Anti-wear combustion-supporting dual-effect diesel additive and preparation method thereof

A technology of additives and diesel oil, which is applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of reducing the natural lubricating performance of diesel oil, polluting the environment with photochemical smog, reducing the service life, etc., and achieves improved lubricity, strong polarity, and sixteen The effect of raising the alkane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

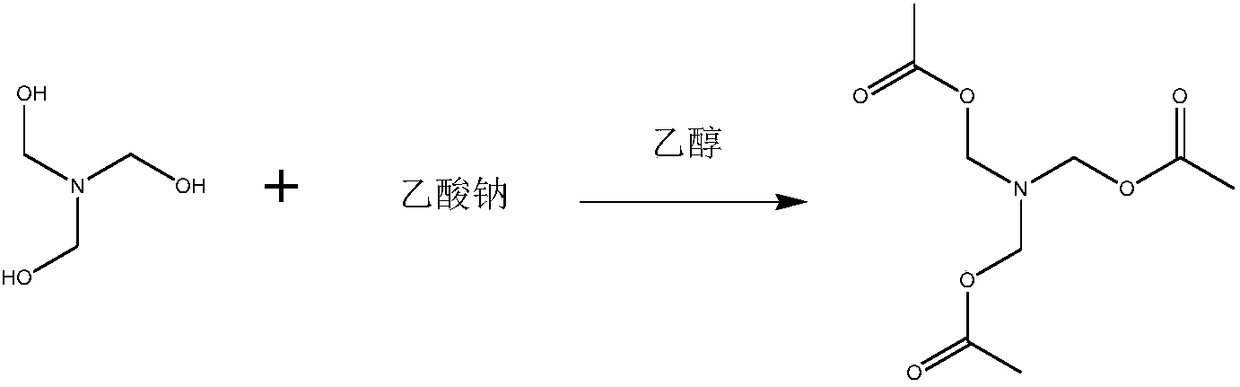

[0024] Preparation of triethanolamine triethyl ester:

[0025] Sodium acetate (40mmol), triethanolamine (10mmol), and 500ml ethanol were successively added to a 1000mL three-neck flask equipped with a reflux condenser, a thermometer, and a magnetic stirrer, and the temperature was raised to reflux with magnetic stirring, and the reaction was stopped after 10 hours of reaction, and cooled to room temperature. Rectify under reduced pressure at 10mmHg pressure and 75°C. After observing that there is no distillate, raise the temperature to 110°C to continue the rectification. After observing again that there is no distillate, raise the temperature to 140°C to continue the rectification, collect the product, and obtain the final product , yield 43.3%.

[0026] The specific synthesis method is as follows:

[0027]

Embodiment 2

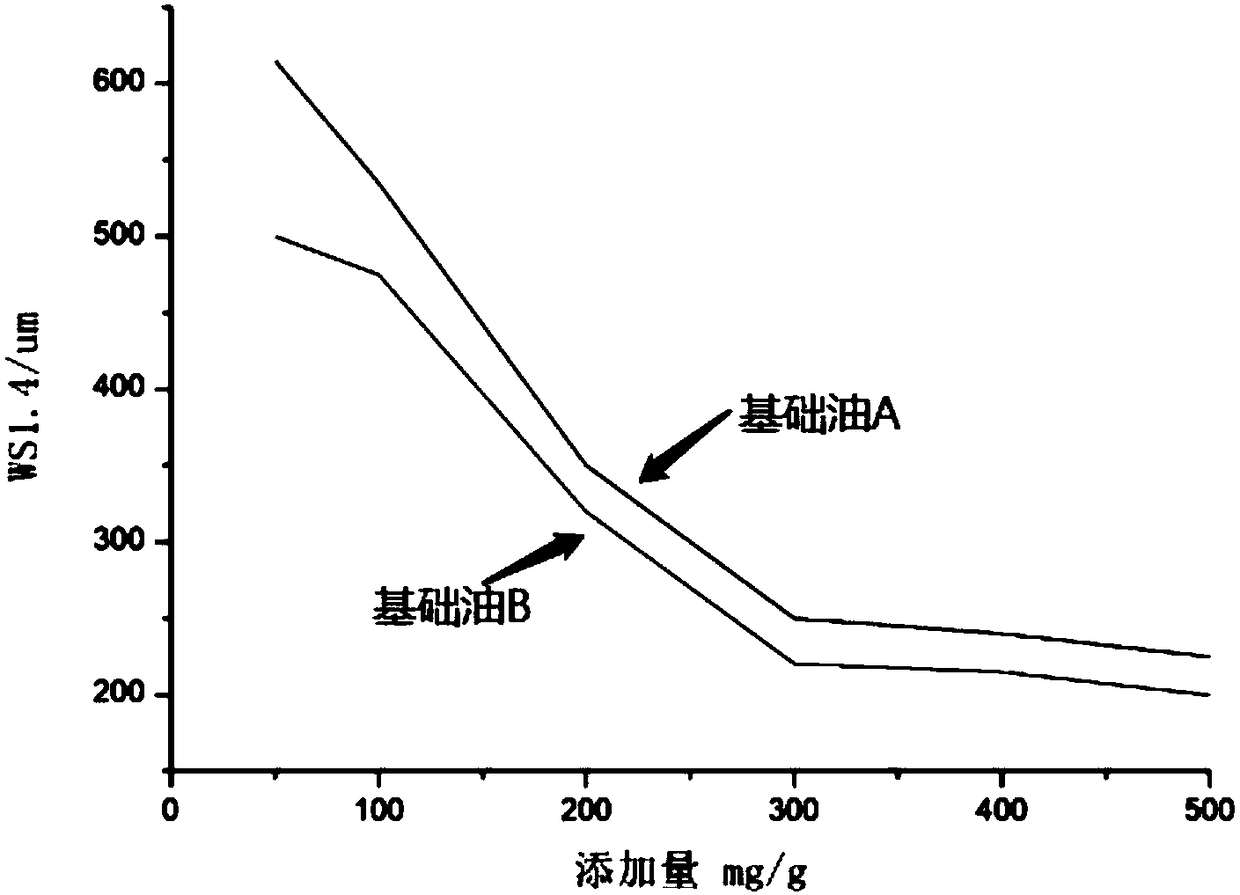

[0029] Triethanolamine triethyl ester cetane modification and flammability:

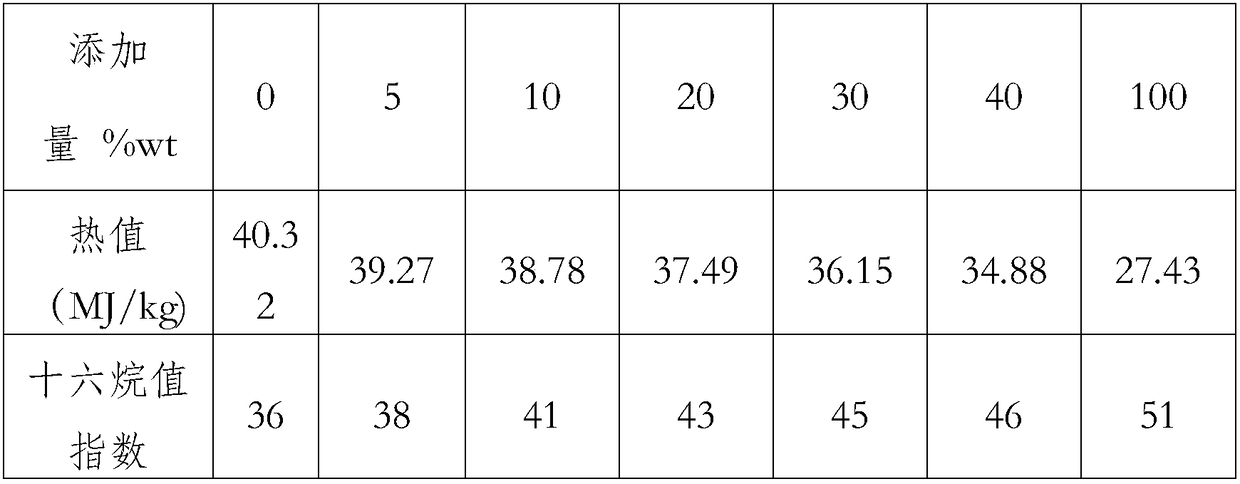

[0030] The effects of adding different proportions of triethanolamine triethyl ester to diesel oil on the heat of combustion and cetane number of diesel oil are shown in Table 1.

[0031] Table 1 Effect of different proportions of triethanolamine triethyl ester on heat of combustion and cetane number of diesel oil

[0032]

[0033] It can be seen from Table 1 that the heat of combustion of triethanolamine triethyl ester is about 27kJ / g, which is about 65% of that of diesel oil. After mixing triethanolamine triethyl ester in diesel oil, the heat of combustion is generally slightly reduced, with a drop rate of about 2-5kJ / g, which is directly related to the proportion of triethanolamine triethyl ester added to gasoline. The heat of combustion of the mixture of triethanolamine triethyl ester / diesel with a mass ratio of 30% is about 80% of the heat of combustion of diesel. These results indicate tha...

Embodiment 3

[0036] Physicochemical properties of triethanolamine triethyl ester:

[0037] The physical and chemical properties of triethanolamine triethyl ester were carried out in Guangzhou Analysis and Testing Center, China, including density, dynamic viscosity, cetane number, and distillation range. The results are shown in the table below:

[0038] The physicochemical properties of table 2 triethanolamine triethyl ester

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com