Patents

Literature

170 results about "Cold filter plugging point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold filter plugging point (CFPP) is the lowest temperature, expressed in degrees Celsius (°C), at which a given volume of diesel type of fuel still passes through a standardized filtration device in a specified time when cooled under certain conditions. This test gives an estimate for the lowest temperature that a fuel will give trouble free flow in certain fuel systems. This is important as in cold temperate countries, a high cold filter plugging point will clog up vehicle engines more easily.

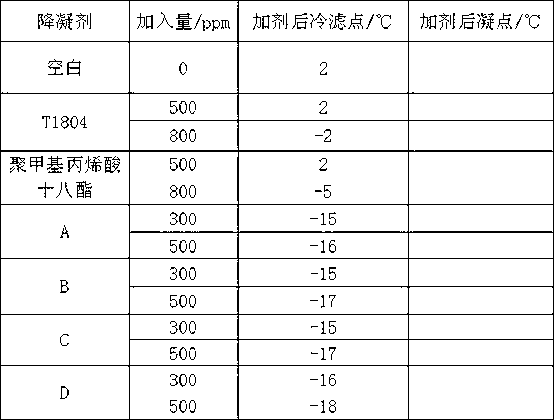

Pour point depressant for diesel oil

ActiveCN103289760APrevent mutual stickingAvoid generatingLiquid carbonaceous fuelsFuel additivesWaxNitrogen

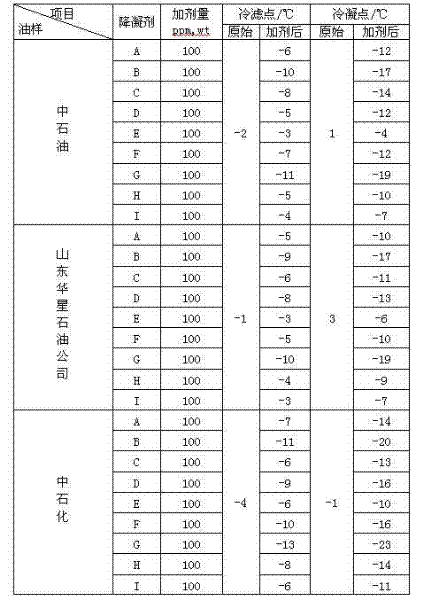

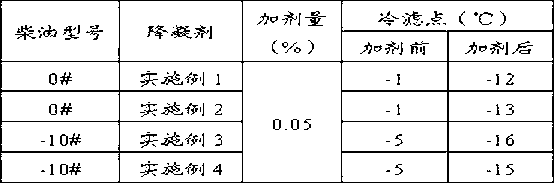

The invention discloses a pour point depressant for diesel oil, wherein polymethylacrylic acid higher ester is used as a host agent, and an arene compound, span, twain and a polar nitrogen-containing compound are used as an assistant. The substances are uniformly mixed and used for effectively reducing the cold filter plugging point of all diesel oils, and are especially better in perceptibility to diesel oils with high wax content and narrow fraction. In low temperature condition, the flowing property of diesel oils with high wax content and narrow fraction is better increased. The pour point depressant is simple to prepare, low in cost and remarkable in effect, has excellent market value, and can be used for solving the problem that the pour point depressant for diesel oil in the petrochemical industry in China is strong in pertinence, single in function and poor in broad spectrum.

Owner:SHANDONG JINGBO PETROCHEM

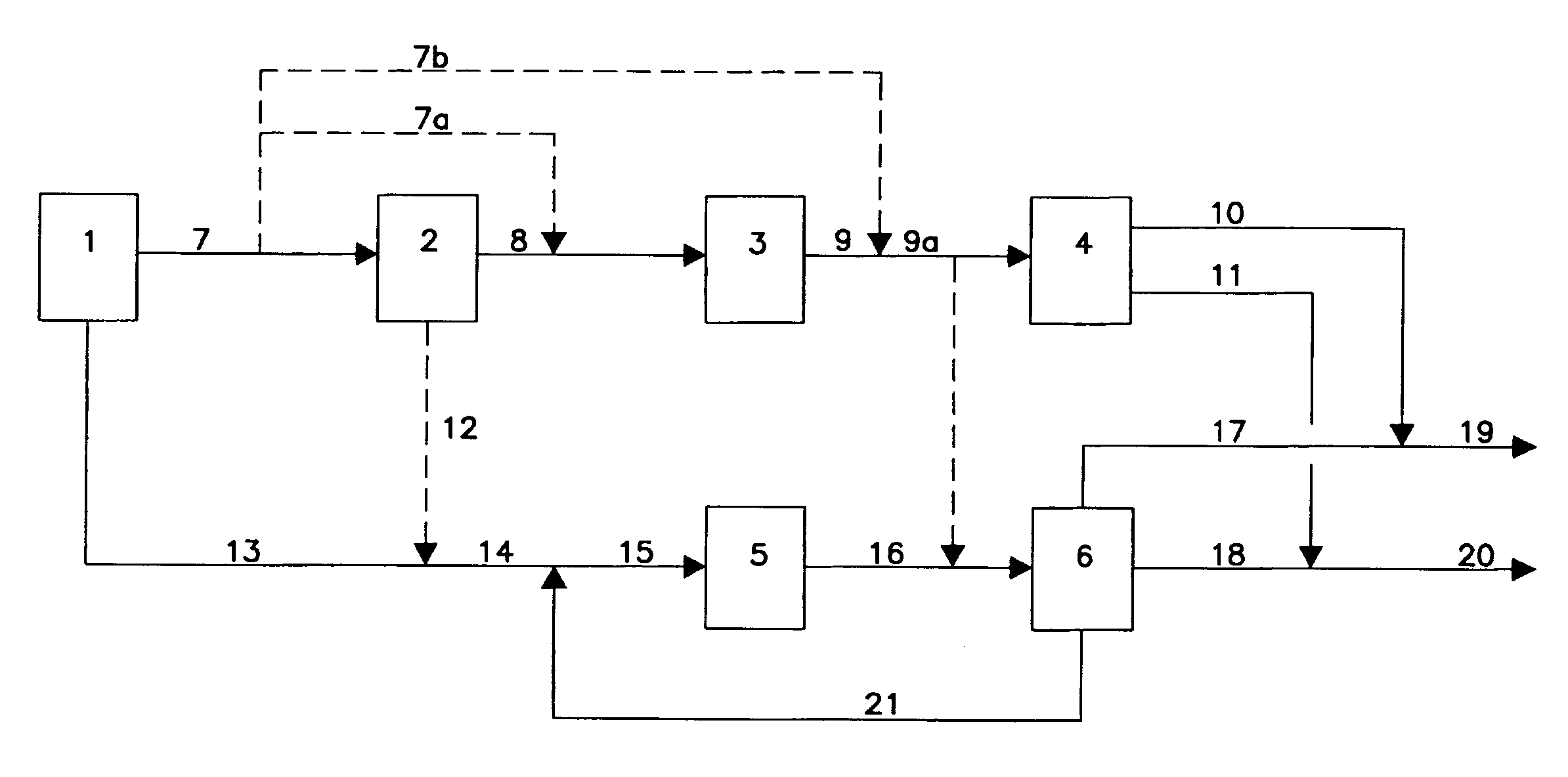

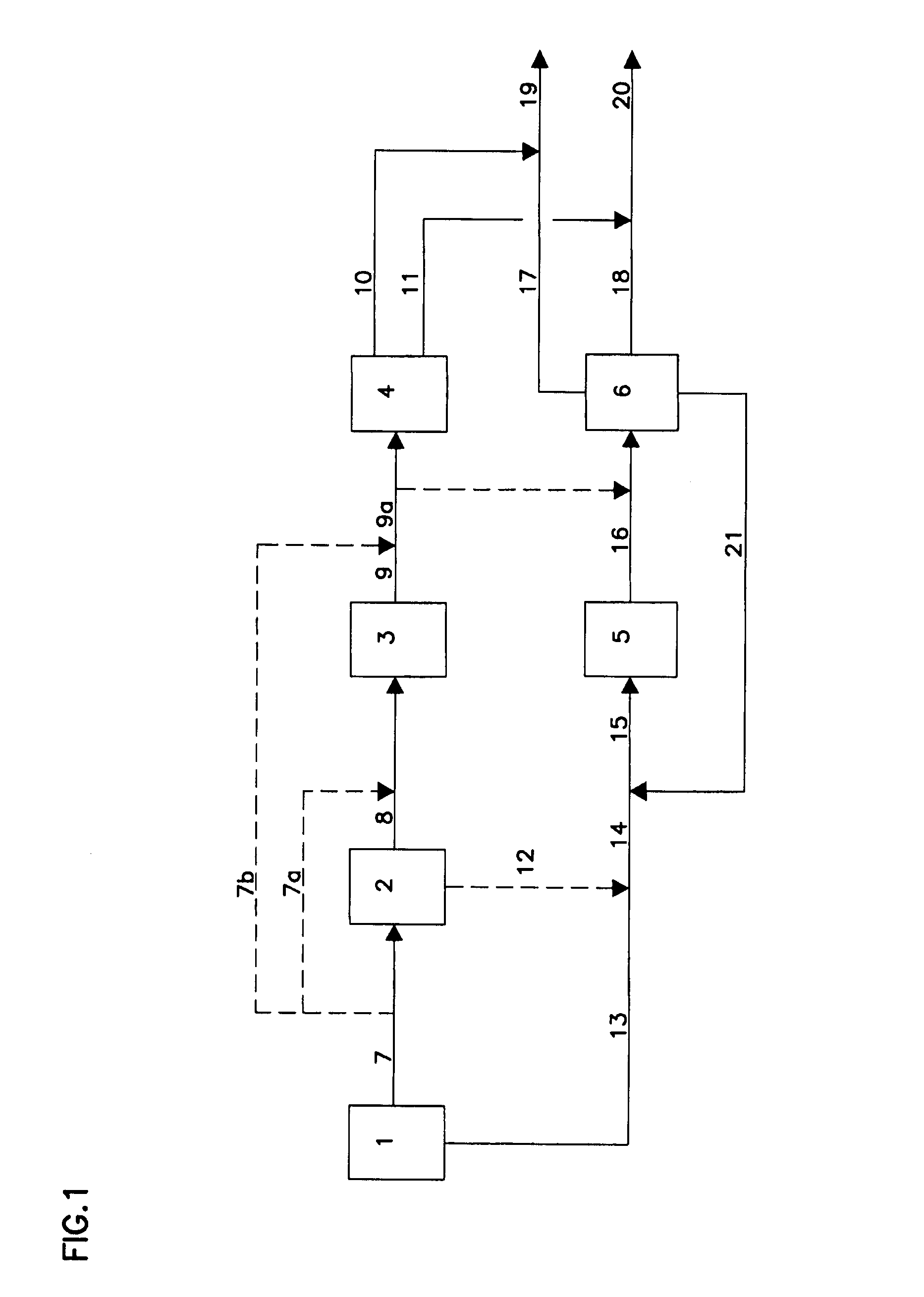

Process for producing middle distillates

InactiveUS7294253B2Increase cetane numberImprove cold flowOrganic compounds purification/separation/stabilisationOrganic compound preparationAlkanePolymer science

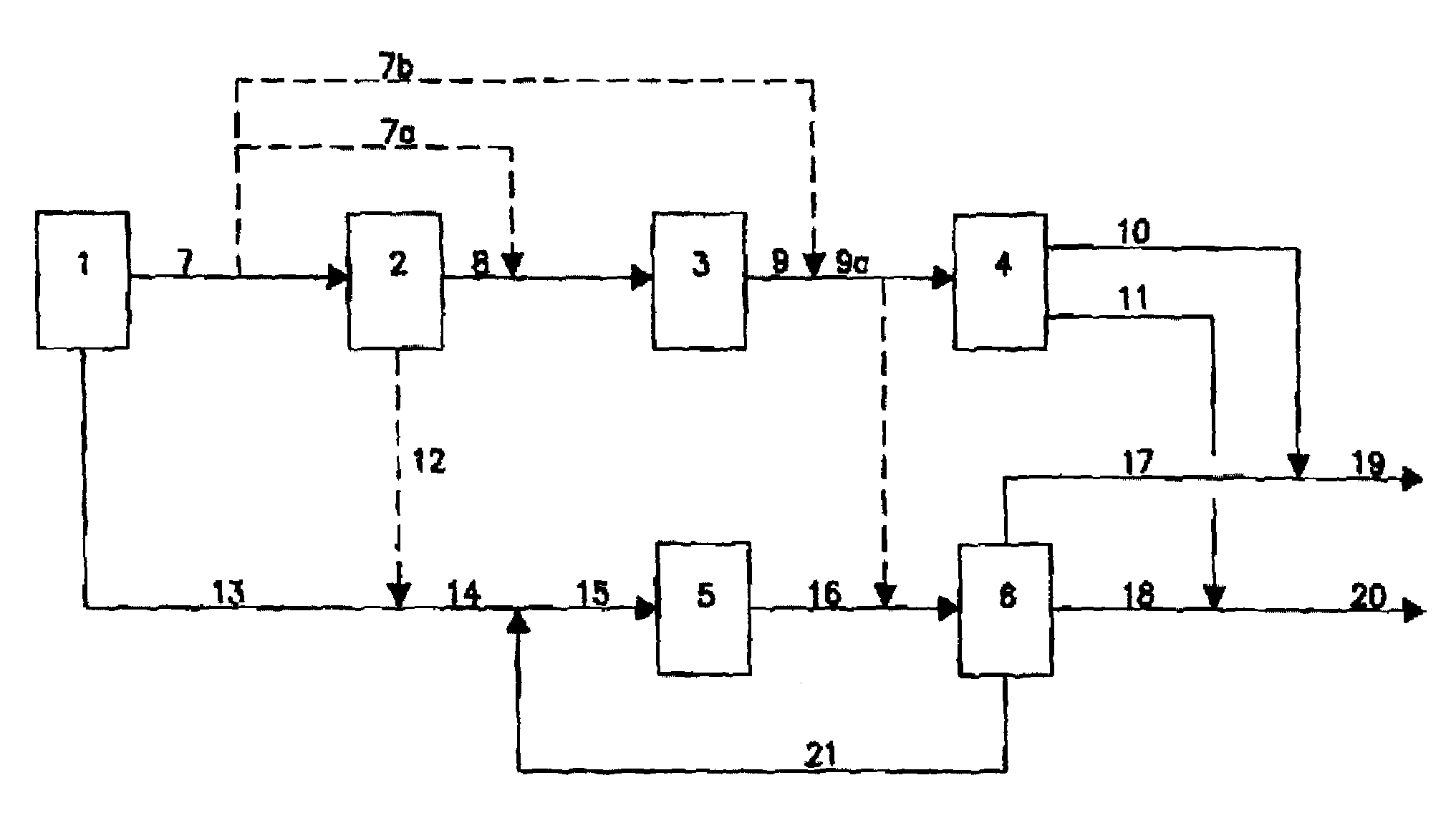

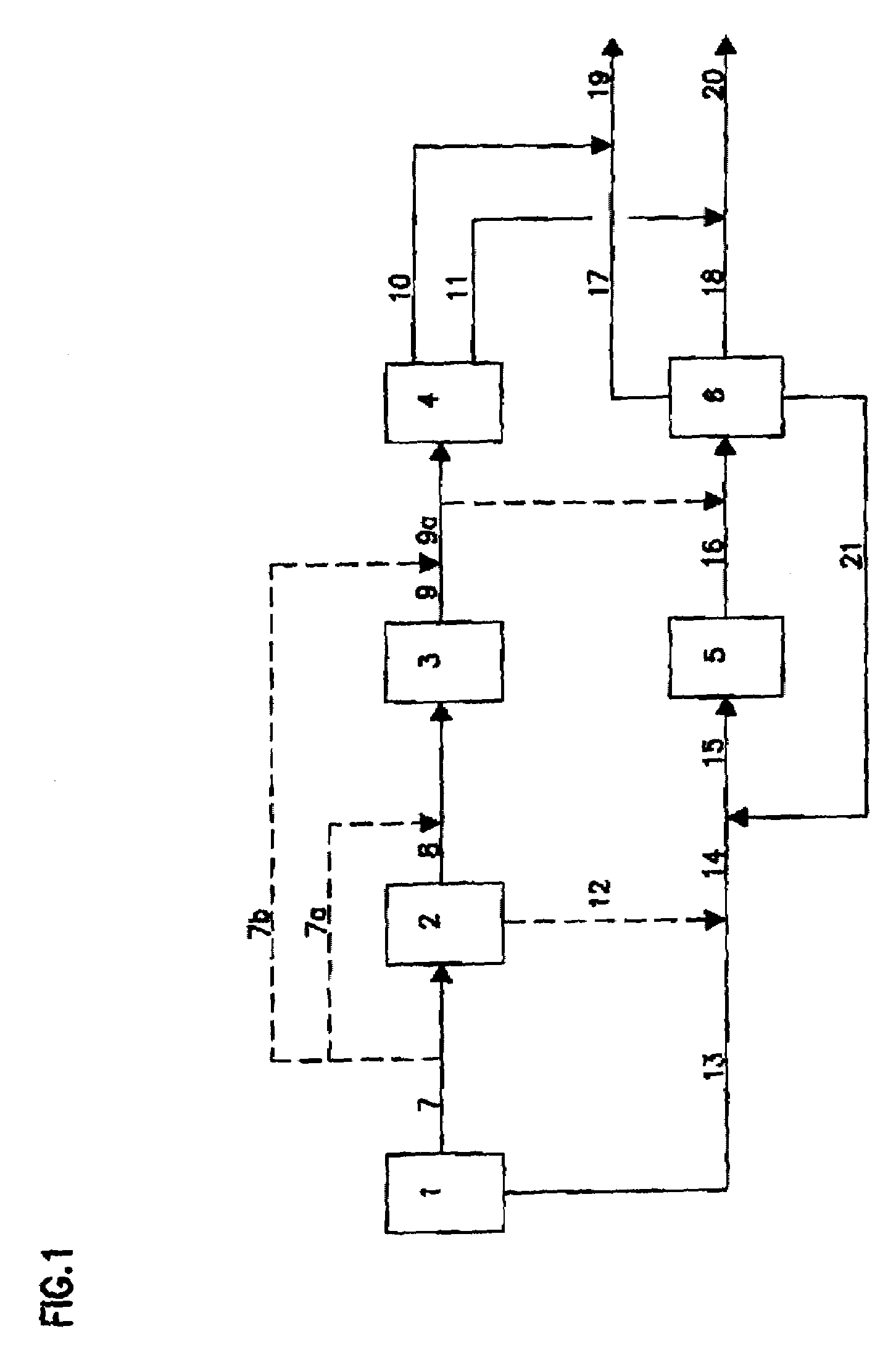

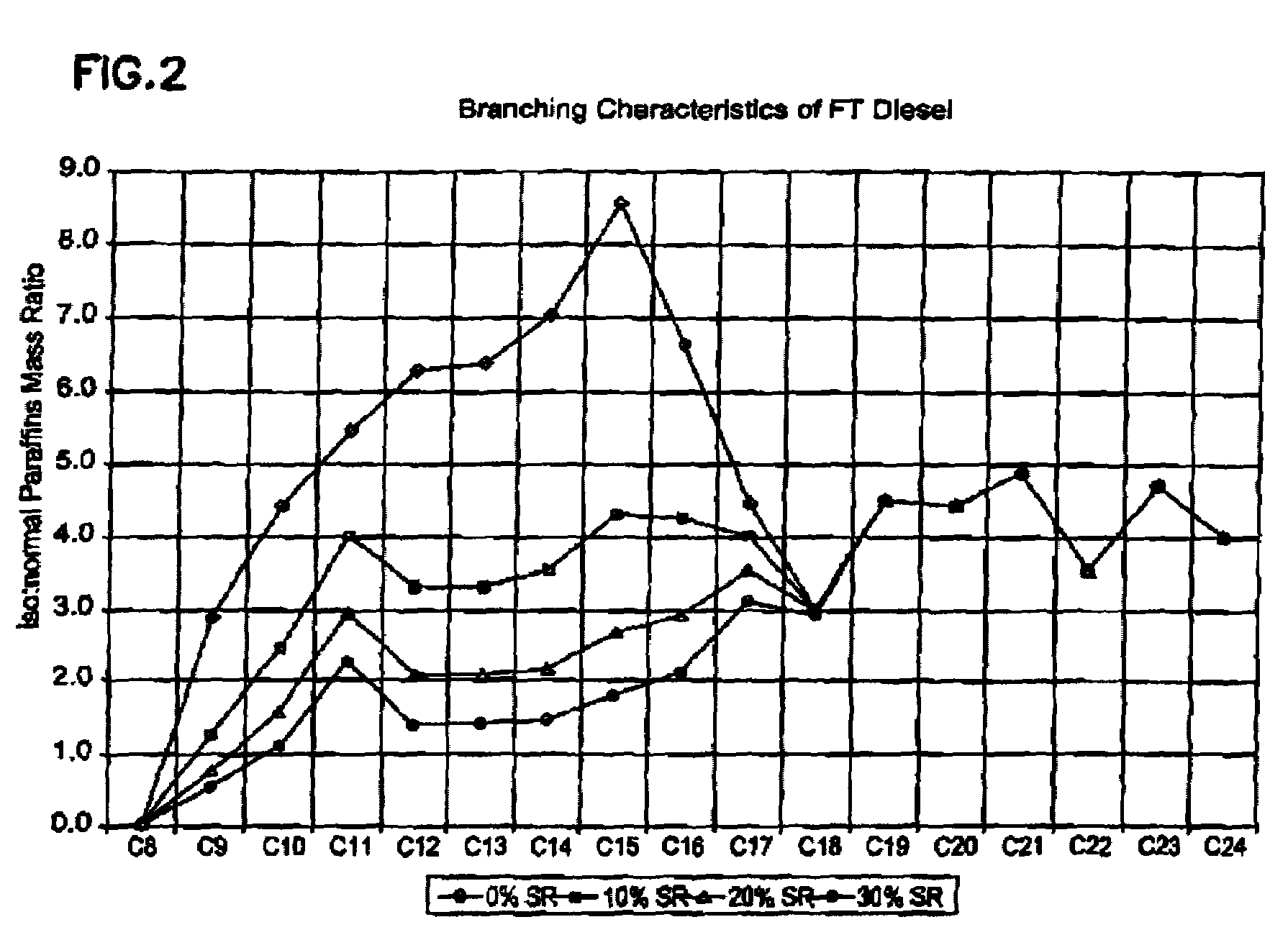

This invention relates to process for producing middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method 309, and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to a process in which middle distillates are produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates produced by the process of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched.

Owner:SASOL TECHNOLOGY (PTY) LTD

Process for producing middle distillates and middle distillates produced by that process

InactiveUS7217852B1Increase cetane numberImprove cold flowHydrocarbon by hydrogenationHydrocarbon distillationAlkaneCold filter plugging point

This invention relates to middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method (309), and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to middle distillates produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched. The invention also provides a diesel fuel composition including the middle distillates in accordance with the invention. A process for preparing the middle distillates is also included in the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

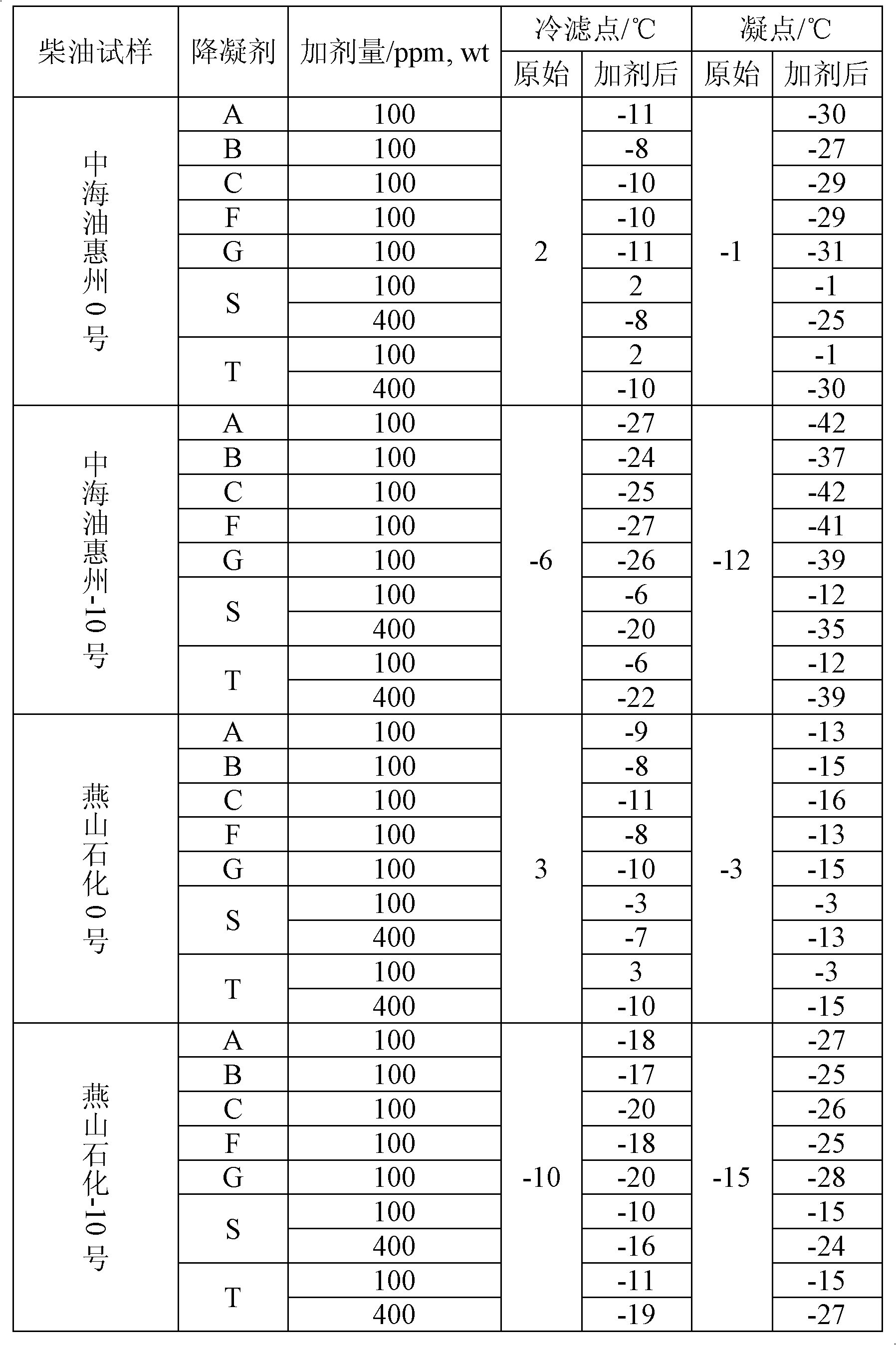

Diesel pour point depressant and preparation method thereof

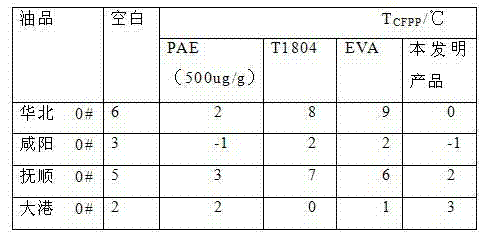

ActiveCN102559302AUniversalGood fluidity at low temperatureLiquid carbonaceous fuelsControl theoryCold filter plugging point

The invention belongs to the field of diesel additive and particularly relates to a diesel pour point depressant and a method for preparing the diesel pour point depressant. The diesel pour point depressant overcomes the defects of the prior pour point depressant and can be used for greatly reducing the cold filter plugging point and the pour point of diesel. In addition the diesel pour point depressant can be widely applied to various diesels, thereby having low limitation.

Owner:山东星火知识产权服务有限公司

Diesel oil pour-point and viscosity reducer, and preparation method thereof

InactiveCN103642546AGood fluidity at low temperatureImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesActive agentEthyl acetate

The invention discloses a diesel oil pour-point and viscosity reducer, and a preparation method thereof. The diesel oil pour-point and viscosity reducer comprises following ingredients, by weight, 20 to 30 parts of ethylene-vinyl acetate copolymer, 10 to 20 parts of styrene-maleic acid octadecanol ester copolymer, 10 to 20 parts of polymethacrylate, 5 to 10 parts of a nonionic surfactant, 5 to 10 parts of ethyl acetate, 5 to 10 parts of maleic anhydride, and 25 to 30 parts of solvent oil No.200. The diesel oil pour-point and viscosity reducer is capable of avoiding defects of existing pour-point depressants and viscosity reducers that viscosity reducing rate is low, application is restricted, pour-point reducing amplitude, and viscosity reducing amplitude are both small; is capable of reducing cold filter plugging point, pour point and viscosity of diesel oil greatly; and can be widely used for various diesel oils; and limitation is less.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

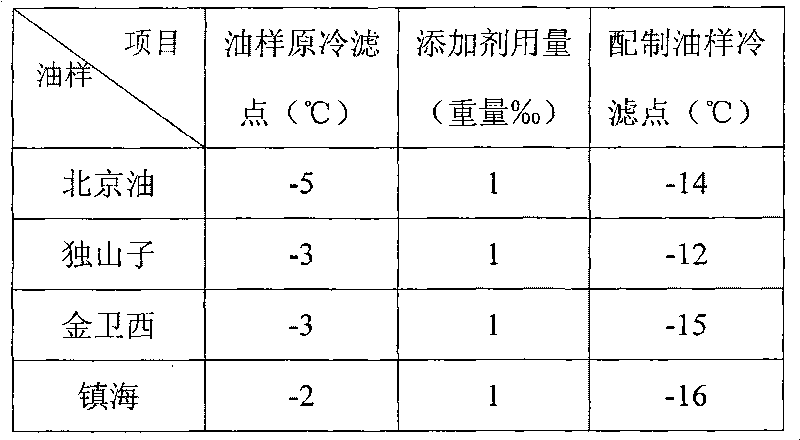

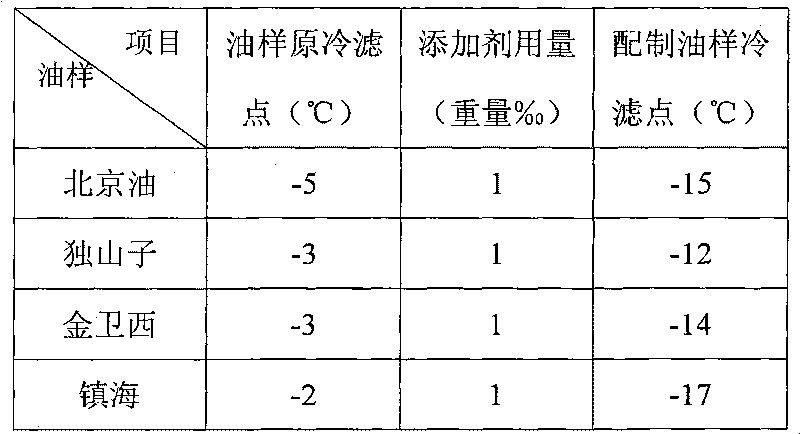

Diesel oil pour point depressant composition, its preparation method and application

ActiveCN102517104AGood dispersionImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesWaxOrganic solvent

The invention discloses a diesel oil pour point depressant composition and its preparation method. The diesel oil pour point depressant composition, i.e. a diesel oil pour point depressant composition formed by mixing acetic ester organic solvents with a pour point depressant, comprises the following raw materials by mass percent: 0-20% of methyl acetate, 0-20% of ethyl acetate, 0-10% of propyl acetate, 0-30% of butyl acetate, and 20-80% of the pour point depressant. The preparation method consists of: mixing all the raw materials and then conducting stirring in water bath at a constant temperature of 50DEG C for 20min, and controlling the rotation speed at 150r / min, thus obtaining the diesel oil pour point depressant composition. Adding of the obtained diesel oil pour point depressant composition into commercially available 0# diesel oil can make the cold filter plugging point of the diesel oil reduced by 5-11DEG C and the condensation point reduced by 6-10DEG C. The diesel oil pour point depressant composition provided in the invention enhances the dispersion effect of pour point depressants on wax crystals, and improves the low temperature fluidity of diesel oil.

Owner:SHANGHAI INST OF TECH

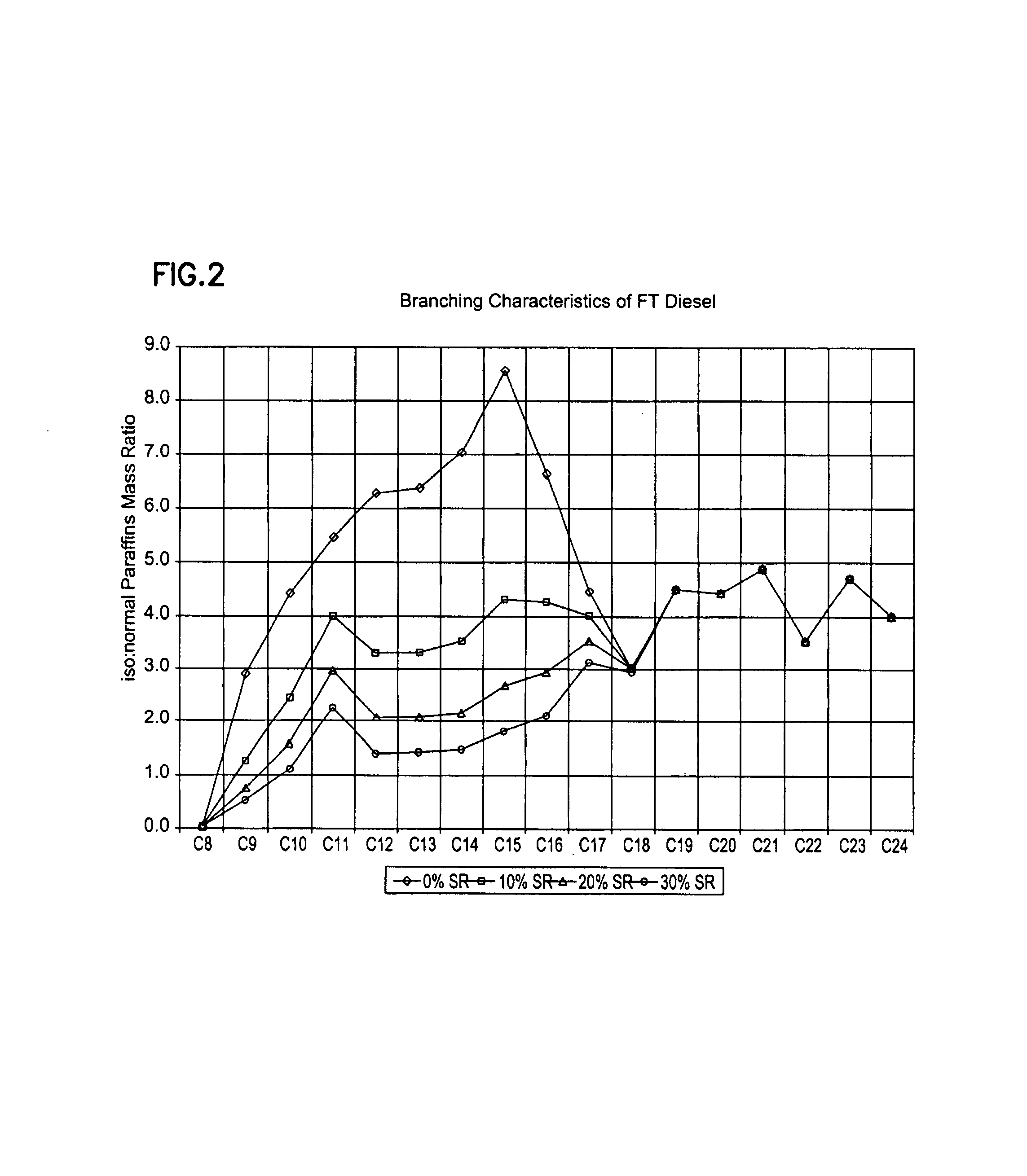

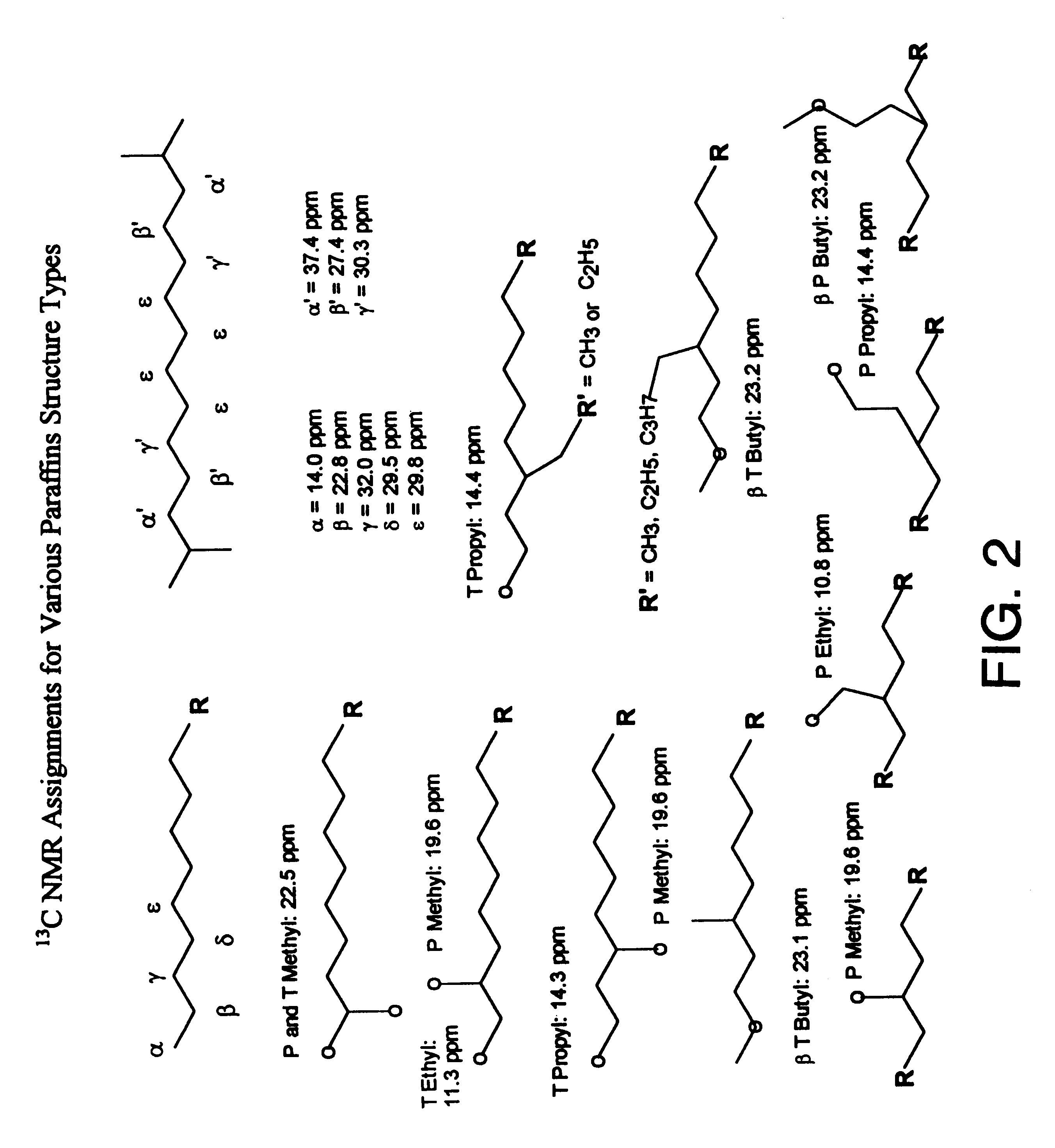

Use of 13C NMR spectroscopy to produce optimum fischer-tropsch diesel fuels and blend stocks

InactiveUS6210559B1Optimize distillate fuel production processEasy to operateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonGasolineProcess engineering

The present invention is a process for producing a distillate fuel heavier than gasoline. The process is a Fischer-Tropsch (hydrocarbon synthesis) process that includes using 13C NMR to measure cetane number and a cold flow property in order to optimize the process. Cold flow properties include cold filter plugging point, cloud point and pour point.

Owner:EXXON RES & ENG CO

Diesel pour point depressant

ActiveCN101812348AImprove solubilityLow viscosityLiquid carbonaceous fuelsFuel additivesOrganic solventDepressant

The invention provides a diesel pour point depressant which comprises the components by weight percent: (1) 20-30% of alkenyl butanediamide acid salt, (2) 15-20% of alpha-olefin and maleic anhydride copolymer, (3) 10-20% of ethylene-vinylacetate and (4) 30-50% of organic solvent. The diesel pour point depressant has better sensitibility for most diesel oil produced in China, low dosage and remarkable effect of reducing condensation point and cold filter plugging point. The invention also provides a preparation method of the diesel pour point depressant.

Owner:TOILX TIANJIN

Method for producing biological diesel oil by using waste oil

InactiveCN101245252ANo pollutionEliminate the effects of production stepsBiofuelsLiquid hydrocarbon mixture productionVegetable oilBiodiesel

The invention provides a method for utilizing waste oil to produce bio-diesel, which regards waste animal and vegetable oil as raw materials, in the producing process, no water-washing is needed, and the method consists of the following steps, first, pretreatment, degumming and dewatering the waste oil, second, pre-esterification, heating the raw material after pretreatment, and stirring the material with methyl alcohol and acid catalyst for reaction, third, alcoholysis, adding methyl alcohol and organic alkali catalyst into the material after pre-esterification for heating reaction, fourth, glaciation, bio-diesel being got after separation. The method degums the waste oil so as to eliminate the influence of gummy matter towards following steps and assure the stability of the process, saponification is avoided, which can cause waste products in block, and the products can reach the main index of 0<model> diesel, the cold filter plugging point is lower than 0 DEG C, the close flash point is more than 65 DEG C, the conversion rate (utilization rate) after pretreatment can reach more than 90 percent, no water-washing is needed so as not to produce a great amount of industrial wastewater to pollute the environment and the post treatment of products is rather convenient.

Owner:NANJING UNIV OF TECH

Diesel oil additive and its preparation method

InactiveCN103911191AReduce displacementCO reductionLiquid carbonaceous fuelsOil additiveSurface-active agents

The invention provides a multiple-component combined diesel oil additive and its preparing method, the diesel oil additive includes, on the basis of 100 parts by weight, 5 to 78 parts by weight of oleic acid; 5 to 88 parts by weight of methanol or ethanol or a mixture thereof; 1 to 31 parts by weight of a surface active agent; 1 to 42 parts by weight of a modified additive and 0 to 73 parts by weight of industrial water which is added according to the concrete application. New a multiple-component biodiesel can be obtained by adding of the additive into conventional fossil diesel, a methanol modified complex or their mixture, and the biodiesel has the advantages of high cetane number, high flash point, low condensation point, low cold filter plugging point, low corrosion, low emission and low cost.

Owner:US ENERGY INC

Fuel oil blending additive and preparation method thereof

InactiveCN103509615APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesFuel oilCold filter plugging point

The invention provides an additive for blending fuel oil. The additive comprises an emulsifier formed by complexing a Span-series emulsifier and a Tween-series (or OP-10) emulsifier, a pH value buffering pair formed by combination of sodium petroleum sulfonate and barium petroleum sulfonate, tricresyl phosphate, isooctyl nitrate, a co-emulsifying dispersing agent, an antioxidant, isobutyl alcohol and an organic solvent. The additive is prepared according to certain content and a certain preparation method. The additive can be used for blending methanol, methanol-oleic acid mixture, and other methanol modified complex into a biological fuel oil, and can be used for further blending biodiesel. The blended biological fuel oil and the biodiesel have the advantages of high cetane number, high flash point, low pour point, low cold filter plugging point, low corrosivity, low emission, and low cost.

Owner:刘粤荣 +1

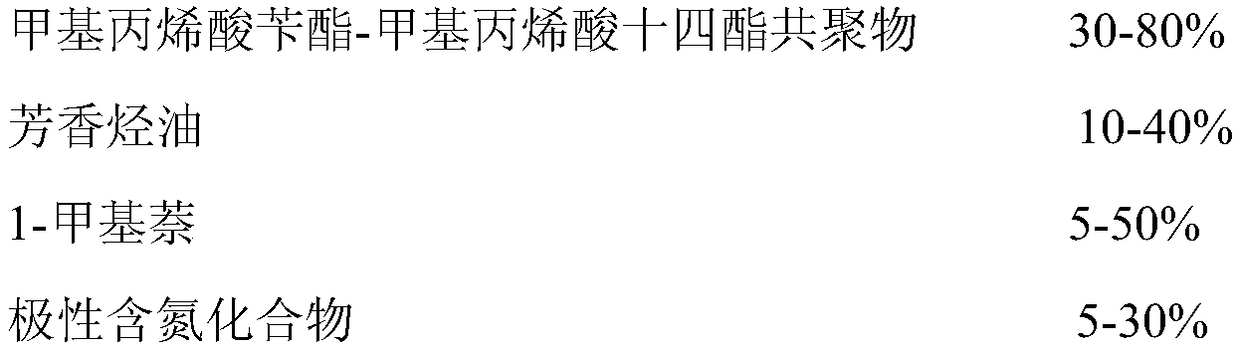

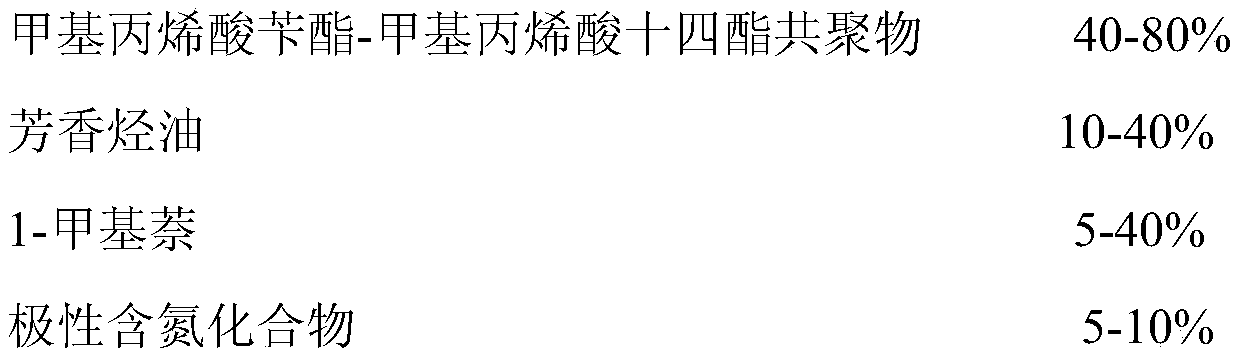

Wide-spectrum diesel pour point depressant composition, preparation method thereof and application of composition

InactiveCN109135846AIncrease polarityImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceNitrogen

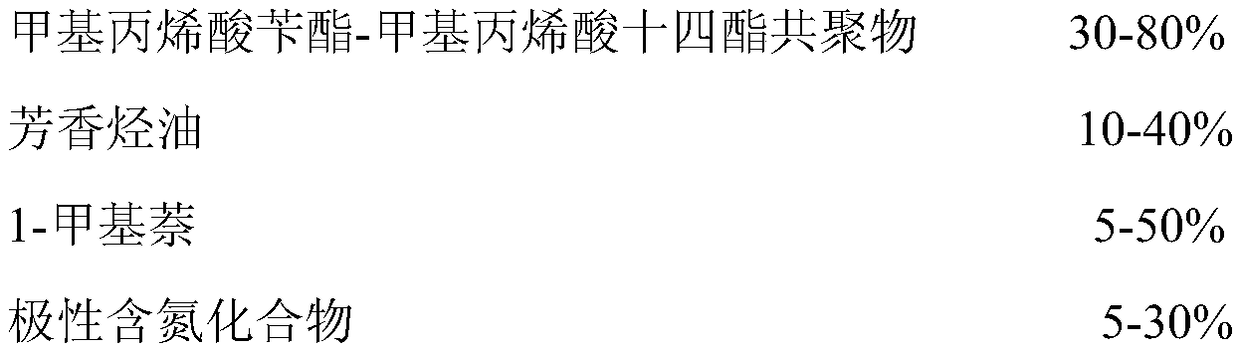

The invention discloses a wide-spectrum diesel pour point depressant composition, a preparation method thereof and an application of the composition. The pour point depressant composition comprises, in weight percent, 30-80% of benzyl methacrylate-methacrylic acid tetradecyl ester copolymers, 10-40% of arene oil, 5-50% of 1-methylnaphthalene and 5-30% of polar nitrogen-containing compounds. The raw materials are uniformly mixed according to predetermined weight percent to obtain the composition. The diesel pour point depressant composition can be rapidly dissolved in diesel oil, is high in spectrum and has remarkable pour point declining effect when being applied to different diesel, and a condensation point and a cold filter plugging point are reduced by 21-26 DEG C and 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

Pour point depressant composition suitable for biodiesel and petroleum diesel blend oil, preparation method and application of pour point depressant composition

ActiveCN105713684AEfficient use ofImprove developmentLiquid carbonaceous fuelsFuel additivesBiodieselDepressant

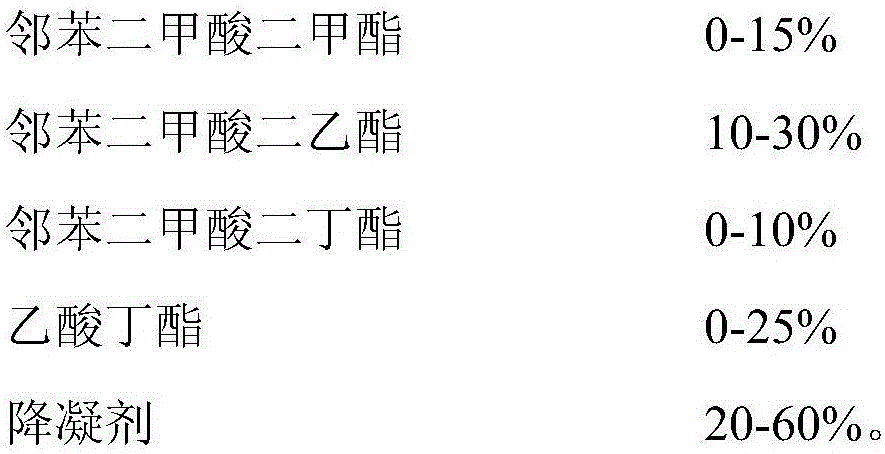

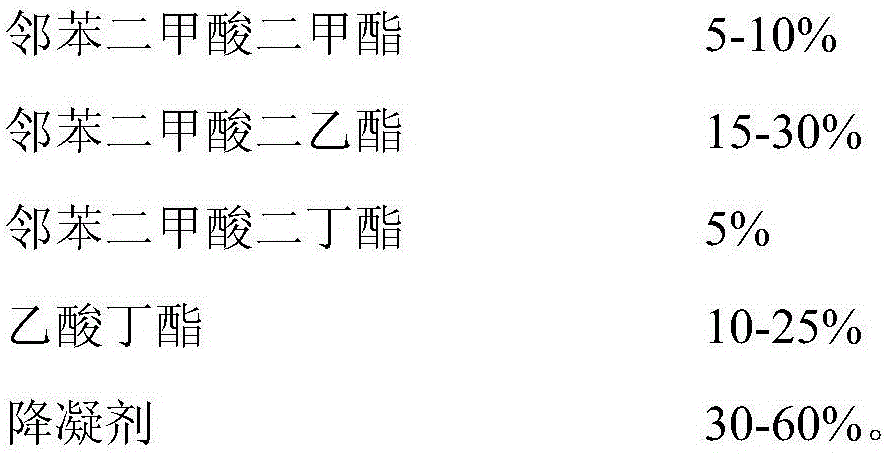

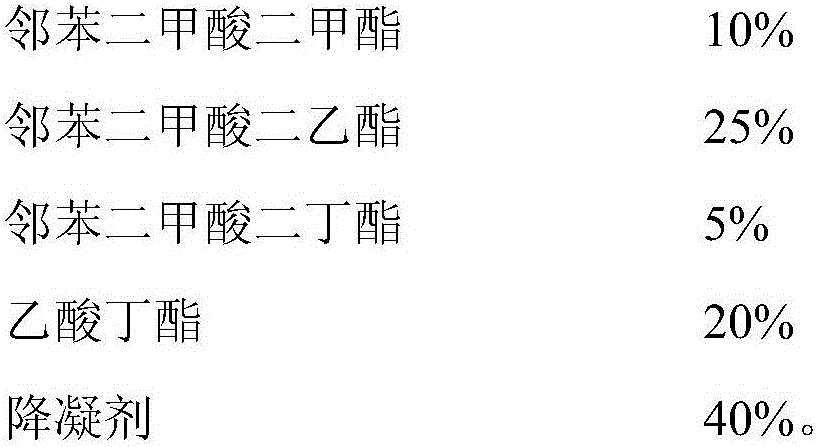

The invention discloses a pour point depressant composition suitable for biodiesel and petroleum diesel blend oil, a preparation method and application of the pour point depressant composition. The pour point depressant composition is formed by mixing phthalic acid ester type organic solvent, acetate type organic solvent and diesel oil pour point depressant. Specifically, the pour point depressant composition is prepared from 0-15 wt% of dimethyl phthalate, 10-30 wt% of diethyl phthalate, 0-10 wt% of dibutyl phthalate, 0-25 wt% of butyl acetate and 20-60 wt% of pour point depressant. By evenly mixing and stirring all the components at normal temperature and normal pressure and conducting ultrasonic dispersion for 25-30 minutes, the pour point depressant composition is prepared. The pour point depressant composition is particularly suitable for improving low-temperature mobility of biodiesel and petroleum diesel blend oil formed by mixing soybean oil biodiesel and 0# biodiesel at normal temperature and normal pressure, the pour point effect is remarkable, the cold filter plugging point can be reduced by 7-11 DEG C, and the pour point can be reduced by 6-10 DEG C.

Owner:SHANGHAI INST OF TECH

Lubricating anti-wear diesel start protection additive

ActiveCN103992828AHelp miscibilityHelp make full use ofLiquid carbonaceous fuelsFuel additivesEtherSolvent

The invention relates to a lubricating anti-wear diesel start protection additive, belonging to the field of diesel additives. The additive comprises the following components in percentage by weight: 5-10% of low-molecular ether A, 10-20% of combustion improver B, 5-15% of detergent C, 10-30% of pour point depressant D, 10-30% of cetane number improver E and 10-60% of solvent F. The additive produced by a conventional production process is added into diesel at a concentration proportion of 800-4,000ppm, and the cold filter plugging point of the diesel can be remarkably reduced while the fluidity, lubricating property, combustibility and start protection of the diesel can be improved.

Owner:QUANZHOU CITY OUMEI LUBRICANT PRODS

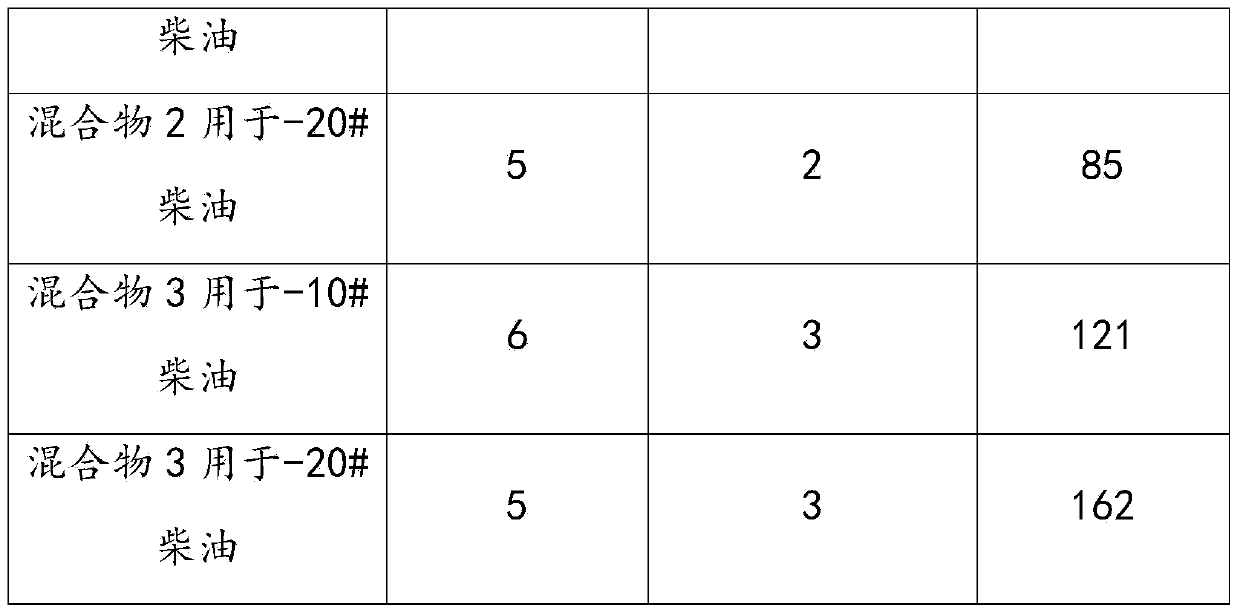

Fuel oil heating auxiliary device of diesel engine

InactiveCN103939247AReduce loadSimple structureMachines/enginesThermal treatment of fuelHeating timeFuel oil

A fuel oil heating auxiliary device of a diesel engine has the functions of heating and exhausting, is provided with a control circuit, an electromagnetic gas valve and an exhaust pump device, is installed in front of an oil supply pump of the engine, and is connected with an oil conveying pipe. A small amount of fuel oil is reserved in an electric heating auxiliary device cup, the temperature of the fuel oil reaches above the cold filter plugging point, and the fuel oil is used for low-temperature starting and initial-stage running of the engine. After the engine is started, an oil tank and other oil paths are heated through the residual heat of an antifreezing solution and the tail gas, and therefore stable operation of the engine is achieved. After the engine stops, the liquid level inside the auxiliary device cup is recovered through the functions of the electromagnetic gas valve and the exhaust pump to facilitate the next time of low-temperature starting. Through the technical scheme, the fuel oil heating auxiliary device of the diesel engine has the advantages that the pre-heating time of the engine in the low-temperature starting process is largely shortened; the load of the storage battery is largely reduced; the diesel engine can use diesel with a high condensation point at low temperature, and oil cost is saved; the structure is simple, installation is convenient, the structure of an original fuel oil system is not changed, and the fuel oil heating auxiliary device of the diesel engine can be widely popularized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Diesel oil pour point depressant

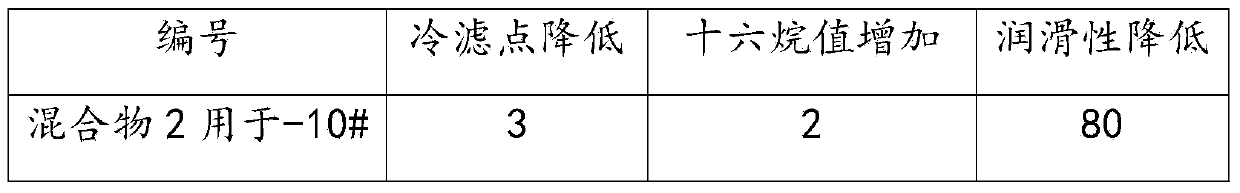

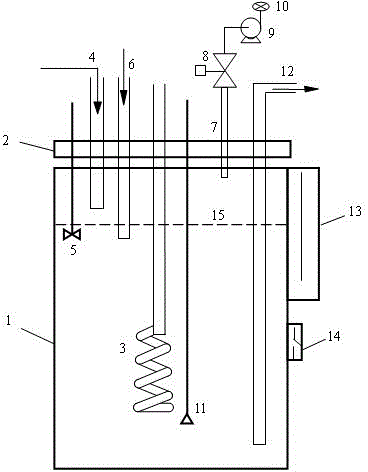

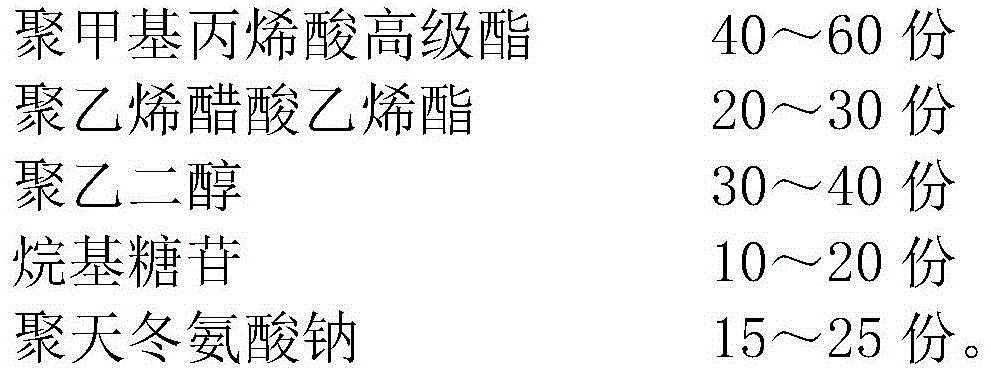

InactiveCN104910977AGood dispersionLowering the freezing pointLiquid carbonaceous fuelsFuel additivesPolyethylene vinyl acetatePolyethylene glycol

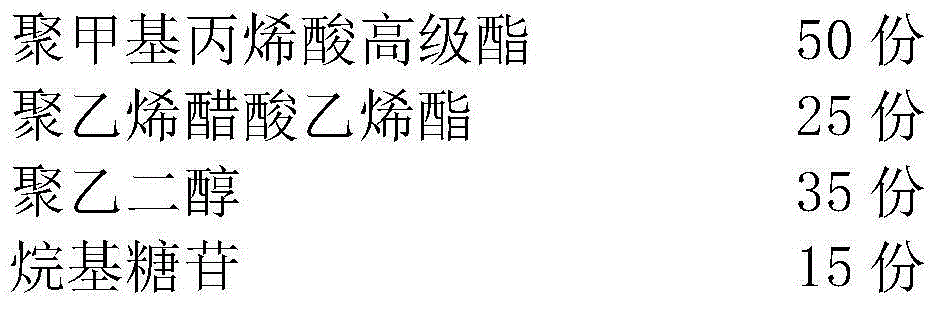

The invention relates to the technical field of pour point depressants and particularly relates to the technical field of a diesel oil pour point depressant. The diesel oil pour point depressant is prepared from the following raw materials in parts by weight: 40-60 parts of high polymethacrylate, 20-30 parts of polyethylene vinyl acetate, 30-40 parts of polyethylene glycol, 10-20 parts of alkyl glycoside and 15-25 parts of sodium polyaspartate. According to the diesel oil pour point depressant disclosed by the invention, the pour point depression effect is remarkably improved, the cold filter plugging point and pour point of all diesel oil can be effectively lowered, particularly the sensitivity to high-wax-content and narrow-fraction diesel oil is relatively good, the flowing property of the high-wax-content and narrow-fraction diesel oil is better improved under low-temperature conditions, the diesel oil pour point depressant is environment-friendly and has an excellent market value, and the problems of the existing diesel oil pour point depressants in China petrochemical industry that the pertinence is high, the performance is single and the broad-spectrum performance is poor are solved.

Owner:马健

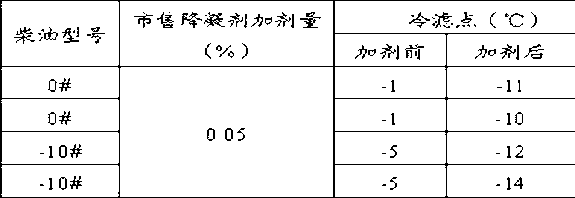

Nano compound pour point depressant and preparation method thereof

InactiveCN105969433ABroaden the crystallization temperature rangeCompact arrangementLiquid carbonaceous fuelsFuel additivesMontmorilloniteCold filter plugging point

The invention discloses a nano compound pour point depressant and a preparation method thereof. The nano compound pour point depressant disclosed by the invention is compounded from a nano material and a polymer pour point depressant by a melting and blending method. A montmorillonite nano material modified by cetyl trimethylammonium bromide is compounded with the polymer pour point depressant in a certain mass ratio by adopting the melting and blending method so as to obtain the nano compound pour point depressant. The pour point depression effect of the nano compound pour point depressant is further enhanced on the basis of pour point depression of the original pour point depressant. When the nano compound pour point depressant is applied to 0# diesel oil, the pour point depression effect is superior to that of a commercially available pour point depressant, and the cold filter plugging point and the condensation point are respectively reduced by 12-20 DEG C and 18-26 DEG C.

Owner:SHANGHAI INST OF TECH

Method for preparing diesel depressant

InactiveCN102153705AExcellent cooling filter pointExcellent pour point depressing performanceLiquid carbonaceous fuelsDistillationReaction temperature

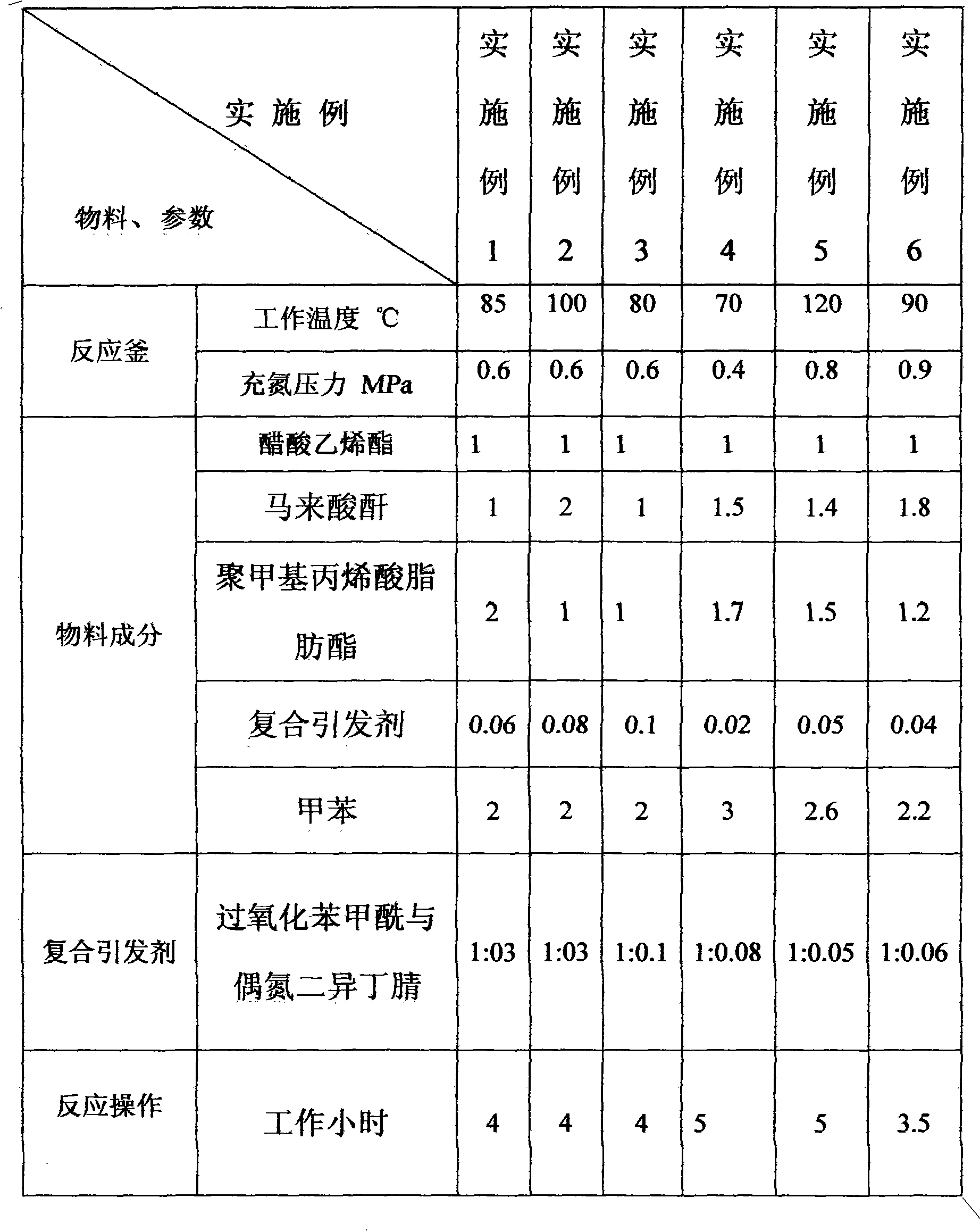

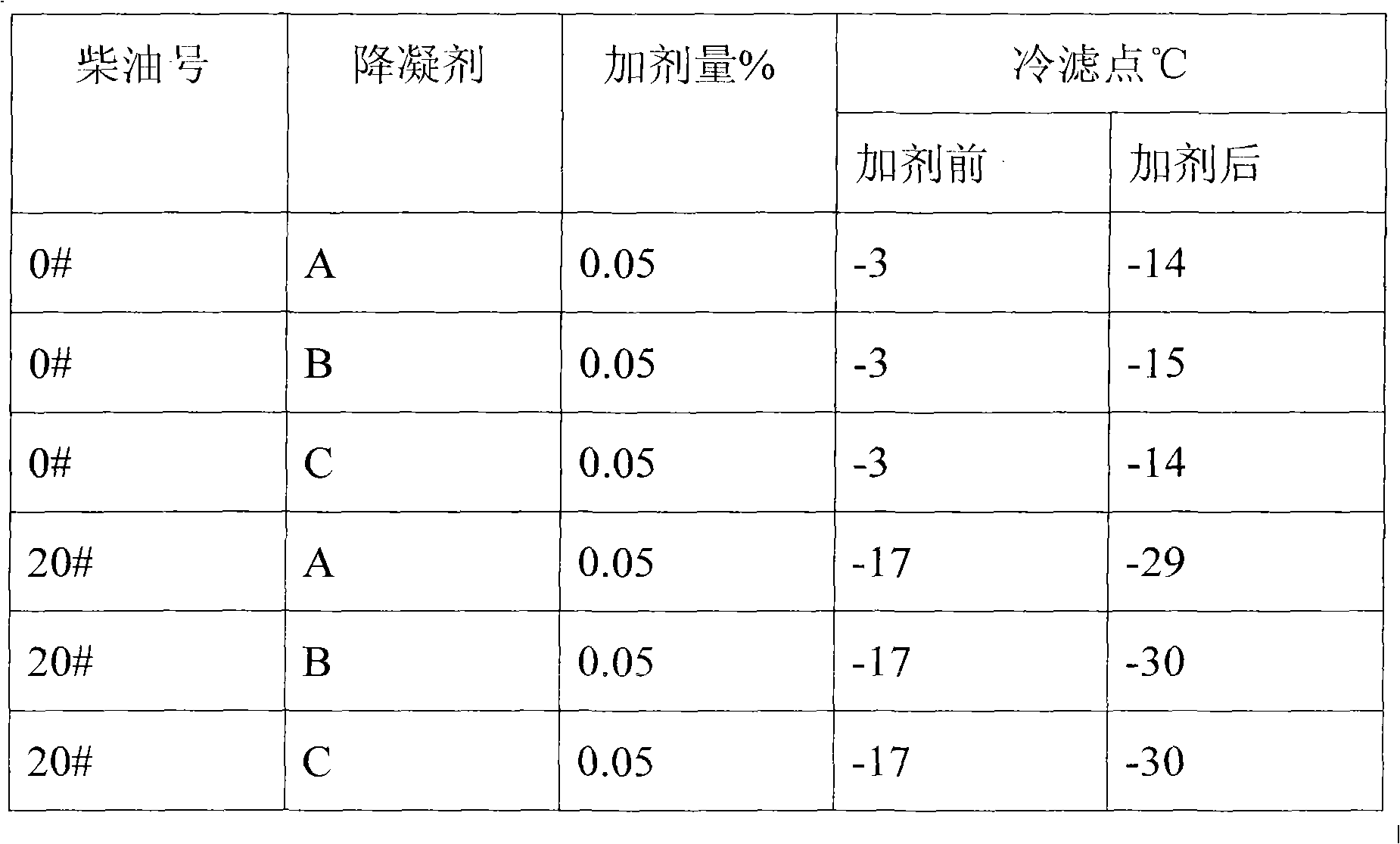

The invention discloses a method for preparing diesel, in particular to a method for preparing diesel depressant. The method is characterized by comprising the following steps: adding vinylacetate, maleic anhydride and poly methyl methacrylate fatty ester mixture solution to a reaction vessel with stirring and heating devices; dropwise adding compound initiator to a reaction filled with methylbenzene, heating the reaction vessel to 70-120 DEG C, introducing nitrogen until the pressure in the reaction vessel is 0.4-0.9 Mpa, enabling the materials react for 3.5-5.5 hours, putting discharged materials to a distillation vessel, distilling unreacted monomers and solvent to obtain the residual which is vinylacetate, maleic anhydride and poly methyl methacrylate fatty ester ternary copolymer, and preparing the vinylacetate, maleic anhydride and poly methyl methacrylate fatty ester ternary copolymer into the dry diesel depressant. Compared with the prior art, the diesel depressant has more excellent cold filter plugging point and solidifying point decreasing properties. Because the compound initiator is adopted, the reaction temperature is reduced, thus the energy consumption is reduced. Compared with the prior art, the method has the characteristics of low reaction pressure, simple process and obvious decrease of cold filter plugging point of a product, and saves energy.

Owner:吉化集团吉林市星云化工有限公司

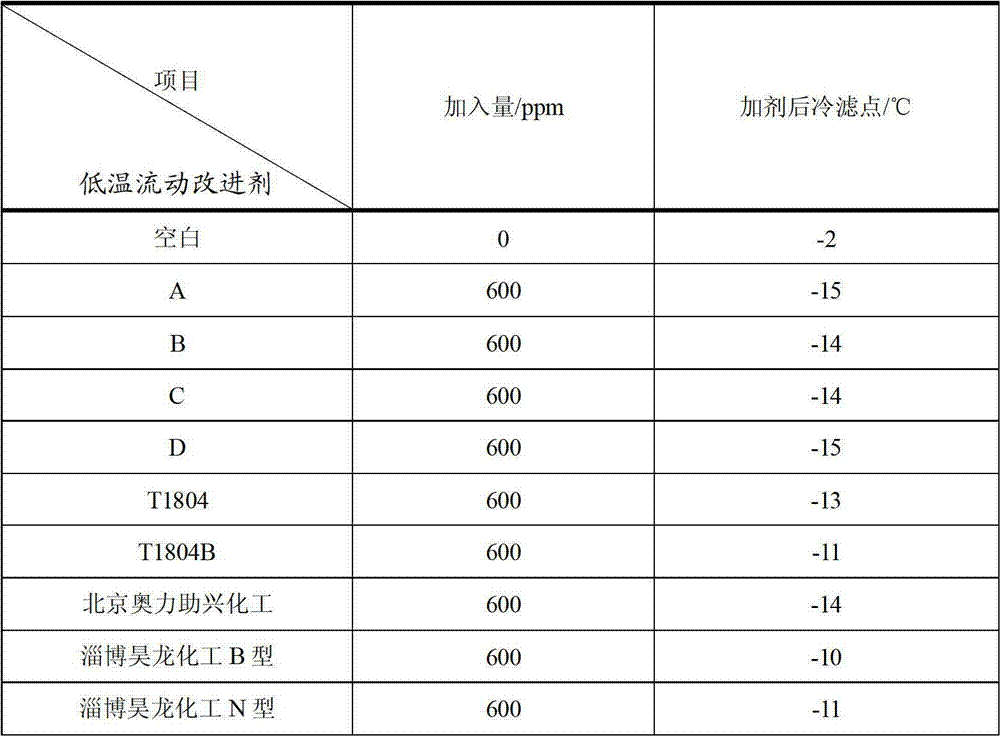

Low-temperature fluidity improver for diesel oil

ActiveCN102766491ALower cold filter pointImprove liquidityLiquid carbonaceous fuelsFuel additivesChemical industryCompound a

The invention relates to the technical field of chemical industry, and relates to a low-temperature fluidity improver for diesel oil, in particular to the low temperature fluidity improver for diesel oil, which is capable of significantly reducing the cold filter plugging point of the diesel oil. The low-temperature fluidity improver is obtained by compounding a proper main agent and proper auxiliary agents and then uniformly mixing. The low-temperature fluidity improver with the ratio is better in sensitivity for most of diesel oil, and particularly can reach better decompression effect for the diesel with higher wax content and narrower boiling range.

Owner:山东京博众诚清洁能源有限公司

Method for preparing low-cold-filter-plugging-point biodiesel

InactiveCN102229865AImprove low temperature fluidityAchieve directional responseFatty acid esterificationFatty acids production/refiningBiodieselEsterification reaction

The invention discloses a method for preparing low-cold-filter-plugging-point biodiesel, which comprises the following steps: (1) preparing free fatty acids by hydrolysis of raw material grease; (2) separating free fatty acids by a urea clathration process to obtain a fraction containing rich saturated fatty acids and fraction containing rich unsaturated fatty acids; and (3) performing esterification reaction of the fraction containing rich saturated fatty acids, which are obtained by the step (2), with short-chain alkanols and the esterification reaction of the fraction containing rich unsaturated fatty acids, which are obtained by the step (2), with methanol, uniformly mixing the two parts of fatty acid esters obtained by the reactions uniformly and obtaining the biodiesel with improvedlow-temperature flowing property. The method for improving the low-temperature flowing property of the short-chain alkanol biodiesel is simple in operation, is highly adaptive to raw material oils, and can realize high utilization rate; and the physical and chemical properties of the product prepared by the method meet the specified values of standards for biodiesel.

Owner:BEIJING UNIV OF CHEM TECH

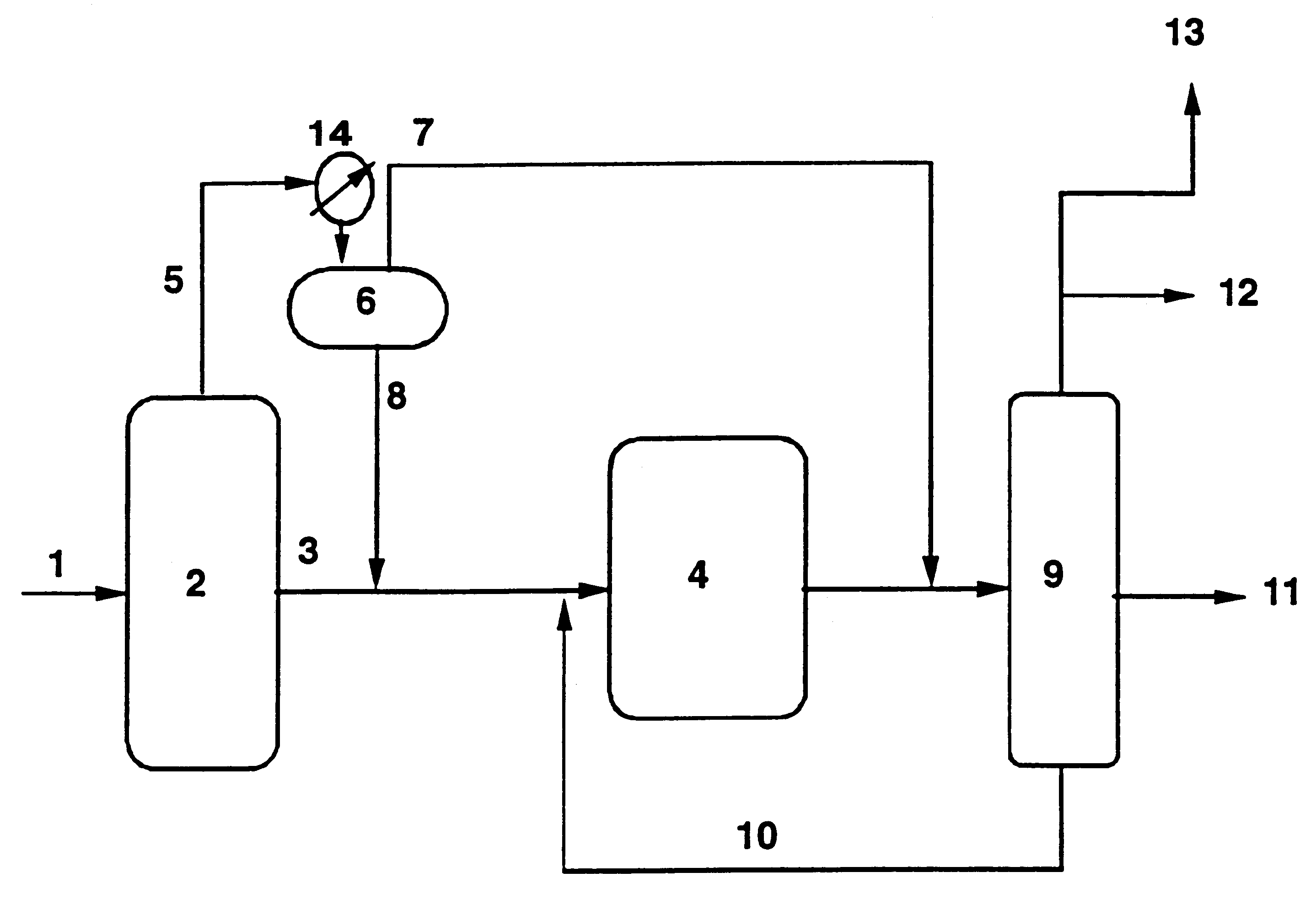

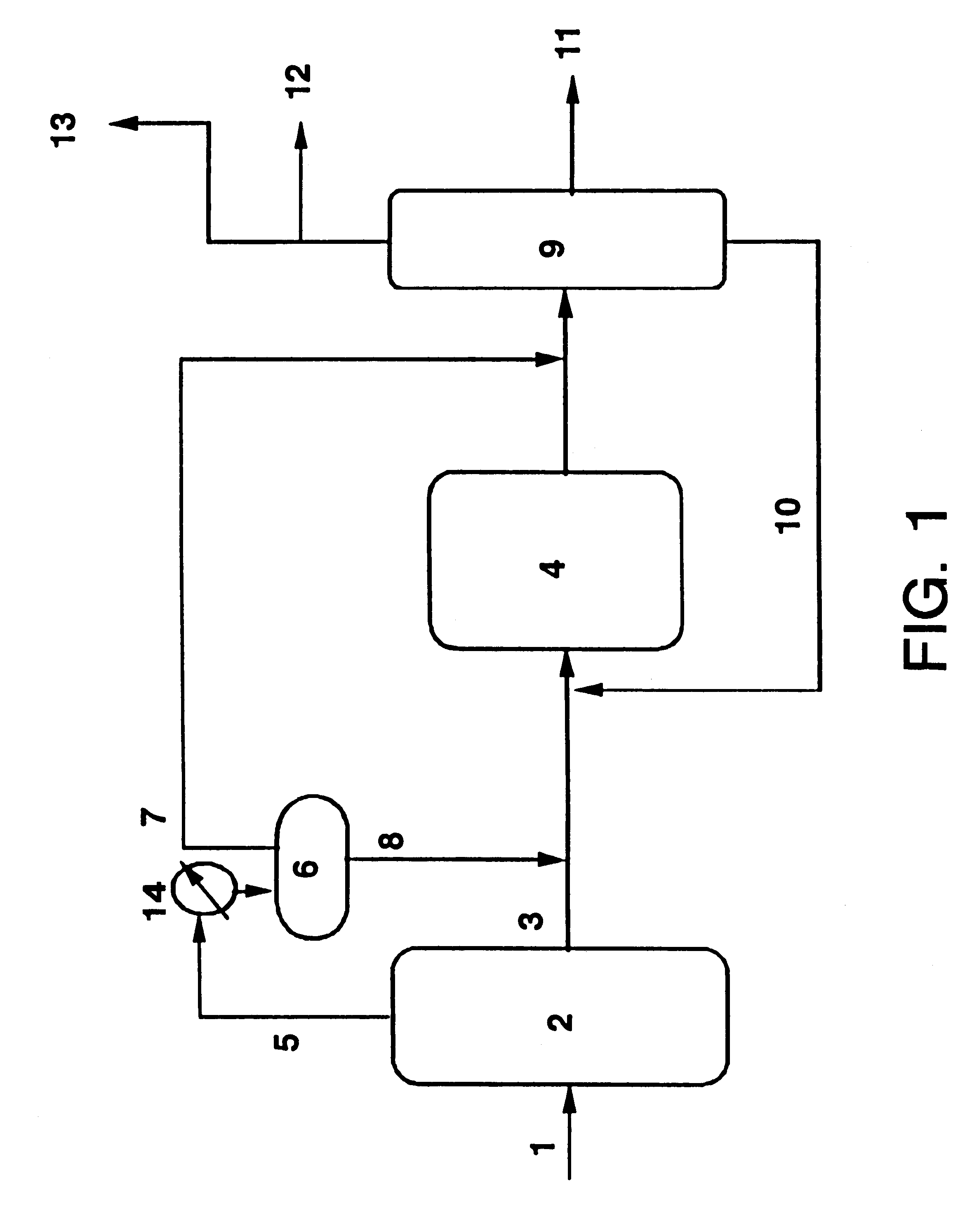

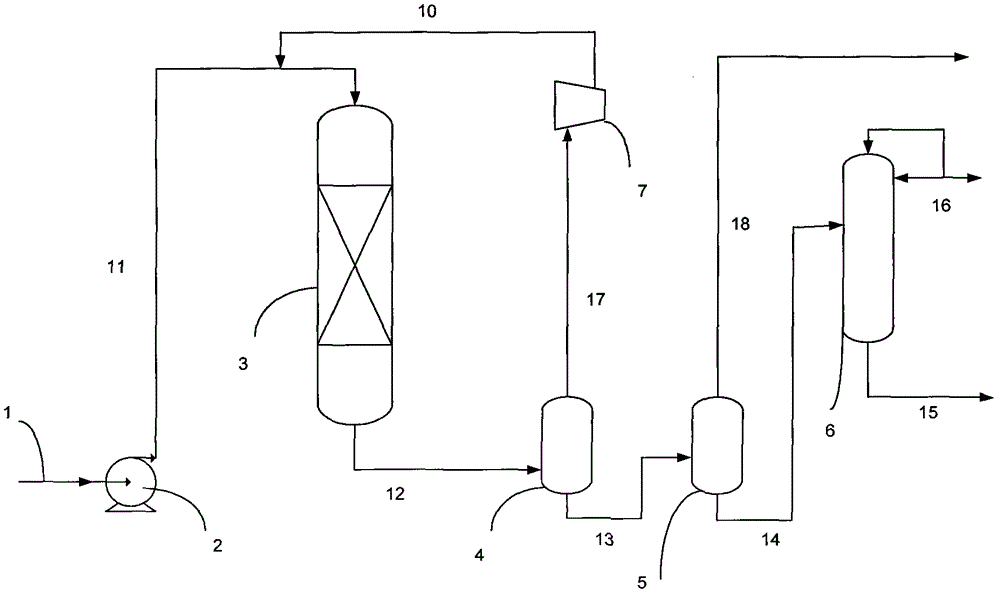

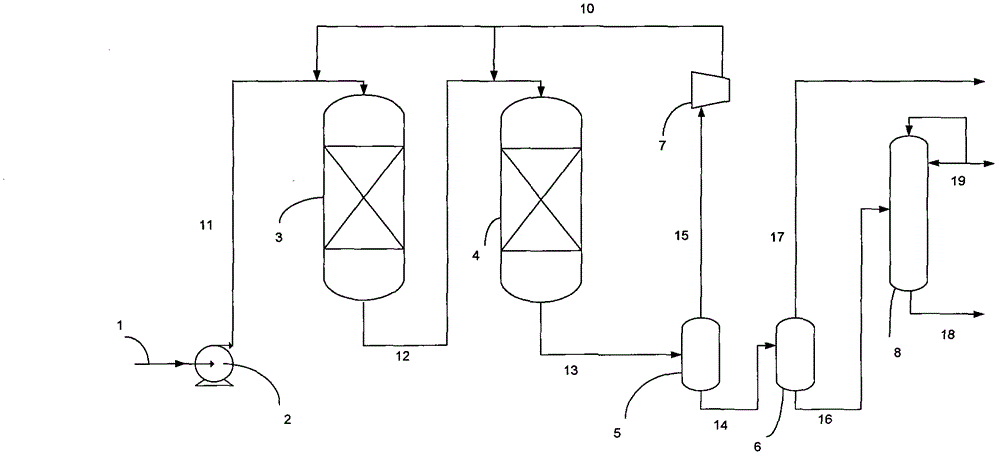

Hydrogenation, modification and pour point depression method by consideration of product quality of diesel oil

ActiveCN103059934ALow densityLowering the freezing pointTreatment with hydrotreatment processesIsomerizationChemical reaction

The invention relates to a hydrogenation, modification and pour point depression method by consideration of product quality of diesel oil, which is characterized in that a mixture of a hydrocarbons raw material and hydrogen are introduced in a hydrofinishing reaction zone, and contacted with a hydrobon catalyst for hydrodesulfurization, hydrodenitrogenation and aromatics saturation reactions, the hydrofinishing reaction product is introduced in a hydrogenation modified reaction zone with any intermediate separation, and is contacted with the hydrogenation modified catalyst for the hydrogenation, modification and pour point depression reaction. According to the invention, the hydrogenation modified catalyst with hydrogenation function, selectivity ring opening function and isomerization function is selected, chemical reactions such as hydrodesulfurization, hydrodenitrogenation, aromatics saturation, annular hydrocarbons selectivity ring opening and cracking, and isomerization and chain hydrocarbon non-selectivity cracking can be realized during the process of hydrogenation modification, thereby the density is reduced, the diesel oil fraction cetane number is increased, diesel oil fraction condensation point and cold filter plugging point can be reduced, and the purpose of diesel oil low temperature fluidity improvement can be reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pour point depressant composition of biodiesel for bus and preparation method of pour point depressant composition

ActiveCN104774659AIncreased sensitivityEvenly dispersedLiquid carbonaceous fuelsFuel additivesMethacrylateProcess engineering

The invention discloses a pour point depressant composition of biodiesel for a bus and a preparation method of the pour point depressant composition. The pour point depressant composition of the biodiesel for the bus is formed by mixing the following components in parts by weight: 2.5-10 parts of isodecyl methacrylate, 2.5-10 parts of ethyl acetoacetate, and 2.5-10 parts of isooctyl methacrylate. The preparation method comprises the following steps of ultrasonically dispersing isodecyl methacrylate, ethyl acetoacetate and isooctyl methacrylate after uniformly mixing and stirring at normal temperature and normal pressure so as to obtain the pour point depressant composition of the biodiesel for the bus. The pour point depressant composition of the biodiesel for the bus is used for depressing the pour point of the biodiesel for the bus formed by mixing illegal cooking oil biodiesel with 0# fossil diesel at normal temperature and normal pressure; the low-temperature flow property of the biodiesel for the bus can be effectively improved; the cold filter plugging point is reduced by 5-8 DEG C; the condensation point is reduced by 4-8 DEG C; and the pour point is reduced by 6-8 DEG C.

Owner:SHANGHAI INST OF TECH

Diesel oil pour point depressant composition, its preparation method and application

ActiveCN102517104BGood dispersionImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesWaxOrganic solvent

The invention discloses a diesel oil pour point depressant composition and its preparation method. The diesel oil pour point depressant composition, i.e. a diesel oil pour point depressant composition formed by mixing acetic ester organic solvents with a pour point depressant, comprises the following raw materials by mass percent: 0-20% of methyl acetate, 0-20% of ethyl acetate, 0-10% of propyl acetate, 0-30% of butyl acetate, and 20-80% of the pour point depressant. The preparation method consists of: mixing all the raw materials and then conducting stirring in water bath at a constant temperature of 50DEG C for 20min, and controlling the rotation speed at 150r / min, thus obtaining the diesel oil pour point depressant composition. Adding of the obtained diesel oil pour point depressant composition into commercially available 0# diesel oil can make the cold filter plugging point of the diesel oil reduced by 5-11DEG C and the condensation point reduced by 6-10DEG C. The diesel oil pour point depressant composition provided in the invention enhances the dispersion effect of pour point depressants on wax crystals, and improves the low temperature fluidity of diesel oil.

Owner:SHANGHAI INST OF TECH

Cold Flow Improvement of Distillate Fuels Using Alpha-Olefin Compositions

The cold flow of middle distillate fuels may be improved by adding an effective improving amount of one or more alpha-olefin compositions. The compositions include, but are not necessarily limited to, polymers of alpha-olefins per se, copolymerized or grafted alpha-olefins with maleic anhydride, acrylic acid, vinyl acetate, alkyl acrylates, methacrylic acid, and / or alkyl methacrylates. These resulting copolymers or grafted polymers may be blended with alkylphenol-formaldehyde resins, which in turn may be blended with ethylene-vinyl acetate (EVA) copolymer. In a non-limiting example, the cold filter plugging point (CFPP) may be synergistically improved as compared with the expected additive effect of using the components separately.

Owner:BAKER HUGHES INC

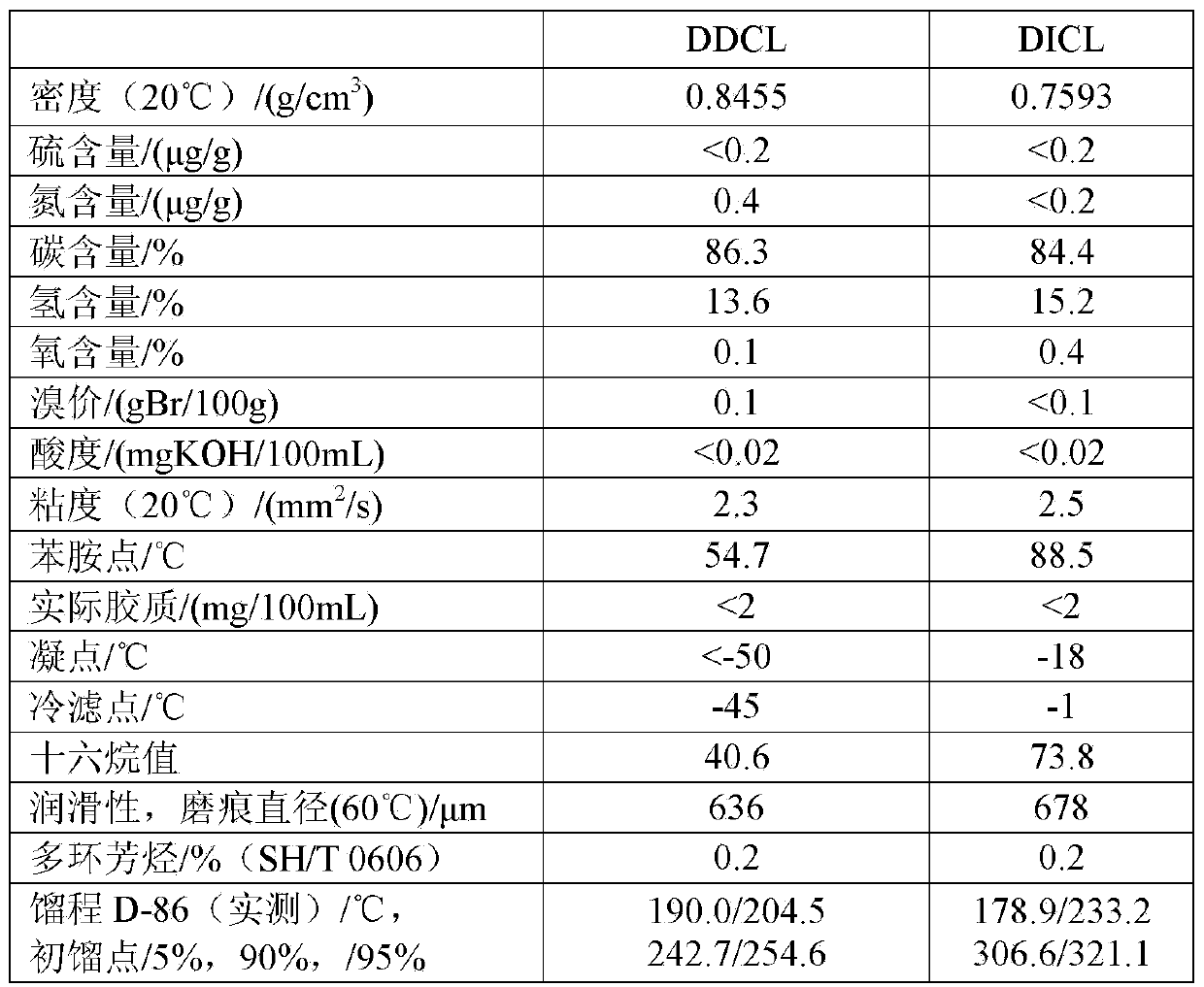

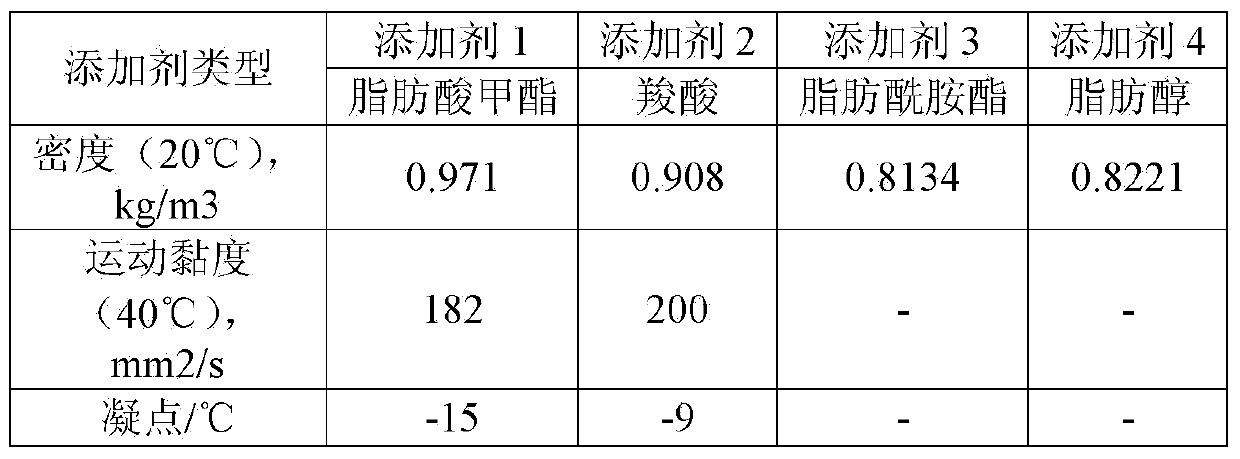

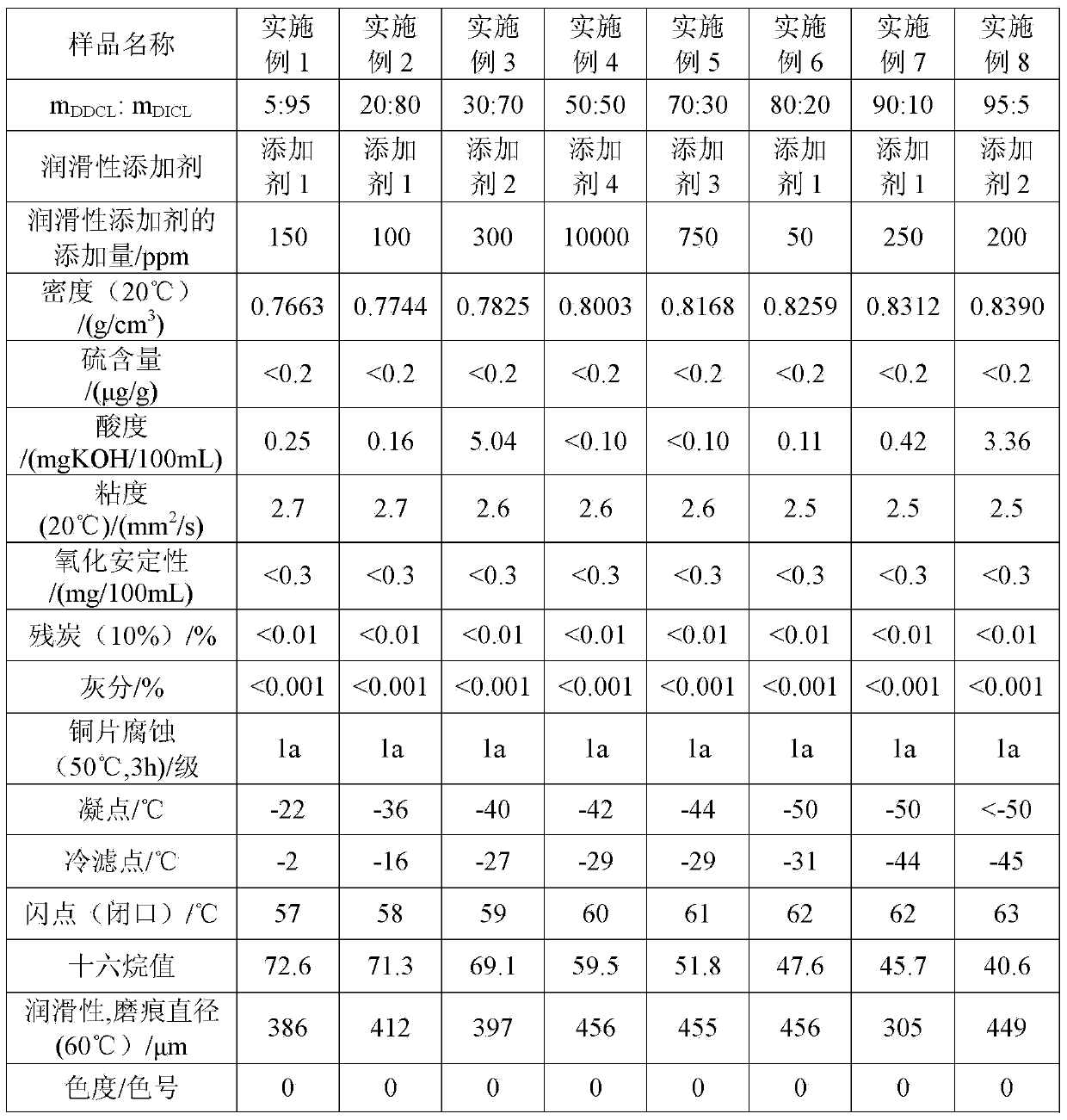

Diesel oil blend component and production method thereof

ActiveCN103740417ALow costSimple processLiquid carbonaceous fuelsCold filter plugging pointViscosity

The invention discloses a diesel oil blend component and a production method thereof. The diesel oil blend component consists of direct coal liquefaction diesel oil, indirect coal liquefaction diesel oil and lubricant additive. Only the direct coal liquefaction diesel oil (DDCL) and indirect coal liquefaction diesel oil (DICL) are blended as raw materials, and the lubricant additive is added to the blended fuel, so as to obtain the diesel oil blend component with indicators such as density, condensation point, cold filter plugging point, viscosity, cetane number and the like meeting requirements; particularly, the DDCL and DICL are optimized and blended to produce a clean diesel oil product consistent with new national IV or Beijing V automotive diesel oil standard. The process disclosed by the invention is low in cost, simple in process and easy to operate.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Diesel oil pour point depressant and preparation method thereof

InactiveCN101724476ALower cold filter pointLiquid carbonaceous fuelsFuel additivesDepressantCold filter plugging point

The invention provides a diesel oil pour point depressant, which comprises the following components in percentage by mass: 20 to 40 percent of phenylethylene-maleic anhydride copolymer fatty ester, 40 to 60 percent of poly alpha-methacrylic acid fatty ester and 20 to 40 percent of alkyl naphthalene. The diesel oil pour point depressant of the invention can obviously improve the low-temperature rheological property of the diesel oil and reduce the cold filter plugging point of the diesel oil.

Owner:SHAANXI UNIV OF SCI & TECH

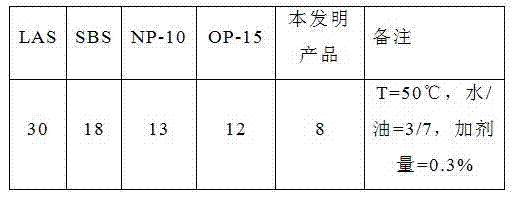

Biodiesel pour point reducer composition as well as preparation method and application thereof

InactiveCN102634391AImprove pour point depressing effectImprove low temperature fluidityLiquid carbonaceous fuelsWaxBiodiesel

The invention discloses a biodiesel pour point reducer composition as well as a preparation method thereof. The biodiesel pour point reducer composition is composed of span-series surface active agents and a diesel pour point reducer through mixing; and the raw materials are composed of 0-5% of span-20, 0-5% of span-40, 0-5% of span-60, 40-60% of span-80 and 30-50% of the pour point reducer by mass. The preparation method comprises the following steps of: mixing the raw materials, and stirring in aqueous thermostat at the rotation rate of 200 r / min for 10 min to obtain the biodiesel pour point reducer composition. After the obtained biodiesel pour point reducer composition is added into the biodiesel, a cold filter plugging point is reduced by 6-10 DEG C, and a condensation point is reduced by 7-11 DEG C. The biodiesel pour point reducer composition disclosed by the invention enhances exposure level of the biodiesel pour point reducer and a wax crystal, and improves the low-temperature fluidity of a biodiesel oil product.

Owner:SHANGHAI INST OF TECH

Polymethacrylate/graphene nano composite polymer pour point reducer and preparation method thereof

ActiveCN106978225AImprove low temperature performanceIncreased sensitivityLiquid carbonaceous fuelsFuel additivesAfter treatmentOrganic solvent

The invention discloses a polymethacrylate / graphene nano composite polymer pour point reducer and a preparation method thereof. The method comprises the following steps: (1) ultrasonically dispersing graphene oxide in an organic solvent to obtain a suspension; then adding methacrylate and an initiator into the suspension, and performing a polymerization reaction at 70 to 90 DEG C in an inert atmosphere to obtain a viscous material; and (2) adding a reducing agent into the viscous material to reduce the graphene oxide, and after the reaction is ended, performing the after-treatment to obtain the polymethacrylate / graphene nano composite polymer pour point reducer. The preparation method is simple and feasible, easy in operation, and high in safety; the obtained pour point reducer is stable in performance and excellent in pour point reduction effect; and moreover, the graphene has flammability, does not block a filter screen of an engine, and is not deposited at the bottom of the engine. The polymethacrylate / graphene nano composite polymer pour point reducer is applied to Number-0 diesel, and a cold filter plugging point and a condensation point of the number-0 diesel can be respectively decreased by 6 to 15 DEG C and 12 to 23 DEG C.

Owner:SHANGHAI INST OF TECH

Synthesis method of diesel fuel depressant

ActiveCN103131487ANo post-processingSimple processLiquid carbonaceous fuelsReaction temperatureCarvacryl acetate

The invention discloses a synthesis method of a diesel fuel depressant. The synthesis method comprises the following steps of: carrying out one-pot polymerization reaction in an initiating agent and a solvent by taking poly-alpha-methylacrylic acid high-carbon alcohol ester, a polar nitrogen compound, vinyl acetic ester and vinyl benzene as raw materials; and mixing a reactant with twain and span to obtain a target product, i.e., the diesel fuel depressant. The synthesis method is free of aftertreatment and simple in process; the synergic initiating agent is adopted to initiate the polymerization reaction, and the raw materials are dropwise added in twice and sufficiently react; the reaction conditions are mild, and the polymerization reaction is carried out in the mixed solvent, so that the reaction temperature range is widened, and the reaction is more easily carried out; and a special raw material proportion is adopted, so that the produced diesel fuel depressant has good perceptibility for diesel fuel with high paraffin content and favorable cold filter plugging point reducing performance, and the low-temperature performance of the diesel fuel is remarkably improved.

Owner:山东京博众诚清洁能源有限公司

Combustible nano-composite pour point depressant and preparation method thereof

ActiveCN106947554AFlammableImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesPolyethylene vinyl acetateCarvacryl acetate

The invention discloses a combustible nano-composite pour point depressant and a preparation method thereof. The combustible nano-composite pour point depressant is a blend of nano-graphene and a polymer pour point depressant, wherein the polymer pour point depressant is any one or two of a polymethacrylate pour point depressant or a polyethylene-vinyl acetate pour point depressant. The combustible nano-composite pour point depressant is prepared from nano-graphene and the polymer pour point depressant by virtue of a solvent blend method; and the preparation method is easy and feasible. Compared with a common nano-composite pour point depressant, the combustible nano-composite pour point depressant has the major advantages that the pour point depressant is combustible and lossless, does not pollute a diesel engine, does not settle at the bottom of the diesel engine and has stable performance and an excellent effect. By applying the combustible nano-composite pour point depressant to 0# diesel, a cold filter plugging point and condensation point of the 0# diesel can be respectively decreased by 11-16 DEG C and 18-25 DEG C.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com