Patents

Literature

38results about How to "Does not affect combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

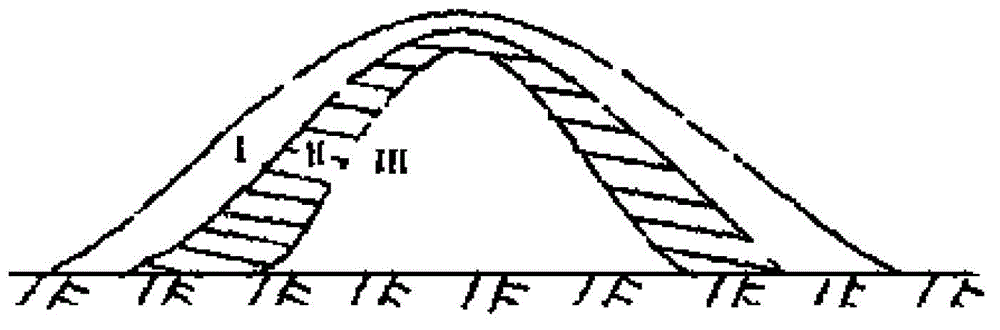

Method for restraining coal pile spontaneous ignition, special inhibitor of method and preparation method of inhibitor

The invention discloses a method for restraining coal pile spontaneous ignition in a coal storage field, a special inhibitor of the method and a preparation method of the inhibitor. The method for restraining the coal pile spontaneous ignition comprises that a free oxygen control agent is mixed uniformly is an oxidation layer of a coal pile so as to restrain oxidation and spontaneous ignition of the coal pile. A free oxygen control agent, a stabilizing agent, an absorbing agent and an auxiliary agent are mixed uniformly to form the inhibitor; the inhibitor comprises 50 to 150 parts of the free oxygen control agent, 20 to 50 parts of the stabilizing agent, 5 to 10 parts of the absorbing agent and 10 to 20 parts of the auxiliary agent; and the free oxygen control agent comprises more than one of scrap iron, sodium hydrogensulfite, di methyl ketoxime, zinc powder and D-sodium ascorbate; the stabilizing agent comprises more than one of citric acid, tartaric acid and salicylic acid, and the auxiliary agent comprises more than one of sodium hydrogen carbonate, potassium bicarbonate, sodium carbonate, potassium carbonate, sodium chloride and potassium chloride. According to the restraining method and the inhibitor, the operation is simple and the effect is obvious.

Owner:广州普凯热伏微能源科技有限公司

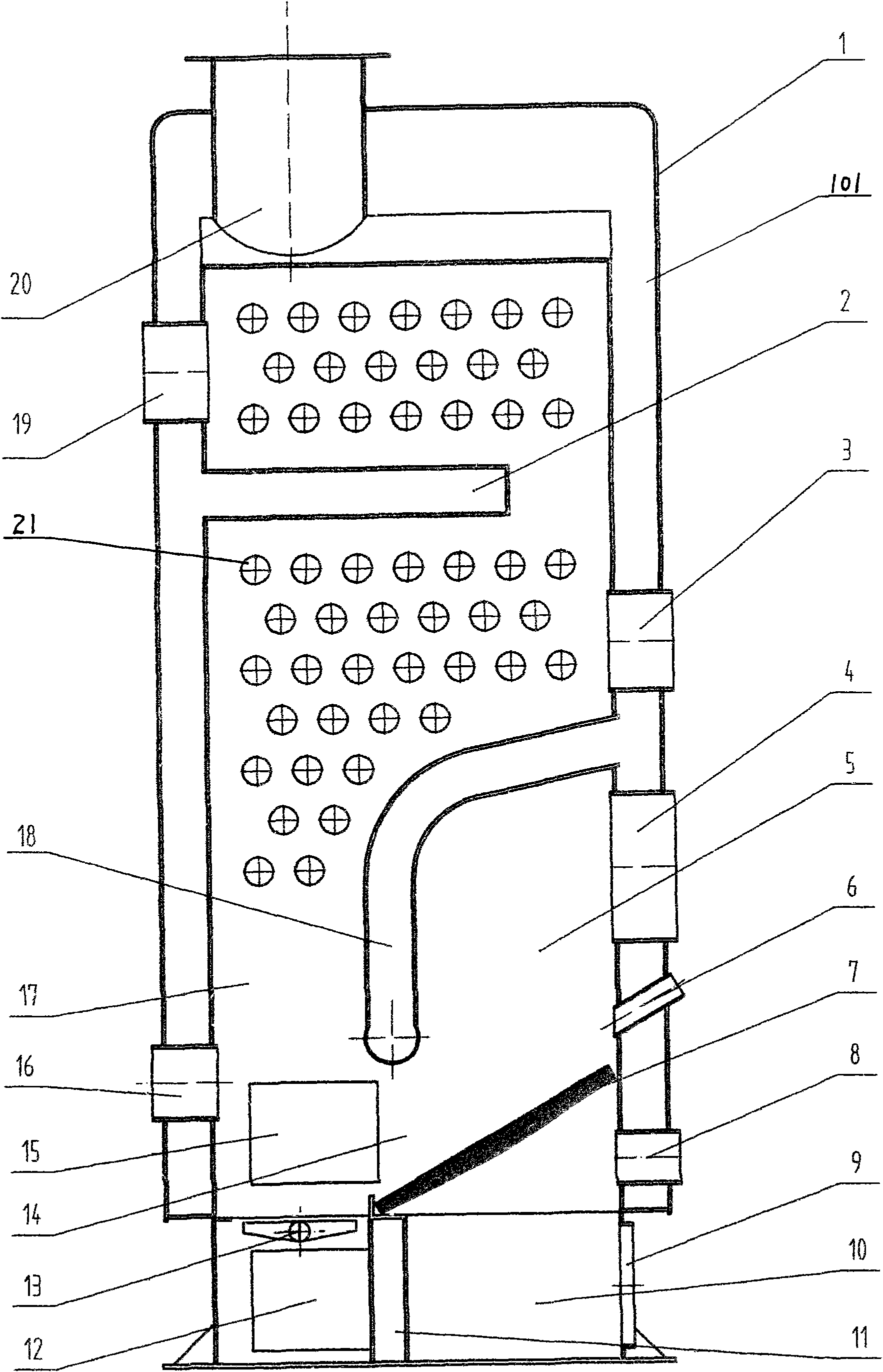

Downdraft gasification coal-fired boiler

InactiveCN101561137ADoes not affect gasificationDoes not affect combustionSolid fuel combustionWater heatersSlagCombustion chamber

The invention relates to a downdraft gasification coal-fired boiler which comprises a boiler body, a base, a grate arranged at the lower end of the boiler body, a smoke exhaust pipe arranged on the top of the boiler body, a vertical clapboard that is arranged at the lower part of the boiler body and divides the boiler body into a gasification chamber and a combustion chamber, a coal throwing gate positioned in front of the gasification chamber and an ash door that is arranged on the base under a fixing grate. The gasification coal-fired boiler is characterized in that the vertical clapboard is arranged on the inner wall of the boiler body, and the lower end of the vertical clapboard is positioned above the grate; the grate is a combined grate and comprises the inclined fixing grate positioned under the gasification chamber and a horizontal moving grate positioned under the combustion chamber; a slag pin hole is positioned on the boiler body above the fixing grate, is inclined and has the angle of inclination being consistent with that of the fixing grate 7. The invention has the advantages of needing not to stop the boiler when in coal throwing or slag removing, no secondary ignition, convenient operation, stable combustion condition, good discharge effect, coal conservation and no special requirement for coal quality.

Owner:生继成

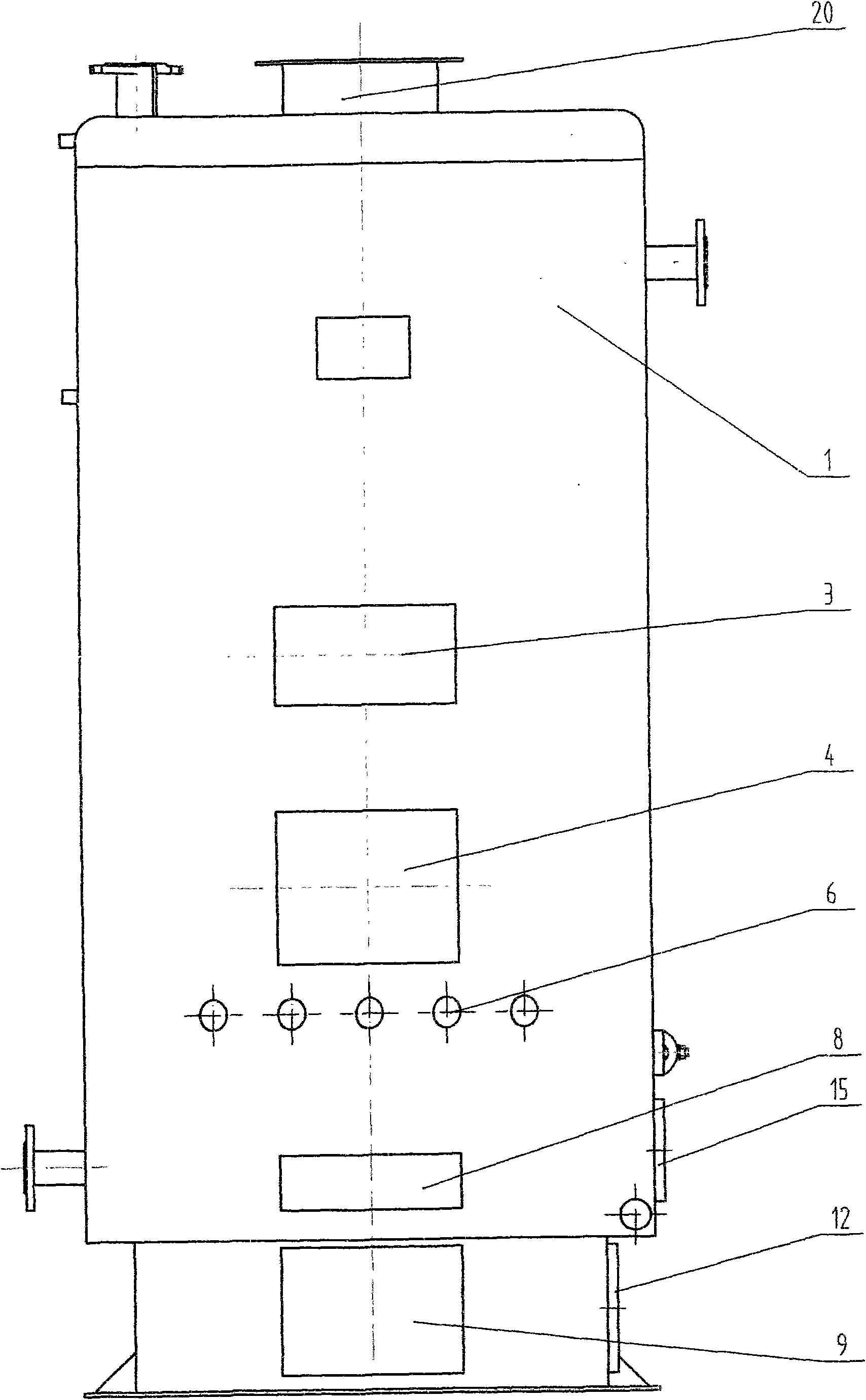

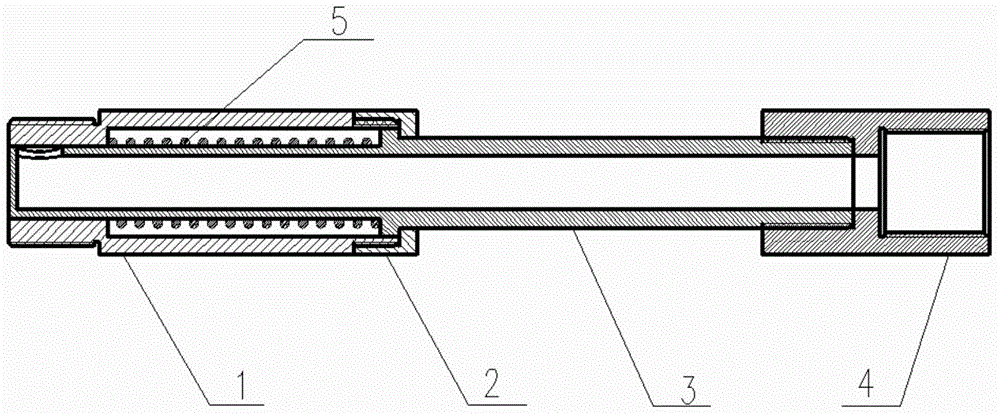

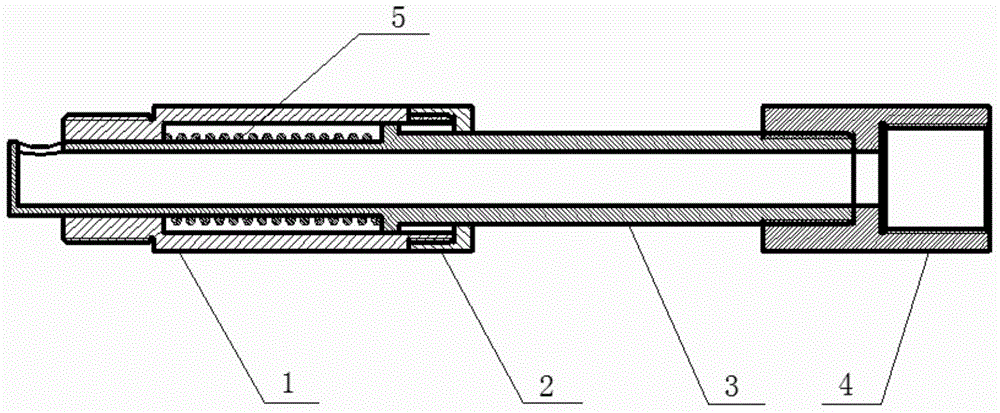

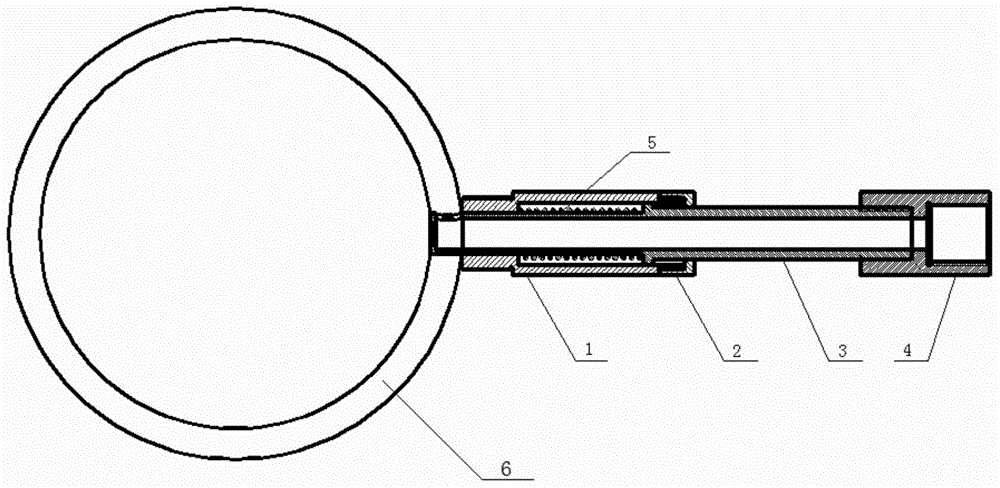

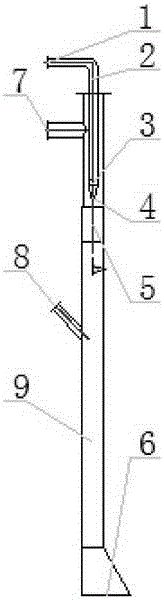

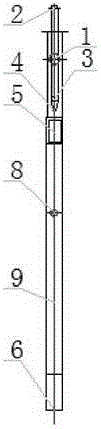

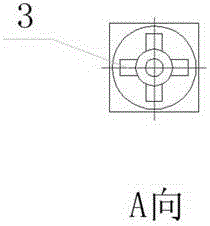

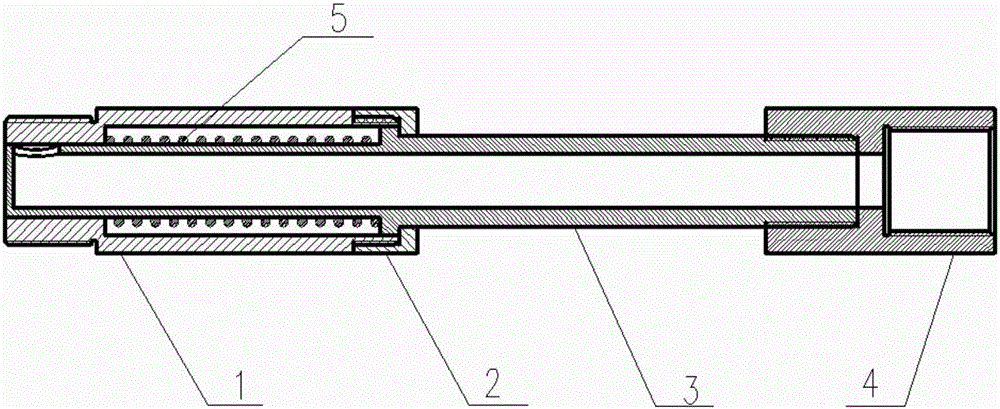

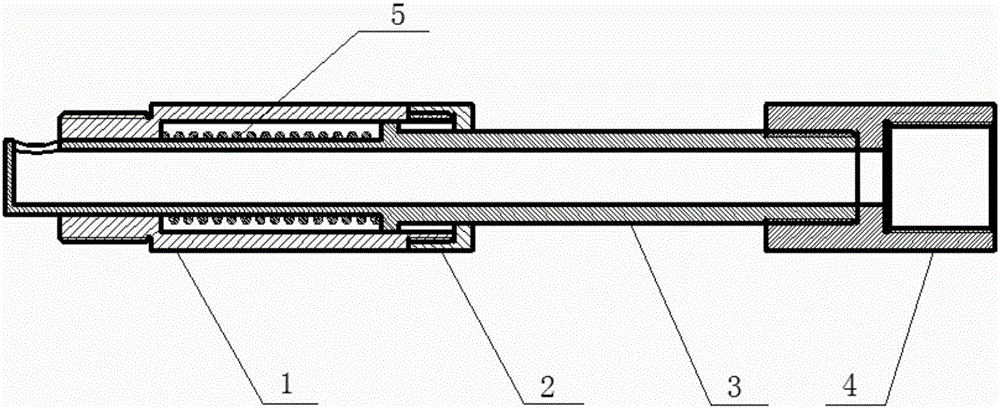

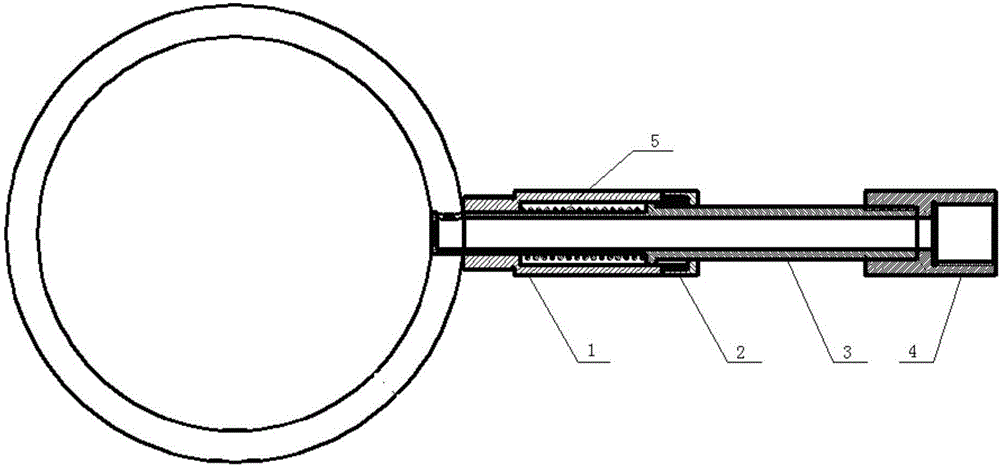

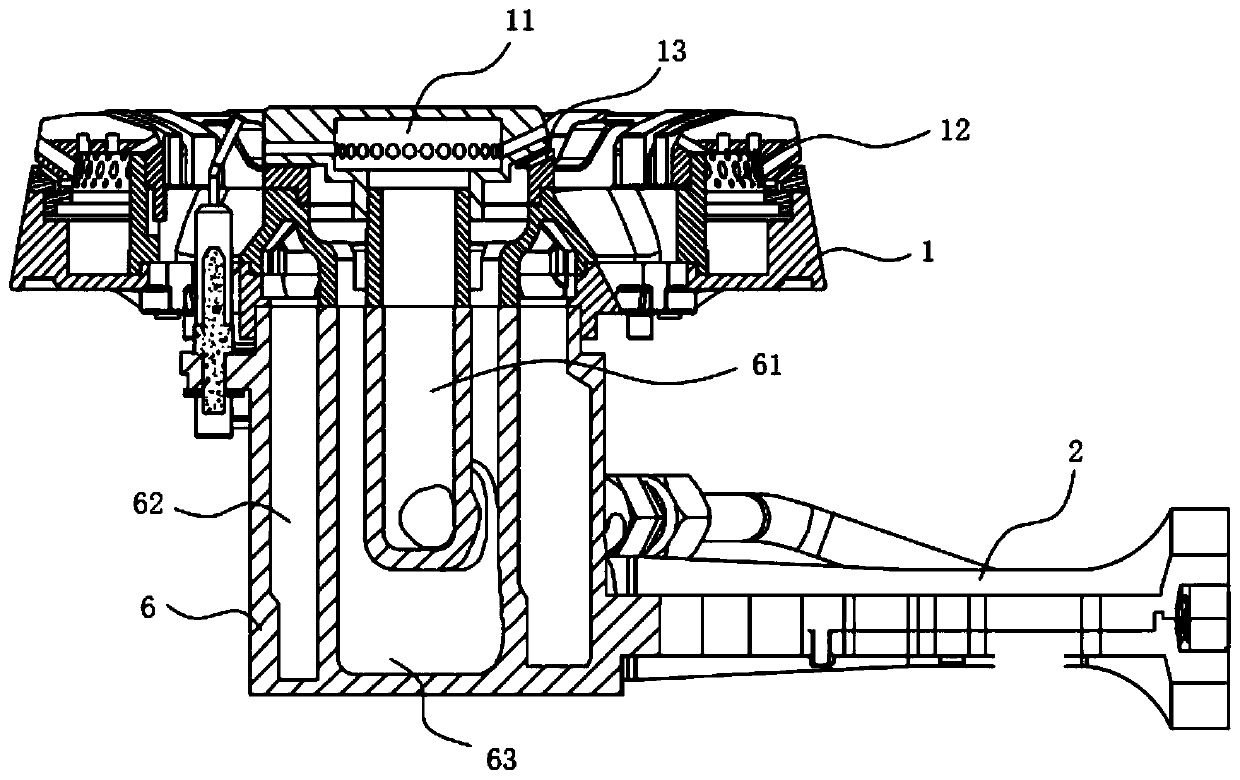

One-way priming device of probing type rotation detonation engine

ActiveCN104612821ADoes not affect combustionOvercome the restart problemInternal combustion piston enginesProbe typeDetonation

The invention discloses a one-way priming device of a probing type rotation detonation engine. The one-way priming device comprises an installing base fixed to the outer wall of the rotation detonation engine, a pre-detonation pipe, a detonation pipe switching device, an installing base end cover and an elastic element, wherein the pre-detonation pipe penetrates through the installing base and is in sliding fit with the installing base, the detonation pipe switching device is used for connecting the pre-detonation pipe and an ignition pipe, the installing base end cover is arranged at the end of the installing base and limits the installing base in the sliding direction of the pre-detonation pipe, and the elastic element on the pre-detonation pipe exerts elastic force on the pre-detonation pipe in the sliding direction of the pre-detonation pipe. An opening for the pre-detonation pipe to stretch into is formed in an annular combustion chamber of the rotation detonation engine, and an opening communicated with the annular combustion chamber is formed in the side wall of the pre-detonation pipe. The rotation detonation wave engine can be detonated in one direction, and the rotating spreading situation of detonation waves in the combustion chamber in the normal working period of the engine is not affected. The restarting problem of the engine is solved, and all components are reasonable in design and high in reliability.

Owner:NANJING UNIV OF SCI & TECH

Alcohol civil fuel with aid and its preparing method

The present invention relates to a kind of alcohol base civil fuel with crude methanol as main material and aid and its preparation process. The technological scheme is that into industrial methanol in 100 weight portions, ignition promoter in 0.05-10 weight portions, corrosion inhibitor in such amount as to reach the material liquid pH 7-8, and saturated sodium EDTA solution in (0íñ05í½1)í‡10< -6 > weight portions are added. The ignition promoter is ether, such as methyl ether and ethyl ether, or light oil; and the corrosion inhibitor is slight alkali corrosion inhibitor amino alkyl phosphate or aliphatic amine. The present invention has the advantages of high efficiency, saving in energy, environment friendship, safety, reliability and convenient operation.

Owner:冯向法

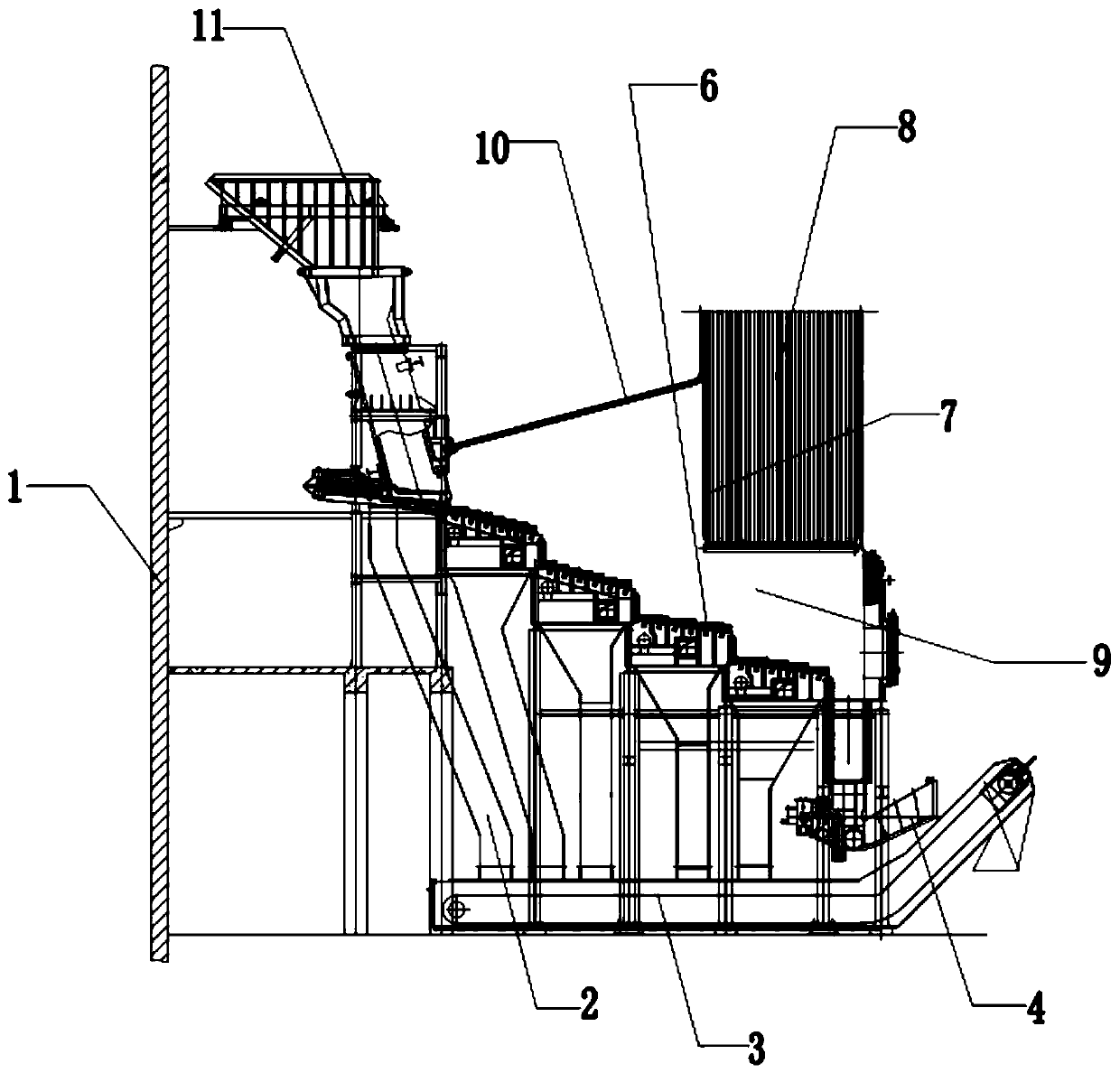

Method for recycling treatment and denitration of municipal domestic garbage with dry rotary kiln

ActiveCN103042024AReduce coal consumptionEliminate secondary pollutionSolid waste disposalWater contentCoal

A method for recycling treatment and denitration of municipal domestic garbage with a dry rotary kiln comprises the following steps of pretreating and dividing the municipal domestic garbage into a combustible component material mainly comprising organic matters, and a residue component material mainly comprising inorganic matters, taking the combustible component material as fuel for a decomposing furnace of the dry rotary kiln to substitute fire coal and a hydrocarbon raw material for denitration, feeding the combustible component material to a space from the lower part to the middle upper part in the decomposing furnace with a feed device for treatment and denitration, and taking the residue component material subjected to chemical analysis as an alternative raw material for a batching flour mill of a raw material vertical mill system, wherein the combustible component material is in a bulk form, and is less than or equal to 200mm in side length and less than or equal to 30% in water content. With the adoption of the method for treating the municipal domestic garbage, the operation is simple, the coal consumption is low, the kiln performance stability is good, the combustion of pulverized coal in a production kiln and the furnace of the dry rotary kiln is unaffected, the treatment cost is low, and the pollution to the environmental is low.

Owner:长沙紫宸科技开发有限公司

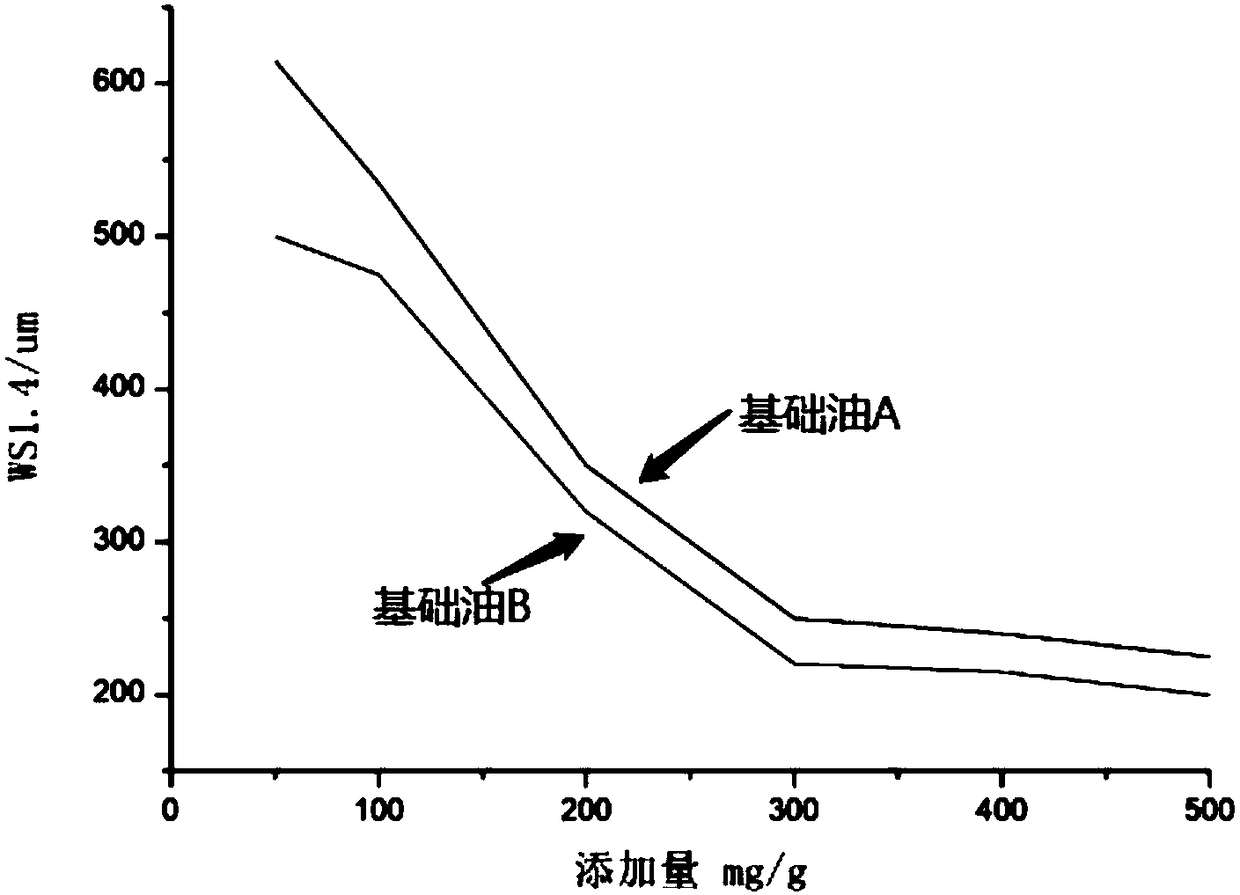

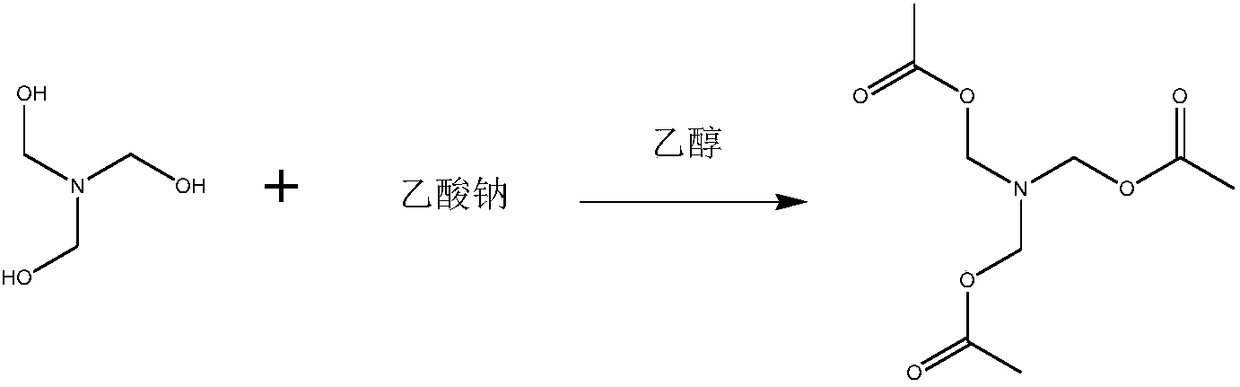

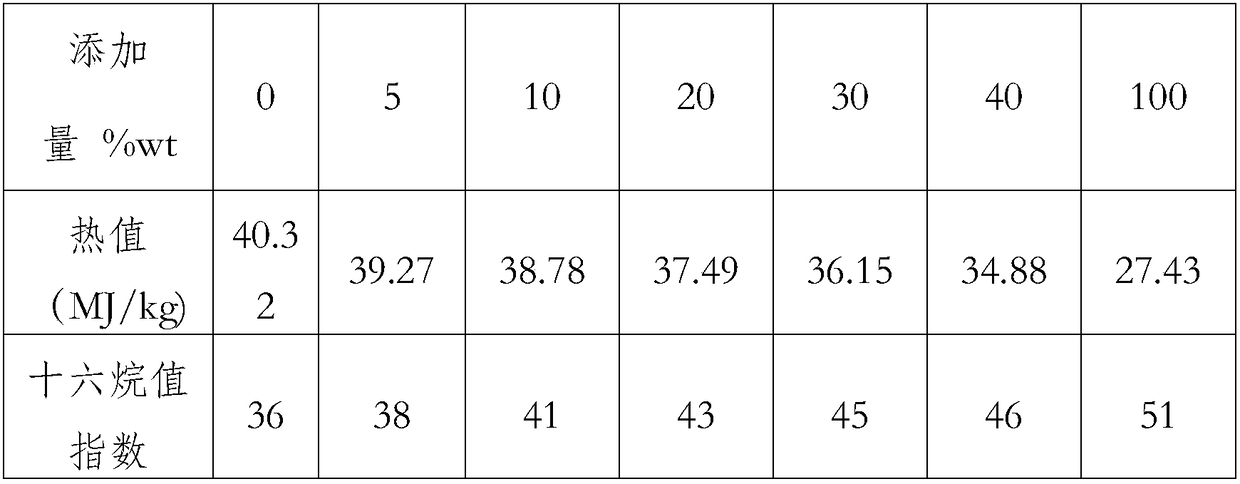

Anti-wear combustion-supporting dual-effect diesel additive and preparation method thereof

InactiveCN108467755AImprove the lubrication effectLower cold filter pointLiquid carbonaceous fuelsFuel additivesDual effectOil additive

The invention discloses an anti-wear combustion-supporting dual-effect diesel additive and a preparation method thereof. The additive comprises triethanolamine triethyl ester, and the cetane number ofthe triethanolamine triethyl ester is 51 or above. The additive provided by the invention obviously improves the cetane number and the lubricity of diesel oil. The diesel additive provided by the invention meets the requirements of high cetane number, low aromatic hydrocarbon content, low density and low sulfur content in the future development of diesel and has a broad application prospect. Thediesel oil additive has good intersolubility with diesel oil and can also reduce the cold filter plugging point of the diesel oil and improve the lubricity. After the additive is added, combustion ofthe diesel oil is basically not influenced, and polluted toxic exhaust gas is not discharged. In addition, the polarity of functional groups containing oxygen atoms is strong, so that the additive hasgood surface extreme pressure wear resistance.

Owner:赛坤(浙江自贸区)能源有限公司

Pyrolyzing furnace, flame path of pyrolyzing furnace and application of pyrolyzing furnace

ActiveCN106047377AReduce the temperatureAvoid the problem of excessive influence of combustion airCoke oven detailsGaseous fuel burnerCold airCombustion chamber

The invention relates to the technical field of low-rank coal medium-and low-temperature pyrolysis application and discloses a pyrolyzing furnace, a flame path of the pyrolyzing furnace and application of the pyrolyzing furnace. The flame path of the pyrolyzing furnace comprises a closed pipeline with two ends open, a flame nozzle with a fuel gas inlet is arranged on the front portion of the closed pipeline, the tail end of the closed pipeline is provided with a flue gas outlet, and a temperature regulation cold air inlet of a temperature regulation cold air branch pipe for input of temperature regulation cold is formed between the flame nozzle and the flue gas outlet. By the flame path of the pyrolyzing furnace, the temperature of flue gas entering a combustion chamber of the pyrolyzing furnace is lower than heat resistance temperature of a furnace body material, cost reduction can be realized, local high-temperature zones in the combustion chamber are avoided, and high pyrolysis uniformity can be achieved.

Owner:HUADIAN HEAVY IND CO LTD

One-way detonation device of penetrating rotary detonation engine

ActiveCN104612821BDoes not affect combustionOvercome the restart problemInternal combustion piston enginesProbe typeDetonation

The invention discloses a one-way priming device of a probing type rotation detonation engine. The one-way priming device comprises an installing base fixed to the outer wall of the rotation detonation engine, a pre-detonation pipe, a detonation pipe switching device, an installing base end cover and an elastic element, wherein the pre-detonation pipe penetrates through the installing base and is in sliding fit with the installing base, the detonation pipe switching device is used for connecting the pre-detonation pipe and an ignition pipe, the installing base end cover is arranged at the end of the installing base and limits the installing base in the sliding direction of the pre-detonation pipe, and the elastic element on the pre-detonation pipe exerts elastic force on the pre-detonation pipe in the sliding direction of the pre-detonation pipe. An opening for the pre-detonation pipe to stretch into is formed in an annular combustion chamber of the rotation detonation engine, and an opening communicated with the annular combustion chamber is formed in the side wall of the pre-detonation pipe. The rotation detonation wave engine can be detonated in one direction, and the rotating spreading situation of detonation waves in the combustion chamber in the normal working period of the engine is not affected. The restarting problem of the engine is solved, and all components are reasonable in design and high in reliability.

Owner:NANJING UNIV OF SCI & TECH

Catalytic cracking oxygen-poor regeneration denitration agent and preparation method thereof

ActiveCN112354358AIncrease the areaLarge acid centerPhysical/chemical process catalystsDispersed particle separationRare-earth elementPhosphate

The invention relates to a catalytic cracking oxygen-poor regeneration denitration agent and a preparation method thereof, and belongs to the field of catalytic cracking assistants. The catalytic cracking oxygen-poor regeneration denitration agent comprises a carrier and an active component, the carrier is active gamma-Al2O3, and the active component is a noble metal compound, a metal compound anda rare earth element compound; the catalytic cracking oxygen-poor regeneration denitration agent is prepared from the following raw materials in percentage by mass: 70 to 90 percent of active gamma-Al2O3, 1.5 to 5 percent of a noble metal compound, 4 to 10 percent of a rare earth element compound, 3 to 10 percent of a metal compound and 1.5 to 5 percent of phosphate. The catalytic cracking oxygen-poor regeneration denitration agent provided by the invention is high in denitration rate; the using process is easy and convenient to operate, secondary pollution is avoided, smoke can meet the emission standard, economic benefits are high, CO components in a regenerator are not consumed at all, and the safety is high; meanwhile, the invention further provides a preparation method.

Owner:山东骏飞环保科技有限公司

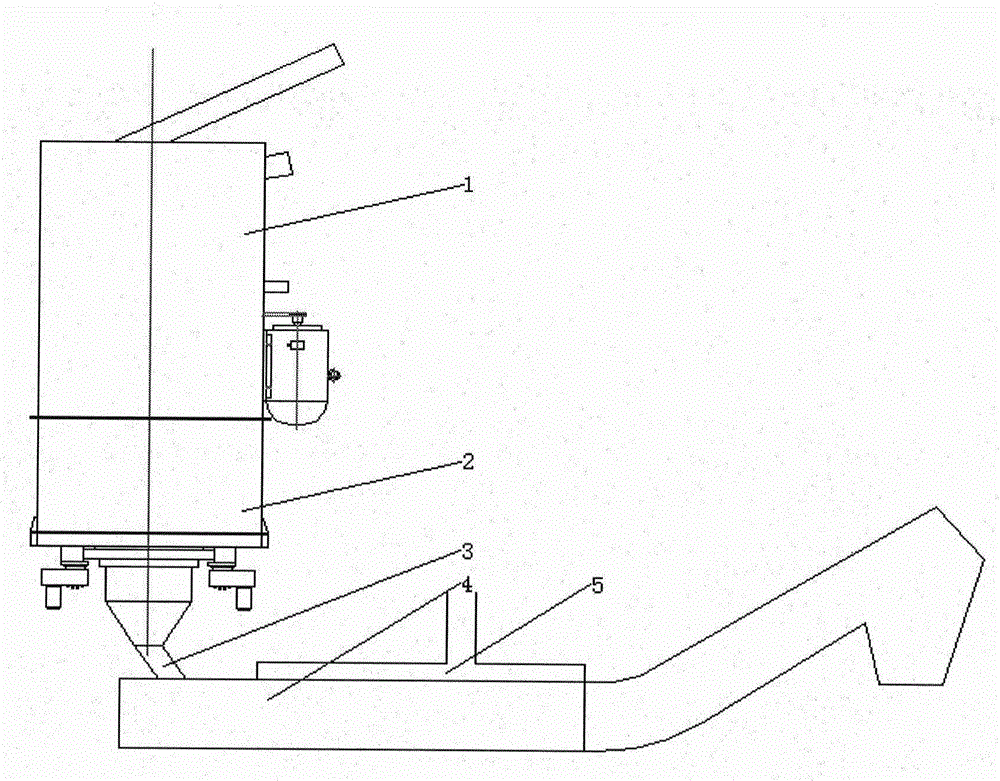

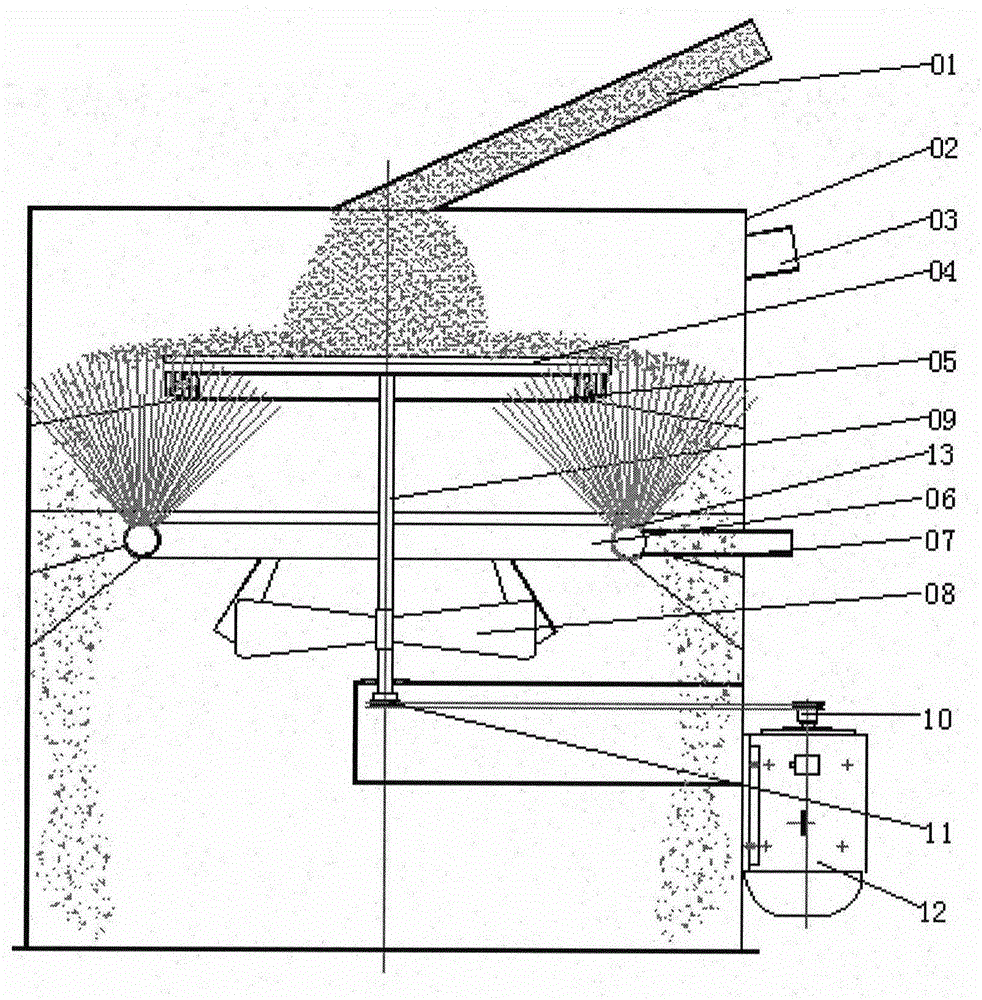

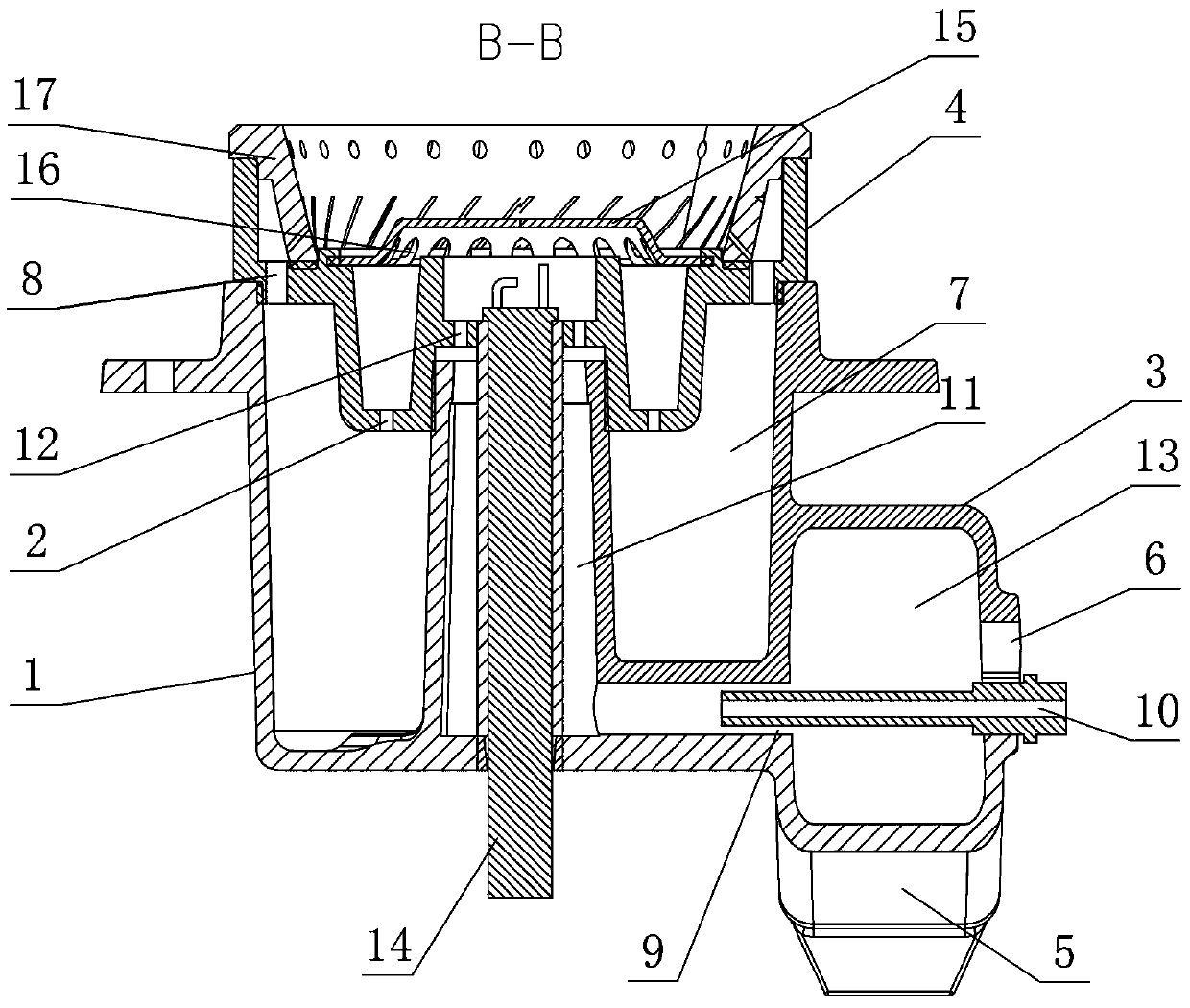

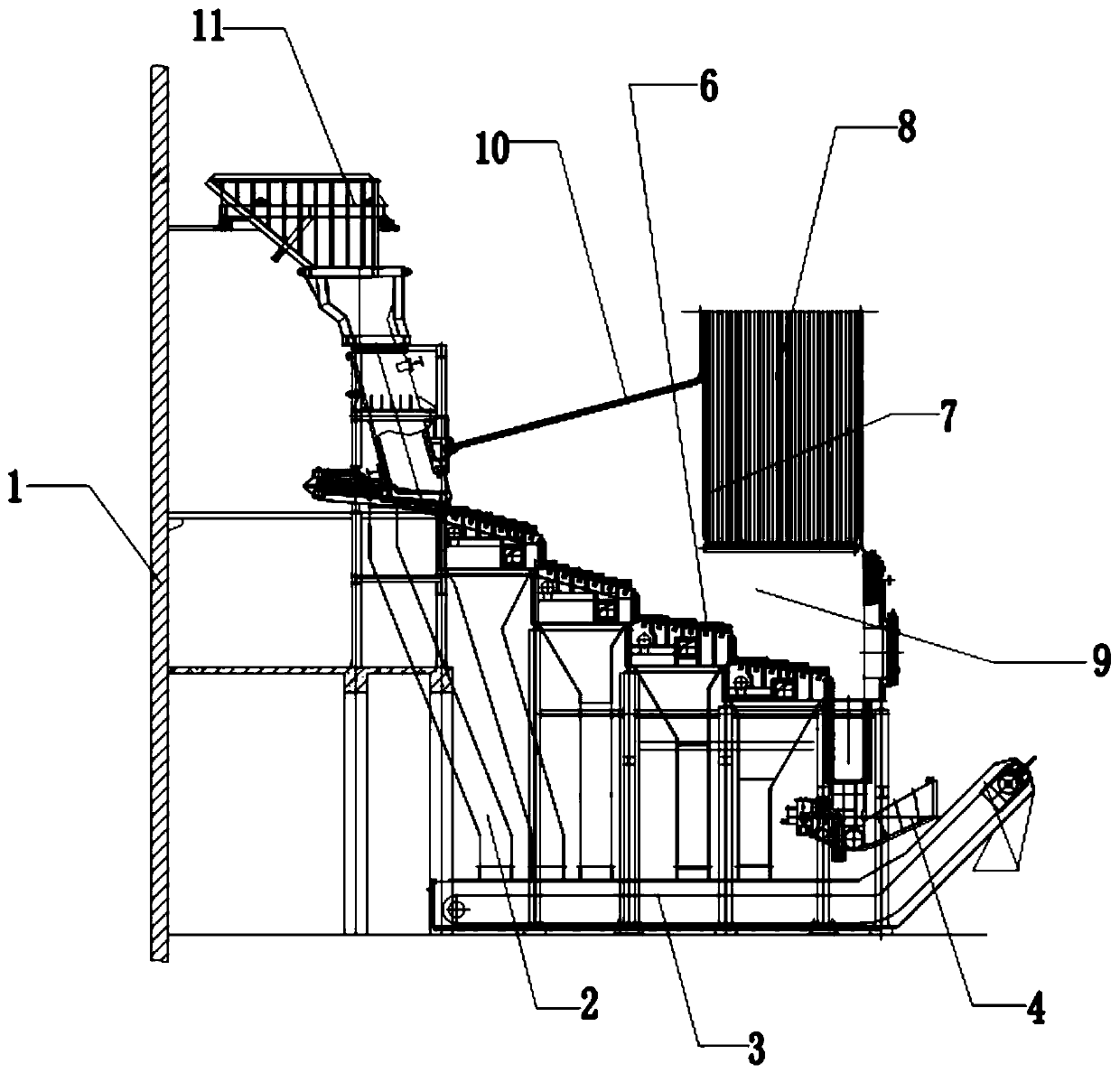

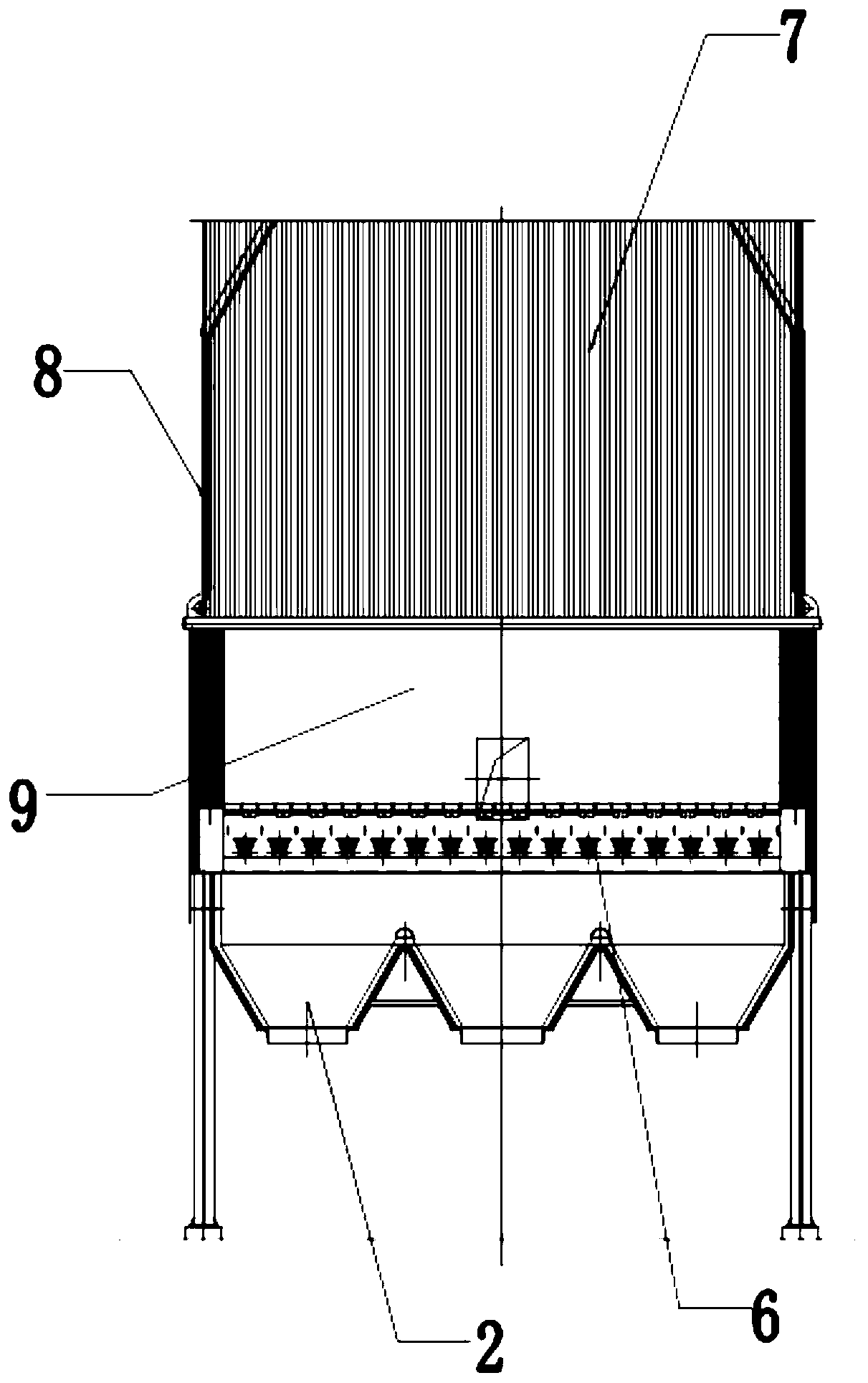

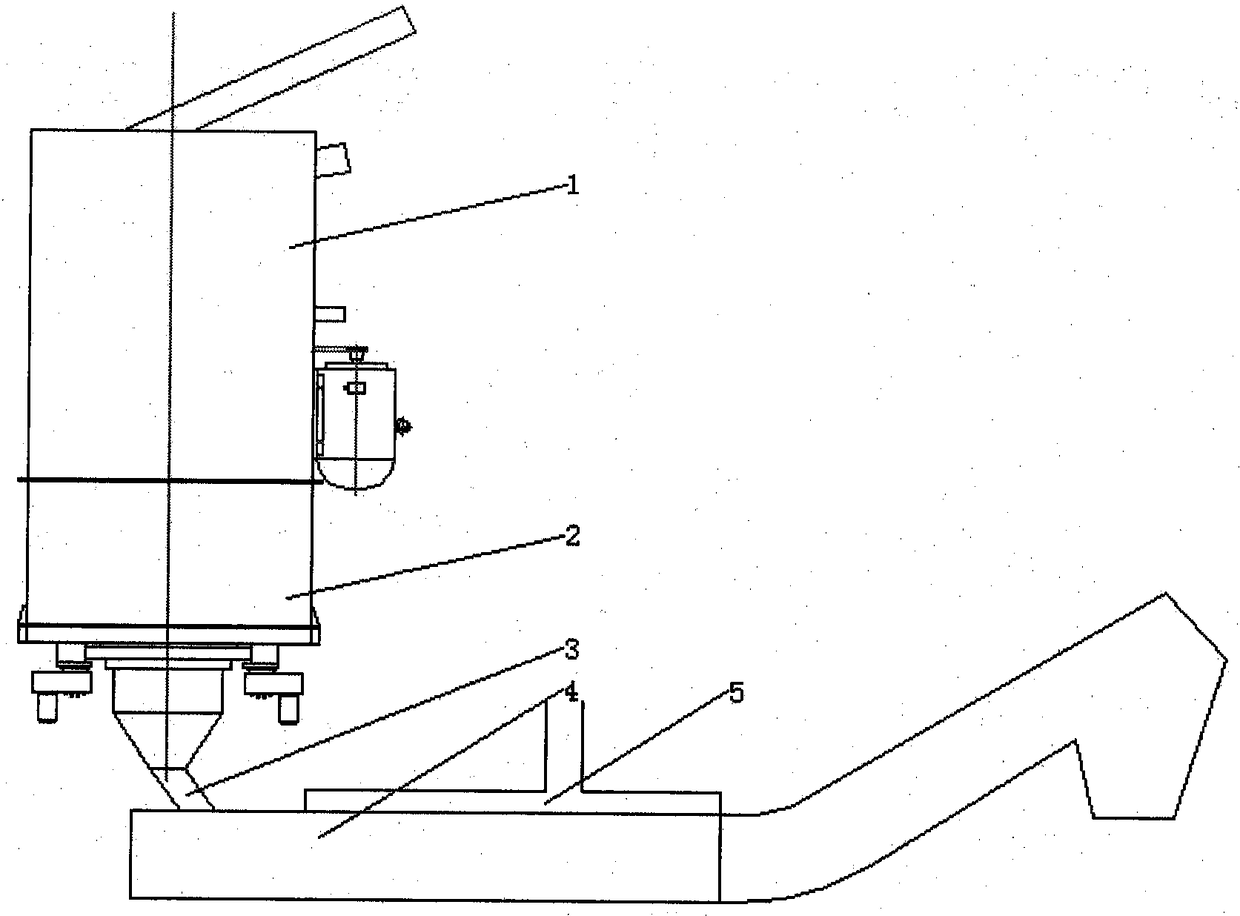

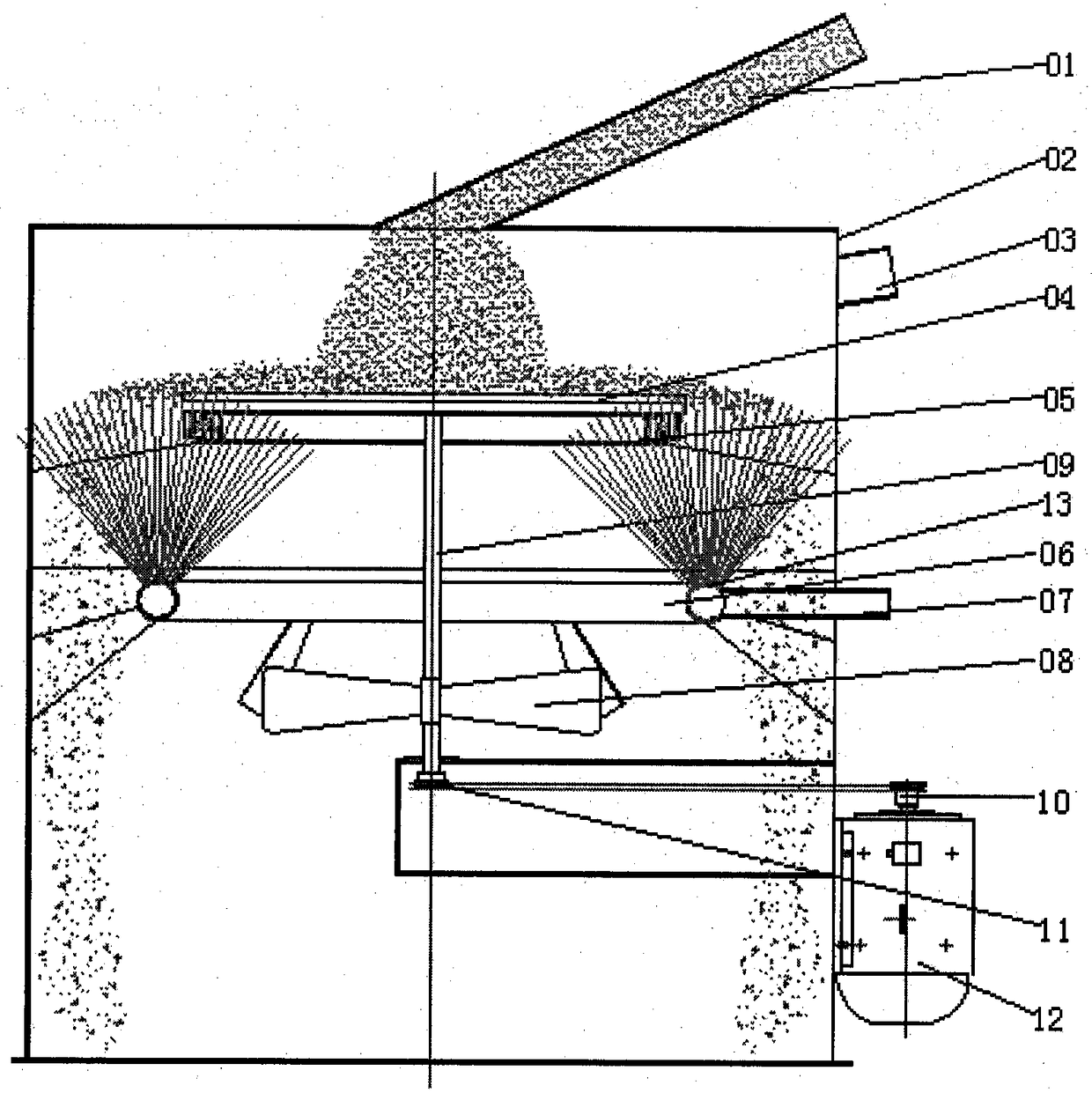

Slag/calcium carbide cooling and waste heat recycling system

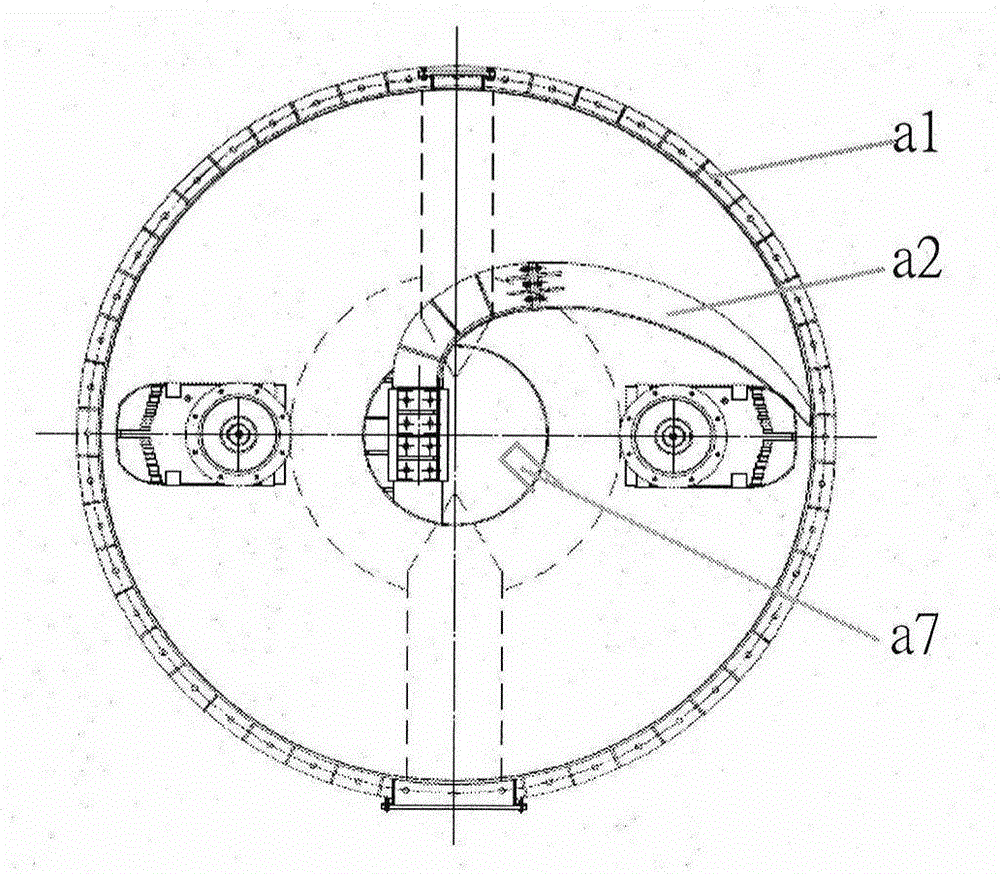

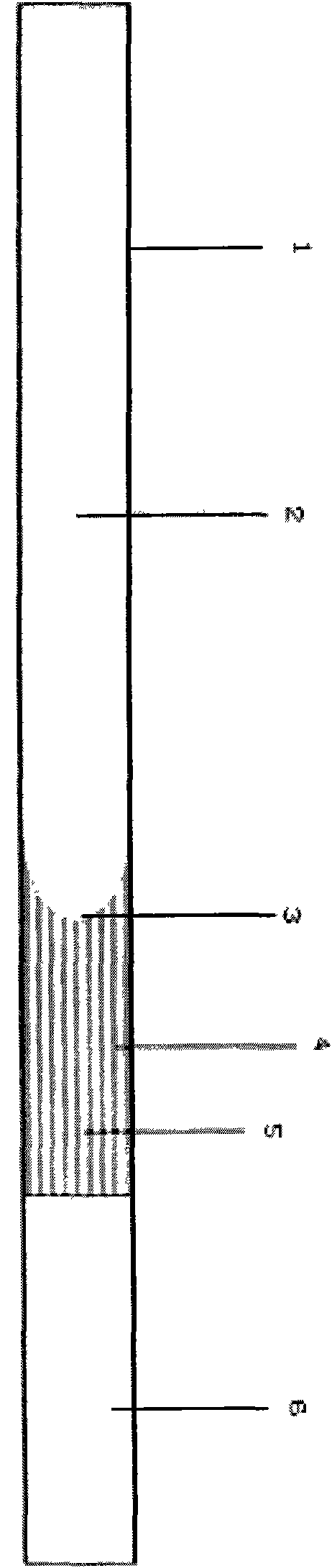

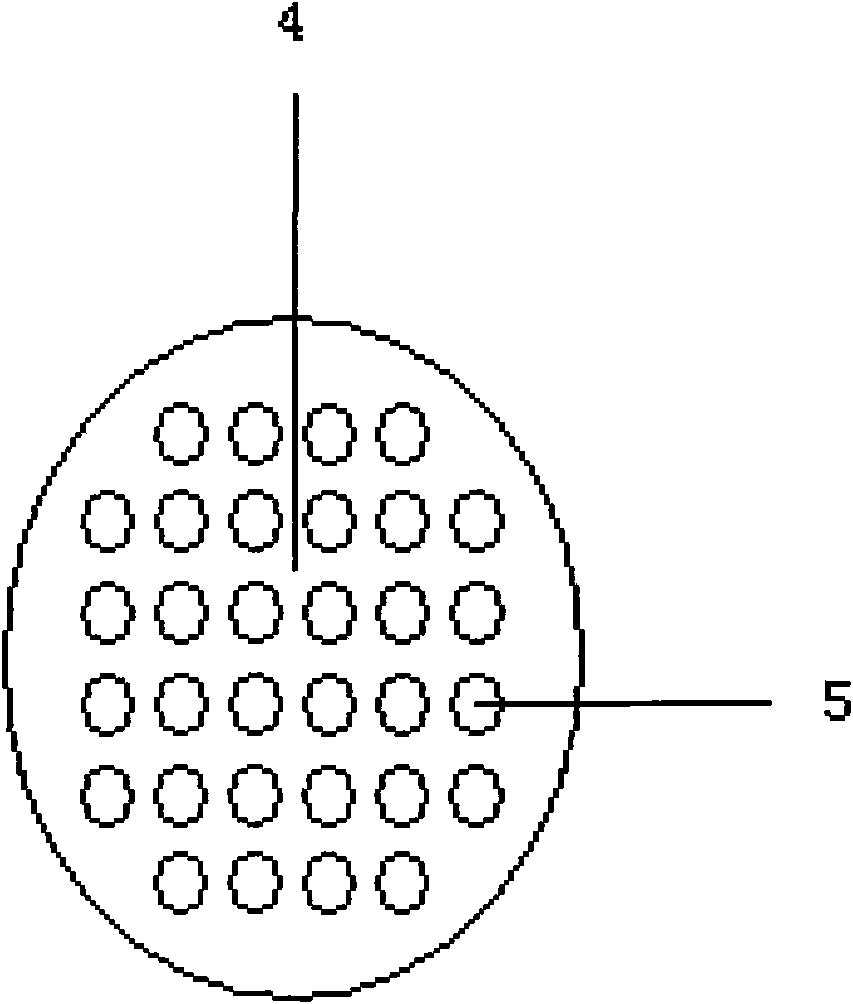

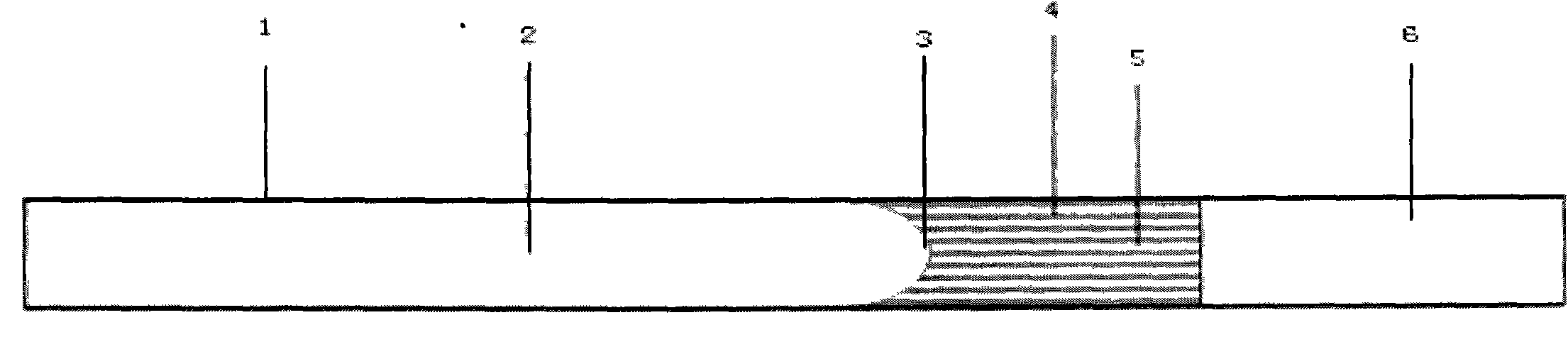

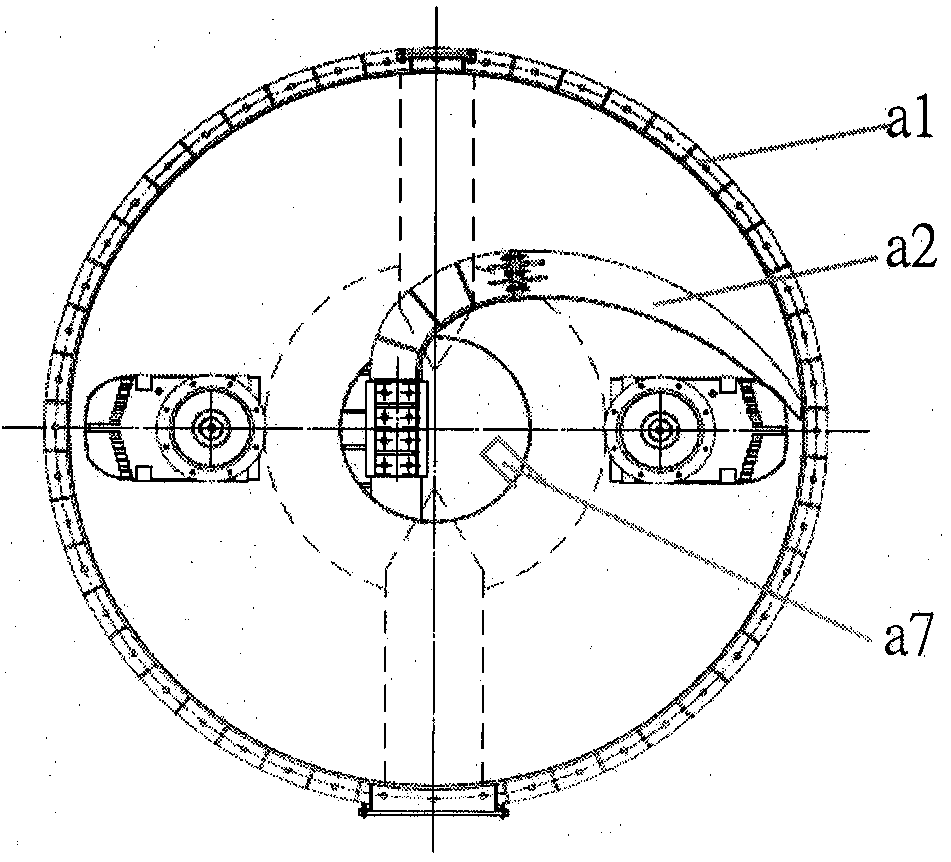

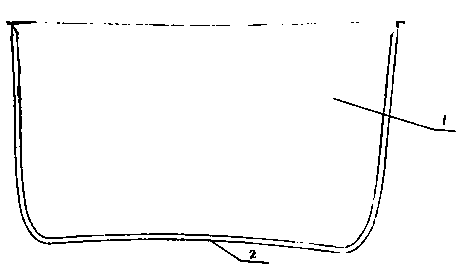

ActiveCN104789719AReduce processing costsSmall and uniformEnergy inputCalcium carbideSlagCalcium carbide

The invention relates to a slag / calcium carbide cooling and waste heat recycling system, which mainly comprises cooling and pelletizing equipment (1), discharging equipment (2) and secondary heat recycling and transporting equipment (4), wherein the cooling and pelletizing equipment (1) comprises a cooling kettle (02); a rotating plate (04) is arranged at the axis position in the cooling kettle (02); a transmission shaft (09) is arranged below the rotating plate (04); a cooling air hose (06) is arranged below the rotating plate (04); a wind wheel (08) is arranged on the transmission shaft (09) below the cooling air hose (06); and the cooling air pipe (06) is connected with an air inlet pipe (07).

Owner:QINGDAO DESHIPU ENG TECH CO LTD

Economical cigarette

The invention discloses a cigarette capable of saving tobacco shreds. The last section of tobacco shreds is replaced by a heat resisting cellular filter section in the cigarette, so that the consumption of the tobacco shreds in the cigarette production is reduced, under the condition of not influencing the actual cigarette combustion length during smoking, the using amount of tobacco shreds in each cigarette is saved, large cost is saved for cigarette enterprises all over the world, the tobacco shreds are combusted completely before the cigarette is discarded, the thread of a common cigarette end to fire safety is reduced, the effect of filtering harmful substances in the cigarette is improved and the adsorption of harmful substances by a smoker is reduced.

Owner:杨茂亮

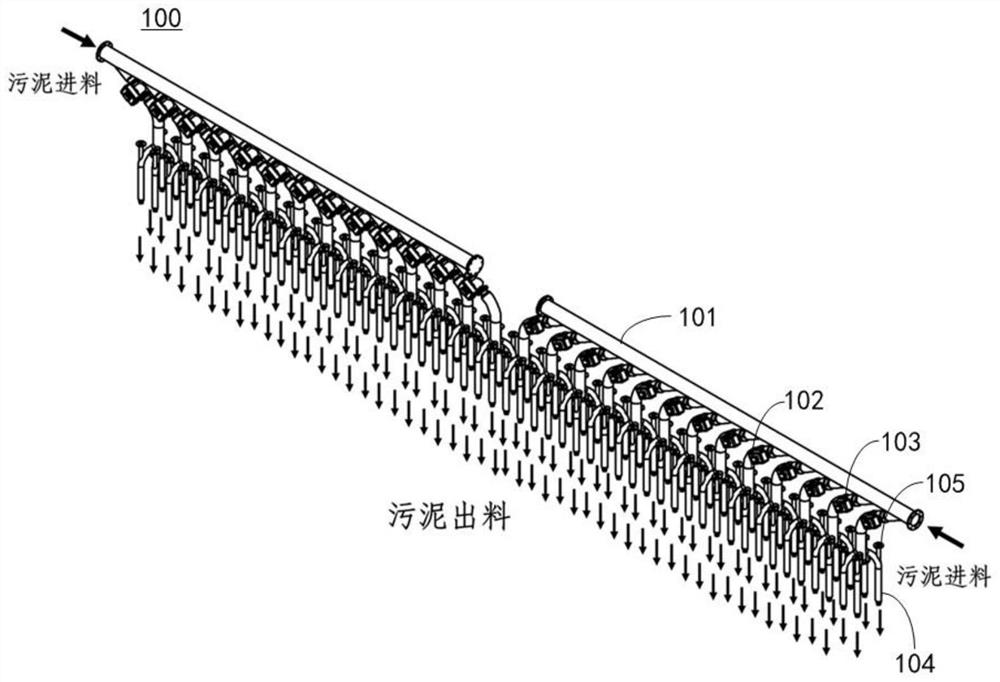

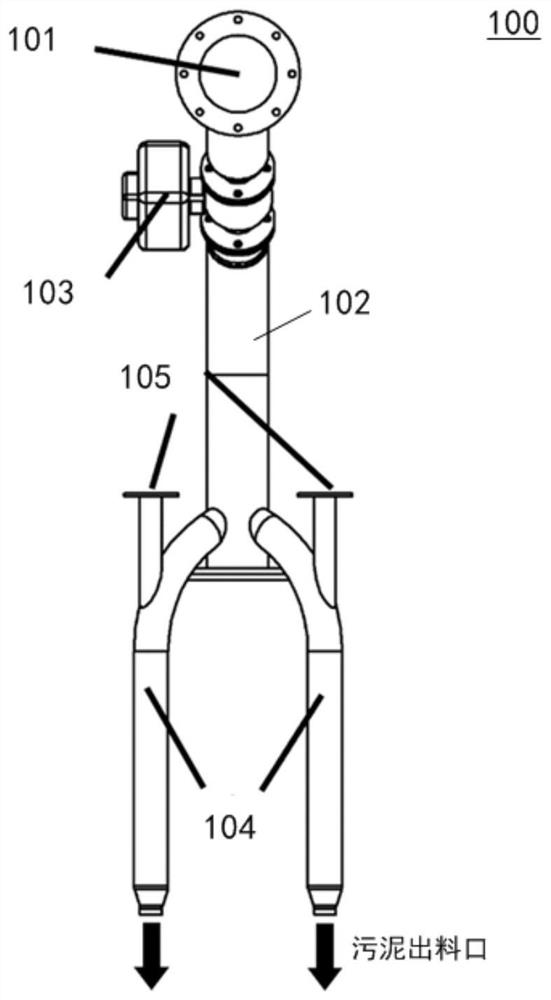

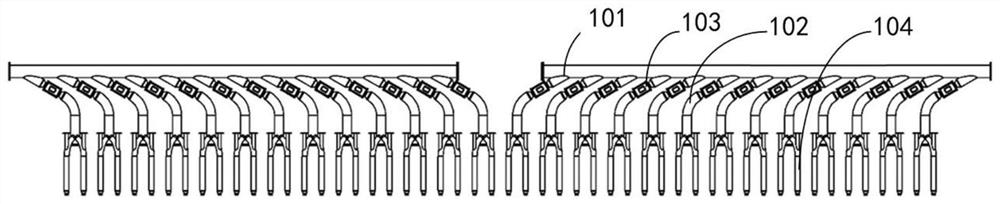

Branch pipe type sludge uniform distribution device and garbage incinerator

PendingCN111828990AScattered evenlyDoes not affect combustionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention provides a branch pipe type sludge uniform distribution device and a garbage incinerator. The device comprises a main pipeline, a plurality of first branch pipelines communicated to thebottom of the main pipeline, and at least two second branch pipelines communicated to the bottoms of the first branch pipelines, wherein a sludge feeding port is formed in the end part of the main pipeline; control valves are arranged on the first branch pipelines; and sludge discharging ports are formed in the bottom ends of the second branch pipelines. The branch pipe type sludge uniform distribution device adopts a branch pipe type design, sludge distribution can be accurately controlled, and sludge is facilitated to be uniformly dispersed in an incineration furnace, so that the sludge canbe fully dried and burned.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +1

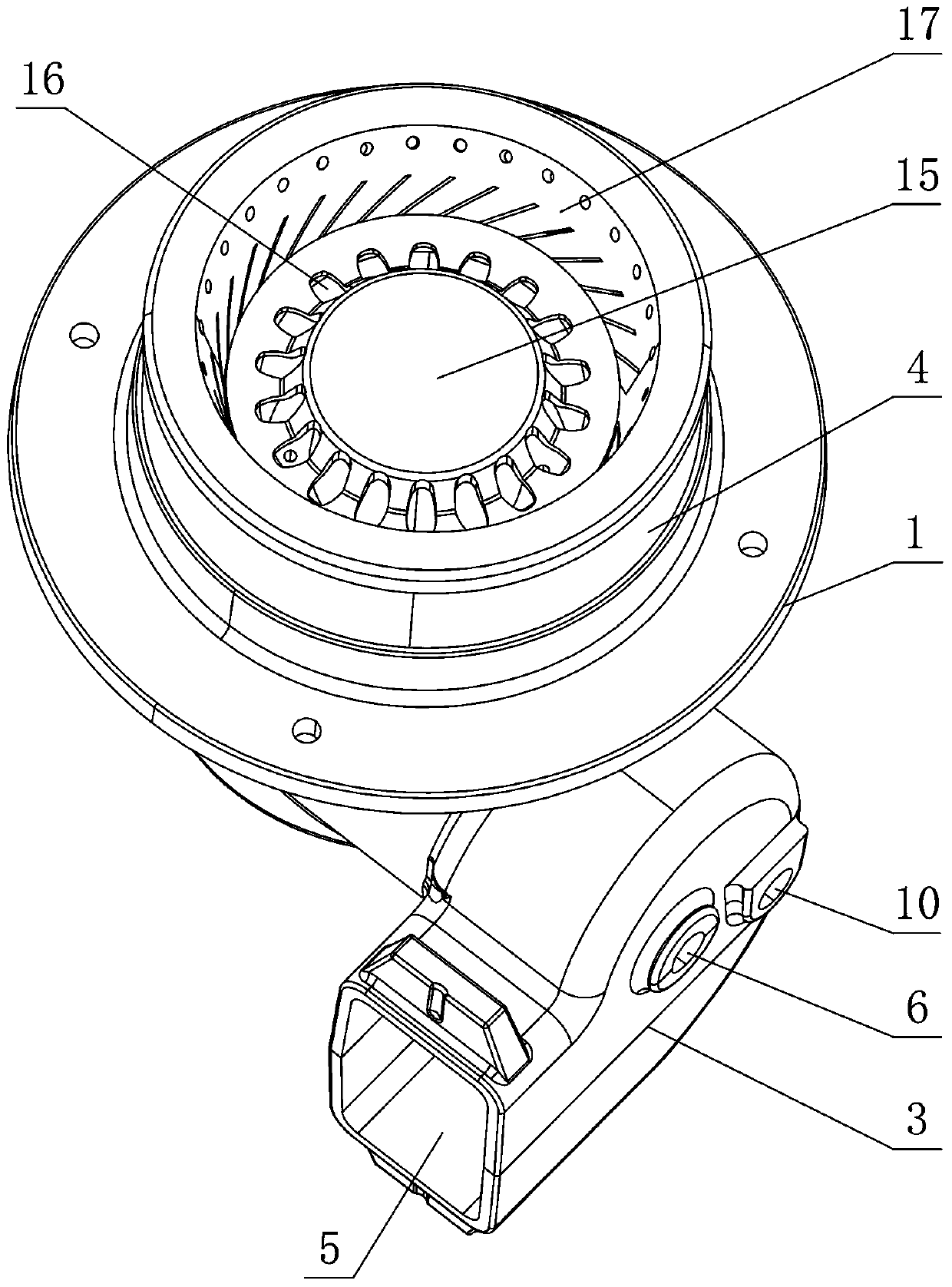

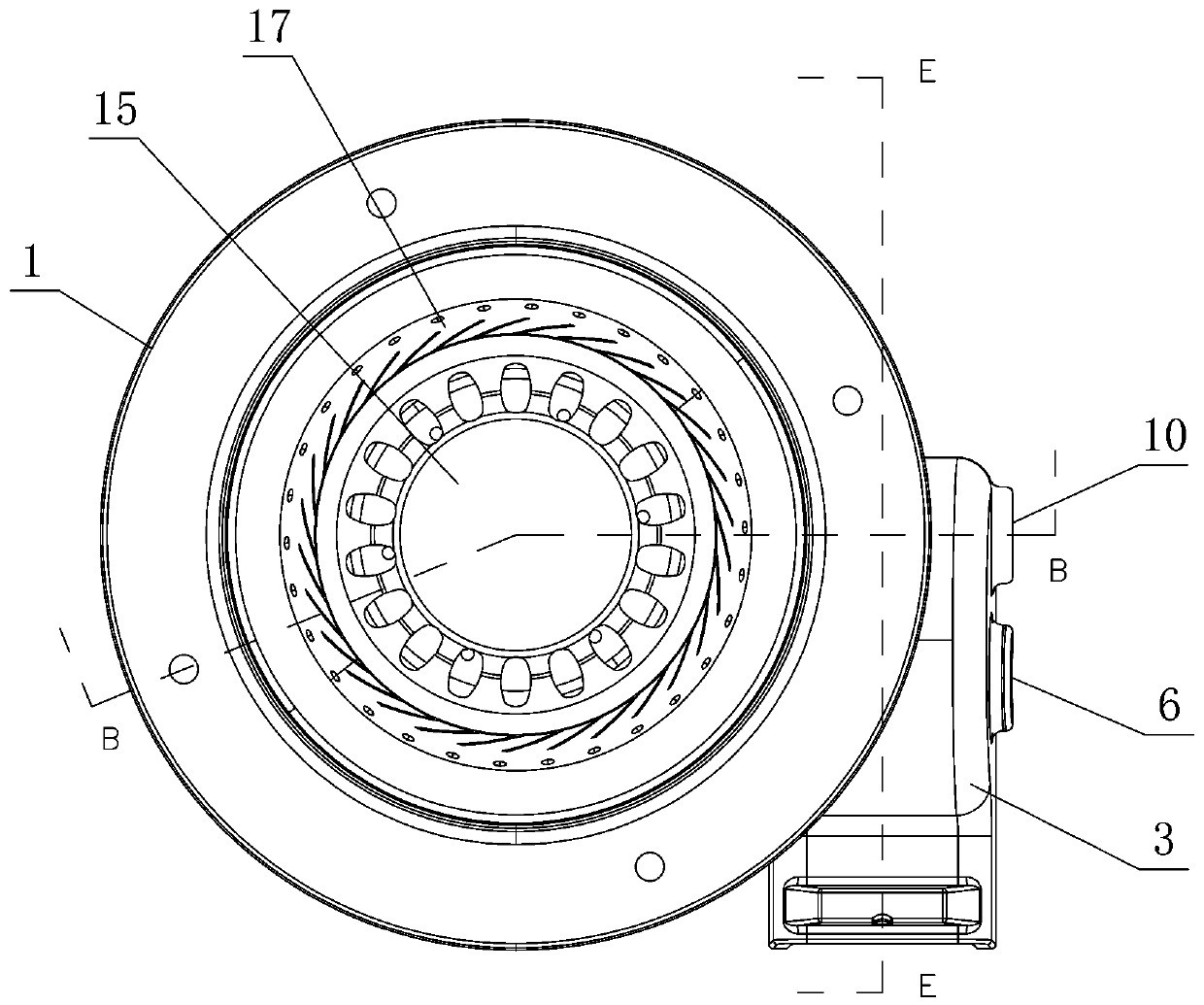

Turbine furnace shell

PendingCN111140889AExtended service lifeAvoid safety hazardsStoves/ranges foundationsDomestic stoves or rangesEngineeringEnvironmental geology

The invention belongs to the technical field of gas stove furnace shells, and particularly relates to a turbine furnace shell. The turbine furnace shell includes a furnace shell body, a turbine-shapedejector tube arranged on one side of the furnace shell body and a furnace core covered on the top of the furnace shell body. A high fire channel and a low fire channel are arranged in the furnace shell body. The high fire channel includes an air inlet, a high fire air inlet, a high fire flow channel and a plurality of high fire air outlets. The low fire channel includes a low fire air supply portfor supplying air to a low fire flow channel, a low fire air inlet, the low fire flow channel and a plurality of low fire air outlets. The low fire flow channel is arranged at the center of the furnace shell body, the high fire flow channel is arranged on the outer circle of the low fire flow channel in a surrounding mode, the top end of the low fire flow channel and the top end of the high fireflow channel are connected with the furnace core, the multiple high fire air outlets are evenly formed in the connection position of the furnace core and the high fire flow channel, and the multiple low fire air outlets are evenly formed in the connection position of the furnace core and the low fire flow channel. The low-fire combustion is more stable, the overall combustion fire force is stronger, and the service life is longer.

Owner:浙江博立灶具科技有限公司

Toxic flammable gas processing and reusing method for liquid produced from oil well and special device

ActiveCN111425181AReduce wasteAvoid pollutionDomestic cooling apparatusFluid removalToxic gasThermodynamics

The invention relates to the field of desulphuration technologies for hot liquid produced from thickened oil, in particular to a toxic flammable gas processing and reusing method for liquid produced from an oil well and a special device. Twice gas-liquid separation is performed on liquid from a single well, and toxic flammable gases including hydrogen sulfide, obtained by separation, enter a gas-fired boiler via a jet device to be burnt. A water-cooling method replaces the conventional air-cooling method, and the toxic gases including hydrogen sulfide, obtained after cooling, are gathered in the gas-fired boiler by the jet device to participate in combustion, such that energy waste is reduced and environmental pollution is prevented. In addition, hydrogen sulfide gas is gathered in gas ofthe gas-fired boiler by the jet device, and no hydrogen sulfide gas and alkaline liquor neutralization device needs to be added. Since less toxic flammable gas is produced after heat exchange, coolingand liquidation, building a special gas collection device is huge in investment but produces very little effect. By use of the special device, building a gas collection device is not required, desulphuration is achieved, and heat energy can be reused.

Owner:XINJIANG HUALONG OILFIELD TECHNOLOGICAL LIABILITY +1

Catalytic cracking oxygen-lean regeneration denitrification agent and preparation method thereof

ActiveCN112354358BDoes not affect combustionEasy to operatePhysical/chemical process catalystsDispersed particle separationRare-earth elementFlue gas

The invention relates to a catalytic cracking oxygen-lean regeneration denitration agent and a preparation method thereof, belonging to the field of catalytic cracking auxiliary agents. The catalytic cracking oxygen-lean regeneration denitrification agent of the present invention includes a carrier and an active component, and the carrier is active γ-Al 2 O 3 , the active components are noble metal compounds, metal compounds and rare earth element compounds; the catalytic cracking oxygen-lean regeneration denitrification agent includes the following raw materials by mass percentage: active γ-Al 2 O 3 70-90%, noble metal compound 1.5-5%, rare earth element compound 4-10%, metal compound 3-10%, phosphate 1.5-5%. The catalytic cracking oxygen-lean regeneration denitrification agent of the invention has high denitration rate; the use process is simple and easy to operate, does not produce secondary pollution, the flue gas can meet the emission standard, the economic benefit is high, and the CO component in the regenerator is not consumed at all, The safety is high; meanwhile, the present invention also provides a preparation method.

Owner:山东骏飞环保科技有限公司

Moxa-moxibustion stick for improving organism immunity and preparation method of moxa-moxibustion stick

InactiveCN106728575AImprove immunityWith health functionInorganic non-active ingredientsImmunological disordersMedicineRhizome

The invention discloses a moxa-moxibustion stick for improving organism immunity and a preparation method of the moxa-moxibustion stick. The moxa-moxibustion stick comprises, by weight, 90-100 parts of argy wormwood leaves, 40-50 parts of common cruculigo rhizome extracts, 15-19 parts of mongolian milkvetch root extracts, 0.3-0.4 part of eucommia bark extract and 0.2-0.3 part of modified konjaku powder. The prepared moxa-moxibustion stick has the health care function and is difficult to be fractured and extinguished, less in smoke amount and high in safety, and the burning process is more stable.

Owner:河南忠澜艾瓷文化开发有限公司

Waste incinerator and construction method thereof

ActiveCN109855102AContain the risk of collapseDoes not affect combustionLinings repairFurnace coolingCombustionEngineering

The invention relates to the technical field of waste incineration power generation, and discloses a waste incinerator. The waste incinerator comprises a drying area, a main combustion area and a burnout area, wherein the main combustion area comprises a hearth, the hearth comprises a rear wall and two side walls which are connected with one another; the rear wall and the two side walls are all heat insulation furnace walls, new water cooling walls covered with the heat insulation furnace walls are arranged on the inner side walls of the heat insulation furnace walls; and the invention furtherdiscloses a construction method of the waste incinerator. According to the waste incinerator and the construction method, the problems that the furnace wall near the main combustion area of an existing waste incinerator is easy to coke is effectively solved.

Owner:广州广重企业集团有限公司

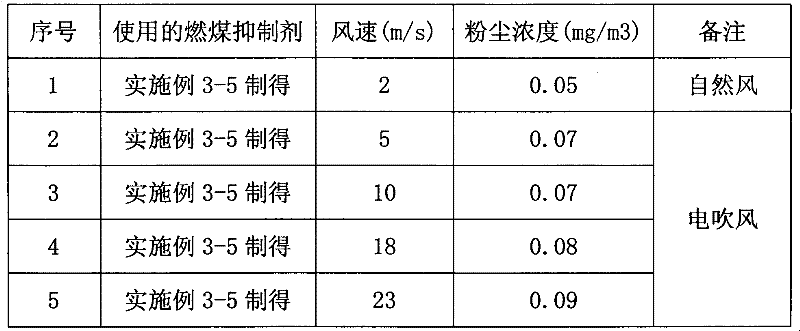

Fire coal dust suppressant and preparation method thereof

ActiveCN101899284BDo not change natureDoes not affect combustionOther chemical processesEpoxyDibutyl tin dilaurate

The invention discloses a fire coal dust suppressant and a preparation method thereof. The fire coal dust suppressant is prepared from isophorone diisocyanate or hexamethylene diisocyanate, polyether glycol of which the molecular weight is 1,000, polyether glycol of which the molecular weight is 2,000, diethylene glycol, epoxy resin E-51 or epoxy resin E-40 or epoxy resin E-20, 2,2-dimethylolpropionic acid, dibutyltin dilaurate T-12 or dibutyltin dilaurate T-9, triethylamine or quadrol and deionized water in a weight ratio through a reaction. The fire coal dust suppressant has the advantages of low production cost, environmental-friendly products, easy spraying, simple construction and good film-forming effect of fire coal surfaces.

Owner:广州普凯热伏微能源科技有限公司

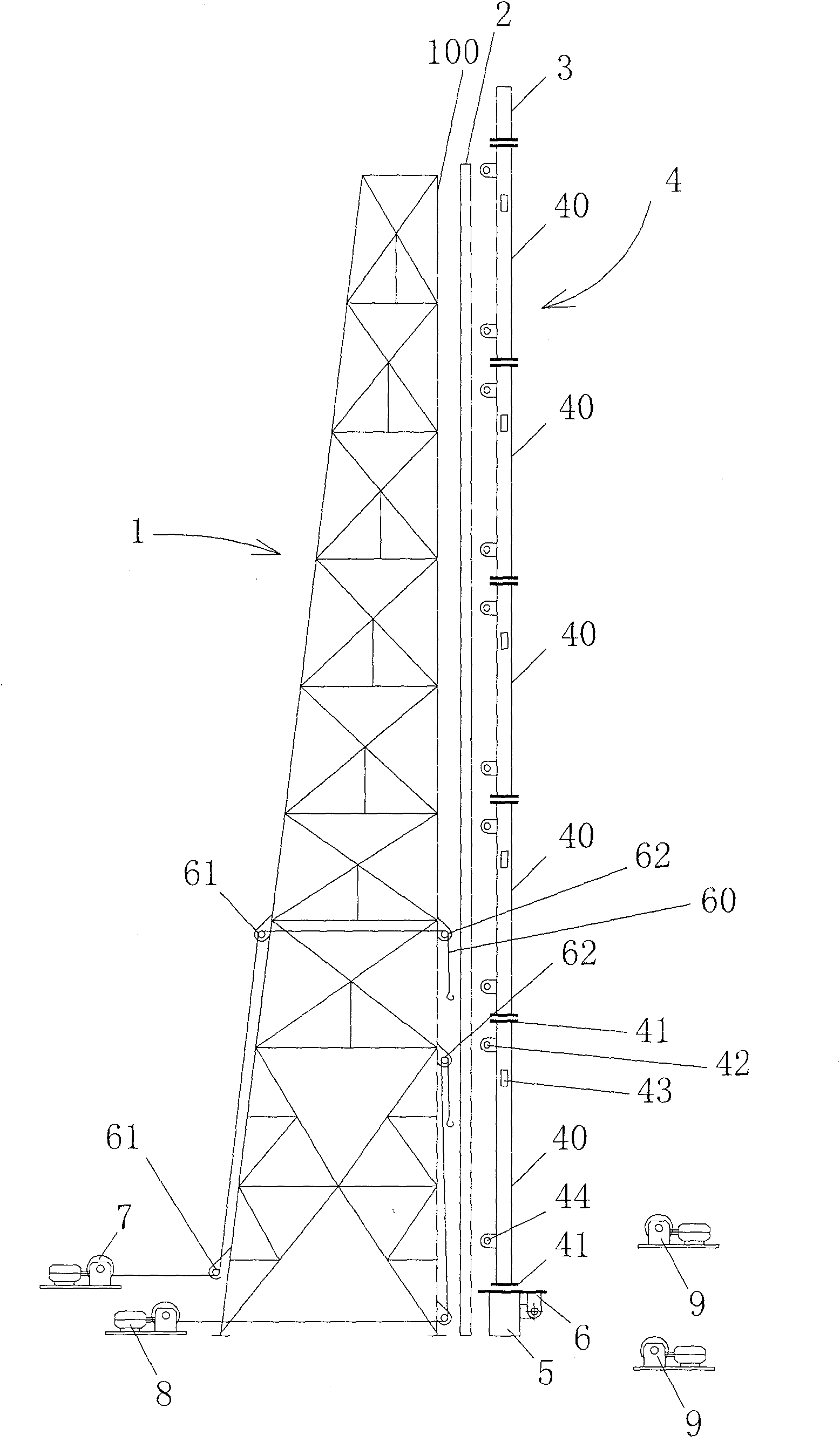

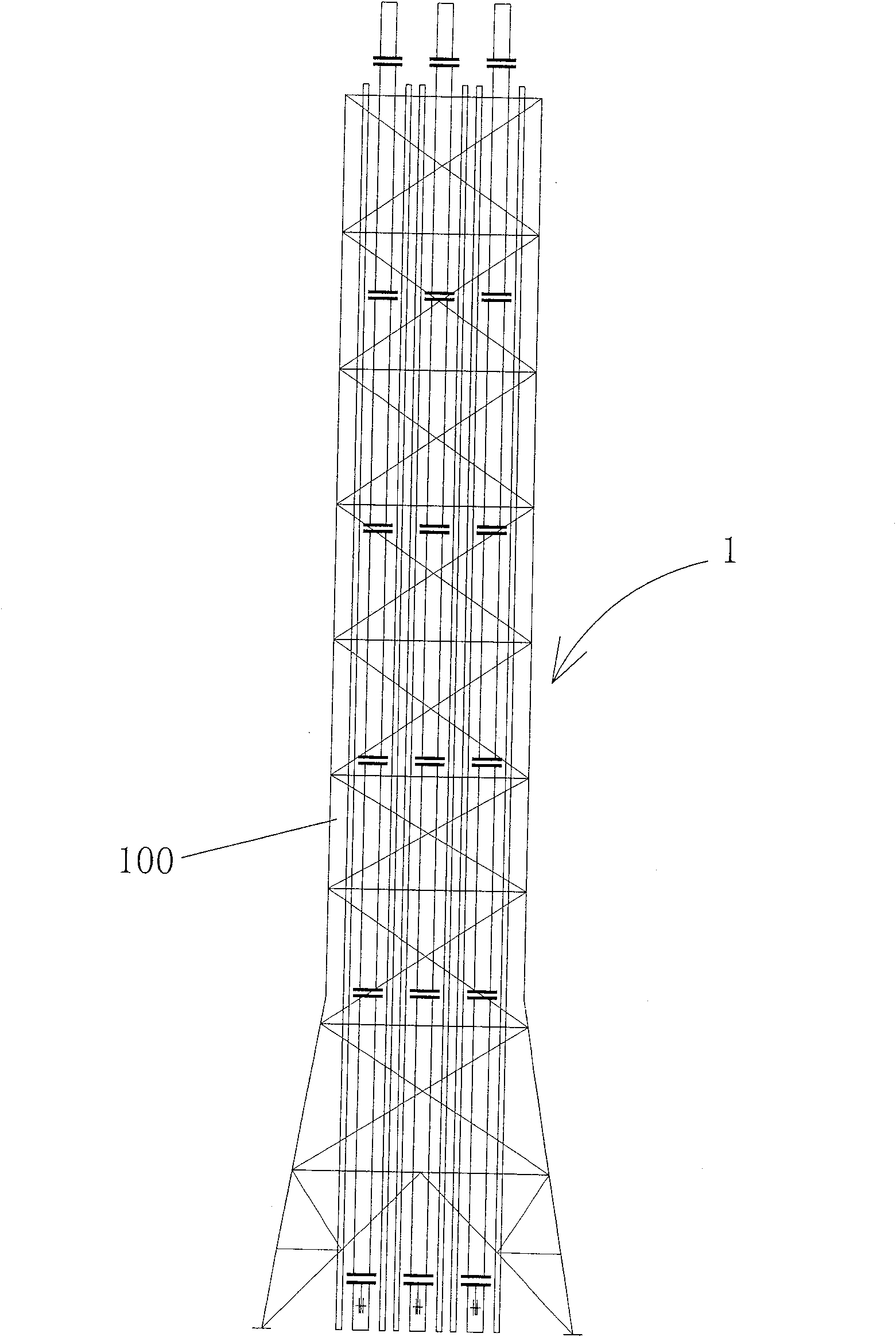

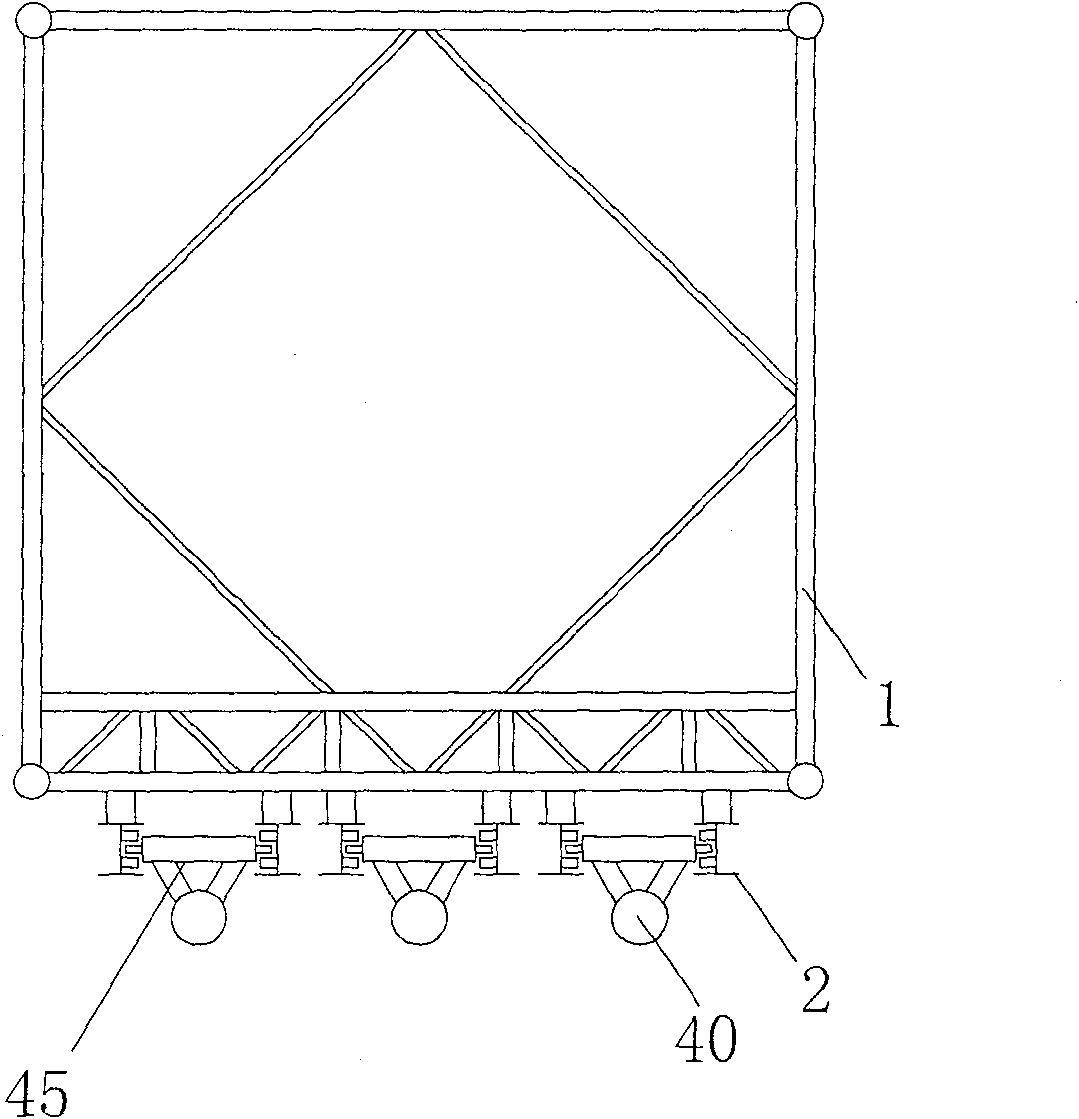

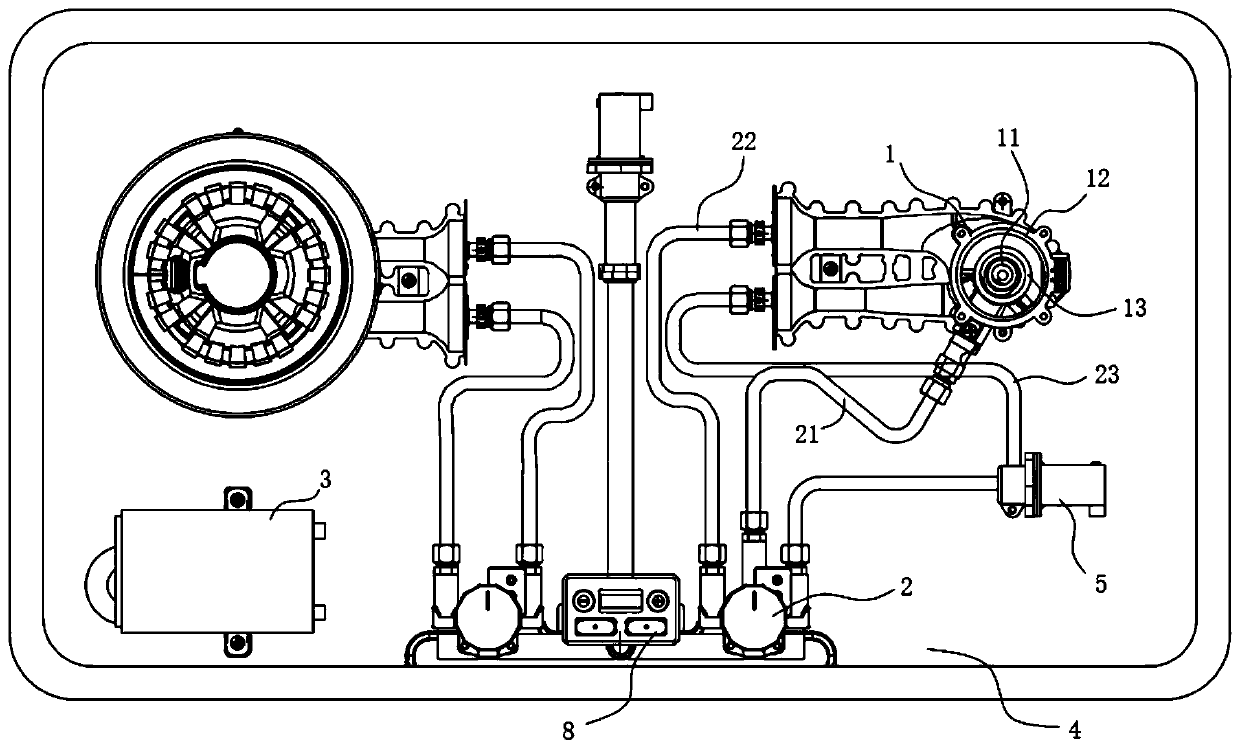

Loading and unloading system and its loading and unloading method for self unloading binding overhead torch

InactiveCN100552295CFully automatedDoes not affect combustionGaseous fuel burnerCombustionCylinder head

The invention provides a loading and unloading system for a self-unloading bundled elevated torch, the torch includes a torch head and a torch cylinder composed of multiple sections of cylinders, and each section of the cylinder is respectively provided with a first end connection between the cylinders at both ends. A connecting element, the bottom of the flare head is provided with the first connecting element; its loading and unloading system includes a hoist, a tower, a rope and the flare and guide rails arranged on the side of the tower, and each section of the barrel of the flare includes a The support element that the guide rail is slidably connected; The hoist wherein comprises the hoist hoist that is used to lift every section cylinder body, and each section cylinder body includes the second connection element that is used to be connected with hoist hoist by rope; The present invention also provides a A method for loading and unloading the elevated torch by using the loading and unloading system, that is, loading and unloading the torch barrel and the torch head of the elevated torch in sections, thereby realizing the centralized bundling of multiple torches, and meeting the maintenance work of the faulty torch without affecting other torches combustion.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Gas stove with stir-frying function

PendingCN110986114AFirepowerDoes not affect ejectionDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

The invention provides a gas stove with a stir-frying function. The gas stove comprises a combustor, a gas pipeline, a stir-frying controller and a gas stove body. The combustor, the gas pipeline andthe stir-frying controller are mounted in the gas stove body. The combustor comprises an inner fire ring, an outer fire ring and a stir-frying fire ring, wherein the stir-frying fire ring is located between the inner fire ring and the outer fire ring. The gas pipeline comprises an inner ring gas path, an outer ring gas path and a stir-frying gas path. The inner fire ring, the outer fire ring and the stir-frying fire ring are communicated with the inner ring gas path, the outer ring gas path and the stir-frying gas path respectively. The stir-frying controller controls the opening and closing of the stir-frying gas path, so that the stir-frying fire ring can generate fire or can be extinguished. The stir-frying gas path of the gas stove of the invention can increase the firepower of the gasstove and instantaneously provide strong fire required by stir-frying; the stir-frying gas path does not influence the injection and combustion of the inner ring gas path and the outer ring gas path;and the problems of insufficient combustion and the like caused by instantaneous strong fire can be solved without facilities such as an air blower and the like.

Owner:VATTI CORP LTD

Steel slag/calcium carbide cooling and waste heat recovery system

ActiveCN104789719BReduce processing costsSmall and uniformEnergy inputCalcium carbideSlagMaterials science

The invention relates to a slag / calcium carbide cooling and waste heat recycling system, which mainly comprises cooling and pelletizing equipment (1), discharging equipment (2) and secondary heat recycling and transporting equipment (4), wherein the cooling and pelletizing equipment (1) comprises a cooling kettle (02); a rotating plate (04) is arranged at the axis position in the cooling kettle (02); a transmission shaft (09) is arranged below the rotating plate (04); a cooling air hose (06) is arranged below the rotating plate (04); a wind wheel (08) is arranged on the transmission shaft (09) below the cooling air hose (06); and the cooling air pipe (06) is connected with an air inlet pipe (07).

Owner:QINGDAO DESHIPU ENG TECH CO LTD

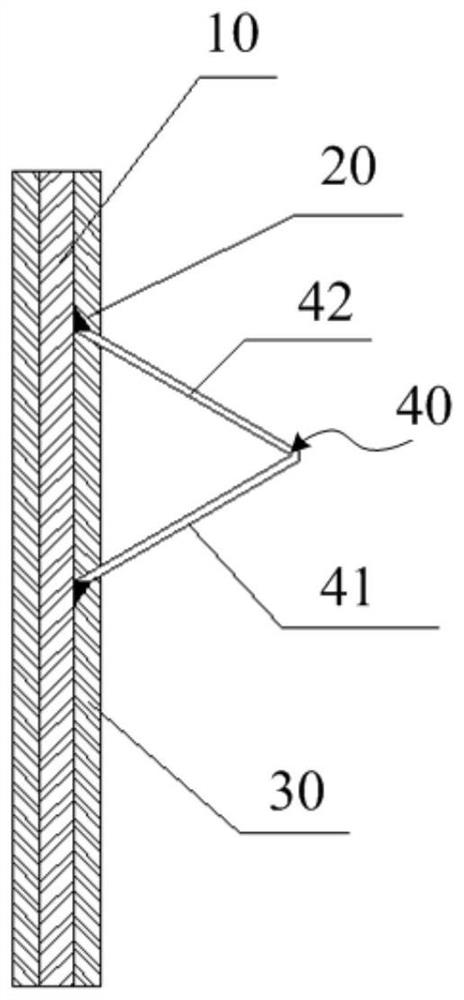

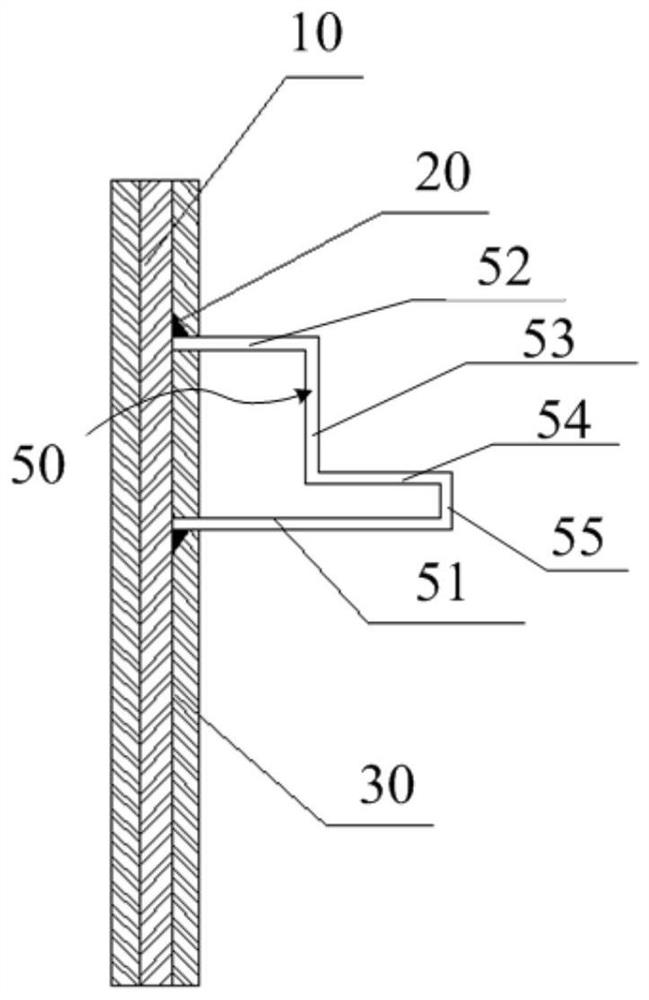

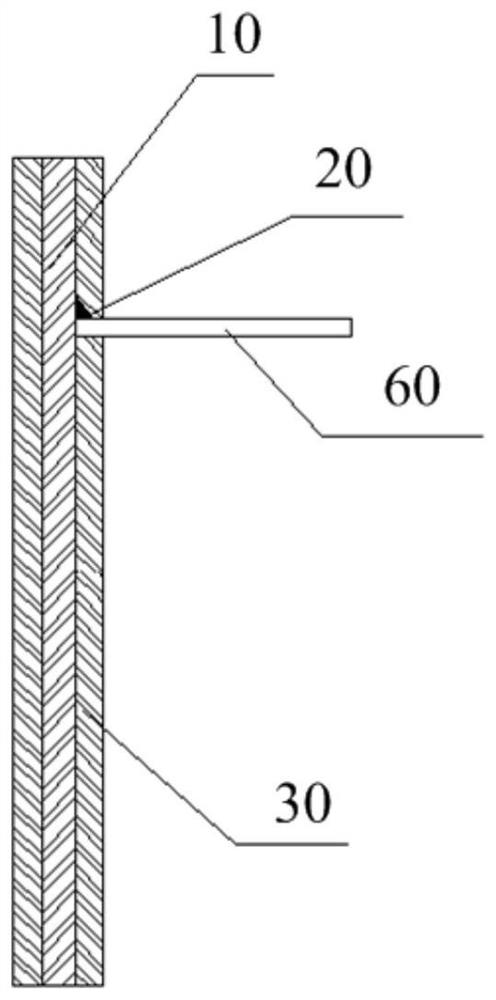

Wear prevention device for wear prevention of circulating fluidized bed water cooling wall and installation method of wear prevention device

PendingCN112361330AMinor changesImprove thermal conductivityFluidized bed combustionCasings/liningsFluidized bedMetallic materials

The invention belongs to the technical field of water cooling walls of fluidized bed boilers, and provides a wear prevention device for wear prevention of a circulating fluidized bed water cooling wall and an installation method of the wear prevention device to solve the technical problems of a poor wear prevention effect and high cost of existing wear prevention treatment of the circulating fluidized bed water cooling wall. The wear prevention device comprises a plurality of wear prevention blocks connected with circulating fluidized bed water wall cooling wall tubes separately, wherein eachwear prevention block is made of stainless steel plates, semicircular open-loop grooves opposite to the corresponding circulating fluidized bed water cooling wall tube are separately formed in each wear prevention block; a preset thermal expansion gap is formed between the outer wall, facing one water cooling wall tube, of each semicircular open-loop groove and the circulating fluidized bed watercooling wall tube, and protrusions at two sides of each semicircular open-loop groove and corresponding fins are welded together. The wear prevention blocks are made of metal materials, so that the installation process is simple and convenient, and the wear prevention device has good thermal conductivity, wear resistance and high temperature resistance.

Owner:山西昱光发电有限责任公司 +1

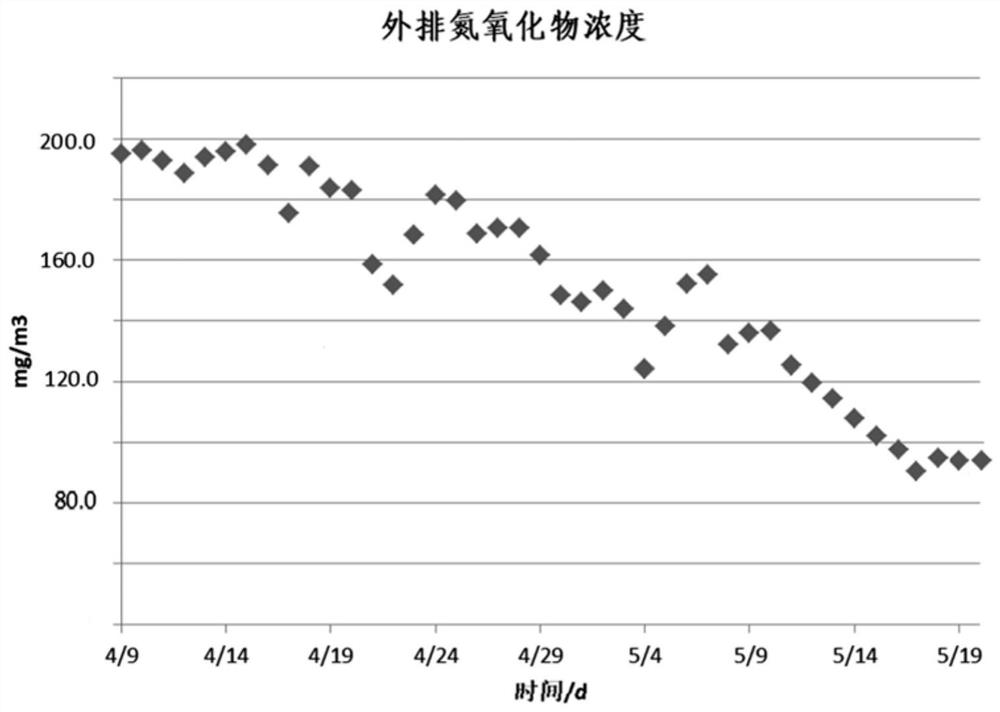

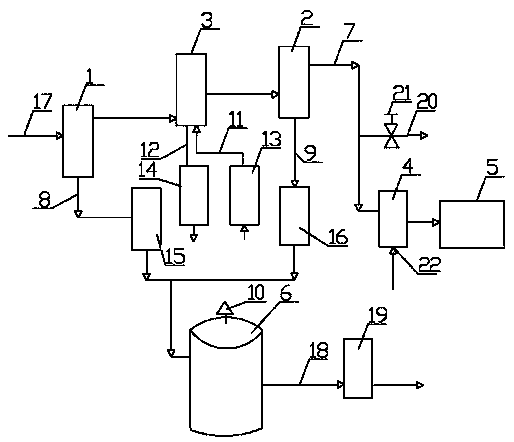

Method for recycling treatment and denitration of municipal domestic garbage with dry rotary kiln

ActiveCN103042024BDoes not affect production capacitySimple processSolid waste disposalCombustionEnvironmental engineering

A method for recycling treatment and denitration of municipal domestic garbage with a dry rotary kiln comprises the following steps of pretreating and dividing the municipal domestic garbage into a combustible component material mainly comprising organic matters, and a residue component material mainly comprising inorganic matters, taking the combustible component material as fuel for a decomposing furnace of the dry rotary kiln to substitute fire coal and a hydrocarbon raw material for denitration, feeding the combustible component material to a space from the lower part to the middle upper part in the decomposing furnace with a feed device for treatment and denitration, and taking the residue component material subjected to chemical analysis as an alternative raw material for a batching flour mill of a raw material vertical mill system, wherein the combustible component material is in a bulk form, and is less than or equal to 200mm in side length and less than or equal to 30% in water content. With the adoption of the method for treating the municipal domestic garbage, the operation is simple, the coal consumption is low, the kiln performance stability is good, the combustion of pulverized coal in a production kiln and the furnace of the dry rotary kiln is unaffected, the treatment cost is low, and the pollution to the environmental is low.

Owner:长沙紫宸科技开发有限公司

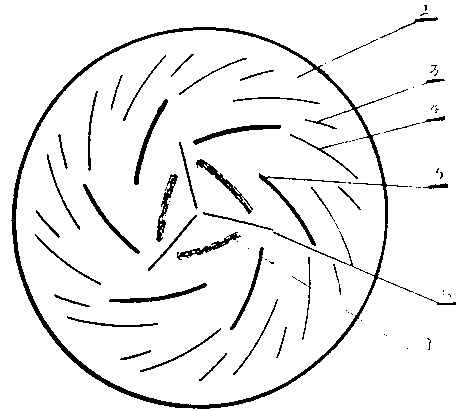

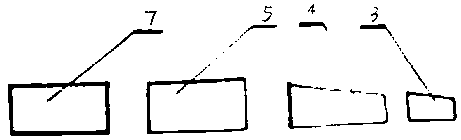

Energy-saving pot

InactiveCN110200470ADoes not affect combustionDoes not affect emissionsCooking vessel constructionsImpellerEngineering

The invention provides an energy-saving pot. The design of the energy-saving pot is that a concave pot bottom is arranged, a plurality of heat collecting sheets are arranged in different levels evenlyand symmetrically on the concave pot bottom and in a plurality of concentric circles with the center of the concave pot bottom as the center, the heat collecting sheets on the inner layer is in a radial shape, the heat collecting sheets on the middle layer and the outer layer are generally in an impeller shape, the heat collecting sheets are not connected one another, and the radiation heating surface and the heat absorbing area of the pot bottom are expanded. The design is novel and reasonable, the structure is simple, manufacturing is convenient, and energy saving is achieved.

Owner:刘从荡

A garbage incinerator and its construction method

ActiveCN109855102BContain the risk of collapseDoes not affect combustionLinings repairFurnace coolingThermodynamicsCombustion

The invention relates to the technical field of waste incineration power generation, and discloses a waste incinerator. The waste incinerator comprises a drying area, a main combustion area and a burnout area, wherein the main combustion area comprises a hearth, the hearth comprises a rear wall and two side walls which are connected with one another; the rear wall and the two side walls are all heat insulation furnace walls, new water cooling walls covered with the heat insulation furnace walls are arranged on the inner side walls of the heat insulation furnace walls; and the invention furtherdiscloses a construction method of the waste incinerator. According to the waste incinerator and the construction method, the problems that the furnace wall near the main combustion area of an existing waste incinerator is easy to coke is effectively solved.

Owner:广州广重企业集团有限公司

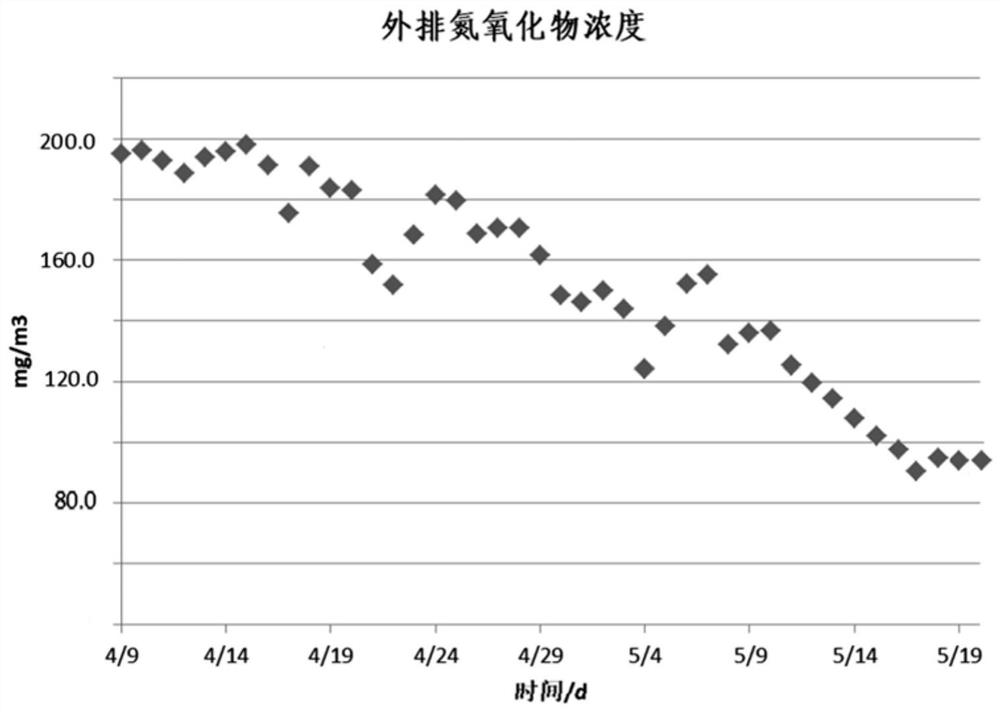

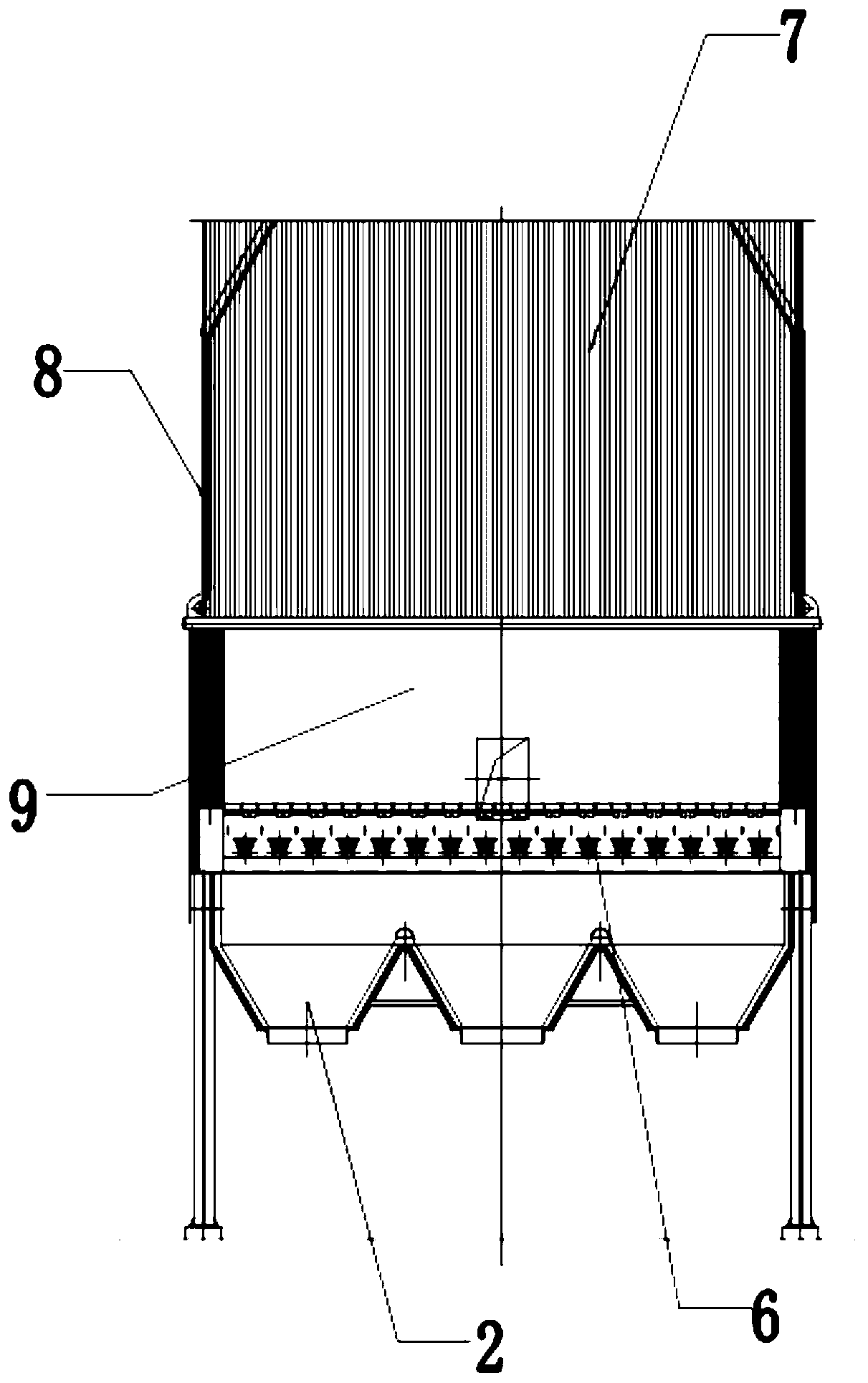

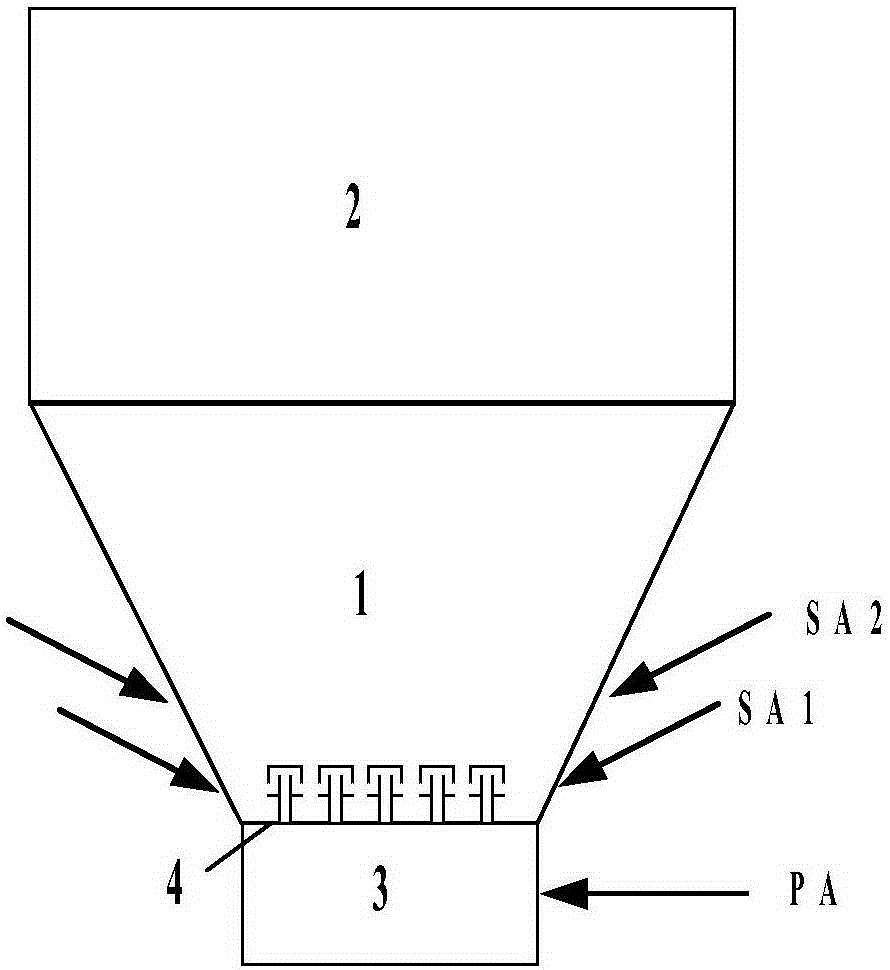

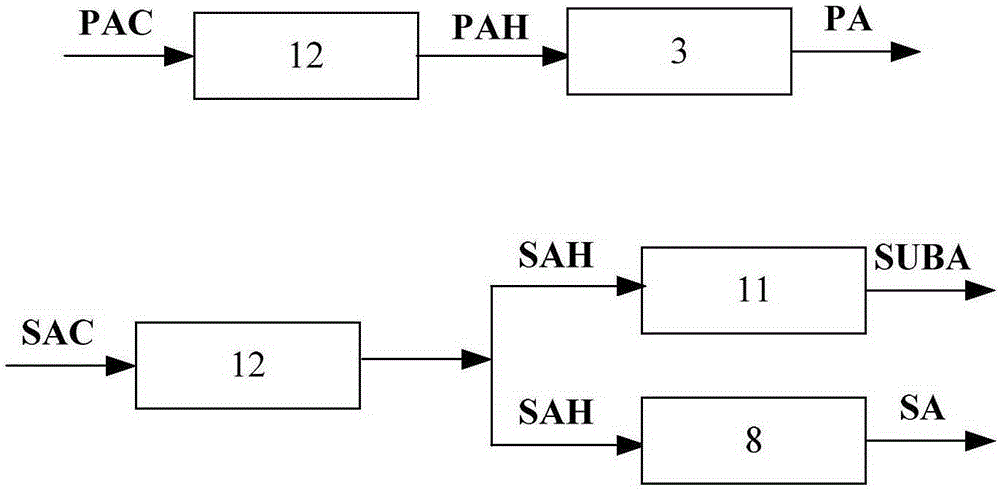

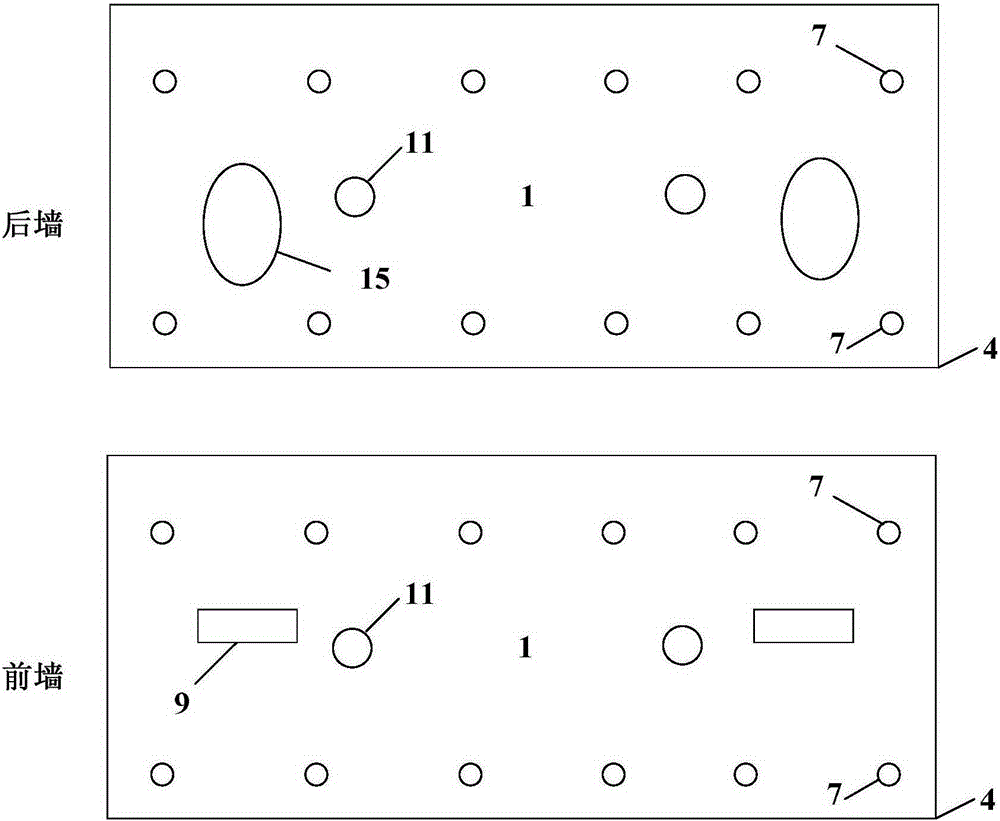

A low-nitrogen combustion modification method for a circulating fluidized bed boiler

ActiveCN103912867BReduce emission concentrationGood environmental benefitsFluidized bed combustionApparatus for fluidised bed combustionEnvironmental resistanceWear resistant

The invention discloses a low-nitrogen combustion transformation method for a circulating fluidized bed boiler. The method comprises the following steps: simultaneously transforming a low-share primary air system (PAS), an accurate secondary air feeding system (SAS) and an over-bed combustor supplemented air system (SUBS); arranging a bell jar type air cap on an air distribution plate, and building a fire-resistant and wear-resistant material lug boss at the outermost circle of the air distribution plate; independently feeding secondary air (SA) according to a region, regulating the amount of the SA through a regional SA total flow control device and an independent SA accurate flow control device respectively, and arranging three or four layers of SA ports along the height direction of a dense-phase region of a hearth, wherein an air source is primary cold air (PAC), and the amount of over-bed combustor air (SUBA) accounts for 5-10 percent of the amount of total combustion air (TA). After transformation, the proportion of primary air to secondary air can be flexibly regulated, combustion air feeding can be accurately controlled, and low nitrogen oxide emission level and high combustion efficiency are realized finally. The boiler can operate, and the characteristic of environmental protection can be remarkably improved without additional equipment. The method has the advantages of low investment cost, short transformation period, no operation cost, stability in operation of the boiler and the like.

Owner:HUANENG CLEAN ENERGY RES INST

Method for decreasing tar content in cigarette

InactiveCN1255060CDoes not affect combustionReduce tar contentTobacco treatmentTobacco smoke filtersChemical compositionBurn cigarette

The invention relates to a method for reducing tar content in cigarettes (tar reduction and harm reduction). The invention mainly solves the problem that it is difficult to further reduce the tar content of existing cigarettes. The present invention uniformly mixes specially processed diatomite in shredded tobacco of cigarettes. It does not increase smoke resistance and is easy to add. Since the main chemical component of diatomite is silicon dioxide, it has high adsorption. When smoking, diatomaceous earth will absorb a large amount of cigarette tar, which can reduce the tar content by 10-60% or higher. The production process is simple; the cost is low; and it can be suitable for different cigarette making equipment. It will not affect the burning of cigarettes, will not produce other harmful substances to health, and will not produce peculiar smell.

Owner:习杰峰

Method for restraining coal pile spontaneous ignition, special inhibitor of method and preparation method of inhibitor

Owner:广州普凯热伏微能源科技有限公司

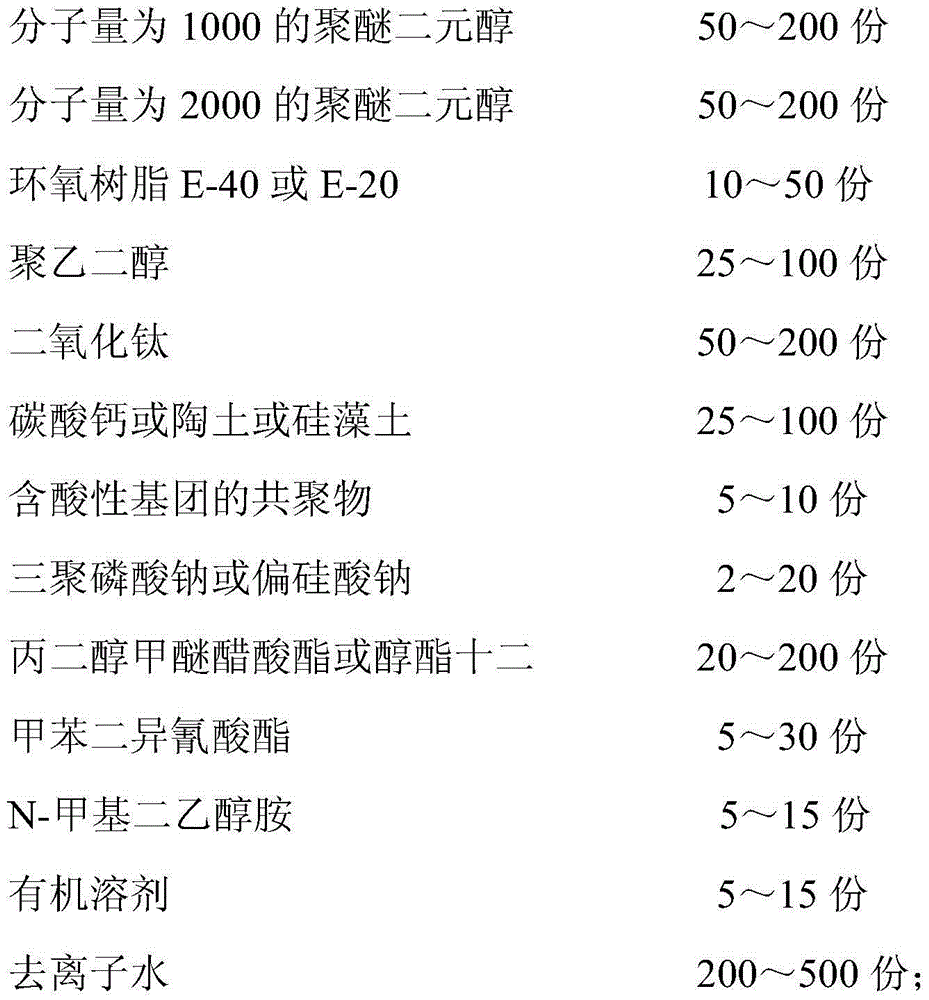

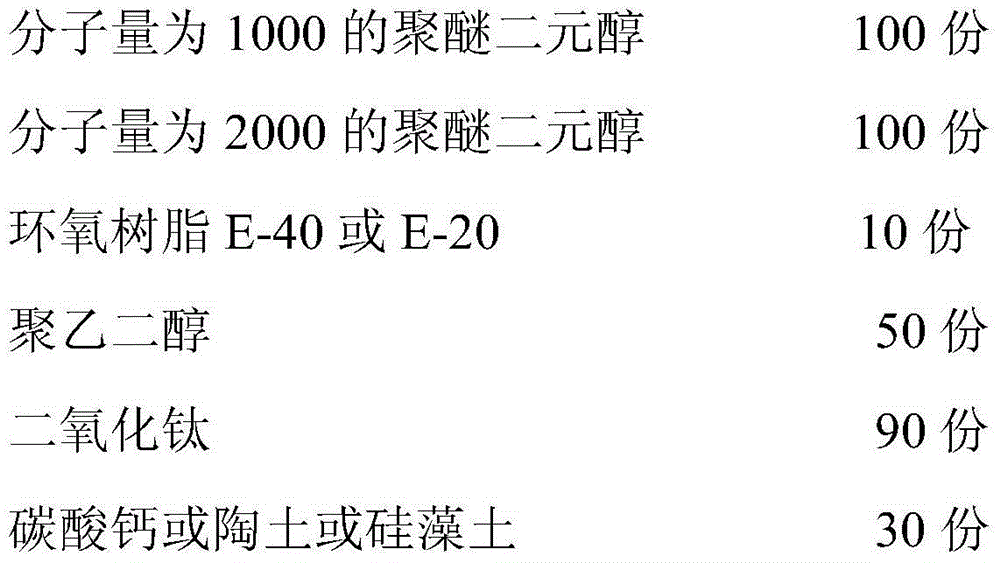

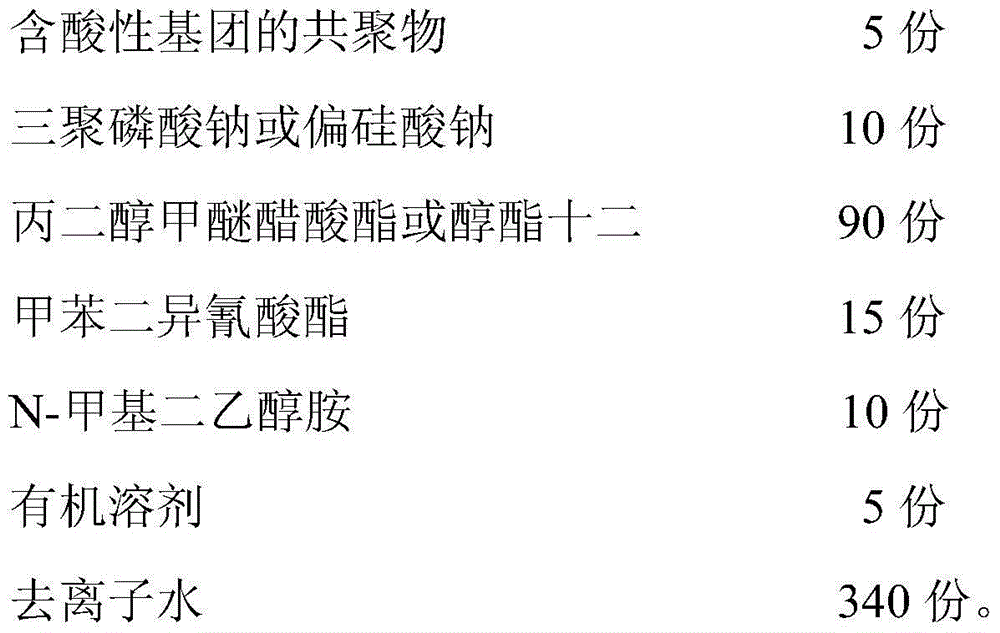

White dust suppressant and preparation method and application thereof

ActiveCN103834364BDoes not affect combustionEasy to stack managementOther chemical processesEpoxySodium metasilicate

The invention belongs to the technical field of prevention and controlling of unorganized emission of dust in storing and transporting processes of coal, and discloses a white dust suppressant and a preparation method and application thereof. The white dust suppressant is prepared by the following raw materials in parts by weight: 50-200 parts of polyether diol with molecular weight of 1000, 50-200 parts of polyether diol with molecular weight of 2000, 10-50 parts of epoxy resin E-40 or E-20, 25-100 parts of polyethylene glycol, 50-200 parts of titanium oxide, 25-100 parts of calcium carbonate or argil or diatomite, 5-10 parts of copolymer containing acid group, 2-20 parts of sodium tripolyphosphate or sodium metasilicate, 20-200 parts of propylene glycol methyl ether acetate or 2,2,4-trimethyl-1,3-amyl glycol monoisobutyrate, 5-30 parts of toluene diisocynate, 5-15 parts of N-methyldiethanolamine, 5-15 parts of organic solvent, and 200-500 parts of deionized water.

Owner:广州普凯热伏微能源科技有限公司

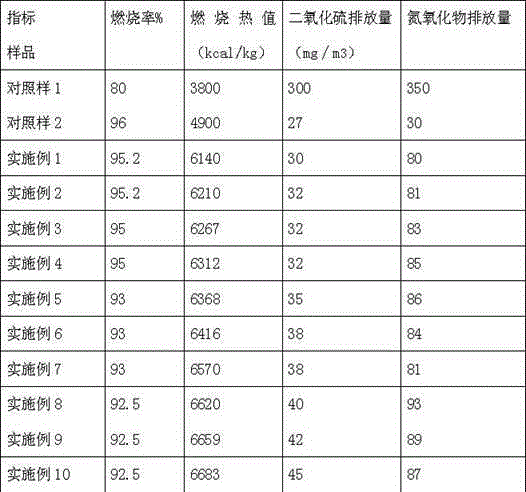

High-energy carbon-alcohol slurry clean fuel and preparation method thereof

The invention provides high-energy carbon alcohol clean fuel slurry and a preparation method thereof. The clean fuel is prepared from the following components in percentage by weight: 45-63 percent of pulverized coal which is over 300mesh and 37-55 percent of methanol, as well as, by total weight of the pulverized coal and methanol, 1-2 percent of a stabilizing agent, 1-3 percent of a dispersing agent, 0.1-0.3 percent of micron-metal powder, 0.1-0.2 percent of a catalyst, 0.5-1 percent of a desulfurizing agent, and a pH regulator which is used for regulating the pH value to 6.5-7.5. The clean fuel has the advantages of high combustion rate, high heat value, low cost and small emission of sulfur dioxide and nitrogen oxide, and can be widely applied to various boilers, diesel engines, gas turbines, tunnel type ceramic firing kilns, refractory brick down-draft kilns, hot-blast stoves of ceramic spray drying towers, rotary cement kilns, iron ore sintering machines and the like.

Owner:ZHONGLAN ENERGY SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com