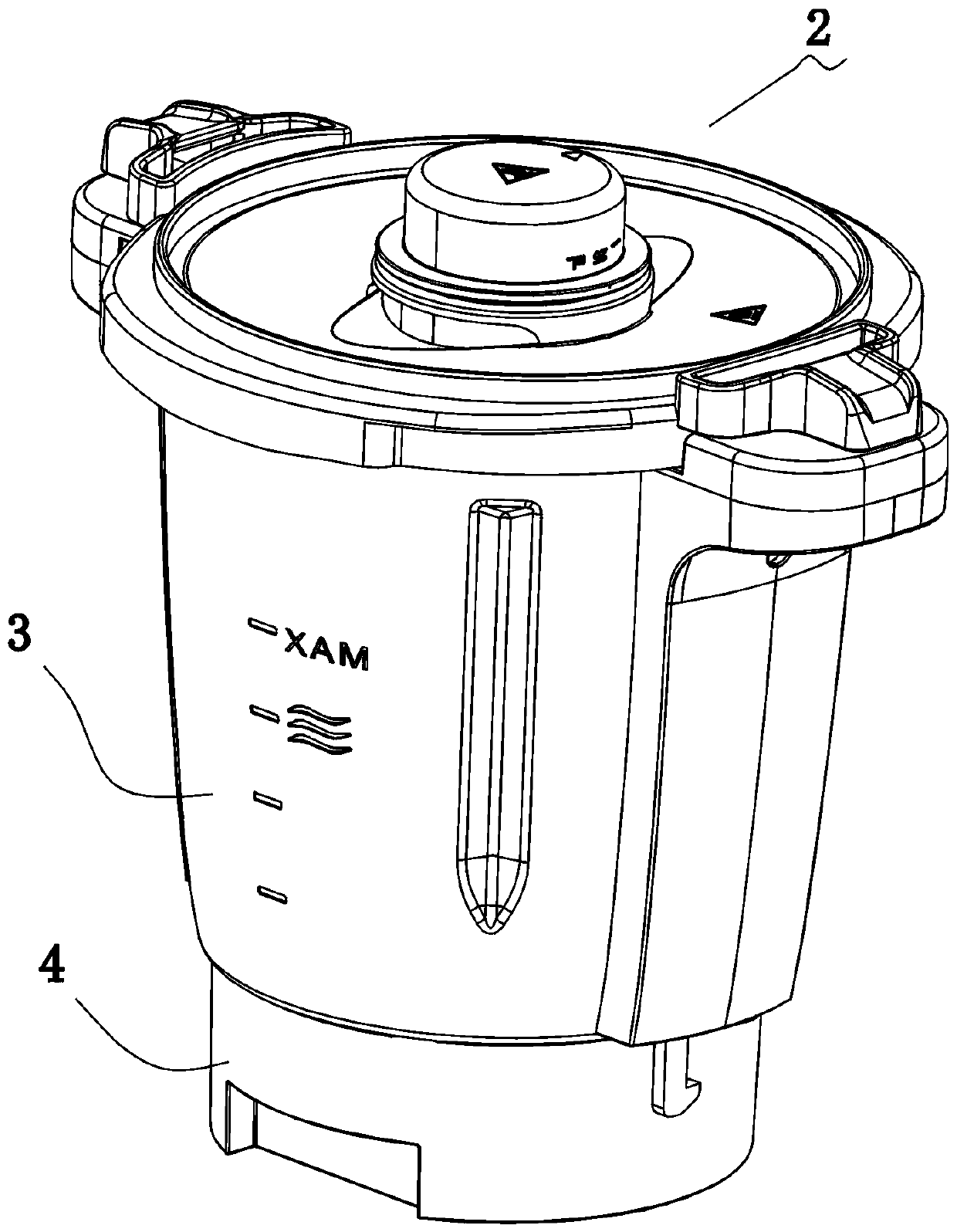

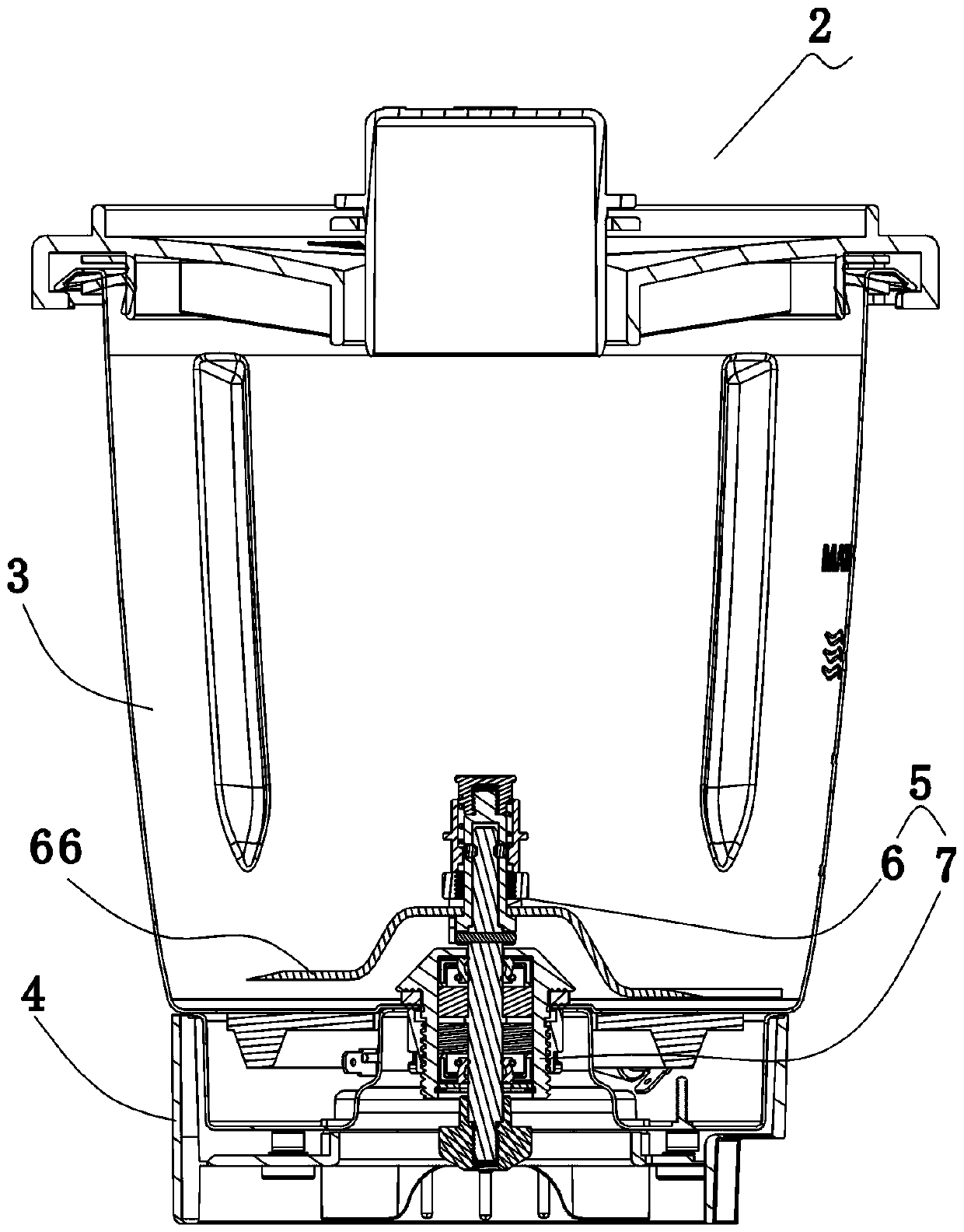

Food processing device and bowl assembly and stirring knife assembly thereof

PendingCN107713823AImprove experienceEasy to cleanCooking vesselsPulp and paper industryKnife blades

The invention relates to a food processing device and a bowl assembly and a stirring knife assembly thereof. The stirring knife assembly comprises a knife head part and a knife seat part which can bemutually assembled / disassembled; the knife head part comprises a blade; the knife seat part comprises a stirring shaft and a clutch which is connected with the stirring shaft; the stirring shaft is used for driving the blade to rotate. The invention is convenient to maintain and has excellent user experience.

Owner:LIANCHUANG SANJIN ELECTRIC APPLIANCE SHENZHEN

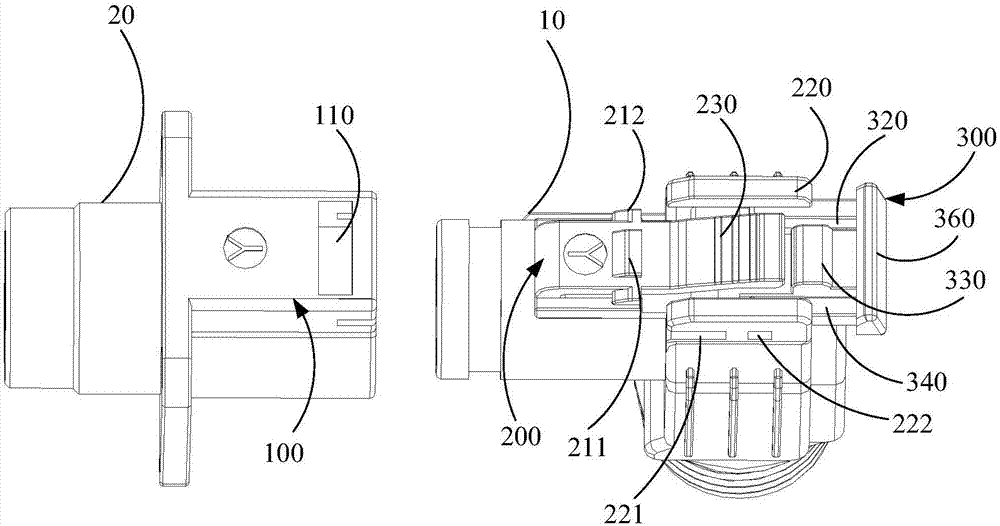

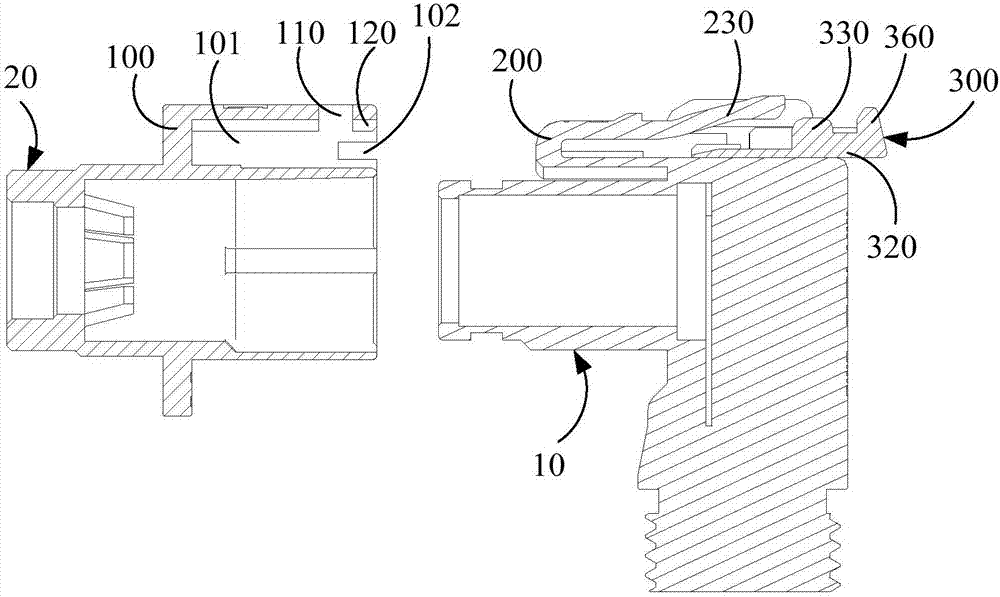

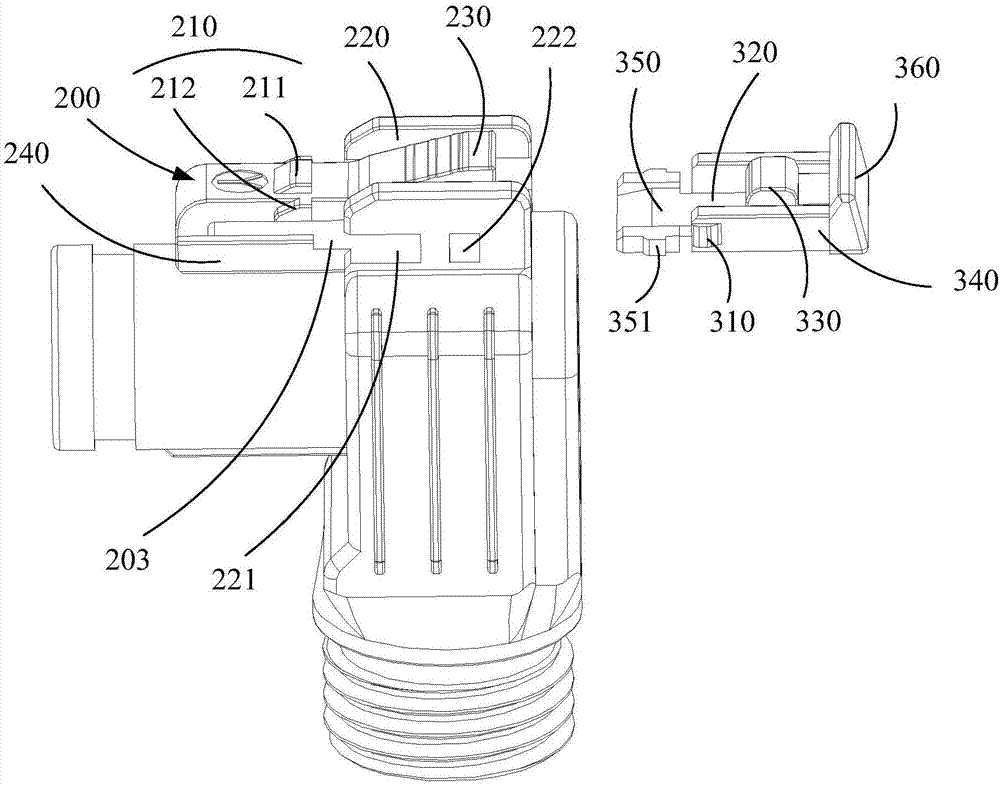

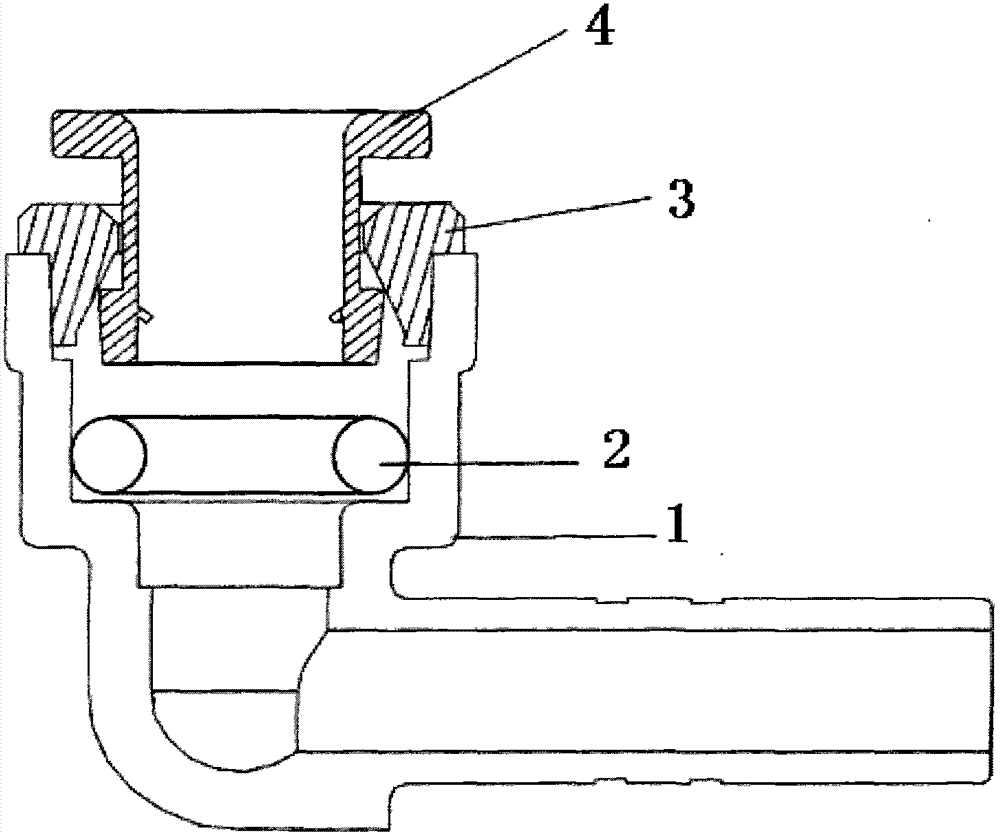

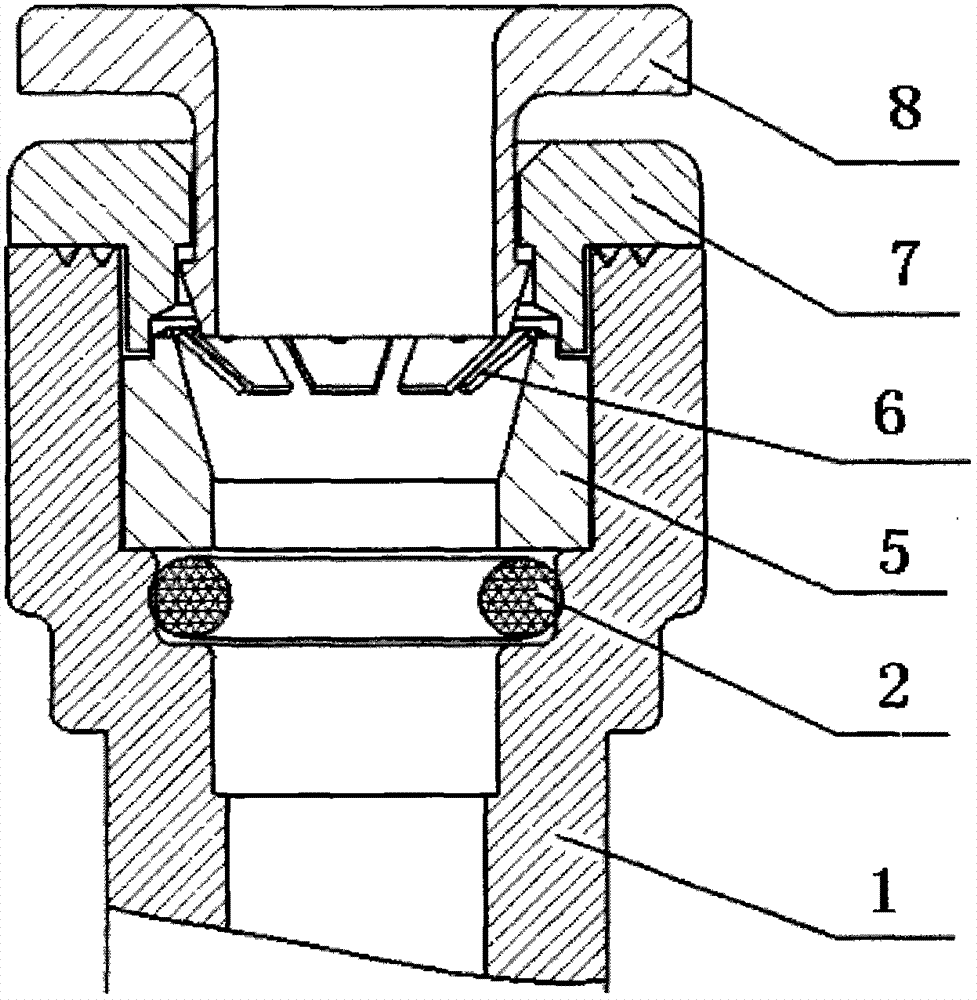

Electric connector

PendingCN107069334ARealize the first locking functionRealize the second locking functionVehicle connectorsCoupling device detailsEngineeringElectrical connector

The invention discloses an electric connector. The electric connector comprises a male seat and a female seat, wherein the female seat is provided with a socket, the male seat is provided with a plug in matching with the socket and a sliding block arranged on the plug, the socket is provided with a chamber for plugging of the plug, the plug is provided with a first locking member in locking matching with the socket, the sliding block is provided with a second locking member in locking matching with the plug and a convex block, the sliding block is pressed in the plug through the convex block, the sliding block is clamped in the plug, and the plug and the socket are in tight plugging. The electric connector is advantaged in that the mounting and dismounting effect of the male seat and the female seat is improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +2

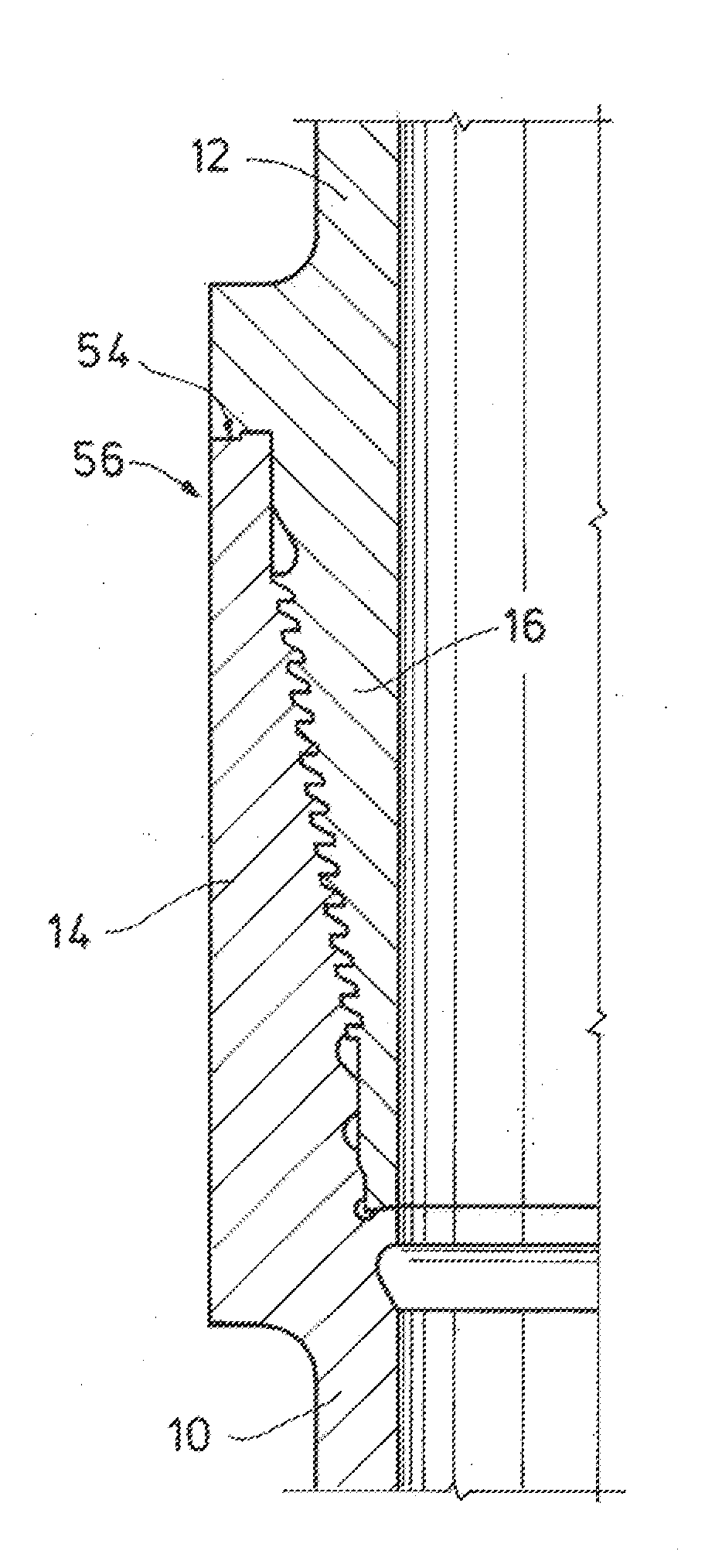

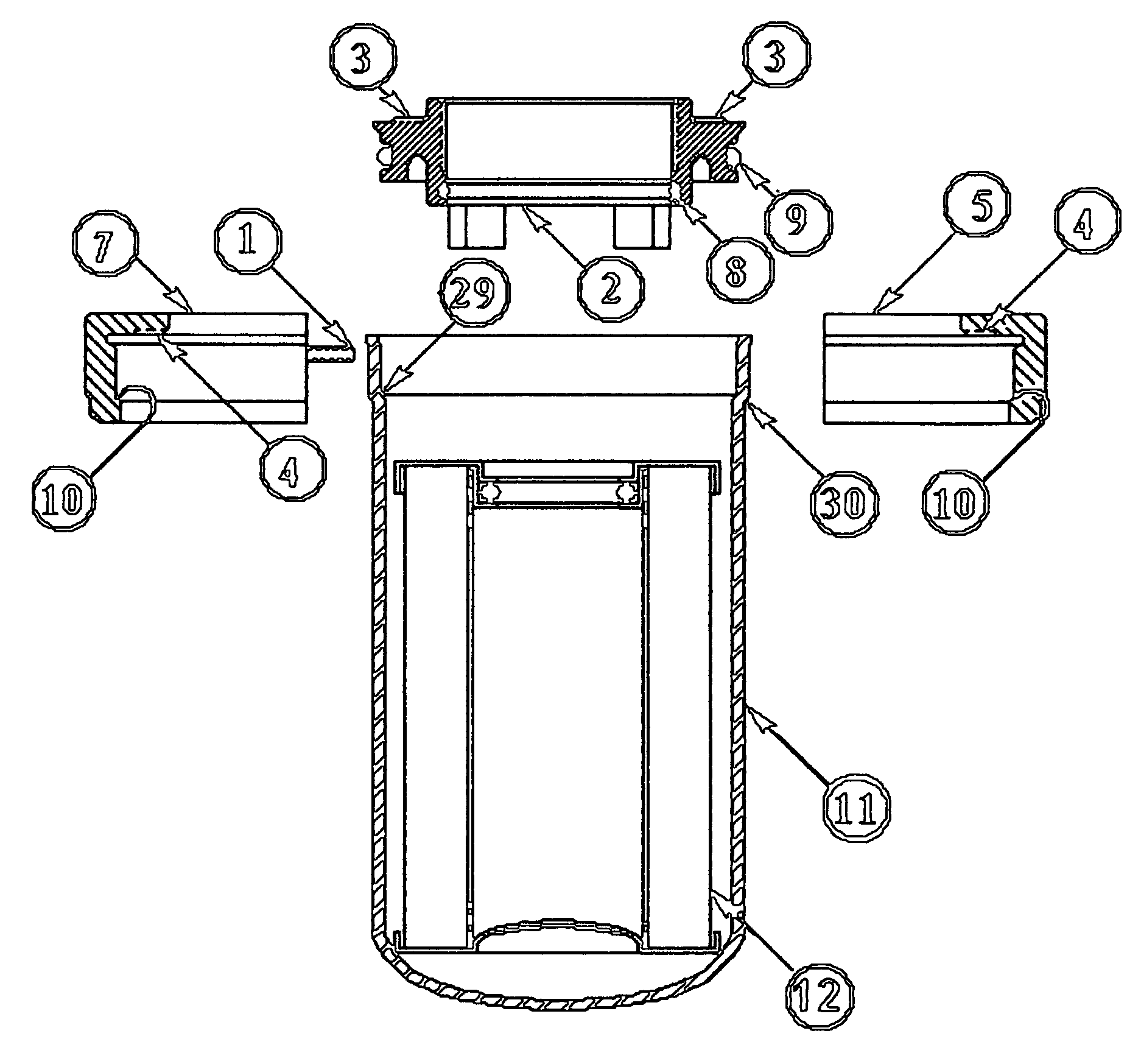

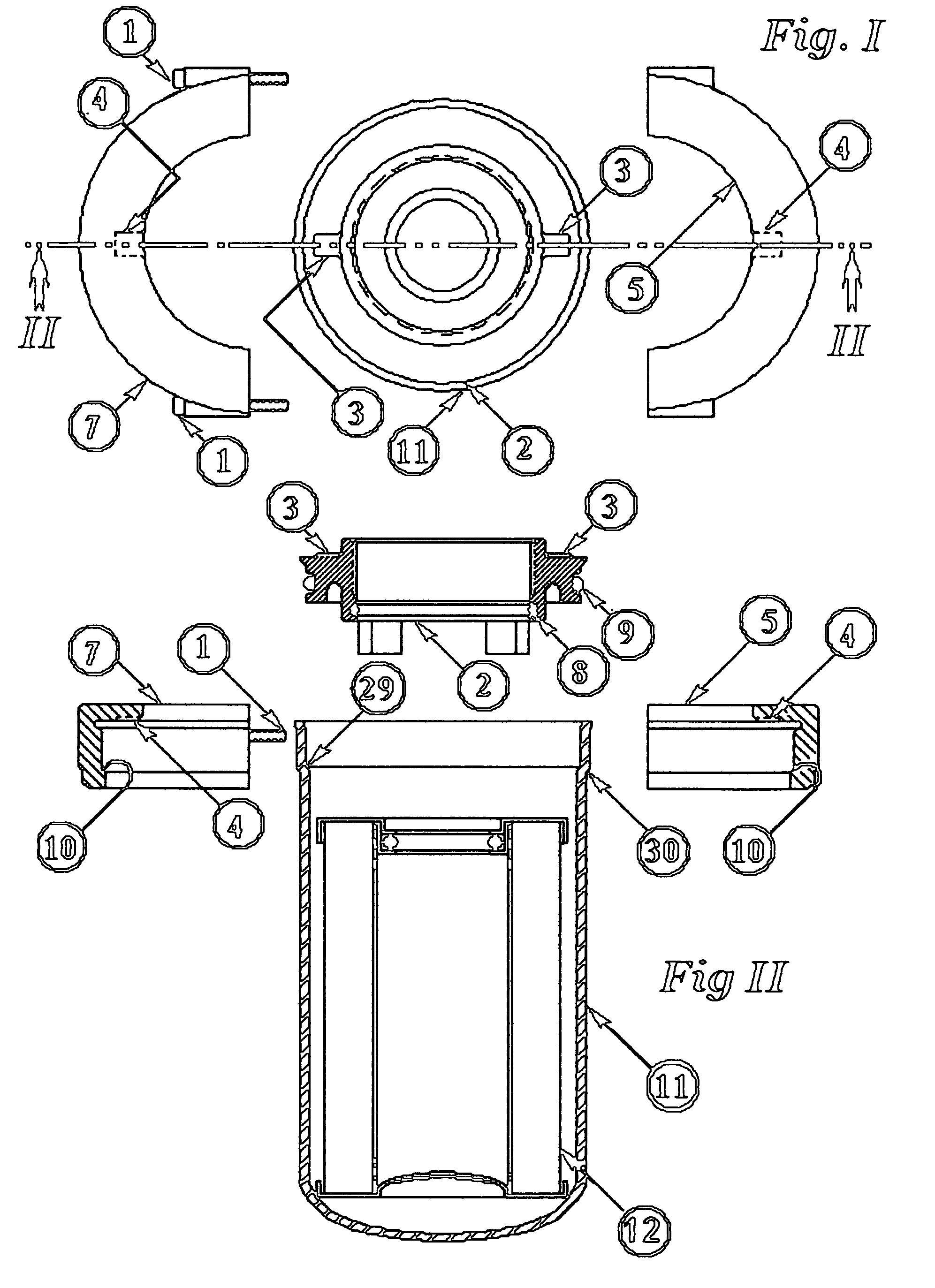

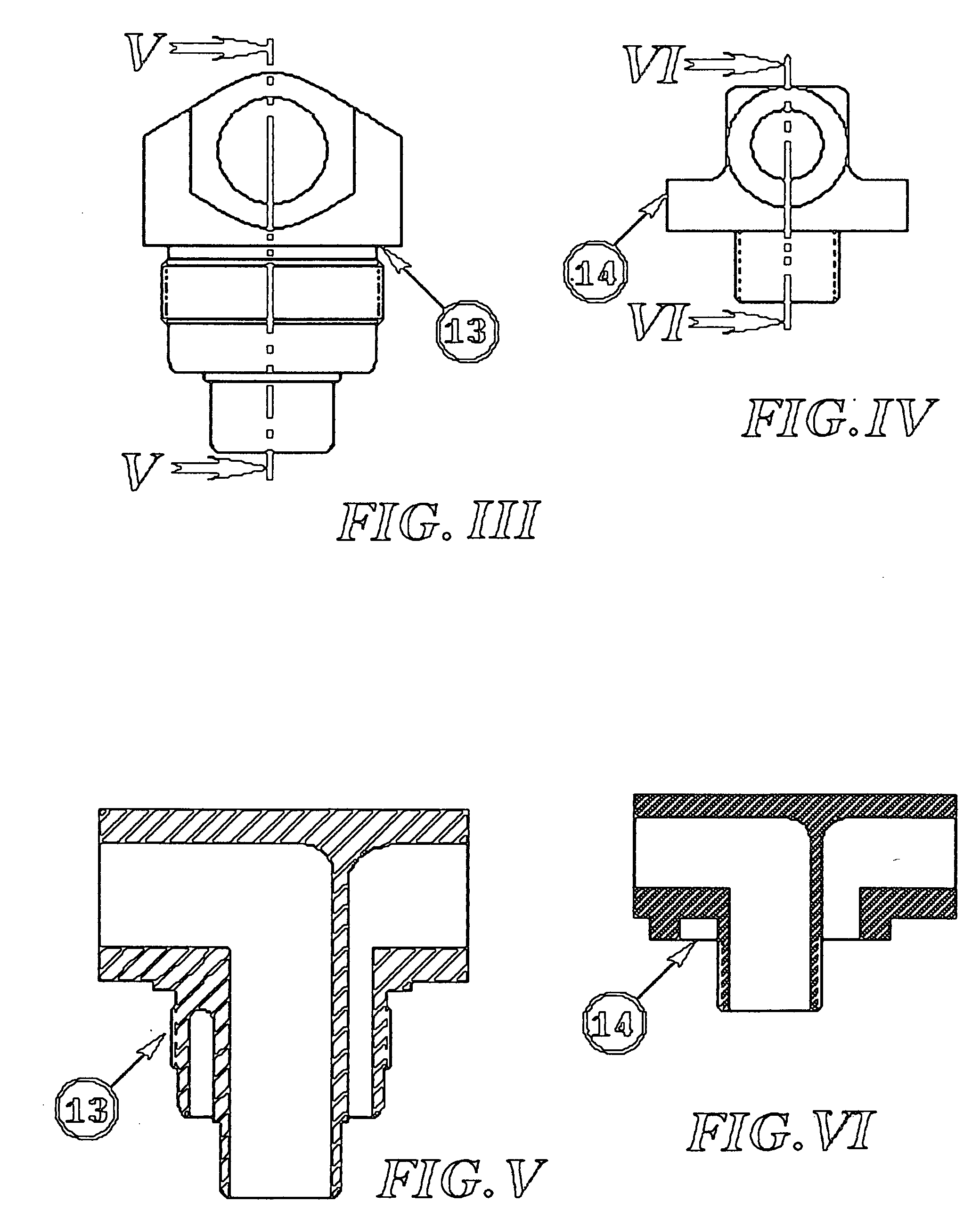

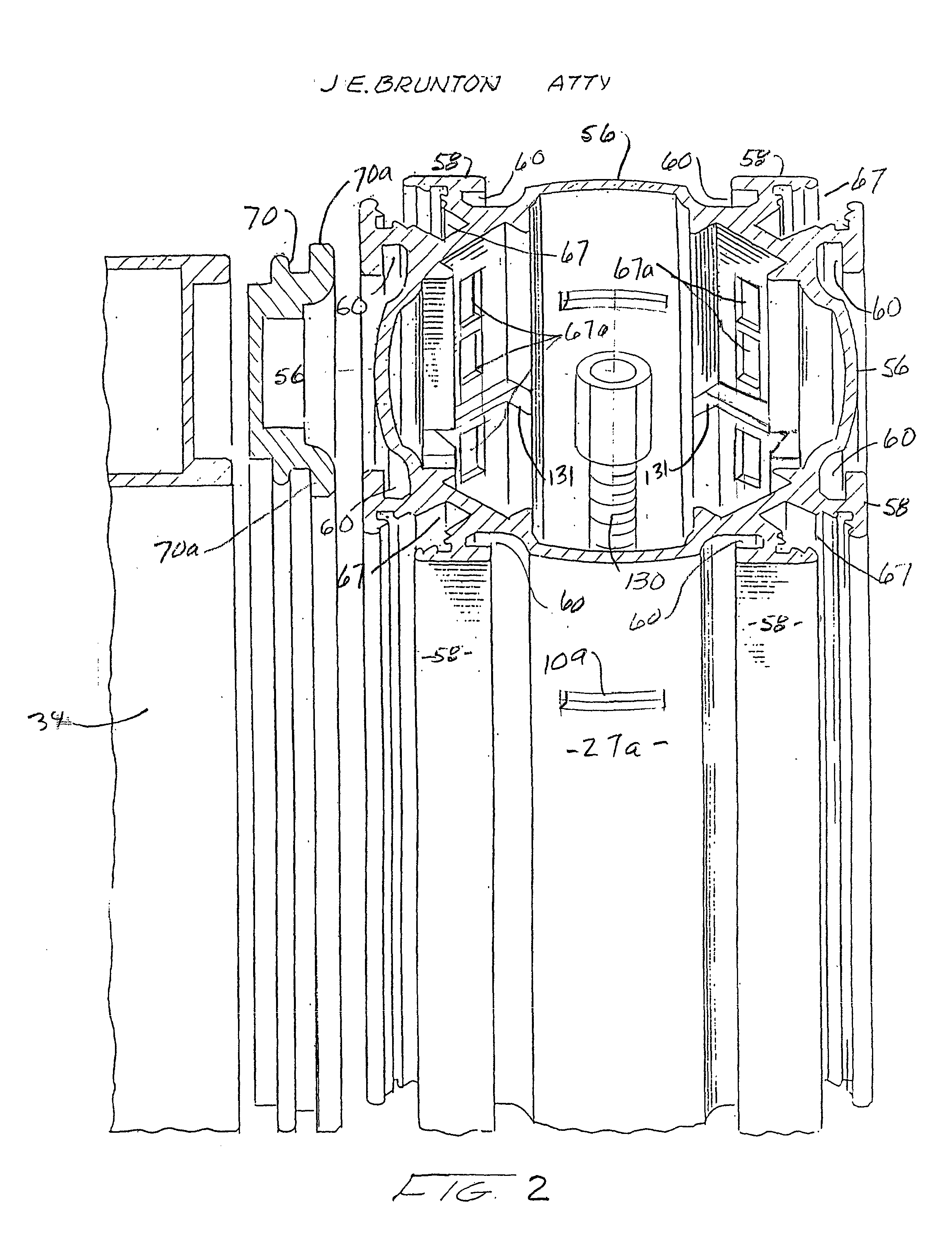

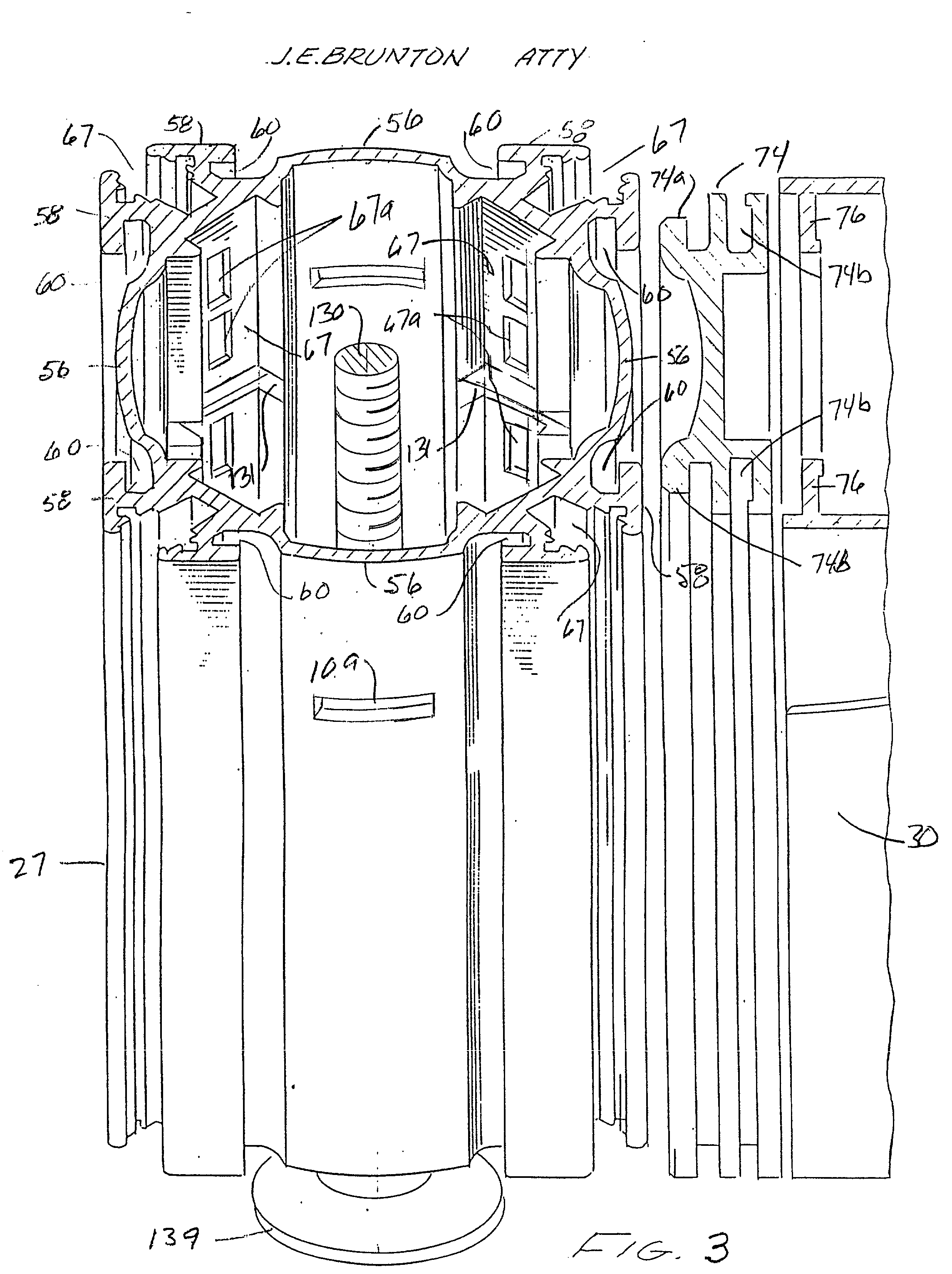

Re-usable structure which attaches to the same filter head as originally intended to receive a throw-away spin-on

InactiveUS20060021925A1High pressure ratingMethod securityMembrane filtersCartridge filtersSplit ringSpins

A re-usable, spin-on filter cannister for hydraulic use, which can attach to a block-like head; said head being previously existent for attachment of a conventional, throw-way, spin-on type cannister. The invention is designed with metal parts which can be assembled or dis-assembled without damage. Thus, when the spent filter element is discarded, the housing parts can be reused with a fresh element, without physical alteration to any of the metal container parts. The assembly / dis-assembly mode, which enables reuse, is by means of a radial displacement of split rings which, in engagement with the cannister and plate, act to contain the hydraulic stresses within the filter assembly.

Owner:STIFELMAN JACK

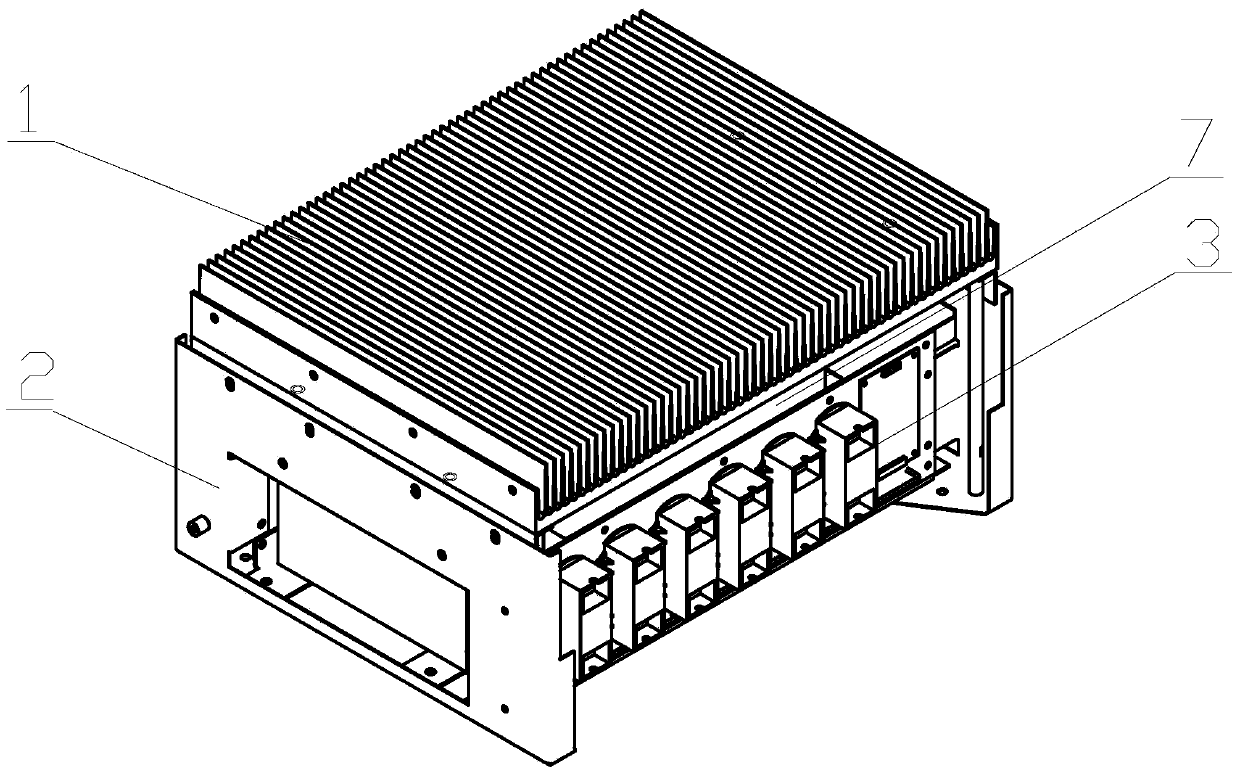

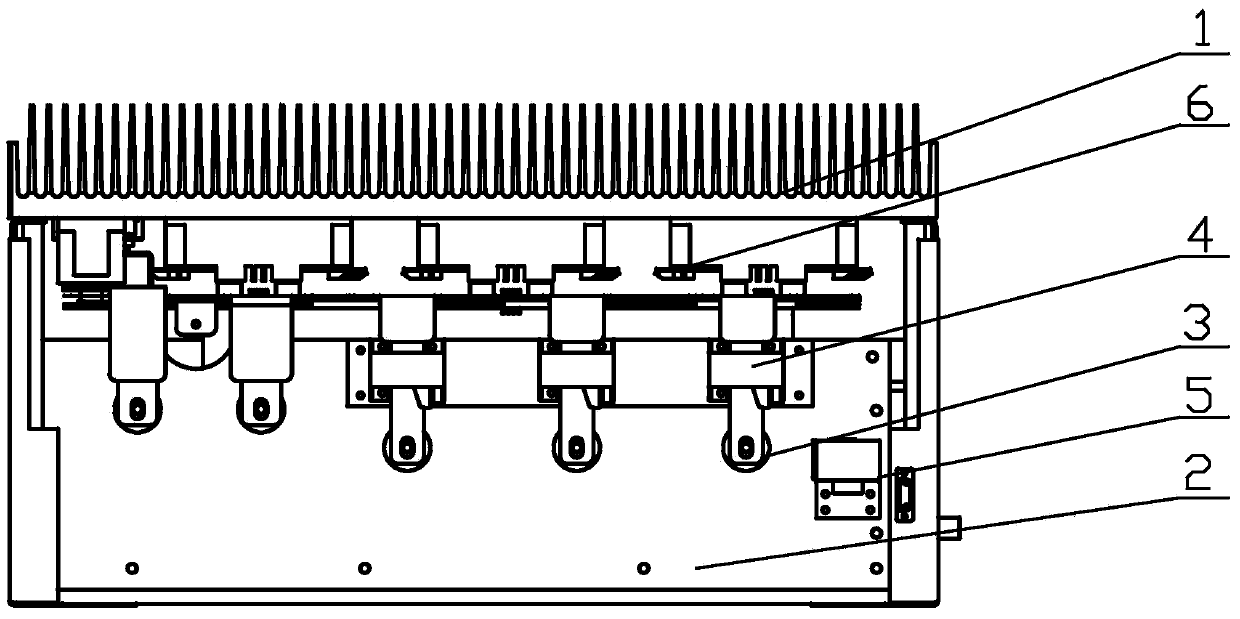

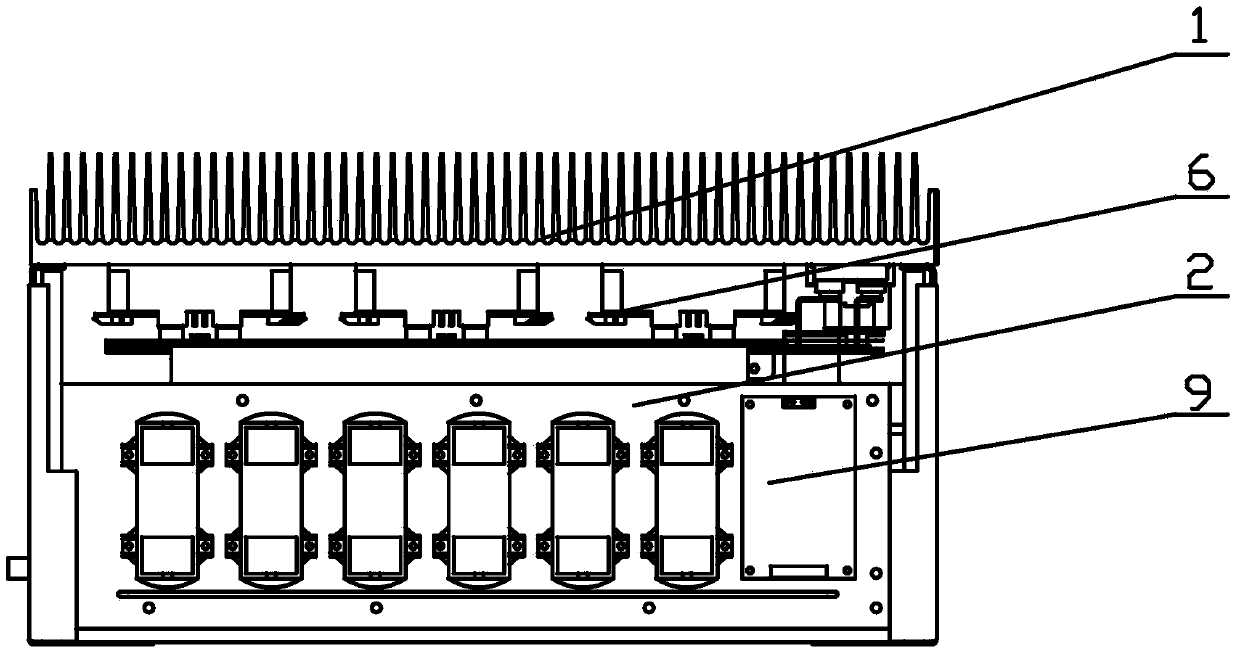

Vehicular converter power module

InactiveCN103427669AGood temperature characteristicsHave self-healing abilityAc-dc conversionBus-bar installationCapacitanceBusbar

The invention discloses an auxiliary converter for railway vehicles in the technical scheme, and particularly relates to a converter power module for the railway vehicles. The converter power module comprises a power circuit, a driving circuit, a power supply module, a radiator, a supporting capacitor C1, a busbar and a mechanical shell, the power circuit is a three-phase full-bridge inverter circuit, the busbar is a composite laminated low-sensitivity busbar and of a structure with two sides bending downwards, one side of the busbar is electrically connected with the supporting capacitor C1, and one end of the busbar is electrically connected with wiring terminals. The converter power module has the advantages that the low-sensitivity busbar can effectively reduce loop step-down voltage and heating loss, and the converter power module is compact in integral structural arrangement, reasonable in layout of components, and simple and convenient to assemble and disassemble.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

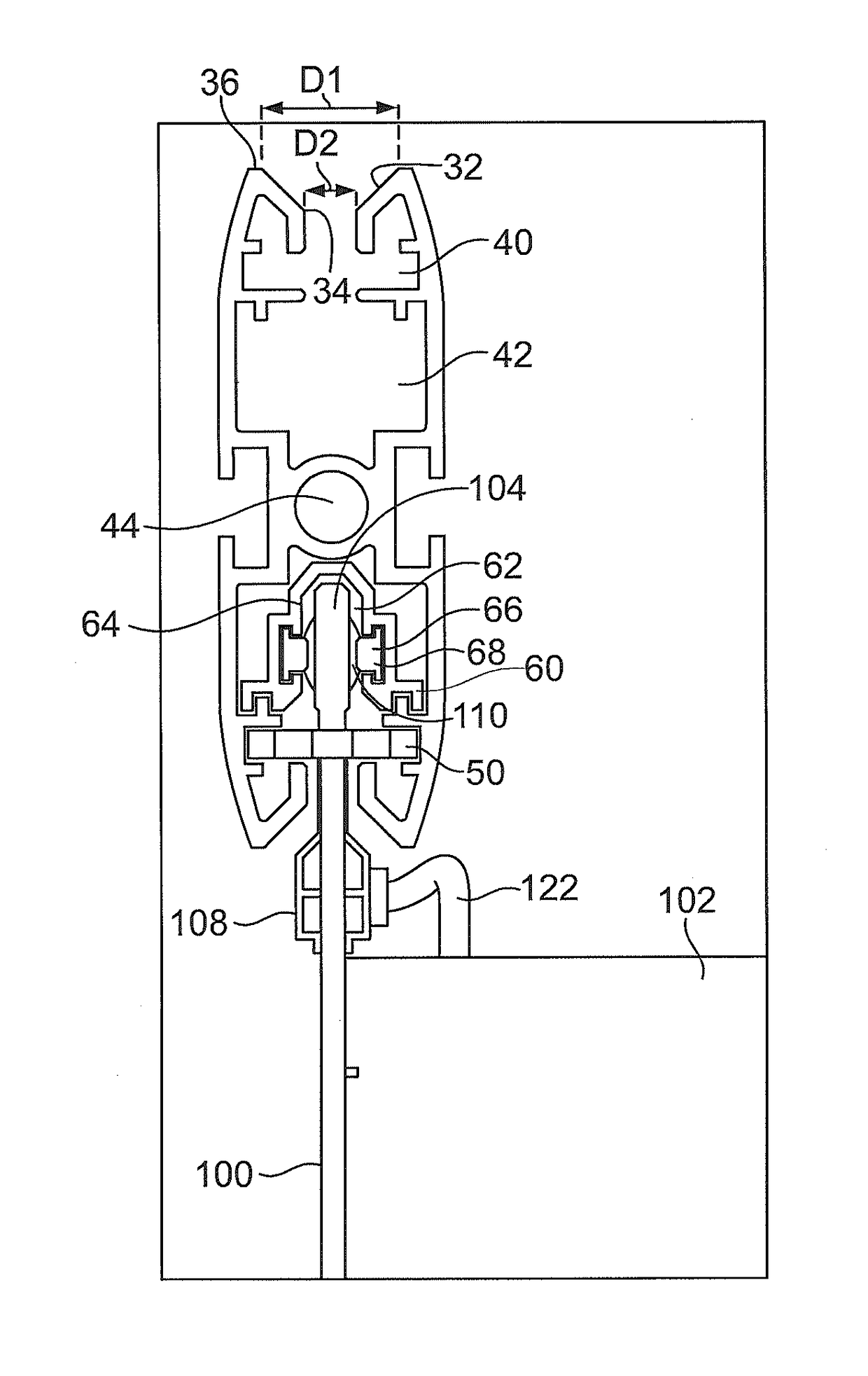

Shelf attached to post by connector with rotatable latch and method of assembly

A shelving system includes one or more shelving units. Each shelving unit has posts each post having one or more indents, connectors with slots for mounting the post and one or more shelves. Each shelf has protrusions on a periphery to insert into one of the connector slots. Each shelving unit and shelving system can be assembled, disassembled, and adjusted without the use of tools or other components. The shelving units can be assembled together to create a multiple shelving unit system without the use of tools or other components.

Owner:ORGANIZE IT ALL

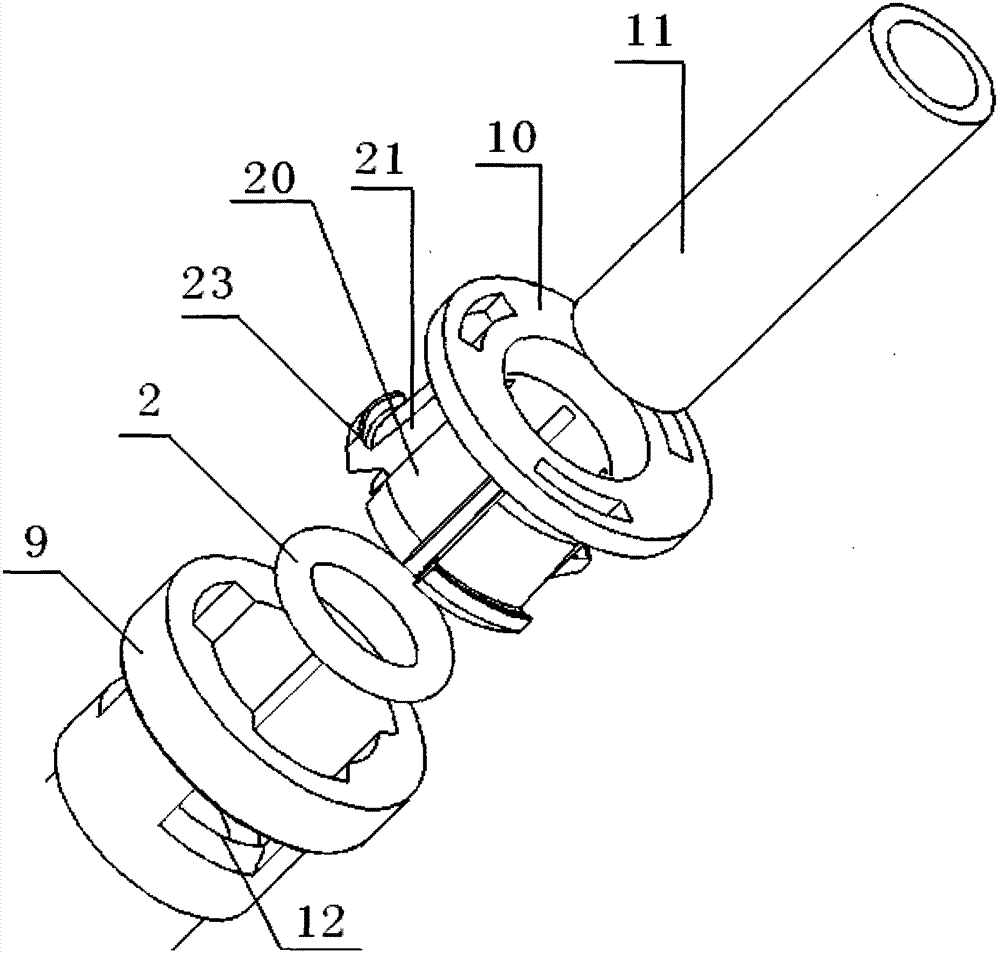

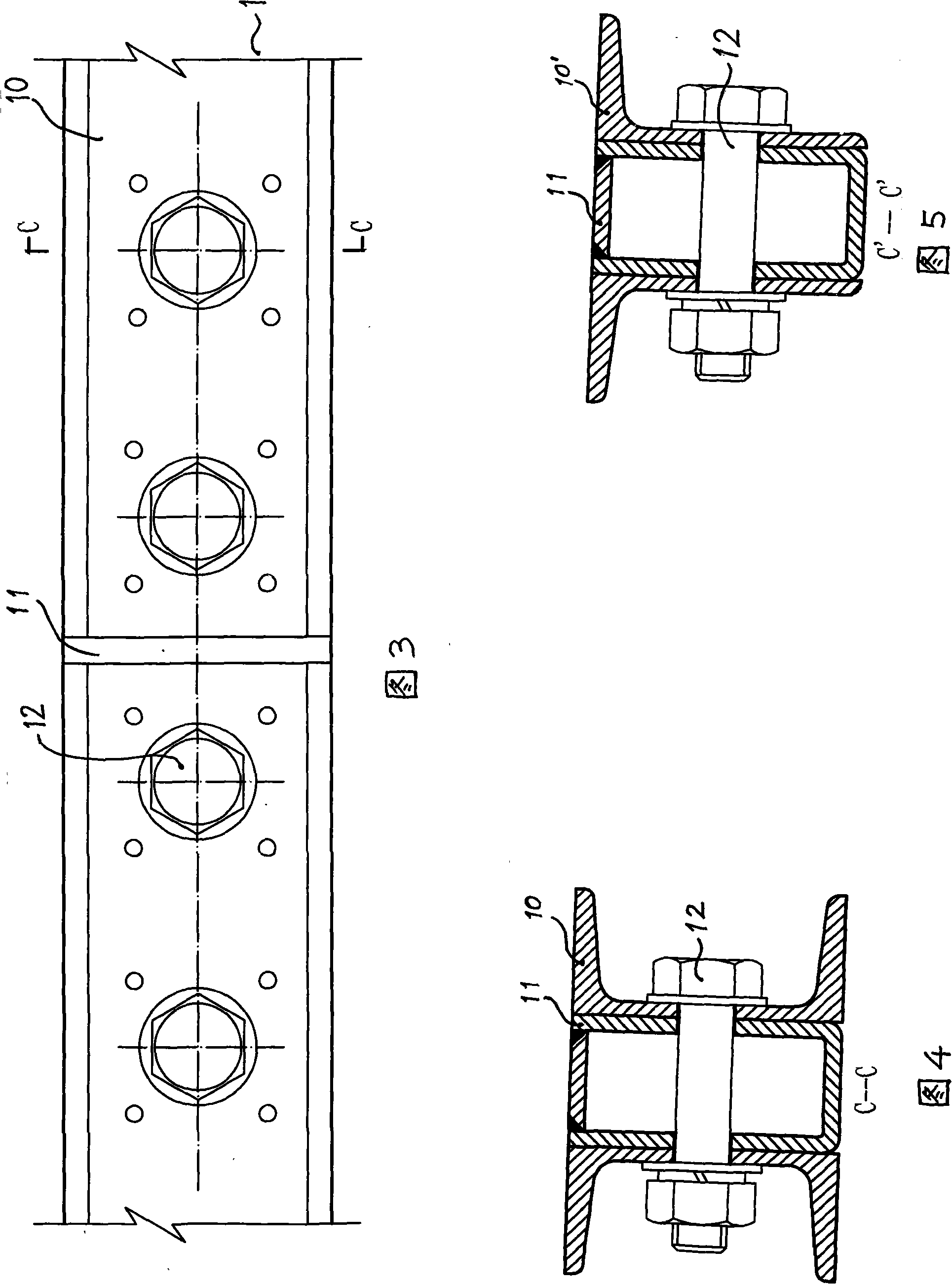

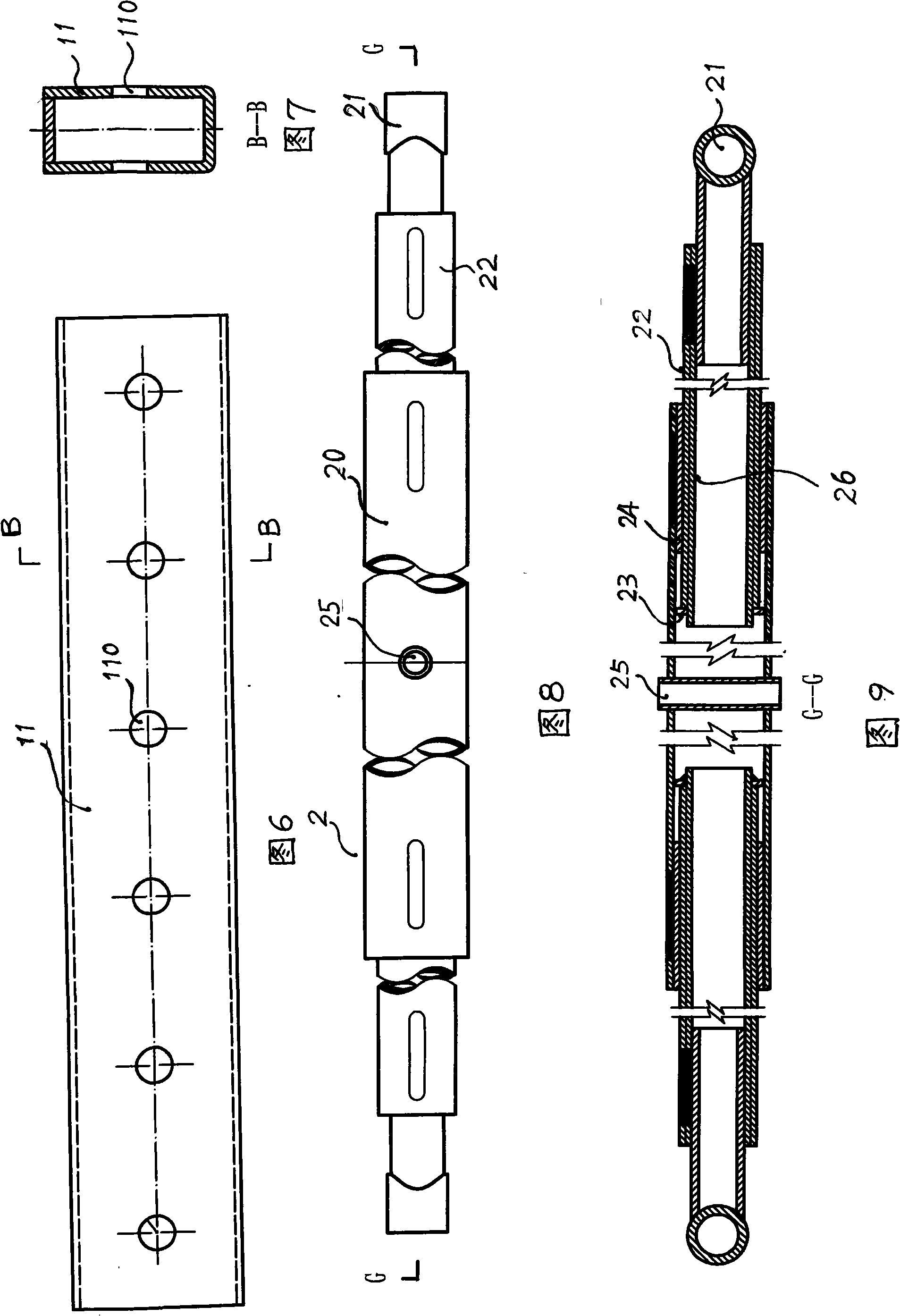

Quick coupling

InactiveCN102927392AEasy to install and disassembleSimple structureCouplingsCouplingAssembly disassembly

The invention belongs to the field of pipe connection, and particularly relates to a rapid coupling which is applied to the connection pipes and valves of fluids such as gas and liquid. The quick coupling comprises three components, namely a connection body, a sealing ring and a multifunctional movable sleeve; the three components can be freely assembled, disassembled and changed; the sealing ring is arranged between a ring-shaped boss in the connection body and a fixed limiting pin of the multifunctional movable sleeve and only moves in the range of the sealing wall of the connection body; the quantity of square side through holes of the connection body is equal to the quantity of elastic arm barb claws on the multifunctional movable sleeve; the elastic arm barb claws are correspondingly arranged and hooked on the hook walls of the square side through holes; and the inclined planes of the square side through holes of the connection body are staggered away from the inclined planes of the barb claws of the multifunctional movable sleeve. The quick coupling provided by the invention has the effects of overcoming the defects of the conventional quick couplings, enabling the mounting and dismounting between the connection pipes as well as between the connection pipes and the valves to be convenient and quick, being simple in structure, simple in manufacturing process and high in production efficiency, reducing the production cost and having wide application.

Owner:史在恒

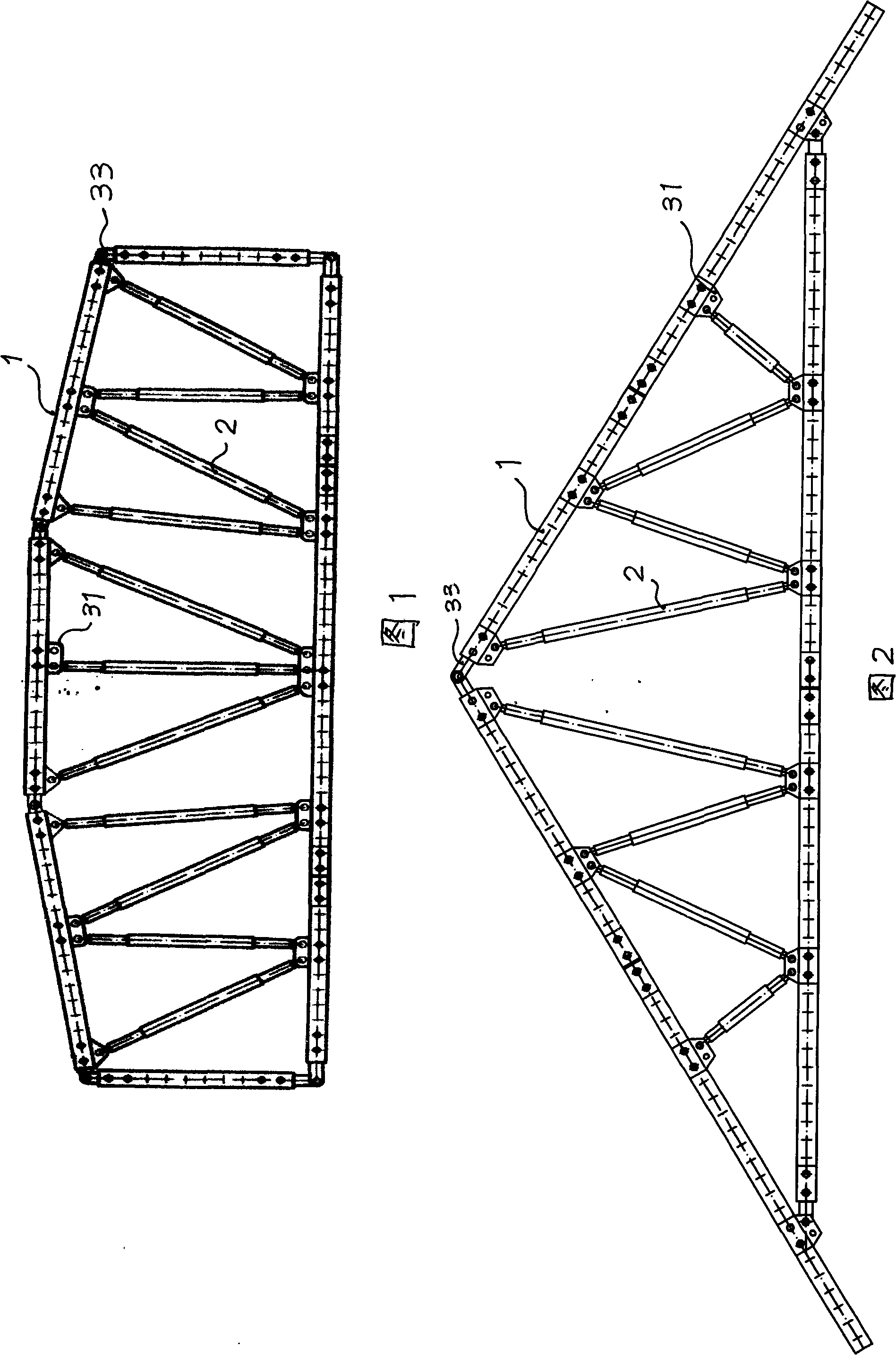

Girders assembling external member as well as girders and girders support system

InactiveCN101280613AEasy to processImprove general performanceGirdersJoistsFalseworkSupporting system

The invention relates to the technology of the load bearing truss. Aiming at solving the technical problem that the truss components can not be repeatedly circulated and used, and that the construction thereof is time-consuming and energy-consuming, the invention provides a truss mounting kit, a truss and a truss supporting system. The truss mounting kit comprises a chord component, a web member component and a node connection component. The truss system is a vertical supporting system for the truss, wherein a plurality of axial trusses, which are constructed with the chord component, the web member component and the node connection component, are placed in parallel and fixed to a longitudinal scaffold steel pipe by using a connector; a short scaffold steel pipe and the longitudinal scaffold steel pipe compose a bridging. The technical proposal adopted by the invention is characterized by convenient and quick assembly and disassembly, high universality, repeated and flexible assembly and disassembly and adjustment according to the requirements of the design and construction, and has the advantages of high applicability.

Owner:POWERCHINA CONSTR GRP

Safety grounded tree

An artificial lighted tree is presented with power routed through the trunk of the tree and three-wire safety grounding. The tree is divided into sections for easy assembly, disassembly, and storage. Safety electrical connectors at the ends of each section are not powered until the sections are assembled. The tree can also accommodate multiple lighting circuits utilizing different voltages simultaneously.

Owner:NCP

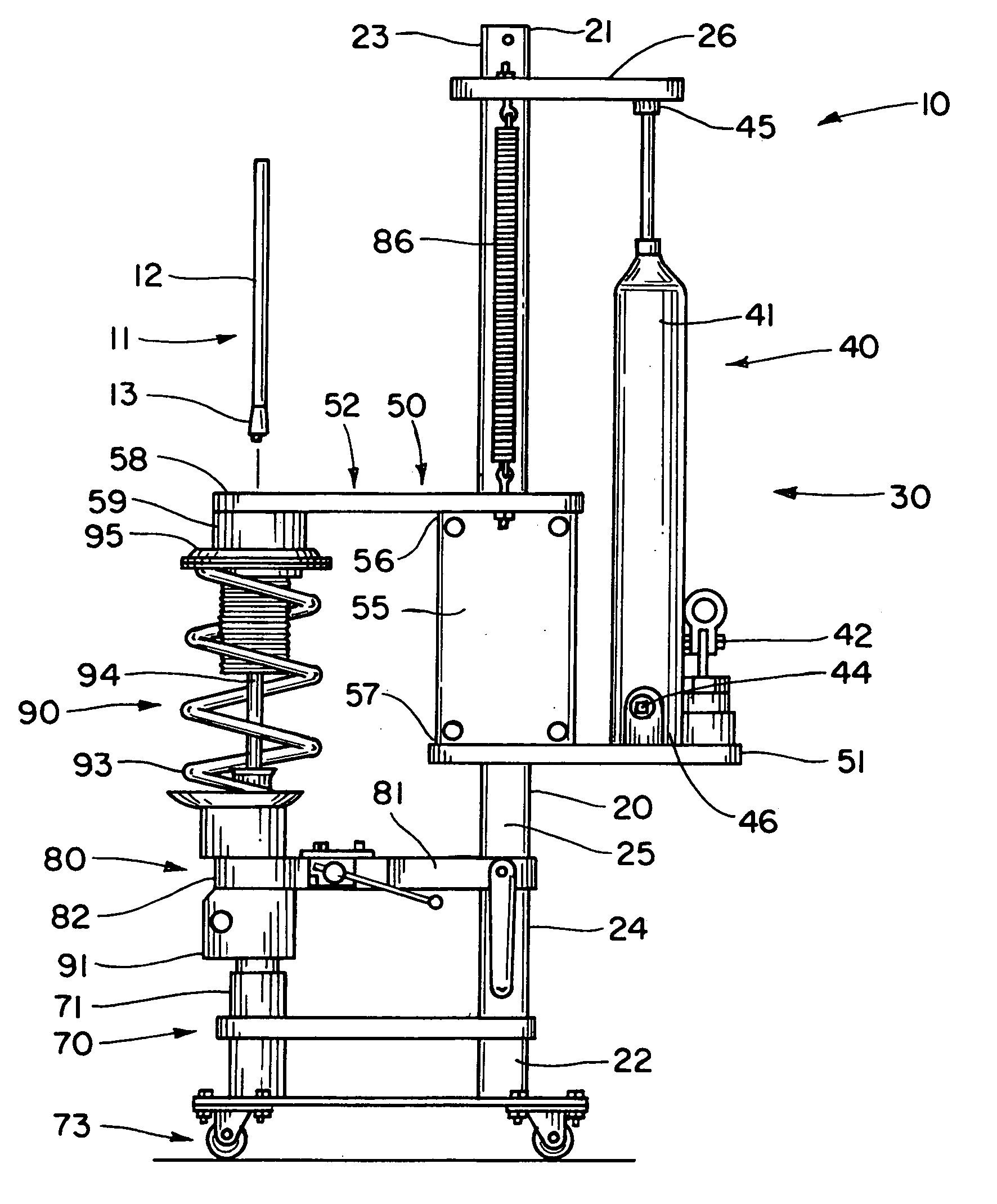

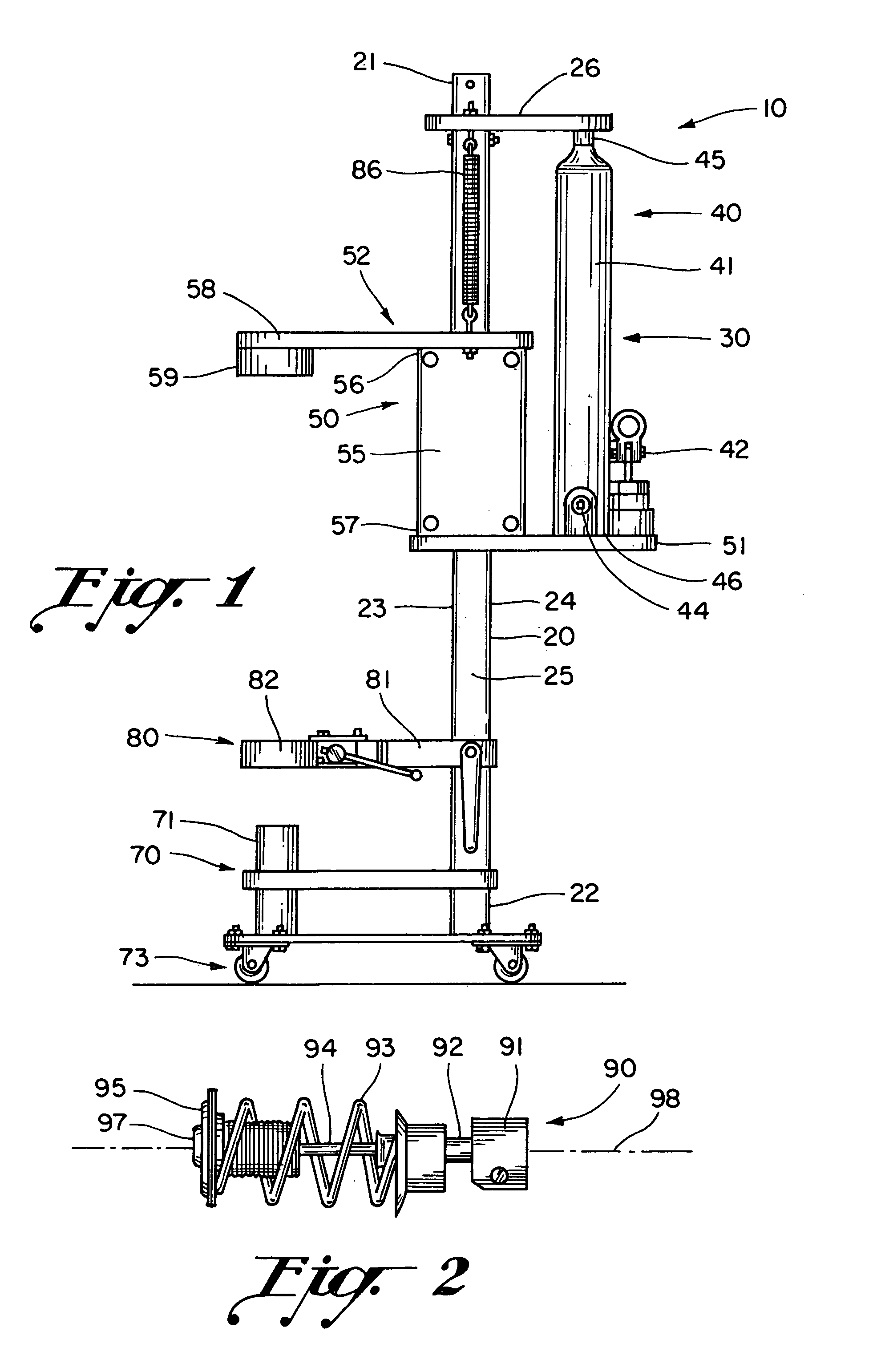

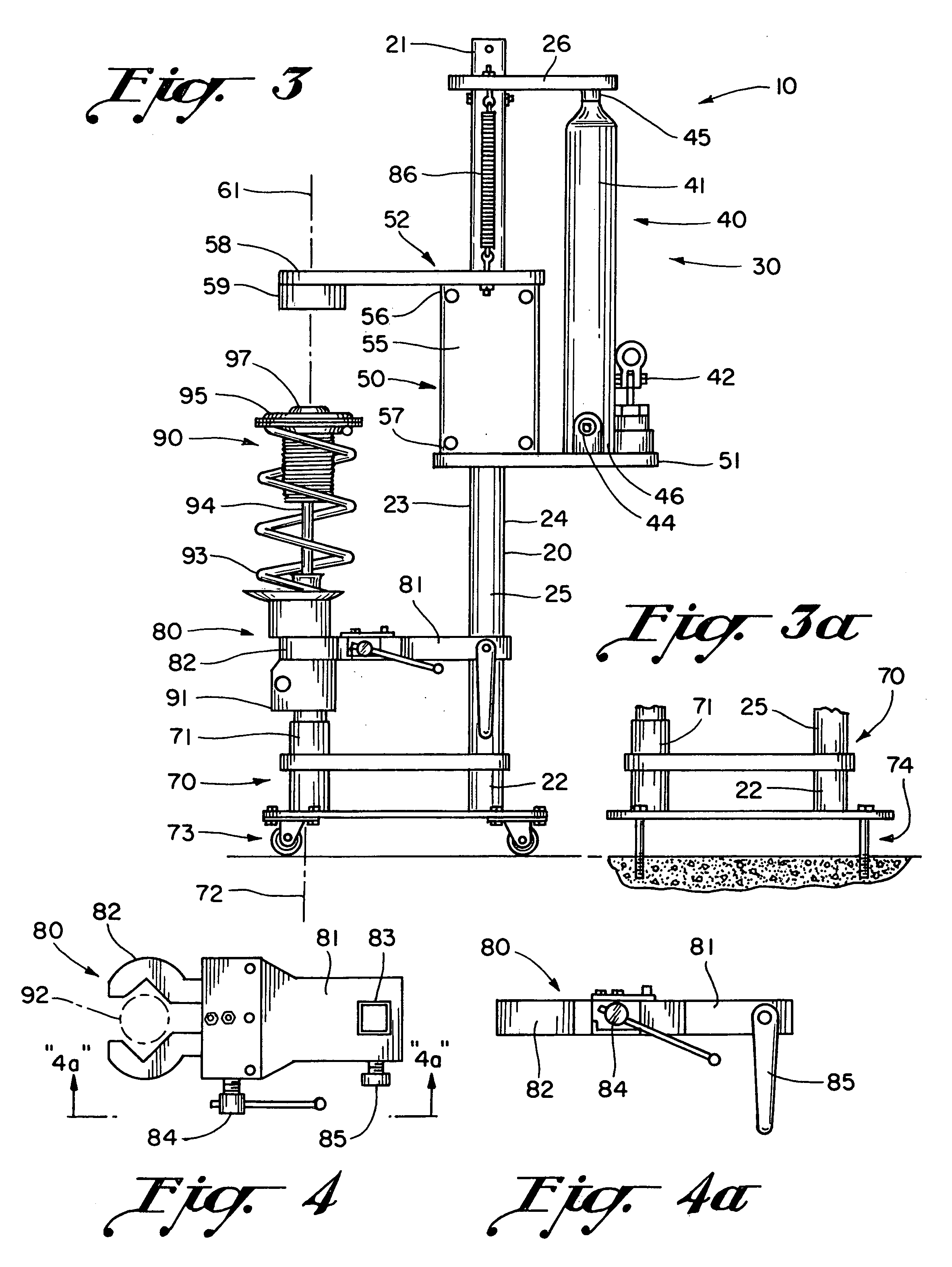

Strut spring compression apparatus

InactiveUS7103951B2Quickly and efficiently disassembleEasy maintenanceSuspensionsVehicle with pivoted armsAssembly disassemblyDetent

A spring-compression apparatus for facilitating maintenance of a strut assembly comprises a guide member, a carriage assembly, and a rest assembly. The guide member comprises a first member end and a second member end. The carriage assembly comprises a jack assembly and a slide assembly. The jack assembly is operable to otherwise displace the slide assembly along the guide member. The slide assembly comprises a locator assembly, which comprises a locator extension arm and a center locator. The rest assembly comprises a center rest. A first strut end is positionable upon the center rest. The center locator is engageable with a second strut end for compressing the strut spring. The locator assembly further enables a user to remove a mounting nut from the second strut end when the strut spring is compressed, thus enabling strut assembly disassembly.

Owner:UZUN ISMET

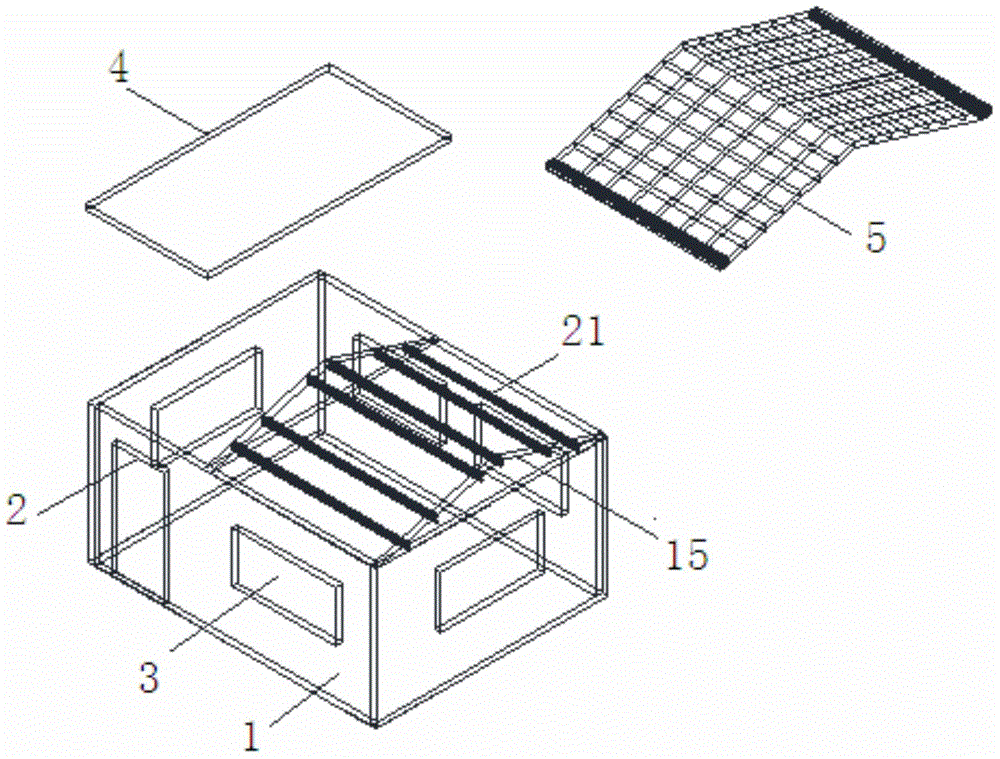

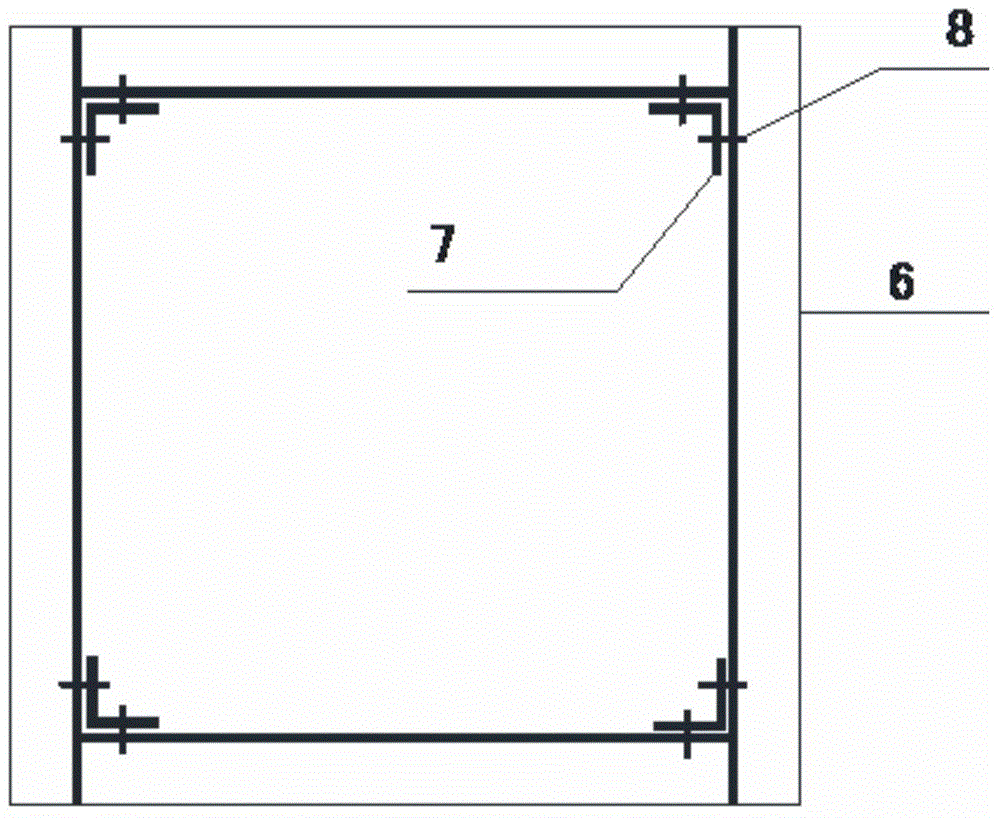

Novel house capable of being fast disassembled and assembled and assembling method thereof

ActiveCN104389349AEasy to operateSimple processBuilding material handlingBeam angleAssembly disassembly

The invention discloses a novel house capable of being fast disassembled and assembled and an assembling method thereof. The novel house comprises a wall. The lower portion of the wall is connected with ground ring beam angle iron. The upper portion of the wall is connected with top ring beam angle iron. One side of the top ring beam angle iron is connected with a flat roof. A waterproof layer is disposed on the flat roof. The upper portion of one side of the top ring beam angle iron is connected with a house frame. An inclined roof is disposed on the house frame. A waterproof layer covers the inclined roof. The wall, the flat roof and the inclined roof are formed by a plurality of wall module units which are connected in a threaded manner. The ground ring beam angle iron and the top ring beam angle iron are of an angle iron structure. The wall module units are connected with the ground ring beam angle iron and the top ring beam angle iron through threads. The wall module units are spliced to form a door opening and window openings. The wall module units above and below the door opening and the window openings are respectively connected with the wall module units on the outer sides of the door opening and the window openings through angle fixing angle iron in a threaded and matched manner. The novel house is convenient to assemble and disassemble, fast in construction and recyclable.

Owner:SHANDONG SHUANGDELI CONSTR TECH

Office furniture system

An improved, multifunction office furniture system having a novel interlocking connecting mechanism which permits the easy assembly of a variety of different structural components in a variety of different configurations to form highly efficient work areas. The system includes uniquely configured, vertical support columns to which a number of different types of structural components can be quickly and easily connected and provides a highly versatile work station system which is very attractive, is easy to assembly, disassemble and adjust, and yet, is structurally sound and durable in use. Because of its novel construction, the system is capable of readily accommodating changing work conditions in the users' facilities.

Owner:VIRCO MFG

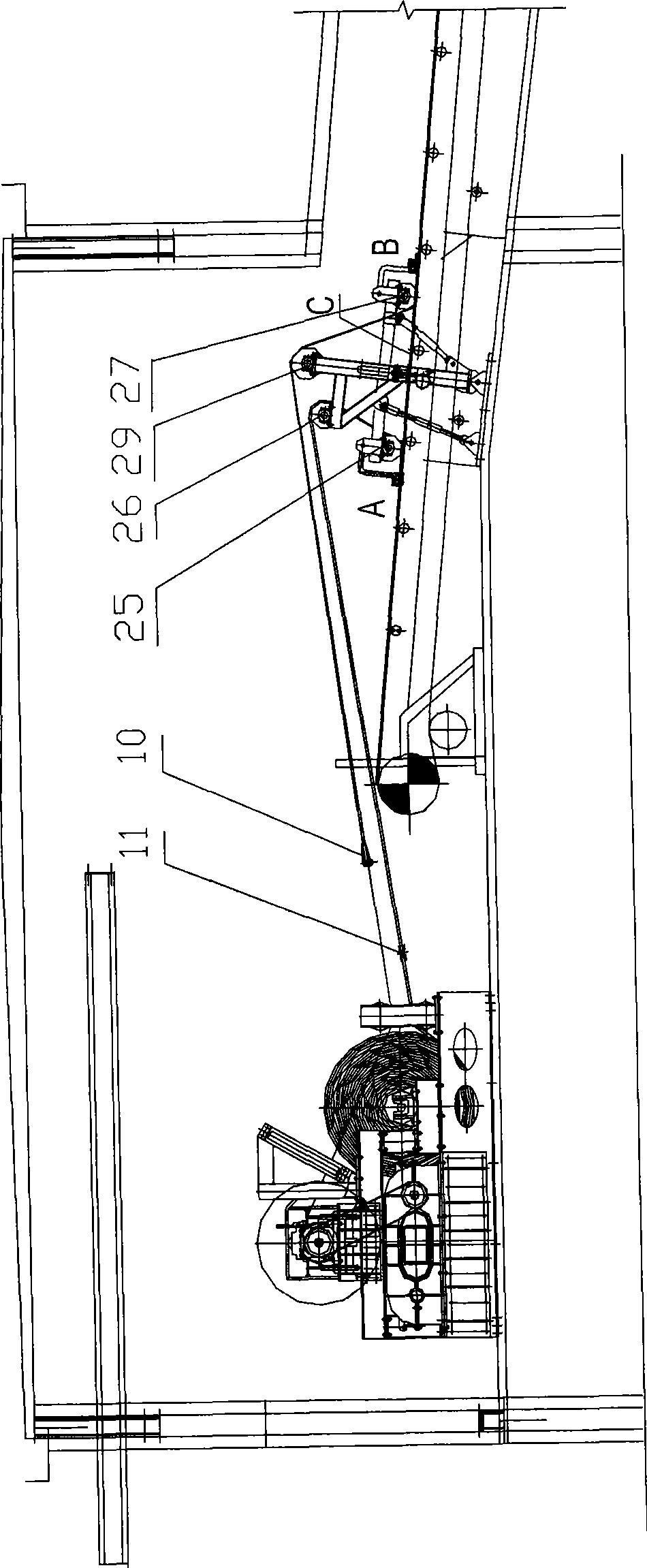

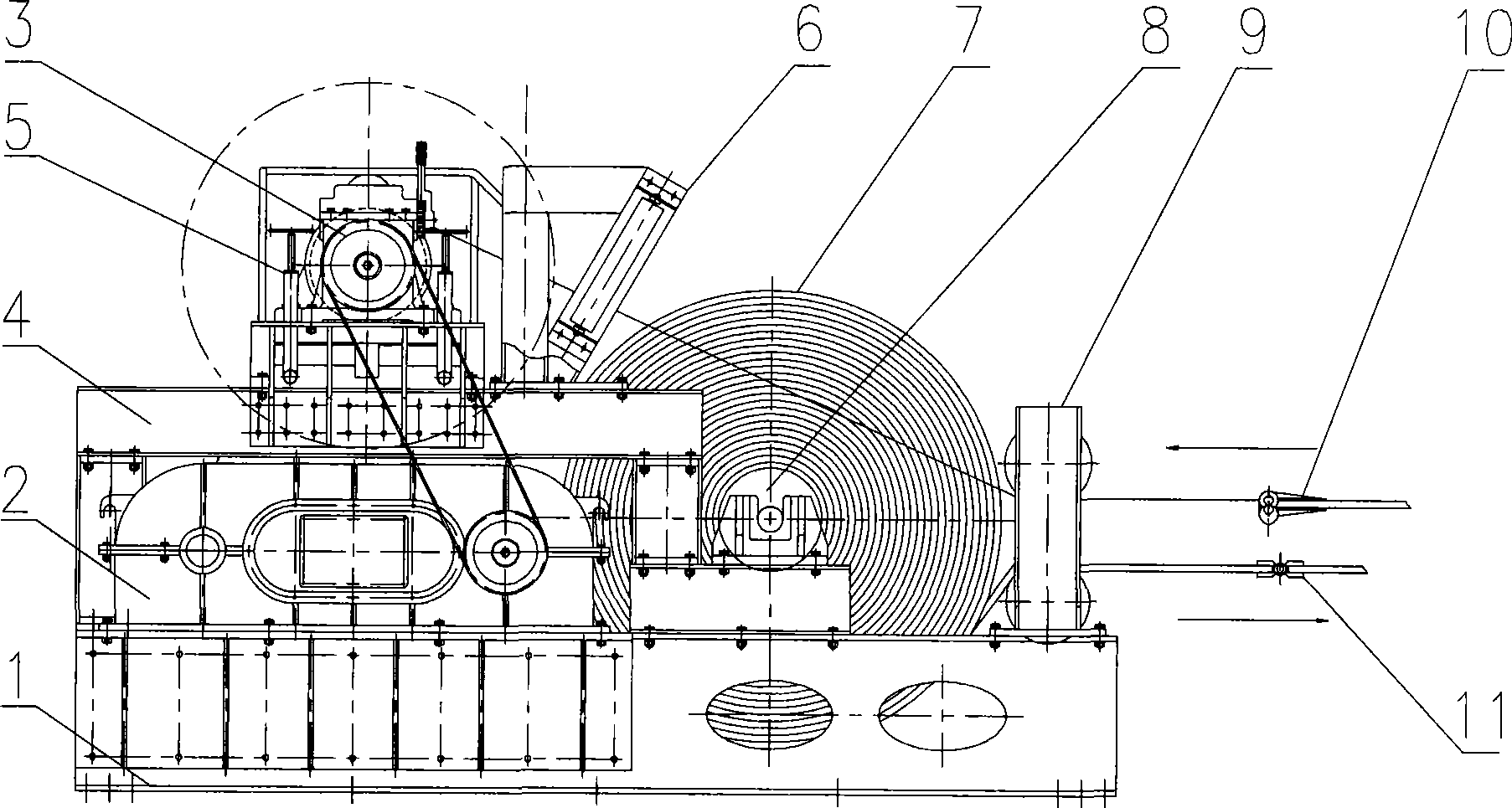

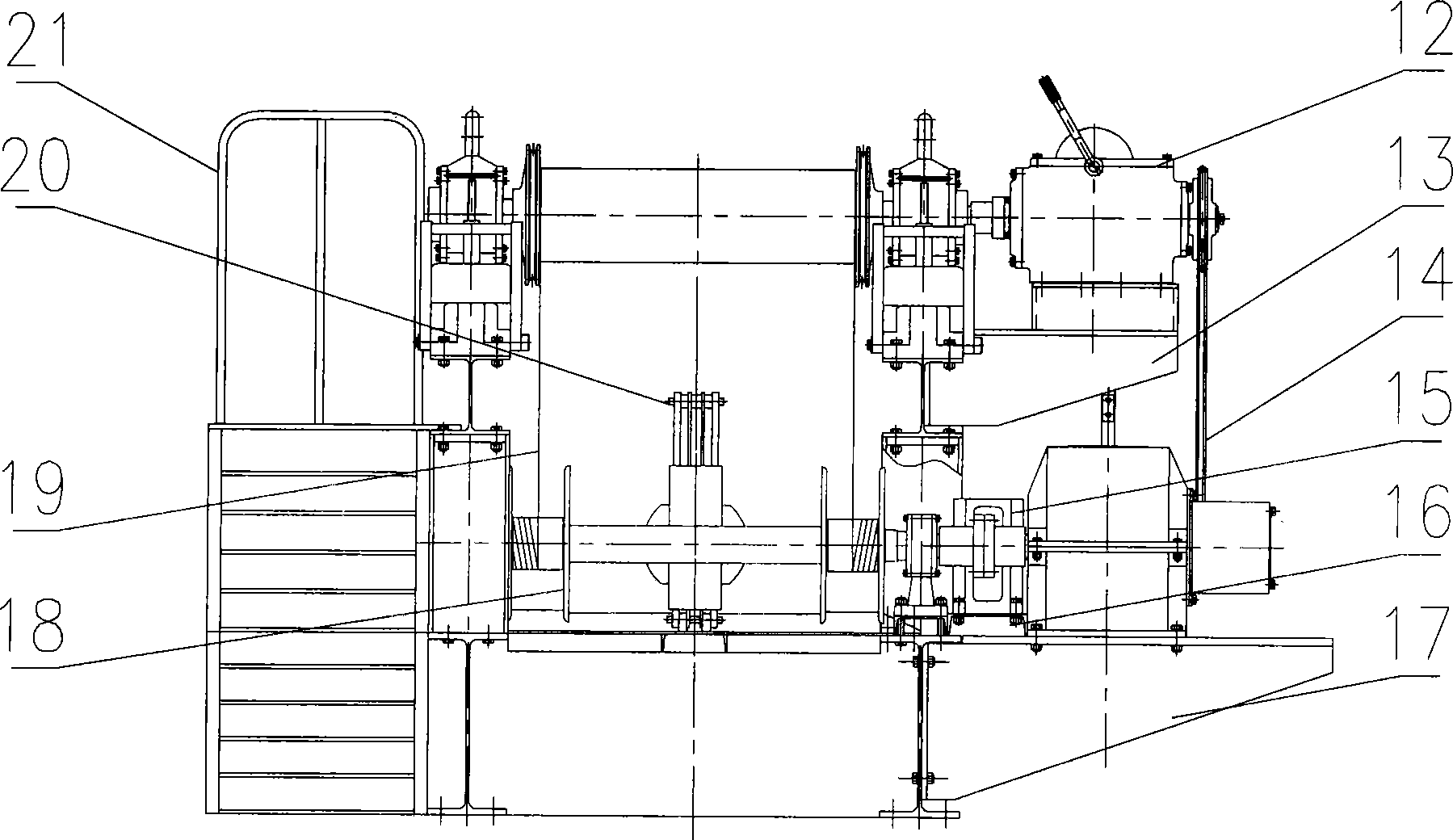

Hose collecting machine

Owner:黄振灵

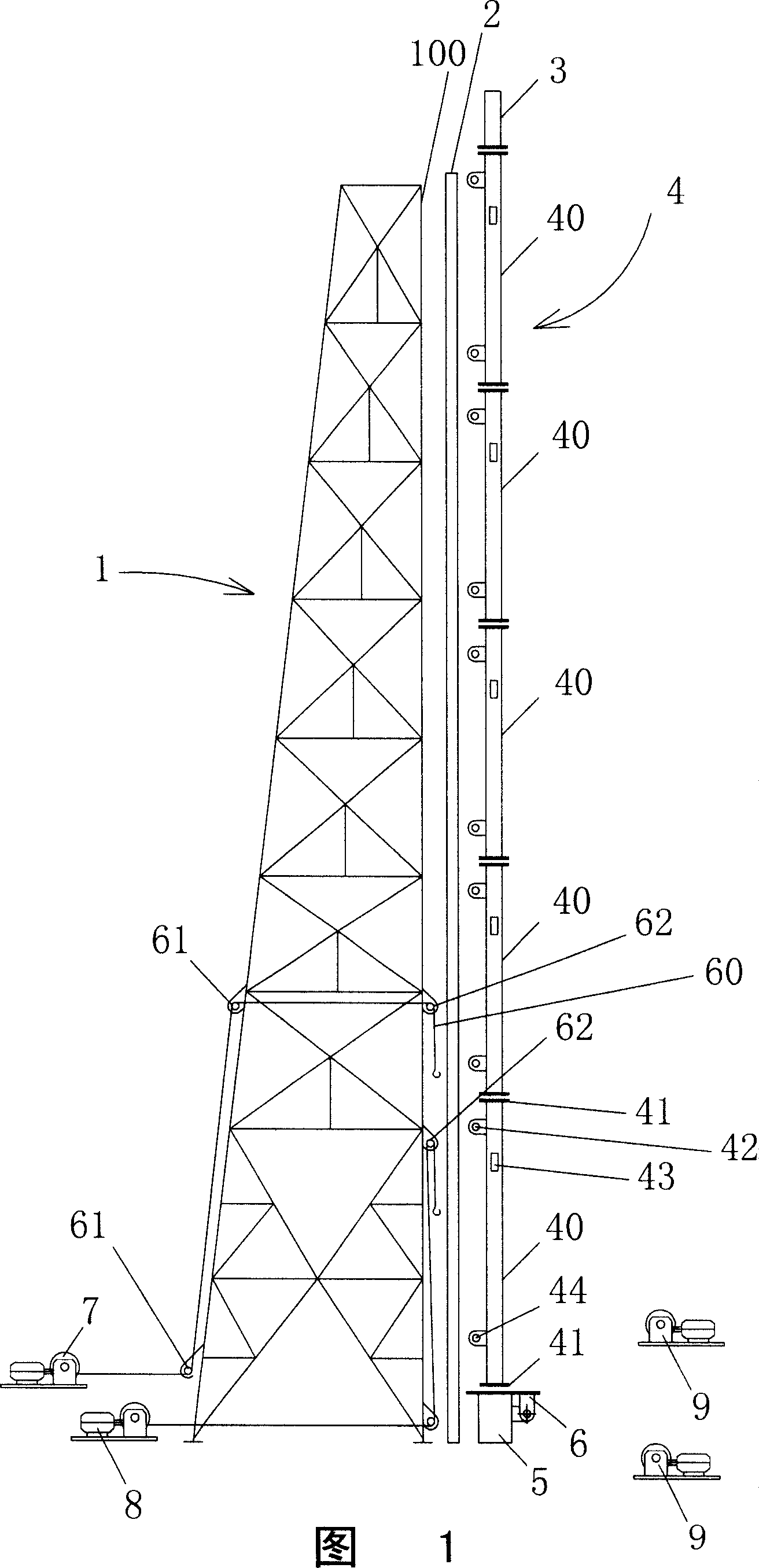

Self unloading binding overhead torch, its loading and unloading system and its loading and unloading method

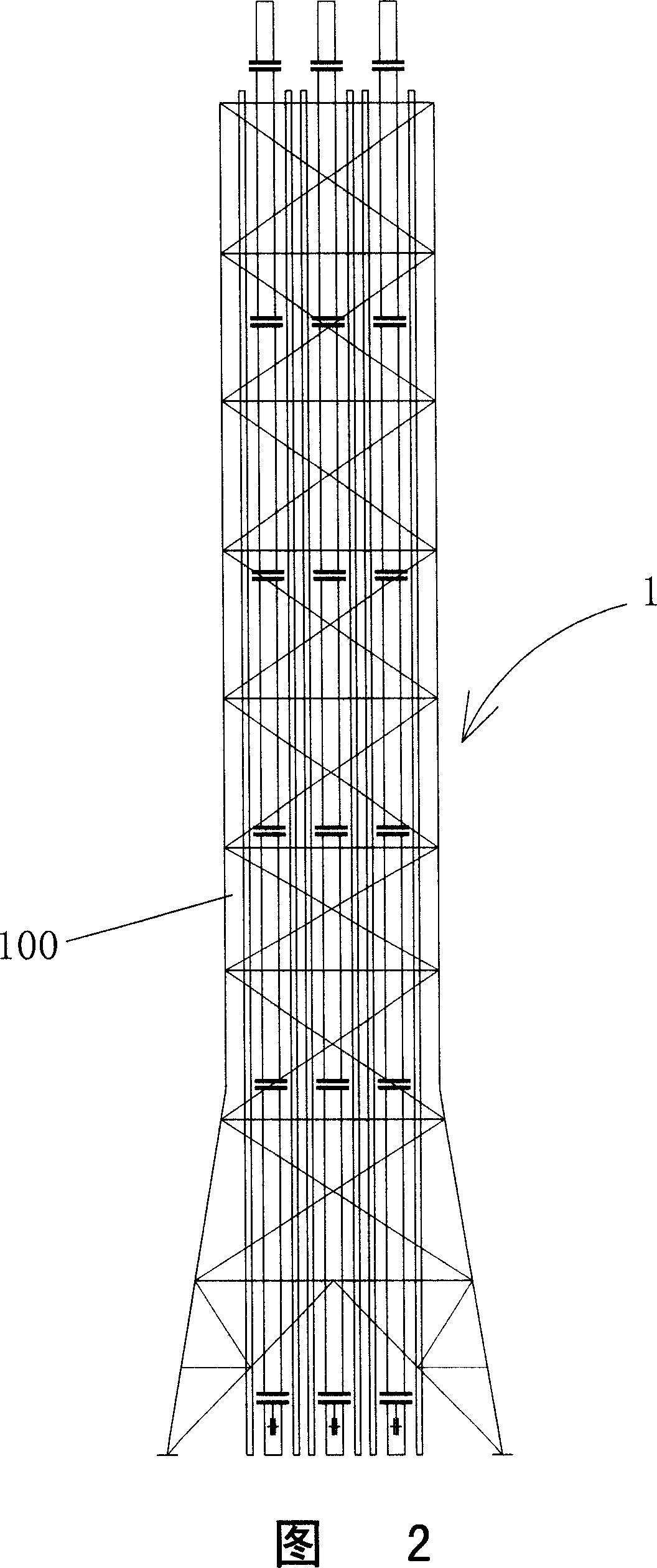

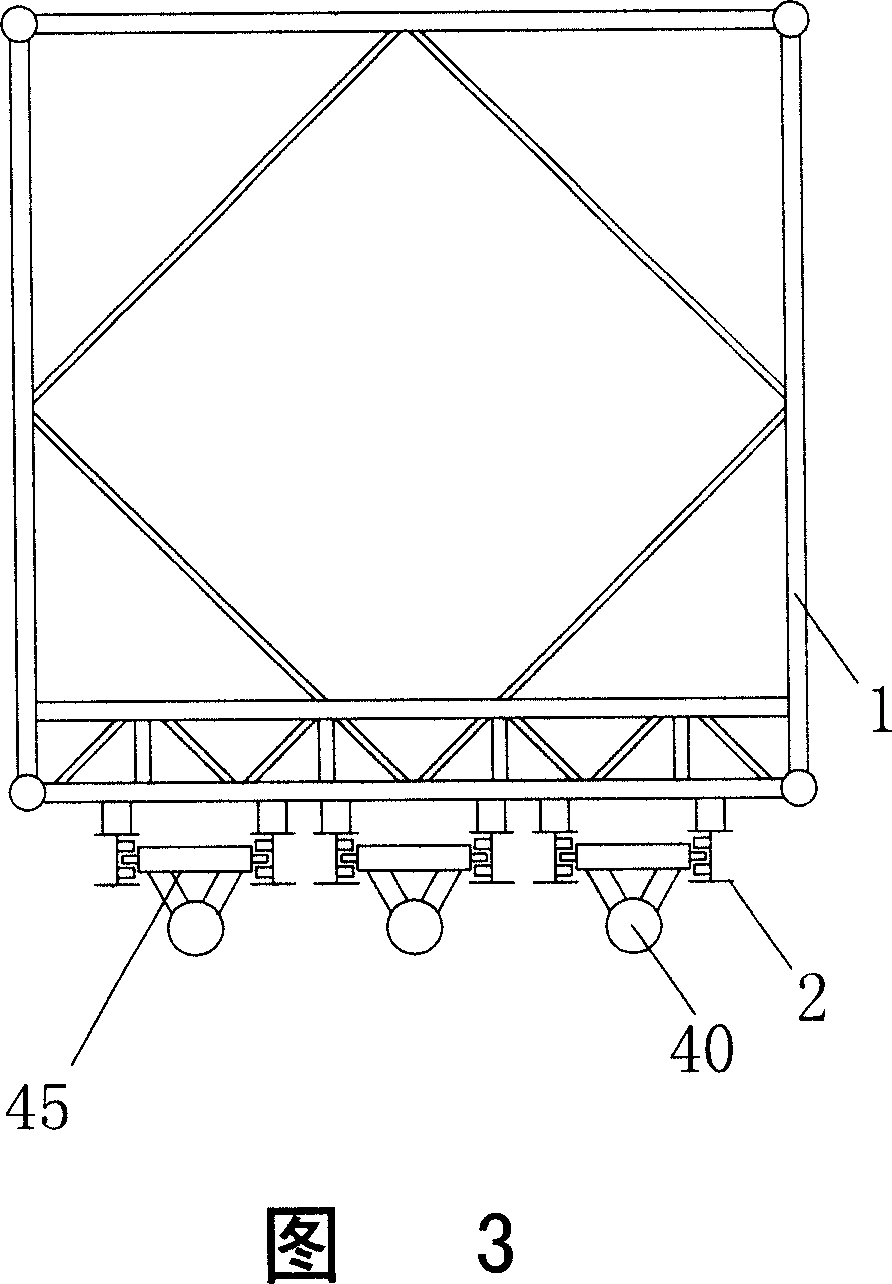

InactiveCN1987200AFully automatedDoes not affect combustionGaseous fuel burnerAssembly disassemblyTorch

A self-detachable bound high torch is composed of a torch head, a cylindrical body consisting of multiple cylindrical segments, and the first jointers at both ends of each cylindrical segment for jointing adjacent two cylindrical segments and at the bottom of torch head. Its assembly-disassembly system is composed of a winder, a tower frame, a cable, guide track on the lateral surface of said tower frame for said cylindrical segments, and the second jointer for jointing winder with cable. Its assembly-disassembly method is also disclosed.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

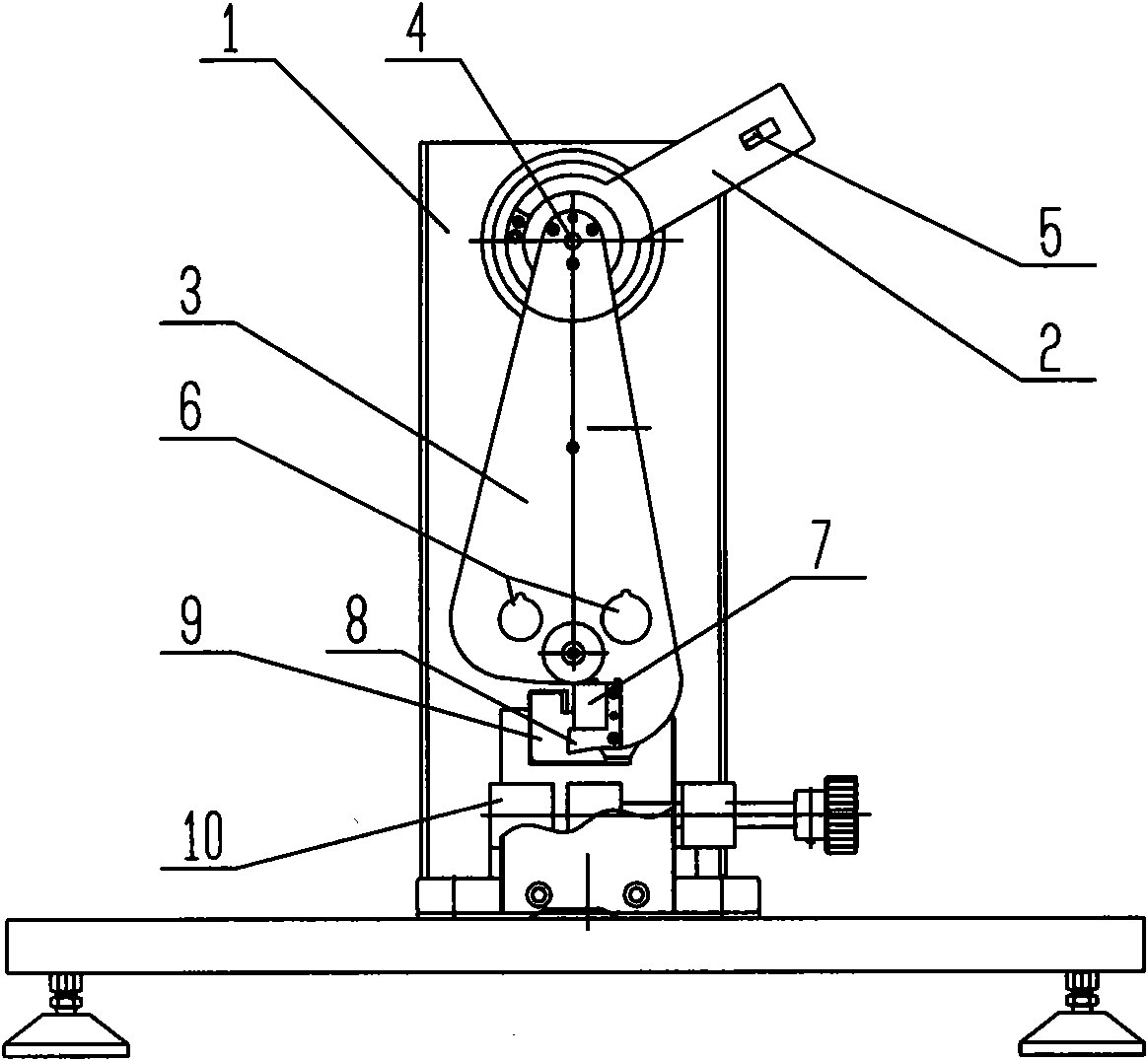

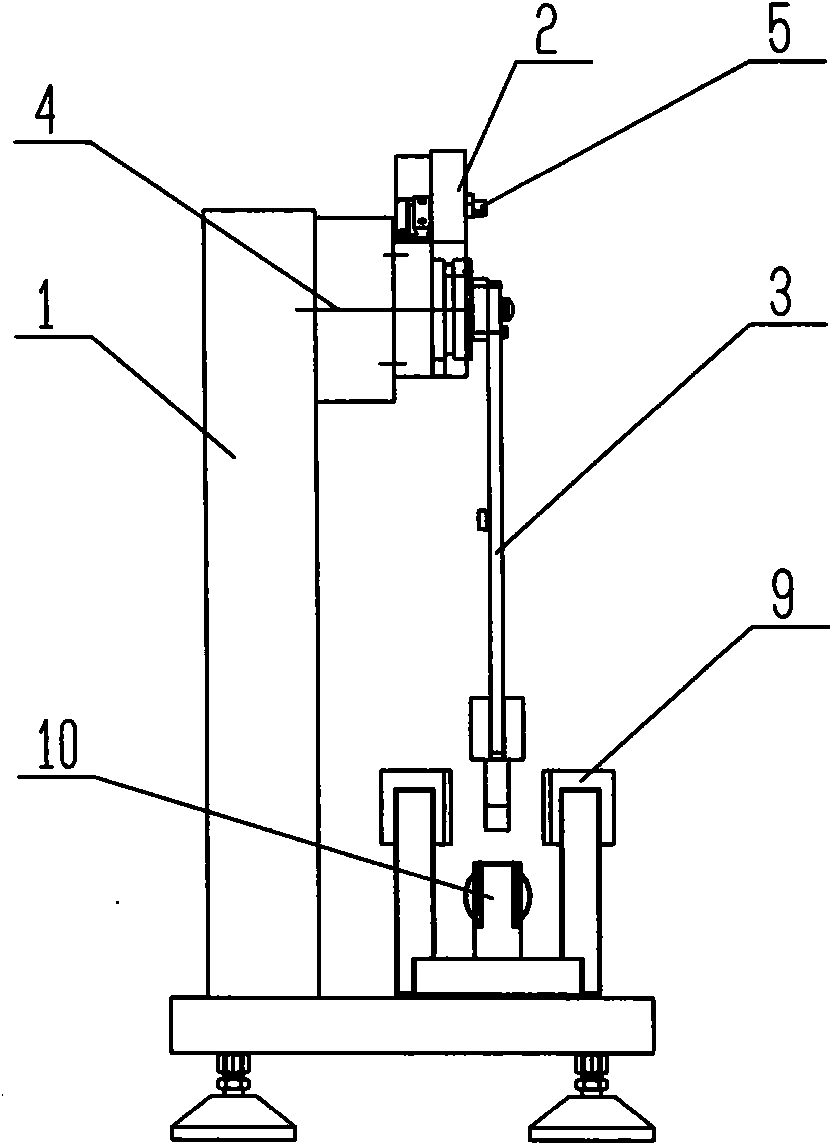

Pendulum-type impact tester

ActiveCN101603905AChange the pre-launch angleEasy to change the pre-lift angleStrength propertiesAssembly disassemblyEngineering

The invention discloses a pendulum-type impact tester. The impact tester consists of a machine frame, a pendulum bob, a jaw seat and a pendulum hanging mechanism, wherein a pendulum body of the pendulum bob adopts a sectorial structure; the pendulum is provided with a certain amount of balancing weight holes in different size, so that the simply supported beam impact and cantilever beam impact tests are realized, and by changing a pendulum angle, the impact energy and the impact speed can be changed, the requirements of a plurality of measuring ranges are met, the wind resistance of the pendulum body with sectorial face is small, the energy loss is small, and the phenomenon of bent pendulum rod caused when the impact point deviates the mass center can be avoided. Moreover, the tester has the advantages of convenient assembly-disassembly and debugging, reasonable structure, low cost and convenient use, and is convenient to be used by production enterprises and is favorable for research tests.

Owner:承德市金建检测仪器有限公司

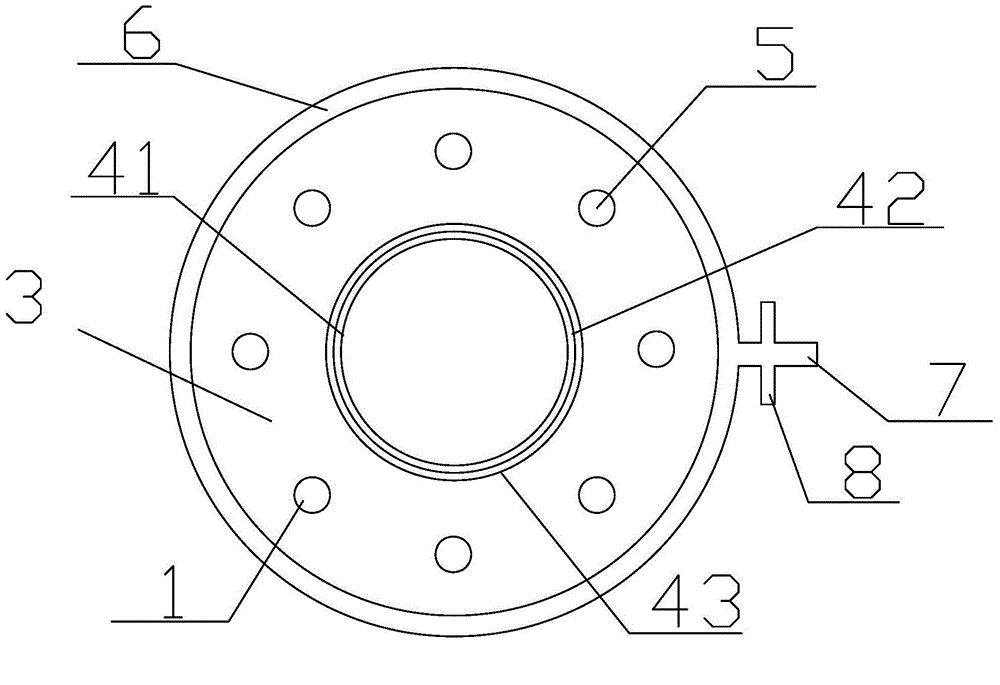

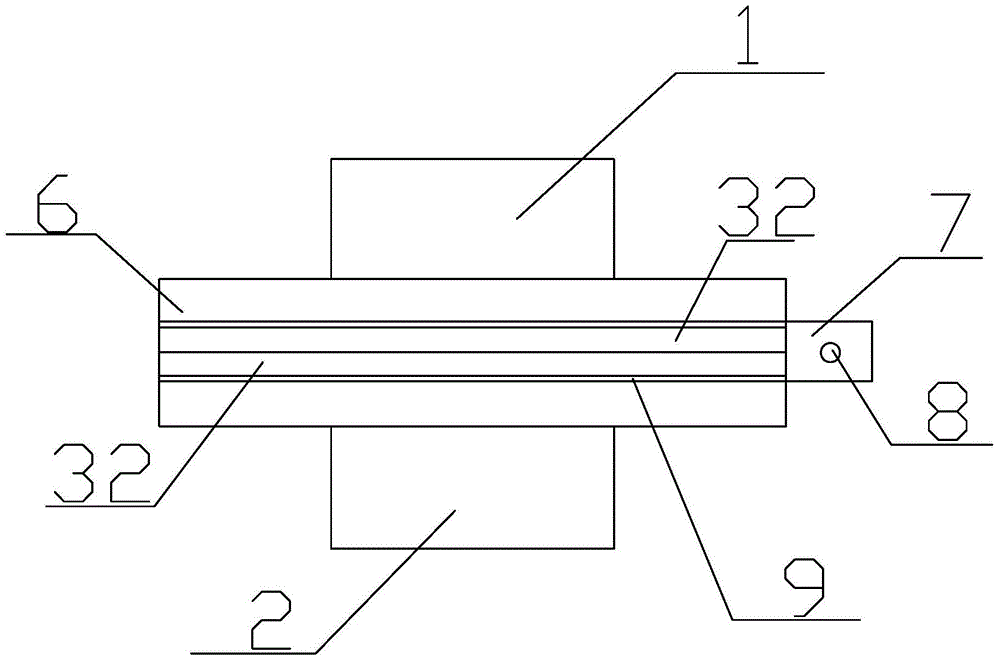

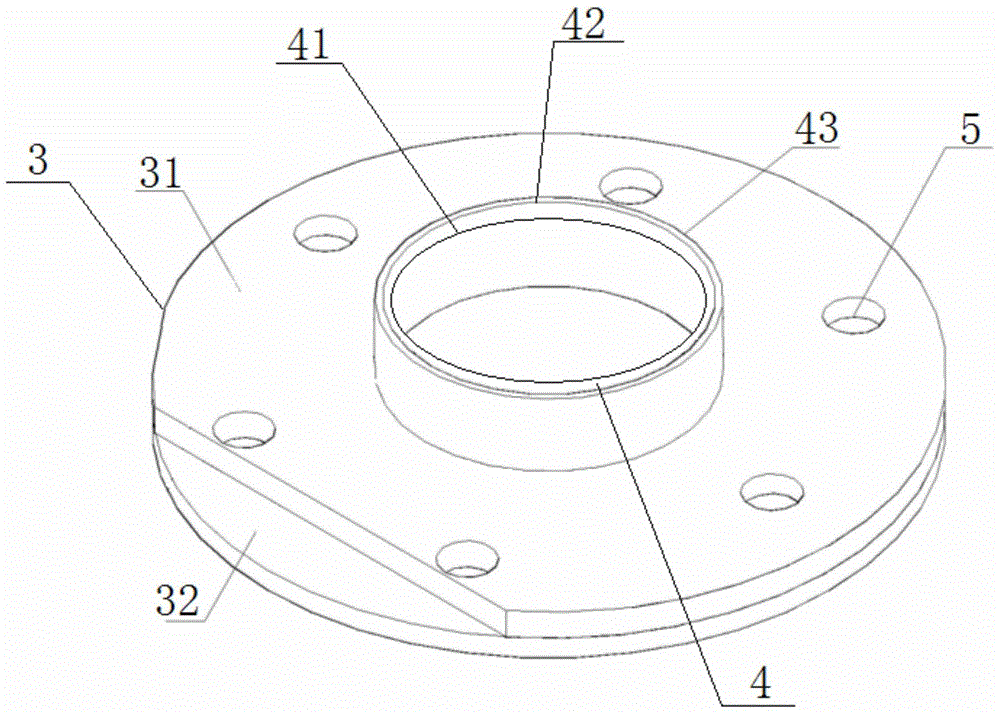

C276 Hastelloy alloy flange and production technology thereof

ActiveCN104791564AFirmly connectedEasy to assemble and disassembleFlanged jointsTemperature control deviceAssembly disassemblyMaterials science

The invention discloses a C276 Hastelloy alloy flange. The C276 Hastelloy alloy flange comprises an upper flange body and a lower flange body which are of the same structure, wherein the upper flange body and the lower flange body are fixedly connected through a fixing device, the upper flange body is composed of a flange main body and a sleeve, the flange main body is of a two-layer structure and comprises an alloy layer and an abrasion-resistant layer which are coaxially arranged, the flange main body is further evenly provided with bolt holes, the sleeve comprises an inner pipe, an outer pipe and a middle pipe which are all coaxially arranged in a sleeving mode, the fixing device comprises a fixing groove containing the upper flange body and the lower flange body, a fixing edge and a fixing pin, holes are formed in the annular periphery of the fixing groove, and a fixing hole is formed in the fixing edge. The invention further relates to a production technology of the C276 Hastelloy alloy flange. The production technology is simple and easy to perform, low in production cost, small in pollution in the production process, and good in safety, the produced C276 Hastelloy alloy flange has good corrosion resistance and abrasion resistance, seal welding performance of the C276 Hastelloy alloy flange and a pipeline is excellent, assembly and disassembly are convenient, and installing efficiency is improved.

Owner:WUXI HUAERTAI MACHINERY MFG

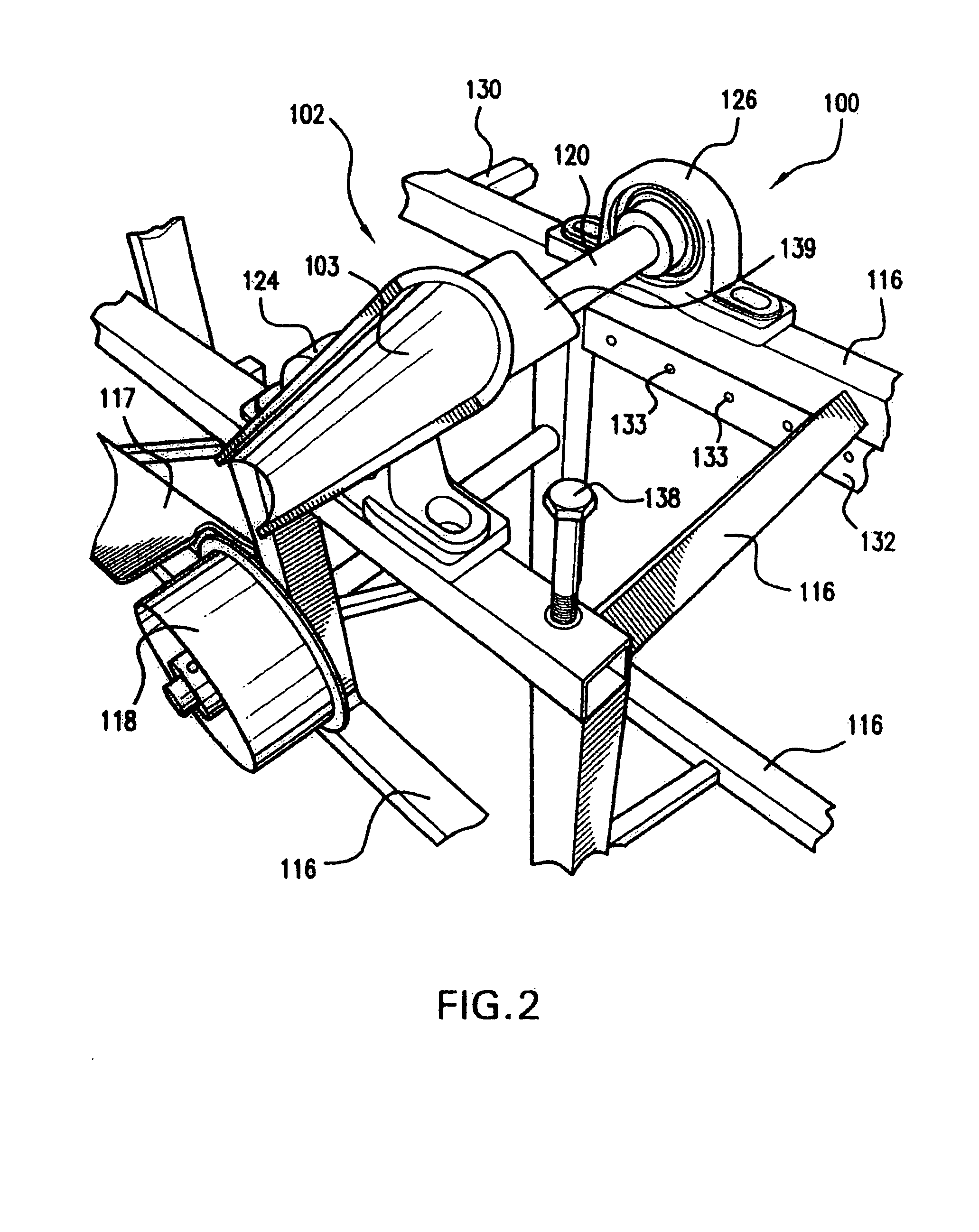

Apparatus and method for mounting belt of belt conveyor

ActiveCN101503143AFlexible installation and disassemblyEasy to transportConveyorsBelt fasteningsAdhesive beltAssembly disassembly

The invention relates to a device and a method for mounting a belt conveyer adhesive tape. The device comprises a host and a middle switching guiding device; a new adhesive tape wound roll, an old adhesive tape wound roll and a wire cable wound roll assembly are arranged on the base frame of a same host machine; the driving mechanism of the old adhesive tape wound roll is connected with a cycloidal planetary gear speed reducer by a drive chain and a transmission shaft; the cycloidal planetary gear speed reducer is connected with the wire cable wound roll by the transmission shaft; and the middle switching guiding device is arranged on one point at the middle part of a belt conveyer. A cut point is discretionarily arranged on the old adhesive tape of the belt conveyer between the host machine and the middle switching guiding device; the two sides of the cut point respectively connect the old adhesive tape with the wire cable by the drawstring clamp of the wire cable and connect the old adhesive tape with the new adhesive tape by the connecting clamp of a new belt and an old belt. Therefore, by a switchable hand--electric conversion device, the invention can realize fast power output switch from the drawstring of the wire cable to the old adhesive tape wound roll. The invention has the advantages that structure is compact, loading and unloading are flexible, and the paving of the new adhesive tape and the rolling of the old adhesive tape can be synchronously carried out.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

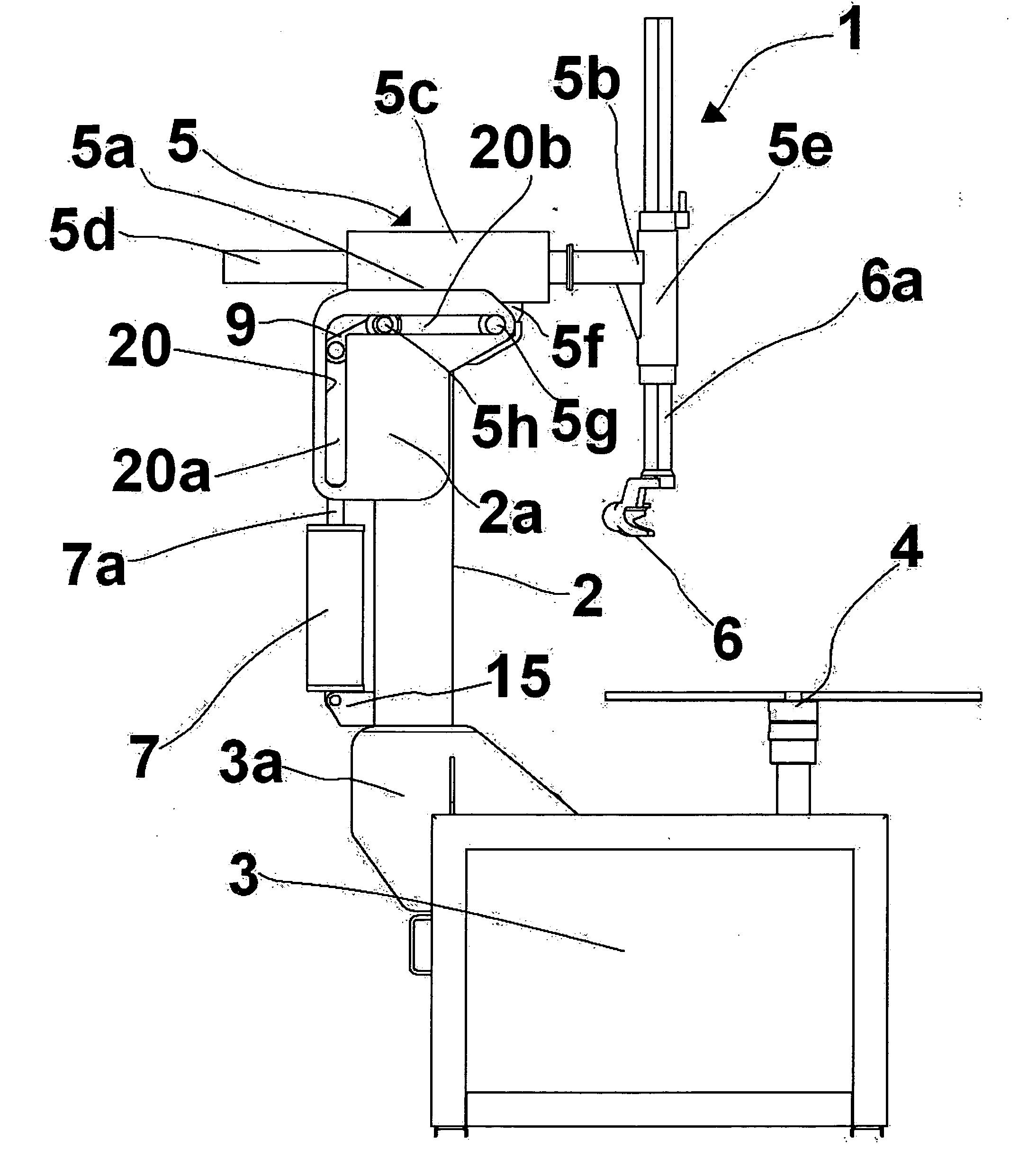

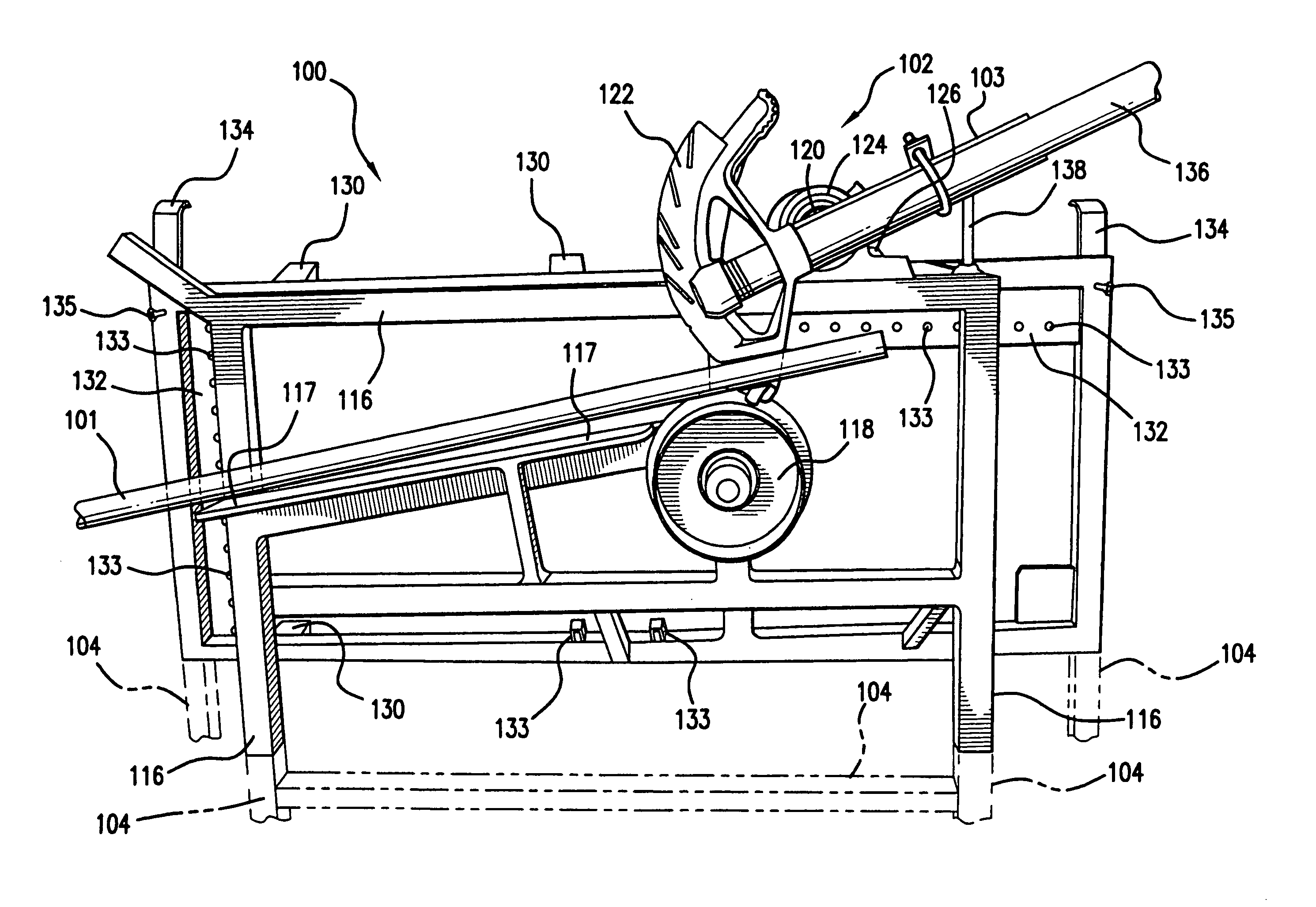

Assembling-disassembling machine provided with a overturnable mounting-dismounting tool

ActiveUS20070000617A1Minimal effortRapidly and effectively changeTyre repairingRest positionAssembly disassembly

The present invention relates to an assembling-disassembling machine provided with a base, a rotating support device (4) for a wheel rim or tyred wheel, an upright or column element (2) extending upwards from the base, and at least one mounting / dismounting tool (6) supported by the upright or column element (2) and mounted on one end of a tool carrying arm (5) in order to transversely extend from the upright element (2). The assembling-disassembling machine also comprises rotating and shifting support means located between the upright or column element (2) and the tool-carrying arm (5) at an upper level with respect to the rotating support device (4), whereby said tool-carrying arm (5) can be rotated and shifted with respect to the upright or column element (2) between a working position, in which the tool (6) is close to the rotating support device (4) and at least one rest position far from the rotating support device (4).

Owner:BUTLER ENG & MARKETING

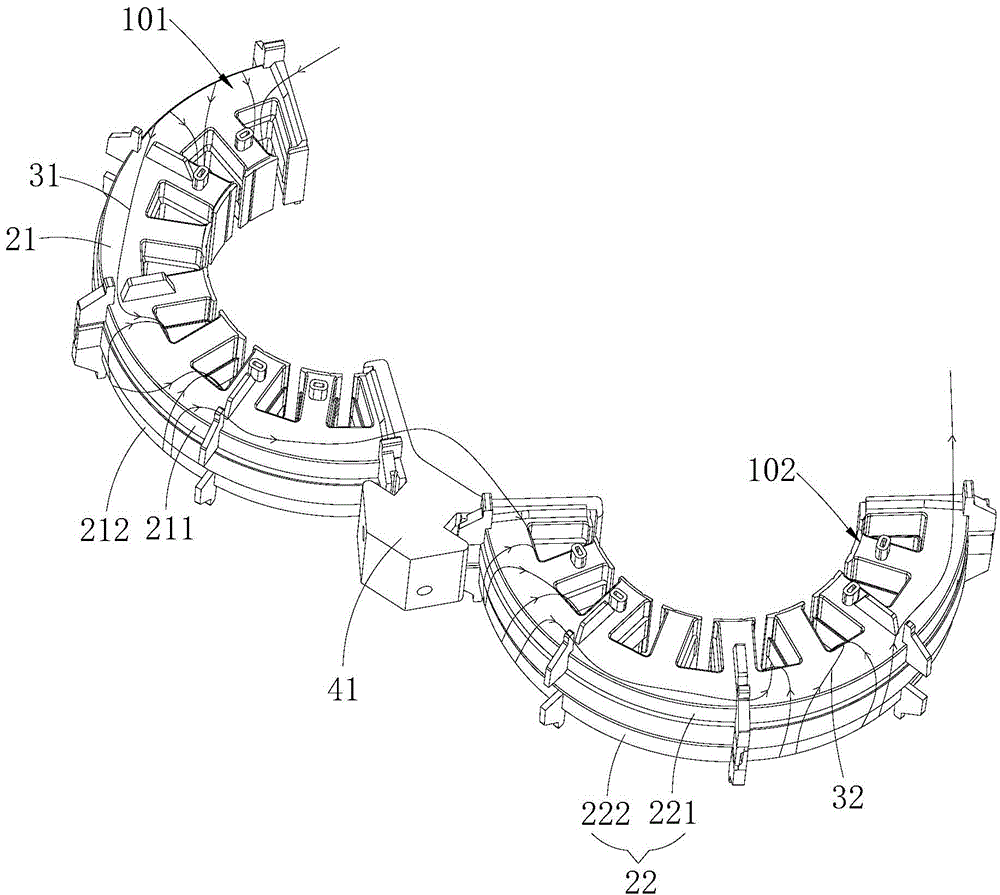

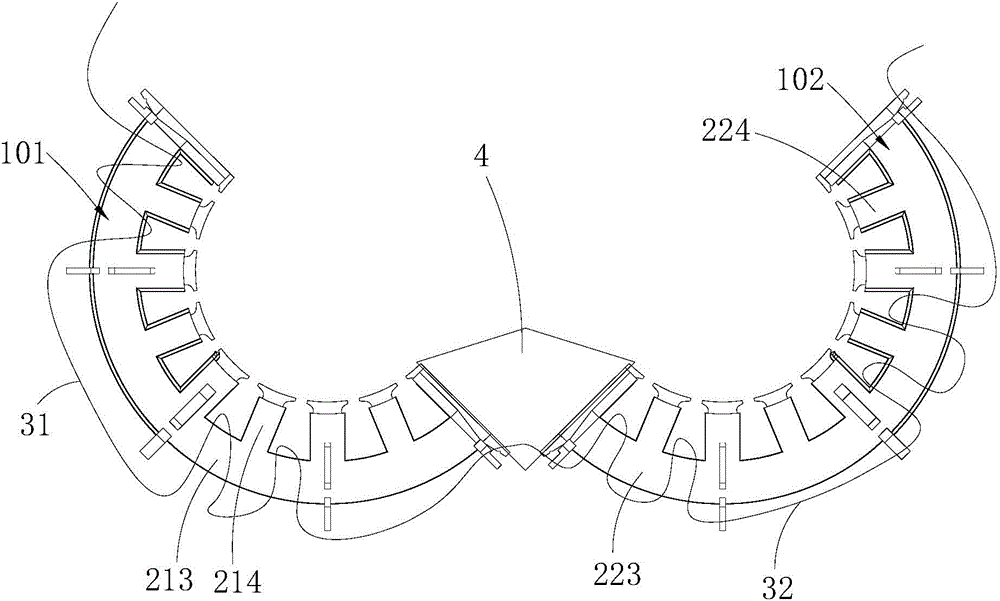

Stator wire winding method, stator and motor

ActiveCN104319957AIncrease productivityImprove product qualityMagnetic circuit stationary partsManufacturing dynamo-electric machinesWinding machineAssembly disassembly

The invention belongs to the motor field and discloses a stator wire winding method, a stator made through adopting the stator wire winding method, and a motor with the stator. The stator wire winding method comprises the following steps that: a clamping step: a first half stator core component and a second half stator core component are locked on a fixture of a wire winding machine; a wire winding step: wire winding is performed on the first half stator core component, so that a first half winding can be formed, and after the wire winding of the first half winding is accomplished, an enameled wire which is connected between the first half winding and the wire winding machine bridges onto the second half stator core component, and wire winding is performed continuously, so that a second half winding can be formed; and a disassembling step: the first half stator core component and the second half stator core assembly disassembly are disassembled from the fixture. With the stator wire winding method of the invention adopted, the wire winding mode of the stator can be improved, and production efficiency of subsequent stator assembly can be improved, and labor output cost can be saved, and at the same time, the production quality of the motor can be improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Weeds and fallen leaves treatment vehicle for gardens

InactiveCN108718654AQuick cutFlexible assembly and disassemblyMowersAssembly disassemblyArchitectural engineering

The invention discloses a weeds and fallen leaves treatment vehicle for gardens. The weeds and fallen leaves treatment vehicle comprises a treatment box, an air suction drum and a discharging tube; aclamping block is fixedly disposed on the top of one side of the treatment box; one side of the clamping block is connected with a fixing rod in a clamping manner; a first electric telescopic rod is hinged to a middle portion of the fixing rod; a protective box is hinged to an output end of the first electric telescopic rod; an intermediate plate is fixedly disposed at the bottom end of the protective box; side plates are hinged to two sides of the intermediate plate; and first motors are mounted on sides of the two side plates. According to the invention, through the side plates hinged to thetwo sides of the intermediate plate, and by cooperation of the first motors and a second motor, the rapid cutting of the weeds by utilizing a lateral blade and a vertical blade can be realized; at the same time, cutting angles can be flexibly adjusted by the first electric telescopic rod, so as adapt to the weed cutting on different planes; and the fixing rod is connected with the clamping blockin a clamping manner, and can be flexibly assembled, disassembled and utilized, so that the operation is more convenient.

Owner:HUNAN ARTS & CRAFTS VOCATIONAL COLLEGE

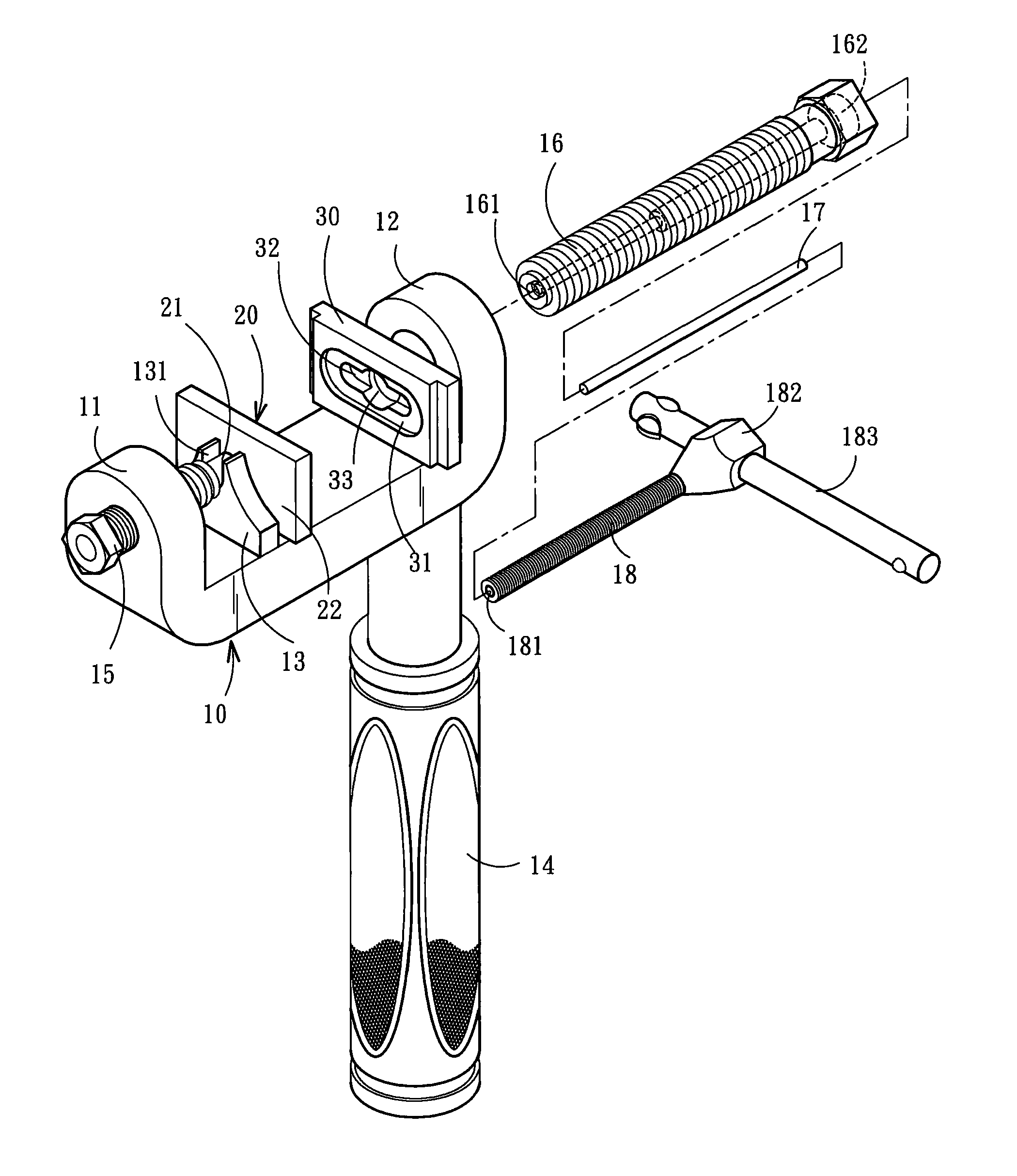

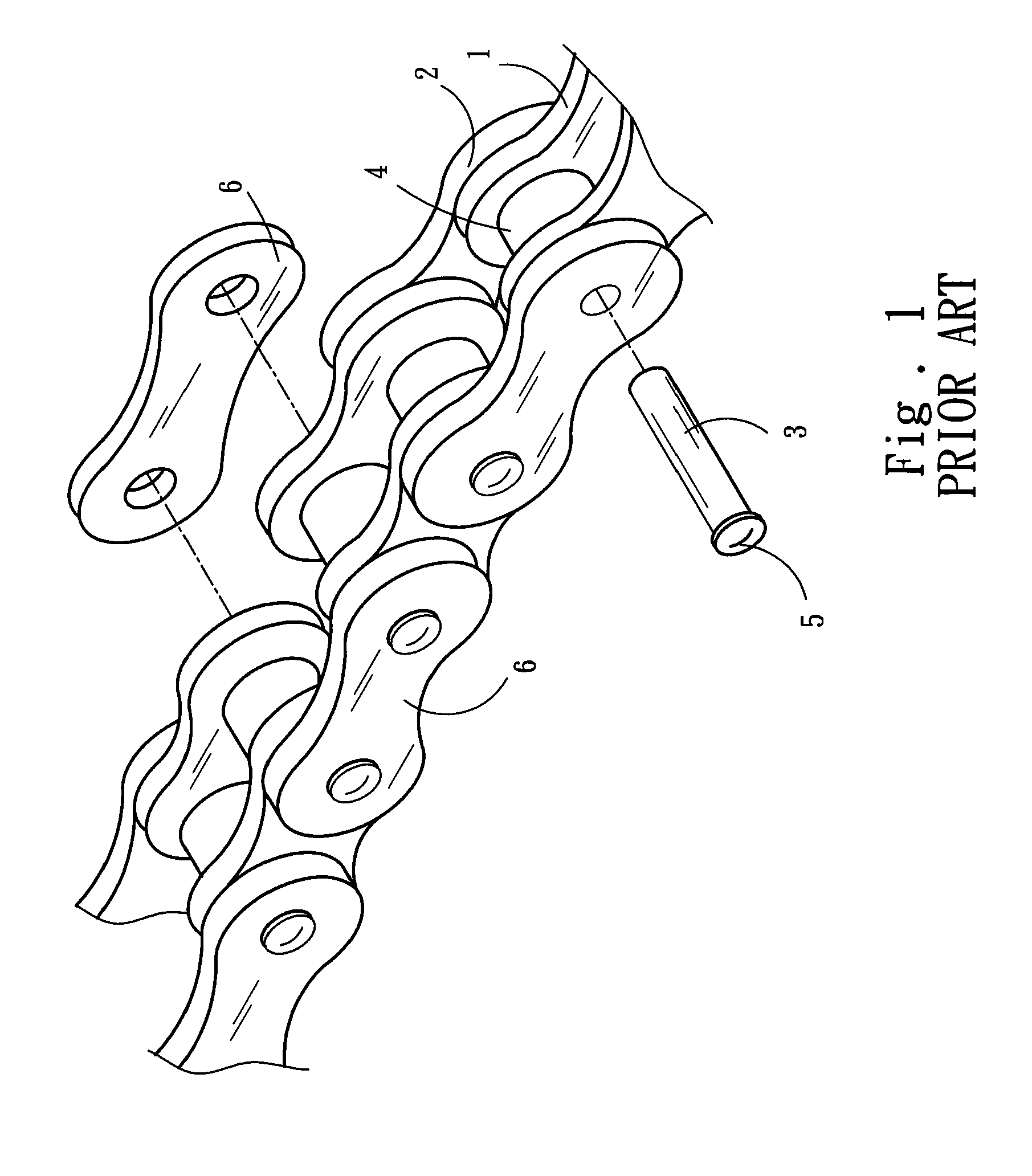

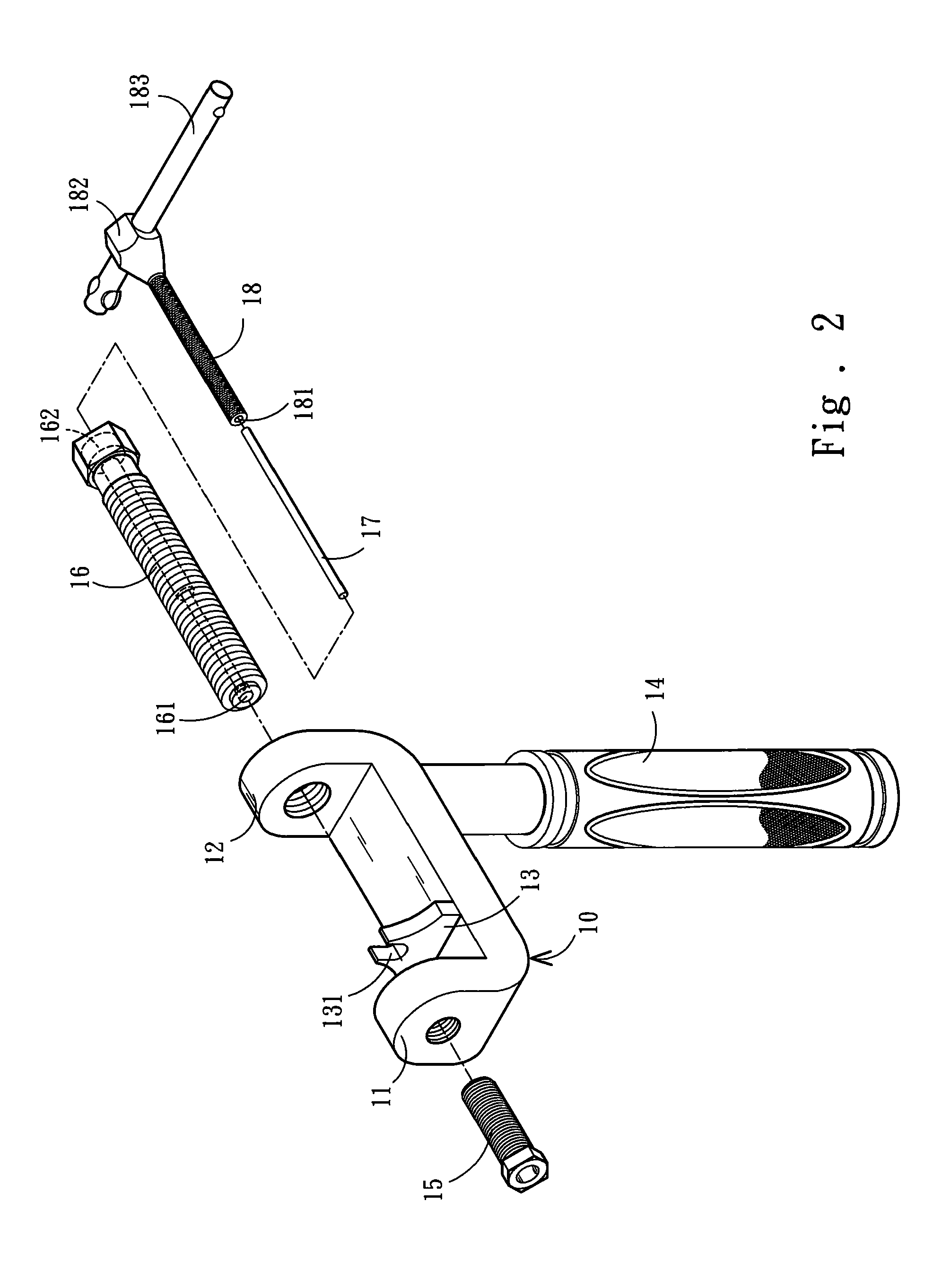

Chain assembling-disassembling structure

InactiveUS8141333B2Quick releaseThe method is simple and convenientSpannersWrenchesAssembly disassemblyDrive shaft

A chain assembling-disassembling structure includes an assembling base, a first clamping component, a second clamping component, a penetrating shaft and a driving shaft. The assembling base has a fixing portion and the fixing portion has a concave edge for receiving a bushing of the chain section. And, the assembling base includes a first portion and a second portion vertically formed at two opposite ends thereof for respectively engaging with the first and second clamping components. Here, the first and second clamping components together clamp and restrict the chain. The second clamping component has a tubular shape for being inserted by the penetrating shaft, and then, the driving shaft can further be locked into the second clamping component. By turning the driving shaft, the penetrating shaft can be forced to push out a pin, which is used for jointing the inner and outer link plates of the chain.

Owner:HO CHI ENTERPRISES

Apparatus and method for bending tubing

InactiveUS7055362B2Improve versatilityLow costForging/hammering/pressing machinesEngineeringAssembly disassembly

An apparatus and method for bending a tube, a pipe, a conduit and / or a rod. A bender is rotatably mounted with respect to a frame. A guide element, such as a guide roller, is mounted with respect to the frame. The guide element or the guide roller can be fixed or can move with respect to the frame. The combination of the frame, the bender and the guide element can be conveniently transported, assembled, disassembled and used at any job site or construction location.

Owner:WIDMAYER JOSEPH B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com