C276 Hastelloy alloy flange and production technology thereof

A technology of Hastelloy and flange, applied in the field of flange and its production process, C276 Hastelloy flange and its production process, can solve the problems of poor wear resistance, achieve enhanced connection effect, low cost, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

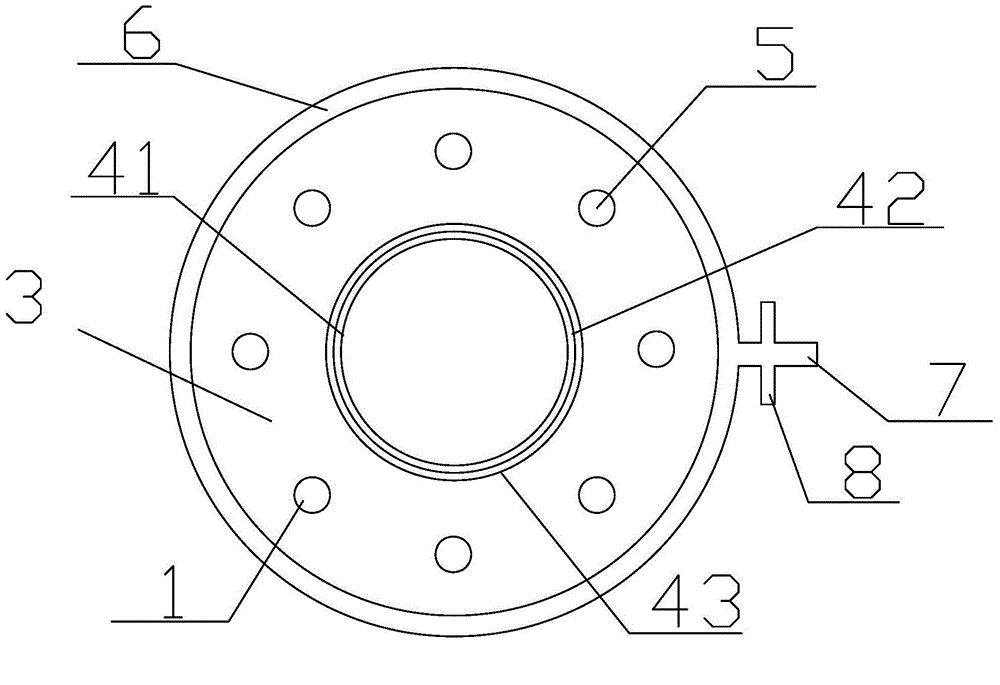

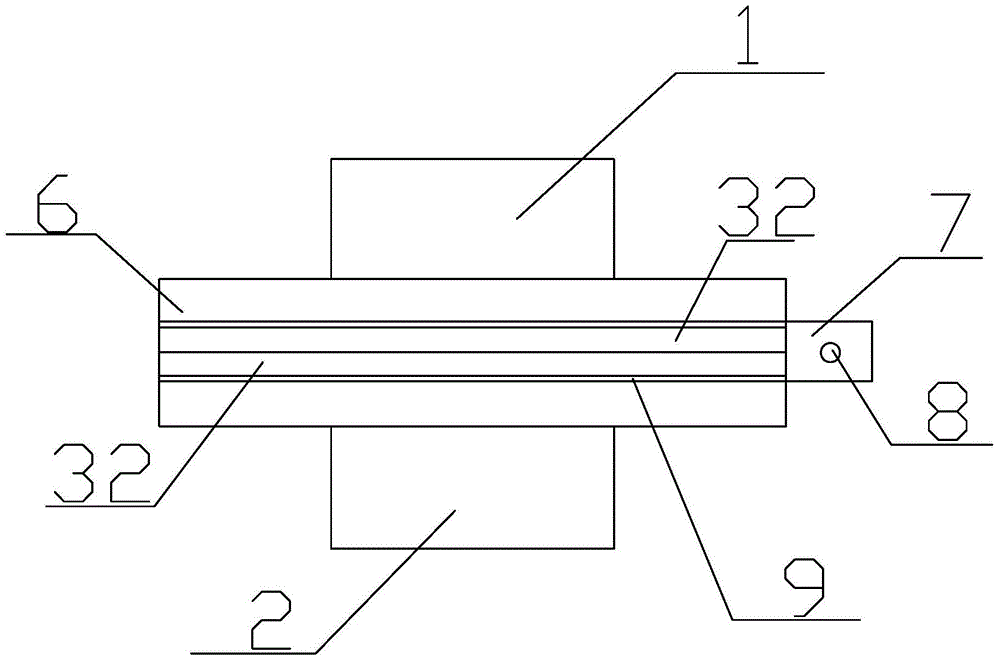

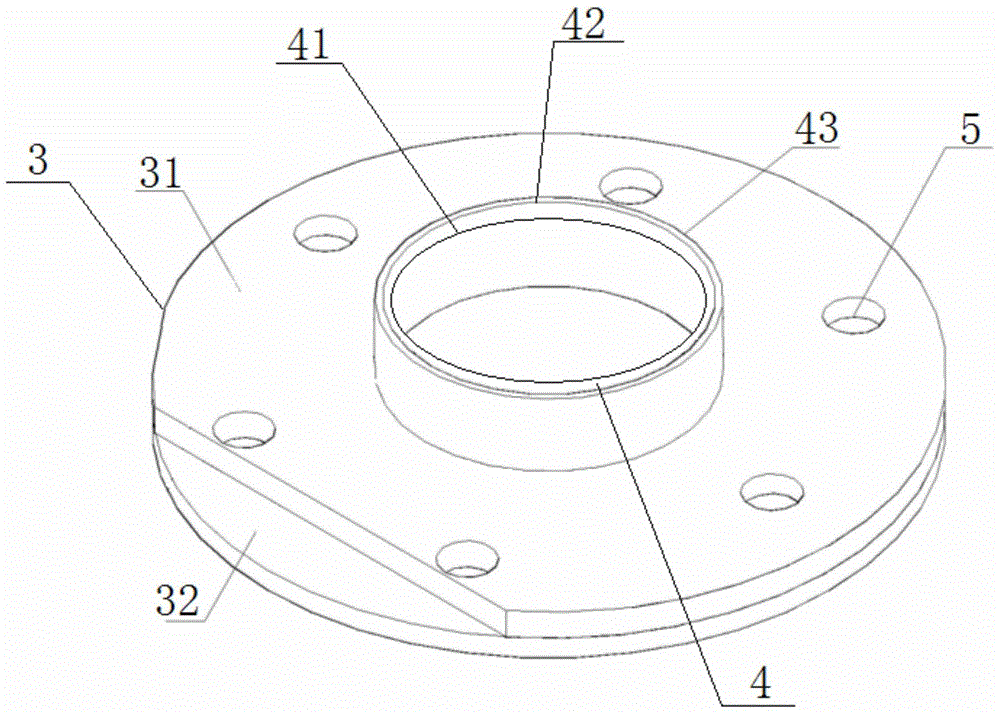

[0042] A C276 Hastelloy flange provided in this embodiment has a structure such as Figure 1-3 As shown, including upper and lower flanges 1 and lower flanges 2 which are arranged symmetrically up and down and have the same structure, such as image 3 As shown, the upper flange 1 and the lower flange 2 are fixedly connected by a fixing device, and the upper flange 1 is composed of a flange body 3 and a sleeve 4 arranged on the flange body 3, wherein:

[0043] The flange body 3 has a two-layer structure including an alloy layer 31 and a wear-resistant layer 32 arranged concentrically. The alloy layer 31 is made of C276 Hastelloy steel, and the wear-resistant layer 32 is made of ultra-high molecular weight polyethylene wear-resistant material. The alloy layer 31 and the wear-resistant layer 32 are both cylindrical structures, and the diameter of the alloy layer 31 does not exceed the diameter of the wear-resistant layer 32. The alloy layer 31 and the wear-resistant layer 32 are ...

Embodiment 2

[0047] This embodiment provides the production process of the C276 Hastelloy flange in Example 1. The forging process of the C276 Hastelloy flange specifically includes the following steps:

[0048] (1) According to the shape of the C276 Hastelloy flange, use quartz sand, water glass and bentonite as the molding materials to make the corresponding casting mold, and open the gate on the casting mold, and then place the casting mold in the oven Drying is carried out at 150°C, and the surface of the mold after drying is coated with a layer of paint. The paint contains the following components in parts by mass:

[0049] Zircon powder: 50 parts, polyvinyl acetal resin: 10 parts, phenolic resin: 10 parts, organic bentonite: 4 parts, titanium dioxide: 2 parts;

[0050] (2) Send the raw material of C276 Hastelloy flange into EBT electric arc furnace for rough refining to melt and oxidize the components of C276 Hastelloy flange. The LF refining furnace performs refining and degassing ...

Embodiment 3

[0060] This embodiment provides the production process of the C276 Hastelloy flange in Example 1. The forging process of the C276 Hastelloy flange specifically includes the following steps:

[0061] (1) According to the shape of the C276 Hastelloy flange, use quartz sand, water glass and bentonite as the molding materials to make the corresponding casting mold, and open the gate on the casting mold, and then place the casting mold in the oven Drying is carried out at 190°C, and a layer of paint is coated on the surface of the mold after drying, and the paint contains the following components in parts by mass:

[0062] Zircon powder: 40 parts, polyvinyl acetal resin: 15 parts, phenolic resin: 15 parts, organic bentonite: 2 parts, titanium dioxide: 1 part;

[0063] (2) Send the raw material of the C276 Hastelloy flange into the EBT electric arc furnace for rough refining to melt and oxidize the components of the C276 Hastelloy flange. The LF refining furnace performs refining a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com